Peak Atlas DCA Pro

Advanced Semiconductor Component Analyser

with Graphics Display and PC connectivity

Model DCA75

Designed and manufactured with pride in the UK

User Guide

©

Peak Electronic Design Limited 2012/2015

In the interests of development, information in this guide is subject to change without notice - E&OE

GB75-1.4

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 2

Want to use it now?

We understand that you want to use your Atlas DCA Pro right now.

The unit is ready to go and you should have little need to refer to this

user guide, but please make sure that you do at least take a look at the

notices on page 5.

Contents Page

Introduction....................................................................................4

Important Considerations...............................................................5

Analysing Semiconductors - Standalone mode..............................6

Diodes......................................................................................8

Zener Diodes............................................................................9

Diode Networks .....................................................................10

LEDs......................................................................................11

Bicolour LEDs (2-lead types) ................................................12

Bicolour LEDs (3-lead types) ................................................13

Bipolar Junction Transistors (BJTs).......................................14

Darlington Transistors ...........................................................18

Enhancement Mode MOSFETs .............................................21

Depletion Mode MOSFETs ...................................................22

Enhancement Mode IGBTs....................................................23

Depletion Mode IGBTs..........................................................24

Junction FETs (JFETs) ..........................................................25

Thyristors (SCRs) and Triacs.................................................27

Voltage Regulators ................................................................28

Contents continued on next page…

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 3

Contents (continued) Page

PC Software Installation............................................................29

Windows XP Installation .......................................................30

Windows Vista, 7 and 8 Installation ......................................31

Running the DCA Pro software for the first time ........................32

Analysing Semiconductors – PC mode ........................................33

PC mode - Curve Tracing functions.......................................34

PC mode - Exporting your data..............................................35

PC mode - Special functions..................................................36

Audible Settings...........................................................................37

Care of your Atlas DCA Pro........................................................38

Self Test Procedure ......................................................................39

Appendix A - Troubleshooting ....................................................40

Appendix B - Technical Specifications........................................41

Appendix C - Analysis test circuits..............................................43

Transistor test circuit .............................................................43

JFET/MOSFET/IGBT test circuit..........................................44

Diode test circuit....................................................................45

Voltage regulator test circuit..................................................46

Appendix D - Warranty Information............................................47

Appendix E - Disposal information .............................................47

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 4

Introduction

The Peak Atlas DCA Pro is an advanced semiconductor analyser that

combines simplicity, ease of use and a range of advanced features. You can use

your DCA Pro on its own or in combination with a laptop or desktop PC.

Summary Features:

• Automatic component type identification and schematic display:

Bipolar transistors.

Darlington transistors.

Enhancement Mode and Depletion Mode MOSFETs.

Enhancement Mode and Depletion Mode IGBTs.

Junction FETs.

Low power sensitive Triacs and Thyristors.

Light Emitting Diodes.

Bicolour LEDs.

Diodes and Diode networks.

Zener diodes.

Voltage regulators.

• Automatic pinout identification, just connect any way round.

• Special feature identification such as free-wheeling diodes and

resistor shunts.

• Gain measurement for bipolar transistors.

• Leakage current measurement for bipolar transistors.

• Silicon and Germanium detection for bipolar transistors.

• Gate threshold measurement for Enhancement Mode MOSFETs.

• Semiconductor forward voltage measurement for diodes, LEDs and

transistor Base-Emitter junctions.

• Zener voltage measurement.

• PC connectivity providing:

Larger component identification display.

Detailed characteristics measurement.

Curve tracing functions.

• Single alkaline AAA battery (not used when USB connected).

• Automatic and manual power-off.

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 5

Important Considerations

Please observe the following guidelines:

•

This instrument must NEVER be connected to powered

equipment/components or equipment/components with any

stored energy (e.g. charged capacitors). Failure to comply

with this warning may result in personal injury, damage to

the equipment under test, damage to your DCA Pro and

invalidation of the manufacturer’s warranty.

•

The DCA Pro is designed to analyse semiconductors that

are not in-circuit, otherwise complex circuit effects will

result in erroneous measurements.

•

Avoid rough treatment, hard knocks and extreme

temperatures.

•

This unit is not waterproof.

•

Only use a good quality AAA Alkaline battery.

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 6

Testing...

Analysing Semiconductors – Standalone mode

The DCA Pro is designed to analyse discrete,

unconnected, unpowered components. This

ensures that external connections don’t

influence the measured parameters. The three

test probes can be connected to the component any

way round. If the component has only two terminals, then

any pair of the three test probes can be used.

The DCA Pro will start component analysis when the on-test button is

pressed.

For the first analysis (after the unit has

been switched off) the tests are

performed while displaying the Peak

logo.

For subsequent testing when the unit

is already powered-up, the unit

displays the “Testing…” screen.

Depending on the component type, analysis may take a few seconds to

complete, after which, the results of the analysis are displayed.

Information is displayed a “page” at a time, each page can be smoothly scrolled

by briefly pressing the scroll-off button.

Although the DCA Pro will switch itself off if left unattended, you

can manually switch the unit off by holding down the scroll-off

button for a couple of seconds.

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 7

No component

detected.

Unknown/faulty

component.

Red & Blue

leads shorted.

Red, Green & Blue

leads shorted.

If the DCA Pro cannot detect any

component between any of the test

probes, the following message will be

displayed:

If the component is not a supported

component type, a faulty component or

a component that is being tested incircuit, the analysis may result in the

following message being displayed:

Some components may be faulty due to

a shorted junction between a pair of the

probes. If this is the case, the following

message (or similar) will be displayed:

If all three probes are shorted (or very

low resistance) then the following

message will be displayed:

It is possible that the DCA Pro may detect one or more diode

junctions or other component type within an unknown or faulty part.

This is because many semiconductors comprise of PN (diode)

junctions. Please refer to the section on diodes and diode networks for

more information.

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 8

Diode junction

Green-K Blue-A

V

F

=0.694V at 5.00mA

Diodes

The DCA Pro will analyse almost any type of diode. Any

pair of the three test clips can be connected to the diode, any way

round. If the unit detects a single diode, a message similar to the following

will be displayed:

In this example, the Cathode (symbol of

K) is connected to the Green test clip

and the Anode (symbol of A) is

connected to the Blue test clip,

additionally, the Red test clip is unconnected.

The forward voltage drop is also displayed; this gives an indication of the

diode technology. In this example, it is likely that the diode is a standard

silicon diode. A germanium or Schottky diode may yield a forward voltage of

about 0.25V. The current at which the diode was tested is also displayed. The

DCA Pro typically tests diodes (PN junctions) at a forward current of 5mA.

Note that the DCA Pro will detect only one diode even if two diodes

are connected in series when the third test clip is not connected to the

junction between the diodes. The forward voltage drop displayed

however will be the voltage across the whole series combination.

The DCA Pro will determine that the diode(s) under test is an LED if

the measured forward voltage drop exceeds 1.50V. Please refer to the

section on LED analysis for more information.

