Page 1

PeakTech

®

1190/1230

Operation manual

Digital Oscilloscope /

with 16-CH logic analyzer

Page 2

1. Safety Precautions

This product complies with the requirements of the following European Community Directives: 2004/108/EC

(Electromagnetic Compatibility) and 2006/95/EC (Low Voltage) as amended by 2004/22/EC (CE-Marking).

Overvoltage category II; pollution degree 2.

To ensure safe operation of the equipment and eliminate the danger of serious injury due to short-circuits

(arcing), the following safety precautions must be observed.

Damages resulting from failure to observe these safety precautions are exempt from any legal claims

whatever.

Do not use this instrument for high-energy industrial installation measurement.

Prior to connection of the equipment to the mains, check that the available mains voltage corresponds

to the voltage setting of the equipment.

Connect the mains plug of the equipment only to a mains outlet with earth connection.

Do not place the equipment on damp or wet surfaces.

Do not operate the equipment near strong magnetic fields (motors, transformers etc.).

Do not exceed the maximum permissible input ratings (danger of serious injury and/or destruction of

the equipment).

The meter is designed to withstand the stated max voltages. If it is not possible to exclude without that

impulses, transients, disturbance or for other reasons, these voltages are exceeded a suitable presale

(10:1) must be used.

Replace a defective fuse only with a fuse of the original rating. Never short-circuit fuse or fuse holding.

Disconnect test leads or probe from the measuring circuit before switching modes or functions.

Check test leads and probes for faulty insulation or bare wires before connection to the equipment.

Conduct measuring works only in dry clothing and rubber shoes, i. e. on isolating mats.

Never touch the tips of the test leads or probe.

Comply with the warning labels and other info on the equipment.

The measurement instrument is not to be to operated unattended.

Always start with the highest measuring range when measuring unknown values.

Do not subject the equipment to direct sunlight or extreme temperatures, humidity or dampness.

Do not subject the equipment to shocks or strong vibrations.

Keep hot soldering irons or guns away from the equipment.

Allow the equipment to stabilize at room temperature before taking up measurement (important for

exact measurements).

Do not input values over the maximum range of each measurement to avoid damages of the

instrument.

Use caution when working with voltages above 35V DC or 25V AC. These Voltages pose shock

hazard.

-118-

Page 3

Warning:

To avoid fire or electrical shock, when the oscilloscope input signal connected is more than 42V peak

(30Vrms) or on circuits of more than 4800VA, please take note of below items:

- Only use accessory insulated voltage probes and test lead.

- Check the accessories such as probe before use and replace it if there are any damages.

- Remove probes, test leads and other accessories immediately after use.

- Remove USB cable which connects oscilloscope and computer.

- Do not apply input voltages above the rating of the instrument because the probe tip voltage will

directly transmit to the oscilloscope. Use with caution when the probe is set as 1:1.

- Do not use exposed metal BNC or banana plug connectors.

- Do not insert metal objects into connectors.

Periodically wipe the cabinet with a damp cloth and mid detergent. Do not use abrasives or solvents.

The meter is suitable for indoor use only

Do not store the meter in a place of explosive, inflammable substances.

Opening the equipment and service – and repair work must only be performed by qualified service

personnel

Do not place the equipment face-down on any table or work bench to prevent damaging the controls

at the front.

Do not modify the equipment in any way.

Measuring instruments don’t belong to children hands.

Cleaning the cabinet

Prior to cleaning the cabinet, withdraw the mains plug from the power outlet.

Clean only with a damp, soft cloth and a commercially available mild household cleanser. Ensure that no water

gets inside the equipment to prevent possible shorts and damage to the equipment.

-119-

Page 4

2. Safety Terms and Symbols

The following terms may appear in this manual:

Warning.

A warning statement indicates the conditions and actions which may endanger the life safety.

Note.

A note statement indicates the conditions and actions which may cause damage to this product or

other property.

The following terms may appear on this product:

Danger:

It indicates that there may be an immediate injury to you when you encounter this mark.

Warning:

It indicates that there may not be an immediate injury to you when you encounter this mark.

Note:

It indicates that there may be damage to this product or other property.

Symbols on the product. The following symbol may appear on the products:

High Voltage

Please Consult the

Manual

Protective Ground

End

Earth End on the

Shell

Grounding End for

Measurement

To avoid body damage and prevent product and connected equipment dam. This product can only be used in

the specified applications. Carefully read the following safety information before using the test tool.

Warning:

The channels of the oscilloscope are non-isolated electrically. The channels should adopt common basis

during measuring. To prevent short circuits, the probe ground must not be connected to different non-isolated

DC level.

Warning:

The channels should adopt common basis during measuring. To prevent short circuits, the probe ground must

not be connected to different non-isolated DC level.

The diagram of the oscilloscope ground wire connection:

Ground Clip

Signal Input

Electrical Outlet

Probe

Oscilloscope AC Adapter

-120-

Page 5

3. General Characteristics of the PeakTech® 1190 / 1230 Oscilloscopes

3.1. Digital Storage Oscilloscope

* With the bandwidth of 100 MHz (P 1190) / 200 MHz (P 1230)

* Sample Rate 500 MSa/s (P 1190) / 1 GSa/s (P 1230)

* Record length for each channel of 2 Mpoints

* Reading-out with the cursor

* Twenty automatic measurement functions

* Autoscale function

* Color liquid crystal display of high resolution and high contrast with adjustable back light

* Storage and call-out of waveforms

* Automatic setting function provided capable of fast setting

* Multiple-waveform calculation function

* Built-in FFT function

* Implementation of detecting the average and peak values of the waveform

* Digital real-time oscilloscope

* Edge, video; pulse, slope and alternate triggering function

* USB communication ports

* Different continuous displaying time

* Multiple Language User Interface (English, German, Chinese)

3.2. Logic Analyzer

* With the bandwidth of 100MHz (P1190) or 200MHz (P1230)

* 16 input channel

* 20Sa/s up to 1GSa/s sampling rate for each channel

* 4 M max Storage for each channel

* Plenty of trigger Mode

* Convenient data measurement & data search

* Freely setting of all kinds of threshold level

-121-

Page 6

4. Introduction to the Front Panel and the User's Interface

When you get a new-type oscilloscope, you should get acquainted with its front panel at first and the

PeakTech® digital storage oscilloscope is no exception. This chapter makes a simple description of the

operation and function of the front panel of the PeakTech® oscilloscope, enabling you to be familiar with the

use of the PeakTech® oscilloscope in the shortest time. The PeakTech® oscilloscope offers a simple front

panel with distinct functions to users for their completing some basic operations, in which the knobs and

function pushbuttons are included. The knobs have the functions similar to other oscilloscopes. The 5 buttons

in the column on the right side of the display screen are menu selection buttons (defined as F1 to F5 from top

to bottom respectively), through which, you can set the different options for the current menu. The other

pushbuttons are function buttons, through which, you can enter different function menus or obtain a specific

function application directly.

4.1. Front panel

Fig. 1 Front panel overview

1. Power on/off

2. Display area

3. Control (key and knob) area

4. USB slot

5. Logic Analyzer signal input

6. Oscilloscope signal input

7. Measurement signal output

8. Power and charging indication: Green light indicates AC supply and battery full charged; yellow light

indicates under charging

-122-

1.

2.

3.

4.

5.

6.

7.

8.

8

4

5 7 1 2 3

Page 7

4.2. Control area (key and knob)

Fig. 2 Keys Overview

1. Menu option setting: F1~F5

2. Switch

Switch includes two keys and one knob. Press “OSC/LA” to switch between Oscilloscope and Logic

Analyzer.

For Oscilloscope “cursor” knob and “info” key are idle. But the “cursor” knob takes effect in magnifying or

minificating the waveform after FFT operation when the mode is FFT.

For Logic Analyzer, “cursor” knob to adjust current cursor position and “info” key to loading setting info for

acquired waveform and current waveform.

3. Function key area

For Oscilloscope 0~5 keys are idle and 6~F refer to different Oscilloscope function menu.

For LA, 3.4.5.6.7 refers to figure and other keys refer to digit or function menu.

4. Vertical control area

It’s including 3 keys and 4 knobs.

For Oscilloscope: “CH1 menu” and “CH2 menu” correspond to setting menu in CH1 and CH2, “Wave Math”

key refer to math menu, the math menu consists of six kinds of operations, including CH1-CH2, CH2-CH1,

CH1+CH2, CH1*CH2, CH1/CH2 and FFT .Two “Vertical position” knob control the vertical position of CH1.

CH2, and two “Volts/Div” knob control voltage scale of CH1, CH2.

For Logic Analyzer, “CH1 menu”, “CH2 menu”, “Wave math” keys and “CH2 Volts/Div” knob are idle. “CH1

Vertical”, “CH2 Vertical” to adjust the M1, M2 position in Cursor menu when cursor display is on “CH1

Volts/Div”.

-123-

Page 8

5. Horizontal control area with 2 knobs and 1 key.

For Oscilloscope, “Horizontal position” knob control trigger position, “Volts/Div” control time base,

“Horizontal

menu” key refer to horizontal system setting menu.

For Logic Analyzer, “Horizontal menu” key is idle. “Horizontal position” knob to adjust the position of value

displayed currently quickly. “Sec/Div” knob to adjust value resolution displayed currently.

6. Trigger control area with 4 keys and 1 knob.

For Oscilloscope, “Trig adjust” knob is to adjust trigger voltage. Other four keys refer to trigger system

setting.

For Logic Analyzer “Force trig” key is idle. “Trig menu” refer to trigger menu control. “Trig adjust” knob to

adjust trigger position in memory, “SET 50%” is to set trigger position as 50% and “SET Zero” set trigger

position as 0.

4.3. User interface introduction

Fig. 3 Illustrative Drawing of Display Interfaces

1. The Trigger State indicates the following information:

Auto: The oscilloscope is under the Automatic mode and is collecting the waveform under the

non-trigger state.

Trig' d: The oscilloscope has already detected a trigger signal and is collecting the after-triggering

information.

Ready: All pre-triggered data have been captured and the oscilloscope has been already ready for

accepting a trigger.

Scan: The oscilloscope captures and displays the waveform data continuously in the scan mode.

Stop: The oscilloscope has already stopped the waveform data acquisition.

-124-

Page 9

2. Waveform Viewing Area.

3. The purple pointer indicates the horizontal trigger position, which can be adjusted by the horizontal

position control knob.

4. The pointer indicates the trigger position in the internal memory.

5. This reading shows the time deviation between the horizontal trigger position and the window centre l

ine, which is regarded as 0 in the window center.

6. It indicates the current function menu.

7. It indicates the operation options for the current function menu, which changes with the function menus.

8. The purple pointer shows the trigger level position.

9. The reading shows the trigger level value.

10. The reading shows the trigger source.

11. It shows the selected trigger type:

Rising edge triggering

Falling edge triggering

Video line synchronous triggering

Video field synchronous triggering

12. The reading shows the window time base set value.

13. The reading shows the main time base set value.

14. The two yellow dotted lines indicate the size of the viewing expanded window.

15. The icon shows the coupling mode of the CH2 channel.

“—” indicates the direct current coupling

“ ~ ” indicates the AC coupling

“ Ground” indicates GND coupling.

16. The reading shows the vertical scale factor (the Voltage Division) of the CH2 channel.

17. The icon indicates the coupling mode of the CH1 channel:

The icon "–" indicates the direct current coupling

The icon " ~ " indicates the AC coupling

The icon "Ground” indicates GND coupling.

18. The reading indicates the vertical scale factor (the Voltage Division) of the CH1 channel.

19. The information shows the zero point positions of CH1 or CH2 channel.

20. The yellow pointer shows the grounding datum point (zero point position) of the waveform of the CH2

channel. If the pointer is not displayed, it shows that this channel is not opened.

21. The red pointer indicates the grounding datum point (zero point position) of the waveform of the CH1

channel. If the pointer is not displayed, it shows that the channel is not opened.

22. The positions of two purple dotted line cursors measurements.

23. The reading shows the frequence of the two channels. It is a 6 digits cymometer.Its measurement range

of frequency is 2Hz to full bandwidth. when the triggering mode is edge triggering,it is a one channel

cymometer and it can only measure the frequency of the tiggering channel. When the triggering mode is

alternating triggering,it is a two channel cymometer and it can measure the frequency of two channels.

-125-

Page 10

5. How to implement the Function Inspection

Make a fast function check to verify the normal operation of the instrument, according to the following steps:

1. Connect the Instrument to the Power and Push down the Power Switch Button.

The instrument carries out all self-check items and shows the prompt “Press any Key Enter system”.

Press the “8 (UTILITY)” button to get access to the “FUNCTION” menu and push down F2 the menu

selection button to call out the function “Recall Factory”. The default attenuation coefficient set value of

the probe in the menu is 10X,

2. Set the Switch in the Oscilloscope Probe as 10X and Connect the Oscilloscope with CH1 Channel.

Align the slot in the probe with the plug in the CH1 connector BNC, and then tighten the probe with

rotating it to the right side.

Connect the probe tip and the ground clamp to the connector of the probe compensator.

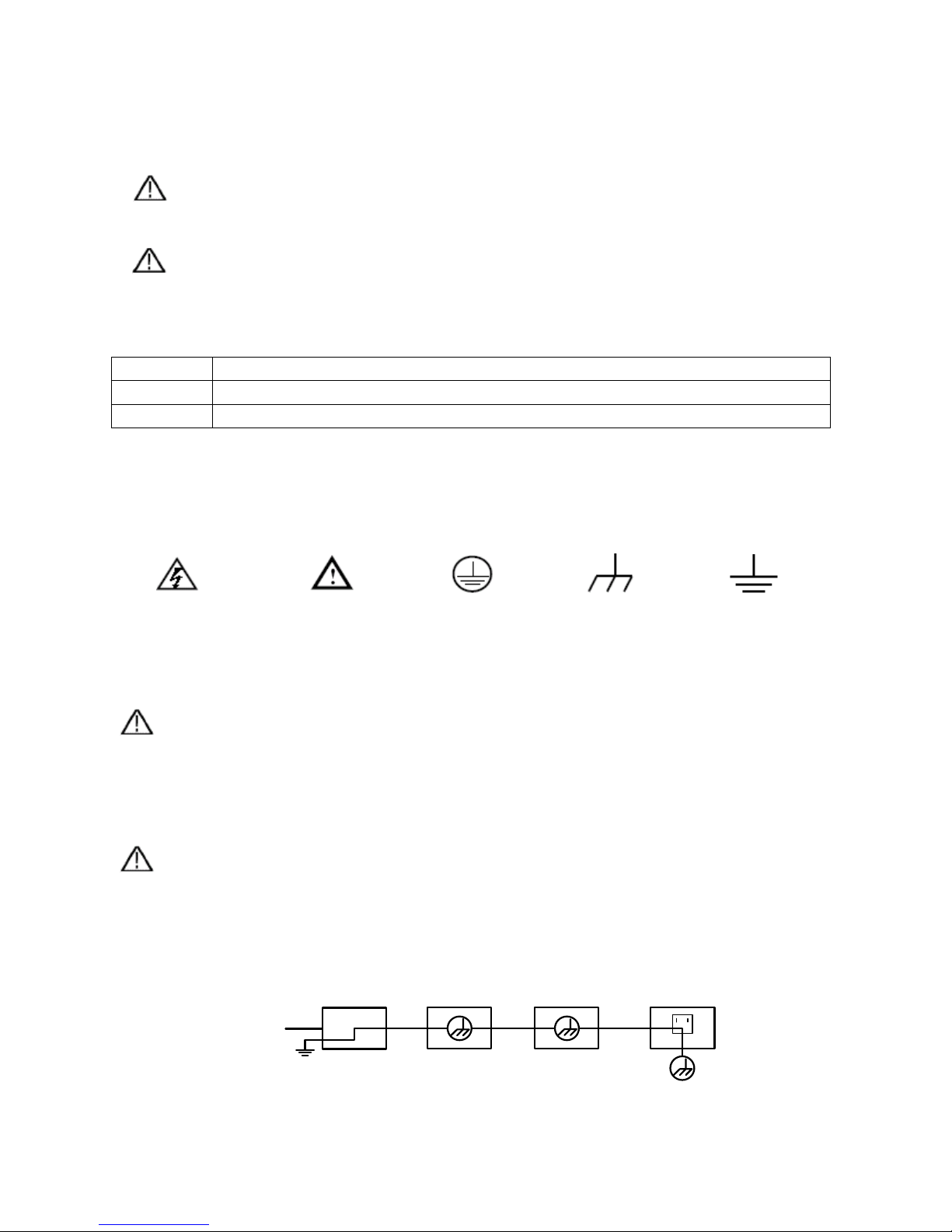

3. Press the “7(AUTOSET)” Button.

The square wave of 1 KHz frequency and 5Vpp value will be displayed in several seconds (see Fig.4).

Fig. 4 Auto set

Check CH2 by repeating Step 2 and Step 3.

-126-

Page 11

6. How to Implement the Probe Compensation

When connect the probe with any input channel for the first time, make this adjustment to match the probe with

the input channel. The probe which is not compensated or presents a compensation deviation will result in the

measuring error or mistake. For adjusting the probe compensation, please carry out the following steps:

1. Set the attenuation coefficient of the probe in the menu as 10X and that of the switch in the probe as 10X,

and connect the oscilloscope probe with the CH1 channel. If a probe hook tip is used, ensure that it keeps

in close touch with the probe. Connect the probe tip with the signal connector of the probe compensator

and connect the reference wire clamp with the ground wire connector of the probe connector, and then

press the button “7(AUTOSET)”.

