Page 1

INSTALLATION AND OPERATING INSTRUCTIONS

1. GENERAL INFORMATION

Before using the product carefully read the information

contained in this instruction manual, the manual should be kept

for future reference.

Italian is the original language of this instruction manual, this

language is the reference language in case of discrepancies in

the translations.

This manual is part of the essential safety requirement and must

be retained until the product is finally decommissioned.

The customer, in case of loss, can request a copy of the manual

by contacting the manufacturer or their agent, specifying the

type of product data shown on the label of the machine (see 2.3

Marking)

Any changes, alterations or modifications made to the product or

part of it, not authorized by the manufacturer, will revoke the “CE

declaration” and warranty.

This appliance should not be operated by children younger

than 8 years, people with reduced physical, sensory or mental

capacities, or inexperienced people who are not familiar with the

product, unless they are given close supervision or instructions

on how to use it safely and are made aware by a responsible

person of the dangers its use might entail.

Children must not play with the appliance. It is the user’s

responsibility to clean and maintain the appliance.

Children should never clean or maintain it unless they are given

supervision.

Do not use in ponds, tanks or swimming pools or where people

may enter or come into contact with the water.

Read carefully the installation section which sets forth:

- The maximum permissible structural working pressure

(chapter 3.1).

- The type and section of the power cable (chapter 6.5).

- The type of electrical protection to be installed (chapter 6.5).

1.1. SYMBOLS

To improve the understanding of the manual, below are

indicated the symbols used with the related meaning.

Information and warnings that must be observed,

otherwise there is a risk that the machine could damage or compromise personnel safety.

The failure to observe electrical information and

warnings, could damage the machine or compromise

personnel safety.

Information and warnings that must be observed,

otherwise there is a risk that compromise personnel

safety.

Notes and warnings for the correct management of the

machine and its parts.

i

MXA-MSC

Horizontal multistage pumps

Operations that could be performed by the final user.

After carefully reading of the instructions, is responsible

for maintenance under normal conditions. They are

authorized to affect standard maintenance operations.

Operations that must be performed by a qualified electrician. Specialized technician authorised to affect all

electrical operations including maintenance. They are

able to operate with in the presence of high voltages.

Operations that must be done performed by a qualified

technician. Specialized technician able to install the

device, under normal conditions, working during “maintenance”, and allowed to do electrical and mechanical

interventions for maintenance. They must be capable of

executing simple electrical and mechanical operations

related to the maintenance of the device.

Indicates that it is mandatory to use individual protection devices.

Operations that must be done with the device

switched off and disconnected from the power

OFF

supply.

Operations that must be done with the device

ON

switched on.

1.2. MANUFACTURER NAME AND ADDRESS

PD Water Systems

3000 W. 16 Ave. Miami, FL 33012

Tel: (954) 4749090 | Fax: (954) 8890413

info@pdwatersystems.com | www.pdwatersystems.com

1.3. AUTHORIZED OPERATORS

The product is intended for use by expert operators divided into

end users and specialized technicians.

(see the symbols above).

It’s forbidden, for the end user, carry out operations which must

be done only by specialized technicians. The manufacturer

declines any liability for damage related to the non-compliance

of this warning.Provide enough clearance around the unit for

motor ventilation and for filling and draining the pump.

Page 2

1.4. WARRANTY

For the product warranty refer to the general terms and

conditions of sale.

The warranty covers only the replacement and the repair

of the defective parts of the goods (recognized by the

i

manufacturer).

The Warranty will not be considered in the following cases:

- Whenever the use of the device does not conform to the

instructions and information described in this manual.

- In case of changes or variations made without authorization of

the manufacturer.

- In case of technical interventions executed by a nonauthorized

personnel.

- In case of failing to carry out adequate maintenance.

1.5. TECHNICAL ASSISTANCE

Any further information about the documentation, technical

assistance and spare parts, shall be requested to the:

manufacturer (paragraph 1.2).

2. TECHNICAL DESCRIPTION

Horizontal Multi-Stage Close Coupled Pumps.

MSC: version in AISI 304 with impeller PPO-GF.

MXA: version in AISI 304 with impeller PPO-GF.

