Page 1

PeakTech

®

4094, 4095, 4096

Operation manual

Graphical Bench-Type Multimeter

Page 2

i

Table of Contents

1.Safety Information ................................................................................................ 1

Safety Terms and Symbols ......................................................................................... 1

General Safety Requirements ..................................................................................... 2

Measurement Limits .................................................................................................... 3

Main Input Terminals (HI Input and LO Input) Measurement Limits .......................................... 3

Current Input Terminal (I) Measurement Limits ......................................................................... 4

Sense Terminals (HI Sense and LO Sense) Measurement Limits ............................................ 4

Measurement Category ............................................................................................... 4

2.Quick Start ........................................................................................................... 6

General Inspection ....................................................................................................... 6

Dimensions .................................................................................................................. 7

Foot Stool Adjustment ................................................................................................. 7

Front Panel Overview .................................................................................................. 8

Rear Panel Overview .................................................................................................. 11

User Interface ................................................................ ............................................. 12

AC Power Input Setting ............................................................................................. 13

Power On .................................................................................................................... 14

Measurement Connections ....................................................................................... 14

3.Functions and Operations ................................................................................... 16

To Set The Range ....................................................................................................... 16

Measurement Speed and Resolution ........................................................................ 18

Basic Measurement Functions.................................................................................. 19

Measuring DC Voltage ............................................................................................................. 19

Measuring AC Voltage ............................................................................................................. 20

Measuring DC Current ............................................................................................................. 22

Page 3

ii

Measuring AC Current ............................................................................................................. 23

Measuring Resistance ............................................................................................................. 24

Continuity Test ......................................................................................................................... 27

Diode Test ................................................................................................................................ 28

Measuring Capacitance ........................................................................................................... 29

Measuring Frequency and Period ............................................................................................ 30

Measuring Temperature .......................................................................................................... 32

Dual Display ............................................................................................................... 34

Triggering ................................................................................................................... 36

Auto Trigger ............................................................................................................................. 36

Single Trigger ........................................................................................................................... 36

External Trigger ....................................................................................................................... 37

Math ............................................................................................................................ 38

Statistics ................................................................................................................................... 38

Limits ........................................................................................................................................ 38

dB/dBm .................................................................................................................................... 39

Relative Value .......................................................................................................................... 40

Display ........................................................................................................................ 41

Number .................................................................................................................................... 41

Bar Meter ................................................................................................................................. 41

Trend Chart .............................................................................................................................. 42

Histogram ................................................................................................................................. 43

Data Record Function ................................................................................................ 45

Manual Record ......................................................................................................................... 45

Auto Record ............................................................................................................................. 46

Port Configuration ..................................................................................................... 48

Serial ........................................................................................................................................ 48

Trigger ...................................................................................................................................... 48

Page 4

iii

Output ...................................................................................................................................... 48

Net Type .................................................................................................................................. 49

LAN........................................................................................................................................................ 49

Utility Menu................................................................................................................. 49

Language ................................................................................................................................. 49

Backlight .................................................................................................................................. 49

Clock ........................................................................................................................................ 49

SCPI ......................................................................................................................................... 49

Default ...................................................................................................................................... 49

System Info .............................................................................................................................. 53

Update firmware ....................................................................................................................... 53

LCD Test .................................................................................................................................. 54

Key Test ................................................................................................................................... 54

4.Measurement Tutorial ......................................................................................... 56

Loading Errors (DC Voltage) ..................................................................................... 56

True RMS AC Measurements .................................................................................... 57

Loading Errors (AC Voltage) ..................................................................................... 59

5.Troubleshooting ................................................................................................. 60

6.Technical Specifications ...................................................................................... 61

7.Appendix ............................................................................................................ 68

Appendix A: Enclosure ............................................................................................ 689

Appendix B: General Care and Cleaning ................................................................ 689

Appendix C: Line Fuse Replacement ....................................................................... 70

Page 5

1

1. Safety Information

Safety Terms and Symbols

Safety Terms

Terms in this Manual. The following terms may appear in this manual:

Warning: Warning indicates the conditions or practices that could result

in injury or loss of life.

Caution: Caution indicates the conditions or practices that could result in

damage to this product or other property.

Terms on the Product. The following terms may appear on this product:

Danger: It indicates an injury or hazard may immediately happen.

Warning: It indicates an injury or hazard may be accessible potentially.

Caution: It indicates a potential damage to the instrument or other property might

occur.

Safety Symbols

Symbols on the Product. The following symbol may appear on the product:

Direct current (DC)

Warning, risk of electric shock

Alternating current (AC)

Caution, risk of danger (refer to this manual for

specific Warning or Caution information)

Both direct and alternating current

Conforms to European Union directives

Ground terminal

Chassis Ground

IEC Measurement Category I. The maximum measurable voltage is 1000 Vpk in the HI -LO

terminal.

IEC Measurement Category II. Inputs may be connected to AC mains power (up to 600

VAC) under Category II overvoltage conditions.

This product complies with the WEEE Directive (2002/96/EC) marking equipment. The

affixed product label indicates that you must not discard this electrical/electronic product in

domestic household waste.

Page 6

1.General Safety Requirements

2

General Safety Requirements

Before any operations, please read the following safety precautions to avoid

any possible bodily injury and prevent this product or any other products

connected from damage. In order to avoid any contingent danger, this

product is only used within the range specified.

Check AC power input setting according to the standards in your own country

(see page 13, AC Power Input Setting).

Use Proper Power Cord. Use only the power cord supplied with the product

and certified to use in your country.

Product Grounded. This instrument is grounded through the power cord

grounding conductor. To avoid electric shock, the grounding conductor must

be grounded. The product must be grounded properly before any connection

with its input or output terminal.

Limit operation to the specified measurement category, voltage, or

amperage ratings.

Check all Terminal Ratings. To avoid instrument damage and the risk of

electric shock, check all the Measurement Limits and markers of this product.

Refer to the user's manual for the Measurement Limits before connecting to

the instrument. Do not exceed any of the Measurement Limits defined in the

following section.

Do not operate without covers. Do not operate the instrument with covers or

panels removed.

Use Proper Fuse. Use only the specified type and rating fuse for this

instrument.

Avoid exposed circuit. Do not touch exposed junctions and components

when the instrument is powered.

Do not operate if in any doubt. If you suspect damage occurs to the

instrument, have it inspected by qualified service personnel before further

operations.

Use your instrument in a well-ventilated area. Inadequate ventilation may

cause increasing of temperature or damages to the device. Please keep well

ventilated and inspect the intake regularly.

Do not operate in wet conditions. In order to avoid short circuiting to the

interior of the device or electric shock, please do not operate in a humid

environment.

Do not operate in an explosive atmosphere.

Keep product surfaces clean and dry.

Only the qualified technicians can implement the maintenance.

Page 7

1.General Safety Requirements

3

Measurement Limits

The protection circuitry of the multimeter can prevent damage to the instrument

and protect against the danger of electric shock, when the Measurement Limits

are not exceeded. To ensure safe operation of the instrument, do not exceed the

Measurement Limits shown on the front panel, it is defined as follows:

The user-replaceable 10 A current-protection fuse is on the front panel. To

maintain protection, replace fuse only with fuse of the specified type and rating.

About the specified type and rating of the fuse, please refer to "7 Current Terminal

Fuse" in "Front Panel Overview" on page 9.

Main Input Terminals (HI Input and LO Input) Measurement

Limits

The HI and LO input terminals are used for voltage, resistance, continuity,

frequency (period), capacitance, diode, and temperature test measurements. Two

Measurement Limits are defined for these terminals:

HI Input to LO Input Measurement Limit

The Measurement Limit from HI Input to LO Input is 1000 VDC or 750 VAC,

which is also the maximum voltage measurement. This limit can also be

expressed as 1000 Vpk maximum.

