Page 1

4MWP

4” Submersible Motors

INSTALLATION AND OPERATING INSTRUCTIONS

Page 2

4MWP

4” Submersible Motors

OVERVIEW

1.

Please read this documentation carefully before installation.

This manual gives important information concerning the installation, use and maintenance of the motors.

The contents of this manual refer to the standard product, as presented in the sales documentation.

The installation and operation must comply with the safety regulations in the country in which the product

is installed.

The entire operation must be carried out in a workmanlike manner.

Failure to comply with the safety regulations not only causes risk to personal safety, it can also damage

the equipment and it will invalidate every right to assistance under guarantee.

2. SAFTEY

Below are the warning symbols used in this manual to warn of perticular dangers

ELECTRIC SHOCK DANGER

The non observance of the prescription involves electric shock risk.

DANGER

The non observance of the prescription involves the risk of damages to persons

and / or equipment.

MECHNICAL DANGER

The non observance of the prescription involves the risk of technical damages

to the motor and / or installation.

3. APPLICATIONS

All the motors in the 4MWP ranges can be used to drive

submersible pumps in the conditions established in

CSA Standard C22.2 No. 100-14 (Motors and Generators)

UL Standard 1004-1 (Electric Motors),

and at the supply voltage / frequency specified on the rating plate.

The shaft extension and flange size of these motors comply with NEMA MG1:2016.

The power of the pumps coupled to these motors must be less than or equal to that of the motors.

Page 3

4” Submersible Motors

4. LIQUIDS IN WHICH THE MOTOR CAN OPERATE

This motor can be used in cold water.

Do not use this motor with corrosive or explosive liquids

Do not use this motor with particularly dirty or hard water

(impurities may deposit on the outer casing.

5. COMPATIBLE PUMPS

Make sure the motor is compatible with the pump. Incompatible combinations may cause problems.

In particular, before coupling the motor to the pump check that:

- The power of the motor is greater than or equal to the power absorbed by the pump end.

4MWP

- The rpm of the pump matches the rotational frequencey of the motor.

- The pump has a NEMA motor connection and that the shaft turns freely.

6. MOTOR POWERED BY A FREQUENCY CONVERTER

Variable Frequencey Drive’s VFD’s are used to change the rotational speed of the motor so that the out-put of the

attached pump adjusts to the users demand for water.

VFD’s also reduce the starting current and “water hammer” during starting.

PEARL’s three-phase, encapsulated submersible motors can be used with variable frequency drives (VFD) when

used within the guidelines listed here.

All three-phase, encapsulated submersible motors must have the VFD sized based on the motor’s nameplate maximum amps, NOT horsepower. The continuous rated amps of the VFD must be equal to or greater than the motor’s

nameplate maximum amps or warranty will be void.

The VFD must have one RLC output filter to limit the voltage peaks and/or to reduce the dV/dt of the pulses generated by the inverter. The application of the filter will help to reduce the stress on the motor insulation (thermal and

electrical). The filter can be installed at the inverter output to reduce the dV/dt value or at the motor terminals to

attenuate the voltage peaks amplitude.

The motor must reach or pass the 30 Hz operating speed within 1 second of the motor being energized.

If this does not occur, the motor bearings will be damaged and the motor life reduced.

Page 4

4MWP

4” Submersible Motors

6. VFD continued.

PD WATER SYSTEMS suggests these MAX values for three phase encapsulated submersible motors

Max. Vpeak voltage: 1000 V phase-phase

Max. dV/dt :2000 V/μs

Filters are usually applied when the power cable to the motor is longer than 50ft (15.2m)

PD WATER SYSTEMS suggests the use of an input filter when the VFD is used in a residential area, to protect other

devices connected to the same mains from noise caused by the VFD

Frequency range: 30 Hz – 60 Hz

Drive carrier frequency: The range must be from 4.5k to 5k Hz .

Higher values will increase the quantity of Voltage Spikes x per second and reduce motor insulation lifetime.

Lower values give a poor shape to the power curve.

Ramp-up time / Ramp down time: | df/dt | > 30 Hz/sec (where f indicates the frequency) to ensure the life of the

thrust bearings

The motor’s operating speed must always operate so the minimum cooling flows are reached.

0.50 ft/sec for 6-inch motors

0.98 ft/sec for 4-inch motors

Motor overload protection must trip within a time equal to or faster than how indicated by Class 10 overload curve

and must trip within 115% of the nameplate Max. Amp.

PEARL’s encapsulated submersible motors are not declared inverter duty motors by NEMA MG1

standards. The reason is NEMA MG1 standard part 31 does not include a section covering

encapsulated winding designs.

PEARL’s submersible motors can be used with VFDs without problems or warranty concerns providing

all PD WATER SYSTEMS guidelines are followed.

PEARL’s single-phase, 2- and 3-wire, encapsulated submersible motors hould only be used with the

appropriate variable speed drive.

7. INSTALLATION

Before installing the motor, read both the motor and pump instructions manuals.

Keep both manuals an a safe place.

If the product shows any signs of damage, do not proceed with installation and call your local

stockest / distributor.

You must use suitable equipment and protective devices. Observe all accident prevention regulations.

Installations must always e in accordance with current local and/or national regulations, legislation and bylaws

governing installation of water and power equipment.

PEARL submersible motors are designed to be used in a shaft up vertical position.

During acceleration, the pump thrust increases as its output head increases. In cases where the pump head stays

below its normal operating range during startup and full speed condition, the pump may create upward thrust. This

creates upward thrust on the motor upthrust bearing. This is an acceptable operation for short periods at each start,

but running continuously with upthrust will cause excessive wear on the upthrust bearing.

Page 5

4MWP

4” Submersible Motors

8. ELECTRICAL CONNECTIONS TO THE ELECTRIC PUMP

Electrical connections may only be performed by a qualified installer in compliance with current

regulations.

Make sure that the supply voltage and frequency are compatible with the electrical panel.

The relative information is shown on the motor rating plate and in the documents supplied with the panel.

Provide suitable short circuit protection on the supply line.

Before proceeding, make sure that all the connections (even if they are potential-free) are voltage-free.

Unless otherwise specified in local bylaws, the supply line must be fitted with:

- a short circuit protection device,

- a high sensitivity ground-fault circuit interrupter (GFCI) residual current circuit breaker (30mA)

for additional protection from electrocution in case of inefficient grounding,

- a general switch with a contact aperture of at least 3 millimetres.

Ground the system in compliance with current regulations

Table 1: Power supply voltage tolerances

Power supply voltage tolerances:-

Frequencey in Hz Phase ~ Voltage Tolerance %

60 1 115v -10% +6 %

60 1 230v -10% +6 %

60 3 480v -10% +6 %

60 3 575v -10% +6 %

Single-phase version

Connect the electric pump to a supply line via a suitable electrical control panel containing the

overload protection and the capacitor.