2. Check the displayed wave forms and regulate the probe till a correct compensation is achieved (see Fig.5

and Fig. 5).

Fig. 5 Displayed Wave Forms of the Probe Compensation

3. Repeat the steps mentioned if necessary.

Fig. 6 Adjust Probe

-127-

Page 12

7. How to Set the Probe Attenuation Coefficient

The probe has several attenuation coefficients, which will influence the vertical scale factor of the oscilloscope.

If it is required to change (check) the set value of the probe attenuation coefficient, press the function menu

button of the channels used, then push down the selection button corresponding to the probe till the correct set

value is shown.

This setting will be valid all the time before it is changed again.

Note: The attenuation coefficient of the probe in the menu is preset to 10X when the oscilloscope

is delivered from the factory.

Make sure that the set value of the attenuation switch in the probe is the same as the menu selection of the

probe in the oscilloscope.

The set values of the probe switch are 1X and 10X (see Fig. 7).

Fig. 7 Attenuation Switch

Note: When the attenuation switch is set to 1X, the probe will limit the bandwidth of the

oscilloscope in 5MHz. If it is needed to use the whole bandwidth of the oscilloscope, the

switch must be set to 10X.

8. How to Implement Auto-calibration

The auto-calibration application can make the oscilloscope reach the optimum condition rapidly to obtain the

most accurate measurement value. You can carry out this application program at any time, but when the range

of variation of the ambient temperature is up to or over 5°C, this program must be executed.

For the performing of the self-calibration, all probes or wires should be disconnected with the input connector

first. Then, press the “8 (UTILITY)” button to call out the FUNCTION menu; push down the F3 menu selection

button to choose the option “Auto calibration”; finally, run the program after confirming that everything is ready

now.

-128-

Page 13

9. Introduction to the Vertical System

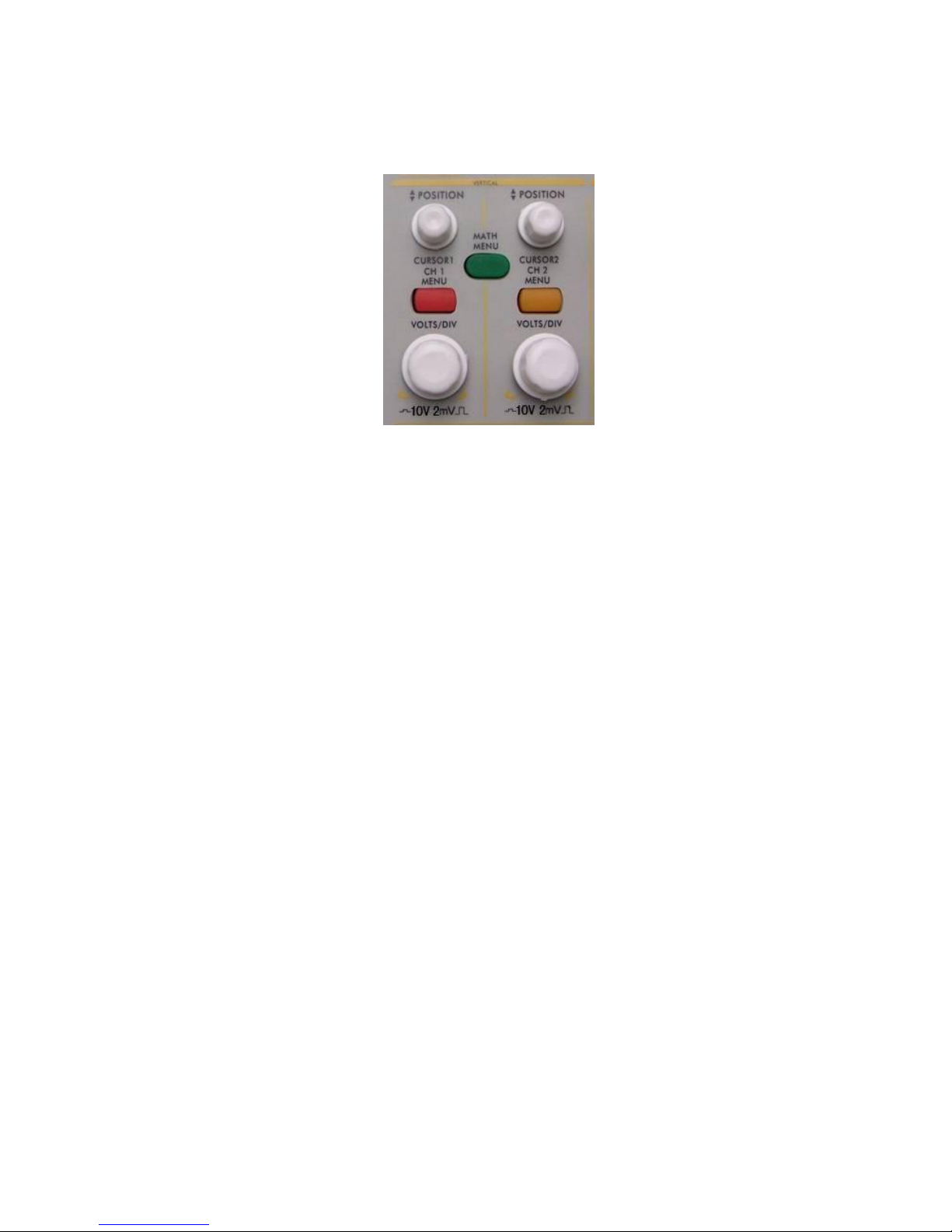

Shown as Fig. 8, there are a series of buttons and knobs in VERTICAL CONTROLS. The following practices

will gradually direct you to be familiar with the using of the vertical setting.

Fig. 8 Vertical Control Zone

1. Use the button “VERTICAL POSITION” knob to show the signal in the center of the waveform

window. The “VERTICAL POSITION” knob functions the regulating of the vertical display

position of the signal. Thus, when the “VERTICAL POSITION” knob is rotated, the pointer of the

earth datum point of the channel is directed to move up and down following the wave form.

Measuring Skill

If the channel is under the DC coupling mode, you can rapidly measure the DC component of the signal

through the observation of the difference between the wave form and the signal ground.

If the channel is under the AC mode, the DC component will be removed by filtration. This mode helps

you display the AC component of the signal with a higher sensitivity.

2. Change the Vertical Setting and Observe the Consequent State Information Change.

With the information displayed in the status bar at the bottom of the waveform window, you can determine

any changes in the channel vertical scale factor.

* Rotate the vertical “VOLTS/DIV” knob and change the “Vertical Scale Factor (Voltage Division)”, it can

be found that the scale factor of the channel corresponding to the status bar has been changed

accordingly.

* Press buttons of “CH1 MENU”, “CH2 MENU” and “MATH MENU”, the operation menu, symbols, wave

forms and scale factor status information of the corresponding channel will be displayed in the screen.

-129-

Page 14

10. Introduction to the Horizontal System

Shown as Fig. 9, there are a button and two knobs in the “HORIZONTAL CONTROLS”. The following

practices will gradually direct you to be familiar with the setting of horizontal time base.

Fig. 9 Horizontal Control Zone

1. Use the horizontal “SEC/DIV” knob to change the horizontal time base setting and observe the

consequent status information change. Rotate the horizontal “SEC/DIV” knob to change the horizontal

time base, and it can be found that the “Horizontal Time Base” display in the status bar changes

accordingly. The horizontal scanning speed steps from 2ns up to 100s in the sequence of 1-2-5.

2. Use the “HORIZONTAL POSITION” knob to adjust the horizontal position of the signal in the waveform

window. The “HORIZONTAL POSITION” knob is used to control the triggering displacement of the signal

or for other special applications. If it is applied to triggering the displacement, it can be observed that the

wave form moves horizontally with the knob when you rotate the “Horizontal Position” knob.

3. With the “HORIZ MENU” button pushed down, you can set and initiate the Window Expansion.

-130-

Page 15

11. Introduction to the Trigger System

Shown as Fig.10, there are a knob and four buttons in the “TRIGGER CONTROLS”. The following practices

will direct you to be familiar with the setting of the trigger system gradually.

Fig. 10 Trigger Control Zone

1. Press the “TRIG MENU” button and call out the trigger menu. With the operations of the 5 menu selection

buttons, the trigger setting can be changed.

2. Use the “LEVEL” knob to change the trigger level setting.

With the rotation of the “LEVEL” knob, it can found that the trigger indicator in the screen will move up

and down with the rotation of the knob. With the movement of the trigger indicator, it can be observed that

the trigger level value displayed in the screen changes.

3. Press the button “SET TO 50%” to set the trigger level as the vertical midpoint values of the amplitude of

the trigger signal.

4. Press the “FORCE TRIG” button to force a trigger signal, which is mainly applied to the “Normal" and

"Single” trigger modes.

5. The “SET TO ZERO” button is used to reset the trigger horizontal position.

-131-

Page 16

12. Logic Analyzer

Logic Analyzer input connection

Insert the plug of OL-16 Logic Analyzer module 50P into the Logic Analyzer signal input on front panel and fix

two screws. Then 16 channel clamp of OL-16 Logic Analyzer connect to target signal and ready for

measurement

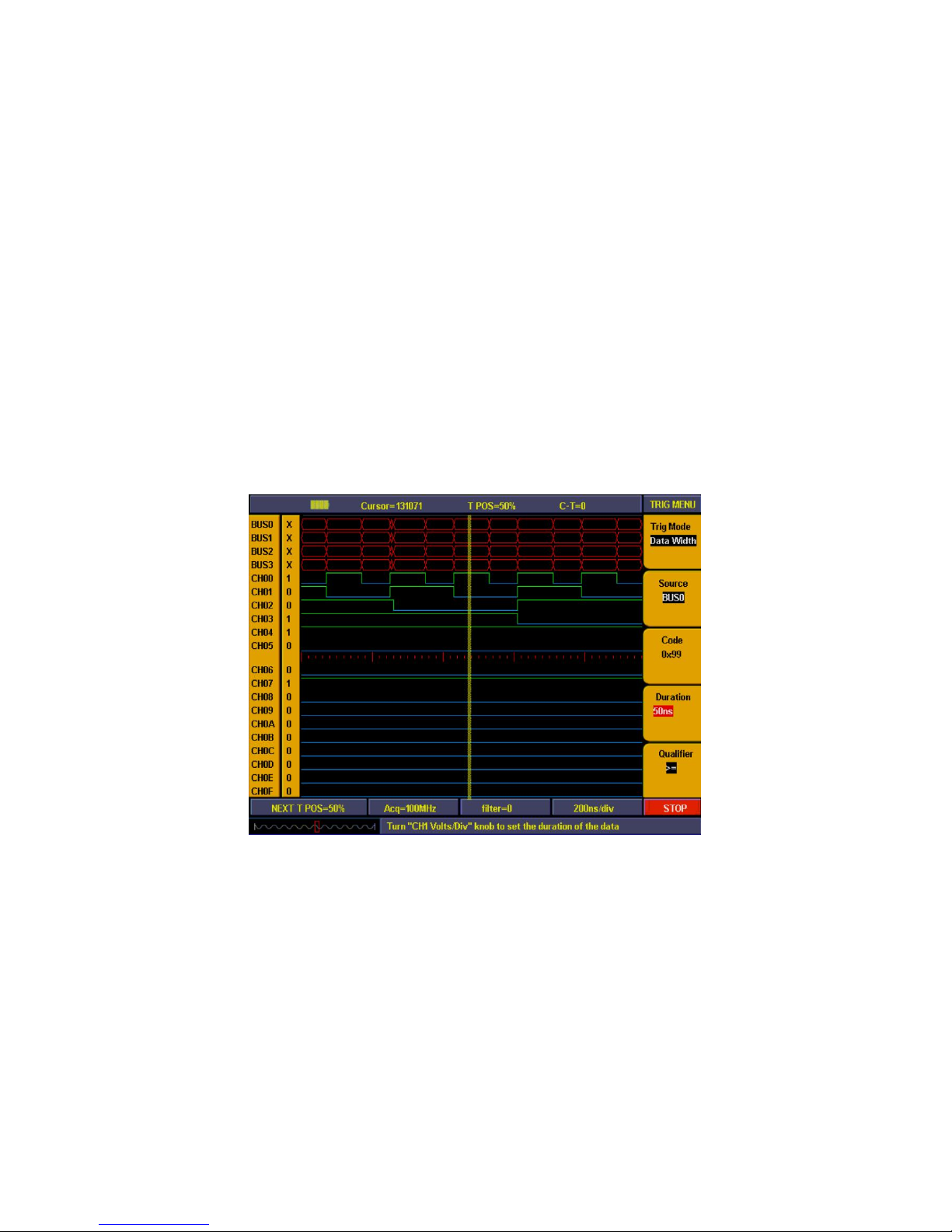

13. User interface introduction of Logic-Analyzer

Fig.11 User interface of logic analyzer

1. Channel and Bus indicate: display current working channel and bus.

2. Channel binary value display: display binary system value for the channel position in current cursor.

3. Battery powers indicate: indicate battery power when battery inside.

4. Decimal system value indicates the position of current cursor in storage area.

5. Yellow dashed line indicates current cursor.

6. Blue dashed line indicates current trigger position.

7. Percentage value indicates current trigger position in storage area.

8. Sample data area indication: red for bus, blue and green for “0”, “1” in each channel data.

9. Decimal system value indicate the position of current cursor relate to current trigger.

10. Operation options indicate current function menu and different function menu have different display.

-132-

Page 17

11. Sample status indicate: “RUN” for sampling and wait for trigger, “TRIG” for trigger detected and wait

for sample finished. “STOP” for sampling finished.

12. Value indicate current time base.

13. Info windows: different operation display different info.

14. Value display current filter modulus setting.

15. Value display current sample rate setting.

16. Two purple lines for cursor 1 and cursor 2 in cursor measurement

17. Percentage value indicates trigger position for next sampling in storage area.

18. Red square indicates the current sampling data position in storage area.

19. Red scale line indicates the time base width in sampling data display area and totally 4.8 divisions. The

width between two long scale lines is 1 division and between short scale lines are 0.1 divisions.

14. How to acquire data

When you start to acquire LA begins sampling data from the probes. Then each time clock occurs the data will

be sampled.

Then sampled data is sent to trigger function block and store in main memory. The trigger program checks

specific events with the sampled data and take specific action. The trigger program can check events as rising

edge, data values, and data ranges etc. LA module enables a post trigger delay counter when trigger reach

specified value and to allow post trigger portion of the acquisition memory to fill before data acquisition stops.

Press “F” to get into data acquisition mode after finish setting for trigger and sampling. Then running status

display as “RUN” and running status display “TRIG” when detected trigger signal and display “STOP” when

data acquisition finished. Then you can start to analyze data. Data acquisition can be stopped by press “F”

again during the process.

Note:

When running status display as “RUN”, “TRIG” during data acquiring process, only "F" key

for operate and other keys or knobs are idle. Only till status display as "STOP" then others

operations are working.

-133-

Page 18

15. How to observe and analyze the data

Follow up below steps to observe and analyze the current data acquired:

1. Turn “Sec/Div” knob to adjust the time length for data display in each division (to adjust the data

resolution displayed).

2. Turn “Cursor” knob to observe more details for the data of current cursor position. The data of binary

value for current cursor position display in binary system area and power on measure menu then bus

value for current cursor position will display in measurement window.

3. Turn “horizontal position” knob can move the current displayed data to left/right position in storage area

quickly.

We will use a simple measurement example to explain the primary setting for LA measurement.

We need to measure a three lines SPI signal, three signals are enable, clock and data. Clock is in effect when

enable is low clock data, and clock frequency is 1M, data width is 32 digits, every clock corresponds to one

data. Signal voltage is 3.3V.

16. Display systems

We need only three channels as what we measure is 3 signals. And other channel and bus can be off. In this

way the display resolution in using channel will be increased.

Display system mainly to set on/off for measure channel. We use CH00, CH01, CH02 as measure channel

correspond to signal enable, clock, data accordingly. Other channel and bus is off.

1. Press “A(DISPLAY)” and display menu appears.

2. Press “F1” till signal sources display as “Channel”

3. Press “F2” or turn “CH1 Volts/Div” knob till channel No. display as “CH00”.

4. Press “F3” and set the signal sources as “ON”. Repeat operation of steps 3.4 and set CH01, CH02

as “ON” and CH03-CHOF as “OFF”. Refer to Fig. 13.

5. Press “F1” till sources display as “BUS”.

6. Press “F2” till Bus No. display as “BUS0”

7. Press “F3” and set signal sources as “OFF”. Repeat operation of steps 6.7 and set BUS1, BUS2, BUS3

all as “OFF”. Ref to Fig. 14.

