Peak MC-600H Installation And Service Manual

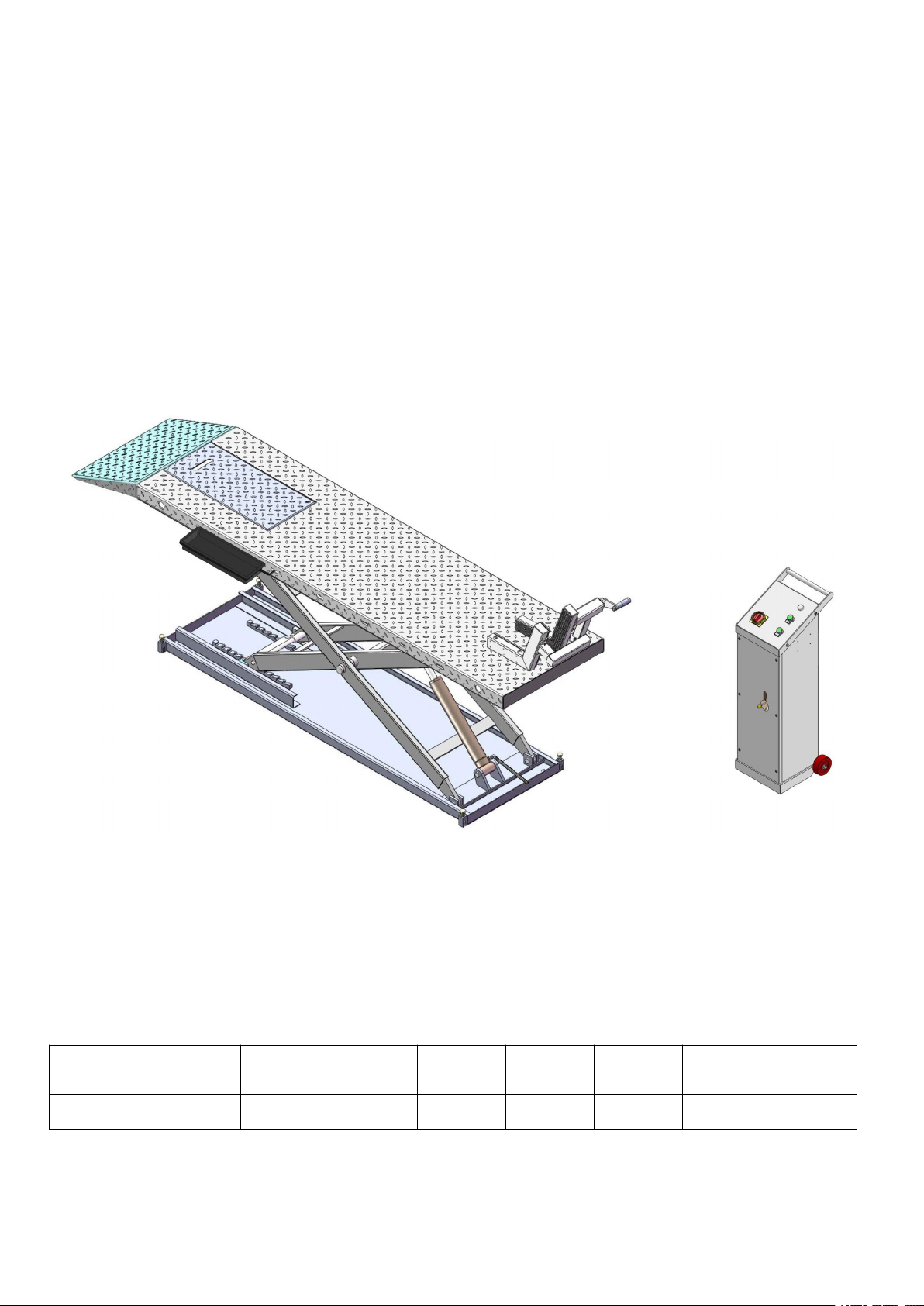

MC-600H

Motorcycle lift

CONTENTS

I. Product Features and Specifications…………………..................…….2

II. Installation requirement...…………………………..................……..…3

III. Steps of Installation...………………………….................…………..…4

IV. Exploded View………………………………………….....................….…..9

V. Test Run…….……………………………………..…….…..........................12

VI. Operation Instruction.…………………………................…..…….…...13

VII. Maintenance……………………………………..................….……….....14

VIII. Trouble shooting.……………………………….…................……….…15

IX. MC-600H parts list……..…………….………...................................….16

1

I .PRODUCT FEATURES AND SPECIFICATIONS

● Hydraulic direct-drive cylinders, designed and made on ANSI standard,

utilizing oil seal in cylinder

● Self-lubricating UHMW Polyethylene sliders and bronze bush

● Non-skid diamond platforms

● Automatic safety release system

● Optional: Width extension kit and platform extension kit

Model

Capacity

Lifting

Height

Lifting

Time

Overall

Length

Overall

Width

Minimum

Height

Gross

weight

Motor

MC-600H

600KG

1090mm

23s

2745mm

750mm

155mm

290kg

1.5HP

Fig.1

Motorcycle lift MC-600H:

MODEL MC-600H SPECIFICATION

2

II . INSTALLATION REQUIREMENT

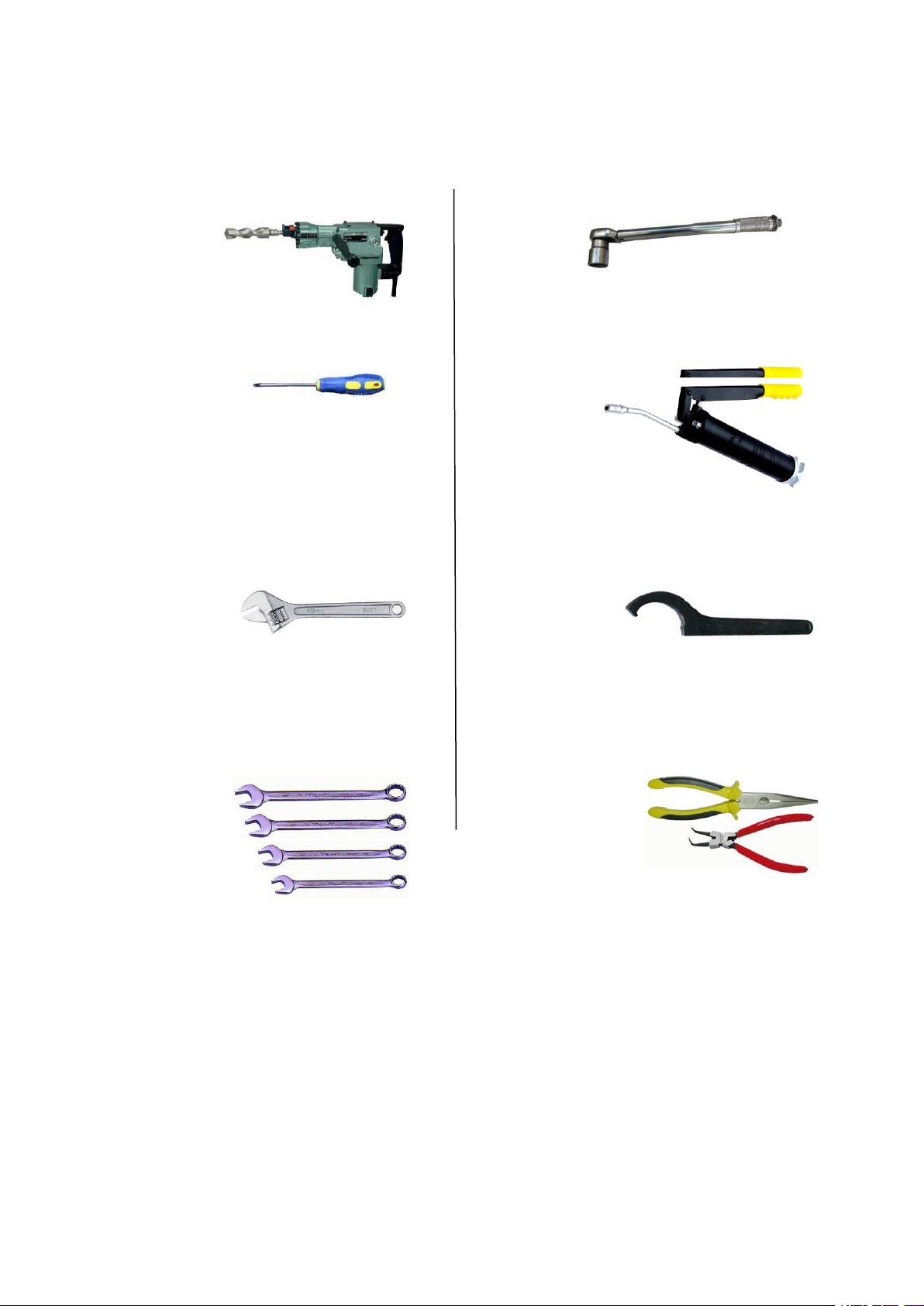

Fig.2

Pliers

Grease gun

Hook Spanner(40~42mm)