Refer to the wiring diagram on the outer casing of the motor and in figure 1 and the documentation supplied with

the electrical panel.

Refer to the motor rating plate for the capacity of the capacitor.

Install the electrical panel in a sheltered area.

Three-phase version

Connect the electric pump to a supply line via a suitable electrical control panel .

Install the electrical panel in a sheltered area.

Refer to the documentation supplied with the electrical panel.

For connections to any external control devices (e.g.: pressure switch, float) follow the instructions supplied with

these devices

9. MAINTENANCE, SERVICE

Before proceeding, always make sure the motor is disconnected from the supply line.

Maintenance operations may only be performed by expert and qualified people.

Use suitable equipment and protective devices. Observe all accident prevention regulations.

Do not attempt to disconnect the connector from the motor head cable.

This may only be done by authorised personnel.

The motor does not require any scheduled routine maintenance.

Users wishing to prepare a maintenance schedule should bear in mind that maintenance frequencies depend on the

conditions of use.

For any requirements, please contact our Sales and Service Department.

Page 6

4MWP

4” Submersible Motors

10. SPARE PARTS

Only use original spare parts to replace faulty components.

Always specify the exact type of motor and code when requesting our Sales and Assistance Service for technical

information or spare parts.

Only use origional spare parts to replace faulty components. Unsuitable spare parts may cause the product to work

incorrectly and cause hazards for people and property.

11. STORAGE

PEARL submersible motors are a water-lubricated design.

The fill solution consists of a mixture of deionized water and Propylene Glycol (a non-toxic antifreeze).

The solution will prevent damage from freezing in temperatures to -23°F (-5°C);

motors should be stored in areas that do not go below this temperature.

There may be an interchange of fill solution with well water during operation. Care must be taken with motors

removed from wells during freezing conditions to prevent damage.

When the storage temperature does not exceed 104°F (40°C), storage time should be limited to two years. Where

temperatures reach 100° to 130°F, storage time should be limited to one year.

Loss of a few drops of liquid will not damage the motor as an excess amount is provided, and the filter check valve

will allow lost liquid to be replaced by filtered well water upon installation. If there is reason to believe there has

been a considerable amount of leakage, consult the factory for checking procedures.

PEARL recommend that you leave the motor in its original packaging until the day of installation.

When standing the motor upright make sure that it cannot fall over (shaft always upwards).

Do not subject the motor to direct sunlight or other heat sources.

12. FREQUENCY OF STARTS

The average number of starts per day over a period of months or years influences the life of a

submersible pumping system.

Excessive cycling affects the life of control components such as pressure switches, starters, relays and capacitors.

Rapid cycling can also cause motor spline damage, bearing damage, and motor

overheating.

All these conditions can lead to reduced motor life.

The pump size, tank size and other controls should be selected to keep the starts per day as low as practical for

longest life.

4 Inch motors should run a minimum of two minutes in order to dissipate heat built up from starting.

Table2: Maximum # starts per day

Motor Rating

Maximum # starts per day

HP KW SINGLE-PHASE THREE-PHASE

0.5 - 1.0 0.37 - 0.75 300 300

1.5 - 5.0 1.1 - 3.7 100 300

7.5 - 10 5.5 - 7.5 50 200

Page 7

4MWP

4” Submersible Motors

13. MOUNTING POSITION

PEARL submersible motors are designed primarily for operation in the vertical, shaft-up position.

During acceleration, the pump thrust increases as its output head increases. In cases where the pump head stays

below its normal operating range during startup and full speed condition, the pump may create upward thrust. This

creates upward thrust on the motor upthrust bearing. This is an acceptable operation for short periods at each start,

but running continuously with upthrust may cause excessive wear on the upthrust bearing

With certain restrictions, motors are also suitable for operations in positions from shaft-up to shaft-horizontal. As

the mounting position becomes further from vertical and closer to horizontal, the probability of shortened thrust

bearing life increases. For normal thrust bearing life expectancy with motor positions other than shaft-up, follow

these recommendations:

1. All the motors in the range can be installed horizontally as long as the axial thrust of the

pump never falls below 100 N while it is working.

2. Do not use in systems which can run even for short periods at full speed without thrust

toward the motor

3. Minimize the frequency of starts, Six inch motors should have a minimum of 20 minutes

between starts or starting attempts

Page 8

4” Submersible Motors

14. WATER TEMPERATURE AND FLOW

PEARL standard submersible motors are designed to operate up to maximum service factor

horsepower in water up to 95°F (35°C).

A minimum flow of 0.98 ft/sec for 4” motors is required for proper cooling.

Table 3: Minimum GPM required for motor cooling in water up to 95°F (35°C)

Minimum GPM required for motor cooling in water up to 95°F (35°C)

4MWP

Casing or Sleeve

I.D. Inches (mm)

4" 102 6.5 (24.5)

5" 127 28 (106)

6" 152 55 (208)

7" 178 86 (325)

8" 203 122 (461)

10" 254 209 (791)

12" 305 315 (1192)

14" 356 440 (1665)

16" 406 585 (2214)

The table shows minimum flow rates, in GPM, for various well diameters and motor sizes

