PE PE-2015 Owners manual

~~~"'-~~~r'O~

-

~

~~ .~

~ ~.~

!;:.~

ti

r

. ~,

U '_"~1'- ~

,~~- - --~'-_.'-', #. & ,~ -"-'

L ~,

b-

~

~"!!

r~

iJl '::i

I

\.ti

...

~

Technical

Information

i'" ~ ." ~~ =

J

",.

,.

~~=

"'"

~. '\

~l

f'~

"

-,."

~

..

,.-

Service Instructi.efmis

?HiFi AutoQ1!~lliie 'urntable

"

.'

,'-,

"

- '

"\

PE 20i,S'

P;Ii:~è12 == PE 2055

~~

--

- - Content'W

Technical Specifications

Functional Description

Page

2

3- 6

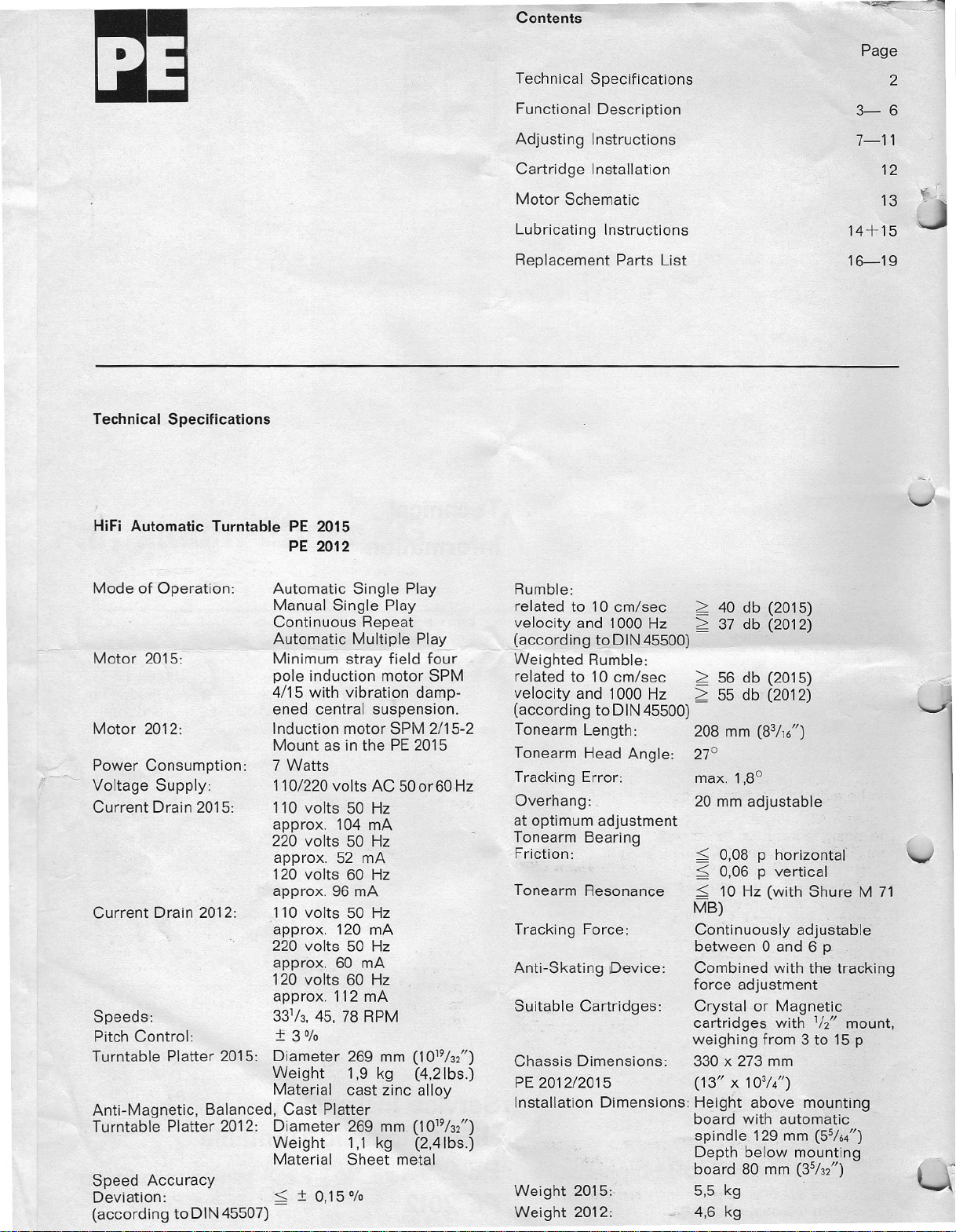

Technical Specifications

HiFi Automatic Turntable

Mode of-Operation:

"-' .., ;...c.~.. ~ """ ~ - ~~.. '.- " ~~ -

tVlotor2015:-- . Minimum stray field four

Motor 2012:

Power Consumption:

I~ Voltage Supply:

Current Drain 2015:

Current Drain 2012:

Speeds:

Pitch Control:

Turntable Platter 2015:

Anti-Magnetic, Balanced, Cast Platter

Turntable Platter 2012: Diameter 269 mm (101%2")

Speed Accuracy

Deviation: < ::!:0,15 %

(according to DIN45507)-

PE 2015

PE 2012

Automatic Single Play

Manual Single Play

Continuous Repeat

Automatic Multiple Play

pole induction motor SPM

4/15 with vibration damp-

ened central suspension.