Now display panel only show CH00, CH01, CH02 and others channel and bus are all off. Ref to Fig. 12

-134-

Page 19

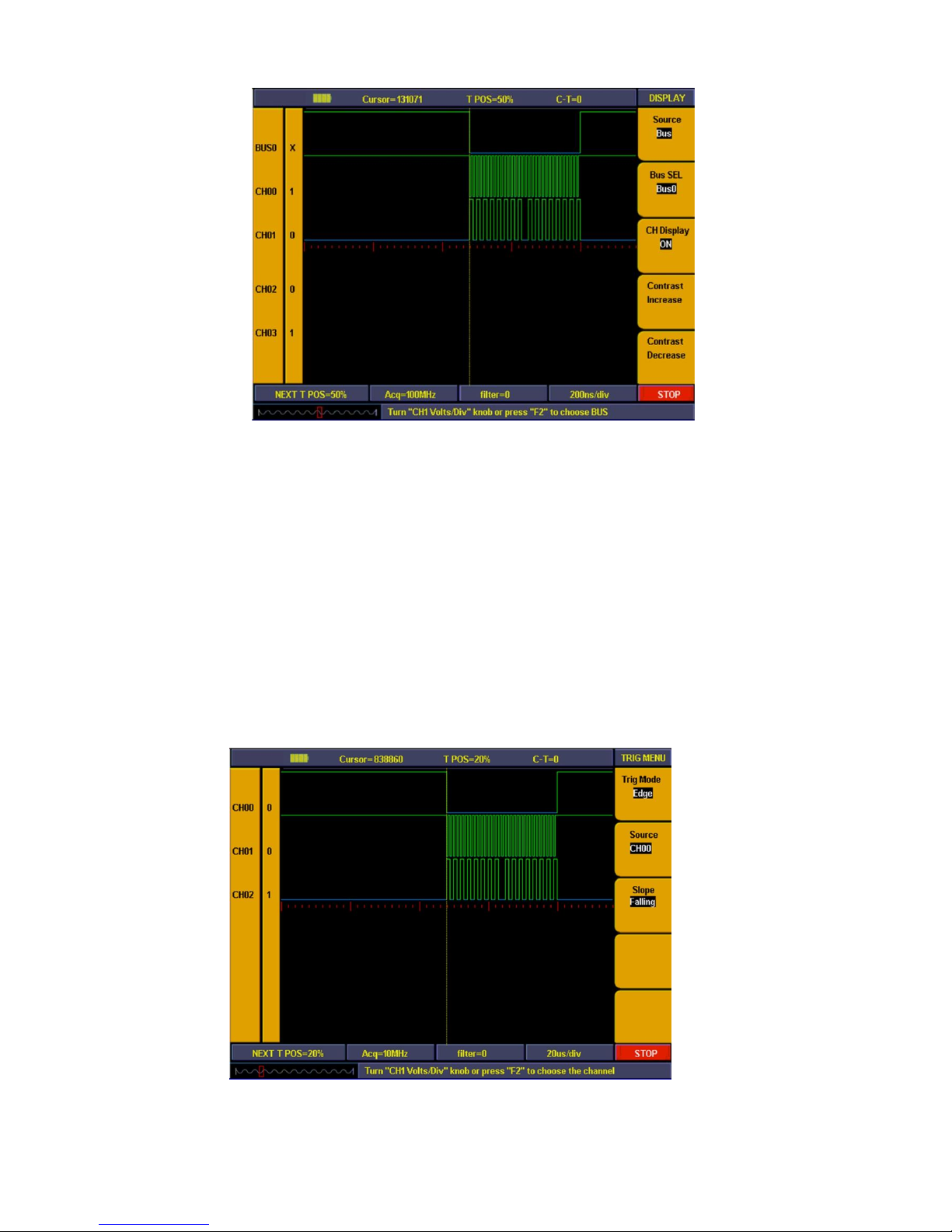

Fig. 12

Fig. 13

-135-

Page 20

Fig. 14

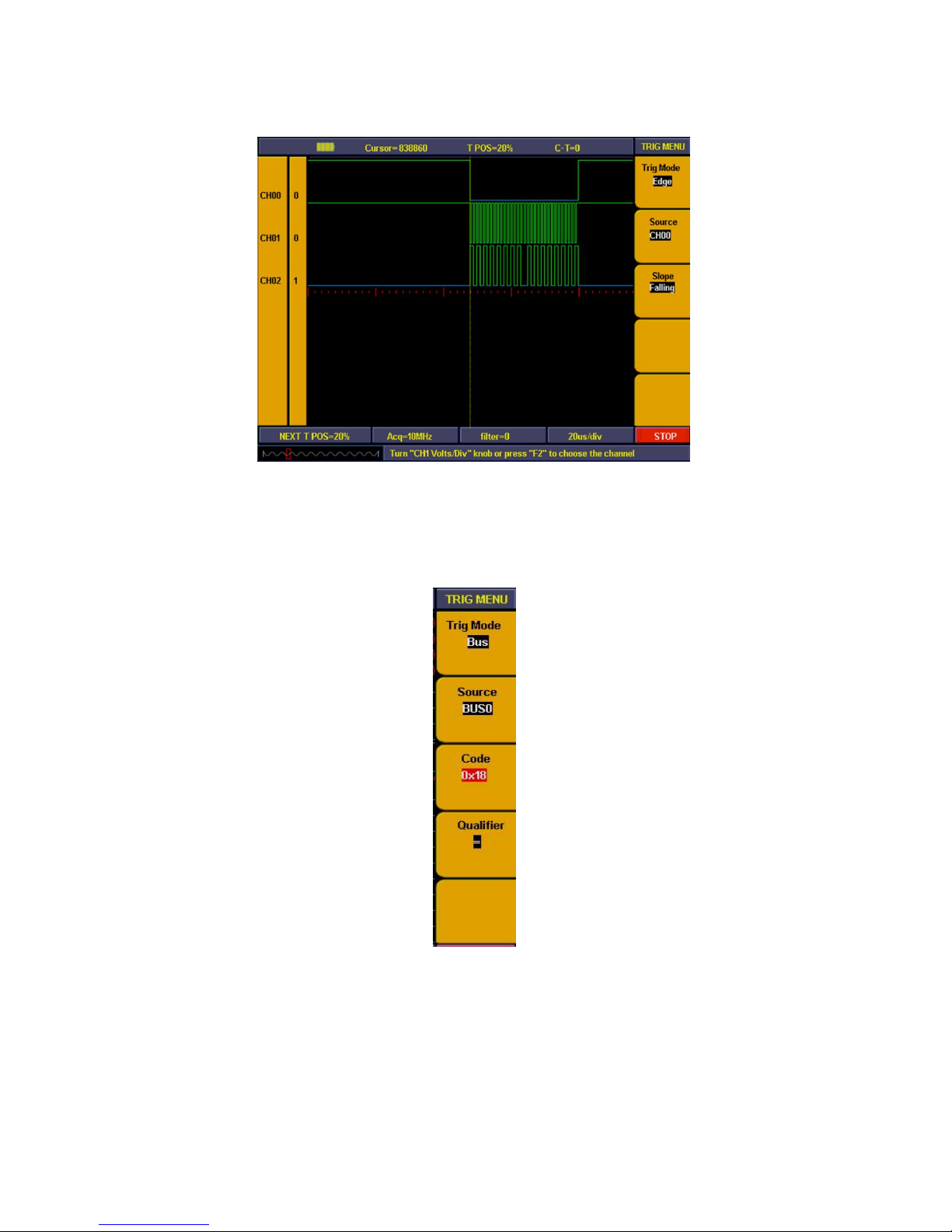

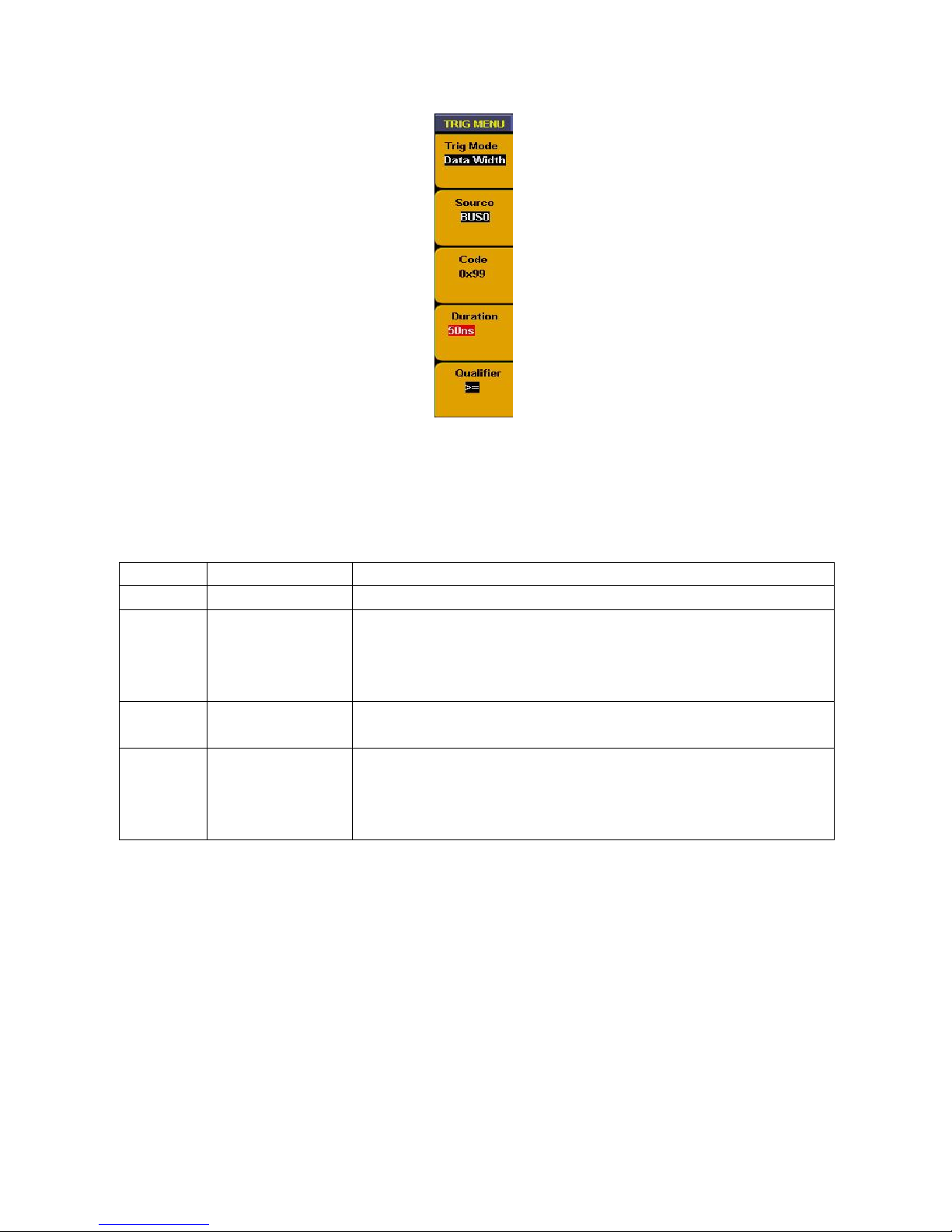

17. Trigger system

Logic Analyzer is same as Oscilloscope and need to make trigger to synchronize data. The trigger system

mainly to set trigger sources, trigger mode and trigger position.

We make CH00 as trigger source and trigger mode as falling edge, trigger position in 50%. Trigger system

setting steps as below:

1. Press “Trig menu” and menu appears.

2. Press “F1” till trigger mode display as “Edge”.

3. Press “F2” or turn “CH1 Volts/Div” till trigger sources display as “CH00”.

4. Press “F3” till trigger type display as “Falling”.

5. Turn “Trigger adjust” knob or press “SET 50%”till “NEXT T POS” window display as “50%”.

Then trigger system setting finished (ref to Fig. 15).

Fig. 15

-136-

Page 21

18. Threshold voltage system

Threshold voltage system is to set high/low of the trigger voltage. The system already fixed the setting for

normal logic voltage as CMOS, LVMOS etc. And you can set any trigger voltage using custom setting.

The signal voltage is 3.3V and we set threshold voltage as “LVCMO3.3/1.7V” as below steps:

1. Press “1 (Threshold)” key and the menu appears.

2. Press “F1” key till Channel display as “CH00 ~ CH03”

3. Press “F2” key till threshold display as “LVCMOS3.3/1.7V”.

Then the threshold setting is finished (ref to Fig. 16).

Fig. 16

-137-

Page 22

19. Sampling system

The waveform accuracy reverts from sample data depend on sample rate for measured signals. The

waveform reverted in Logic Analyzer is referring to the sample signals storage in the memory. The recorded

data will display in error if the sample rate is too lower. Below figures explains how sample rate influence the

waveform recorded in Logic Analyzer.

Fig. 17

There is an importance compromise between recorded signal resolution and its continuance (relate to time).

The sample memory depth of the Logic Analyzer is fixed and once adding sample rate then resolution will get

better accordingly. But it will decrease the continuance for acquire signal. In a word, sample rate are quicker

than the continuance for recorded signal will get smaller but with better resolution.

Sampling system can set difference sample rate and storage depth.

We use 10 times sampling rate to measure the signal clock frequency of 1M. and storage depth set as

“Normal”. Sampling system setting steps as below:

1. Press “E(ACQUIRE)” and menu appears.

2. Press “F1” or turn “CH1 Volts/div” knob till sample rate setting display as“10M”.

3. Press “F2” till storage depth display as “General”.

Sampling system setting finished (ref to the fig. 18)

-138-

Page 23

Then press “F” and start to sampling data. Display show as fig. 18 when sampling finished.

Fig. 18

20. How to Set the Vertical System

The VERTICAL CONTROLS includes three menu buttons such as CH1 MENU, CH2 MENU and MATH

MENU, and four knobs such as VERTICAL POSITION, VOLTS/DIV (one group for each of the two channels).

Setting of CH1 and CH2

Every channel has an independent vertical menu and each item is set respectively based on the channel.

With the “CH1 MENU” or “CH2 MENU” menu button pushed down, the system shows the operation menu of

the corresponding channel (see Fig. 19).

Fig. 19 Channel Setting Menu

-139-

Page 24

The description of the Channel Menu is shown as the following list:

Function Menu

Setting

Description

Coupling

AC

DC

GROUND

Block the DC component in the input signal.

Unblock the AC and DC components in the input signal.

The Input signal is interrupted.

Band Limit

OFF 100 MHz

ON 20 MHz

Get full bandwidth.

Limits the channel bandwidth to 20MHz to reduce display noise.

Channel

OFF

ON

Close the measurement channel.

Open the measuring channel.

Probe

1X

10X

100X

1000X

Choose one according to the probe attenuation factor to make the

vertical scale reading accurate.

Inverted

OFF

ON

The wave form is displayed normally.

Initiate the wave form inverted function.

1. Setting Channel Coupling

Taking the Channel 1 for example, the measured signal is a square wave signal containing the direct

current bias. The operation steps are shown as below:

1. Press the CH1 MENU button and call out the CH1 SETUP menu.

2. Press the F1 menu selection button and select the Coupling item as “AC” to set the channel coupling

as ac mode, under which the direct current component in the signal will be blocked.

3. Then, press the F1 menu selection button again and select the Coupling item as “DC”, setting the

channel coupling as dc mode, under which both dc and ac components in the signal will be

unblocked.

The wave forms are shown as Fig. 20 and Fig. 21.

-130-

Fig. 20 AC Coupling Oscillogram

-140-

Page 25

Fig. 21 DC Coupling Oscillogram

2. Setting the“Band Limit”

Taking the Channel 1 for example, the operation steps are shown as below:

1. Press the CH1 MENU button and call out the CH1 SETUP menu.

2. Press the F2 menu selection button and select the Band Limit as OFF 200MHz, with Channel 1 Band

Limit switched off.

3. Press F2 menu selection button again, select the Band Limit as ON 20MHz, with Channel 1 Band

Limit is switched on.

3. Setting the Channel “ON/OFF”

Taking the Channel 1 for example, the operation steps are shown as below:

1. Press the CH1 MENU button and call out the CH1 SETUP menu.

2. Press the F3 menu selection button and select the Channel as OFF, with Channel 1 switched off.

3. Press F3 menu selection button again, select the channel as ON, with Channel 1 is switched on.

Note: In FFT mode, both CH1 and CH2 are not allowed to be ON when F3 is pressed. See Fig. 22.

Fig. 22 Channel CH1 is diable under FFT mode

-141-

Page 26

4. Regulate the Attenuation Ratio of the Probe

In order to match the attenuation coefficient of the probe, it is required to adjust the attenuation ration

coefficient of the probe through the operating menu of the Channel accordingly. If the attenuation

coefficient of the probe is 1:1, that of the oscilloscope input channel should also be set to 1X to avoid any

errors presented in the displayed scale factor information and the measured data.

Take the Channel 1 as an example, the attenuation coefficient of the probe is 10:1, the operation steps is

shown as follows:

1. Press the CH1 MENU button, access CH1 SETUP menu.

2. Press the F4 menu selection button and select 10X for the probe.

The Fig. 23 illustrates the setting and the vertical scale factor when the probe of the attenuation

coefficient of 10:1 is used.

Fig. 23 Regulation of the Attenuation Ratio of the Probe

List of the Attenuation Coefficient of Probes and the Corresponding Menu Settings.

Attenuation Coefficient of the Probe

Corresponding Menu Setting

1:1

1X

10:1

10X

100:1

100X

1000:1

1000X

-142-

Page 27

5. Setting of Wave Form Inverted

Wave form inverted: the displayed signal is turned 180 degrees against the phase of the earth potential.

