Pearl Iron Jet IRONJ 05, Iron Jet IRONJH 05, Iron Jet IRONJ 10, Iron Jet IRONJ 07, Iron Jet IRONJ 15 Installation And Operating Instructions Manual

...Page 1

INSTALLATION AND OPERATING INSTRUCTIONS

TO AVOID SERIOUS OR FATAL PERSONAL INJURY OR MAJOR

PROPERTY DAMAGE, READ AND FOLLOW ALL SAFETY

INSTRUCTIONS IN MANUAL AND ON PUMP.

This is a SAFETY ALERT SYMBOL. When

you see this symbol on the pump or in the

manual, look for one of the following signal

words and be alert to the potential for

personal injury or property damage.

Warns of hazards that WILL cause serious

personal injury, death or major property

!

damage.

DANGER

Warns of hazards that CAN cause serious

personal injury, death or major property

!

damage.

WARNING

IRONJET

shallow well jet pumps

Warns of hazards that CAN cause personal

!

injury or property damage.

CAUTION

NOTICE: PLEASE READ AND UNDERSTAND THIS MANUAL

BEFORE OPERATE OR INSTALL THE PRODUCT. IF YOU HAVE

ANY QUESTION, PLEASE CONTACT YOUR DISTRIBUTOR FOR

INSTRUCTION.

THIS MANUAL MUST BE KEPT WITH THE PUMP.

MAINTAIN ALL SAFETY LABELS.

IMPORTANT PRE-INSTALLATION INFORMATION

Hazardous voltage can shock, burn or cause

death. All electrical work must be performed

by a qualied technician. Always follow the

local applicable electrical code.

The pump must be connected to a dedicated

electrical circuit protected by a properly sized

circuit breaker or fuses. Install a disconnect

Control Panel where required by the local

code.

Code questions should be directed to your electrical inspector.

See Chart 1 for specific information.

Always disconnect the power source before

installing or servicing the pump. This motors

come with an automatic thermal overload

protection, this feature may allow an

overheated pump to restart suddenly.

Water and electricity can be dangerous if

certain precautions are not adhered to. This

pump is designed to operate in a safe way in

!

a water environment; however, improper use

DANGER

and installation can result in personal harm

from electrical shock. Please pay attention to

the following warnings.

Never touch this pump, when it is touching

water, in water, or even in a moist

environment. Always unplug (disconnect the

!

electricity) when working on or installing

DANGER

the unit.

Do not use this pump with ammable or

explosive liquids such as oil, gasoline,

kerosene, ethanol, etc. Using this pump

with or near ammable liquids can cause an

explosion or re, resulting in property damage,

serious personal injury and/or death. Pumping

any of the above mentioned liquids voids the

warranty. Always make sure that this pump

is pumping liquid with same composition as

water.

Do not stand in water when the pump is

connected to the power supply.

This pump has been evaluated for use with

!

water only.

CAUTION

NOTICE: This pumps has been designed for working in presence

of water. Working without water will cause severe damage to

the pump.

Page 2

A qualied electrician must perform all the

!

wiring.

CAUTION

1. GENERAL INFORMATION

1.1. Read this Instruction Manual thoroughly prior to any work.

Work should be undertaken by qualified persons only.

ATTENTION!

Important information for installers of

this equipment!

This equipment is intended for installation by technically

qualified personnel. Failure to install it in compliance with

national and local electrical codes, and with motor suppliers

recommendations, may result in electrical shock or fire hazard,

unsatisfactory performance, and equipment failure. Installation

information is available from pump manufacturers and directly

from motor suppliers. Retain this information sheet with the

equipment for future reference.

WARNING

Serious or fatal electrical shock may result from failure to

connect the motor, control enclosures, metal plumbing, and all

other metal near the motor or cable, to the power supply ground

terminal using wire no smaller than motor cable wires. To reduce

risk of electrical shock, disconnect power before working on or

around the water system.

1. LOCATION

The pump should be installed in a dry, accessible place not

subject to freezing temperatures. If installed in a pump pit or

other location subject to dampness, proper ventilation must be

provided to avoid moisture damage to the electrical equipment.