Induction motor SPM 2/15-2

Mount as in the PE 2015

7 Watts

110/220volts AC 500r60Hz

110 volts 50 Hz

approx. 104 mA

220 volts 50 Hz

approx. 52 mA

120 volts 60 Hz

approx. 96 mA

J10 volts 50 Hz

approx. 120 mA

220 volts 50 Hz

appro0. 60 mA

120 volts 60 Hz

approx. 112 mA

33113.45, 78 RPM

:f3%

Diameter 269 mm (1019132")

Weight 1,9 kg (4,2Ibs.)

Material cast zinc alloy

Weight 1,1 kg (2,4Ibs.)

Material Sheet metal

Adjusting Instructions

Cartridge Installation

Motor Schematic

Lubricating Instructions

Replacement Parts List

Rumble:

related to 10 cm/sec > 40 db (2015)

velocity and1 000 Hz > 37 db (2012)

(accÇ>rding !9.DIN~5500)

~~ .'.' ...~,

. Weighted Rumble:

related to 10 cm/sec > 56 db (2015)

velocity and 1000 Hz > 55 db (2012)

(according to DIN45500)

Tonearm Length: 208 mm (8311/')

Tonearm Head Angle: 27°

Tracking Error: max. 1,8°

Overhang: 20 mmadjustable

at optimum adjustment

Tonearm Bearing

Friction:

~,

Tonearm Resonance

Tracking Force:

Anti-Skating Device:

Sl:Jitable Cartridges:

< 0,08 p norizontal'

< 0,06 P vertical

< 10Hz (with Shure 'M 71

MB)

Continuously adjustable

between 0 and 6 p.

Combined with the tracking

force adjustment

Crystal or Magnetic

cartridges with 112" mount,

weighing from 3 to 15 p

Chassis Dimensions:' 330 x 273 mm

PE 2012/2015 ("3" ~ 10%")

Installation Dimensipns: Heigl1t above mounting

.,.".

