Page 1

INSTALLATION AND OPERATING INSTRUCTIONS

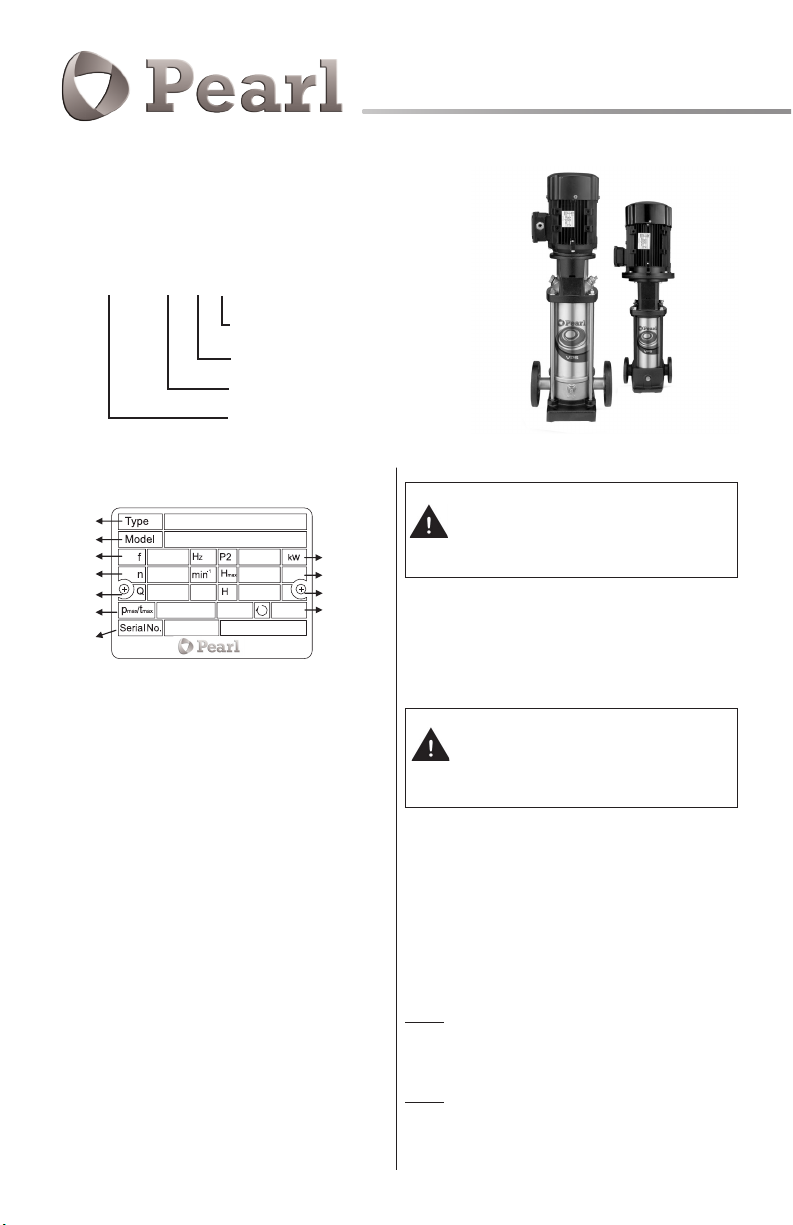

1. MODEL NUMBERING AND NAMEPLATE INFORMATION

1.1 Model numbering

VPC/VPS 5 16 SQQE

Code for

Shaft Seal

Number of Stages

Nominal Flow

Type Ranges

1.2 Nameplate format

1

2

3

5

7

9

11

1. Pump Type – Seal Type

2. Pump Model

3. Frequency

4. Rated Power

5. Speed

6. Maximum Head

7. Capacity

8. Head Range

9. Maximum Operating Pressure

10. Rotating Direction

11. Serial Number

GPM

psi/˚F

4

ft

6

ft

8

10

2. HANDLING

Read these instructions carefully before beginning installation.