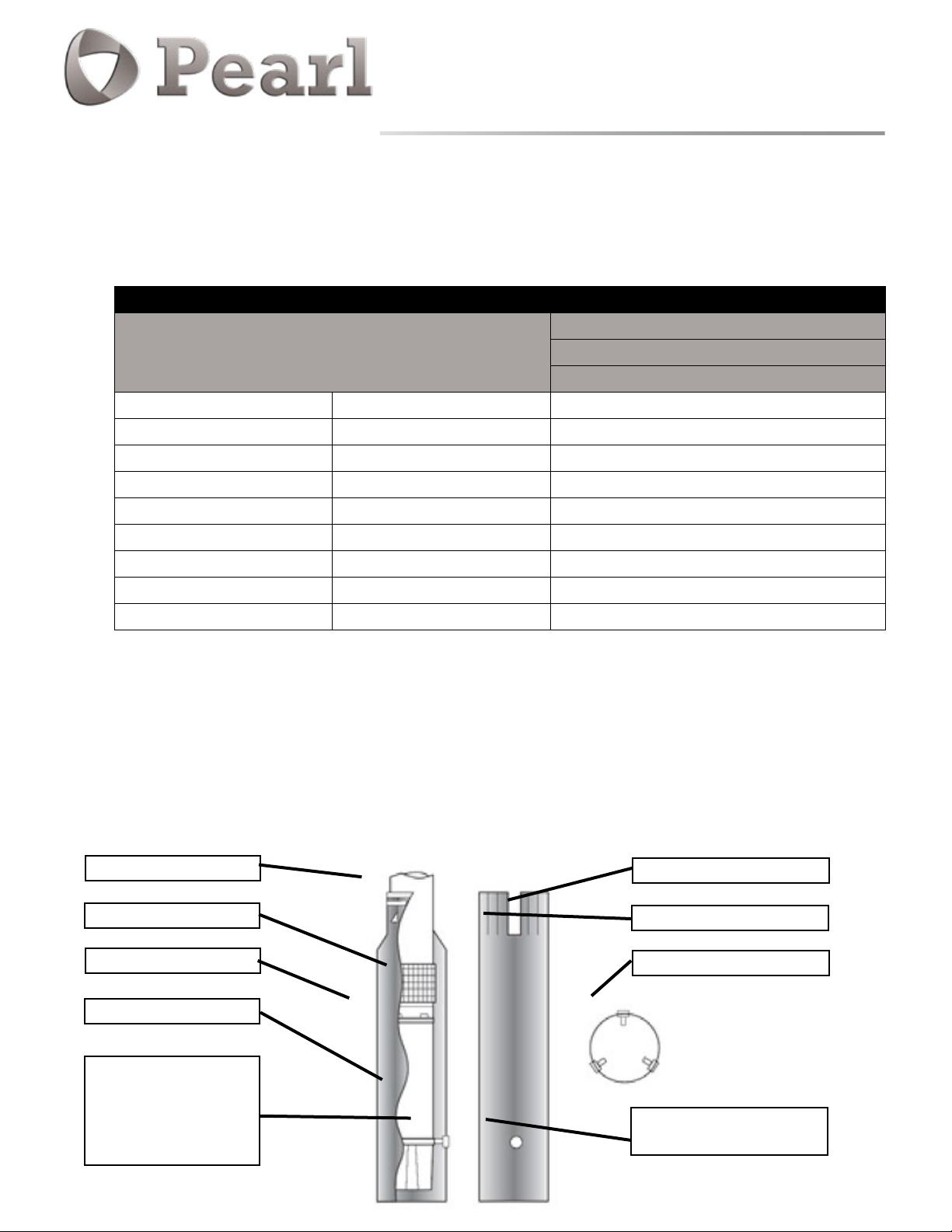

15. FLOW INDUCER SLEEVE

If the flow rate is less than specified or coming from above the pump, then a flow inducer sleeve must be used. A flow

sleeve is always required in an open body of water.

Figure shows a typical flow inducer sleeve construction.

Example : A four-inch motor and pump that delivers 60 GPM will be installed in a 8” well.

From Table 2

A 122 GPM flow would be required to maintain proper cooling in an 8” casing, as the 6” casing

requires a min flow of 55gpm then adding an 6” or smaller flow sleeve provides the required cooling.

Worm Worm clamps

4" Motor (1/2-10Hp)

0.98 ft/sec (0.3m/sec)

GPM (l/min)

Saw cuts

Intake

Flow inducer sleeve

Submersible motor

Centering bolt

Centering bolts must

be located on motor

casting. Do not locate

on stator shell

Notch out for cable guard

Lock nuts inside sleeve

Bottom view

Centering bolt hole

(3 required) 120°

Page 9

4MWP

4” Submersible Motors

16. HOT WATER APPLICATION

When the pump-motor operates in water hotter than 95°F (35°C), a flow rate of at least 11.5 ft/sec is required. When

selecting the motor to drive a pump in over 95°F (35°C) water, the motor horsepower must be de-rated per the

following procedure.

Using next Table to determine pump GPM required for different well or sleeve diameters.

If necessary, add a flow sleeve to obtain at least 11.5 ft/sec flow rate.

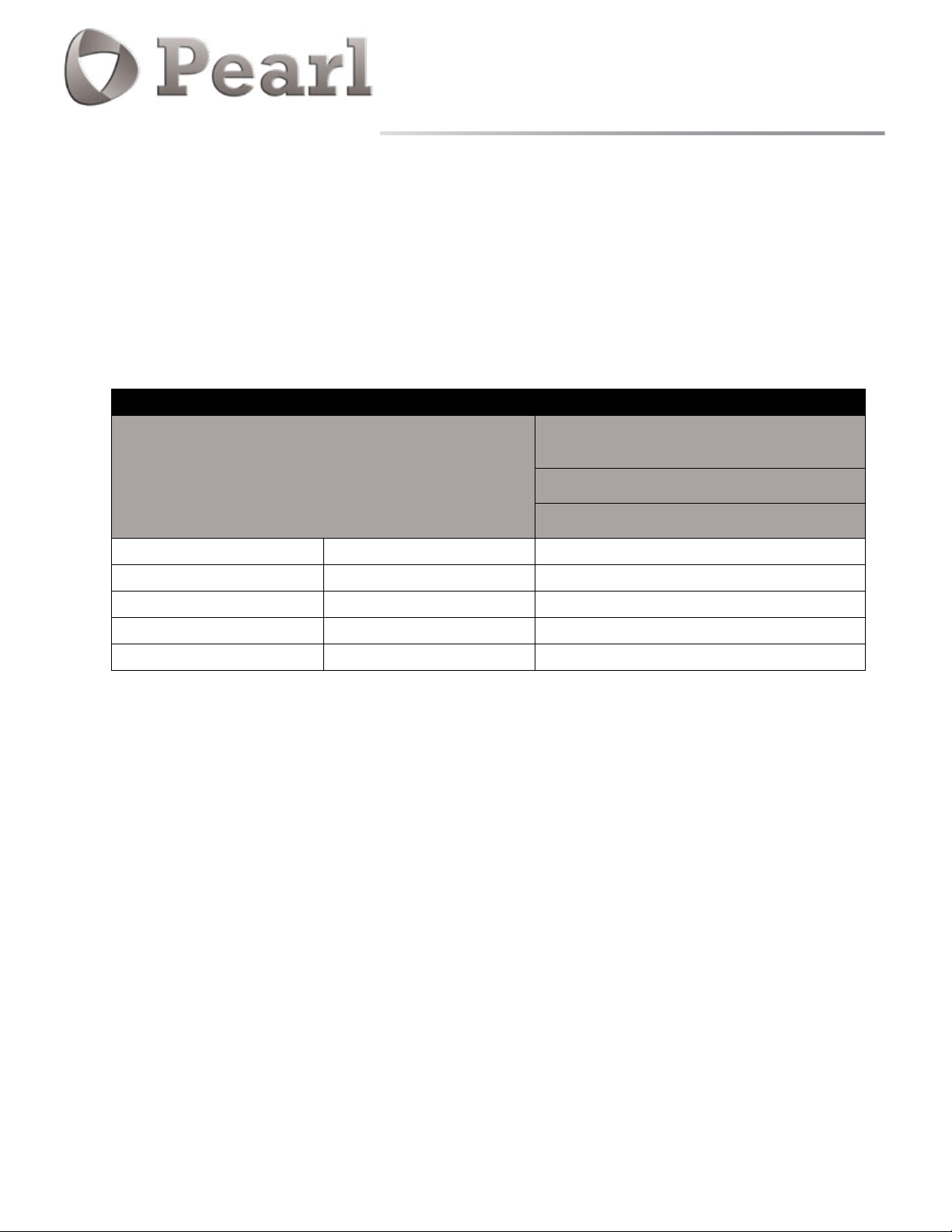

Table 4: Minimum GPM required for motor cooling in water above 95°F (35°C)