A. TOOLS REQUIRED

Rotary Hammer Drill (Φ19)

Screw

English Spanner (12")

Ratchet Spanner with Socket:(28

#

)

Wrench Set:(13

#

、15#、17#、19#)

3

B. SPECIFICATIONS OF CONCRETE

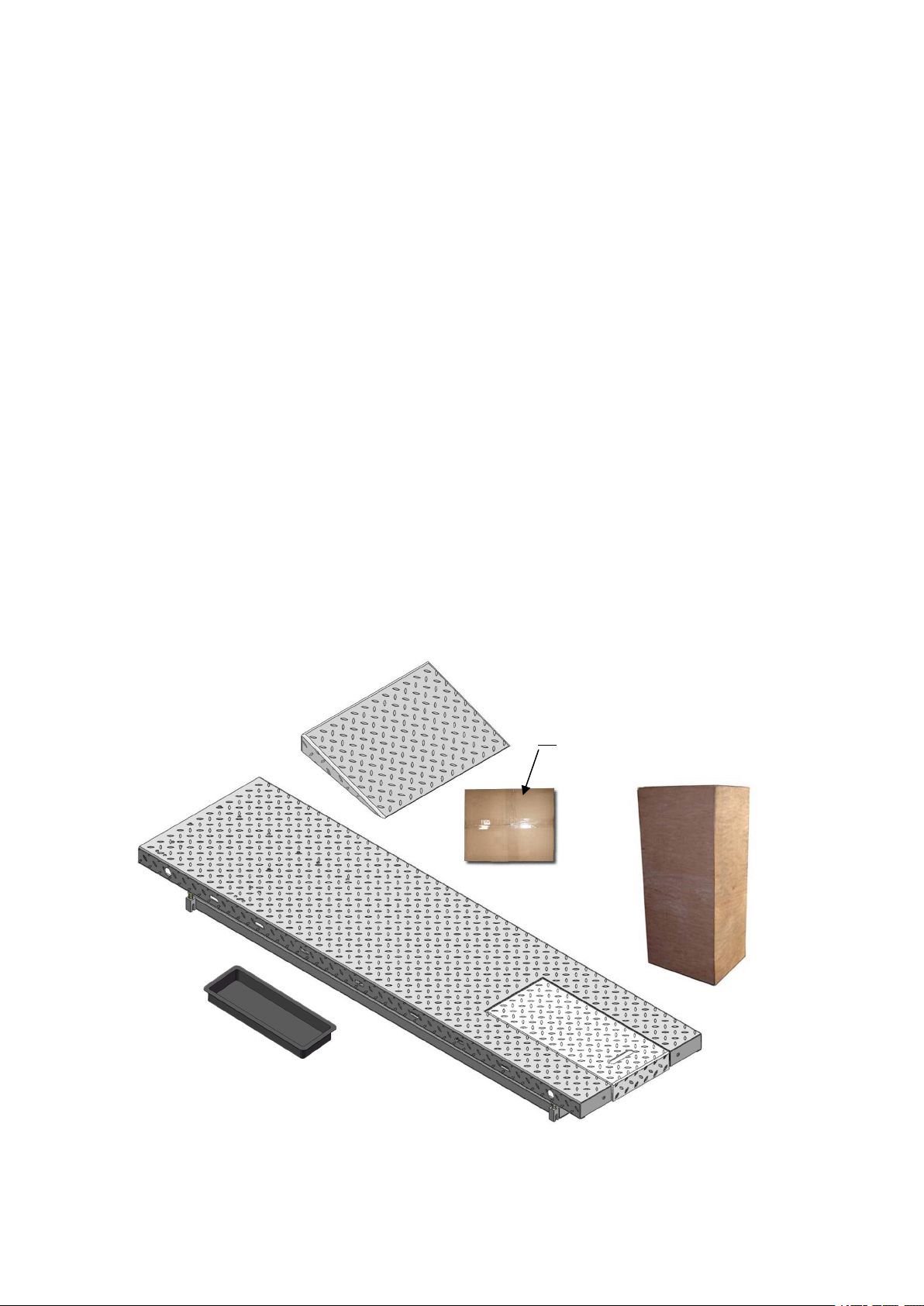

A. Check the parts before assembly to make sure all the parts are completed.

1. Packaged cargo( lift, drive-in ramp, Parts box, control cabinet). Move the parts

aside, open the outer packing and check the parts according to the shipment parts

list. see Fig.3

Fig.3

57

Specifications of concrete must be adhere to the specifications as

following. Failure to do so may result in lift and/or vehicle falling.

