Page 1

88 SERIES TIMPANI

INSTRUCTION MANUAL

Tuning your Pedal Timpani

Tuning Gauge

Pearl timpani are carefully adjusted with appropriate tuning at the factory, but new heads tend to

stretch during shipment and storage, and would need to be retuned before using. Please follow

the below steps to readjust your instrument.

Tuning is adjusted on the lowest note of the timpani.

Fully depress the pedal as shown right.

By using the provided tuning key, turn the tuning bolts following the sequence shown below.

At this time, do not fully tighten.

With 88LL (32") and 88L(29" ),

turn the tuning bolts in the

sequence as shown.

With 88M(26 "),88 S(23") and

88SS(20") turn the tuning bolts

in the sequence as shown.

Tuning point

Center

Standard Tonal Ranges

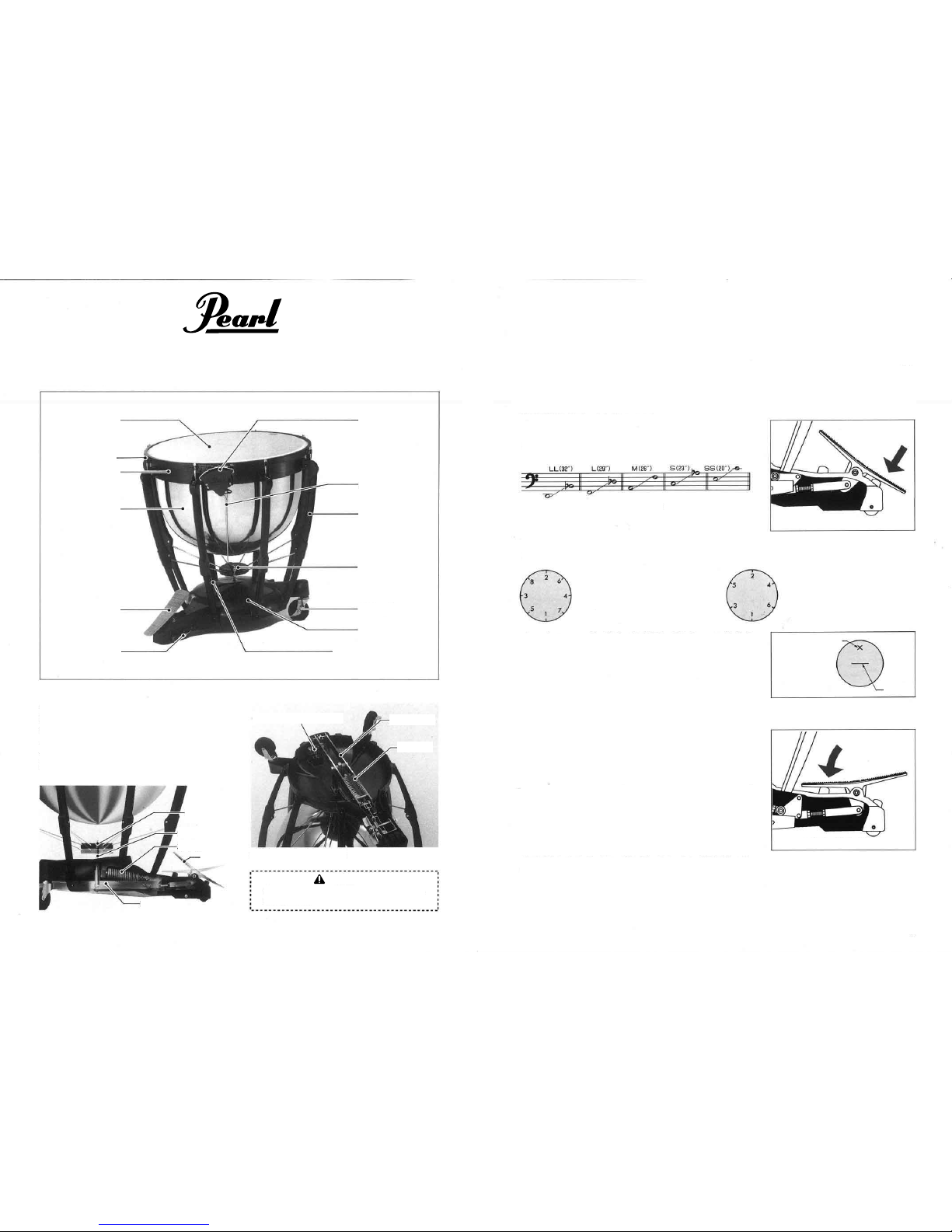

Head

Hoop

Support Ring

Kettle

Pedal

Sub Wheel

Master Wheel

Tuning Rod

Post

Master Wheel

Main Wheel

Base

Spring Tension

Adjustment Bolt

Balance Spring Action Pedal System

By keepi ng the appropriate bal ance of the

spring tension and the head ten sion, this

system allows swift and smooth pedal action

as well as achieving accurate tuning.