Lift and handle these pumps carefully. VPC & VPS series are

vertical multi-stage non-self priming pumps coupled with

standard electric motors. This manual applies to standard version pumps and for standard applications. Contact your supplier

or the factory for information about special pump versions and

applications.

3. APPLICATIONS

VPC & VPS series in-line pumps booster pumps are designed

for a wide range of applications in various industries – for water

treatment, water boosting, water supply, cooling, cleaning, etc.

3.1 Pumped liquids

The pumps are designed for use with clean, viscous and nonexplosive liquids that do not contain abrasive matter.

Vertical Multistage Centrifugal In-line

These pumps are not designed to be used

with abrasive, solid containing, explosive

and corrosive liquids.

For special application, please contact

your supplier or the factory.

4. TECHNICAL DATA

4.1 Temperatures

Ambient temperature: 32 F to +104 F

If ambient temperatures are above +104° F

or if the pump is located at elevations more

than 3,000 feet above sea level, the motor’s

output must be decreased to compensate

for less eective cooling, and may have to

be replaced with a stronger motor.

Liquid temperature: -5 F to +248 F

4.2 Maximum operating pressure

Refer to page 8

4.3 Minimum inlet pressure-NPSH

To avoid cavitation, make sure that there is a minimum pressure

on the suction side of the pump.

NPSHA: Net Positive Suction head Available

The net positive suction head available is a function of the pump

suction system.

NPSHR: Net Positive Suction head required

The net positive suction head required is a function of the pump

design at the operating point on the pump performance curve.

Pumps Spare Parts

VPC-VPS

Page 2

NPSHA=Ha-Hs-Hf-Hv-Hst (in meters head)

Ha: Barometric pressure. (That can be set to 15 psi.)

Hs: Suction lift.

Hf: Friction loss in suction pipe.

Hv = KT+KH: Vapor pressure

KT: Flow resistance due to liquid temperature.

KH: Flow resistance due to elevation above sea level.

If the liquid is water, you can consult the tables to determine the

values of KT and KH.

T(F) 68 86 104 122 140 158 176 194 212 230 248

KT

0.7 1.3 2.6 4.3 7.2 11 16.4 24 36 49 72

(Ft)

H

0 1640 3280 4921 6461 8202 9842

(Ft)

KH

0 1.80 3.61 5.41 7.22 9.02 10.8

(Ft)

Hst: Safety margin. (minimum: 7 FEET head)

>

NPSHA = NPSHR: Pump running will be fine.

NPSHA < NPSHR: The pump will be dry running or cavitating.

Stop operation of the pump if cavitation

occurs. Cavitation will cause pump damage

and the resultant damage is not subject to

warranty

4.6 Electrical data

See the motor nameplate.

Make sure that the supply voltages, phase

and frequencies correspond to the motor

specications.

4.7 Number of starts per hour

Motors up to and including 5 HP: Maximum 100 times per hour.

Motors of 7.5 HP and up: Maximum 40 times per hour.

If you use another brand of motor then check

the manufacturer’s instructions for the

maximum frequency of starts.

5. INSTALLATION

Always refer to the local or national regulations and codes relating to the selection of the installation site, the water and power

connections, etc.

5.1 Position

Pumps should be installed in a protected environment – not

exposed to weather. Make sure that there are no obstructions to

prevent proper motor cooling.

4.4 Minimum nominal flow rate

To prevent overheating of the internal pump components, the

pump should not be used at flows below the minimum flow

rate.

Do not run the pump against a closed discharge valve for longer than a few seconds.

The curve below shows the minimum ow

rate as a percentage of the nominal ow rate

in relation to the liquid temperature.

5.2 Anchoring

The pump must be secured to a solid foundation by bolts

through the holes in the flange or base plate. An illustration of

page 9 shows the bolt location and the pipe connections.