1. Concrete must be thickness 100mm minimum and without reinforcing steel bars,

and must be dried completely before lift installation.

2. Concrete must be of test strength 210kg/cm2minimum.

C. POWER SUPPLY

The power capacity must be more than 2.2kw, The source cable size must be

2.5mm² and in good condition of contacting with floor.

III.STEPS OF INSTALLATION

4

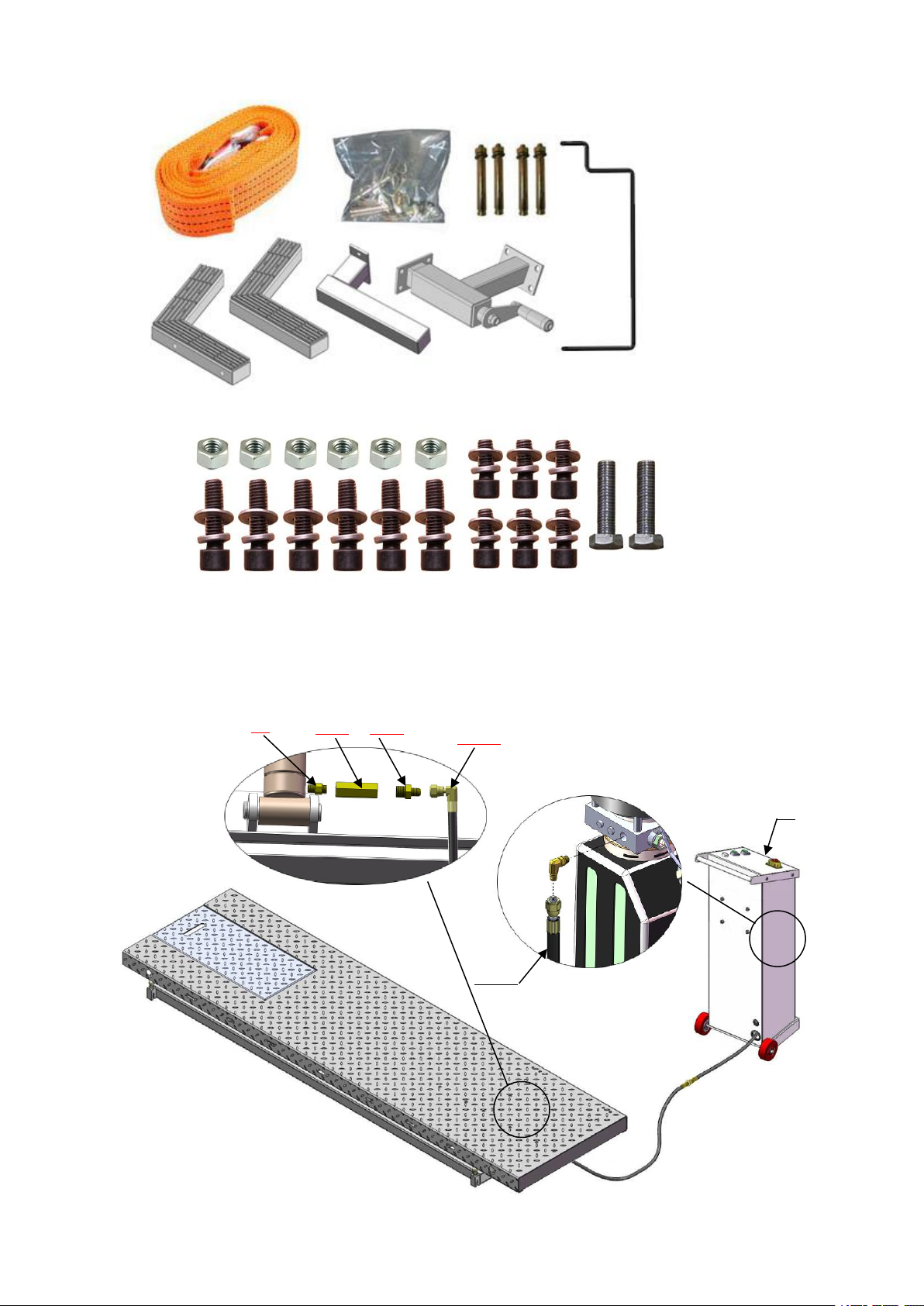

2. Open the parts box, check the parts according to the parts list (See Fig. 4).

Fig.4

Fig.5

Fig.6

53

53-12

51

51-1

51-2

53-12

3. Open the parts bag, check the parts according to the parts list (See Fig. 5).