2.1. INTENDED USE

For clean liquids: non-explosive and non-flammable, nonhazardous for health or the environment, nonaggressive for pump

materials, not containing abrasives, solid or fibrous particles.

For MXH with seal rings in EPDM the pump is not suitable for

use with oil.

Liquid temperature:

- MSC, MCC from 32 °F to + 122 °F.

- MXA from 32 °F to + 95 °F.

2.2. IMPROPER USE

The device is designed and built only for the purpose described

in paragraph 2.1.

Improper use of the device is forbidden, as is use under

conditions other than those indicated in these

instructions.

Improper use of the product reduces the safety and the efficiency

of the device, the manufacturer shall not be responsible for

failure or accident due to improper use.

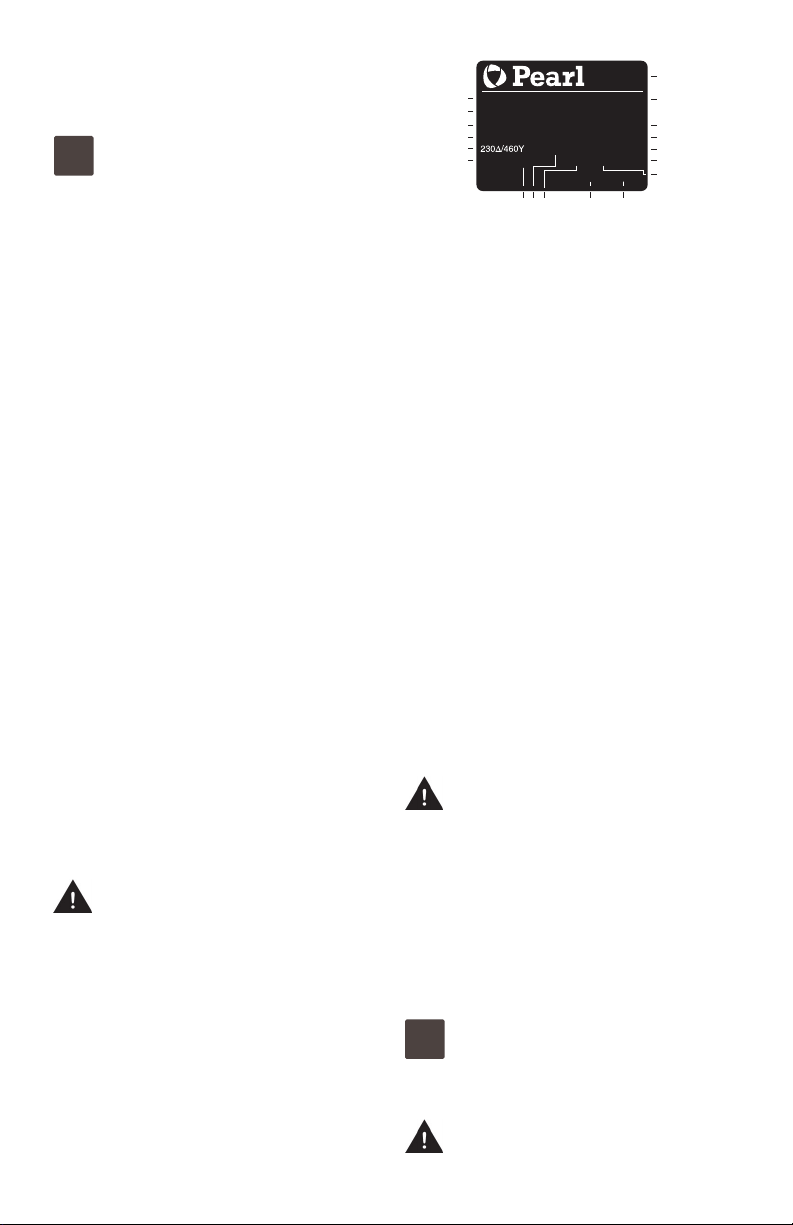

2.3. MARKING

The following picture is a copy of the name-plate that is on the

external case of the pump.

18

XXXXXXX

Q min/max X/X US gpm

H max/min X/X ft TEFC

X kW (XHp) S.F.