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 9

Zener diode

Red-K Blue-A

V

R

=5.094V at 5.00mA

Red-K Blue-A

V

R

=5.094V at 5.00mA

V

F

=0.702V at 5.00mA

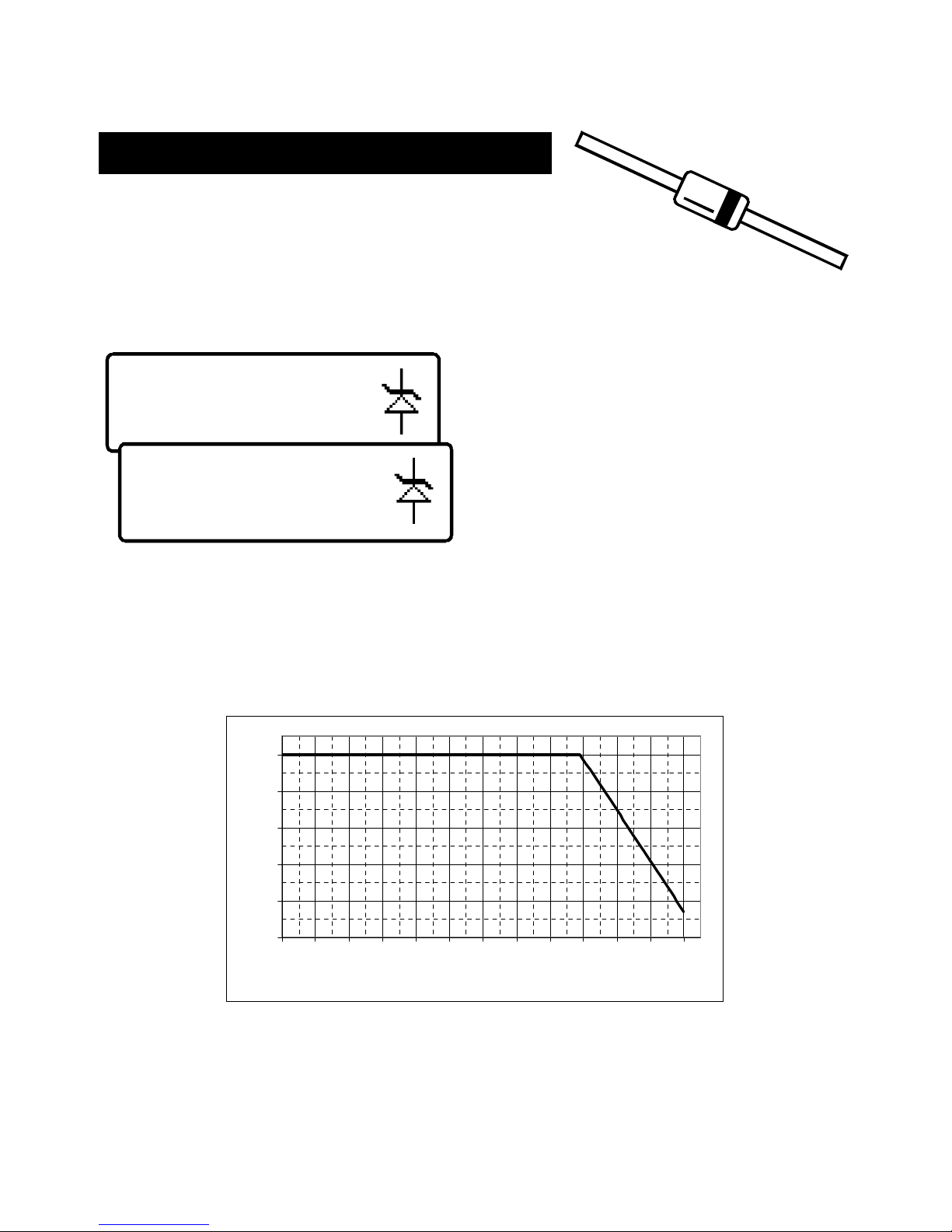

Zener Diodes

The DCA Pro supports Zener diodes (and Avalanche

diodes). Additionally, the instrument can measure the Zener

voltage*.

Connect any pair of the 3 test leads to the Zener diode.

Following analysis, the component

details are displayed.

In this example, a Zener diode with a

reverse voltage (Zener voltage) of

nearly 5.1V has been detected.

Additionally, the forward biased

voltage characteristic is measured, 0.702V at 5mA for this example.

The DCA Pro attempts to test the Zener diode with a current of nominally

5mA. For Zener diodes with a Zener voltage of more than about 9V, a lower

test current will be used. This is illustrated in the following graph:

0

1

2

3

4

5

0 1 2 3 4 5 6 7 8 9 10 11 12

Zener Voltage (Volts)

Test Current (mA)

*The DCA Pro may not be able to identify Zener diodes with a Zener voltage

of more than 11V. It will however still identify the diode junction in its

forward biased mode.

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 10

2 diode junctions

#1: Diode junction

Green-K Blue-A

#1: Diode junction

Green-K Blue-A

VF=0.699V at 5.00mA

#2: Diode junction

Red-A Blue-K

VF=0.683V at 5.00mA

Diode Networks

The DCA Pro will identify multiple diode junctions

between the probes. For three terminal devices such as

SOT-23 diode networks, all three test clips must be

connected.

The instrument will show the results for each diode junction in turn.

Firstly, the unit will show that it has

found a number of diode junctions:

The details for the first diode are then

displayed (Diode #1). In this example,

the Green test clip is on the Cathode of

diode #1 and the Blue test clip is on the

Anode.

The details for the second diode are

then displayed (by briefly pressing

scroll-off):

It can be seen in the above example, that the blue test clip is connected to both

the anode on Diode #1 and to the cathode of Diode #2. This means that the two

diodes are effectively connected in series, with the blue clip at the mid point.

This example is illustrated below:

#1

Green Red

Blue

#2

In the same way as the single diode analysis, the forward voltage for each

diode is measured for a nominal test current of 5mA.

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 11

LED

Red-K Blue-A

V

F

=1.962V at 5.00mA

LEDs

An LED (light emitting diode) is really just another type of

diode, however, the DCA Pro will determine that an LED or

LED network has been detected if the diode’s measured

forward voltage drop is larger than 1.5V. This also enables the

DCA Pro to intelligently identify bicolour LEDs, both two-lead

and three-lead varieties. See the section on bicolour LEDs for more

information.

For two leaded parts, connect any pair of the 3 test clips to your LED. Leave

the 3rd lead unconnected.

In this example, the Red test clip is

connected to the LED’s Cathode

(negative) and the Blue test clip is

connected to the Anode (positive).

The forward voltage of the LED is measured at a nominal current of 5mA.

During the analysis process, the LED will briefly illuminate (so you

can see it’s illumination colour). The test current of 5mA means that it

may not be as bright as you expect, LEDs are often used at currents of

10-20mA. Power LEDs are sometimes driven at 350mA or more.