B. Put the lift and control cabinet in good order and connect the oil hose, see

Fig.6

5

C. Install Electrical System

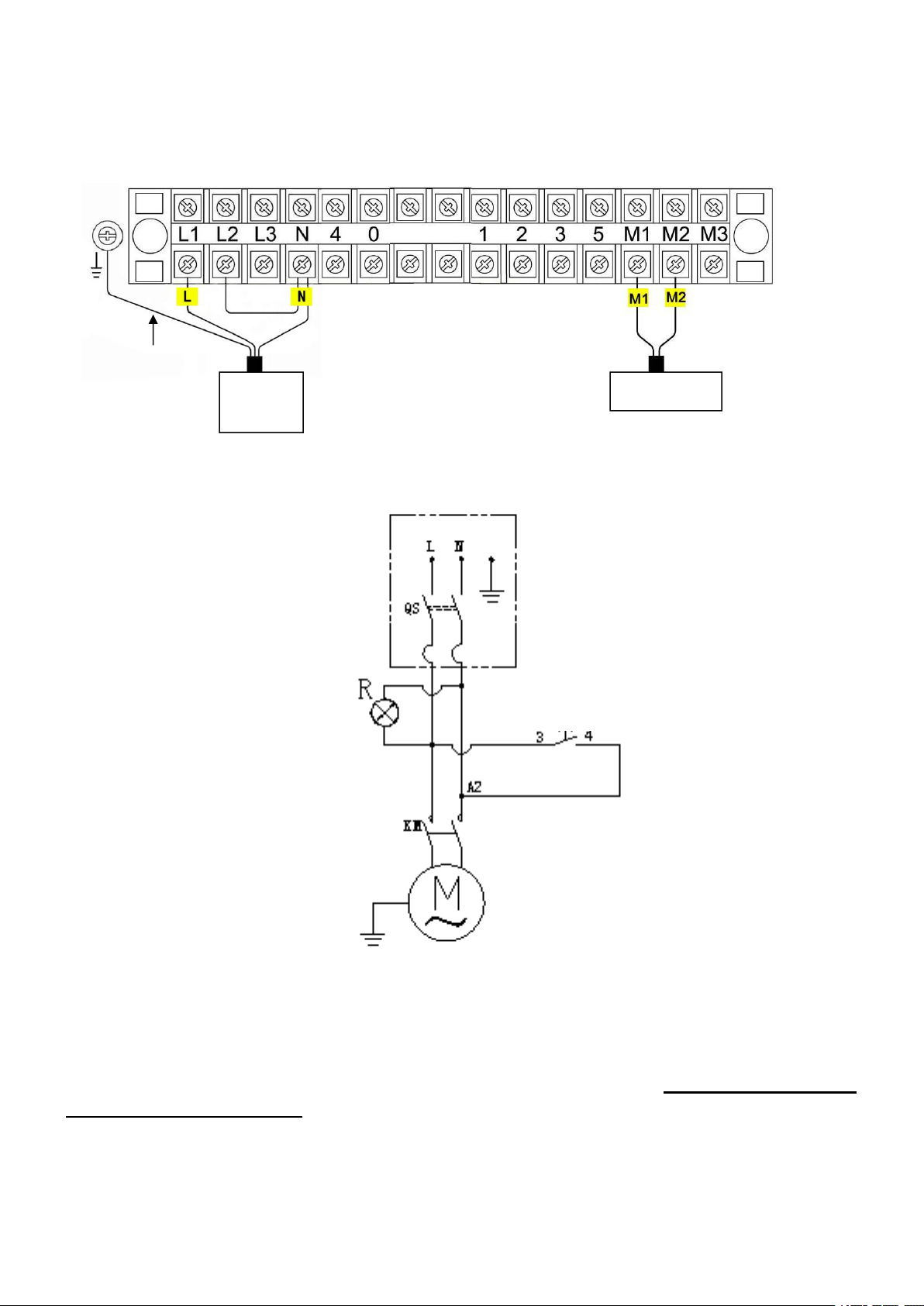

1. Connect the wire according to below diagram. ( Fig.7 )

Power

wire

Motor wire

Fig.7

Ground

Fig.8

3PH

Switch button

SB(UP)

2.2 Schematic circuit diagram(Fig.8)

D. Fastening all the oil hose fittings, fill the power unit with right amount

hydraulic oil ( in order to ensure the working life of hydraulic system and the

machine reach the best performance, please fill in the no.46 high quality

anti-wear hydraulic oil. )

E. Install adjustable fixing device. See Fig 9

Loading...

Loading...