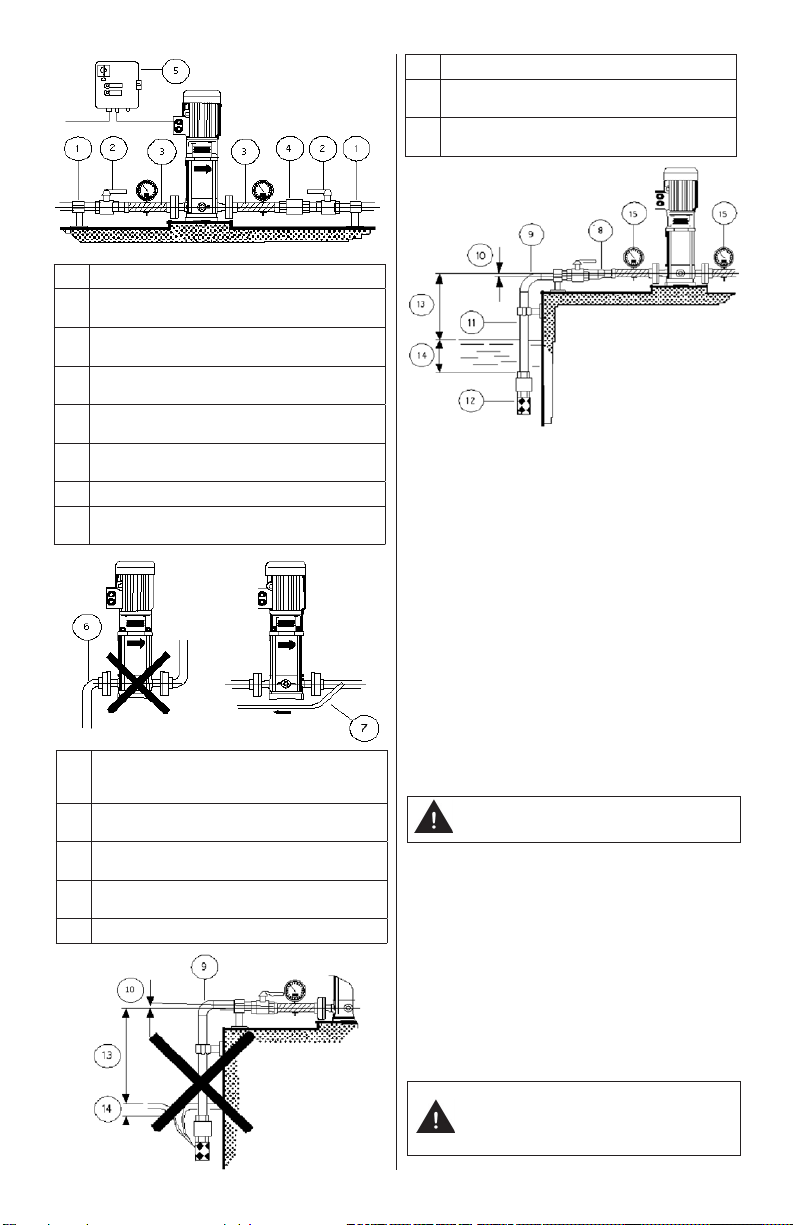

5.3 Installation example

When positioning and installing the pump, follow the installation

examples next page in order to avoid damaging the pump.

Page 3

Pos. DESCRIPTION

1 Pipe support: Support piping system properly to avoid stresses

on connections.

2 On-off valves: Install on-off valves for easy access- before the

pump intake and after the pump discharge.

3 Use flexible piping on both input and output sides of the pump

to reduce vibration and transmission of noise.

4 Check valves will prevent return flow of pumped liquid when

pump is stopped, reducing the danger of pump damage.

Control Panel: Use high quality components. Make sure that

5

the panel conforms to local standards and regulations.

6 Do not place elbows next to the pump intake and discharge.

If pump needs to be operated with on-off valve closed, install a

7

by-pass line to avoid damaging the pumping system.