Weight 20.15:-

Weight 2012:

- board with automatic

spindie 129 mm (5%/')

Depth bel()w mounting

board 80 mm (3%2")

5,5 kg

4,6 kg

7-11

12

f'

13

.(1

14+15

16-19

'"-"

v

I

, -~

u

(1"':

'--'\1

~

1

~

~

"\,

t"

~~,

~

~

~,

,

-,

'

1

7

B

46

1

I 89

20

23

28

A 132

~

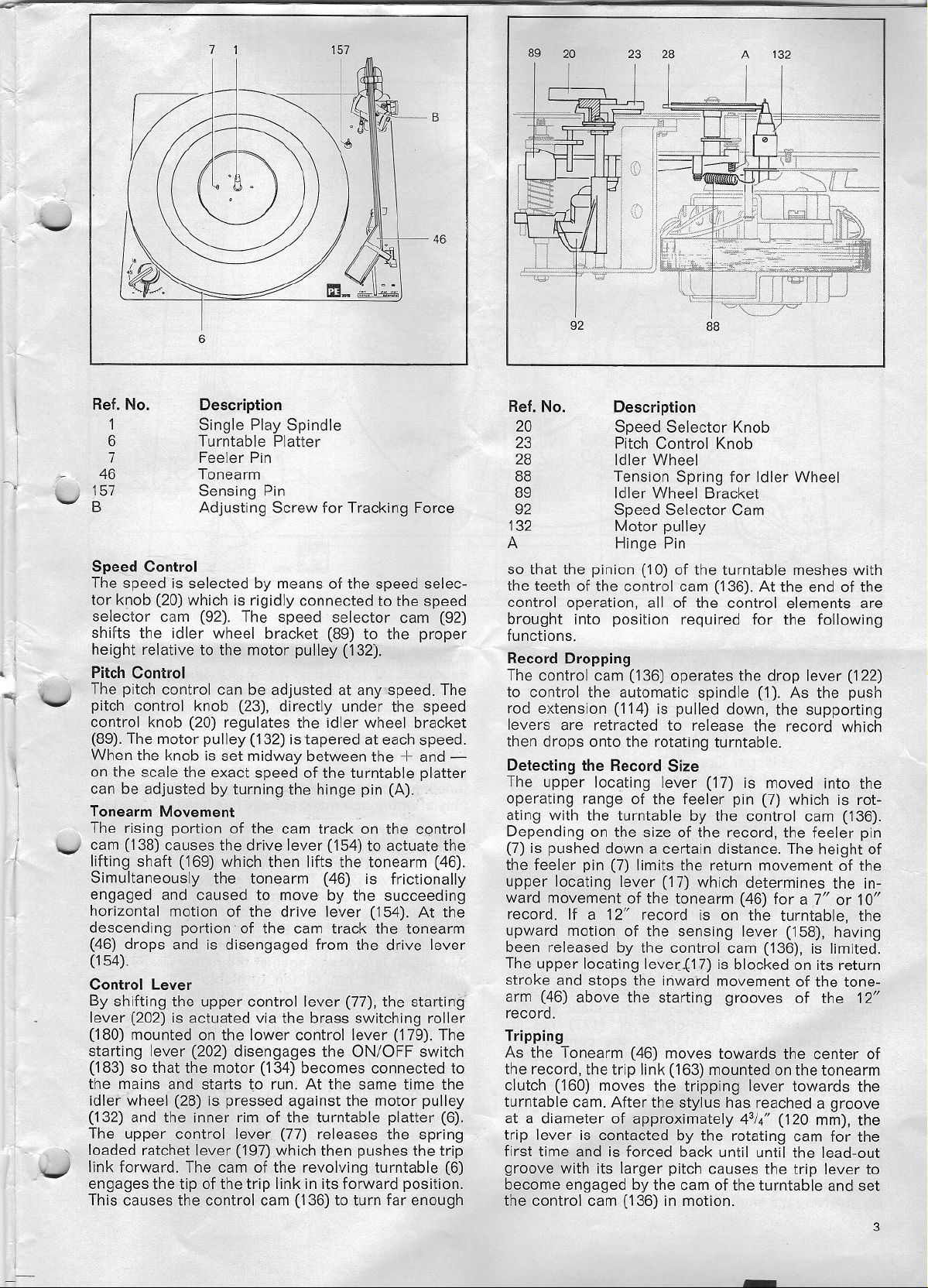

Ref. No.

l

1

6

7

j

'f

",

.,

~~

r 46

'\.} J57

B

Sp~~d CO'1trol

The speed is selected by means of the speed selec-

'f'

1

'" A~, PitchControl

.

. ,The pitch contral can be adjusted at any~speed. The

0

I

tor knob

seleêtor cam (92). The speed selector cam

shifts the idler wheel bracket (89) to the praper

height relative to tbe motor,pujJey

.. pitch control knob (23), directly under the speed

control knob (20) regulates the idler wheel bracket

(89). The motor pulley (132) is tapered at each speed.

When the knob is set midway between the + and -.:...

on the scale the exact speed of the turntable platter

can be adjusted by tuçnin!):Jthe hinge pin (A).!:,..'