LO Input to Ground Measurement Limit

The LO input terminal can safely "float" a maximum of 500 Vpk relative to

ground, where ground is defined as the Protective Earth Conductor in the AC

mains power cord connected to the instrument.

As implied by the above limits, the Measurement Limit for the HI input terminal is

a maximum of 1500 Vpk relative to ground when LO Input is at its maximum of

500 Vpk relative to ground.

Page 8

1.General Safety Requirements

4

Current Input Terminal (I) Measurement Limits

The Measurement Limit from the current input terminal (I) to the LO Input terminal

is 10 A (DC or AC). Note that the current input terminals will always be at

approximately the same voltage as the LO Input terminal, unless a current

protection fuse is open.

Sense Terminals (HI Sense and LO Sense) Measurement

Limits

The HI and LO sense terminals are used for four-wire resistance measurements.

The Measurement Limit from HI Sense to LO Input is 200 Vpk.

The Measurement Limit from HI Sense to LO Sense is 200 Vpk.

The Measurement Limit from LO Sense to LO Input is 2 Vpk.

Note: The 200 Vpk limit on the sense terminals is the Measurement Limit.

Operational voltages in resistance measurements are much lower – up to ± 12 V

in normal operation.

Measurement Category

The safety rating of the multimeter:

1000 V, CAT I

IEC Measurement Category I. The maximum measurable voltage is 1000 Vpk in

the HI -LO terminal.

600 V, CAT II

IEC Measurement Category II. Inputs may be connected to AC mains power (up

to 600 VAC) under Category II overvoltage conditions.

Page 9

1.General Safety Requirements

5

Measurement category definition

Measurement CAT I applies to measurements performed on circuits not directly

connected to the AC mains. Examples are measurements on circuits not derived

from the AC mains and specially protected (internal) mains- derived circuits.

Measurement CAT II applies to protect against transients from energyconsuming equipment supplied from the fixed installation, such as TVs, PCs,

portable tools, and other household circuits.

Measurement CAT III applies to protect against transients in equipment in fixed

equipment installations, such as distribution panels, feeders and short branch

circuits, and lighting systems in large buildings.

Measurement CAT IV applies to measurements performed at the source of the

low- voltage installation. Examples are electricity meters and measurements on

primary over current protection devices and ripple control units.

Page 10

6

2. Quick Start

General Inspection

After you get a new multimeter, it is recommended that you should make a check

on the instrument according to the following steps:

1. Check whether there is any damage caused by transportation.

If it is found that the packaging carton or the foamed plastic protection cushion

has suffered serious damage, do not throw it away first till the complete device

and its accessories succeed in the electrical and mechanical property tests.

2. Check the Accessories

The supplied accessories have been already described in the Appendix A:

Enclosure of this Manual. You can check whether there is any loss of

accessories with reference to this description. If it is found that there is any

accessory lost or damaged, please get in touch with the distributor of

PEAKTECH responsible for this service or the PEAKTECH's local offices.

3. Check the Complete Instrument

If it is found that there is damage to the appearance of the instrument, or the

instrument can not work normally, or fails in the performance test, please get in

touch with the PEAKTECH's distributor responsible for this business or the

PEAKTECH's local offices. If there is damage to the instrument caused by the

transportation, please keep the package. With the transportation department or

the PEAKTECH's distributor responsible for this business informed about it, a

repairing or replacement of the instrument will be arranged by the PEAKTECH.

Page 11

7

Dimensions

Foot Stool Adjustment

Unfold the foot stool on the bottom of the multimeter.

235 mm

110 mm

295 mm

Page 12

8

Front Panel Overview

Figure 2-1 Front panel overview

Ite

m

Name

Description

1

LCD

Display the user interface

2

Menu selection

Keys

Activate the corresponding menu

3

Operation Keys

Save

Collect data in manual record. The instrument saves

current reading each time the Save key is pressed.

See page 45, Manual Record.

Record

Access menus of manual record and auto record.

See page 45, Data Record Function.

Run/Stop

When the trigger source is set as Auto, start or stop

auto trigger.

When the trigger source is set as Single, the

instrument issues one trigger each time this key is

pressed.

2

3

4

5

12

1

6

7

8

11 13

9

10

Page 13

9

Math

Perform math operations (statistic, limits, dB/dBm,

REL) on the measurement results.

Utility

Set the auxiliary system function, including Language,

Backlight, Clock, SCPI, Set to default, System

information, LCD test, Key test.

Port

Set Serial, Trigger, Output connector, Net Type.

4

HI and LO Sense

Terminals

Signal input terminals, used for four-wire resistance

measurements.

5

HI and LO Input

Terminals

Signal input terminals, used for voltage, resistance,

continuity, frequency (period), capacitance, diode, and

temperature test measurements.

6

Range/Direction

Keys

When the Range softkey is shown on the right menu,

you can press the key to switch between auto

and manual range. Press to enable manual

range, and increase or decrease the measurement

range.

When setting a parameter, press to move the

cursor, press to increase or decrease the value.

7

Current Terminal

Fuse

The rating is 10 A, 250 VAC.

To replace the fuse:

Turn off the multimeter and remove the power cord.

Use a flat-blade screw driver to turn the fuse holder

counter-clockwise, and pull out the fuse holder. Put

the new specified fuse into the fuse holder, and insert

the assembly back into the instrument, turning the

fuse holder clockwise to lock it in place.

Page 14

10

8

AC/DC Current

Input Terminals

Signal input terminals, used for AC/DC current

measurements.

9

Power button

Turn on/off the multimeter.

10

Measurement

Function Keys

DC or AC voltage measurements

DC or AC current measurements

Resistance, continuity, and diode

measurements

Capacitance measurements

Frequency/Period measurements

Temperature measurements

11

Graph

Choose what is displayed: number, bar meter, trend

chart, or histogram.

12

Dual

Press this key to display the function list on the right

menu, select a function, if the function is supported,

the reading will be displayed in the Vice Display.

13

USB Connector

Connect with an external USB device, such as

connect a USB memory device to the instrument.

Page 15

11

Rear Panel Overview

Figure 2-2 Rear panel overview

Ite

m

Name

Description

1

External Trigger

Input

Trigger the multimeter by connecting a trigger pulse.

The external trigger source must be selected.

( → Trigger → Source (External) )

2

Auxiliary Output

Connector

Defaults to Voltmeter Measurement Complete Output,

outputs a pulse whenever the multimeter finishes

taking a measurement to allow you to signal other

devices. This connector can also be configured to

output a pulse when limits are exceeded in Math limits

function ( → Output → Output (P/F)).

3

RS232

Connect the PC through this interface.

4

USB (type B)

Connector

This can be used to connect a USB type B controller.

Connect with an external device, such as connected

to a PC and controlled via PC software.

5

Local Area

Network (LAN)

Connector

The multimeter can be connected to the network for

remote control via this connector.

1

2

3

4

5

6

8

7

9

10

Page 16

12

6

AC Mains Line

Voltage Selector

Select a proper voltage scale according to the AC

supply used. Switch between 110 V and 220 V.

7

Line Fuse

Use the specified fuse according to the voltage scale.

To replace the fuse, see page 69, Appendix C: Line

Fuse Replacement.

Voltage

Fuse

100 - 120 V AC

250 V, F1AL

220 - 240 V AC

250 V, F0.5AL

8

AC Mains Input

AC mains input connector.

9

Chassis Ground

Screw

To ground the chassis.

10

Instrument

Cable Lock

You can lock the instrument to a fixed location using

the security lock (please buy it yourself) to secure the

instrument.