V3~60HzP F X

X/X AT amb XX F CONT l.cl. X X lb

81 01 1

1 Pump type

97

2 Delivery

3 Head

4 Rated power

5 Tension nominale

6 Nom. motor current

7 Ambient temperature

8 Fréquence

9 Operation Duty

XXXXXXX

n XXXX/min

Tmax liq.XX F SF

10 Liquid temperature

11 Service factor

12 Insulation class

13 Weight

14 Power factor

15 Rotation speed rpm

16 Protection

17 Serial number

17

16

15

14

13

XX

12

18 Certifications

3. TECHNICAL FEATURES

3.1. TECHNICAL DATA

Dimensions and weight (see technical catalogue).

Nominal speed 3450 rpm

Protection TEFC

The electric data marked on the label are referred to

the nominal power of the motor.

Sound pressure: < 70 dB (A).

Max. starts per hour: 15 at regular intervals.

Maximum permissible pressure in the pump casing:

262 ft (116 PSI).

3.2. OPERATING CONDITIONS

Installation in well ventilated location protected from

the weather, with a maximum ambient temperature of

104 °F.

4. SAFETY

4.1. GENERAL PROVISIONS

Before using the product it is necessary to know all the

safety indications.

Carefully read all operating instructions and the indications defined for the different steps: from transportation to disposal.

The specialized technicians must carefully comply with all applicable standards and laws, including local regulations of the

country where the pump is sold.

The device has been built in conformity with the current safety

laws. The improper use could damage people, animals and objects.

The manufacturer declines any liability in the event of damage

due to improper use or use under conditions other than those

indicated on the name-plate and in these instructions.

Follow the routine maintenance schedules and the

promptly replace damaged parts, this will allows the

i

device to work in the best conditions.

Use only original spare parts provided by the manufacturer or

from an authorized distributor.

Don’t remove or change the labels placed on the device.

Do not start the device in case of defects or damaged

parts.

Page 3

Maintenance operations, requiring full or partial

disassembly of the device, must be done only after

disconnection from the supply.

4.2. SAFETY DEVICES

The device has an external case that prevents any contact with

internal parts.

4.3. RESIDUAL RISKS

The appliance, designed for use, when used in-line with the

design and safety rules, doesn’t have residual risks.

4.4. INFORMATION AND SAFETY SIGNALS

For this kind of product there will not be any signals on the

product.

4.5. INDIVIDUAL PROTECTION DEVICES

During installation, starting and maintenance it is suggested

to the authorized operators to consider the use of individual

protection devices suitable for described activities.

During ordinary and extraordinary maintenance interventions,

safety gloves are required.

Signal individual protection device HAND PROTECTION

(gloves for protection against chemical, thermal and

mechanical risks).

5. TRANSPORTATION AND HANDLING

The product is packed to maintain the content intact.

During transportation avoid to stack excessive weights.

Ensure that during the transportation the box cannot move.

It is not necessary to use any special vehicle to transport the

packaged device.

The transport vehicles must comply, for the weight and

dimensions, with the chosen product (see technical catalogue

dimensions and weights).

5.1. HANDLING

Handle with care, the packages must not receive impacts.

Avoid to impact onto the package materials that could damage

the pump.

If the weight exceeds 55 lbs the package must be handled by two

person at the same time.

6. INSTALLATION

6.1. DIMENSIONS

For the dimensions of the device (see technical catalog).

6.2. AMBIENT REQUIREMENTS AND INSTALLATION SITE DIMENSIONS

The customer has to prepare the installation site in order to

guarantee the right installation and in order to fulfill the device

requirements (electrical supply, etc.).

The place where the device will be installed must fulfill the

requirements in the paragraph 3.2.

It’s absolutely forbidden to install the machine in an environment

with potentially explosive atmosphere.

6.3. UNPACKING

Inspect the device in order to check any damages which

i

may have occurred during transportation.

Package material, once removed, must be discarded/recycled

according to local laws of the destination country.

6.4. INSTALLATION

See installation examples, par. 13 fig. 1 and 2.