Center Shaft

Spring

Spring

Do not put your hands or your feet under

the pedal to avoid injury.

Pedal

Action Bar

Action Bar

Pedal Torque Control

CAUTION

1.

2.

3. Lightly strike the head with a mallet approximately 5cm

from the edge at each tuning bolt, and find the tuning

bolt with the highest pitch ("Home Tone").

4. When you have found the bolt with the highest pitch,

tighten the other bolts to match the "Home Tone" pitch

in the sequence shown above. Do not strike the heads

too hard, and make sure that you strike lightly so that

you can distinguish the sound of each tuning bolt.

5.

When every bolt has been tuned, the lowest note has

been fixed. Next press and depress the pedal a few

times to have the head fix to the kettle. Tighten the bolt

with care when the head stretches during this procedure.

6.

After the lowest note has been fixed, press the pedal and

check the highest note. Make adjustments if neccesary.

Repeat the above process a few times, and you can tune the timpani from the lowest note to the

highest note by pressing and depressing the pedal smoothly.

Page 2

Replacing the Head

Pedal Torque

Adjustment

Maintenance

Tuning Gauge (TG-50)

The kettle is very fragile. Take extra caution

and p revent any damage or harm to the

kettle.

Use soft cloth to wipe off any dirt. Use extra

care and do not wipe with strength.

Place your foot on the pedal and loosen the

tuning bolts i n the sequence previou sly

mentioned. Do not turn the bolts at once

and loosen by 1/2 or 1/4 of a turn.

When you loosen th e

tuning bolts, the pedal

will suddenly be pulled

down. Place a tennis

ball under the pedal to

prevent injury.

Kettle

After using the instrument, press the pedal so

that the pointer comes to the middle of the

gauge . Wh en you ar e no t us ing the

instrument for a long time, press the pedal

fully on the heel side to be tuned at the lowest

note.

Make sure to wi pe t he head a fter use,

especially where you hands have touched.

Do not forget to place the head protection

cover included to protect the heads.

Head

Place a

Tennis Ball

CAUTION

CAUTION

1.

2.3.When yo u have a ll the te nsio n rods

unscrewed, remove the head off with the hoop.

4.

Put the hoop back on and turn the tuning

bolts. Follow the procedures p reviously

mentioned in "Tuning your Pedal Timpani"