User Interface

Trigger Mode

Reading

Range Function

Operation Menus

Unit

Status Icon

Trigger Mode

Status Icon

Page 17

13

Figure 2-3 User interface (Single display)

Figure 2-4 User interface (Dual display)

AC Power Input Setting

Adopt 100 - 120 VAC or 220 - 240 VAC power source. Users should regulate the

voltage scale of the AC Mains Line Voltage Selector according to the standards

in their own country (see Figure 2-2 Rear panel overview) at the rear panel, and

use an appropriate fuse.

Voltage

Fuse

100 - 120 V AC

250 V, F1AL

220 - 240 V AC

250 V, F0.5AL

To change the voltage scale of the instrument, do the following steps:

(1) Turn off the power button at the front panel, and remove the power cord.

Secondary function reading

Primary function reading

Primary function

Display

Description

Trigger

Auto trigger

Ext

External

Icon

Description

LAN is connected

Connect as a slave device

Auto record function is running

USB memory device is

Manual record

Page 18

14

(2) Check if the fuse installed before leaving factory (250 V, F0.5AL) can match

with the selected voltage scale; if not, change the fuse. (See page 69,

Appendix C: Line Fuse Replacement.)

(3) Regulate the AC Mains Line Voltage Selector to the desired voltage scale.

Power On

(1) Connect the instrument to the AC supply using the supplied power cord.

Warning:

To avoid electric shock, the instrument must be grounded

properly.

(2) Press down the power button at the front panel, the screen shows the boot

screen.

Measurement Connections

After selecting the desired measurement function, please connect the signal

(device) under test to the multimeter according to the method below. To avoid

instrument damage, do not discretionarily switch the measurement function when

measuring.

DC Voltage Measurement

AC Voltage Measurement

DC Current Measurement

AC Current Measurement

DC Voltage

AC Voltage

DC Current

AC Current

Page 19

15

2-wire Resistance Measurement

4-wire Resistance Measurement

Continuity Test

Diode Measurement

Capacitance Measurement

Frequency/Period Measurement

Temperature Measurement

I

2-wire Resistance

I

4-wire Resistance

Open or Closed Circuit

I

Forward Bias

I

Capacitance

AC Signal

Temp Transducer

I

Page 20

16

3. Functions and Operations

To Set The Range

The instrument provides auto and manual range. In auto range, the multimeter

selects a proper range automatically according to the input signal; in manual

range, you can use the front panel key or menu softkey to set the range. The auto

range can bring a lot of convenience for users while the manual range provides

higher reading precision.

1st Method: Use the front panel key to set the range.

When the Range softkey is shown on the right menu, you can press the key

to switch between auto and manual range. Press to enable manual range,

and increase or decrease the measurement range.

2nd Method: Select the range in the measurement function menu.

Select auto range: In the measurement function menu, press the Range softkey,

select Auto.

Select manual range: In the measurement function menu, press the Range

softkey, select a range except Auto.

Page 21

17

Note:

When the input signal exceeds the current range, "overload” will be displayed.

By default, the range is set to Auto at power-on or after a reset.

Auto range is recommended if you are not sure about the measurement range in

order to protect the instrument and obtain accurate data.

The range of continuity test is fixed at 2 kΩ; the range of diode measurement is fixed at

2 V.

Page 22

18

Measurement Speed and Resolution

The instrument provides three types of measurement speed:

"Low" speed is 5 reading/s; "Mid" speed is 50 reading/s; "High" speed is 150

reading/s.

In DCV, ACV, DCI, ACI and 2-wire / 4-wire resistance measurements, the

measurement speed is selectable.

The reading resolution of P4095 is 4½.

The reading resolution of P4096 can be 4½ or 5½ digits. The selection of

measurement speed affects the reading resolution. The multimeter automatically

selects a reading resolution according to the current measurement settings.

Relationship between measurement speed and reading resolution:

Function

Measurement speed

Reading resolution

DCV

ACV

DCI

ACI

2-wire/4-wire

resistance

"Low" speed

P4095

4½ digits

P4096

5½ digits

"Mid" speed

"High" speed

4½ digits

Continuity test

Fixed at "High" speed

4½ digits

Diode

Fixed at "High" speed

4½ digits

Capacitance

Fixed at "Mid" speed

4½ digits

(only display the first four

digits)

Frequency/Peri

od

Fixed at "Mid" speed

4½ digits

Temperature

Fixed at "Mid" speed

4½ digits

Page 23

19

Basic Measurement Functions

Measuring DC Voltage

This section describes how to configure DC voltage measurements.

Operating Steps:

1. Enable the DCV measurement.

Press on the front panel to enter DCV measurement mode.

2. Connect the test lead.

3. Set the range.

Press the Range softkey to set the range. Auto range automatically selects

the range for the measurement based on the input.

Note:

1000 V input protection is available in all ranges.

P4096: 20% over range for all ranges except 1000 V range.

P4095: 10% over range for all ranges except 1000 V range.

DC Voltage

Page 24

20

If the reading exceeds 1050 V in 1000 V range, "overload" will be displayed.

4. Set the measurement speed.

Press the Speed softkey to switch between Low, Mid or High. See page 18,

Measurement Speed and Resolution.

5. Set the filter. (Optional operation)

Press the Filter softkey to turn on or off the AC filter. When the AC component

exists in the inputted DC signal, it can be filtered by the AC filter to make the

measurement data more exactly.

6. Set the input impedance. (Optional operation, only for 200 mV and 2 V

range)

Press the Input Z softkey to select "10M" or "10G", specify the input

impedance to the test leads. The default is "10M".

In the range of 200 mV or 2 V, you can choose "10G" to reduce the loading

error to the measured object caused by the multimeter (refer to Loading

Errors (DC Voltage) on page 56).

Note:

10M: Set the input impedances in all ranges to 10 MΩ.

10G: Set the input impedances in ranges of 200 mV and 2 V to 10 GΩ, while

in ranges of 20 V, 200 V and 1000 V, the impedances are still 10 MΩ.

7. Set the relative value. (Advanced operation)

Press the Rel softkey to turn on or off the relative operation. For relative

operation, the multimeter subtracts the pre-specified value of REL operation

from the actual measurement result and displays the result. See page 40,

Relative Value.

Measuring AC Voltage

This section describes how to configure AC voltage measurements.

Operating Steps:

1. Enable the ACV measurement.

Press on the front panel, press it again to enter ACV measurement

mode.

Page 25

21

2. Connect the test lead.

3. Set the range.

Press the Range softkey to set the range. Auto range automatically selects

the range for the measurement based on the input.

Note:

750 V input protection is available in all ranges.

P4096: 20% over range for all ranges except 750 V range.

P4095: 10% over range for all ranges except 750 V range.

If the reading exceeds 787.5 V in 750 V range, "overload" will be displayed.

4. Set the measurement speed.

Press the Speed softkey to switch between Low, Mid or High. See page 18,

Measurement Speed and Resolution.

5. Set the relative value. (Advanced operation)

Press the Rel softkey to turn on or off the relative operation. For relative

operation, the multimeter subtracts the pre-specified value of REL operation

AC Voltage

Page 26

22

from the actual measurement result and displays the result. See page 40,

Relative Value.

Measuring DC Current

This section describes how to configure DC current measurements.

Operating Steps:

1. Enable the DCI measurement.

Press on the front panel to enter DCI measurement mode.

2. Connect the test lead.

3. Set the range.

Press the Range softkey to set the range. Auto range automatically selects

the range for the measurement based on the input.

Note:

The multimeter uses two kinds of fuses for current protection: the 10 A

current input fuse on the rear panel and the built-in 12 A current input fuse.

DC Current

Page 27

23

P4096: 20% over range for all ranges except 10 A range.

P4095: 10% over range for all ranges except 10 A range.