The pumps must be installed with the rotor axis in the horizontal

position and with the feet under the pump. Place the pump as

close as possible to the suction source.

Provide space around the pump for motor ventilation, to allow

for checking of shaft rota-tion, for filling and draining the pump

and to allow for collection of the liquid to be removed (especially

for draining liquids which are harmful or have to be removed at

temperatures higher than 140 °F).

6.4.1. PIPES

Ensure the insides of pipes are clean and unobstructed before

connection.

ATTENTION: The pipes connected to the pump should be

secured to rest clamps so that they do not transmit stress, strain or

vibrations to the pump (par. 13 fig. 3).

Tighten the pipes or union coupling to the extent sufficient to

ensure a tight seal.

Excessive torque may cause damage to the pump.

When the pipe or union coupling is mounted, keep the pump

casing connection blocked with a second wrench, making sure

the connection is not deformed by excessive tightening.

The pipe diameters must not be smaller than the pump

connections.

6.4.2. SUCTION PIPE

If the suction pipe is longer than 33 ft, use an internal pipe

diameter larger than the pump suction connection.

The suction pipe must be perfectly airtight and be led upwards in

order to avoid air pockets.

With a pump located above the water level (suction lift operation,

par. 13. fig. 2) fit a foot valve with strainer which must always

remain immersed.

If operating with flexible hoses use a reinforced spiral suction

hose, in order to avoid the hose narrowing due to suction vacuum.

With the liquid level on the suction side above the pump (inflow

under positive suction head, par. 13. fig.1) fit an inlet gate valve.

For suction from a storage tank fit an anti-backflow valve. Follow

local specifications if increasing network pressure.

Install a strainer on the suction side of the pump to prevent

foreign particles from entering the pump.

6.4.3. DELIVERY PIPE

Fit a gate valve in the delivery pipe to adjust delivery and head.

Install a pressure gauge.

With a geodetic head at outlet over 49 ft fit a check valve between the pump and the gate valve in order to protect the pump

from water hammering.

6.5. ELECTRICAL CONNECTION

OFF

Electrical connection must be carried out only by a qual-

ified electrician in accordance with local regulations.

Page 4

Always follow the National Electrical Code (NEC), or the

Canadian Electrical Code, as well as all local, state and provincial

codes. Code questions should be directed to your local electrical

inspector. Failure to follow electrical codes and OSHA safety

standards may result in personal injury or equipment damage.

Failure to follow manufacturer’s installation instructions may

result in electrical shock, fire hazard, personal injury or death,

damaged equipment, provide unsatisfactory performance, and

may void manufacturer’s warranty.

Install, ground and wire according to local and National

Electrical Code Requirements.

Electrical supply MUST match pump’s nameplate specifications.

Incorrect voltage can cause fire, damage to the motor and voids

the warranty.

Pumps not protected MUST be provided with contactors and

thermal overloads for single phase motors. See motor nameplate.

Use only copper wire to motor and ground. The ground wire

MUST be at least as large as the wire to the motor.

Wires should be color coded for ease of maintenance.

Compare the frequency and mains voltage with the name-plate

data and connect the supply conductors to the terminals in accordance with the appropriate diagram inside the terminal box

cover.

ATTENTION: Never allow washers or other metal parts to

fall into the internal cable opening between the terminal

box and stator. If this occurs, dismantle the motor to recover the object which has fallen inside.

If the terminal box is provided with an inlet gland, use a flexible

power supply cord of the H07 RN-F type with section of cable not

less than 11 TAB IEC 60335-1.

If the terminal box is provided with an inlet bushing, connect the

power supply cord through a conduit.

For use in swimming pools (not when persons are in the pool),

garden ponds and similar places, a residual current device with

IΔN not exceeding 30 mA must be installed in the supply circuit.

Install a device for disconnection from the mains (switch) with a

contact separation of at least 0,12 inch in all poles.

With a three-phase motor install an overload protection device

with curve D appropriate for the rated current of the pump.

Single-phase, are supplied with a capacitor connected to the terminals with an incorporated thermal protector.

ATTENTION: When the pump is fed by a frequency converter, the

minimum frequency should not fall below 25Hz and in any case

the total head of the pump should never be lower than 10 ft.