Taking the Channel 1 for example, the operation steps are shown as follows:

1. Press the CH1 MENU button and get access to the CH1 SETUP menu.

2. Press the F5 menu selection button and select ON in the Inverted. The wave form inverted function

is initiated.

3. Press the F5 menu selection button again and select OFF for Inverted item. The function of wave

form inverted is closed off.

For the screen display, see Fig. 24 and Fig. 25.

Fig. 24 Wave Form not inverted

Fig. 25 Wave Form Inverted

-143-

Page 28

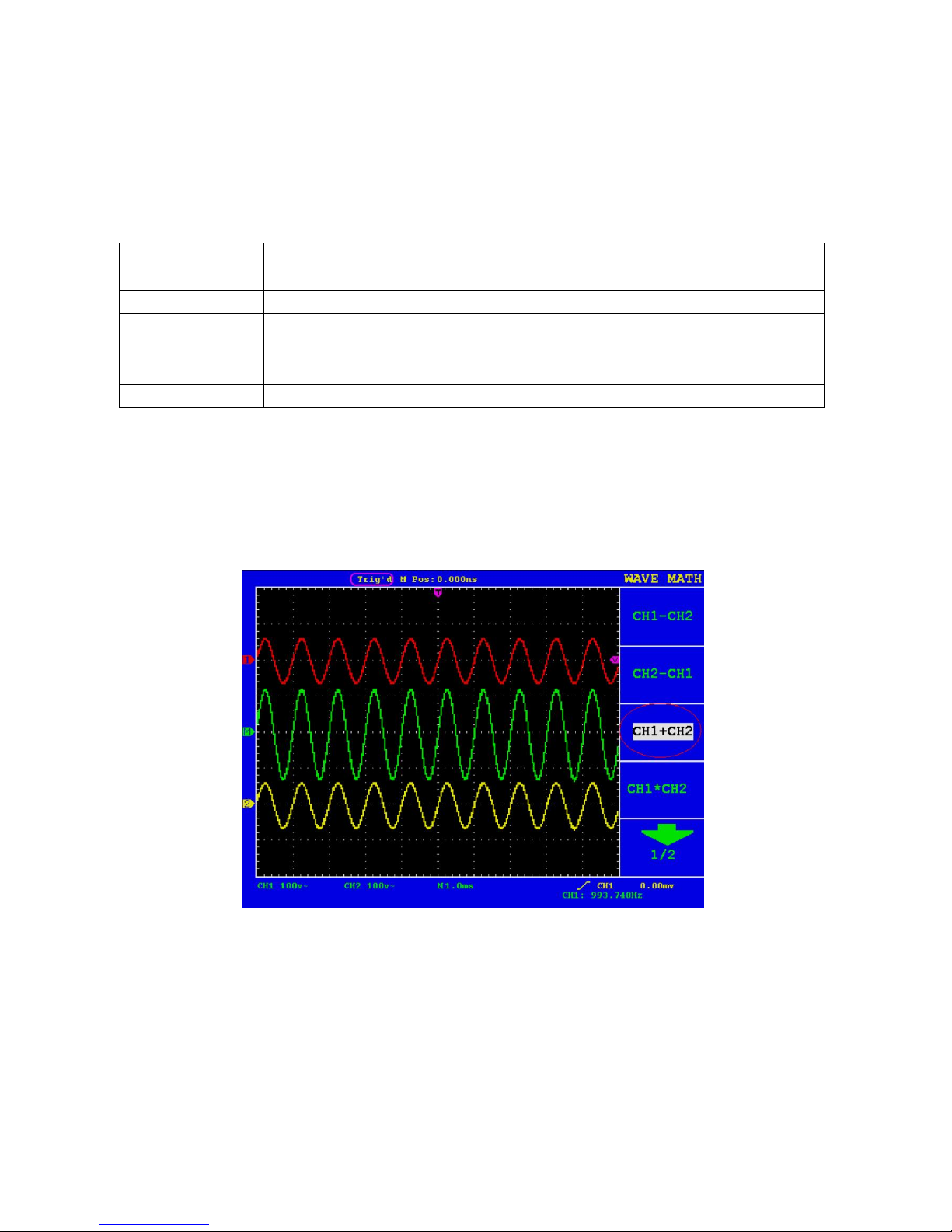

21. Implementation of Mathematical Manipulation Function

The Mathematical Manipulation function is used to show the results of the additive, multiplication, division,

subtraction and FFT operations between Channel 1 and Channel 2, and the FFT operation of CH1 or CH2.

The corresponding FCL (Functional Capabilities List) of the Wave Form Calculation

Setting

Description

CH1-CH2

Subtract the Channel 2 wave form from the Channel 1 wave form.

CH2-CH1

Subtract the Channel 1 wave form from the Channel 2 wave form.

CH1+CH2

Add the Channel 1 wave form to the Channel 2.

CH1*CH2

Multiply Channel 1 wave form by Channel 2 wave form.

CH1/CH2

Channel 1 wave form is divided by the Channel 2 wave form.

FFT

Waveform of Corresponding FFT operation.

Taking the additive operation between Channel 1 and Channels 2 for example, the operation steps are as

follows:

1. Press the MATH MENU button and call out the WAVE MATH menu.

2. Press the F3 menu selection button and choose CH1+CH2. The green calculated wave form M is

displayed in the screen; press the F3 menu selection button again, the wave form M is closed off

(see Fig.26).

Fig. 26 Wave Form resulted from CH1 +CH2 Mathematical Manipulation

-144-

Page 29

22. Using FFT function

An FFT breaks down signals into component frequencies, which the oscilloscope uses to display a graph of

the frequency domain of a signal, as opposed to the oscilloscope’s standard time domain graph. You can

match these frequencies with known system frequencies, such as system clocks, oscillators, or power

supplies.

FFT in this oscilloscope can transform 2048 points of the time-domain signal into its frequency components

and the final frequency contains 1024 points ranging from 0Hz to Nyquist frequency .

The following table describes the FFT menu:

Function Menu

Setting

Instruction

FFT

ON

OFF

Turn on FFT function.

Turn off FFT function.

Source

CH1

CH2

Select CH1 as FFT source.

Select CH2 as FFT source.

Window

Rectangle

Blackman

Hanning

Hamming

Select window for FFT.

Format

dB

Vrms

Select dB for Format.

Select Vrms for Format.

Zoom

*1

*2

*5

*10

Set multiple *1.

Set multiple *2.

Set multiple *5.

Set multiple *10.

Taking the FFT operation for example, the operation steps are as follows:

1. Press the MATH MENU button and call out the WAVE MATH menu.

2. Press F1 to turn on/off FFT after entering FFT menu, and please note that FFT is prohibited in Window

setting mode. The green waveform F is shown in the screen after calculation.

3. Press F2 selection button to switch over source channel CH1 and CH2.

4. Press F3 button to select WINDOW, including Rectangle, Hamming, Hanning and Blackman.

5. Press F4 to choose the Format as dB or Vrms.

6. Press F5 to zoom in or out the wave of the multiple including *1, *2, *5, *10.

7. Adjust the “Horizontal” knob in horizontal control zone to move the waveform and the shown frequency of

M Pos is the exact frequency of the cursor point in the middle of spectrum.

8. Turn off FFT and then press math menu button to go back to the second page of wave math.

-145-

Page 30

22.1. Selecting a FFT Window

The FFT feature provides four windows. Each one is a trade-off between frequency resolution and magnitude

accuracy. What you want to measure and your source signal characteristics help you to determine which

window to use. Use the following guidelines to select the best window.

Type

Description

Window

Rectangle

This is the best type of window for resolving frequencies that

are very close to the same value but worst for accurately

measuring the amplitude of those frequencies. It is the best

type for measuring the frequency spectrum of nonrespetitive

signals and measuring frequency components near DC.

Use rectangle for measuring transients or bursts where the

signal level before and after the event are nearly equal. Also,

use this window for equal-amplitude sine waves with

frequencies that are very close and for broadband random

noise with a relatively slow varying spectrum.

Hamming

This is a very good window for resolving frequencies that are

very close to the same value with somewhat improved

amplitude accuracy over the rectangle window. It has a slightly

better frequency resolution than the Hanning.

Use Hamming for measuring sine, periodic and narrow band

random noise. This window works on transients or bursts

where the signal levels before and after the event are

significantly different.

Hanning

This is a very good window for measuring amplitude accuracy

but less so for resolving frequencies.

Use Hanning for measuring sine, periodic, and narrow band

random noise. This window works on transients or bursts

where the signal levels before and after the event are

significantly different.

Blackman

This is the best window for measuring the amplitude of

frequencies but worst at resolving frequencies.

Use Blackman-Harris for measuring predominantly single

frequency waveforms to look for higher order harmonics.

-146-

Page 31

Fig.27, 28, 29, 30 show four kinds of window function referring to sine wave of 1KHz.

Fig. 27 Blackman window

Fig. 28 Hamming window

Fig. 29 Rectangle window

-147-

Page 32

Fig. 30 Hanning window

22.2. Quick Tips

* If desired, use the zoom feature to magnify the FFT waveform.

* Use the default dBV RMS scale to see a detailed view of multiple frequencies, even if they have very

different amplitudes. Use the linear RMS scale to see an overall view of how all frequencies compare to

each other.

* Signals that have a DC component or offset can cause incorrect FFT waveform component magnitude

values. To minimize the DC component, choose AC Coupling on the source signal.

* To reduce random noise and aliased components in repetitive or single-shot events, set the oscilloscope

acquisition mode to average.

22.3. Term interpretation

Nyquist frequency: The highest frequency that any Real Time Digital Oscilloscope can measure is exactly

half of the sampling rate under the condition of no mistakes, which is called Nyquist

frequency. If under-sampling occurs when the frequency sampled is higher than Nyquist

frequency, “False Wave” phenomenon will appear. So pay more attention to the relation

between the frequency being sampled and measured.

NOTE:

In FFT mode, the following settings are prohibited:

1. Window set;

2. change source channel (in CH1 Setup or CH2 Setup menu);

3. XY Format in DISPLAY SET;

4. “SET 50%” (the triggering level at the vertical point of signal amplitude) in Trigger setting;

5. Autoscale.

-148-

Page 33

23. Application of VERTICAL POSITION and VOLTS/DIV Knobs

1. The VERTIVAL POSITION knob is used to adjust the vertical positions of the wave forms of all Channels

(including those resulted from the mathematical operation).

The analytic resolution of this control knob changes with the vertical division.

2. The VOLTS/DIV knob is used to regulate the vertical resolution of the wave forms of all channels

(including those obtained from the mathematical manipulation), which can determine the sensitivity of the

vertical division with the sequence of 1-2-5. The vertical sensitivity goes up when the knob is rotated

clockwise and goes down when the knob is rotated anticlockwise.

3. When the vertical position of the channel wave form is adjusted, the screen shows the information

concerning the vertical position at the lower left corner (see Fig. 31).

Fig. 31 Information about Vertical Position

-149-

Page 34

24. How to Set the Horizontal system

The HORIZONTAL CONTROLS includes the HORIZONTAL MENU button and such knobs as HORIZONTAL

POSITION and SEC/DIV.

1. HORIZONTAL POSITION knob: this knob is used to adjust the horizontal positions of all channels

(include those obtained from the mathematical manipulation), the analytic resolution of which changes

with the time base.

2. SEC/DIV knob: it is used to set the horizontal scale factor for setting the main time base or the window.

3. HORIZONTAL MENU button: with this button pushed down, the screen shows the operating menu

(see Fig. 32).

Fig. 32 Time Base Mode Menu

The description of the Horizontal Menu is as follows:

Function Menu

Setting

Description

Main Time Base

The setting of the horizontal main time base is used to display the

wave form.

Set Window

A window area is defined by two cursors. This function is forbidden

at the FFT mode disable

Zone Window

The defined window area for display is expanded to the full screen.

-150-

Page 35

25. Main Time Base

Press the F1 menu selection button and choose the Main Time Base. In this case, the HORIZONTAL

POSITION and SEC/DIV knobs are used to adjust the main window. The display in the screen is shown as

Fig.33.

Fig. 33 Main Time Base

26. Set Window

Press the F2 menu selection button and choose Set Window. The screen will show a window area defined by

two cursors. In this case, the HORIZONTAL POSITION and SEC/DIV knobs can be used to adjust the

horizontal position and size of this window area (see Fig. 30(a)). Press F2 menu button under the FFT mode, it

will notice ”FFT mode disable”. See Fig.34.

Fig. 34 Window Setting

-151-

Page 36

Fig.35 FFT mode disable

27. Window Expansion

Press the F3 menu selection button and choose Zone Window. As a result, the window area defined by two

cursors will be expanded to the full screen size (see Fig. 36).

Fig. 36 Zone Window

-152-

Page 37

28. Trigger Control

Trigger is to determine when Oscilloscope starts to acquire data and waveform display. Once trigger to be set

correctly then it will convert the unstable display to meaning waveform.

When Oscilloscope starts to acquire data it will acquire enough data to form waveform on left of trigger point.

Oscilloscope continues to acquire data when it waits for trigger condition happen. Once it detect out the trigger

it will acquire enough data continuously to form the waveform on right of trigger point.

Trigger control area include 1 knob and 4 menu keys.

Trigger level: trigger level knob to set signal voltage correspond to trigger point.

SET 50%: set trigger level in middle vertical point of trigger signal voltage range, this setting is disable at

the FFT mode.

Force trig: Force to a trigger signal and mainly to use in “Normal” and “Single” mode.

SET Zero: Trigger horizontal position set to Zero.

Trig menu: Press this key and panel display menu.

There are two trigger modes: single trigger and alternate trigger.

Single trigger: Use a trigger level to capture stable waveforms in two channels simultaneously

Alternate trigger: Trigger synchronous signals steadily. The two channels could acquire the

waveforms when the CH1 and CH2 are inputting two different frequency signals.

Single

Single trigger mode have edge trigger and video trigger, you can see different

trigger type for two vertical channels in this menu.

Edge

It happens when the trigger input passes through a given level along the set

direction.

Video

Carry out the field or line video trigger of the standard video signal.

Pulse

Use this trigger type to catch pulses with certain pulse width.

Slope

The oscilloscope begins to trigger according to the signal rising or falling speed.

-153-

Page 38

The four trigger modes in Single Trigger are described respectively as follows:

28.1. Edge Trigger

Under the Edge Trigger mode, a trigger happens in the trigger threshold value of the input signal edge. When

the Edge Trigger is selected, a trigger will occur in the rising or falling edge of the input signal.

The Edge Trigger Menu is shown as Fig.37.

Fig. 37 Edge trigger menu

Edge menu list:

MENU

SETTING

INSTRUCTION

Source

CH1

CH2

EXT

EXT/5

Select CH1 as the trigger source.

Select CH2 as the trigger source.

Ext-trigger

Ext-trigger divide to 5 and extend trigger level range.

Mode

Edge

Set vertical channel trigger type for edge trigger.

Slope

Rising

Falling

Trigger in signal rising edge

Trigger in signal falling edge

-154-

Page 39

Trigger

mode

Auto

Normal

Single

Acquire waveform whatever detect trigger condition or not

Only acquire waveform when match trigger condition

Only acquire waveform for single time when detect trigger condition then

stop

Coupling

AC

DC

HF

LF

Not allow DC portion to pass.

Allow all portion pass.

Not allow high frequency of signal pass and only low frequency portion

pass.

Not allow low frequency of signal pass and only high frequency portion

pass

Holdoff

100ns ~

10s

Turn “TRIG LEVEL” knob to set time slot before another trigger event.