2. PIPING

Galvanized steel or plastic pipe is recommended. If copper or

other dis-similar metal piping is used, a di-electric union or

bushing is recommended where the piping is connected to the

pump body. The pipe used should be cleaned and free of scale.

Ream ends of pipe to remove burrs. Check threads to see that

they are clean and not damaged. Horizontal runs of suction

pipe must slope upwards from the well to the pump to avoid air

pockets in the line which will make it difficult, if not impossible, to

prime the pump. The recommended slope is one inch in ten feet.

If pump must be offset an appreciable distance from the well,

the size of horizontal pipe should be increased to reduce

friction losses.

If using di-electric bushing, hand start bushing into female end of

pump housing (or other female connection) first. Use a six-sided

socket to tighten the bushing.

The bushing should be fully inserted into the female

connection. After the male end of the bushing is fully installed, hand

start pipe (or other male connection) into the female end of the

bushing. Failure to follow these guidelines may damage the bushing.

Caution should be taken to not cross-thread the bushing.

temporarily wasting the water outdoors or to drain. The pump

should be operated until the water runs clear, without sand, mud

or rust.

This procedure will eliminate the danger of pumping dirty water

into the pressure tank and home appliances. When water runs

clear, re-connect discharge line to tank and service.

4. WIRING (Use copper conductors only)

Be certain that wire and fuses of correct size are installed. Be

certain the phase, voltage, and cycles of the supply circuit are

the same as that shown on the motor name plate.

It is strongly recommended that a separate electric line, well

protected against fire, be run from electrical service to the pump,

with a fused switch box at the pump.

In the event of fire, this precaution will permit continuous

operation of your pumping system. For added safety, the pump

and motor should be properly grounded to the well casing or to a

separate ground rod driven eight feet into the ground.

NOTE: For proper fuse, circuit breaker and wire sizes in your

area, follow local codes. Otherwise:

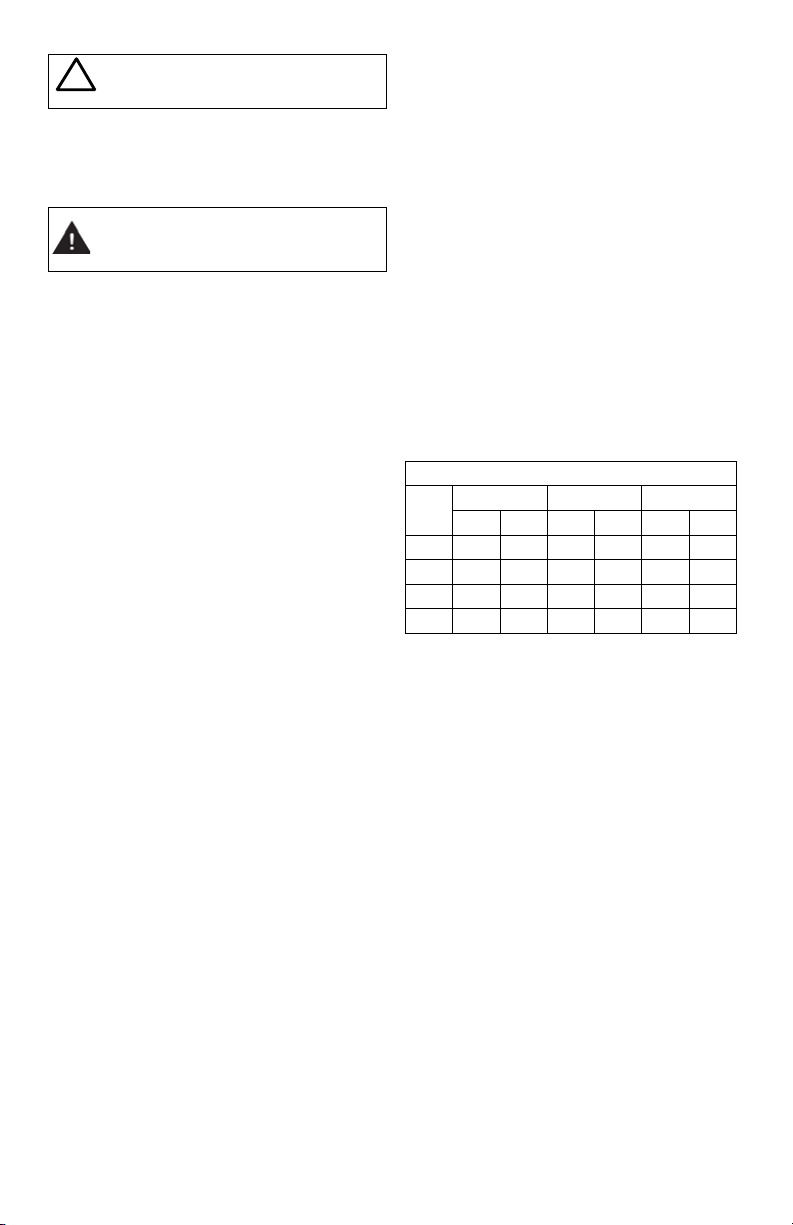

Wire Gage and Standard Fuse Sizes

MOTOR

1/2 HP 12 12 20 amp 15 amp 20 amp 15 amp

3/4 HP 10 12 25 amp 15 amp 30 amp 15 amp

1 1/2 HP 6 10 35 amp 25 amp 40 amp 20 amp

* Time delay fuses and circuit breakers (Single Phase).

For distances of 100 feet and over from meter to motor, larger

wire than shown may be required.

WIRE SIZE *FUSETRON *CIRCUIT BRKR

SIZE

115 V 230 V 115 V 230 V 115 V 230 V

1 HP 8 12 30 amp 20 amp 35 amp 20 amp

5. MOTORS

Motors are equipped with sealed ball bearings and require little

attention.

If motor repeatedly stops, cools off, and starts again, the cause

or trouble must be located and corrected. Do not cover motor

with canvas or other material that may interfere with proper air

circulation and cause over-heating.

6. PRESSURE SWITCH

The pressure switch is set at the factory to start the pump at

30 PSI and stop it at 50 PSI. In the event a change is necessary,

remove the switch cover and adjust either the operating

pressure or differential between start and stop (if available) by

turning screws, marked on switch, in the direction required.

Wiring directions are given on the pressure switch may

damage the bushing. Caution should be taken to not

cross-thread the bushing.

3. FLUSHING

If the pump discharge line is connected to pressure tank or

house service, disconnect it and flush and clean the system by

Page 3

Well Seal

Submerge

5-10 Feet

Figure 1

Tee

We

ent

ll V

Foot Valve

& Strainer

Horizontal

Check Valve

We ll Point

Figure 2

Te e

rtical

Ve

Check Valve

A shallow well system should not be installed where total suction

lift exceeds 25 feet at sea level. Suction lift must be reduced at

the rate of approximately 1 foot per 1000 feet at elevation. Total

suction lift consists of the vertical distance from the water level

when pumping to the pump plus losses due to friction in the pipe

line. The volume of water delivered decreases with an increased

suction lift.

Drilled, bored or dug wells may employ an arrangement as in

Figure 1. Driven wells and sandpoints employ the configuration

in Figure 2.

1. a) Install a foot valve on the bottom of the suction line and

place it 5 to 10 feet below the draw down level, that is, the level

of the water when the unit is pumping its rated capacity. It should

be far enough from the bottom of the well to avoid pumping sand

and mud. (Figure 1)

b) On driven well installation, install a spring dog- check valve

on the vertical pipe at least five feet above the well point, or install a horizontal check valve in the suction line near the pump.

(Figure 2)

2. Check the foot valve, see that it seats properly and that no

obstruction prevents its opening or closing. A leaky foot valve

may cause excessive cycling (motor starts and stops).

3. Lower first length of suction pipe, with attached foot valve

into the well, fill pipe with clean water. If water recedes a leak is

indicated. If no leaks occurs, assemble the remaining section(s)

of pipe and check again for leaks.

4. Install the well seal at the top of the well casing and tighten

well seal bolts. (Figure 1)

5. Install a tee at top of suction pipe, with a plug in the top

opening, and connect through a union to the female thread in

the pump body.

6. Connect pump discharge to pressure tank, and pressure tank

to house plumbing.

7. After piping is completed and motor is properly wired,

remove the priming plug on top of pump and fill pump with clean

water. Allow time for air in the system to escape, and refill pump if

necessary before replacing the priming plug. Start motor and the

unit should operate. If it does not, it may be necessary to reprime.