Tonearm Movement

. The rising portion of the cam track on the egntrol

V cam (138) causes the dr[ve"lever (154) to actuatethe

lifting shaft (169) whiph then lifts the tonearm (46).

6

Description

Single PlaySpindle

Turntable Platter

Feeier Pin

Tonearm

Sensing Pin

Adjusting Screw for Tracking Force

(20) which is rigidly connected to the speed

~1.32h' "..' ~

..,

Simultaneously the Jonearm (46) is frictionally

engaged and caused to move by the succeeding

'"

horizontal motion of the drive lever (154). At the

descending portion' of the cam track the tonearm

(46) drops and is disengaged fram the drive lever

(154):

Control Lever

~

Lu

1

By shifting the upper control lever (77), the starting

(202) is actuated vi,a the bra&s switching roller

lever

(180) mounted on the lower contral lever (179). The

starting lever

(183) so that the motor (134) becomes connected to

the mains amd starts to run. At the same time the

idler\vheer (28) is,<pressed against the motor pulley

(132) and the inner rim of the turntable platter (6).

Toe upper control lever (77) releases the spring

loaded ratchet lever (197) which then pushes the trip

link forward. The cam of the revolving turntable (6)

engages the tip of the trip link in itsforward position.

This causes the contra I cam (136) to turn far enough

(202) disèngages the ON/OFF switch

(92)

92 88

Ref. No. Description

20 Speed Selector Knob

23 Pitch Contra I Knob

28 Idler Wheel

88 Tension Spring for Idler Wheel

89 Idler Wheel Bracket

92 Speed SelectorCam

132 Motor pulley

A Hinge Pin

so that the pinion

the teeth of the control

control operation, all of the control elements are

brought into position required for the following

functions.

Record Dropping

The contral cam (136) operates the drop lever (122)

to control the automatic spindie (1). As the push

rod extension (114) is pulled doyvn, the supporting

levers are retracted to release the record which

then draps onto the rotating turntable.

Detecting the Record Size

1he upper locating lever

operating range of the feeier pin (7) which is rot-

ating with the turntable by the contra I cam (136).

(10) of the turntable meshes with

cam (136). At the end of the

(17) is moved into the

Depending on the size of the record, the feeier pin

(7) is pushed down a certain distance. The height of

the feeier pin (7) limits the return movement of the

upper locating lever (17) which determines the in-

ward movement of the tonearm (46) for a)" or 10"

record. If a 12" record is on the turntable, the

upward motion of the sensing lever (158), having

been released by the control cam (136), is limited.

The upper locating leve(.~l:ZJ is blocked on its return

stroke and stops the iriwärd movement of the tone-

arm (46) above the starting graoves of the 1"2"

record.

Tripping

As the Tonearm

the record, the trip link (163) mounted on the tonearm

clutch (160) moves the tripping lever towards the

turntable cam. Af ter the stylus has reached a graove

at a diameter of ÇlPproximately 4%" (120 mm), the

trip lever is contacted by the rotating cam for the

first time ~l1\d is forced back until until the lead-out

groove with its larger pitch causes the trip lever to

become engaged by the cam of the turntable and set

tAe control cam (136) in motion.

(46) moves towards the center of

3

r~

-

'I.