7. STARTUP AND OPERATION

7.1. Preliminary checks before start-up of the pump

Do not start-up the device in case of damaged parts.

7.2. FIRST STARTING

OFF

ATTENTION: never run the pump dry. Start the pump after filling

it completely with liquid.

When the pump is located above the water level (suction lift operation par. 13 fig. 2) or with a positive suction head which is too

low (less than 33 ft) to open the non-return valve, fill the pump

through the priming hole (par. 13 fig. 4).

When the liquid level on the suction side is above the pump (inflow under positive suction head par. 13 fig. 1), fill the pump by

opening the suction gate valve slowly and completely, keeping

the delivery gate valve open to release the air.

Before starting, check that the shaft turns by hand. For

this purpose use the screwdriver notch on the shaft end on the

ventilation side.

When starting, with a three-phase motor, check that the direction

of rotation is as shown by the arrows on the lantern bracket.

Otherwise, disconnect electrical power and reverse the

connections of two phases.

Check that the pump works within its field of perfor-mance

and that the absorbed current shown on the name-plate is not

exceeded. Otherwise adjust the delivery gate valve or the setting

of any pressure switches.

If a priming loss occurs (interruption of delivery flow) or if a

pressure oscillation is indicated by the pressure gauge, make

sure all the suction pipe couplings are perfectly sealed and

tighten the two sealed plugs on the pump casing.

Never run the pump for more than five minutes with a

closed gate valve.

Prolonged operation without a change of water in the pump

causes dangerous increases of temperature and pressure.

When the water is overheated due to prolonged operation with a

closed port, stop the pump before opening the gate valve.

To avoid any risk of danger to users and the creation of harmful

thermal stress in the pump and system due to large temperature

differentials, wait until the water has cooled inside the pump before starting again.

If the water is overheated on account of prolonged operation with

a non-primed or insufficiently filled pump (suction lift operation),

wait until cool before opening the draining and filling plugs.

Care must be taken when the pumped fluid has a high

temperature. Do not touch the fluid when its tempera-

ture is higher than 140 °F. Do not touch the pump when

the surface temperature is higher than 176 °F.

7.3. SELF-PRIMING (ONLY FOR MXA)

(Capability to clear the air in the suction pipe when starting with

the pump located above the water level).

Conditions for self-priming:

• suction pipe with connections perfectly airtight and properly

immersed in the water to be lifted;

• discharge pipe with a straight vertical free line above discharge

port, before a non-return valve.

• pump casing completely filled with clean cold water berfore

starting.

The pump is not self-priming with liquids containing oil, alcohol

or foaming substances.

The check valve prevents reverse siphoning through the pump

when the pump is stopped and retains water in the pump for

the next start.

Without a foot valve or a check valve on the suction connection

the filling operation must be repeated before each start-up.

ATTENTION: avoid a prolonged operation with unprimed

pump, without water delivery from the completely

opened outlet.

If the pump does not prime in 5 minutes: stop the motor,

remove the priming plug and add more water.

If necessary, repeat the priming operation after the pump has

been first emptied and then completely filled with clean cold

water.

7.4. SWITCH OFF OF THE PUMP

ON

Page 5

The appliance must be switch off every time there are faults.

(see troubleshooting).

The product is designed for a continuous duty, the switch off

is performed by disconnecting the power supply by means the

expected disconnecting devices. (see paragraph “6.5 Electrical

connection”).

8. MAINTENANCE

Before any operations it’s necessary to disconnect the power

supply.

If required ask to an electrician or to an expert technician.

Every maintenance operations, cleaning or reparation

executed with the electrical system under voltage, it

could cause serious injuries to people.

In case of extraordinary maintenance, or maintenance

operations that require part-removing, the operator must be a

qualified technician able to read schemes and drawings.

It is suggest to register all maintenance operation executed.

During maintenance keep particular attention in order to

avoid the introduction of small external parts, that could

i

compromise the device safety.

It is forbidden to execute any operations with the direct

use of hands. Use water-resistant, anti-cut gloves to

disassemble and clean the filter or in other particular

cases.