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 12

Bicolour LED (2 lead)

#1: LED

Red-K Blue-A

#1: LED

Red-K Blue-A

VF=1.823V at 5.00mA

Bicolour LEDs (2-lead types)

Bicolour LEDs are generally available in two main varieties;

2-lead and 3-lead types.

This section describes the testing of 2-lead

bicolour LEDs. These types are internally

connected in inverse parallel (back-to-back).

Similar to the diode network analysis, each LED within the

bicolour LED is detailed in turn.

This example shows that LED #1 has

its Cathode connected to the Red test

clip and its Anode connected to the

Blue test clip. The forward bias

characteristic is shown for LED#1,

1.823V at 5mA in this example.

Pressing scroll-off then shows the

details for the 2nd LED in the bicolour

LED package.

As expected for 2-lead bicolour LEDs,

we can see in this example that LED#2 has its connections in exactly the

opposite configuration to LED#1.

Note that it is common for the two LEDs within a bicolour LED to

have different forward voltage characteristics. Red is often the lowest

forward voltage, progressing through amber, yellow, green and then

blue (or white) with the highest forward voltage. See the table at the

bottom of the next page.

#2: LED

Red-A Blue-K

VF=1.944V at 5.00mA

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 13

Bicolour LED (3 lead)

Common Cathode

#1: LED

#1: LED

Red-A Green-K

VF=1.935V at 5.00mA

#2: LED

Green-K Blue-A

VF=1.877V at 5.00mA

Bicolour LEDs (3-lead types)

3-lead bicolour LEDs are available in

common cathode and common anode

varieties. The DCA Pro supports both types.

In the same way as the 2-lead bicolour LED

analysis, each internal LED is detailed separately on the

DCA Pro screen.

The type of bicolour LED is shown

here, in this example we have a

common cathode variety.

The details for each internal LED are

then shown.

It can be seen here that our example has

its common cathode terminal connected

to the Green test clip.

Typical values of forward voltage for LED colours are shown here:

(LED types/manufacturers may vary significantly)

LED Colour Typical VF @ 5mA

Red 1.81V

Amber 1.86V

Yellow 1.90V

Green (standard type) 1.95V

Green (deep green / emerald) 2.84V

Blue (and white) 2.95V

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 14

Bipolar Junction Transistors (BJTs)

Bipolar Junction Transistors are simply “conventional”

transistors, although variants of these do exist such as

Darlingtons, devices with free-wheeling diodes, resistor

shunted types and combinations of these types. All of these

variations are automatically identified by the DCA Pro and their schematic

symbol is displayed on the screen. Both NPN and PNP types are supported.

The 3 test clips can be applied to the transistor in any configuration.

As an example, testing a common

PNP transistor such as the 2N5401

will result in a display similar to this:

This example shows that the Red test

clip is connected to the Emitter, the

Green is connected to the Base and

the Blue test clip is connected to the

Collector.

Pressing scroll-off allows further details to be displayed.

The DC current gain (hFE), base emitter voltage drop (VBE) and collector

leakage current (ICLeak) are all shown along with their test conditions.

Refer to the following sections for more details on these measurements.

PNP Silicon BJT

Red-E Green-B Blue-C

hFE=106

hFE=106

at IC=5.00mA

VBE=0.754V

VBE=0.754V

at IB=5.00mA

I

C

Leak=0.000mA

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 15

Current Gain (h

FE

)

DC current gain (hFE) is the ratio of the

collector current (less leakage) to the

base current for a particular operating

condition.

The DCA Pro measures hFE at a collector

current of nominally 5.0mA and a

collector-emitter voltage of between 3V

and 9V.

The gain of all transistors can vary

considerably with collector current,

collector voltage and also temperature.

The displayed value for gain therefore

may not represent the gain experienced at other collector currents and voltages.

This is particularly true for large devices.

The displayed value of gain is very useful however for comparing transistors of

a similar type for the purposes of gain matching or fault finding.

Darlington transistors can have very high gain values and more variation of

gain will be evident as a result of this.

The current gain of germanium transistors can vary a large amount

with changes in temperature. Even the warmth from your fingers can

alter the gain of a germanium device.

It is quite normal for transistors of the same type to have a wide range

of gain values. For this reason, transistor circuits are often designed so

that their operation has little dependence on the absolute value of

current gain.

I

C

=5.0mA

I -I

(I = leakage

current)

C Cleak

Cleak

h

FE

=

I

B

I

B

hFE=167

at IC=5.00mA

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 16

VBE=0.703V

at IB=5.00mA

Base-Emitter Voltage Drop

The DC characteristics of the base-emitter

junction are displayed, both the base-emitter

forward voltage drop (VBE) and the base

current (IB) used for the measurement.

This example shows an NPN base-

emitter voltage (VBE) of 0.703V for a

base test current (IB) of 5mA.

The forward base-emitter voltage drop can aid in the identification of silicon or

germanium devices. Germanium devices can have base-emitter voltages as low

as 0.2V, Silicon types exhibit readings of about 0.7V and Darlington transistors

can exhibit readings of about 1.2V because of the multiple base-emitter

junctions being measured.

It is important to note that the DCA Pro does not perform the base-

emitter voltage drop tests at the same base current as that used for the

current gain measurement. VBE is measured at a base current of

approximately 5mA. The base current used during the gain

measurement is equal to IC/hFE.

I

B

V

BE

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 17

VBE=0.270V

at IB=5.00mA

ICLeak=0.177mA

Collector Leakage Current

The collector current that takes place

when no base current is flowing is

referred to as Leakage Current.

Most modern transistors exhibit

extremely low values of leakage

current, often less than 1µA, even for

very high collector-emitter voltages.

Older Germanium types however can

suffer from significant collector leakage

current, particular at high temperatures (leakage current can be very

temperature dependant).

Leakage current is automatically taken into account for the gain measurement

(unlike many multimeters’ gain measurement that can be fooled by leakage

current).

If your transistor is a Silicon type, you should expect to see a leakage

current of close to 0.000mA unless the transistor is faulty.

The leakage current of germanium transistors can vary a large amount

with changes in temperature (roughly doubling with every 5°C

increase). Even the warmth from your fingers can alter the leakage

current of a germanium device. Conversely, a cooling transistor (after

a little handling) can result in a falling leakage current measurement

over the period of a few seconds/minutes. This is completely normal.

I

C

Leakage

IB = 0

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 18

Darlington Transistors

If the device is a Darlington transistor (two BJTs connected

together), the unit will display a similar message to this:

As expected, for Darlington devices

that do not have internal resistors, the

gain (hFE) can be very high.

This second example however, (left)

shows the display for a Darlington

transistor that has internal resistors

connected to the base-emitter

connections. This causes the hFE measurement to become much lower at the

test currents used by the DCA Pro. This is normal and is not a fault with the

transistor or the DCA Pro.