Holdoff

Reset

Reset hold time to 100ns

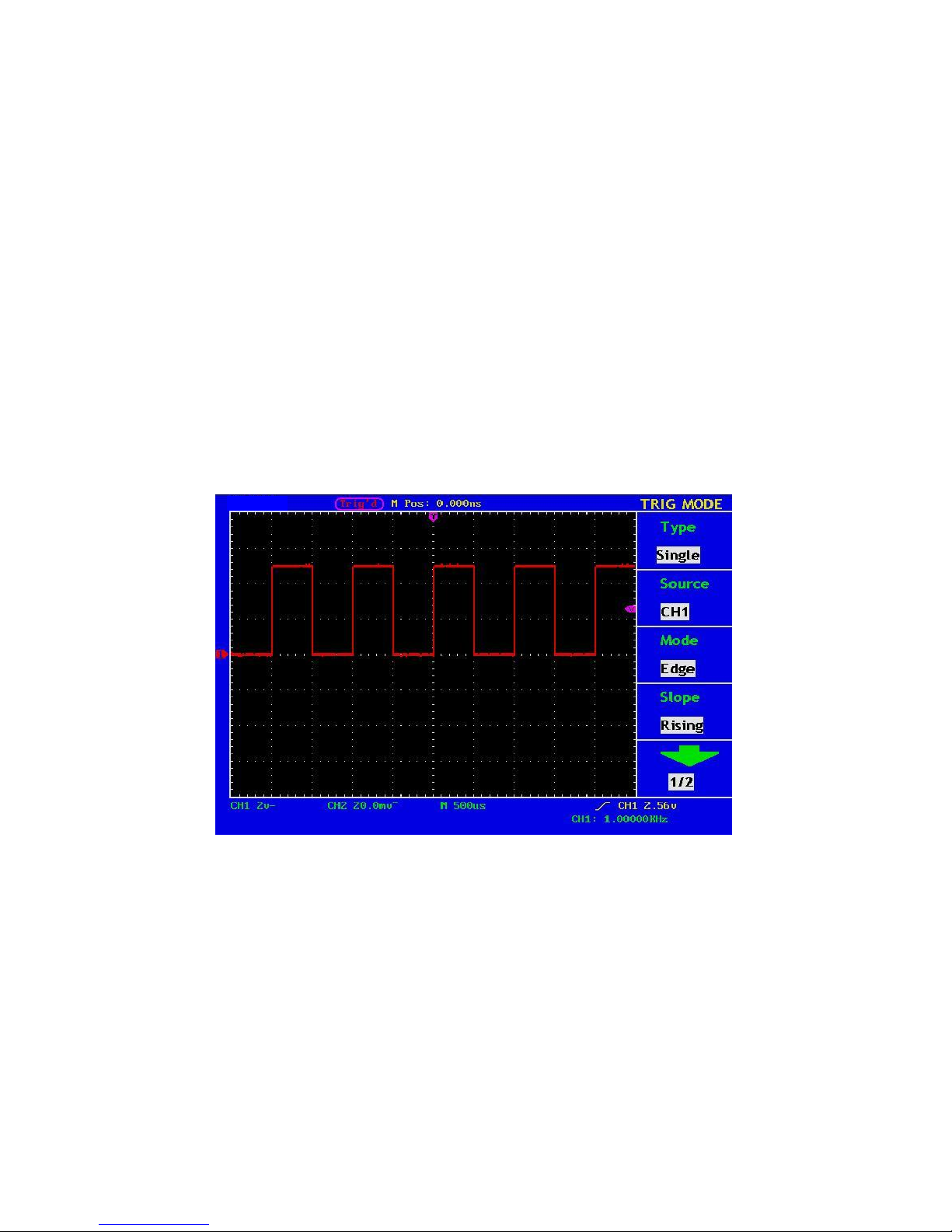

Follow up below step to set CH1 as rising slope edge trigger and trigger mode is auto, coupling is DC.

1. Press “Trig menu”

2. Press “F1” to choose type as “Single”

3. Press “F2” to choose source as “CH1”

4. Press “F3” to choose mode as “Edge”

5. Press “F4” to choose slope as “Rising”. Display as Fig.38

6. Press “F5” to choose “Next menu”, then press “F2” to choose trigger mode as “Auto”.

7. Press “F3” to choose coupling as “DC”.

8. Press ”F4” menu button to select Holdoff, use trig level knob to adjust Holdoff. Display as Fig. 39

-155-

Page 40

Fig. 38 Edge trigger (Rising Wave, the first menu)

Fig. 39 Edge trigger (Rising Wave, the second menu)

-156-

Page 41

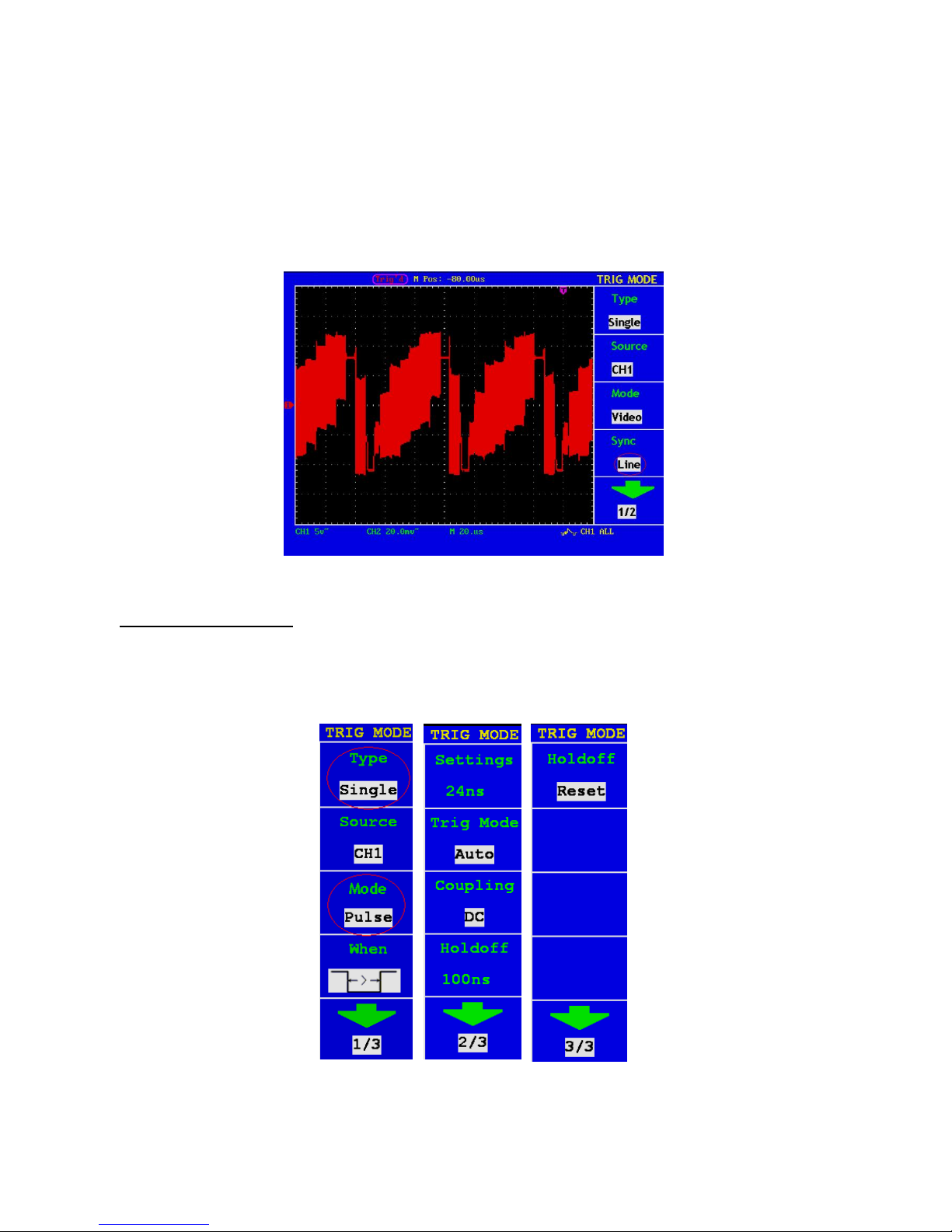

28.2. Video

Choose “Video” and trigger in field/line of NTSC, PAL or SECAM standard video signals. Trig menu refer to

Fig.40

Fig. 40 Video trigger menu

Video trigger menu

MENU

SETTING

INSTRUCTION

Quelle

CH1

CH2

EXT

EXT/5

Select CH1 as the trigger source.

Select CH2 as the trigger source.

Ext-trigger

Ext-trigger divide to 5 to extend trigger level range

Mode

Video

Sync

Line

Field

Odd Field

EvenField

Designed Line

Synchronic trigger in video line.

Synchronic trigger in video field.

Synchronic trigger in video odd filed

Synchronic trigger in video even field

Synchronic trigger in designed video line

to Next menu

Back to previous menu

MODU

NTSC

PAL/SECAM

Video modulation setting

Holdoff

100ns~10s

Turn “TRIG LEVEL” knob to set time slot before another trigger

event

Holdoff

Reset

Reset hold time to 100ns

-157-

Page 42

Follow up below steps to set CH1 as video trigger

1. Press “Trig menu”

2. Press F1 to choose type as “Single”

3. Press F2 to choose source as “CH1”.

4. Press F3 to choose mode as “Video”.

5. Press F4 to choose synchronization as “Line” (refer to Fig.41)

6. Press F5 to Next menu.

7. Press F2 to choose modulation as “NTSC”.

Fig. 41 Video field trigger Oscillogram

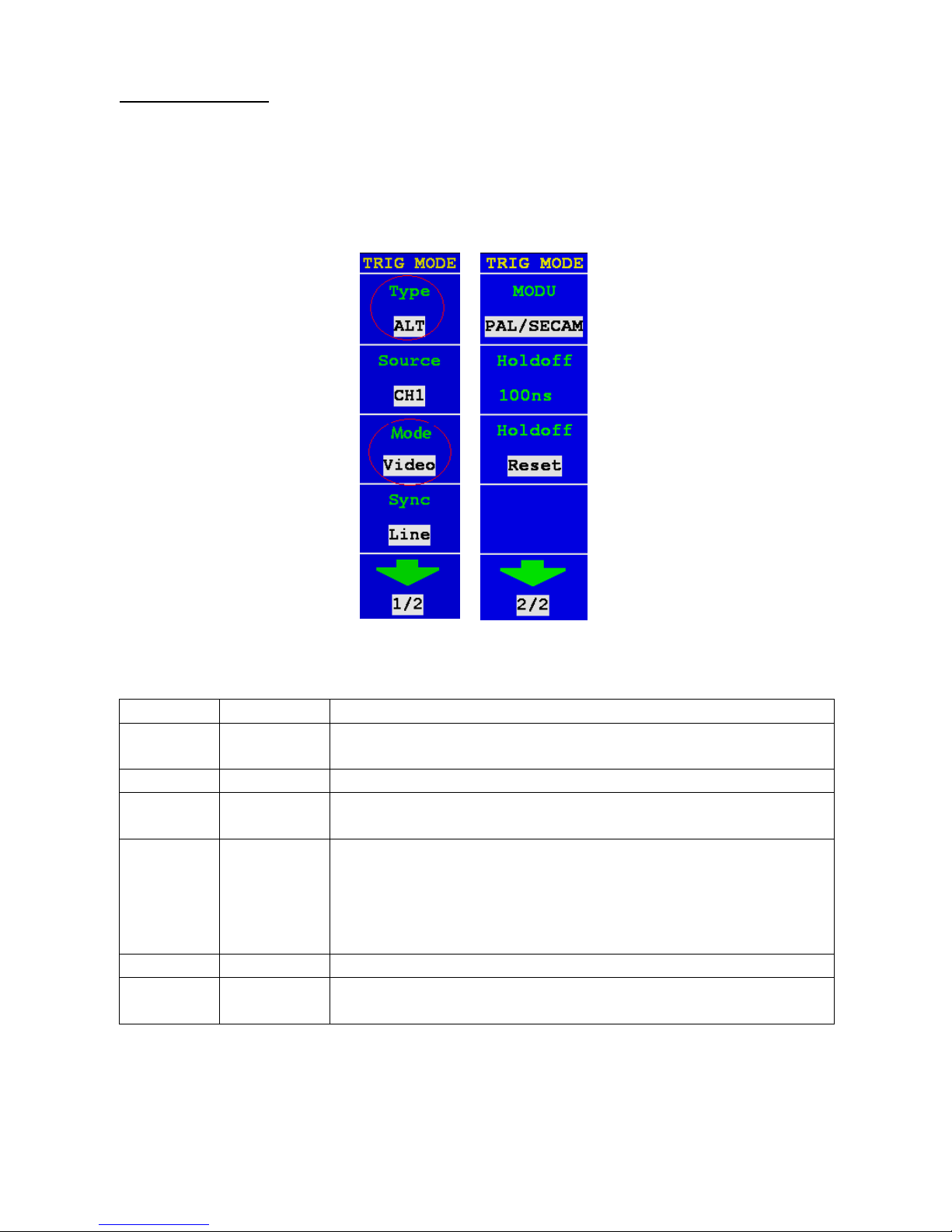

28.3. Pulse Width Trigger

Pulse trigger occurs according to the width of pulse. The abnormal signals can be detected through setting up

the pulse width condition.

The Pulse Width Trigger Menu is shown as Fig. 42.

Fig. 42 Pulse Width Trigger menu

-158-

Page 43

Pulse Width Trigger menu list

MENU

SETTING

INSTRUCTION

Source

CH1

CH2

Select CH1 as the trigger source.

Select CH2 as the trigger source.

Mode

Pulse

when

(+pulse width less than )

(+pulse width more than )

(+Pulse width equal to)

(-Pulse width less than)

(-Pulse width more than)

(-Pulse width equal to)

To select pulse width condition

Time setting

24ns~10s

Turn “TRIG LEVEL” knob to set time

Trigger mode

Auto

Normal

Single

Acquire waveform whatever detect trigger

condition or not

Only acquire waveform when match trigger

condition

Only acquire waveform for single time when detect

trigger condition then stop

Coupling

AC

DC

HF

LF

Not allow DC portion to pass.

Allow all portion pass.

Not allow high frequency of signal pass and only

low frequency portion pass.

Not allow low frequency of signal pass and only

high frequency portion pass

Holdoff

100 ns~10 s

Turn “TRIG LEVEL” knob to set time slot before

another trigger event

Holdoff

Reset

Reset hold time to 100ns

-159-

Page 44

28.4. Slope Trigger

Slope trigger sets the oscilloscope as the positive/negative slope trigger within the specified time.

The Slope Trigger Menu is shown as Fig. 43.

Fig. 43 Slope Trigger menu

Slope Trigger menu list

MENU

SETTING

INSTRUCTION

Source

CH1

CH2

Select CH1 as the trigger source.

Select CH2 as the trigger source.

Mode

Slope

When

Set slope condition

Settings

24ns~10s

Turn “TRIG LEVEL ”knob to set slope time

High level

Turn “TRIG LEVEL ”knob to set the High level

Low level

Turn “TRIG LEVEL ”knob to set Low level

Slew rate

Slew rate=( High level- Low level)/ Settings

Trigger

mode

Auto

Normal

Single

Acquire waveform whatever detect trigger condition or not

Only acquire waveform when match trigger condition

Only acquire waveform for single time when detect trigger condition then stop

Holdoff

100ns ~

10s

Turn “TRIG LEVEL” knob to set time slot before another trigger event

Holdoff

Reset

Reset hold time to 100ns

-160-

Page 45

28.5. Alternate trigger

Trigger signal comes from two vertical channels when alternate trigger is on. This mode is used to observe two

unrelated signals. You can choose different trigger modes for different channels. The options are as follows:

edge, video, pulse or slope.

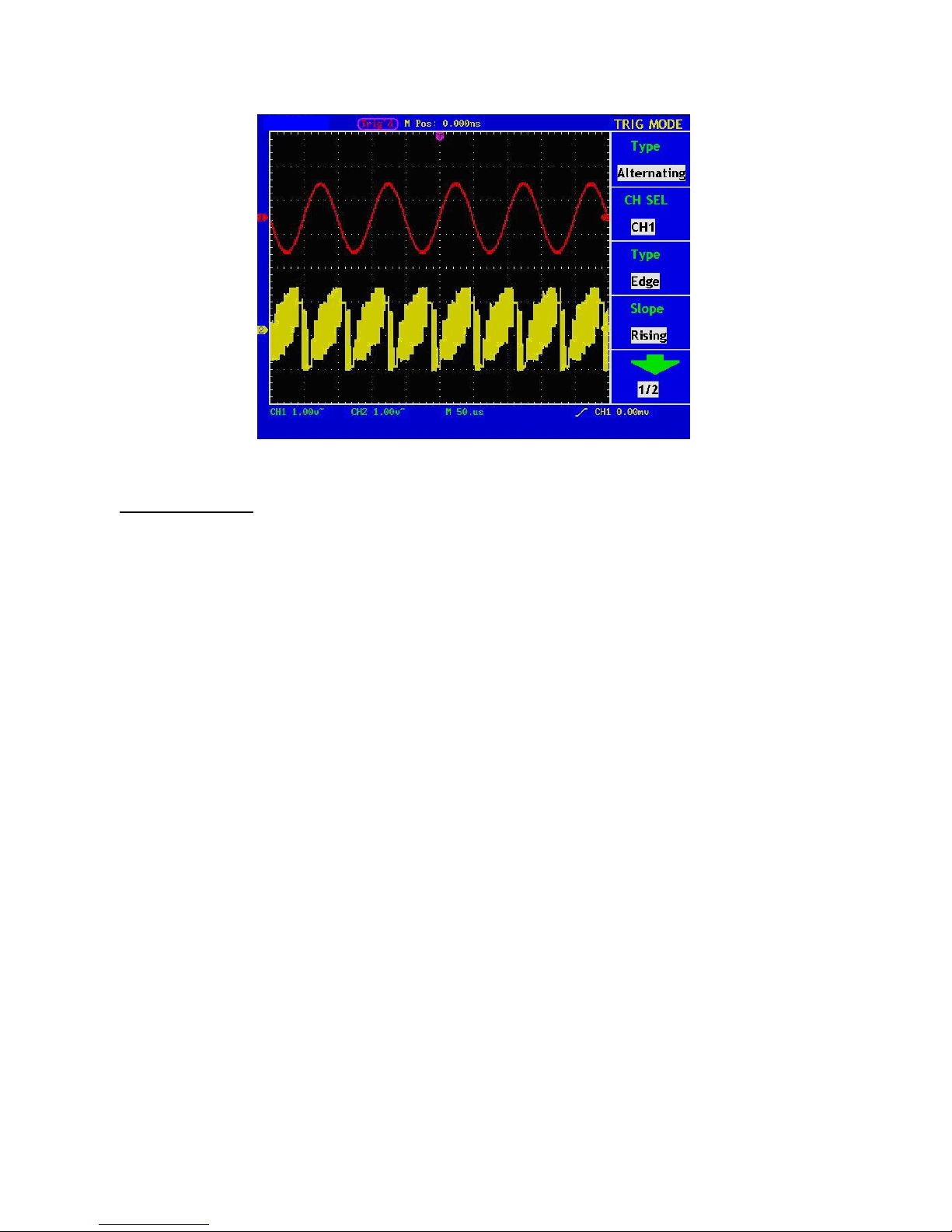

Alternate trigger (Trigger mode: Edge)

Alternate trigger (Trigger Type: Edge) Menu is shown as Fig.44.