During maintenance operations external personnel is

i

not allowed.

Maintenance operations that are not described in this manual

must be made only by special personnel authorized by the

manufacturer.

For further technical information regarding the use or the

maintenance of the device, contact the manufacturer.

8.1. ROUTINE MAINTENANCE

ON

Before every maintenance operations disconnect the

power supply and make sure that the device could not

accidentally operate.

For good measure, as in the case of temporary

operation with dirty liquids, run the pump briefly with

clean water to remove deposits.

When the pump remains inactive it must be emptied completely

if there is a risk of freezing (par. 13 fig. 5).

Before restarting the unit, check that the shaft is not jammed and

fill the pump casing completely with liquid.

8.2. DISMANTLING THE SYSTEM

Close the suction and delivery gate valves and drain the pump

casing before dismantling the pump.

8.3. DISMANTLING THE PUMP

casing before dismantling the pump (par. 13 fig. 5).

For dismantling and re-assembly see construction in the cross

section drawing.

9. DISPOSAL

OFF

The final disposal of the device must be done by specialized

company.

Make sure the specialized company follows the classification of

the material parts for the separation.

Observe the local regulations and dispose the device accordingly

with the international rules for environment protection.

10. SPARE PARTS

10.1. Spare-parts request

When ordering spare parts, please quote their

designation, position number in the cross section

drawing and rated data from the pump name plate

(type, date and serial number).

The spare parts request shall be sent to the

manufacturer by phone, fax, e-mail.

11. PARTS

Nr. Designation

14.00 Pump casing

14.04 Plug (filling)

14.06 O-ring

14.12 Plug (draining)

14.16 O-ring

14.20 O-ring

14.24 Screw

14.28 Square nut

14.54 Wear ring (1)

16.00 Suction casing

16.14 Plunger

16.15 Spring

16.16 O-ring

16.17 Valve

20.00 Delivery casing

22.12 O-ring

22.16 O-ring

25.01 First stage casing

25.02 Stage casing

25.05 Last stage casing

25.10 Washer for missing

impeller

25.11 First stage spacer

28.00 Impeller

28.04 Impeller nut

28.08 Washer

32.00 Lantern bracket

34.00 Casing cover

34.12 Screw

36.00 Mechanical seal

36.51 Retaining ring, split

36.52 Shoulder ring

46.00 Deflector

64.13 Spacer sleeve

64.14 Spacer sleeve

64.15 Spacer sleeve

70.00 Lantern bracket

70.18 Screw

70.20 Screw

73.00 Pump-side bearing

76.00 Motor casing with winding

76.04 Cable gland

76.16 Support

76.20 Pin

76.54 Terminal box, set

78.00 Shaft with rotor packet

81.00 Fan-side bearing

82.00 Motor end shield, fan side

82.04 Compensating spring

82.08 Screw

88.00 Motor fan

88.04 Compensating spring

90.00 Fan cover

90.04 Screw

92.00 Tie-bolt

94.00 Capacitor

94.02 Capacitor gland

98.00 Terminal box cover

98.04 Screw

98.08 Gasket

OFF

Close the suction and delivery gate valves and drainthe pump

Page 6

PROBLEM POSSIBLE CAUSE SOLUTION

Check that the mains frequency and voltage correspond to the

electrical characteristics shown on the indicator plate.

Connect the power supply cable to the terminal board correctly.

Check that the thermal overload protection is set correctly (see

data on the engine indicator plate) and make sure that the

fuseboard upline of the engine has been properly connected.

Check the power supply and make sure that the pump shaft is

turning freely. Check that the thermal overload protection has

been set correctly (see engine indicator plate).

Replace the fuses, check the electric power supply and points.

Check that the mains frequency and voltage correspond to the

electrical characteristics shown on the indicator plate.

Check the power supply and make sure that the pump shaft is

turning freely. Check that the thermal overload protection has

been set correctly (see engine indicator plate).

Remove the cause of blockage as indicated in the “Blocked

pump” instruction booklet.

Repair or replace the engine by applying to an authorized

service center.

Rotation may be started directly from the pump shaft or from

thejoint (remember to turn off the electricity supply first ) or

contact an authorised service centre.