It is important to note that if a Darlington does contain a base-emitter

shunt resistor network, any measurements of current gain (hFE) will be

very low at the test currents used by the DCA Pro. This is due to the

resistors providing an additional path for the base current. The

readings for gain however can still be used for comparing transistors

of a similar type for the purposes of matching or gain band selecting.

Note that the DCA Pro will determine that the transistor under test is a

Darlington type if the base-emitter voltage drop is greater than 1.00V

for devices with a base-emitter shunt resistance of greater than 60kΩ

or if the base-emitter voltage drop is greater than 0.80V for devices

with a base-emitter shunt resistance of less than 60kΩ. The measured

base-emitter voltage drop is displayed as detailed later in this section.

NPN Darlington

Red-B Green-E Blue-C

h

F

E

=9410

NPN Darlington

Red-C Green-E Blue-B

h

F

E

=67

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 19

Free Wheeling Diode

Some transistors, particularly CRT deflection transistors and many large

Darlingtons have a protection diode (“free wheeling diode” or “body diode”)

inside their package connected between the collector and emitter.

If a free-wheeling diode has been detected, it is shown on the schematic

symbol. Some examples are shown here:

PNP Silicon BJT

Red-B Green-C Blue-E

h

F

E

=61

The Philips BU505DF is a typical example of a diode protected bipolar

transistor. Remember that the diode (if present) is always internally connected

between the collector and the emitter so that it is normally

reverse biased.

For NPN transistors, the anode of the diode is connected to

the emitter of the transistor. For PNP transistors, the anode

of the diode is connected to the collector of the transistor.

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 20

No component

detected.

Unknown/faulty

component.

Faulty or Very Low Gain Transistors

Faulty transistors that exhibit very low gain

may cause the DCA Pro to only identify one or

more diode junctions within the device. This is

because NPN transistors consist of a structure

of junctions that behave like a common anode

diode network. PNP transistors can appear to be

common cathode diode networks. The common

junction represents the base terminal. This is normal for situations where the

current gain is so low that it is immeasurable at the test currents used by the

DCA Pro.

Please note that the equivalent diode pattern may not be correctly

identified by the DCA Pro if your transistor is a darlington type or has

additional diode(s) in its package (such as a collector-emitter

protection diode). This is due to multiple pn junctions and current

paths that cannot be uniquely resolved.

In some circumstances, the unit may not be able to deduce anything sensible

from the device at all, in which case you may see one of these messages:

B

C

E

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 21

N-Ch Enhancement

mode MOSFET

Red-G Green-S Blue-D

Gate threshold

VGS(on)=3.625V

at ID=5.00mA

Enhancement Mode MOSFETs

MOSFET stands for Metal Oxide Semiconductor Field Effect

Transistor. Like bipolar transistors, MOSFETs are available in

two main types, N-Channel and P-Channel. Most modern

MOSFETs are of the Enhancement Mode type, meaning that

the bias of the gate-source voltage is always positive (For N-Channel types).

The other (rarer) type of MOSFET is the Depletion Mode type which is

described in a later section.

MOSFETs of all types are sometimes known as IGFETs, meaning Insulated

Gate Field Effect Transistor. This term describes a key feature of these

devices, an insulated gate region that results in negligible gate current for both

positive and negative gate-source voltages (up to the maximum allowed values

of course, typically ±20V). IGFETs are not to be confused with IGBTs

(Insulated Gate Bipolar Transistors), these are dealt with in a later section.

The first screen to be displayed gives

information on the type of MOSFET

detected and the pinout.

Pressing scroll-off will then result in

the gate threshold of the MOSFET being

displayed.

The (on) gate threshold voltage is the gate-source voltage at which conduction

between the source and drain starts. The DCA Pro determines that drain-source

conduction has started when it reaches a current of 5.00mA, this is confirmed

on the display.

An enhancement MOSFET will always have a gate threshold voltage of greater

than 0V (i.e. always positive relative to the source pin for N channel devices).

The DCA Pro can drive the gate from 0V to 10V for enhancement mode

MOSFETs.

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 22

N-Ch Depletion

mode MOSFET

Red-S Green-G Blue-D

Gate threshold

VGS(on)=-2.918V

at ID=5.00mA

Depletion Mode MOSFETs

The fairly rare Depletion Mode MOSFET is very similar to the

conventional Junction FET (JFET) except that the gate

terminal is insulated from the other two terminals. The input

resistance of these devices can typically be greater than

1000MΩ for negative and positive gate-source voltages.

Depletion Mode devices are

characterised by the gate-source

voltage required to control the drainsource current.

Modern Depletion Mode devices are

generally only available in N-Channel

varieties and will conduct some current

between its drain and source terminals even with a zero voltage applied across

the gate and the source. The device can only be turned completely off by taking

its gate significantly more negative than its source terminal, say –5V. It is this

characteristic that makes them so similar to conventional JFETs.

V

GS

Depletion mode

MOSFET

Enhancement mode

MOSFET

I

DS

5.0mA

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 23

N-Ch Enhancement

mode IGBT

Red-G Green-C Blue-E

Gate threshold

VGE(on)=5.778V

at IC=5.00mA

Enhancement Mode IGBTs

IGBT is an acronym for Insulated Gate Bipolar Transistor.

It combines the input characteristics of a MOSFET with

the output characteristics of a Bipolar Junction Transistor.

IGBTs are available in N or P channel types, enhancement mode or depletion

mode and with or without a free-wheeling diode.

Generally, their operation is very similar to MOSFETs. The saturation

capability of an IGBT is often better than an equivalent sized MOSFET at high

currents. At low currents, the saturation voltage of an IGBT is often worse than

an equivalent sized MOSFET.

In this example we have an NChannel IGBT with an integral free

wheeling diode.

Note the names of the leads; Gate,

Collector and Emitter.

Similar to the MOSFET analysis, the gate threshold is the voltage between the

gate and emitter that causes the device to start conducting (between the

collector and emitter). The DCA Pro determines that conduction has started if

the collector current has reached 5.0mA.

The DCA Pro can drive the gate from 0V to 10V for enhancement mode

IGBTs.

(IGBT symbol based on EN60617: 05-05-19)

G

C

E

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 24

N-Ch Depletion

mode IGBT

Red-E Green-G Blue-E

Gate threshold

VGE(on)=-3.955V

at IC=5.00mA

Depletion Mode IGBTs

Like MOSFETs, IGBTs are available as enhancement

mode and depletion mode types.

Depletion mode IGBTs are characterised by the fact that

current can flow between the collector and emitter when there is zero voltage

across the gate-emitter terminals.

For an N-Channel depletion mode IGBT, the device can only be turned off

fully if the gate terminal is taken more negative with respect to the emitter lead.

In this example we have an NChannel depletion mode IGBT with

no free wheeling diode.

Note the negative gate threshold

voltage, characteristic of a depletion

mode device.

G

C

E

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 25

Junction FETs (JFETs)

Junction FETs are conventional Field Effect Transistors.

The voltage applied across the gate-source terminals controls

current between the drain and source terminals. N-Channel

JFETs require a negative voltage on their gate with respect to their source, the

more negative the voltage, the less current can flow between the drain and

source.