If the reading exceeds 10.5 A in 10 A range, "overload" will be displayed.

4. Set the measurement speed.

Press the Speed softkey to switch between Low, Mid or High. See page 18,

Measurement Speed and Resolution.

5. Set the filter. (Optional operation)

Press the Filter softkey to turn on or off the AC filter. When the AC component

exists in the inputted DC signal, it can be filtered by the AC filter to make the

measurement data more exactly.

6. Set the relative value. (Advanced operation)

Press the Rel softkey to turn on or off the relative operation. For relative

operation, the multimeter subtracts the pre-specified value of REL operation

from the actual measurement result and displays the result. See page 40,

Relative Value.

Measuring AC Current

This section describes how to configure AC current measurements.

Operating Steps:

1. Enable the ACI measurement.

Press on the front panel, press it again to enter ACI measurement

mode.

Page 28

24

2. Connect the test lead.

3. Set the range.

Press the Range softkey to set the range. Auto range automatically selects

the range for the measurement based on the input.

Note:

The multimeter uses two kinds of fuses for current protection: the 10 A

current input fuse on the rear panel and the built-in 12 A current input fuse.

P4096: 20% over range for all ranges except 10 A range.

P4095: 10% over range for all ranges except 10 A range.

If the reading exceeds 10.5 A in 10 A range, "overload" will be displayed.

4. Set the measurement speed.

Press the Speed softkey to switch between Low, Mid or High. See page 18,

Measurement Speed and Resolution.

5. Set the relative value. (Advanced operation)

Press the Rel softkey to turn on or off the relative operation. For relative

operation, the multimeter subtracts the pre-specified value of REL operation

from the actual measurement result and displays the result. See page 40,

Relative Value.

Measuring Resistance

This section describes how to configure 2-wire and 4-wire resistance

measurements.

The multimeter provides 2-wire and 4-wire resistance measurements. When the

measured resistance is lower than 100 kΩ, the 4-wire resistance measurement is

AC Current

Page 29

25

recommended to reduce the measurement error caused by test lead resistance

and contact resistance between the probe and the testing point, because these

two resistances can not be ignored any more, compared to the measured

resistance.

Operating Steps:

1. Enable the Ω2W/Ω4W measurement.

Press on the front panel to enter resistance measurement mode.

Press the Ω2W/Ω4W softkey to switch between Ω2W and Ω4W.

(2-wire Resistance)

(4-wire Resistance)

2. Connect the test lead.

I

2-wire Resistance

Page 30

26

3. Set the range.

Press the Range softkey to set the range. Auto range automatically selects

the range for the measurement based on the input.

Note:

1000 V input protection is available in all ranges.

P4096: 20% over range for all ranges except 100 MΩ range.

P4095: 10% over range for all ranges except 100 MΩ range.

If the reading exceeds 105 MΩ in 100 MΩ range, "overload" will be

displayed.

4. Set the measurement speed.

Press the Speed softkey to switch between Low, Mid or High. See page 18,

Measurement Speed and Resolution.

5. Set the relative value. (Advanced operation)

Press the Rel softkey to turn on or off the relative operation. For relative

operation, the multimeter subtracts the pre-specified value of REL operation

from the actual measurement result and displays the result. See page 40,

Relative Value.

Tip:

If the measured resistance is small, relative operation is recommended in

order to reduce the error caused by test lead.

Both ends of the measured resistance should be placed far away from your

hands and desks that can conduct electricity; otherwise, the measurement

result might be inaccurate. The greater the measured resistance is, the

greater the affect will be.

I

4-wire Resistance

Page 31

27

Continuity Test

This section describes how to configure continuity test.

Operating Steps:

1. Enable the continuity test.

Press on the front panel, press it again to enter continuity test mode.

2. Connect the test lead.

3. Set the beeper.

Press the Beeper softkey to enable or disable the beeper. When the beeper is

enabled, the reading is below 30 Ω, the multimeter will beep continuously.

4. Set the short-circuit resistance.

Press the Threshold softkey to set the short-circuit resistance.

Press to move the cursor, press to increase or decrease the

value. The range for P4096 is 1 Ω to 2400 Ω; the range for P4095 is 1 Ω to

1100 Ω. The default is 50 Ω.

Open or Closed Circuit

I

Page 32

28

5. Continuity measurements behave as follows:

P4096

P4095

Display and beep

≤ Short-circuit

resistance

≤ Short-circuit

resistance

Displays measured resistance

and beeps (if beeper enabled)

Short-circuit

resistance to 2.4

kΩ

Short-circuit

resistance to 1.1

kΩ

Displays measured resistance

without beeping

> 2.4 kΩ

> 1.1 kΩ

Displays "Open" with no beep

Diode Test

This section describes how to configure diode test.

Operating Steps:

1. Enable the diode test.

Press on the front panel, press it twice to enter diode test mode.

2. Connect the test lead.

3. Set the beeper.

Press the Beeper softkey to enable or disable the beeper. When the beeper is

enabled, the diode is connected, the multimeter will beep continuously.

Forward Bias

I

Page 33

29

4. Diode measurements behave as follows:

P4096

P4095

Display and beep

0 to 2 V

0 to 3 V

Displays measured voltage, and the multimeter

beeps when the voltage is below 0.7 V (if beeper

enabled)

> 2 V

> 3 V

Displays "Open" with no beep

Measuring Capacitance

This section describes how to configure capacitance measurements.

Operating Steps:

1. Enable the capacitance measurement.

Press on the front panel to enter capacitance measurement mode.

2. Connect the test lead.

Tip: Please short contact the two feet of an electrolytic capacitor by using a

test lead before measuring the electrolytic capacitor.

3. Set the range.

Capacitance

Page 34

30

Press the Range softkey to set the range. Auto range automatically selects

the range for the measurement based on the input.

Note:

1000 V input protection is available in all ranges.

P4096: 20% over range for all ranges except 10000 μF range.

P4095: 10% over range for all ranges except 10000 μF range.

If the reading exceeds 10500 μF in 10000 μF range, "overload" will be

displayed.

4. Set the relative value. (Advanced operation)

Press the Rel softkey to turn on or off the relative operation. For relative

operation, the multimeter subtracts the pre-specified value of REL operation

from the actual measurement result and displays the result. See page 40,

Relative Value.

Measuring Frequency and Period

When measuring AC voltage or AC current, you can use the dual display function

to obtain the measured signal’s frequency and period (see page 34, Dual

Display), or press to measure the frequency or period directly.

This section describes how to configure frequency and period measurements.

Operating Steps:

1. Enable the frequency/period measurement.

Press on the front panel to enter frequency/period measurement

mode. Press the Freq/Period softkey to switch between frequency and period.

Page 35

31

2. Connect the test lead.

3. Set the range.

Press the Range softkey to set the range. Auto range automatically selects

the range for the measurement based on the input.

Note:

Frequency range: P4096 is 20 Hz to 1 MHz; P4095 is 20 Hz to 500 kHz.

Period range: P4096 is 0.05 s to 1 μs; P4095 is 0.05 s to 2 μs.

750 V input protection is available in all ranges.

AC Signal

Page 36

32

4. Set the relative value. (Advanced operation)

Press the Rel softkey to turn on or off the relative operation. For relative

operation, the multimeter subtracts the pre-specified value of REL operation

from the actual measurement result and displays the result. See page 40,

Relative Value.

Measuring Temperature

This section describes how to configure temperature measurements. Temperature

measurements require a temperature transducer probe. The supported probes

are type B, E, J, K, N, R, S, T thermocouples, and PT100, PT385 platinum RTD

sensor.

Operating Steps:

1. Enable the temperature measurement.

Press on the front panel to enter temperature measurement mode.