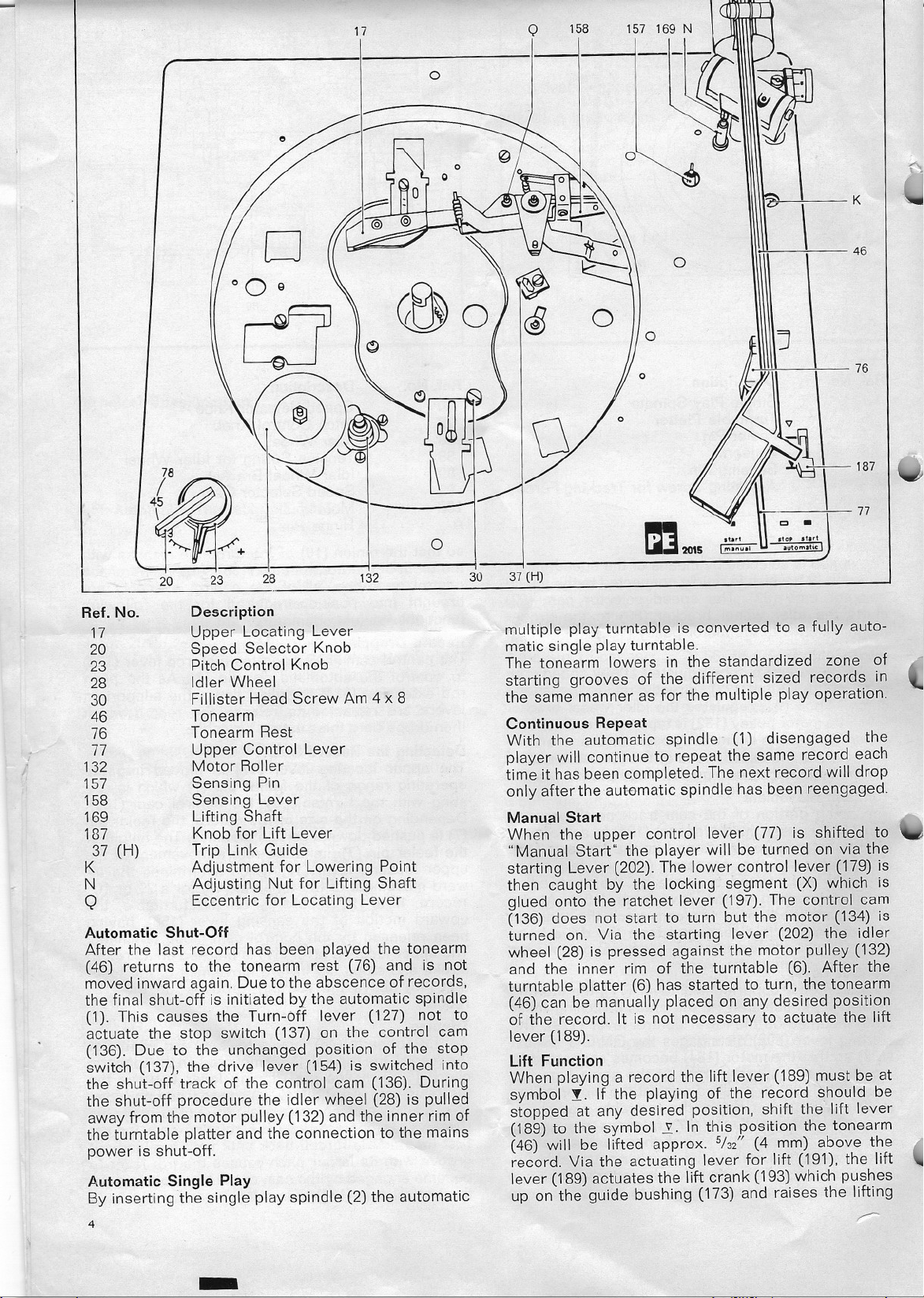

17

158 157 169 N

Q

0

0

0

~

~ i K I ~

- 46

0

0

0

<.)

\

0

+c 20

Ref. ~o.

17

20

23

28

30

46

76

i'"

.,

""

77

132

157

158

169

187

37 (H)

K

N

Q

Automatic Shut-Off

After the last record has. been played the tonearm

(46) returns to the tonearm rest (76) and is not

moved inward again. Due to the abscence of records,

the final shut-off is initiated by the automatic spindie

(1). This causes the Turn-àff lever (127) not to

actuate the stop switch (137) on the control cam

(136). Due to the unchanged position of the stop

switch (137), the drive lever (154) is switched into

the shut-off track of the control cam (136). During

the shut-off procedure the idler wheel (28) is pulled

away from the motor pulley (132) and the inner rim of

the turntable platter and the connection to the mains

power is shut-off.

Automatic Single Play

By insertingthe single play spindie (2) the automatic

4

23

Description

Upper Locating Lever

Speed Selector Knob

Pitch Control Knob

Idler Wheel

Fillister Head Screw Am 4 x 8

Tohearm

Tonearm Rest

Upper Control Lever

Motor Roller

Sensing Pin

Sensing Lever

Lifting Shaft

Knob for Lift Lever

Trip Link Guide

Adjustment for Lowering Point

Adjusting Nut for Lifting Shaft

Eccentric for Locating Lever

28

132

j

30

37eH)

cC--o"multipleplay turntable is converted to a fully auto-

matic single play turntable.