Unlike Depletion Mode MOSFETs, JFETs have no insulation layer on the gate.

This means that although the input resistance between the gate and source is

normally very high (greater than 100MΩ), the gate current can rise if the

semiconductor junction between the gate and source or between the gate and

drain become forward biased. This can happen if the gate voltage becomes

about 0.6V higher than either the drain or source terminals for N-Channel

devices or 0.6V lower than the drain or source for P-Channel devices.

The internal structure of JFETs is

essentially symmetrical about the gate

terminal, this means that the drain and

source terminals are often

indistinguishable by the DCA Pro. The JFET type, gate terminal and measured

parameters are displayed however.

Pinch-Off

A common parameter to be specified for JFETs is “Pinch-Off”. This is the

voltage needed between the gate-source

to turn off the JFET. The DCA Pro will

determine that the JFET is off when the

drain current is less than 5µA.

N-Ch Junction FET

Green-G

Symmetrical Src/Drn

VGS(off)=-6.65V

at ID=5.0uA

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 26

VGS(on)=-1.10V

at ID=5.00mA

“On” Characteristics

The DCA Pro measures the gate-source

voltage required to reach the onset of

good conduction through the JFET’s

drain-source. Good conduction is determined when the drain-source current

reaches 5mA. For JFETs that have a lower saturation current than 5mA, the

DCA Pro will try to use a lower “on” current.

Transconductance

While the JFET is conducting, the JFET’s gain (transconductance) is measured.

Transconductance is often measured in mA/V, mmhos or mSiemens. This

refers to the change in drain current resulting from a change in gate-source

voltage:

gfs = ∆IDS / ∆VGS

The DCA Pro measures transconductance by determining the gate voltage

change necessary to obtain a drain current change from 3.0mA to 5.0mA. If the

JFETs saturation current is less than

5.0mA then a proportionately lower

current span will be used.

I

DSS

Drain Current (for VGS=0)

Finally, the drain current for a zero

gate-source voltage is measured. This is

measured for a drain-source voltage of

nominally 3.0V but may be lower if the

drain current exceeds 12mA.

Transconductance is measured by the DCA Pro over a small range of

drain current (typically a span of 3mA-5mA). Values of

transconductance higher than 20mA/V can yield a coarse

measurement resolution as the required change in gate voltage is so

tiny. Values above 99mA/V are displayed as “>99mA/V”.

I

DSS

=6.67mA

at VDS=3.00V

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 27

Thyristor (SCR)

Red-G Green-K Blue-A

Triac

Red-MT1 Green-G

Blue-MT2

Thyristors (SCRs) and Triacs

Sensitive low power thyristors (Silicon Controlled

Rectifiers - SCRs) and triacs that require gate

currents and holding currents of less than 10mA

can be identified and analysed with the DCA Pro.

Thyristor terminals are the anode (A), cathode (K) and the gate (G).

This example shows that a thyristor has

been detected:

Triac terminals are MT1, MT2 (MT

standing for main terminal) and gate.

MT1 is the terminal with which gate

current is referenced.

1. The unit determines that the device under test is a triac by checking

the gate trigger quadrants that the device will reliably operate in.

Thyristors operate in only one quadrant (positive gate current, positive

anode current). Triacs can typically operate in three or four quadrants,

hence their use in AC control applications.

2. The gate trigger currents used by the DCA Pro are limited to less

than 10mA. Some thyristors and triacs will not operate at low currents

and these types cannot be analysed with this instrument. Note also that

if only one trigger quadrant of a triac is detected then the unit will

conclude that it has found a thyristor. Please see the technical

specifications for more details. The Atlas SCR (model SCR100)

instrument is designed for analysing triacs and thyristors that require

currents up to 100mA to operate.

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 28

Voltage Regulator

Red-IN Green-OUT

Blue-GND

V

OUT

=5.024V

IQ=2.54mA

V

DO

=1.83V

Voltage Regulators

Voltage regulators are available in many different types and

different packages.

The DCA Pro is able to identify many types of regulator,

typically regulators with outputs less than 8V, depending on

current requirements.

When a regulator is identified, its

pinout, output voltage, quiescent current

consumption and drop-out voltage are

displayed.

Negative voltage regulators (such as

the popular 79L05) will be shown with

a negative V

OUT

figure.

The displayed drop-out voltage (VDO) is the voltage that is required

between input and output of the regulator to enable voltage regulation

to take place. Common regulators have a drop-out voltage of around

2V. Many “Low drop-out” regulators may have a drop-out voltage of

0.5V or less. The DCA Pro measures drop-out at very low load

currents on the regulator’s output (typically less than 1mA). The dropout voltage of a regulator increases significantly with load current.

Some voltage regulators are not stable when used outside of their

intended circuitry (decoupling capacitors, proper loads etc). The

DCA Pro may not be able to identify the regulator correctly if it is not

stable during analysis.

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 29

PC Software Installation

The DCA Pro can be used in conjunction

with a PC running Windows XP or later.*

Software is provided on the included USB

flash drive. Alternatively, you can download the

latest PC software package from:

www.peakelec.co.uk/downloads/dcaprosetup.exe

Before you install the software, ensure you have sufficient (administrator)

rights on your machine. Additionally, ensure your PC meets the following

requirements:

Windows XP(SP3), Vista, 7 or later.*

1GB RAM.

1GB Hard Disk free.

Display size 1024 x 600 minimum (typical netbook resolution).

16 bit colour or better.

USB 1.1 or better.

.NET framework 4 (automatically installed if required).

Internet connection required for online updates.

* Verified on UK localisation of Windows 8 at time of this user guide going to

print.

The installation process varies depending on your version of Windows. Select

the appropriate section over the next few pages and follow the step-by-step

instructions very carefully.

Please don’t connect your DCA pro just yet

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 30

Windows XP Installation

1. Make sure you have the latest Windows Updates and Service Pack 3.

2. Run “Setup.exe” on the supplied USB flash drive. Alternatively, you can

download and run the digitally signed installation file from our website:

www.peakelec.co.uk/downloads/dcaprosetup.exe

3. During the setup process, you may be asked to install .NET Framework 4.

The installation files for that are included on the USB flash drive and don’t

need to be downloaded. If you are running the installation from a

downloaded copy of our software then you may be prompted to download

the .NET package. You need to accept the Microsoft agreement and the

process will complete in a few minutes (sometimes up to 10 minutes).

4. When the DCA Pro software installation

is complete, you can plug in your

DCA Pro to a convenient USB socket.

It’s best to choose a socket directly on

your computer rather than a hub. After a

few seconds, you should be presented

with the “Found New Hardware

Wizard”. Make sure you select “Install

from a list or specific location” and then click Next.

5. You will then be presented with this

window. Make sure the box “Include

this location in the search” is checked.

It should already be filled with the

location for the Peak Driver. Then click

Next.

6. Your DCA Pro should chime when

your software is ready to use.