Fig. 44 Alternate trigger(Trigger Type: Edge) Menu

Alternate trigger(Trigger Type: Edge) Menu list:

MENU

SETTING

INSTRUCTION

Source

CH1

CH2

Select CH1 as the trigger source.

Select CH2 as the trigger source.

Mode

Edge

Set vertical channel trigger type for edge trigger.

Slope

Rising

Falling

Trigger in signal rising edge

Trigger in signal falling edge

Coupling

AC

DC

HF

LF

Not allow DC portion to pass.

Allow all portion pass.

Not allow high frequency of signal pass and only low frequency portion

pass.

Not allow low frequency of signal pass and only high frequency portion pass

Holdoff

100ns~10s

Turn “TRIG LEVEL” knob to set time slot before another trigger event.

Holdoff

Reset

Reset hold time to 100ns

-161-

Page 46

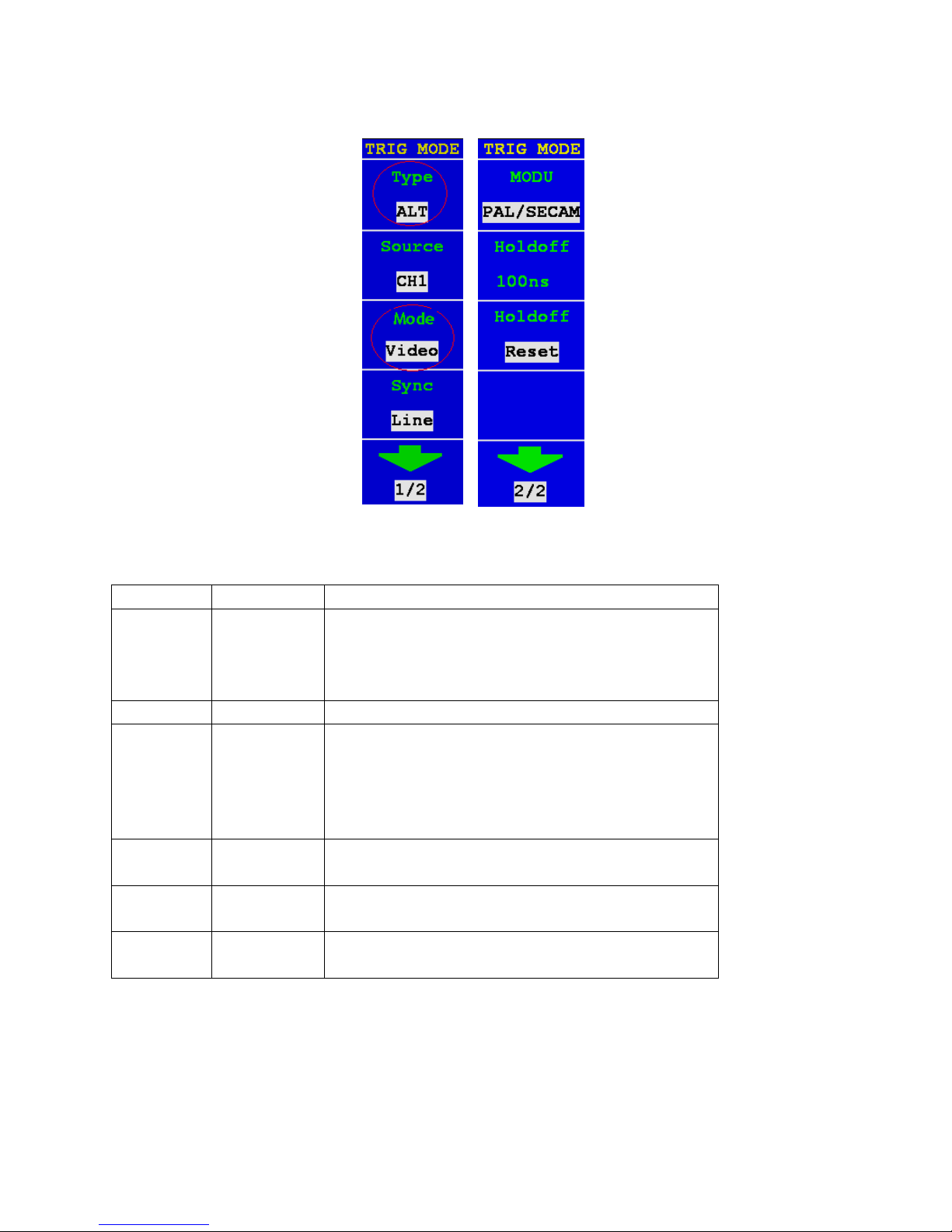

Alternate trigger (Trigger Mode:video)

Alternate trigger (Trigger Type:video) Menu is shown as Fig. 45.

Fig. 45 Alternate trigger (Trigger Type:video) Menu

Alternate trigger (Trigger Type: video) Menu list:

MENU

SETTING

INSTRUCTION

Source

CH1

CH2

EXT

EXT/5

Select CH1 as the trigger source.

Select CH2 as the trigger source.

Ext-trigger

Ext-trigger divide to 5 to extend trigger level range

Mode

Video

Sync

Line

Field

Odd Field

EvenField

Designed Line

Synchronic trigger in video line.

Synchronic trigger in video field.

Synchronic trigger in video odd filed

Synchronic trigger in video even field

Synchronic trigger in designed video line

Modulation

NTSC

PAL/SECAM

Video modulation setting

Holdoff

100ns~10s

Turn “TRIG LEVEL” knob to set time slot before another

trigger event

Holdoff

Reset

Reset hold time to 100ns

-163-

Page 47

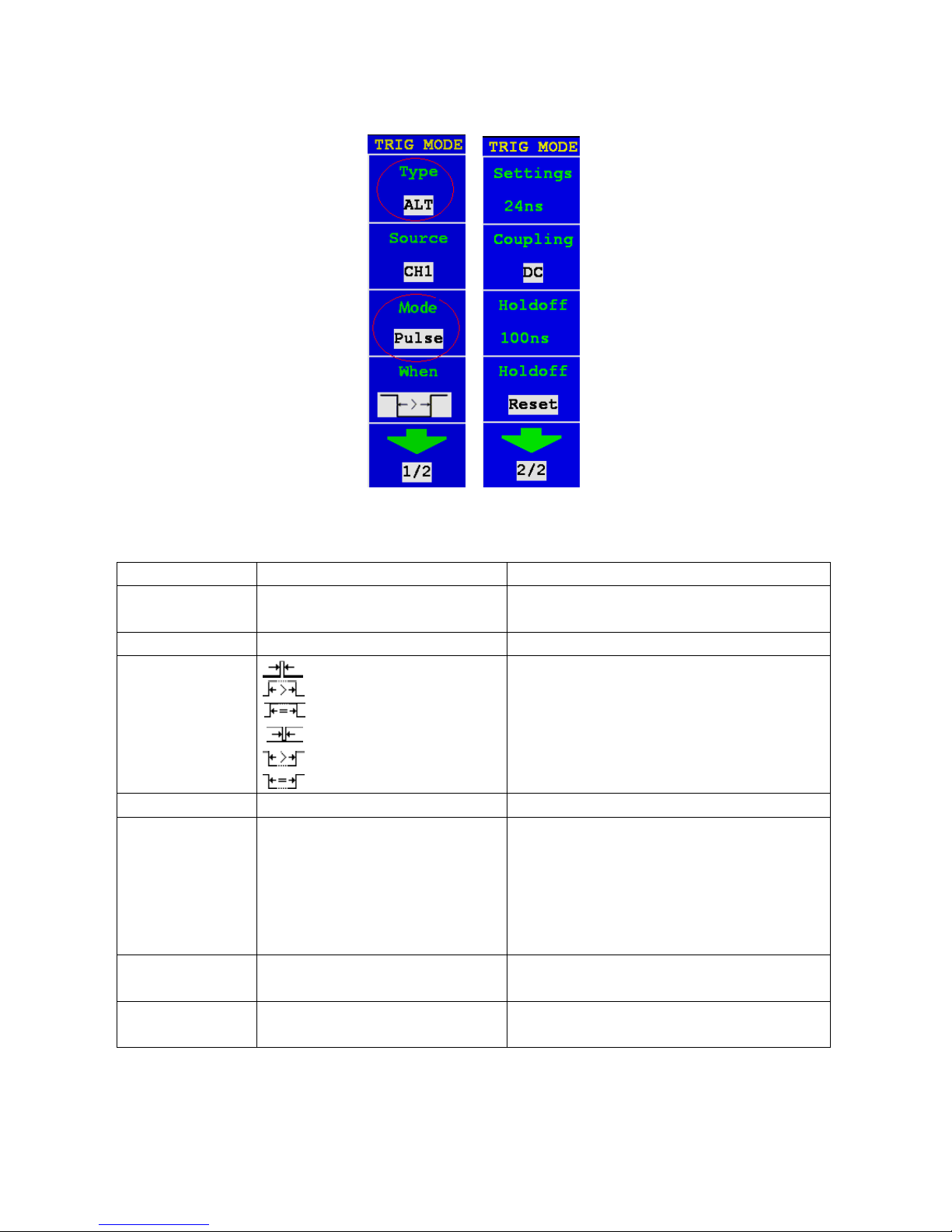

Alternate trigger (Trigger Mode: Pulse)

Alternate trigger (Trigger Type: Pulse) Menu is shown as Fig. 46.

Fig. 46 Alternate trigger (Trigger Type: Pulse) Menu

Alternate trigger (Trigger Type: Pulse) menu list

MENU

SETTING

INSTRUCTION

Source

CH1

CH2

Select CH1 as the trigger source.

Select CH2 as the trigger source.

Mode

Pulse

when

(+pulse width less than )

(+pulse width more than )

(+Pulse width equal to)

(-Pulse width less than)

(-Pulse width more than)

(-Pulse width equal to)

To select pulse width condition

settings

24ns~10s

Turn “TRIG LEVEL” knob to set time

Coupling

AC

DC

HF

LF

Not allow DC portion to pass.

Allow all portion pass.

Not allow high frequency of signal pass and

only low frequency portion pass.

Not allow low frequency of signal pass and only

high frequency portion pass

Holdoff

100 ns ~ 10 s

Turn “TRIG LEVEL” knob to set time slot before

another trigger event

Holdoff

Reset

Reset hold time to 100ns

-163-

Page 48

Alternate trigger (Trigger Mode: Slope)

Alternate trigger(Trigger Type: Slope )Menu is shown as Fig. 47.

Fig. 47 Alternate trigger(Trigger Type: Slope )Menu

Alternate trigger(Trigger Type: Slope) menu list:

MENU

SETTING

INSTRUCTION

Source

CH1

CH2

Select CH1 as the trigger source.

Select CH2 as the trigger source.

Mode

Slope

Slope

Condition

Rising Edge and more than.

Rising Edge and less than.

Rising Edge and equal to .

Falling Edge and more than

Negative pulse and less than

Negative pulse and equal to

settings

24ns~10s

Turn “TRIG LEVEL”knob to set slope time

High level

Turn“TRIG LEVEL”knob to set the High level

Low level

Turn “TRIG LEVEL”knob to set Low level

Slew rate

Slew rate=( High level- Low level)/ Settings

Coupling

AC

DC

HF

LF

Not allow DC portion to pass.

Allow all portion pass.

Not allow high frequency of signal pass and only low frequency portion pass.

Not allow low frequency of signal pass and only high frequency portion pass

Holdoff

100ns~10s

Turn “TRIG LEVEL” knob to set time slot before another trigger event

Holdoff

Reset

Reset hold time to 100ns

-164-

Page 49

Fig. 48 gives the resulted signal.

Fig. 48 Wechseltriggersignal

Term interpretation

Trigger: With this oscilloscope there are three types of trigger modes: automatic,

normal and single.

Automatic trigger mode: The oscilloscope can detect in this mode the curve without a selected trigger

condition. During a particular waiting time a Force-Trigger is done when no

trigger condition occurs. If an invalid trigger condition is used, the

oscilloscope cannot keep the curve in phase.

Normal trigger mode: In this mode, the oscilloscope cannot detect the curve before it is triggered.

Without trigger the oscilloscope displays the original curve without new

curves are recorded.

Single mode: In this mode, the oscilloscope detects a trigger and captures the curve

whenever the operator presses the RUN / STOP (Run / Stop) button.

Sensitivity: Trigger circuit with delay line to avoid effects due to noise and to obtain a

stable trigger. The delay line is adjustable between 0.2div and 1.0div. This

means that when set to 1.0div the trigger circuit does not respond to a signal

with a peak-to-peak value ≤1.0div, eliminating the effects of interference.

-165-

Page 50

Term interpretation

1. Source:

Trigger can occur from several sources: Input channels (CH1, CH2), AC Line, Ext, Ext/5.

* Input: It is the most commonly used trigger source. The channel will work when selected as a

trigger source whatever displayed or not.

* Ext Trig: The instrument can trigger from a third source while acquiring data from CH1 and CH2. For

example, you might want to trigger from an external clock or with a signal from another part

of the test circuit. The Ext, Ext/ 5 trigger sources use the external trigger signal connected to

the EXT TRIG connector. Ext uses the signal directly; it has a trigger level range of +1.6 V to

-1.6 V. The EXT/ 5 trigger source attenuates the signal by 5X, which extends the trigger level

range to +8 V to -8 V. This allows the oscilloscope to trigger on a larger signal

* AC Line: AC power can be used to display signals related to the power line frequency, such as lighting

equipment and power supply devices. The oscilloscope gets triggered on its power cord, so

you do not have to input an AC trigger signal. When AC Line is selected as trigger source,

the oscilloscope automatically set coupling to DC, set trigger level to 0V.

2. Trigger Mode:

The trigger mode determines how the oscilloscope behaves in the absence of a trigger event. The

oscilloscope provides three trigger modes: Auto, Normal, and Single.

* Auto: This sweep mode allows the oscilloscope to acquire waveforms even when it does not

detect a trigger condition. If no trigger condition occurs while the oscilloscope is waiting for a

specific period (as determined by the time-base setting), it will force itself to trigger.

* Normal: The Normal mode allows the oscilloscope to acquire a waveform only when it is triggered. If

no trigger occurs, the oscilloscope keeps waiting, and the previous waveform, if any, will

remain on the display. Single: In Single mode, after pressing the RUN/STOP key, the

oscilloscope waits for trigger. While the trigger occurs, the oscilloscope acquires one

waveform then stop.

* Single: In Single mode, after pressing the RUN/STOP key, the oscilloscope waits for trigger. While

the trigger occurs, the oscilloscope acquires one waveform then stop.

3. Coupling:

Trigger coupling determines what part of the signal passes to the trigger circuit. Coupling types include AC,

DC, LF Reject and HF Reject.

* AC: AC coupling blocks DC components.

* DC: DC coupling passes both AC and DC components.

* LF Reject: LF Reject coupling blocks DC component, and attenuates all signal with a frequency lower

than 8 kHz.

* HF Reject: HF Reject coupling attenuates all signals with a frequency higher than 150 kHz.

4. Hold off:

A time interval before the oscilloscope responses to next trigger signal. During this Hold off period, the

trigger system becomes “blind” to trigger signals. This function helps to view complex signals such as an

AM waveform. Press Hold off button to activate “TRIG LEVEL” knob, then turn it to adjust Hold off time.

-166-

Page 51

29. How to Operate the Function Menu

The function menu control zone includes 7 function menu buttons and 3 immediate-execution buttons:

SAVE/RCL, MEASURE, ACQUIRE, UTILITY, CURSOR, DISPLAY, AUTOSCALE, AUTOSET, RUN/STOP

and U-DISK COPY.

30. How to Implement Sampling Setup

Press the ACQUIRE button and the menu is displayed in the screen, shown as Fig. 49.

Fig. 49 ACQU MODE Menu

The description of the Sampling Setup Menu is shown as follows:

Function Menu

Setting

Description

Sample

General sampling mode.

Peak Detect

It is used for the detection of the jamming burr and the

possibility of reducing the confusion.

Average

It is used to reduce the random and don’t-care noises, with

the optional number of averages.

Averages

4, 16, 64, 128

Choose the number of averages.

Change the ACQU Mode settings and observe the consequent variation of the wave form displayed.

-167-

Page 52

Fig. 50 Peak Detect mode, under which the burrs on the falling edge of the square wave, can be detected and

the noise is heavy.

Fig. 51 Common ACQU Mode display, in which no burr can be detected.

Fig. 52 The displayed wave form after the noise is removed under the Average Mode, in which the average

number of 16 is set.