The' tonearm lowers in the standardized zone of

starting grooves of the different sized records in

the same manner as for the multiple play operation.

Continuous Repeat

With the automatic spindie' (1) disengaged the

player will continue to repeat the same record each

time it has been completed. The next record will drop

only after theautomatic spindie has been reengaged.

Manual Start €\

When the upper control lever e77) is sfiifted to.,

"Manual Start" the player will be turned on via the -

starting Lever (202). The lawer control lever (179) is

then caught by the locking segment (X) which is

glued onto the ratchet lever (197). The control cam

(136) does not start to turn but the motor (134) is

turned on. Via the starting lever (202) the idler

wheel (28) is pressed against the motor pulley (132)

and the inner rim of the turntable (6). Af ter the

turntable platter (6) has started to turn, the tonearm

(46) can be manually placed on any desired position

of thè record. It is not necessary to actuate the lift

lever (189).

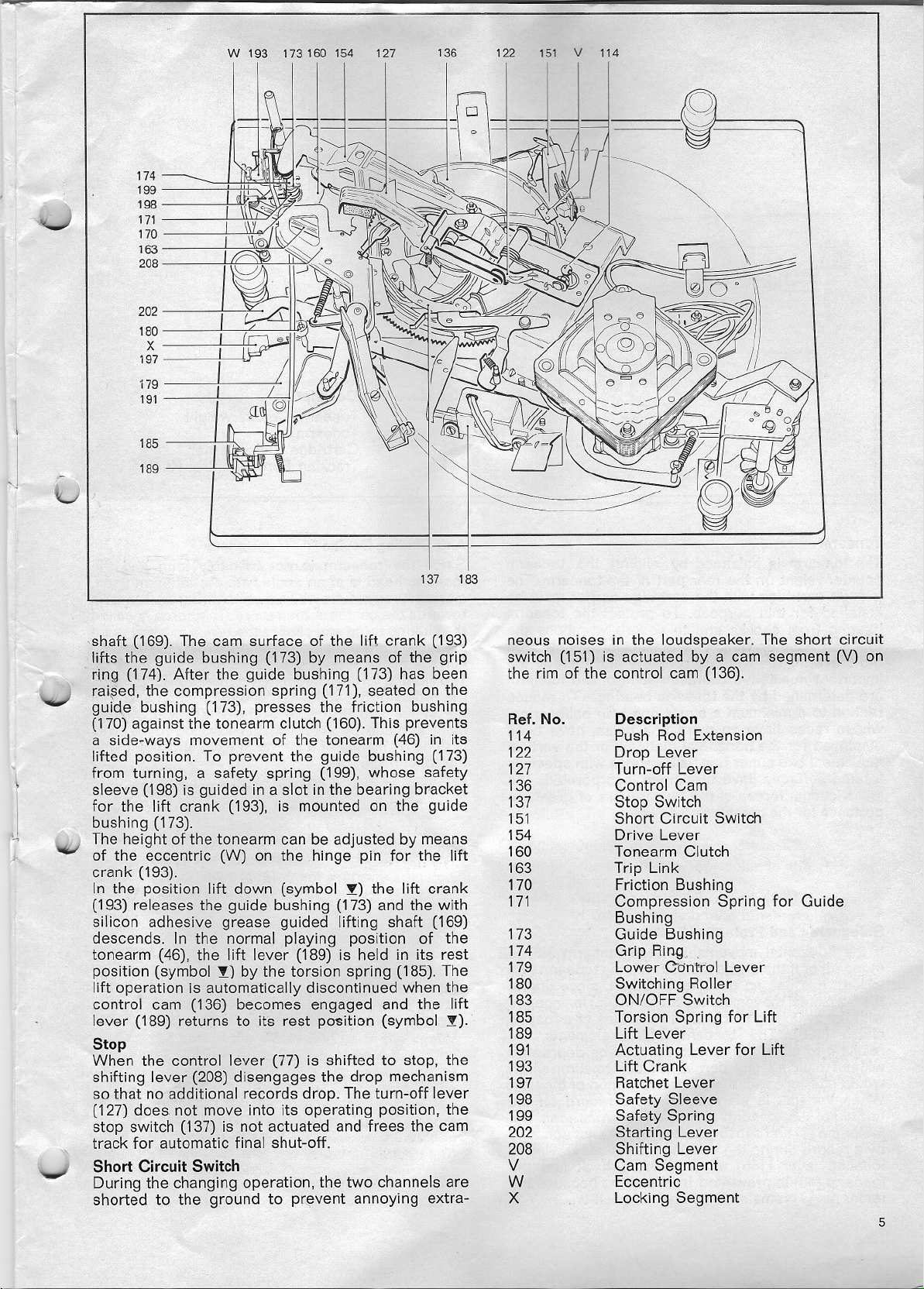

Lift Function

When playing a record the lift lever

symbol y.. If the playing of the record should be

stopped at any desired position, shift the' lift lever

(189) to the symbol .Y. In this position the tonearm

(46) will be lifted approx. 513/' (4 mm) above the

record. Via the actuating lever for lift (191), the lift'

lever (189) actuates the lift crank (193) which pushes

up on the guide bushing (173) and raises the lifting

~ 2015

"0' .t...