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 31

Windows Vista, 7 and 8 Installation

1. Make sure you have the latest Windows Updates and Service Pack.

2. Run “Setup.exe” on the supplied USB flash drive. Alternatively, you can

download and run the digitally signed installation file from our website:

www.peakelec.co.uk/downloads/dcaprosetup.exe

3. During the setup process, you may be asked to install .NET Framework 4.

The installation files for that are included on the USB flash drive and don’t

need to be downloaded. If you are running the installation from a

downloaded copy of our software then you may be prompted to download

the .NET package. You need to accept the Microsoft agreement and the

process will complete in a few minutes (sometimes up to 10 minutes).

4. Some systems may warn you that the

driver is not signed. The driver is in

fact a standard Microsoft WinUSB

driver that is set to look for the

DCA Pro identifier, so it is fine to

accept the warning and proceed.

5. When the DCA Pro software installation is complete, you can plug in your

DCA Pro to a convenient USB socket. It’s best to choose a socket directly

on your computer rather than a hub. Windows should install the drivers

automatically although it can take a minute or

two. You should see the driver installation

activity in the bottom right of your screen.

6. If prompted, let Windows download the latest WinUSB drivers. Don’t

worry if it takes a few minutes.

7. Your DCA Pro should chime when your software is ready to use.

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 32

Running the DCA Pro PC software for the first time

Now you’re ready to start the DCA Pro

companion software. You can start the software in

the following ways:

All Windows Versions

Double click on the desktop icon.

or

Click on the “DCA Pro” item in the “Peak” folder

of your start menu.

Windows Vista, 7 and 8 (Desktop mode)

Type “DCA Pro” into your start menu search box.

It doesn’t matter if you connect your DCA Pro before or after starting the

software.

When your DCA Pro is connected and your software is running, you should see

the green message DCA Pro connected in the bottom left corner of the

program window.

For the first time you use the software, if you see the message:

DCA Pro disconnected then try unplugging the USB cable, wait a few

seconds and plug back in. If that doesn’t work (depending on your version of

Windows) then you may need to restart your PC to allow the WinUSB drivers

to initialise.

If you’re still having problems then you may wish to try uninstalling the

software and drivers and then re-trying the installation process by following the

step-by-step instructions shown earlier.

Please contact us if you have any difficulties, we’re here to help.

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 33

Analysing Semiconductors – PC mode

When the DCA Pro is connected to the PC and the PC is running the

companion software, the instrument can be used from the PC screen or from

the instrument itself.

Pressing “Test” will initiate a component analysis in just the same way as the

standalone mode.

Any test results are automatically passed to the PC software and displayed in a

text window. Additionally, the component schematic and the colour-coded

pinout are also displayed:

Note that the component schematic is displayed in colour to illustrate which

colour test lead is connected to each component lead.

or

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 34

Curve Tracing

After a component has been analysed, you can perform further tests on the

component, such as curve tracing various component parameters.

Curve tracing is best performed after the DCA Pro has correctly identified the

component and correctly identified the pinout.

Depending on the component type, various curve options will become

available from the “Graphs” menu.

Selecting the desired curve type will take you to a fresh curve tab.

In many cases, you can simply start a new curve with the

automatically selected parameters by clicking the curve

“start” button.

You may adjust the parameters, but any parameters that are out of range may

lead to unexpected results. Refer to Appendix C in this user guide that shows

the analysis test circuits to see how test parameters are applied.

You may not be able to perform curve tracing in the following circumstances:

Transistor gain is very low and the DCA Pro is unable to generate

sufficient base current to obtain a sufficient span of collector current.

Transistor (Darlington) gain is extremely high which means that the tiny

base currents cannot be generated with fine enough resolution.

If the component requires more than 12mA (into a short circuit) to analyse.

If the component requires more than 12V (into an open circuit) to analyse.

If the component requires a combination of voltage and current that cannot

be generated (due to 700 Ohm current limiting resistance).

If you want to test other components using the same test parameters

(to easily compare parts), connect your component in exactly the same

configuration and press “Start” on the graph tab. Don’t press “Test” as

that will cause the test parameters to be re-evaluated for the new

component and you won’t be able to plot with the same values as your

previous test.

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 35

Curve Tracing – Export Raw Data

After the curve tracing operation has completed, you can copy the raw

measurement data into the clipboard ready to be pasted into your spreadsheet

program.

Pasting the data into a spreadsheet is an ideal way of documenting important

test results.

Simply right-click on one of the curves and select “Copy all”. All the raw

measurement data that created the curves is now in the clipboard. You can then

paste the data into your spreadsheet.

This feature has been tested with Microsoft Excel™©, Softmaker Planmaker©

and Apache Open Office™©. Other spreadsheet programs should work fine

too.

Once the raw data is pasted into your spreadsheet, you can perform your own

tasks such as charting and mathematical analysis.

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 36

Special Functions

Firmware Upgrade

From the program’s “Help” menu, select “Check for Updates”.

If you are connected to the internet, the program will check for new PC

Software (that includes the latest firmware). If newer software is available, you

will be guided to the download location.

The programming operation should take no more than a minute or so. Don’t

interrupt the process and wait for the confirmation that the programming

operation has been successfully completed.

Don’t worry if the firmware upgrade process doesn’t succeed first

time. Windows sometimes takes time to prepare the built-in HID

driver that is used during the firmware upgrade process. If the

firmware upgrade process fails, don’t panic, just try again, it should be

fine once Windows gets its built-in driver initialised.

LCD Contrast

The PC software allows you to adjust the instrument’s LCD contrast.

From the program’s “DCA Pro” menu, select “LCD Contrast”.

You will then be presented with a simple slider to make your contrast

adjustments. When you’re finished, you can click on the cross of the slider

window. Your new contrast value is automatically saved within the DCA Pro.

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 37

Audible Settings

Your DCA Pro has a built-in sounder for alerting you to various

test results and conditions. Additionally, the sounder produces

short tones to reinforce the tactile feedback when pressing

buttons.

Here is a summary of the various tone types:

Condition Tone Type

Power-up. Rising 3 notes.

Power-down, including auto-off. Falling 3 notes.

Button press. Very short “blip”.

Component detected. Short Low-High.

Faulty, unknown or no part detected. Long High-Low.

If you wish, you can switch the audible alerts on or off.

To change the current setting for audible alerts, while the unit is already on,

simply press and hold the on-test button for a few seconds.

The new sound setting will then be confirmed on the screen.

Sound is Off

Sound is On

To change back again, simply press and hold the on-test button again for a

few seconds.

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 38

Please replace

the battery.

Care of your Atlas DCA Pro

Your DCA Pro should provide many years of service if used in

accordance with this user guide. Care should be taken not to expose

your unit to excessive heat, shock or moisture. Additionally, the

battery should be replaced at least every 12 months to reduce the

risk of leak damage.

If a low battery warning message

appears, immediate replacement of the

battery is required.