If possible, dismantle the pump casing and remove any

solid foreign bodies inside the rotor, if necessary contact an

authorized service center.

If the bearings are damaged replace them or if necessary

contact an authorized service center.

Check which part is not tight and seal the connection

adequately.

Clean or replace the bottom valve and use a suction pipe

suitable for the application.

Clean the filter, if necessary, replace it . Rotation may be started

directly from the pump shaft or from the joint (remember to

turn off the electricity supply first) or contact an authorised

service centre.

Use pipes and accessories suitable for the specific application.

Clean the rotor and install a suction filter to prevent other

foreign bodies from entering.

Replace the rotor, if necessary, contact an authorized service

center.

The pump is unsuitable.

Invert the electrical connections on the terminal board or

control panel.

Try to close the feeder gate partially and/or reduce the

difference in level of the pump and the liquid being aspirated.

Bring the pump closer to the suction tank so as to use a shorter

pipe. If necessary use a pipe of a wider diameter.

The motor does not start

Pump blocked

The pump functions but

no water comes out

Insufficient flow

Unsuitable power supply

Incorrect electrical connections

Engine overload protective device cuts in.

Blown or defective fuses

Shaft blocked

If the above causes have already been checked,

the engine may be malfunctioning

Prolonged periods of inactivity with

formation of rust inside the pump

Presence of solid bodies in the pump

rotor

Bearings siezed

Possible infiltration of air from suction tube

connections, drain plugs or filling of pump or from

the gaskets of the suction pipe

Foot valve blocked or suction pipe not fully

immersed in liquid

Suction filter blocked

Pipes and accessories with diameter too small

causing excessive loss of head

Presence of deposits or solid bodies in

the internal passages of the rotor

Rotor deteriorated

Worn rotor and pump case Replace the rotor and the pump casing.

Excessive viscosity of the liquid

pumped (if other than water)

Incorrect direction of rotation

Suction head excessive in relation to

the suction capacity of pump

Suction pipe too long

Page 7

PROBLEM POSSIBLE CAUSE SOLUTION

Rotating part unbalanced Check that no solid bodies are obstructing the rotor.

Worn bearings Replace the bearings.

Pump and pipes not firmly attached Anchor the delivery and suction piping as needed.

Noise and vibrations from

the pump

Leakage from the

mechanical seal

Flow too strong for the diameter of the

delivery pipe

Functioning in cavitation

Unbalanced power supply Check that the mains voltage is right

Incorrect alignment of pump-motor unit If necessary, the unit must be re-aligned

The mechanical seal has functioned

when dry or has stuck.

Mechanical seal scored by presence

of abrasive parts in the liquid pumped.

Mechanical seal unsuitable for the

type of application.

Slight initial drip during filling or on first

start-up.

Use bigger diameters or reduce the pump flow.

Reduce the flow by adjusting the feeder gate and/or using pipes

with a bigger internal diameter. Try to close the feeder gate

partially and/or reduce the difference in level of the pump and

the liquid being aspirated.

Replace the seal, if necessary contact an authorized service

center.

Make sure that the pump casing (and the suction pipe if the

pump is not self-priming) are full of liquid and that all the air

has been expelled.

Replace the seal, if necessary contact an authorized service

center.

Reduce the flow by adjusting the feeder gate and/or using pipes

with a bigger internal diameter.

Install a suction filter and use a seal suited to the

characteristics of the liquid being pumped.

Replace the seal, if necessary contact an authorized service

center.

Choose a seal with characteristics suitable for the specific

application

Wait for the seal to adjust to the rotation of the shaft. If the

problem persists.

Make sure that the pump casing (and the suction pipe if the

pump is not self-priming) are full of liquid and that all the air

has been expelled.

Install a suction filter and use a seal suited to the

characteristics of the liquid being pumped.

Choose a seal with characteristics suitable for the specific

application.

Or contact an authorized service center.

PD WATER SYSTEMS - 3000 W. 16 Ave. Miami, FL 33012. TEL: (954) 474 9090 FAX: (954) 889 0413

www.pdwatersystems.com | pdwatersystems

Loading...

Loading...