Minimum GPM required for motor cooling in water above 95°F (35°C)

4" Motor (1/2-10Hp)

Casing or Sleeve

I.D. Inches (mm)

11.5 ft/sec (3.2m/sec)

6" Motor

GPM (l/min)

4" 102 75 (283)

5" 127 330 (1244)

6" 152 650 (2450)

7" 178 86 (325)

8" 203 122 (461)

The table shows minimum flow rates, in GPM, for various well diameters and motor sizes

17. CONTROL BOX MOUNTING

Single phase submersible control boxes feature NEMA 3R enclosures for indoor or outdoor mounting. They should be

mounted in a vertical position as relay manufacturers recommend correct relay

positioning for proper, trouble-free operation.

Control boxes should be shaded from direct sunlight in areas where temperatures exceed 95°F (35°C) as excessive

heat may dry out capacitors and shorten their life. It is advisable to paint the enclosure white if outside in very hot,

sunny climates.

Page 10

L

38,17

-

0,12

+

0,13

23

±0,5

15

0

+

0,5

15,5

+

0,03

+

0,05

B

0,5

+

0

15

A

15,5

+

0,05

+

0,03

18. 4MWP 2 WIRE MOTOR DIMENSIONS

4MWP

4” Submersible Motors

0,12

Table 5: 4MWP 2 WIRE MOTORS

0,13

-

+

D

±0,5

C

38,17

23

L

4MWP DIMENSIONS

SINGLE PHASE MOTORS

Typ e

P2

Tipo

Tipo

[hp] [kW]

0.5/115v

0.5/230v

60 Hz

0.75

1

1.5

4MWP DIMENSIONS

Pos.

mm

Ø 15.5

+0.5

15

+0.5

23

38.17

-0.5

+0.05

-0

+0.13

-0.03

-0.12

A

B

C

D

L

[mm] [inch]

0.37 341

0.37 331

0.55 351

0.75 426

1.1 471

13.425

13.031

13.819

16.772

18.543

inch Pos.

+0.002

0.61”

0.591”

0.906”

1 1/2"

+0.02

+0.02

+0.005

-0.003

-0

-0.005

-0.02

E

F

G

Weight TW

Peso TW

Peso TW

[Kg] [lbs]

9.7

9.5

10.5

13.1

15.1

mm

+0.4

37.2

Ø 76.2

Ø 87.3

21.4 500

21 500

23.2 500

28.9 700

33.3 700

inch

1.465”

+.01

+0

-0.4

-0.1

+0.004

3"

3.437”

-0

+0.

-0

Axial thrust

Spinta assiale

Empuje axial

[lbf]

+0.016

-0.016

-0.004

5/16

”

24 UNF

M

8

E

F

37,2

±0,4

G

+

0,1

76,2

0

0

87,3

-

0,1

Page 11

L

23

±0,5

38,17

-

0,12

+

0,13

15

0

+

0,5

15,5

+

0,03

+

0,05

19. 4MWP 3 WIRE MOTOR DIMENSIONS

0,12

0,13

-

+

D

38,17

L

C

±0,5

23

B

0

0,5

+

15

A

15,5

+

0,05

+

0,03

4” Submersible Motors

Table 6: 4MWP 3 WIRE MOTORS

4MWP DIMENSIONS

SINGLE PHASE MOTORS

Typ e

60 Hz

3W

THREE PHASE MOTORS

Typ e

60 Hz

P2

[hp] [kW]

0.5

0.75

1

1.5

2

3

5

0.37 266

0.55 286

0.75 346

1.1 411

1.5 411

2.2 544

3.7 684

P2

[hp] [kW]

0.5

0.75

1

1.5

2

3

0.37 236

0.55 266

0.75 286

1.1 346

1.5 391

2.2 504

5.5

7.5

10

5.5 684

7.5 764

[mm] [inch]

[mm] inch]

4 614

L

10.472

11.26

13.622

16.181

16.181

21.417

26.929

L

9.291

10.472

11.26

13.622

15.394

19.843

24.173

26.929

30.079

4MWP

8.8

9.7

12.6

14.7

14.8

20.5

27.1

7.4

8.8

9.7

11.7

13.8

18.5

23.5

27.1

31.1

Weight GG

[Kg] [lbs]

19.4 500

21.4 500

27.8 700

32.5 700

32.7 700

45.2 1500

59.8 1500

Weight GG

[Kg] [lbs]

16.3 500

19.4 500

21.4 500

25.8 700

30.5 700

40.8 1500

51.9 1500

59.8 1500

68.7 1500

Axial thrust

[lbf]

Axial thrust

[lbf]

5/16

”

24 UNF

M8

E

F

37,2

G

76,2

87,3

±0,4

+

-

4MWP DIMENSIONS

Pos.

A

B

C

D

0,1

0

0

0,1

Ø 15.5

15

23

38.17

mm

+0.05

+0.5

+0.5

+0.13

inch Pos.