The battery can be replaced by carefully opening the DCA Pro by removing

the three screws from the rear of the unit. Take care not to damage the

electronics.

Avoid touching

this area

We recommend that the battery is replaced with a high quality battery

equivalent to an Alkaline AAA, LR03 or MN2400 (1.5V). Replacement

Alkaline AAA batteries are available from many retail outlets.

DO NOT OVER-TIGHTEN THE SCREWS

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 39

Self test failed

CODE: 2

Self Test Procedure

Each time the DCA Pro is powered up, a self test procedure is performed. In

addition to a battery voltage test, the unit measures the performance of many

internal functions such as the voltage and current sources, amplifiers, analogue

to digital converters and test lead multiplexers. If any of these function

measurements fall outside tight performance limits, a message will be

displayed and the instrument will switch off automatically.

If the problem was caused by a

temporary condition on the test clips,

such as applying power to the test clips,

then simply re-starting the unit may

clear the problem.

If a persistent problem does arise, it is likely that damage has been caused by

an external event such as excessive power being applied to the test clips. If the

problem persists, please contact us for further advice, quoting the displayed

fault code.

If there is a low battery condition, the automatic self test procedure

will not be performed. For this reason, it is highly recommended that

the battery is replaced as soon as possible following a low battery

warning.

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 40

Appendix A – Troubleshooting

First thing to do:

It is important that you ensure you’ve got the latest version of firmware

(software that’s inside the DCA Pro instrument) and the latest version of PC

software. You can do this by connecting the unit to your PC and selecting the

“Help” menu and then click on “Check for Updates”.

It is possible that a firmware update and/or a PC software update will resolve

your problem.

Here’s a further guide to helping you with your DCA Pro if you’re having

problems:

Problem Possible Solutions

PC software always says

“Disconnected” even when

the DCA Pro is connected

and powered up.

Unplug USB, wait a few seconds and plug

back in.

Try a different USB socket on your PC.

Restart your PC.

Uninstall and then Re-install the software.

Unit displays

Boost timeout.

It is possible that your battery is in poor

condition. Replace with a new Alkaline

AAA battery.

Measured parameters don’t

agree with the component

datasheet.

Most semiconductors have very wide

tolerances and even identical transistor types

can show huge gain variation between them.

Characteristics shown in datasheets may be

specified at different test conditions

compared to the test conditions used by the

DCA Pro.

Much more help is available at www.peakelec.co.uk/content/support.html

Feel free to contact us for technical assistance. Our contact details are shown at

the end of this user guide.

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 41

Appendix B – Summary Technical Specifications

All values are at 25°C unless otherwise specified. Specifications subject to change.

Parameter Min Typ Max Note

Bipolar Transistors

Measurable current gain (hFE) range 2 32000 2

hFE accuracy (hFE<2000) ±3% ±5 hFE 2,8

hFE test voltage (V

CEO

) 3.0V 9.0V 2

hFE collector test current

4.75mA 5.00mA 5.25mA

Base current for VBE measurement 4.75mA 5.00mA 5.25mA

VBE accuracy ±1% ±0.006V 8

VBE resolution 3.0mV 6.0mV

VBE for Darlington identification 0.95V 1.00V 1.80V 3

VBE for Darlington (shunted types) 0.75V 0.80V 1.80V 4

VBE threshold for germanium 0.55V

Acceptable VBE 1.80V

Base-emitter shunt threshold

50kΩ 60kΩ 70kΩ

Acceptable collector leakage 1.5mA 6

Leakage current accuracy ±2% ±0.02mA

MOSFETs/IGBTs

Enhancement mode V

GS(ON)

range 0.0V 10.0V 5

Depletion mode V

GS(ON)

range -5.0V 0.0V 5

V

GS(ON)

accuracy ±2% ±0.01V 5

Drain current at V

GS(ON)

4.75mA 5.00mA 5.25mA

Drain-Source voltage at V

GS(ON)

3.5V 9.0V 5

Acceptable gate-source resistance

8kΩ

IGBT collector saturation threshold 0.40V 9

JFETs

Pinch-off V

GS(OFF)

range -10.0V 2.5V

Pinch-off drain-source current 2.5µA 5.0µA 10.0µA

Turn-on V

GS(ON)

range -9.0V 2.5V

Turn-on drain-source test current 4.75mA 5.00mA 5.25mA

VGS accuracy ±2% ±0.01V

Transconductance (gfs) range 99mA/V

gfs test drain current span 3.0mA to 5.0mA

gfs accuracy (<20mA/V) ±5% ±2mA/V

gfs accuracy (>20mA/V) ±10% ±5mA/V

VDS for I

DSS

measurement (VGS=0) 3.0V 3.25V

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 42

Summary Technical Specifications continued:

All values are at 25°C unless otherwise specified. Specifications subject to change.

Parameter Min Typ Max Note

Thyristors and Triacs

Gate trigger test current 8.0mA 10.0mA 12.0mA 7

Load hold test current 10.0mA 15.0mA

Diodes and LEDs

Diode forward test current 4.75mA 5.00mA 5.25mA

Diode forward voltage accuracy ±1% ±0.006V

Acceptable VF for a diode @ 5mA 0.15V

VF for LED identification 1.50V 4.00V

Zener Diodes

Zener voltage range at 5mA 1.8V 9.0V

Zener voltage range below 5mA 9.0V 12.0V

Zener diode test current 0.50mA 5.00mA 5.25mA

Voltage Regulators

Input test voltage range (IQ<3.0mA) 1.10V 10.0V

Input test voltage range (IQ<5.0mA) 8.0V

Quiescent current range (IQ) 0.00mA 5.00mA

Quiescent current accuracy ±2% ±0.02mA

Dropout voltage range (VDO) 0.00V 3.00V

Dropout voltage accuracy ±2% ±0.02V

Output voltage accuracy ±1% ±0.006V

Load test current 0.13mA 1.25mA

General Parameters

Peak test current into S/C -15.5mA 15.5mA 1

Peak test voltage across O/C -13.5V 13.5V 1

Short circuit threshold

5Ω 10Ω 20Ω

1

Battery type 1 x AAA, LR03, MN2400, Alkaline 1.5V

Battery voltage range 1.00V 1.50V 1.60V

Battery warning threshold 1.00V

USB current consumption 500mA peak active. ≤2mA sleep.