2. Connect the test lead.

3. Set the sensor configuration file.

Press the Load softkey, press to select thermocouple or thermo

resistor. Press to access the list, press to select the desired

Temp Transducer

I

Page 37

33

configuration file. Press the Define softkey to view the configuration; press the

Done softkey to apply the sensor configurations.

4. Set the display.

Press the Display softkey to set the display mode of the result.

Temp Val: only the temperature value will be displayed;

Meas Val: only the measurement value will be displayed.

All: both the temperature value (on the main display) and the measurement

value will be displayed.

5. Set the temperature unit.

Press the Units softkey to display temperature in ℃ (degrees Celsius), ℉

(degrees Fahrenheit), or K (Kelvin).

The conversion relations between these units are:

℉ = (9/5) ×℃ + 32

K ≈℃ + 273.15

6. Set the relative value. (Advanced operation)

Press the Rel softkey to turn on or off the relative operation. For relative

operation, the multimeter subtracts the pre-specified value of REL operation

from the actual measurement result and displays the result. See page 40,

Relative Value.

Page 38

34

Dual Display

Using dual display function, you can view the readings of two measurement

functions simultaneously.

Figure 3-1 Dual Display

Secondary function reading

Primary function reading

Primary function

Page 39

35

Operating Steps:

1. Press one of the measurement function keys to turn on the primary

measurement function.

2. Press on the front panel, the secondary function list is shown on the

right menu, select the desired function.

3. When dual display is enabled, press to switch the primary function and

the secondary function. To configure the secondary function, you can switch it

to the primary function, configure in the right menu, then switch back.

4. Press any of the measurement function keys to disable the dual display.

The primary measurement functions and their associated secondary

measurements are: (gray back color indicates valid combinations)

Primary measurement function

DCV

DCI

ACV

ACI

FRE

Q

PERI

OD

2WR 4W

R

CAP

Secondary

DCV

DCI

ACV

ACI

FREQ

PERI

OD

2WR

4WR

CAP

Note:

The multimeter makes the primary and secondary measurements alternately,

the primary and secondary readings update respectively.

If the primary measurement uses dB or dBm scaling, the dual display can not be

enabled. When the dual display is enabled, turning on dB or dBm scaling will

automatically disable the dual display.

When the dual display is enabled, manual record function can save both of the

primary and secondary readings, auto record function can only save the primary

reading.

Page 40

36

Triggering

The multimeter provides three types of triggers: auto, single and external.

Auto Trigger

Press the front panel key, press the Trigger softkey, press the Source

softkey to select Auto. When Auto trigger is used, the instrument continuously

takes measurements, automatically issuing a new trigger as soon as a

measurement is completed.

Press the Delay softkey to select Auto or Manual.

Auto Delay

The instrument automatically determines the delay based on function, range and

measurement speed.

Manual Delay

The first sample starts one trigger delay time after the trigger. The second

sample starts one sample interval after the start of the first sample, and so on.

Set the trigger delay time: Press the Delay softkey to select Manual, press

to move the cursor, press to increase or decrease the value. The

range is 1 ms to 999,999 ms.

Set the number of samples: The multimeter takes the specified number of

readings each time a trigger signal is received. Press the Samples trigger

softkey, press to move the cursor, press to increase or decrease

the value. The range is 1 to 999,999.

Single Trigger

Press the front panel key, press the Trigger softkey, press the Source

softkey to select Single. When Single trigger is used, the instrument takes one or

specified number of readings each time the front panel key is pressed.

Trigger

Delay

Trigger

Sample

#1

Sample

#2

Sample

#3

Interval Interval Interval

Page 41

37

Auto delay is applied for single trigger, the instrument automatically determines

the delay based on function, range and measurement speed.

You can set the number of samples for single trigger. The multimeter takes the

specified number of readings each time a trigger signal is received. Press the

Samples trigger softkey, press to move the cursor, press to

increase or decrease the value. The range is 1 to 999,999.

External Trigger

Press the front panel key, press the Trigger softkey, press the Source

softkey to select External. When External trigger is used, the multimeter receives

the trigger pulse from the [Ext Trig] connector at the rear panel, triggers at the

specified edge of the pulse signal and acquires measured data.

Auto delay is applied for external trigger, the instrument automatically

determines the delay based on function, range and measurement speed.

When using external trigger, you can set the edge type for the pulse from the

[Ext Trig] connector at the rear panel. The multimeter will trigger on the

specified type of edge. Press the Trg Edge softkey to select Rising or Falling.

Page 42

38

Math

The multimeter provides these math functions: statistics, limits, dB/dBm and

relative.

Statistics

Statistics calculates the min, average, max, span, standard deviation and number

of samples of readings during the measurement.

Press the front panel key, press the Statistics softkey, press the Statistics

softkey to select Show.

Remarks

The Span value is the Max minus the Min.

Press the Clear Readings softkey to clear reading memory and restart statistics.

Limits

Limit checking indicates how many samples have exceeded specified limits, and

indicates

the signal testing result exceeded specified limits. The [AUX Output] connector at

the rear panel can be configured to output a pulse when the limits are exceeded

(see page 48, Output).

Press the front panel key, press the Limits softkey to access the limits

menu.

Press the Limits softkey to enable or disable limits.

Page 43

39

Use the High or Low softkey to specify the limits as high and low values. Press

to switch to the Center or Span softkey to specify the limits as a span around a

center value. For example, a Low limit of -5 V and a High limit of +10 V are

equivalent to a Center of 2.5 V and a Span of 15 V. When setting a parameter,

press to move the cursor, press to increase or decrease the value.

Press the Clear softkey to clear all current readings and restart limit checking.

Limit Indications: The red background color (shown below) indicates that the

displayed measurement exceeds the limits, and the multimeter beeps (if beeper

enabled).

dB/dBm

The dB and dBm scaling functions only apply to ACV and DCV measurements.

The functions allow you to scale measurements relative to a reference value.

Press the front panel key, press the dB/dBm softkey to access the menu.

Press the dB/dBm softkey to enable or disable the function.

Press the dB/dBm softkey to

dBm Function

dBm function represents the absolute value of the power. The function calculates

the power of the reference resistance according to the measured voltage, relative

to 1 mW:

dBm = 10 x log10 ( reading2 / reference resistance / 1 mW )

Press the Ref R softkey to select the reference resistance. The value may be 50,

75, 93, 110, 124, 125, 135, 150, 250, 300, 500, 600 (default), 800, 900, 1000,

1200, or 8000 Ω.

Page 44

40

dB Function

dB represents the relative value which is used in the relative operation of dBm

value. When enabled, the multimeter calculates the dBm value of the reading and

subtracts the preset dB from this value and then displays the result:

dB = 10 x Log10 ( reading2 / reference resistance / 1 mW) - dB preset

Press the Ref R softkey to select the reference resistance. The value may be 50,

75, 93, 110, 124, 125, 135, 150, 250, 300, 500, 600 (default), 800, 900, 1000,

1200, or 8000 Ω.

Press the dB Ref Value softkey to select the relative value. The relative value

must be from -120 to +120 dBm (default 0).

Relative Value

When the relative operation is turned on, the reading displayed on the screen in

relative operation is the difference between measured and preset values. The

value is specific to the present function and will persist even if you leave this

function and return to it later.

Reading = Measured value – Preset value

Press the front panel key, press the Rel softkey, set the preset value of the

present function.

In the measurement function menu, press the Rel softkey to turn on or off the

relative operation.

Page 45

41

Display

Press the front panel key to access the menu, press the Display softkey to

select the display type as number, bar meter, trend chart, or histogram.

In each display type, you can press on the front panel, and select the

secondary function. For example, for the DCV measurement function, you can

select ACV as the secondary measurement function. See page 34, Dual Display.