0.610 E

-0.03

0.591 F

-0

-0

-0.12

7

/8" G

1 1/2"

mm

37.2

Ø 76.2

Ø 87.3

+0.4

+.01

+0

-0.4

-0.1

inch

1.465

-0

3"

3 3/8"

Page 12

4MWP

4” Submersible Motors

20. SINGLE PHASE - MOTOR DATA

Table 8: 4MWP 2 WIRE MOTOR DATA

ELECTRICAL DATA 4MWP 2W

SINGLE PHASE MOTORS

P2 V

[hp] [kW]

0.5 0.37

0.75 0.55 230 1.5 6.3 6.9 4.3 0.65 1200 3450 0.82 47 25 3x14 5½

1 0,75 230 1.4 7.7 8.8 4.8 0.68 1500 3450 0.84 50 35 3x14 5½

1.5 1.1 230 1.3 11.8 12.7 4.7 0.7 2120 3450 0.85 53 40 3x14 5½

[V]

115 1.6 8.6 10 4.2 0.65 800 3450 0.88 46 80 3x14 5½

230 1.6 3.9 5 4.6 0.65 800 3450 0.88 46 20 3x14 5½

SF

Table 9: 4MWP 3 WIRE MOTOR DATA

ELECTRICAL DATA 4MWP 3W

[A]

In

In (SF)

Is/In Cs/Cn

[A]

P1

[W]N[min-1]

Cos j

h

%

C

[µF]Ø[AWG ]

LC

[ft]

SINGLE PHASE MOTORS

P2 V

[hp] [kW]

0.5 0.37

0.75 0.55 230 1.5 7.4 8.6 4.6 3.6 1100 3450 0.65 53 - 86-103 4x14 5½

1 0.75 230 1.4 8.0 9.8 5.5 2.9 1350 3450 0.68 58 - 105-126 4x14 5½

1.5 1.1 230 1.3 10.0 12.0 6.0 1.9 1800 3450 0.81 64 10 105-126 4x14 5½

2 1.5 230 1.25 10.5 12.3 5.3 2.3 2200 3450 0.95 69 20 105-126 4x14 5½

3 2.2 230 1.15 14.3 16.2 5.5 2.1 3100 3450 0.97 72 45 208-250 4x14 5½

5 3.7 230 1.15 22.2 25.5 5.5 1.8 5000 3450 0.99 74 2x40 270-324 4x14 8 ¾

P2: Rated output - Potenza nominale - Potencia nominal

V: Rated voltage - Tensione nominale - Tension nominal

SF: Service factor - Fattore di servizio - Factor de servicio

In: Rated current - Corrente nominale - Corriente nominal

In (SF): Service factor current - Corrente al fattore di servizio - Corriente al factor de servicio

Is/In: Locked rotor current/Rated current - Corrente avviamento/Corrente nominale Corriente de arranque/Corriente nominal

Cs/Cn: Locked rotor Torque/Rated Torque - Coppia avviamento/Coppia nominale Cupla de arranque/Cupla nominal

[V]

115 1.6 10.0 12.6 4.0 3.2 800 3450 0.71 48 - 250-300 4x14 5½

230 1.6 5.5 6.8 4.2 3.9 800 3450 0.62 46 - 59-71 4x14 5½

SF

[A]

In

In (SF)

Is/In Cs/Cn

[A]

P1

[W]N[min-1]

P1: Power consumption - Potenza assorbita - Potencia absorbida

N: R.P.M - Giri al minuto - Revoluciones por minuto

Cos φ: Power factor - Fattore di potenza - Factor de potencia

η: Eciency - Rendimento - Rendimiento

C: Capacitor - Condensatore - Capacidad del condensador

Ø: Cable section - Sezione del cavo - Sección del cable

LC: Cable length - Lunghezza del cavo - Longitud de cable

Cos j

100%

Load

h %

100%

LoadC1[µF]C2[µF]Ø[AWG ]LC[ft]

Page 13

4MWP

4” Submersible Motors

21. THREE PHASE - MOTOR DATA

Table 11: 4MWP 3 PHASE MOTOR DATA

ELECTRICAL DATA 4MWP

THREE PHASE MOTORS

P2 V

[hp] [kW]

0.5 0.37

0.75 0.55

1 0.75

1.5 1.1

2 1.5

3 2.2

5.5 4

7.5 5.5

10 7.5 460 1.15 15.4 16.9 7.1 3.9 9100 3450 0.74 82 4x14 11½ 11½

[V]

230 1.6 3.6 3.7 4.4 3.4 690 3450 0.48 54 4x14 5½ 5½

460 1.6 1.6 1.9 5.0 3.2 650 3450 0.54 57 4x14 5½ 5½

230 1.5 4.6 4.9 5.2 3.7 860 3450 0.47 63 4x14 5½ 5½

460 1.5 2.2 2.4 5.5 3.6 840 3450 0.48 65 4x14 5½ 5½

230 1.4 4.7 5.2 6.4 4.3 1200 3450 0.63 63 4x14 5½ 5½

460 1.4 2.6 2.8 5.8 4.2 1200 3450 0.59 63 4x14 5½ 5½

230 1.3 8.1 8.5 5.9 4.2 1800 3450 0.54 61 4x14 5½ 5½

460 1.3 3.6 3.9 6.7 4.1 1720 3450 0.60 64 4x14 5½ 5½

230 1.25 10.2 10.8 6.1 3.9 2290 3450 0.54 65 4x14 5½ 5½

460 1.25 4.6 4.9 6.7 3.8 2160 3450 0.59 69 4x14 5½ 5½

230 1.15 10.7 11.6 7.5 4.8 3100 3450 0.69 71 4x14 5½ 5½

460 1.15 5.6 6.0 7.1 4.8 3050 3450 0.68 72 4x14 5½ 5½

230 1.15 16.7 17.3 7.9 3.7 4300 3450 0.65 70 4x14 8 ¾ 8 ¾

460 1.15 7.2 7.6 7.4 4.0 5300 3450 0.75 75 4x14 8 ¾ 8 ¾

230 1.15 25.7 27.5 7.0 3.9 7260 3450 0.71 76 4x14 8 ¾ 8 ¾

460 1.15 12.0 13.0 7.5 3.8 7050 3450 0.74 79 4x14 8 ¾ 8 ¾

SF

[A]

In

In (SF)

Is/In Cs/Cn

[A]

P1

[W]

N

[min-1]

Cos j

100%

Load

h %

100%

Load

C

[µF]Ø[mm2]

LC

[ft]

Page 14

4” Submersible Motors

22. SINGLE PHASE MOTOR WINDING RESISTANCES

Table 13: 4MWP 1 PHASE 2 WIRE MOTOR WINDING RESISTANCES

ELECTRICAL DATA 2 WIRE

4MWP 2W SINGLE PHASE MOTORS

P2 V

[hp] [kW]

0.5 0.37

0.75 0.5 230 2.5

1.0 0.75 230 1.9

1.5 1.1 230 1.45

Table 14: 4MWP 1 PHASE 3 WIRE MOTOR WINDING RESISTANCES

ELECTRICAL DATA 3 WIRE

4MWP 3W SINGLE PHASE MOTORS

P2 V

[hp] [kW]

0.5 0.37

[V]

115 0.95

230 3.7

MAIN RESISTANCE START RESISTANCE

[V]