and have your timpani fine-tuned

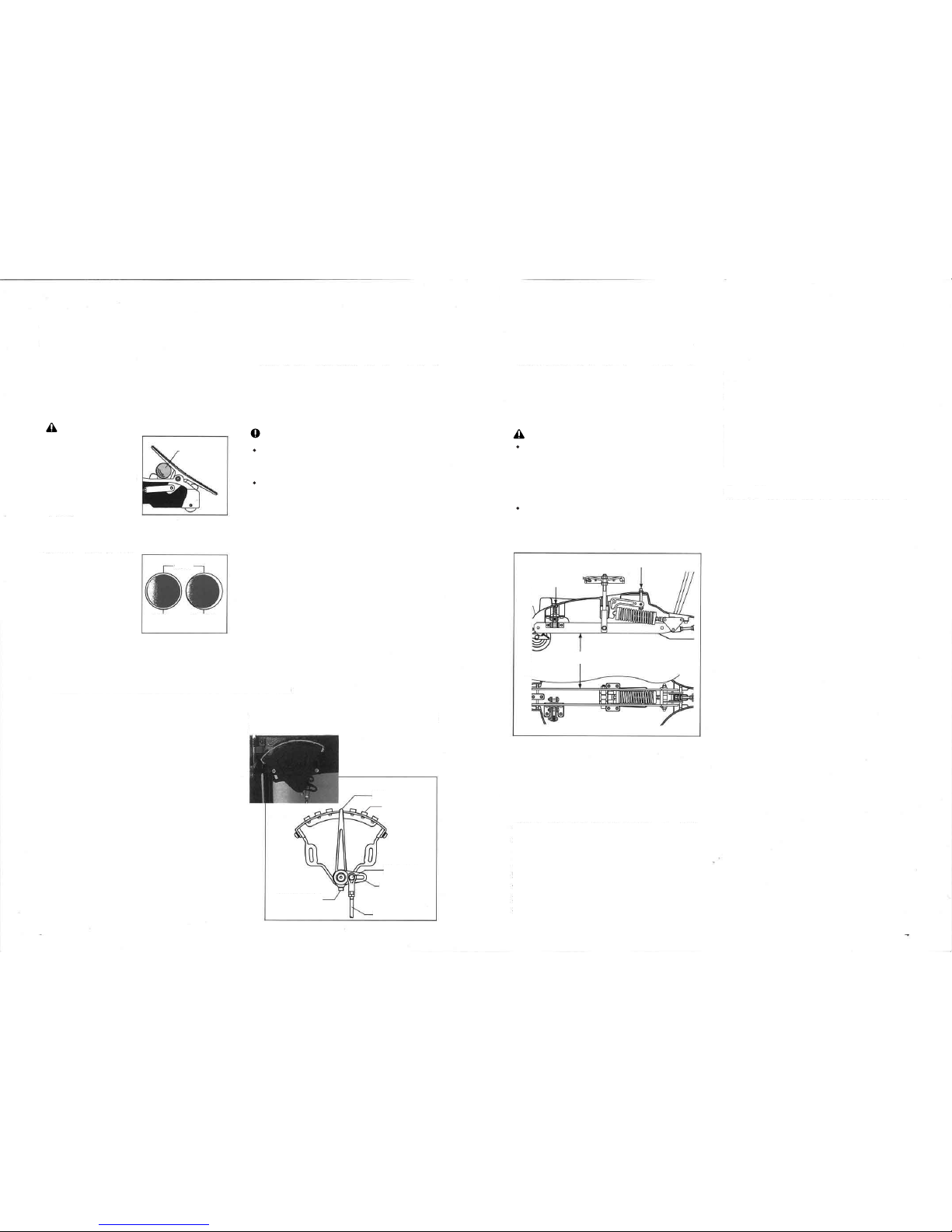

The pedal is adjusted at the factory, but can

be adjusted for lighter or heavier feel. Turn

the Torque Adjustment Screw clock wise

with the provided Allen wrench.

Spring Tension

Adjustment

The pedal spring tension can be adjusted

by turning the Spring Tension Adjustment

Bolt. Turn the bolt clockwise for stronger

tension when the toe part of the pedal rises.

Turn t he b olt anti clock wise for weake r

tension wh en the hee l part of the pedal

rises.

The pedal is adjusted at the lightest feel at

the factory. Do not turn anti cl ockwise.

Forcing the screw to turn with tools other

than provided will cause damage.

This system is not to fix the position of the

pedal. Do not force to turn the screw over

an extent.

The Tuning Gauge equipped on the 88 series

timpani shows where to set the pedal for each

note.

The Tone Mar k is set depe nding on the

timapni size and the position can be adjusted

to match the position of the Pointer.

The Pointer is adjusted at the factory. Make

sure that it moves from the highest tone to the

lowest tone, and make adjustments on the

position of the Tone Marks if neccesary.

If the Pointer does not move in the correct

radius, adjust by loosening the Adjustment

Screw with the provided Allen wrench. Make

sure to retighten after adjustment.

If the Pointer moves out of the radius, loosen

the nut on the Link Ball, and move the Tuning

Rod to the right

It is recommended that the heads should be

replaced at least once in two years.

The head size should be 2" larger than the

kettle size.

For example, 88M (26") should have 28"

heads

Correct position;

head in center

Wrong position;

head off center

Kettle

Pointer

Torque

Adjustment

Screw

Spring Tension Adjustment Bolt

Action Bar

Link Ball

Adjustment

Arm

Adjustment

Screw

Tone Mark

Tuning Rod

Place the new head to

the kettle. Make s ure

that the head is

in the

center of the kettle.

NOTE

Loading...

Loading...