-168-

Page 53

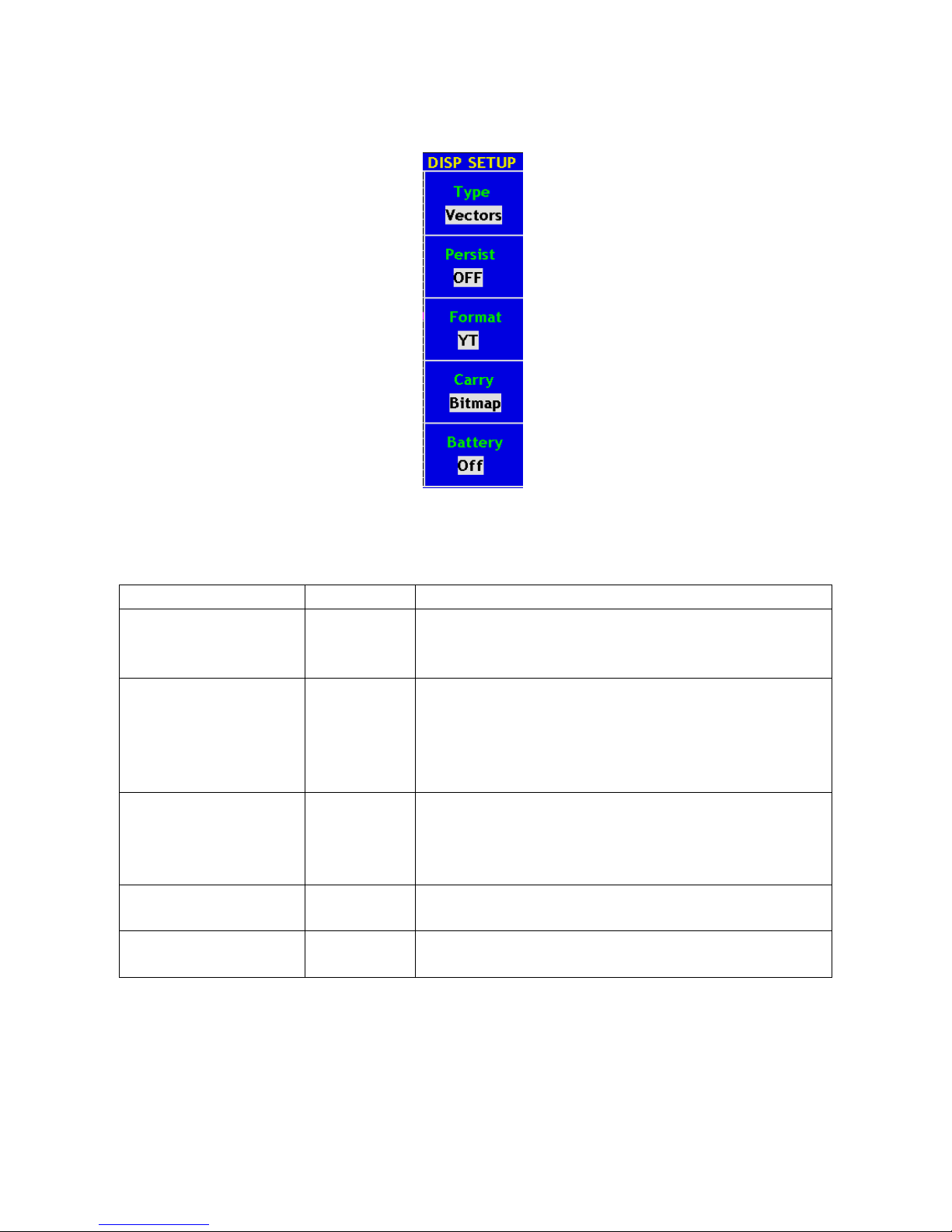

31. How to Set the Display System

Push down the DISPLAY button and the menu displayed in the screen is shown as Fig. 53.

Fig. 53 Display Set Menu

The description of the Display Set Menu is shown as follows:

Function Menu

Setting

Description

Type

Vectors

Dots

The space between the adjacent sampling points in the display

is filled with the vector form.

Only the sampling points are displayed.

Persist

OFF

1sec

2sec

5sec

Infinite

Set the persistence time for each sampling point.

Format

YT

XY

Show the relative relation between the vertical voltage and the

horizontal time.

Channel 1 is displayed on the horizontal axis and Channel 2

on the vertical axis. FFT mode disable.

Carry

Bitmap

Vectors

The data transmitted as screenshot is in bitmap (BMP) form.

The raw-data transmitted is in the vector form.

Battery

On

Off

Battery power content symbol on

Battery power content symbol off

-169-

Page 54

Display Type:

With the F1 menu selection button pushed down, you can shift between Vectors and Dots types. The

differences between the two display types can be observed through the comparison between Fig.54 and

Fig.55.

Fig. 54 Display in the Vector Form

Fig. 55 Display in Dots form

-170-

Page 55

32. Persist

When the Persist function is used, the persistence display effect of the picture tube oscilloscope can be

simulated: the reserved original data is displayed in fade color and the new data is in bright color. With the F2

menu selection button, different persistence time can be chosen: 1sec, 2sec, 5sec, Infinite and Closed.

When the “Infinite” option is set for Persist time, the measuring points will be stored till the controlling value is

changed (see Fig.56).

Fig. 56 Infinite Persistence Display

33. XY Format

This format is only applicable to Channel 1 and Channel 2. After the XY display format is selected, Channel 1

is displayed in the horizontal axis and Channel 2 in the vertical axis; the oscilloscope is set in the un-triggered

sample mode: the data are displayed as bright spots and the sampling rate is 1MS/s and cannot be changed.

The operations of all control knobs are as follows:

* The Vertical VOLTS/DIV and the Vertical POSITION knobs of Channel 1 are used to set the horizontal

scale and position.

* The Vertical VOLTS/DIV and the Vertical POSITION knobs of Channel 2 are used to set the vertical

scale and position continuously.

The following functions cannot work in the XY Format:

* Reference or digital wave form

* Cursor

* Auto Set

* Time base control

* Trigger control

-171-

Page 56

Operation steps:

1. Press the DISPLAY button and call out the Display Set Menu.

2. Press the F3 menu selection button and choose the form as XY. The display format is changed to be XY

mode (see Fig.57).

Fig. 57 XY Display Mode

At the mode of FFT, if switching YT to XY, “FFT MODE is unavailable” prompts as Fig.58

Fig. 58 FFT mode XY Format Disable

-172-

Page 57

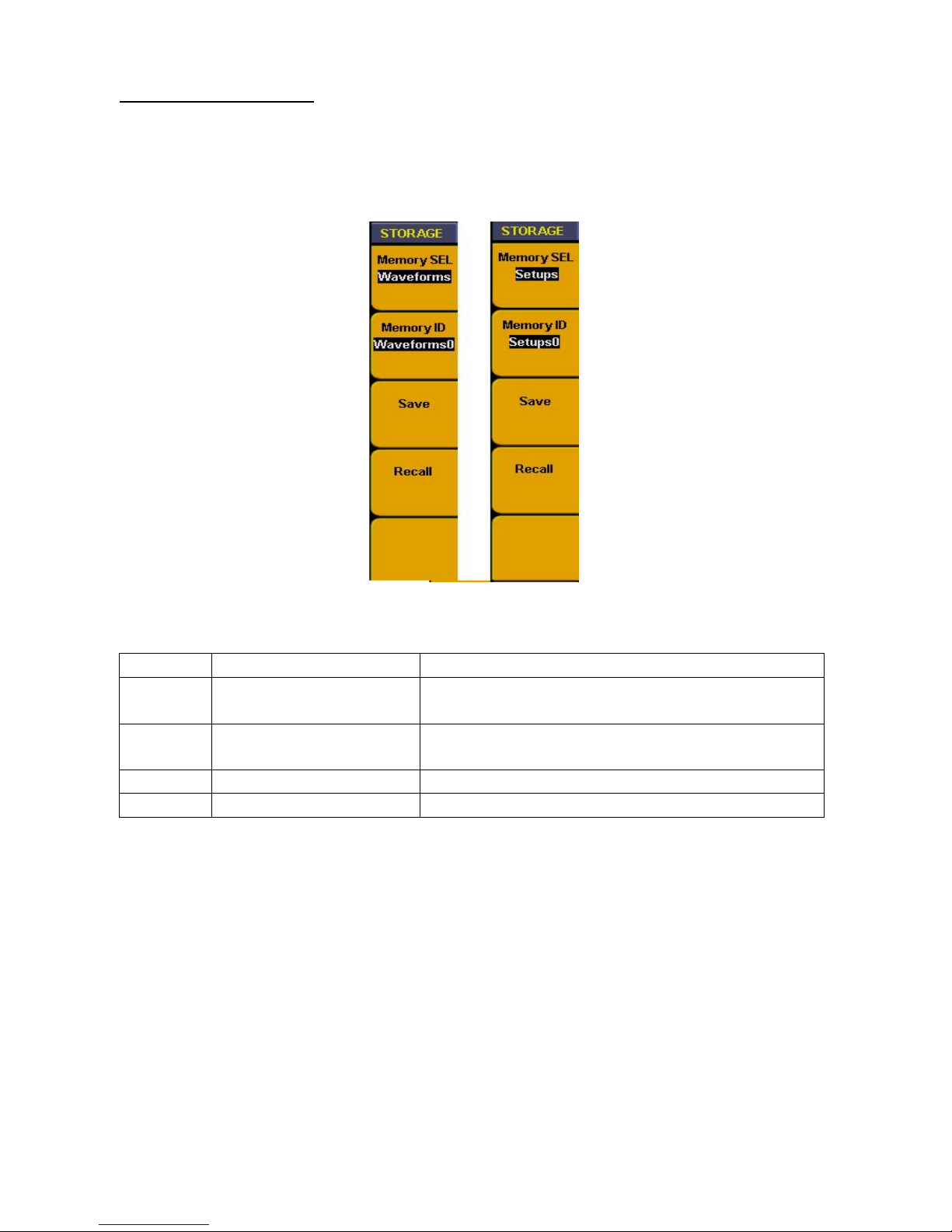

34. How to Save and Recall a Wave Form

Press the SAVE/RCL button, you can save and call out the waveforms in the instrument. The menu displayed

in the screen is shown as Fig.59.

Fig. 59 Wave Form Save Menu

The description of the Wave Form Save Menu is shown as the following table:

Function Menu

Setting

Description

Source

CH1

CH2

MATH

Choose the wave form to be saved.

WAVE

A , B

C , D

Choose the address in or from which the waveform

is saved or can be get access to.

Save

Save the wave form of the source in the selected

address.

CH (X)

X=A,B,C oder D

OFF

ON

Switch on or off the display of the stored waveform.

The PeakTech® 1190 / 1230 oscilloscopes can store four waveforms, which can be displayed with the current

waveform at the same time. The stored waveform called out cannot be adjusted.

In order to save the waveform of the channel CH1 into the address A, the operation steps should be followed:

1. Press the F1 menu selection button and choose CH1 for Source.

2. Press the F2 menu selection button and choose A as save address.

3. Press the F3 menu selection button and save the waveform.

Press the F4 menu selection button and choose ON for CH A. The stored wave form A will be displayed in the

screen.

-173-

Page 58

The voltage level and time base level will also be shown at the upper left corner of the display area at the

same time (see Fig.60).

Fig. 60 Wave Saving

Fig. 61 FFT wave Saving

-174-

Page 59

35. How to Implement the Auxiliary System Function Setting

Press the UTILITY button and the menu is displayed in the screen as Fig. 62.

Fig. 62 Function Menu

The description of the Auxiliary Function Menu is shown as the following table.

Function Menu

Setting

Description

System Status

Display the system function menu.

Recall Factory

Call out the factory settings.

Do Self Cal

Carry out the self-calibration procedure.

Language

Chinese

English

German

Choose the display language of the operating system.

-175-

Page 60

36. Do Self Cal (Self-Calibration)

The self-calibration procedure can improve the accuracy of the oscilloscope under the ambient temperature to

the greatest extent. If the change of the ambient temperature is up to or exceeds 5°C, the self-calibration

procedure should be executed to obtain the highest level of accuracy.

Before executing the self-calibration procedure, disconnect the probe or wire and the input connector. Then,

press the F3 menu selection button and choose “Auto calibration”. After confirming it is all set, push down F3

button and choose “Do Self Cal”, entering the self-calibration procedure of the instrument.

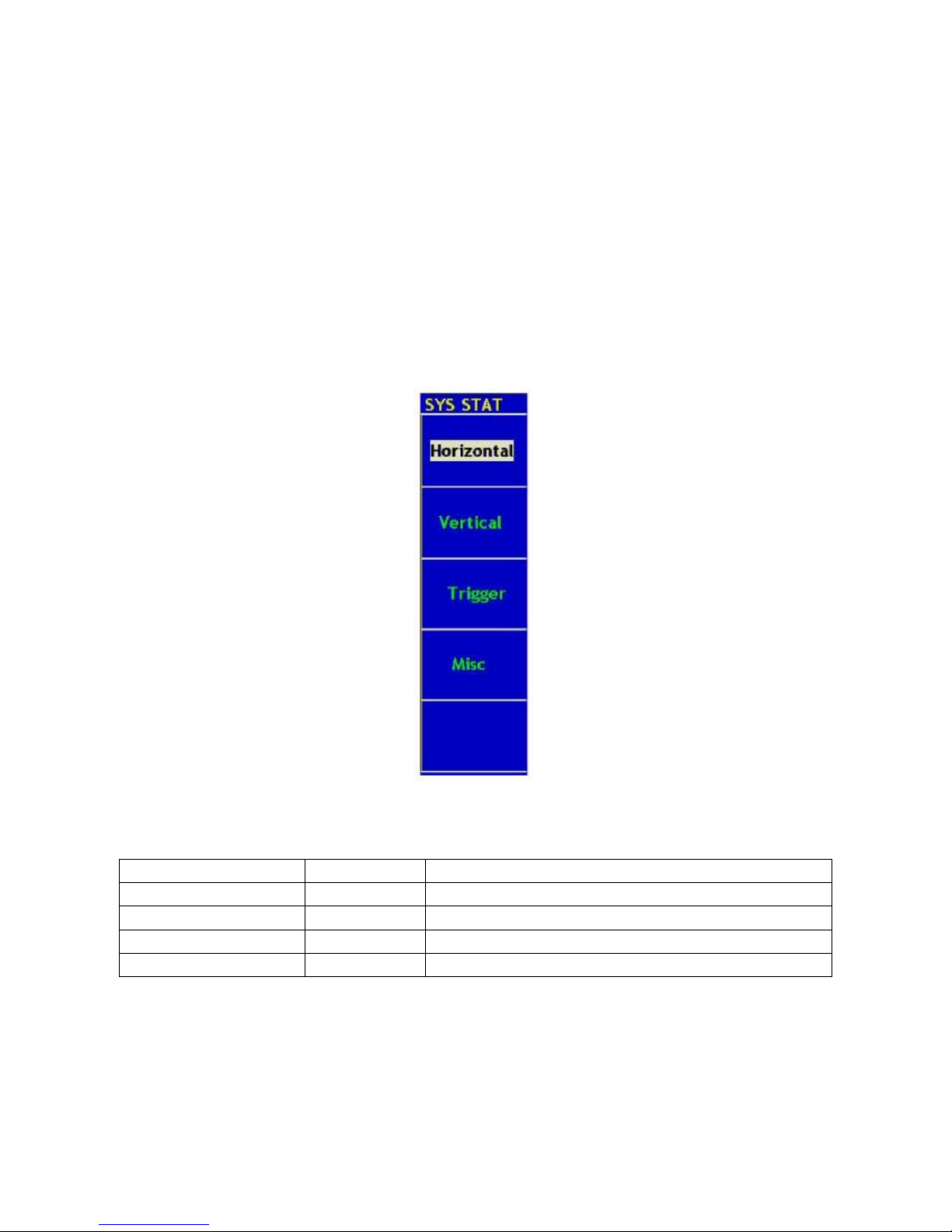

37. System Status (SYS STAT)

Press the F1 menu selection button and choose “System Status” item. The menu pops up in the screen as

Fig. 63.

Fig. 63 SYS STAT Menu

The “SYS STAT” menu is described as the following table:

Function Menu

Setting

Description

Horizontal

Show the horizontal parameter of the channel.

Vertical

Show the vertical parameter of the channel.

Trigger

Show the parameters of the trigger system.

Misc

Show the serial number and edition number.