Number

Press the front panel key to access the menu, press the Display softkey to

select Number, the instrument displays readings as a number. It is the default

display type.

Bar Meter

Press the front panel key to access the menu, press the Display softkey to

select BarMeter. The bar meter adds a moving bar below the standard Number

display.

Press the Scale softkey to select Default or Manual.

Page 46

42

Default: Set the scale to equal the measurement range. For example, for the DCV

measurement function, the horizontal scale will be set as -200 mV to 200 mV

when the present range is 200 mV.

Manual: Allow you to configure the scale either as High and Low values or as a

Span around a Center value. For example, a scale that goes from a Low of -50

mV to a High of 100 mV could also be specified as a Center of 25 mV with a Span

of 150 mV.

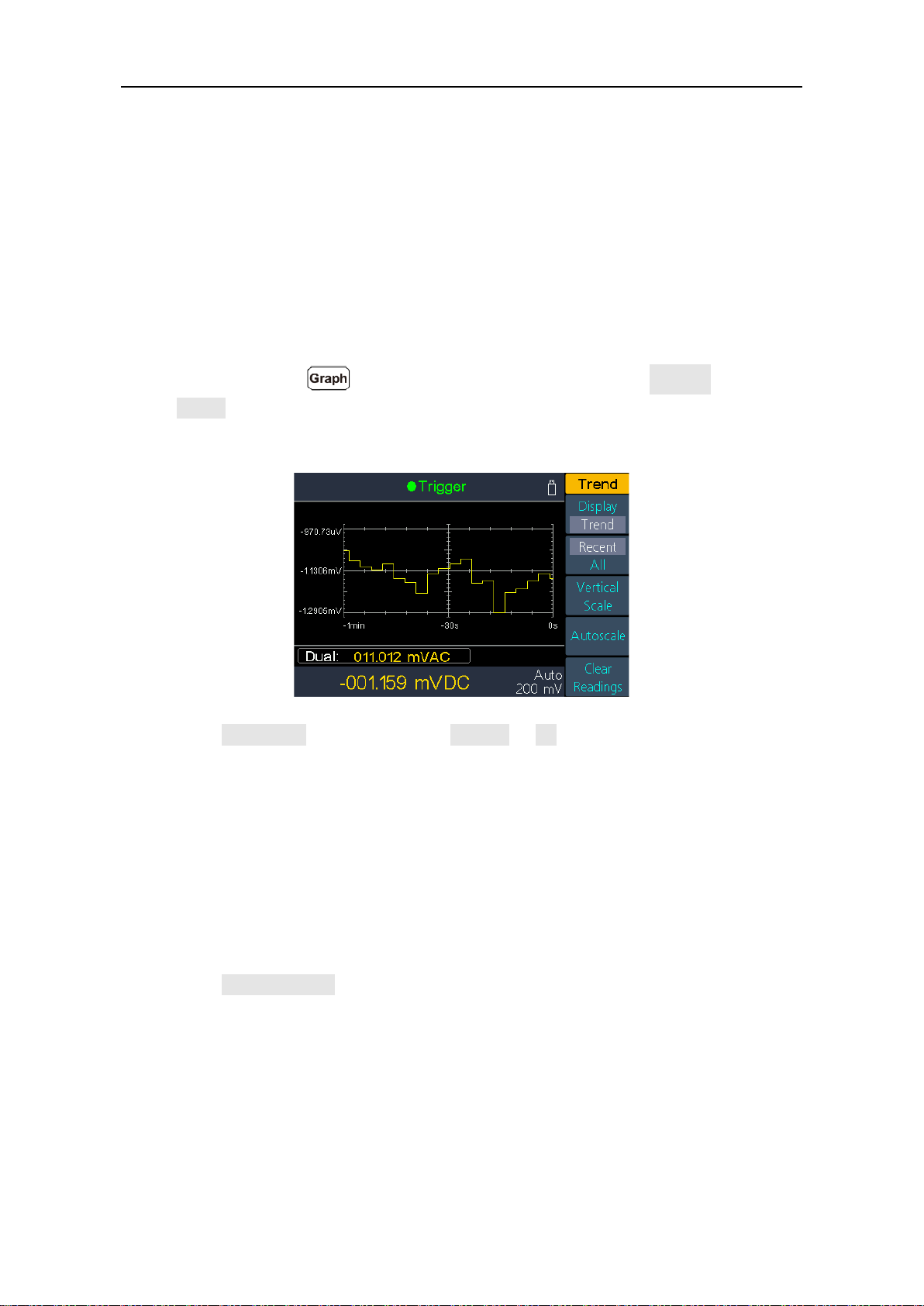

Trend Chart

Press the front panel key to access the menu, press the Display softkey to

select Trend. The trend chart shows data trends over time, users can directly

observe the variation of the measured data.

Press the Recent/All softkey to select Recent or All. In the trend chart, Recent

shows just the most recent data, All shows all of the data.

All: The trend chart displays all readings being taken and builds from left to

right. After the display is filled, the data becomes compressed on the left side of

the display as new data is added on the right side of the display.

Recent: The trend chart displays data taken during the last minute.

Press the Vertical Scale softkey to specifies how the current vertical scale is

determined.

Default: Set the scale to equal the measurement range. For example, for the

DCV measurement function, the vertical scale will be set as -200 mV to 200 mV

when the present range is 200 mV.

Manual: Allow you to configure the scale either as High and Low values or as a

Span around a Center value. For example, a scale that goes from a Low of -50

Page 47

43

mV to a High of 100 mV could also be specified as a Center of 25 mV with a

Span of 150 mV.

Auto: Automatically adjusts the scale to appropriately fit the line currently shown

on the screen.

Press the Autoscale softkey to automatically set the vertical scale once.

Press the Clear Readings softkey to clear reading memory and redraw.

Histogram

Press the front panel key to access the menu, press the Display softkey to

select Histogram. In the histogram display, data is grouped in bins represented by

vertical bars. The histogram shows the distribution of measurement data.

Press the Binning softkey to select Auto binning or Manual binning.

Press the Cumulative softkey to hide or show a line representing the cumulative

distribution of the histogram data.

Press the Clear Readings softkey to clear reading memory and redraw.

Auto binning

The algorithm starts by continuously readjusting the histogram span based on the

readings coming in, completely re-binning the data whenever a new value comes

in outside of the current span. The number of bins shown is a function of the

number of readings received:

Number of

readings

<100

100 -

500

500 1000

1000 -

5000

>5000

Number of bins

10

20

40

100

300

Total number of samples

Total number of bins

Percentage of samples in the largest bin

Number of samples in the largest bin

Page 48

44

Manual binning

Press the Bin Settings softkey to access the bin settings menu.

Press the Num.Bins softkey to set number of bins to 10, 20, 40, 100, or 300.

You can specify the bin range as either Low and High values, or as a Span

around a Center value. For example, the bin range with a Low of -5 V and a

High of 10 V could be specified as a Center of 2.5 V and a Span of 15 V.

Press the Outer Bins softkey to display or hide the outer bins. The outer bins are

two additional bins, for readings above and below the bin range.

Page 49

45

Data Record Function

Data record function includes manual record and auto record. You can use any or

both functions to record the data.

Manual record: Press the front panel key to save current reading to

internal memory. The maximum number of readings is 1000. Once you have

finished collecting data, you can view it in table, and export it to external memory.

Auto record: After setting memory, number of readings, sample interval, press

the Start softkey to start recording. You can view the data in internal memory in

table or graph.

Manual Record

1. Collect data: The instrument saves current reading in internal memory each

time the front panel key is pressed. The instrument beeps, and the

icon will show up on the top of the display.

Note: The measurement function can be switched during manual record.

When the dual display is enabled, both readings can be recorded.