115 1.2 4.9

230 3.9 15

4MWP

WINDING RESISTANCE

0.75 0.5 230 3.0 10.8

1.0 0.75 230 2.4 9.9

1.5 1.1 230 1.8 9.1

2 1.5 230 1.9 5.7

3 2.2 230 1.2 2.5

5 3.0 230 0.8 1.5

Page 15

23. 4MWP THREE PHASE MOTOR WINDING RESISTANCES

Table 16: 4MWP 3 PHASE MOTOR WINDING RESISTANCES

ELECTRICAL DATA 60 Hz

4MWP THREE PHASE MOTORS

P2 V

[hp] [kW]

[V]

230 5.8

4MWP

4” Submersible Motors

WINDING RESISTANCE

0.5 0.37

0.75 0.5

1.0 0.75

1.5 1.1

2 1.5

3 2.2

460 25.6

575 39

230 3.9

460 17.3

575 26

230 2.4

460 13

575 19.7

230 2.2

460 8.9

575 14.6

230 1.5

460 6

575 9

230 1.3

460 5.1

575 7.7

230 0.83

5 3.0

7.5 5.0

10 7.5

460 3.3

575 5.2

230 0.6

460 2.35

575 3.7

460 2

575 3.2

Page 16

4MWP

4” Submersible Motors

24. MAXIMUM CABLE LENGTHS IN FT

Table 18: Single Phase 60Hz

Motor rating Copper Wire Size

Volts Hp 14 12 10 8 6 4 2 0 00 000 0000 250 300

115 0.5 100 160 250 390 620 960 1460 2160 2630 3140 3770

0.5 400 650 1020 1610 2510 3880 5880 8720

0.75 300 480 760 1200 1870 2890 4370 6470 7870 9380

1.0 250 400 630 990 1540 2380 3610 5360 6520 7780 9350

1.5 190 310 480 770 1200 1870 2850 4280 5240 6300 7620

2.0 150 250 390 620 970 1530 2360 3620 4480 5470 6700

230

3.0 120 190 300 470 750 1190 1850 2890 3610 4470 5550

5.0 180 280 450 710 1110 1740 2170 2680

7.5 200 310 490 750 1140 1410 1720

10 250 390 600 930 1160 1430 1760

15 270 430 660 820 1020 1260

Three Phase 60Hz

Motor rating Copper Wire Size

Volts Hp 14 12 10 8 6 4 2 0 00 000 0000 250 300

0.5 930 1490 2350 3700 5760 8910

0.75 670 1080 1700 2580 4190 6490 9860

1.0 560 910 1430 2260 3520 5460 8290

1.5 420 670 1060 1670 2610 4050 6160 9170

2 320 510 810 1280 2010 3130 4770 7170 8780

3 240 390 620 990 1540 2400 3660 5470 6690 8020 9680

230

460

575

5 230 370 510 800 1240 1900

7.5 230 360 570 890 1350 2030

10 270 420 660 1010 1520 1870

15 290 450 690 1040 1280 1540

20 350 530 810 990 1200 1450

25 280 430 650 800 970 1170 1340

30 350 540 660 800 970 1110 1270

0.75 2730 4350 6850

1.0 2300 3670 5770 9070

1.5 1700 2710 4270 6730

2 1300 2070 3270 5150 8050

3 1000 1600 2520 3970 6200

5 590 950 1500 2360 3700 5750

7.5 420 680 1070 1690 2640 4100 6260

10 310 500 790 1250 1960 3050 4680 7050

15 540 850 1340 2090 3200 4810 5900 7110

20 410 650 1030 1610 2470 3730 4580 5530

25 530 830 1300 1990 3010 3700 4470 5430

30 430 680 1070 1640 2490 3060 3700 4500 5130 5860

40 790 1210 1830 2250 2710 3290 3730 4250

50 640 980 1480 1810 2190 2650 3010 3420

60 830 1250 1540 1850 2240 2540 2890

1 3630 5800 9120

1.5 2620 4180 6580

2 2030 3250 110 8060

3 1580 2530 3980 6270

5 920 1480 2330 3680 5750

7.5 660 1060 1680 2650 4150

10 490 780 1240 1950 3060 4770

15 530 850 1340 2090 3260

20 650 1030 1610 2520 3860 5830

25 520 830 1300 2030 3110 4710

30 680 1070 1670 2560 3880 4770 5780 7030 8000

40 790 1240 1900 2860 3510 4230 5140 5830

50 1000 1540 2310 2840 3420 4140 4700 5340

60 850 1300 1960 2400 2890 3500 3970 4520

Page 17

4MWP

4” Submersible Motors

25. TIGHTENING MOTOR LEAD CONNECTOR SCREWS

4”Motors: 1.1 to 1.4 ft-lb. (1.5 to 1.9 N-m)

Screws tightening torques recommended for field assembly are shown. Rubber compression set within the first few

hours after assembly may reduce the screws torque. This is a normal condition which does not indicate reduced seal

effectiveness. Retightening is not required, but is permissible and recommended if original torque was questionable.

A motor lead assembly should not be reused. A new lead assembly should be used whenever one is removed from the

motor, because rubber set and possible damage from removal may prevent proper resealing of the old lead.

All motors returned for warranty consideration must have the lead returned with the motor.

26. SHAFT HEIGHT

Table 19: MOTOR SHAFT HEIGHTS

Motor Normal Shaft Height Dimension Shaft Height

4" 1 1/2" 38.17mm

27. CBWP CONTROL BOX DIMENSIONS

G

A

Free End Play

Min Max

1.508"

1.498"

H

G

C

B

38.30 mm

38.05 mm

CBWP BOX & KNOCKOUT DIMENSION

Pos. mm inch

A 124 4.9”

B 214 8.2”

C 74 2.9”

G PG 13.5 1/2” conduit

H PG 21 3/4” conduit

0.010" 0.045"

0.25 mm 1.14 mm

H

Volts/Hz Hp Motor kW Motor Start Cap. μF Volts

115/60 0.5 0.37 250-300 125

0.5 0.37 59-71 250

230/60

0.75 0.55 86-103 250

1 0.75 105-126 250

Page 18

28. CBWP CONTROL BOX DIMENSIONS

4MWP

4” Submersible Motors

H

G

A

Volts/Hz Hp Motor kW Motor Run Cap.μF Volts Start Cap.μF Volts

1.5 1.1 10 370 105-126 250

1.5 1.1 10 370 105-126 250

G

C

B

BOX & KNOCKOUT DIMENSION

Pos. mm inch

A 210 8.3”

B 249 9.8”

C 150 5.9”

G 34 1” Conduit

H 23

1

/2” Conduit

230/ 60

2 1.5 20 370 105-126 250

2 1.5 20 370 105-126 250

3 2.2 45 370 208-250 250

3 2.2 45 370 208-250 250

5 3.7 80 370 270-324 250

5 3.7 80 370 270-324 250

Page 19

29. 4CBWP - CONTROL BOX - WIRING DIAGRAMS

TO PREVENT HAZARD OF FATAL OR SERIOUS ELECTRIC SHOCK :

Connect this control enclosure, all metal plumbing, and the motor frame to the power supply grounding terminal

using copper wire complying wich electrical codes. A ground wire at least the size of power wires complies.