-176-

Page 61

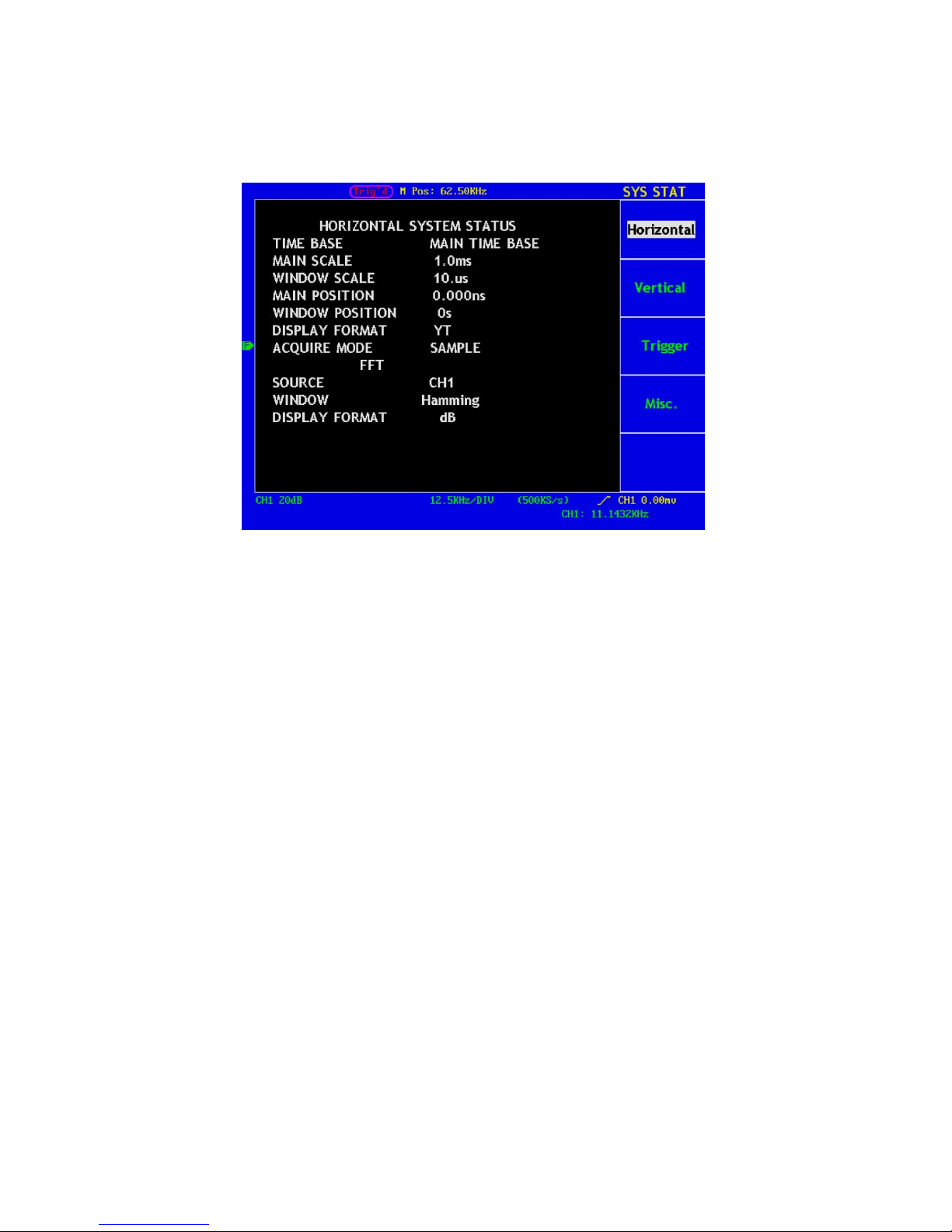

After entering into the SYS STAT menu, choose the corresponding function, with the corresponding

parameters shown in the screen. If press the F1 menu selection button and choose the function item

“Horizontal”, the Horizontal System State will be displayed in the screen. Press any other function button and

exit from the SYS STAT menu (see Fig. 64).

Fig. 64 Horizontal System State

-177-

Page 62

38. How to Implement the Automatic Measurement

With the Measure button pressed down, an automatic measurement can be implemented. There are 20 types

of measurements and 4 measurement results can be displayed simultaneously.

Press the F1 menu selection button to choose Source or Type menu. You can choose the channel to be

measured from the Source menu and choose the measurement Type (Freq, Period, Mean, PK–PK, and Cyc

RMS). The menu is displayed as Fig.65.

Fig. 65 Measure Menu

-178-

Quelle

Typ

Anzeige

Page 63

Term interpretation:

Vpp: Peak-to-Peak Voltage.

Vmax: The maximum amplitude. The most positive peak voltage measured over the entire waveform.

Vmin: The minimum amplitude. The most negative peak voltage measured over the entire waveform.

Vamp: Voltage between Vtop and Vbase of a waveform

Vtop: Voltage of the waveform’s flat top, useful for square/pulse waveforms.

Vbase: Voltage of the waveform’s flat base, useful for square/pulse waveforms.

Overshoot: Defined as (Vmax-Vtop)/Vamp, useful for square and pulse waveforms.

Preshoot: Defined as (Vmin-Vbase)/Vamp, useful for square and pulse waveforms.

Average: The arithmetic mean over the entire waveform.

Vrms: The true Root Mean Square voltage over the entire waveform.

Rise Time: Time that the leading edge of the first pulse in the waveform takes to rise from 10% to 90% of

its amplitude.

Fall Time: Time that the falling edge of the first pulse in the waveform takes to fall from 90% to 10% of its

amplitude.

+Width: The width of the first positive pulse in 50% amplitude points.

-Width: The width of the first negative pulse in the 50% amplitude points.

Delay 1→2 : The delay between the two channels at the rising edge.

Delay 1→2 : The delay between the two channels at the falling edge.

+Duty: +Duty Cycle, defined as +Width/Period.

-Duty: -Duty Cycle, defined as -Width/Period.

39. Measure

Four automatic measured values can be detected on each channel simultaneously. Only if the waveform

channel is in the ON state can the measurement be carried out. No automatic measurement can be made in

the following situation: 1) on the saved waveform. 2) on the mathematical waveform. 3) on the XY format. 4)

on the Scan format.

Measure the frequency, the peak-to-peak value of the Channel CH1 and the mean, the RMS of the Channel

CH2, following below steps:

1. Press the F1 menu selection button and choose Source.

2. Press the F2 menu selection button and choose CH1.

3. Press the F3 menu selection button and choose CH1.

4. Press the F4 menu selection button and choose CH2.

5. Press the F5 menu selection button and choose CH2.

6. Press the F1 menu selection button and choose Type.

7. Press the F2 menu selection button and choose Freq.

8. Press the F3 menu selection button and choose Pk-Pk.

9. Press the F4 menu selection button and choose Mean.

10. Press the F5 menu selection button and choose Cyc RMS.

-179-

Page 64

The measured value will be displayed in the reading window automatically (see Fig. 66).

Fig. 66 Automatic Measurement

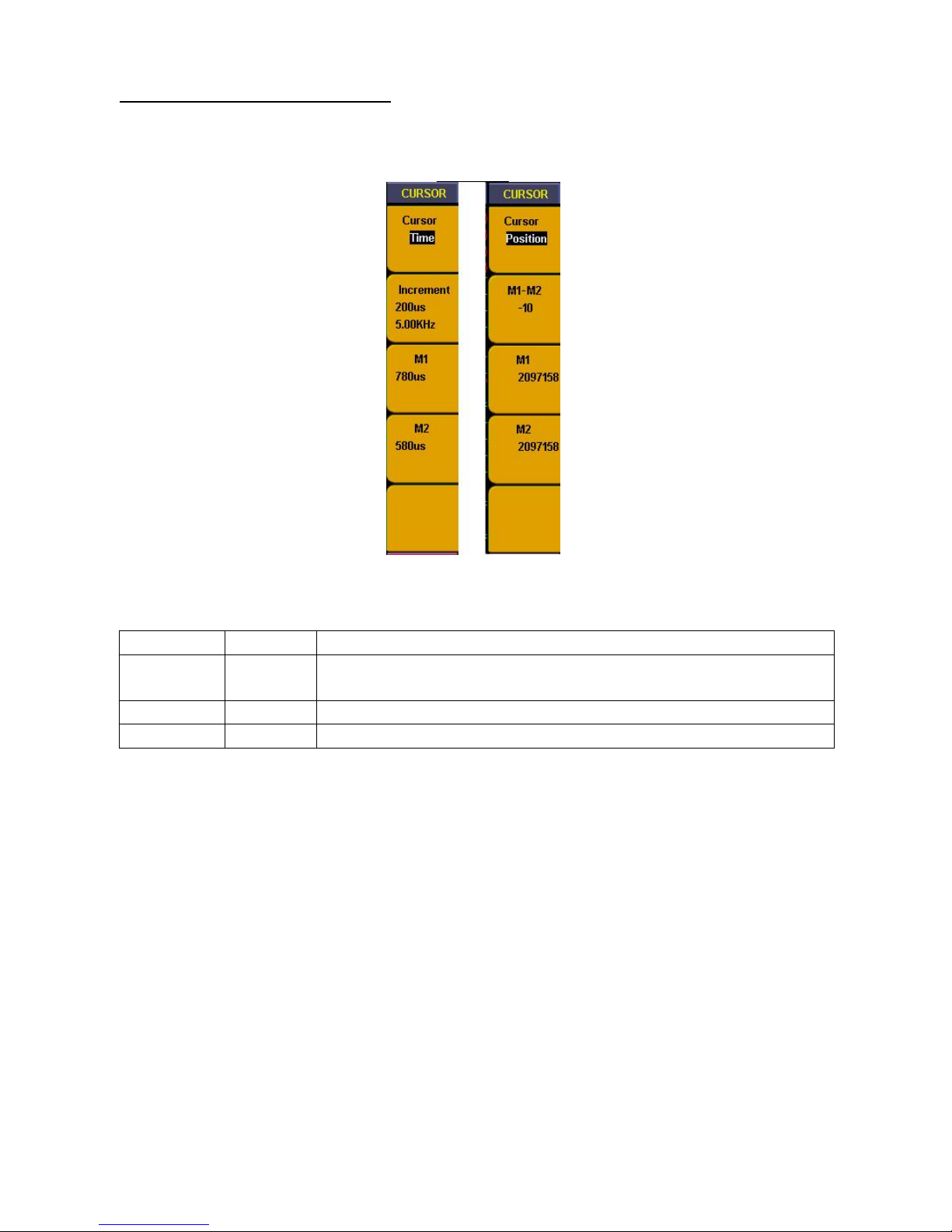

40. How to Implement the Cursor Measurement

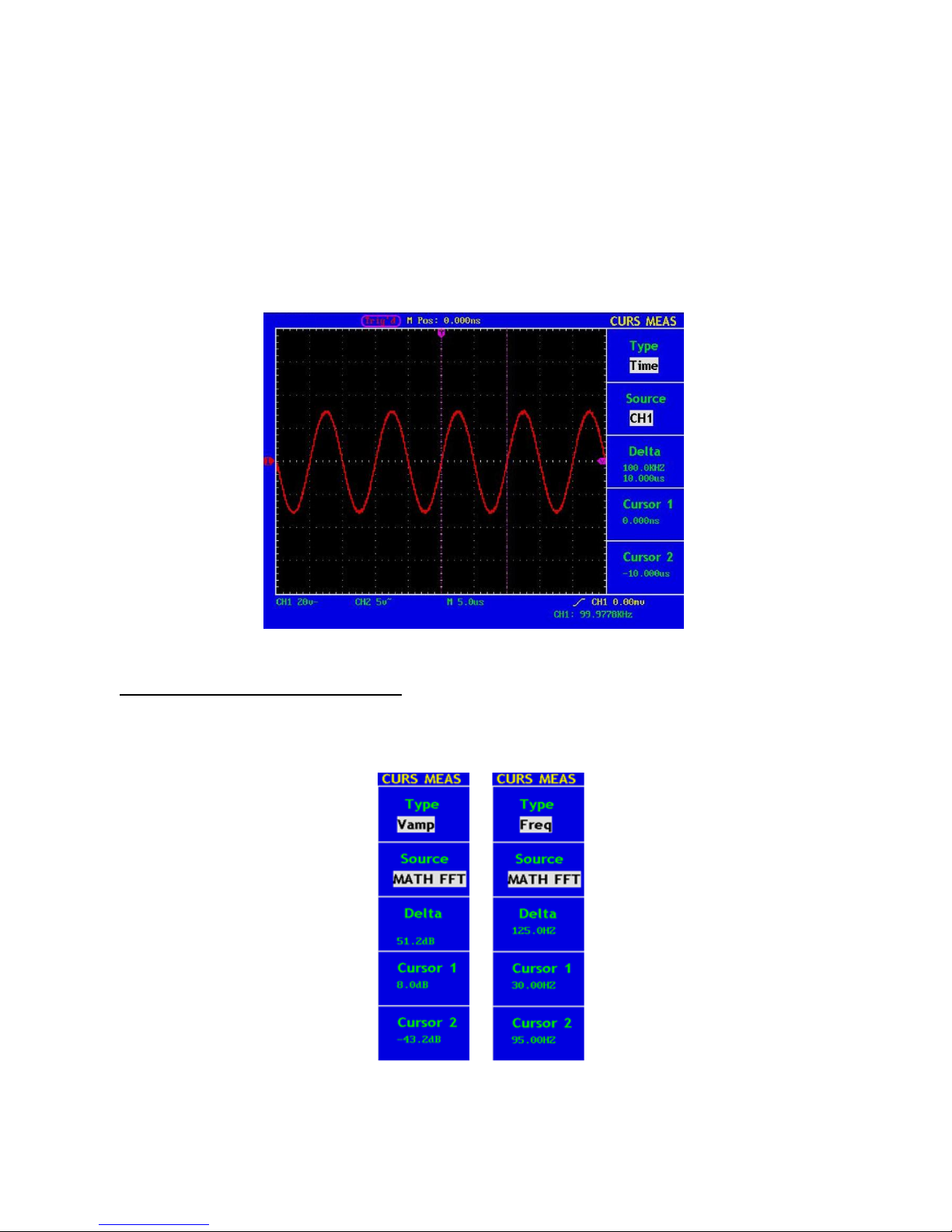

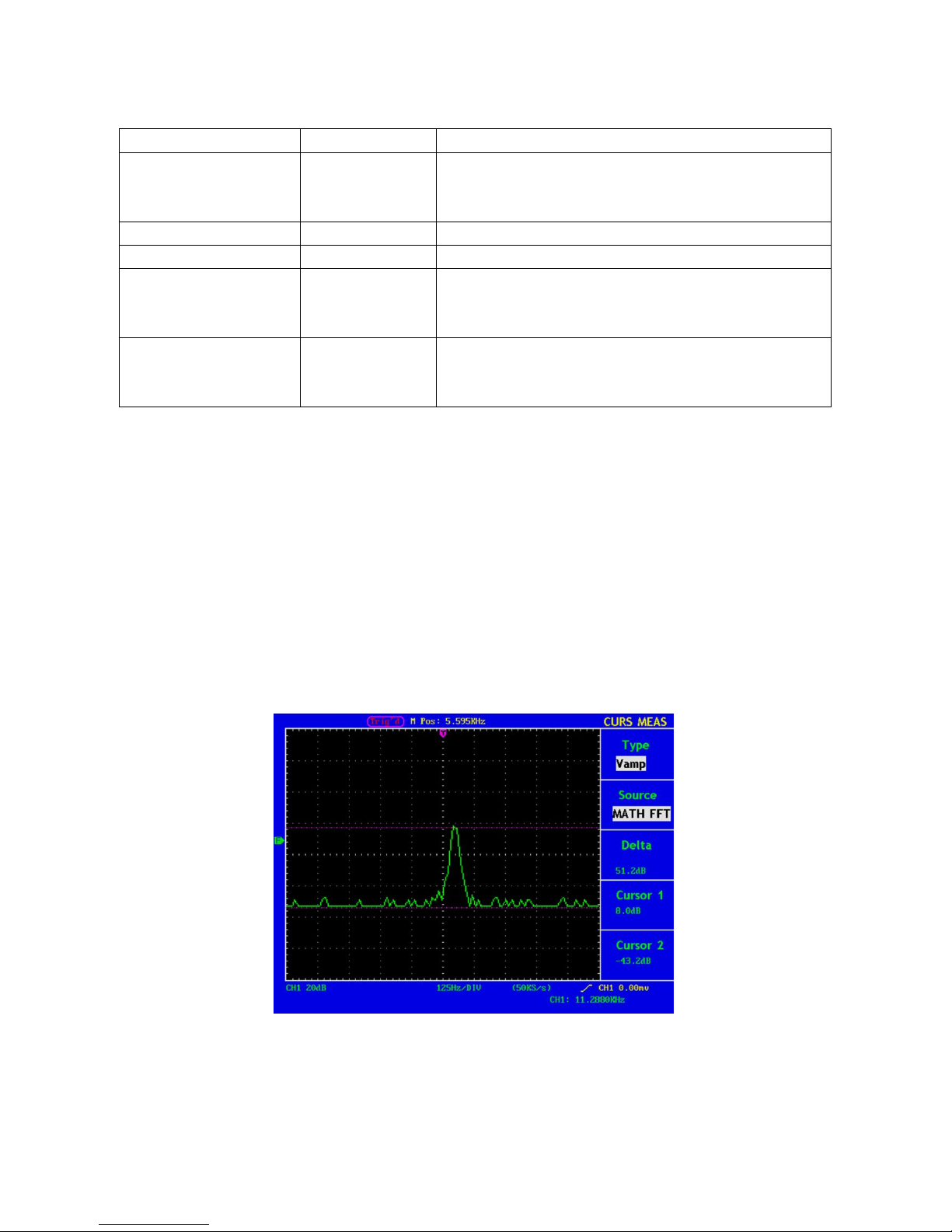

Press the CURSOR button to display the cursor measurement function menu (CURS MEAS) in the screen.

the Cursor Measurement for normal model:

The cursor measurement includes Voltage Measurement and Time Measurement at normal model,

shown as Fig. 67.

Fig. 67 CURS MEAS Menu

-180-

Page 65

The description of the cursor measurement menu is shown as the following table:

Function Menu

Setting

Description

Type

OFF

Voltage

Time

Switch off the cursor measurement.

Display the voltage measurement cursor and menu.

Display the time measurement cursor and menu.

Source

CH1

CH2

Display the channel generating the waveform to which the

cursor measurement will be applied.

Delta