13 Size pump for correct head.

Place the intake of the suction pipe so that the intake is always

14

submerged to prevent entry of air.

Install a compound gauge at the pump suction and a pressure

15

gauge at the pump discharge.

6. ELECTRICAL CONNECTION

• All electrical connection should be in accordance with the

local regulations and made by a qualified electrician.

• Make sure that the supply voltages and frequencies, and

phase are suitable for the motor used.

• Before proceeding, make sure that all the connections are

grounded and well insulated.

• Overload protection should be provided.

• To connect, proceed as shown on the inside of the terminal

board cover.

• The terminal box can be turned to four positions.

• Check the direction of rotation (Three-phase motor only).

• Make sure that the controls are properly grounded.

• To avoid the possibility of dry running, we strongly

recommend installing dry running protection.

If it is necessary to increase the diameter of the suction pipe,

8

place an eccentric reducer between the check valve and the

flexible pipe section.

Using elbows will increase the flow resistance. Wide bends will

9

result in lesser flow resistance.

The piping must have a level or positive gradient to prevent the

10

formation of air pockets.

The diameter of the drop pipe must be bigger than the diam-

11

eter of the pump’s suction port.

12 Use a foot valve in case of negative suction head.

7. START-UP

The pump and suction pipe should be filled with the liquid to be

pumped before start-up to prevent dry running at start-up.

Dry running can damage the pump bearing

and shaft seal.

7.1 Operation

• Start the pump and check the direction of rotation of the

motor (Three –Phase motors).

• Start the pump, keeping the on-off valve of the discharge

side of the pump closed. Then, open the on-off valve

slowly. The pump must run smoothly and noiselessly. If

not, then it may be necessary re-prime the pump.

• Check the current drawn of the motor. If necessary, adjust

the setting of the thermal relay.

• Any air pockets trapped inside the pump may be released

by adjusting the air screw.

If the pump is installed in a location where it

is subject to freezing when not in operation,

then the pump and the pipe system should

be drained to prevent damage from freezing.

Page 4

7.2 Others (Only for VPC, VPS 1, 3, 5 series)

• For these pumps, it is advisable to open the bypass valve

during start-up. The bypass valve connects the suction

and discharge sides of the pump, thus making the filling

procedure easier. When the operation is stable, the bypass

valve can be closed.

• If the pumped liquids contain air, it is advisable to leave the

bypass valve open if the operating pressure is lower than

85 psi. If the operating pressure constantly exceeds 85 psi,

the bypass valve must be closed. Otherwise the material at

the opening will be worn because of the high liquid velocity.

8. MAINTENANCE

Before starting maintenance work on the

pump, the motor, or other parts of the system,

make sure that the power supply has been

switched o.

• The pump does not have a recommended scheduled

maintenance schedule.

• If the motor is fitted with grease nipples, then the motor

should be lubricated with a high temperature lithiumbased grease. If not, then the motor does not require

regular maintenance.

• If the pump and motor are used infrequently with long

intervals of non-operation, then we recommend that the

motor be greased.

• Coupling adjustment: Refer to page 7.

Page 5

9. TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE REMEDY

Supply failure or no power supply. Check connections or restart the power supply.

Pump does not run when

the motor starter is

activated.

Starter overload trips

immediately when the

power is switched on.

The pump starts but, after

a short time, the thermal

protector trips out or the

fuses blow.

The pump starts up but,

after a period of time, the

thermal protector trips.

Main contacts in motor starter are not making

contact or the motor coils are defective

Pump or auxiliary circuits protection fuses

blown.

Pump or piping system may be obstructed

causing a jam.

Motor may have failed. Replace the motor.

Motor protector or thermal relay has tripped

out.

Tripping of anti-dry running protection.

Overload setting is too low. Set the motor starter correctly.

The cable connection is loose or faulty. Fasten or replace the cable connection.