Smaller wire may comply under some conditions.

Permanently close all unused wiring operning in this and other equipment.

Switch off power to this circuit at the power supply panel (not in this control) before working on or around the

control, pipes, cable, pump or motor.

4MWP

4” Submersible Motors

Page 20

29. CBWP - CONTROL BOX - WIRING DIAGRAMS

INSTALLATION AND OPERATION:

Mounting – Be sure that the control box is mounted in a vertical position with the top side up. If it is

mounted in any other position, the starting relay may not function and the overload may trip.

Connections – The control box should be wired to the line and the motors as shown in the diagram.

The pump will not operate without this control box.

Operation without the control box will burn out the motor. Installation of this motor and control must

include circuit and component protection in compliance with U.S. National Electrical Code or Canadian

Electrical Code, Part.1

Protection – Trip of overload indicates a shorted capacitor, voltage problems, an overloaded or

locked pump, or the start relay should be replaced. Reset and analyse for tripping cause.

Do not remove or short out overload protection, since doing so is likely to cause motor burnout.

Use 75° C copper wires/conductors only, 14-10 AWG, tightening torque 20lbs*inch.

4MWP

4” Submersible Motors

For guarantee the Enclosure Type 3R need fix the box using 2 fixing holes.

0.5 – 0.75 1HP 60HZ 115/230 V

How to check the color code of a drop cable (Single-Phase 3-Wire Units)

With an ohmmeter measure:

Cable 1 to Cable 2, Cable 2 to Cable 3, Cable 3 to Cable 1

Find the highest resistance reading.

The lead not used in the highest reading is the yellow lead.

Use the yellow lead and each of the other two leads to get two readings:

Highest is the red lead.

Lowest is the black lead.

EXAMPLE:

The ohmmeter readings were:

Cable 1 to Cable 2 - 6 ohms Cable 2 to Cable 3 - 2 ohms Cable 3 to Cable 1 - 4 ohms

The lead not used in the highest reading (6 ohms) was Cable 3 so Cable 3 = Yellow

From the yellow lead, the highest reading (4 ohms) was To Cable 1 so Cable 1 = Red

From the yellow lead, the lowest reading (2 ohms) was To Cable 2 so Cable 2 = Black

Page 21

30. CBWP - CONTROL BOX - WIRING DIAGRAMS

TO PREVENT HAZARD OF FATAL OR SERIOUS ELECTRIC SHOCK :

Connect this control enclosure, all metal plumbing, and the motor frame to the power supply grounding terminal using copper wire complying wich electrical codes. A ground wire at least the size of power wires complies.

Smaller wire may comply under some conditions

Permanently close all unused wiring operning in this and other equipment.

Switch off power to this circuit at the power supply panel (not in this control) before working on or around the

control, pipes, cable, pump or motor.

INSTALLATION AND OPERATION:

Mounting – Be sure that the control box is mounted in a vertical position with the top side up. If it is mounted

in any other position, the starting relay may not function and the overload may trip.

Connections – The control box should be wired to the line and the motors as shown in the diagram.

The pump will not operate without this control box.

Operation without the control box will burn out the motor. Installation of this motor and control must include

circuit and component protection in compliance with U.S. National Electrical Code or Canadian Electrical Code,

Part.1

Protection – Trip of overload indicates a shorted capacitor, voltage problems, an overloaded or locked pump,

or the start relay should be replaced. Reset and analyse for tripping cause.

Do not remove or short out overload protection, since doing so is likely to cause motor burnout.

4MWP

4” Submersible Motors

Use 75° C copper wires/conductors only, 14-10 AWG, tightening torque 20lbs*inch.

For guarantee the Enclosure Type 3R need fix the box using 2 fixing holes.

CHECKING PROCEDURE: BE SURE POWER IS TURNED OFF:

A) OVERLOAD (Push reset button to make sure contacts are closed)

1. Ohmmeter setting: (Rx1).

2. Terminal connections: ohmmeter leads to overload terminals.

3. Ohmmeter reading: should not be over 0.5 ohms.

B) CAPACITOR (Disconnect one lead from each capacitor prior to checking)

1. Ohmmeter setting: (Rx1000).

2. Terminal connections: individual capacitor teminals.

3. Ohmmeter reading: pointer should swing toward zero then drift back toward infinity.

C) RELAY COIL (Disconnect lead from terminal 5)

1. Ohmmeter setting: (Rx1000).

2. Terminal connections: “5” and “2” on relay.

3. Ohmmeter reading: 4500-7000 ohms

D) RELAY CONTACT (Disconnect lead from terminal 1)

1. Ohmmeter setting: (Rx1).

2. Terminal connections: “1” and “2” on relay.

3. Ohmmeter reading: should be zero.

E) MAGNETIC CONTACTOR ONLY (Disconnect 1 coil lead)

1. Ohmmeter setting: (Rx100).

2. Check coil resistance: 1000-1400 ohms.

3. Remove contact cover and inspect contacts

Page 22

30. CBWP - CONTROL BOX - WIRING DIAGRAMS

2 HP 230V 60Hz BASIC 1.5 HP 230V 60Hz BASIC

4MWP

4” Submersible Motors

Page 23

30. CBWP - CONTROL BOX - WIRING DIAGRAMS

3 HP 230V 60Hz DELUXE 3 HP 230V 60Hz

4MWP

4” Submersible Motors

5 HP 230V 60Hz DELUXE 5 HP 230V 60Hz

Page 24

4MWP

4” Submersible Motors

31. THREE PHASE POWER UNBALANCE

A full three phase supply is recommended for all three phase motors, consisting of three individual transformers or one

three phase transformer. So-called “open” delta or wye connections using only two transformers can be used, but are

more likely to cause problems, such as poor performance overload tripping or early motor failure due to current

unbalance.

Transformer ratings should be no smaller than listed on Transformer Size Chart on the next page.

OPEN DELTA OR WYE FULL THREE PHASE

Checking and correcting rotation and current unbalance.

Establish correct motor rotation by running in both directions. Change rotation by exchanging any two of the three

1.

motor leads. The rotation that gives the most water flow is always the correct rotation.

After correct rotation has been established, check the current in each of the three motor leads and calculate the

2.

current unbalance as explained in 3 below. If the current unbalance is 2% or less, leave the leads as connected.