Dimensions (body) 103 x 70 x 20 mm

1. Between any pair of test clips.

2. Collector current of 5.0mA. Gain accuracy valid for gains less than 2000.

3. Resistance across reverse biased base-emitter > 60kΩ.

4. Resistance across reverse biased base-emitter < 60kΩ.

5. Load current of 5.0mA.

6. Collector-emitter voltage of 10.0V.

7. Thyristor quadrant I, Triac quadrants I and III.

8. BJT with no shunt resistors.

9. Load current typically 10.0mA.

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 43

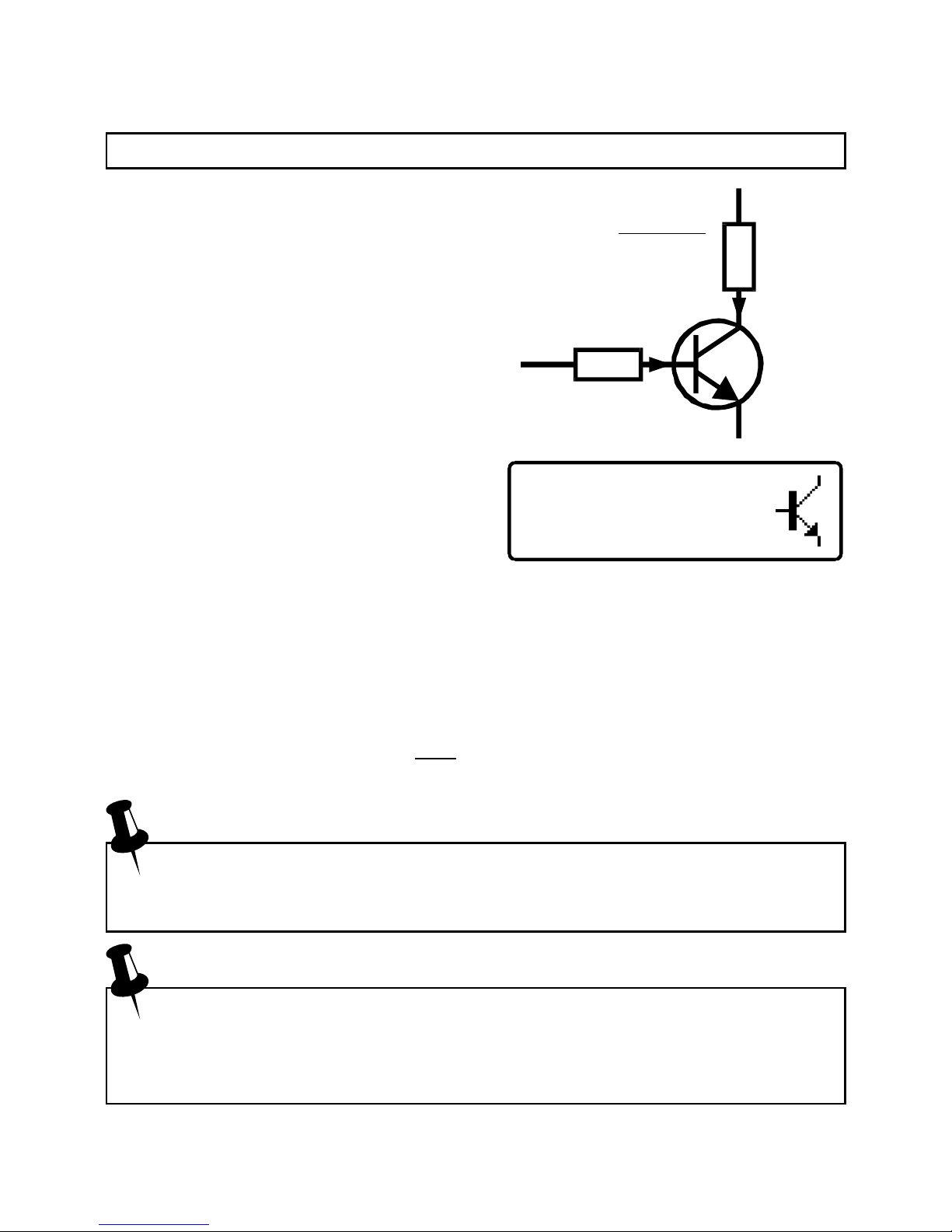

Appendix C – Analysis Test Circuits

The DCA Pro analyses components by applying signals to the

component under test while in a “test circuit”. The test circuits that the

DCA Pro uses to analyse various components are shown below.

These test circuits are presented here to assist in your understanding of

the test conditions that are possible when testing in standalone mode

and in the PC mode (for curve tracing etc).

Transistor Test Circuit

Example shown is for an NPN transistor. Polarities are reversed for

PNP devices.

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 44

JFET/MOSFET/IGBT Test Circuit

It’s important to note that the gate-source voltage can be driven

negative by making the source voltage drive higher than the gate

voltage drive. When this is done however, there is less voltage

available to be across the drain-source nodes and the load resistor.

Example shown is for an N-Channel JFET. Polarities are reversed for

P-Channel devices.

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 45

Diode Test Circuit

This test circuit is used for testing both the forward and reverse

characteristics of diodes. Reverse characteristics are particularly

useful for the testing of Zener diodes.

For the standalone mode, the voltage is automatically adjusted to

obtain a “target” current of 5mA. For Zener diodes that have a

breakdown voltage of more than about 9V, the target current of 5mA

cannot be obtained.

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 46

Voltage Regulator Test Circuit

The test circuit shown here is used for the analysis of voltage

regulators (positive regulators in this example). Note that the range of

regulator voltages supported will depend on the quiescent current (IQ).

A higher quiescent current will cause more voltage to be dropped

across the sense resistor and yield less voltage for the regulator itself.

Note also that some voltage regulators, particularly low dropout types

(LDO), are not stable when tested by the DCA Pro.

Atlas DCA Pro User Guide April 2015 – Rev 1.4

Page 47

Appendix D – Warranty Information

Peak Satisfaction Guarantee -

If for any reason you are not completely

satisfied with your DCA Pro within 14 days of purchase you may return the

unit to your distributor. You will receive a refund covering the full purchase

price if the unit is returned in perfect condition.

Peak Warranty

- The warranty is valid for 24 months from date of

purchase. This warranty covers the cost of repair or replacement due to defects

in materials and/or manufacturing faults. The warranty does not cover

malfunction or defects caused by:

a) Operation outside the scope of the user guide.

b) Unauthorised access of the unit (except for battery replacement).

c) Accidental physical damage or abuse.

d) Normal wear and tear.

Statutory rights unaffected. Claims must be accompanied by proof of purchase.

Appendix E – Disposal Information

WEEE (Waste of Electrical and Electronic Equipment),

Recycling of Electrical and Electronic Products

In 2006 the European Union introduced regulations (WEEE) for the collection

and recycling of all waste electrical and electronic equipment. It is no longer

permissible to simply throw away electrical and electronic equipment. Instead,

these products must enter the recycling process. Each individual EU member

state has implemented the WEEE regulations into national law in slightly

different ways. Please follow your national law when you want to dispose of

any electrical or electronic products. More details can be obtained from your

national WEEE recycling agency. If in doubt, you may send your Peak

Product to us for safe and environmentally responsible disposal.

At Peak Electronic Design Ltd we are committed to continual product development and improvement.

The specifications of our products are therefore subject to change without notice.

© 2012/2015 Peak Electronic Design Limited - E&OE

Designed and manufactured in the UK

www.peakelec.co.uk Tel. +44 (0) 1298 70012 Fax. +44 (0) 1298 70046

Loading...

Loading...