One fuse is blown. Replace fuse and try starting again.

Pump is jammed by an obstruction Check and clean obstruction from system.

Contacts in overload are faulty. Replace motor starter contacts.

The motor winding is defective. Replace the motor.

Low voltage (Especially at peak time). Check the power supply.

The voltage is not within the motor’s operating limits.

The control panel is situated in an excessively

heated area or is exposed to direct sunlight.

A phase in the power supply is missing. Check the power supply.

Worn motor bearings causing motor to

overheat.

The pump’s delivery rate is higher than the

specified rate on the pump nameplate.

There are obstructions inside the pump or

pumping system.

Less viscous liquids may cause the motor to

work too hard and overload the motor, causing the motor to overheat

Reconnect or replace contacts or magnetic coil.

Replace fuses.

Clean the obstruction and restart pump.

Reset the motor or thermal protector.

Check the water level in the tank or the water

system pressure. If everything is in order, check

the protection device and its connection cables.

Check the operating conditions of the pump.

Protect the control panel from heat sources and

from the sun.

Replace motor bearings.

Partially close the on-off valve located

discharge side until the delivery rate returns to

within the specified limits.

Disassemble and clean the pump and piping.

Check the actual power requirements based on

the characteristics of the liquid being pumped,

and replace the motor accordingly.

Page 6

PROBLEM POSSIBLE CAUSE REMEDY

Pump is not primed with liquid. Fill the pump with the liquid to be pumped.

Pump runs but no water

delivered.

The pump capacity is not

constant.

The system’s general

protection cuts in.

The pump, suction or discharge pipes are

blocked by solids in the liquid being pumped.

The foot or check valve is blocked or has

failed.

The suction pipe leaks. Repair or replace the suction pipe.

The air is in the suction pipe or pump. Remove trapped air from system..

Motor operating in wrong direction (threephase motor).

The pump draws in air or the inlet pressure

is too low.

The pump or the suction side of the piping

system partly blocked by foreign bodies.

Short circuit. Check electrical system.

Clean the pump, suction or discharge pipe.

Replace the foot or check valve.

Change the direction of rotation of the motor by

reversing motor connections.

Improve the suction conditions.

Clean the pump or suction pipe.

... troubleshooting cont.

The pump rotates in the

wrong direction when

switched off.

The frequency of

Pump start-up is too high.

Vibration and noise

The foot or the check valve has failed. Check and replace check valve.

Leakage in the suction pipe. Repair or replace the suction pipe.

Leakage in the foot valve, check valve or

system.

Ruptured membrane or no air pre-charge in

surge tank.

Cavitation

Make sure that pump and motor shafts are

properly aligned.

Worn motor bearings. Replace the bearings or the motor.

Operation with frequency converter.

Check vibration and noise damping devices Replace vibration & noise dampers, if worn.

Repair or replace the components.

See relevant instructions in surge tank’s

manual.

Reduce the required flow or improve the operating conditions of the pump (suction conditions, head, flow resistance, liquid temperature,

viscosity,…etc.).

Adjust the pump and/or motor shafts.

Consult a qualified engineer form the supplier

of the frequency converter.

Page 7

Maximum Operating Pressures Maximum Inlet Pressures

STAGES

VPS-VPC 1 2-27 350

VPS-VPC 3

VPS-VPC 5 2-24 350

VPS-VPC 10

VPS-VPC 15

VPS-VPC 20

VPS-VPC 32

VPS-VPC 45

VPS-VPC 64

VPS-VPC 90

VPS-VPC 120 1 - (5-2) 425

VPS-VPC 150

2-25 350

1-10 230

12-17 350

1-8 230

9-12 350

1-7 230

8-10 350

(1-1)-5 230

(6-2)-(10-2) 425

(1-1)-4 230

(5-2)-7 425

(1-1)-3 230

(4-2)-(5-2) 425

(1-1)-3 230

(4-2) 425

(1-1) - (4-2) 425

MAXIMUM OPERATING

PRESSURE

[ PSI ]