If the current unbalance is more than 2%, current read-ings should be checked on each leg using each of the

three possible hook-ups. Roll the motor leads across the starter in the same direction to prevent motor reversal.

3.

To calculate percent of current unbalance:

A. by three, yielding average current.

B. Pick the amp value which is furthest from the average current (either high or low).

C. Determine the difference between this amp value (furthest from average) and the average.

D. Divide the difference by the average. Multiply the re Add the three line amp values together.

E. Divide the sum sult by 100 to determine percent of unbalance.

Current unbalance should not exceed 5% at service factor load or 10% at rated input load. If the unbal-ance

4.

cannot be corrected by rolling leads, the source of the unbalance must be located and corrected. If, on the three

possible hookups, the leg farthest from the average stays on the same power lead, most of the unbalance is

coming from

the power source. However, if the reading farthest from average moves with the same motor lead, the primary

source of unbalance is on the “motor side” of the starter. In this instance, consider a damaged cable, leaking

splice, poor connection, or faulty motor winding

Page 25

31. THREE PHASE POWER UNBALANCE

Phase designation of leads for CCW rotation viewing shaft end.

To reverse rotation, interchange any two leads

Phase 1 or “A” – Black Motor Lead or T1

Phase 2 or “B” – Yellow Motor Lead or T2

Phase 3 or “C” – Red Motor Lead or T3

Notice: Phase 1, 2 and 3 may not be L1, L2 and L3.

4MWP

4” Submersible Motors

Example:

T1 = 51 amps + T1 = 50 amps +

T2 = 46 amps + T2 = 49 amps +

T3 = 53 amps = T3 = 51 amps =

Total = 150 amps Total = 150 amps

150/3 = 50 amps 150/3 = 50 amps 150/3 = 50 amps

50-46 = 4 amps 50-49 = 1 amps 50-48 = 2 amps

4/50 = 0.08 or 8% 1/50 = 0.02 or 2% 2/50 = 0.04 or 4%

32. TRANSFORMER SIZES

A full three phase supply is recommended for all three phase motors, consisting of three phase individual transformers

or one three phase transformer.

“Open” delta or wye connections using only two transformers can be used, but are more likely to cause problems from

current unbalance.

Transformer ratings should be no smaller than listed in the table for supply power to the motor alone.

T1 = 50 amps +

T2 = 48 amps +

T3 = 52 amps =

Total = 150 amps

Page 26

32. TRANSFORMER SIZES

A full three phase supply is recommended for all three phase motors, consisting of three phase individual transformers

or one three phase transformer.

“Open” delta or wye connections using only two transformers can be used, but are more likely to cause problems from

current unbalance.

Transformer ratings should be no smaller than listed in the table for supply power to the motor alone.

Table 20: TRANSFORMER SIZING

4MWP

4” Submersible Motors

KVA Rating (smallest) For Each Transformer

HP kW Required kVa

1.5 1.1 3.0 2.0 1.0

2 1,5 4.0 2.0 1.5

3 2.2 5.0 3.0 2.0

5 3.7 7.5 5.0 3.0

7.5 5.5 10 7.5 5.0

10 7.5 15 10.0 5.0

33. POWER SUPPLY BY A GENERATOR

Attention: the applicable tolerances from main supply must also be applied by power supply via generators

When operating a motor via a generator please bear in mind that the starting current of the motor is five times the

nominal motor current and that mean power factor of 0.6 for starting can be expected.

Also make sure that a sufficient generator power is permanently available and that for

starting the voltage must be at least 65% of the nominal motor Name plate voltage.

Open WYE or D 2

Transformers

Closed WYE or D 3

Transformers

Page 27

4MWP

4” Submersible Motors

INSULATION TESTING

34.

For the necessary inspections and insulation testing one tool is required:

Insulation measuring tester (Megaohmeter) unit 5OOv test, display up to min 200 M Ohm .

The correct execution of the junction (hermetic sealing) can be verified testing it under water for at least 15 min and

measuring with the Megaohmeter the insulation resistance between the metal recipient, filled with water (or water

itself) and each of the phase wires of the cable connected to the motor.

For a new motor the correct measurement has to be at least 200 M Ohm.

Another measure has to be done before installing the motor / pump in the place of use:

1

2

The exact values have to be at least 200 M Ohm for a new motor, and 20 M Ohm with a used motor installed.

It is always suggested to repeat this operation various times while lowering the motor/pump in the well.

connect a measuring cable to the ground lead

connect the other measuring cable to each conductor of the connected motor cable.

35. RESISTANCE OF THE DROP CABLE

The values below are for copper conductors. If aluminum conductor drop cable is used, the resistance will be higher.

To determine the actual resistance of the aluminum drop cable, divide the ohm readings from this chart by 0.61.

This chart shows total resistance of cable from control to motor and back.

Resistance in ohms per 100 ft of Wire @ 50 °F

Table 22: DROP CABLE RESISTANCE

AWG WIRE SIZE (COPPER) Reisitance Ohms MCM WIRE SIZE (COPPER) Reisitance Ohms

14 0.544 250 0.0088

12 0.338 300 0.0073

10 0.214 350 0.0063

8 0.135 400 0.0056

6 0.082 500 0.0044

4 0.052 600 0.0037

2 0.032 700 0.0032

0 0.021

00 0.017

000 0.013

0000 0.010

When measured through the drop cable, the resistance of the drop cablemust be subtracted from the ohmmeter

readings to get the winding resistance of the motor

Page 28

36. BOLT TORQUE SETTINGS

Table 23: TORQUE SETTING

Bolt Size Torque Setting in Nm (ft-lb)

4MWP

4” Submersible Motors

Steel 8.8 Stainless Steel 304-316/904

M6

M8

M10

M12

M14

M16

M18

M20

9 (6.638) 7 (5.163)

Steel 8.8 Stainless Steel 304-316/904

23 (16.964) 17 (12.539)

Steel 8.8 Stainless Steel 304-316/904

45 (33.190) 33 (24.340)

Steel 8.8 Stainless Steel 304-316/904

83 (61.218) 74 (54.580)

Steel 8.8 Stainless Steel 304-316/904

132 (97.3580) 119 (87.770)

Steel 8.8 Stainless Steel 304-316/904

200 (147.51) 183 (134.97)

Steel 8.8 Stainless Steel 304-316/904

275 (202.83) 260 (191.77)

Steel 8.8 Stainless Steel 304-316/904

390 (287.65) 370 (272.90)

WATER SYSTEMS

PD WATER SYSTEMS

3000 W. 16 Ave. Miami, FL 33012.

TEL: (954) 474 9090 FAX: (954) 889 0413

www.pdwatersystems.com | pdwatersystems

Loading...

Loading...