2. View the manual record: Press the front panel key, press the

Manual record softkey to display the data table. Press keys to turn the

page. (When the data table is shown, you can still save current reading by

pressing the key.)

Note:

When the recording data exceeds the current range, the data will be marked

as "overload".

"rel" in the table indicates the relative operation is turned on.

Page 50

46

3. Export to USB memory: Connect a USB memory to the front panel USB

connector. Press the Export softkey to export the manual record in internal

memory to USB memory as a CSV file. The file will be saved in

\Record\Manual folder in USB memory. The file name is

Data_YYYYMMDD_HHMMSS, YYYYMMDD is the data recording start date,

HHMMSS is the start time, e.g. Data_20160804_095622.csv.

4. Clear the manual record: Press the Clear softkey to clear current manual

record.

Auto Record

1. Configure the parameters: Press the front panel key, press the Auto

record softkey.

Press the Memory softkey to select internal or external memory

Press the Points softkey to specify the total number of readings to record. The

range is 1 to 1 M for internal memory, 1 to 100 M for external memory.

Press the Interval softkey to specify the time interval between readings. The

range is 5 ms to 1000 s.

2. Record data: Press the Start softkey to start auto record. The icon will

show up on the top of the display. Press the Stop softkey to stop recording,

the data will be saved in the specified memory as a CSV file. If the external

memory is selected, the file will be saved in \Record\Auto folder in USB

memory. The file name is Data_YYYYMMDD_HHMMSS, YYYYMMDD is the

data recording start date, HHMMSS is the start time, e.g.

Data_20160804_095622.csv.

Note:

When the auto recording mode is running, press another measurement

function key, the instrument will display a message "Press the key again to

switch function and stop recording.".

If you want to continue auto recording, just wait until the message

disappears.

If you want to stop auto recording and switch to the function, press the

function key again when the message is still displayed. The recording data

before switching the function will be saved.

In auto range, the relay switch may cause jitter, the data at this time is

invalid. It will last about a few hundred milliseconds, and the data acquired in

this period will be marked as "invalid".

Page 51

47

When the dual display is enabled, only the reading of main display function

can be saved.

3. Read and view the auto recording file: Press the front panel key,

press the View record softkey.

Memory can only be internal memory.

Press the Display softkey to select Table or Graph to display the readings.

Press the Read softkey to read and view the auto record file in the internal

memory. (If the data is viewed in table, press keys to turn the page.)

Auto recording data displayed in graph

Auto recording data displayed in table

Page 52

48

Port Configuration

You can configure the port parameters in port configuration.

Serial

Press the front panel key, press the Serial softkey to access the serial port

setting menu.

Press the Baud softkey to select the desired baud rate from 1200, 2400, 4800,

9600, 19200, 38400, 57600 or 115200. The default is 9600. Make sure that the

baud rate matches that of the computer.

Press the Data bits softkey, select the data bits from 5, 6, 7, 8.

Press the Odd-Even softkey, select the parity from None, Odd or Even. The

default is None.

Press the Stop bit softkey, select the stop bit from 1, 2.

Trigger

See page 36, Triggering.

Output

Press the front panel key, press the Output softkey to access the output

setting menu.

Press the Output softkey to configure the output of the [AUX Output] connector at

the rear panel.

VMComp

Defaults to Voltmeter Measurement Complete Output, outputs a pulse whenever

the multimeter finishes taking a measurement to allow you to signal other devices.

Press the VMC Out softkey to set the edge slope of the voltmeter complete

output.

P/F

The [AUX Output] connector can be configured to output a pulse when the limits

are exceeded in Math limits function.

Page 53

49

Net Type

Press the front panel key, press the NET Type softkey to select Off, LAN

etc.

LAN

Press the LAN Setting softkey, set the IP address, subnet mask, gateway, port.

Press to move the cursor, press to increase or decrease the value.

Restart the instrument for the parameter changes to take effect.

Contact your LAN administrator for the LAN setting details.

Utility Menu

You can set the parameters of the system-related functions. in utility menu.

Language

Press the front panel key, press the Language softkey to switch display

languages.

Backlight

Press the front panel key, press the BLight softkey to adjust the

brightness.

Clock

Press the front panel key, press the Clock softkey. The clock menu

displays the date and time. The time always uses a 24-hour format (00:00:00 to

23:59:59).

Press the Setup softkey to edit the date and time, press to move the cursor,

press to increase or decrease the value. Press the Done softkey to finish

the clock setting.

SCPI

Press the front panel key, press the SCPI softkey to select the desired

setting.

Default

Press → Next → Default to restore the multimeter to factory defaults. The

measurement function will be automatically set to DCV.

Page 54

50

Factory default settings

Parameter

Factory Setting

Measurement

DCV

Range

Auto

Speed

Low

Filter

Off

Input Z

10M

Rel

Off

ACV

Range

Auto

Speed

Low

Rel

Off

DCI

Range

Auto

Speed

Low

Filter

Off

Rel

Off

ACI

Range

Auto

Speed

Low

Rel

Off

Ω2W/Ω4W

Range

Auto

Speed

Low

Ω 2W/Ω 4W

Ω 2W

Rel

Off

Cont

Beeper

On

Page 55

51

Parameter

Factory Setting

Threshold

50Ω

Diode

Beeper

On

CAP

Range

Auto

Rel

Off

Freq

Range

Auto

Freq/Period

Freq

Rel

Off

Temp

Load

KITS90

Display

All

Units

K

Rel

Off

Math

Statistics

Show/Hide

Hide

Limits

Limits

Off

High

2V/2A/2KΩ/2uF/2Hz/2s/2k

℃

Low

0V/0A/0KΩ/0uF/0Hz/0s/0k

℃

Center

1V/1A/1KΩ/1uF/1Hz/1s/1k

℃

Span

2V/2A/2KΩ/2uF/2Hz/2s/2k

℃

Pass/Fail

Pass

dB/dBm

On/Off

Off

Function

dBm

Ref R

50Ω

Page 56

52

Parameter

Factory Setting

dB Ref Value

0 dBm

Rel

0 V

Beeper

On

Utility

BLight

50%

SCPI

8845

Port

Serial

Baud

115200

Data bits

8

Odd-Even

None

Stop bit

1

Trigger

Source

Auto

Delay

Auto

Delay time

0 s

Samples

trigger

1

Output

Output

VM Comp

VMC Out

Positive

NET Type

IP

192.168.001.099

Subnet Mask

255.255.255.000

Gateway

192.168.001.001

Physical

address

000fea36ea46

Port

3000

Net

Off

Graph

Display

Number

Page 57

53

Parameter

Factory Setting

Bar Meter

Scale

Default

Trend

Recent/All

Recent

Histogram

Binning

Auto

Cumulative

Off

Record

Auto

record

Memory

Internal

Points

1000

Interval

1 s

Start/Stop

Stop

View

record

Display

Graph

System Info

Press → Next → System Info to view the model, firmware version, serial

number.

Update firmware

Use the front-panel USB port to update your instrument firmware using a USB

memory device.

USB memory device requirements: This instrument supports a USB memory

device with a FAT32 or FAT16 file system. If the USB memory device doesn't

work properly, format it into the FAT32 or FAT16 format and try again; or try

another USB memory device.

Caution: Updating your instrument firmware is a sensitive operation, to

prevent damage to the instrument, do not power off the

instrument or remove the USB memory device during the

update process.

To update your instrument firmware, do the following:

1. Press → Next → System Info to view the model and firmware version.

Page 58

54

2. From a PC, visit www.PeakTech.de and check if the website offers a newer

firmware version. Download the firmware file. The file name must be

DMMFW.upp. Copy the firmware file onto the root directory of your USB

memory device.