VPS-VPC 1

VPS-VPC 3

VPS-VPC 5

VPS-VPC 10

VPS-VPC 15

VPS-VPC 20

VPS-VPC 32

VPS-VPC 45

VPS-VPC 64

VPS-VPC 90

VPS-VPC 120

VPS-VPC 150

DIN Flange Connections

STAGES

2-25 142

27 210

2-15 142

17-25 210

2-9 142

10-24 210

1-5 110

6-18 142

1-2 110

3-12 142

1 110

2-10 142

(1-1)-(2) 55

(3-2)-(6) 142

(7-2)-(10-2) 210

(1-1)-1 55

(2-2)-3 142

(4-2)-7 210

(1-1) 55

1-(2-1) 142

2-(5-2) 210

(1-1)-(2-2) 142

(2-1)-(4-2) 210

1 142

(2-2) - (3-1) 210

3 - (5-2) 280

(1-1) 142

(1-2) 210

(3-2) - (4-2) 280

MAXIMUM INLET

PRESSURES

[ PSI ]

Pump

Type

VPC 1 9.8 3.0 1/1 ¼ 3.94 5.55 7.09 8.66 0.55

VPS 1 9.8 3.0 1/1 ¼ 3.94 5.91 7.09 8.66 0.55

VPC 3 9.8 3.0 1/1 ¼ 3.94 5.55 7.09 8.66 0.55

VPS 3 9.8 3.0 1/1 ¼ 3.94 5.91 7.09 8.66 0.55

VPC 5 9.8 3.0 1/1 ¼ 3.94 5.55 7.09 8.66 0.55

VPS 5 9.8 3.0 1/1 ¼ 3.94 5.91 7.09 8.66 0.55

VPC 10 11.0 3.1 1 ½ 5.12 6.81 8.46 10.08 0.57

VPS 10 11.0 3.5 2 5.12 7.87 8.46 9.76 0.55

VPC 15 11.8 3.5 2 5.12 6.81 8.46 10.08 0.59

VPS 15 11.8 3.5 2 5.12 7.87 8.46 9.76 0.55

VPC 20 11.8 3.5 2 5.12 6.81 8.46 10.08 0.59

VPS 20 11.8 3.5 2 5.12 7.87 8.46 9.76 0.55

VPC 32 12.6 4.1 2 ½ 6.69 8.86 9.45 11.69 0.55

VPS 32 12.6 4.1 2 ½ 6.69 8.94 9.45 11.77 0.55

VPC 45 14.4 5.6 3 7.40 9.72 10.55 12.99 0.55

VPS 45 14.4 5.5 3 7.48 9.88 10.43 12.99 0.55

VPC 64 14.4 5.6 4 7.40 9.72 10.55 12.99 0.55

VPS 64 14.4 5.5 4 7.48 9.88 10.43 12.99 0.55

VPC 90 15.0 5.5 4 7.83 10.35 11.02 13.62 0.55

VPS 90 15.0 5.5 4 7.83 10.24 11.02 13.58 0.55

VPS 120 15.0 5.5 5 7.83 10.24 15 18.56 0.69

VPS 150 15.0 7.1 5 10.81 10.24 15 18.56 0.69

L H DN L1 L2 B1 B2 Ø

[inch] [inch] [inch] [inch] [inch] [inch] [inch] [inch]

Page 8

VPC-VPS 1, 3, 5 coupling adjustments VPC-VPS 10, 15, 20 Coupling adjustments

VPC-VPS 32, 45, 64, 90 Coupling adjustments

WATER SYSTEMS

PD WATER SYSTEMS - 3000 W. 16 Ave. Miami, FL 33012. TEL: (954) 474 9090 FAX: (954) 889 0413

www.pdwatersystems.com | pdwatersystems

Loading...

Loading...