8. When unit has built up to maximum pressure, and has

automatically stopped, check all piping both suction and

discharge lines for leaks, as they will be under pressure.

NOTE: If the unit is to be used with a vacuum type air volume

control where the source of supply is on a level with the pump

or above it (artesian well, pond, cistern or shallow well with less

than five feet lift) a valve should be installed in the suction line

that may be partially closed to cause the pump to operate under

a moderate suction lift of 8-10 ft. to insure correct operation of

the air volume control which is operated by vacuum.

7. PERFORMANCE DATA

IRONJ 05

HP

0.5

IRONJH 05

HP

0.5

IRONJ 07

HP

0.75

IRONJ 10

HP

1.0

IRONJ 15

HP

1.5

Suction

Lift Depth

(feet)

5 20 13 8 3 58

10 17 12 7 2 56

15 15 10 6 1.5 52

20 13 9.4 5 51

25 11 8 3 51

Suction

Lift Depth

(feet)

5 12 9 6 3.5 83

10 11 8 5 3.3 80

15 10 7 4.8 2.8 77

20 8 6.5 4.5 2.5 74

25 6.3 6 4.2 2.2 72

Suction

Lift Depth

(feet)

5 22.2 21 16 11 6.5 69

10 22 19 15 9 5.5 67

15 21.5 18 14 8 3.5 65

20 21 15 13 7 2 62

25 20 11 10 6 1.8 60

Suction

Lift Depth

(feet)

5 25 22 16 8 70

10 23 19 14 6.5 69

15 20 18.5 13 4 66

20 18 17 12 2.5 63

25 16 15 10 2 60

Suction

Lift Depth

(feet)

5 29 26 22 16 87

10 25 24 20 15 82

15 21 22 19 13 80

20 19 20 18 11 75

25 16 15 15 9 74

Discharge Pressure - PSI

20 30 40 50 60

Flow US GPM

Discharge Pressure - PSI

20 30 40 50 60

Flow US GPM

Discharge Pressure - PSI

20 30 40 50 60

Flow US GPM

Discharge Pressure - PSI

20 30 40 50 60

Flow US GPM

Discharge Pressure - PSI

20 30 40 50 60

Flow US GPM

Max

Shut-OFF

PSI

Max

Shut-OFF

PSI

Max

Shut-OFF

PSI

Max

Shut-OFF

PSI

Max

Shut-OFF

PSI

Page 4

8. VOLTAGE CHANGE PROCEDURE

8.1 VOLTAGE CHANGE PROCEDURE FOR IRONJ 05 - IRONJH 05 - IRONJ 07

1

Unscrew and

remove the cover.

2

Check the voltage

set from factory.

8.2 VOLTAGE CHANGE PROCEDURE FOR IRONJ 10 - IRONJ 15

1

Unscrew and

remove the cover.

2

Remove the

Voltage plug.

3

If you want to

power the pump

with 115 V,

rotate the plug

to 115 V.

4

If you want to

power the pump

with 230 V,

rotate the plug

to 230 V.

3

Install the Voltage

Plug aligning the

arrow with the

voltage needed.

4

Choose connection

for 230 V.

5

Close the cover.

5

Choose connection

for 115 V.

6

Reinstall the cover

back.

9. PEARL MOTOR DATA

MOTOR

PART #

IRON J-05 0.5 115V / 230V 1 1.90 10.8 / 5.4

IRON J-07 0.75 115V / 230V 1 1.90 14.2 / 7.1

IRON J-10 1 115V / 230V 1 1.75 16.6 / 8.3

IRON J-15 1.5 115V / 230V 1 1.60 21 / 10.5

PD WATER SYSTEMS - 3000 W. 16 Ave. Miami, FL 33012. TEL: (954) 474 9090 FAX: (954) 889 0413

HP VOLTS PHASE

www.pdwatersystems.com | pdwatersystems

SERVICE

FACTOR

Pump MAX.

LOAD AMPS

WATER SYSTEMS

10. PEARL MOTOS ARE PRE-WIRED BY HP:

- 1/2 wired for 115 Volt.

- 3/4 - 1 1/2 HP wired for 230 Volt.

Loading...

Loading...