3. Insert the USB memory device into the front-panel USB port on your

instrument. If the icon appears on the top right of the screen, the USB

memory device is installed successfully.

4. Press → Next → System Info, press the Update firmware softkey.

5. The instrument displays a message telling you not to remove the USB device

or power off the instrument until the update process is complete. The progress

bar of the screen indicates the update process is in progress.

Note: A firmware update usually takes approximately a minute. Do not remove

the USB memory device during the update process. If you accidentally

removed the USB memory device during the update process, do not power off

the instrument. Repeat the installation process from step 3.

6. Wait until the instrument displays "Firmware upgrade success.", and then it

will reboot automatically.

Note: If the operation complete message is not displayed, do not power off the

instrument. Repeat the installation process from step 2 using a different type of

USB memory device.

7. Remove the USB memory device from the front-panel USB connector.

8. Press → Next → System Info, view the firmware version. Confirm that

the firmware has been updated.

LCD Test

The instrument provides the screen self testing, which can test the LCD screen.

Press → Next → LCD Test to access the screen test interface. Press the

Change softkey to switch the color between red, green, and blue. Observe if the

screen has severe color shift, spot, scuffing, or other defect. Press the last softkey

to exit the test.

Key Test

The instrument provides the key self testing, which can test the keys on the front

panel.

Page 59

55

Press → Next → Key Test to access the key test interface. Each shape on

the test interface represents a front panel key. Press any front panel key, the

corresponding shape on the test interface will turn green. Press the Return

softkey to exit the test.

Page 60

56

4. Measurement Tutorial

Loading Errors (DC Voltage)

Measurement loading errors occur when the resistance of the DUT(Device-UnderTest) is an appreciable percentage of the multimeter's input resistance, as shown

below.

Vs = ideal DUT voltage

Rs = DUT source resistance

Ri = multimeter input resistance (10 MΩ or >10 GΩ)

Error

is

s

100 R

()

RR

%

To reduce the effects of loading errors and to minimize noise interference, set the

multimeter's input resistance to 10 GΩ for the 200 mVDC and 2 VDC ranges. The

input resistance is maintained at 10 MΩ for the 20 VDC, 200 VDC, and 1000 VDC

ranges.

HI

LO

Ideal

Meter

R

s

V

s

R

i

Page 61

57

True RMS AC Measurements

The AC measurement of the multimeter has true RMS response. Power

dissipated in a resistor is proportional to the square of an applied voltage,

independent of the wave shape of the signal. This multimeter accurately

measures true rms voltage or current, as long as the wave shape contains

negligible energy above the meter’s effective bandwidth.

The effective AC voltage bandwidth of the multimeter is 100 kHz, while the

effective AC current bandwidth is 10 kHz.

Waveform

Shape

Crest Factor

(C.F.)

AC RMS

AC+DC RMS

2

V

2

V

2

3

V

3

V

3

(50% duty cycle)

1

V

C.F.

V

C.F.

The multimeter's AC voltage and AC current functions measure the AC-coupled

true rms value, the RMS value of only the AC components of the input waveform

are measured (DC is rejected). As seen in the figure above; for sine waves,

triangle waves, and square waves, the AC–coupled and AC+DC values are equal,

because these waveforms do not contain a DC offset. However, for non–

symmetrical waveforms (such as pulse trains) there is a DC voltage content,

which is rejected by the multimeter’s AC–coupled true rms measurements.

The AC coupled true RMS measurement is especially useful for measuring small

AC signals in the presence of large DC offsets. For example, this situation is

common when measuring AC ripple present on DC power supplies. However,

there are situations where you might want to know the AC+DC true RMS value.

You can determine this value by combining results from DC and AC

measurements, as shown below:

0V0

V

0

V

t

T

Page 62

58

22

ac dc ac dc

For the best AC noise rejection, you should select "Low" measurement speed to

get 5½ digits reading resolution when performing the DC measurement.

Page 63

59

Loading Errors (AC Voltage)

In the AC voltage function, the input impedance of the multimeter appears as a 1

MΩ resistance in parallel with 100 pF of capacitance. The cabling that you use to

connect signals to the multimeter also adds capacitance and loading. The table

below shows the multimeter's approximate input resistance at various

frequencies.

Input Frequency

Input Resistance

100 Hz

1 MΩ

1 kHz

850 kΩ

10 kHz

160 kΩ

100 kHz

16 kΩ

For low frequencies, the loading error is:

Error

s

s

100 R

(%

1

)

RM

At high frequencies, the additional loading error is:

Error

2

S in

1

(%) 100

2

1

1 F R C

Rs = source resistance

F = input frequency

Cin = input capacitance (100 pF) plus cable capacitance

Page 64

60

5. Troubleshooting

1. The instrument is powered on but no Display.

1) Check if the power is connected properly.

2) Check if the AC Mains Line Voltage Selector is in the proper voltage scale.

3) Check if the line fuse which is below the AC Mains Input is used

appropriately and in good condition (see page 69, Appendix C: Line Fuse

Replacement).

4) Restart the instrument after the steps above.

5) If the problem still exists, please contact PEAKTECH for our service.

2. The reading does not change when a current signal is input.

1) Check whether the test lead is correctly inserted into the current input

terminals (I terminal and LO Input terminal).

2) Check whether the current terminal fuse at the front panel is burned out.

Please refer to "7 Current Terminal Fuse" in "Front panel overview" on page

9.

3) Check whether the DCI or ACI measurement function is enabled.

4) Check whether the DCI measurement function is used to measure AC

current.

If you encounter other problems, try to reset the settings or restart the instrument.

If it still can not work properly, please contact PEAKTECH for our service, and

provide your device information. ( → Next → System Info)

Page 65

61

6. Technical Specifications

P4096 Specifications

Accuracy: ± (% of reading + % of range)

[1]

Function

Range

[2]

Frequency Range

or Test Current

Accuracy:

1 year

23℃±5℃

Temperature

Coefficient

0℃ - 18℃

28℃ - 50℃

DC Voltage

200 mV

/

0.015±0.004

0.0015 + 0.0005

2 V

0.0010 + 0.0005

20 V

0.0020 + 0.0005

200 V

0.0015 + 0.0005

1000 V

[3]

0.0015 + 0.0005

True RMS

AC Voltage

[4]

200mV, 2V, 20V, 200V, 750V

20 Hz – 45 Hz

1.5 + 0.10

0.01 + 0.005

45 Hz – 20 kHz

0.2 + 0.05

0.01 + 0.005

20 kHz – 50 kHz

1.0 + 0.05

0.01 + 0.005

50 kHz – 100 kHz

3.0 + 0.05

0.05 + 0.010

DC Current

200.000 μA

/

0.055 + 0.005

0.003 + 0.001

2.00000 mA

0.055 + 0.005

0.002 + 0.001

20.0000 mA

0.095 + 0.020

0.008 + 0.001

200.000 mA

0.070 + 0.008

0.005 + 0.001

2.00000 A

0.170 + 0.020

0.013 + 0.001

10.0000 A

[5]

0.250 + 0.010

0.008 + 0.001

True RMS

AC Current

[6]

20.0000 mA, 200.000 mA,

2.00000 A, 10.0000 A

[5]

20 Hz – 45 Hz

1.5 + 0.10

0.015 + 0.005

45 Hz – 2 kHz

0.50 + 0.10

0.015 + 0.005

2 kHz – 10 kHz

2.50 + 0.20

0.015 + 0.005

Resistance

[7]

200.000 Ω

1 mA

0.030 + 0.005

0.0030 + 0.0006

2.00000 kΩ

1 mA

0.020 + 0.003

0.0030 + 0.0005

20.0000 kΩ

100 μA

0.020 + 0.003

0.0030 + 0.0005

200.000 kΩ

10 μA

0.020 + 0.003