.utom.'icI

(189) must be at

r-

(

,

-

'"

""J

~

~r:

'.---....

,"""'"

q

~

~'

,r

'k

185

t- -,

i

101/

189

'"

..

"

l'

1_,\

+~

}

~

..

V Short Circuit Switch

'$haft (199). The cam surface of the lift crank (19,9)

li,ftt$,the guide bushing (173) by means of the grip

riJI1i (174). After the guide bushing (173) has been

ra~ed, the compression spring (171), seated on the

gUiè\e bushing (173), presses the friction bushing

(170) against the tonearm clutch (160). This prevents

a side,ways movement of the tonearm (46) in. its

lifted position. T0 prevent the guide bushing (173)

fram turning, a safety spring (199), whose safety

sleeve (198) is guided in a slot in the bearing bracket

for the lift crank (193), is mounted on ?-the guide

"" . bushing (173). . ,

\.J The height of the tonearm can be adjusted by means

. of the eccentric (W) on the .hinge pin tor the lift

crank (193).

In the position lift down (symbol y) the lift crank

(193) releases the guide bushing (173) and the with

silicon adhesive grease guided lifting shaft (169)

descends. In the normal playing position of the

tonearm (46), the lift lever (189) is held in its rest

position (symbol YJ by the torsion spring (185). The

lift operation is automatically discontinued when th~

contral cam (136) becomes engaged and !he lift

lever (189) returns to its rest position (symool Y). .

Stop

When the contral lever (77) is shifted to stop, the

shifting lever (208) disengages the drop mechanism

so that no additional record,s drop. The turn-off lever

(127) does not move into its operating position, the

stop switch (137) is not actuated and frees the cam

track for automatic final shut-off.

'<t.

During thechanging operation, the two channels are

shorted to the ground to pr~vent annoying extra-

137

183

neous noises in the loudspeaker. The short circuit

switch (151) is actuated bya cam segr;neQt~V) on

the rim of the control cam (136).

Ref. No.

114

122

127

136

137

151

154

160

163

170

171

173

174

179

180

183

185

189

191

193

197

198

199

202

208

V

W

X

Description

Push Rod Extension

Drop Lever

Turn-oft Lever

Control Cam

Stop Switch

Short Circuit Switch

Drive Lever

Tonearm Clutch

Trip Link

Friction Bushing

Compression Spring for Guide

Bushing

Guide Bushing

Grip Rin{J,

Lower c-dn1:r"olLever

Switching Roller

ON/OFF Switch

Torsion Spring forLift

Lift Lever

Actuating Lever for Lift

Lift Crank

Ratchet Lever

SafetySleeve

Safety Spring

Starting Lever

Shifting Lever

Cam Segment

Eccentric

Locking Segment

5

~

--- -- 'c- c_--

- ~-r

'- 43

- 61

51

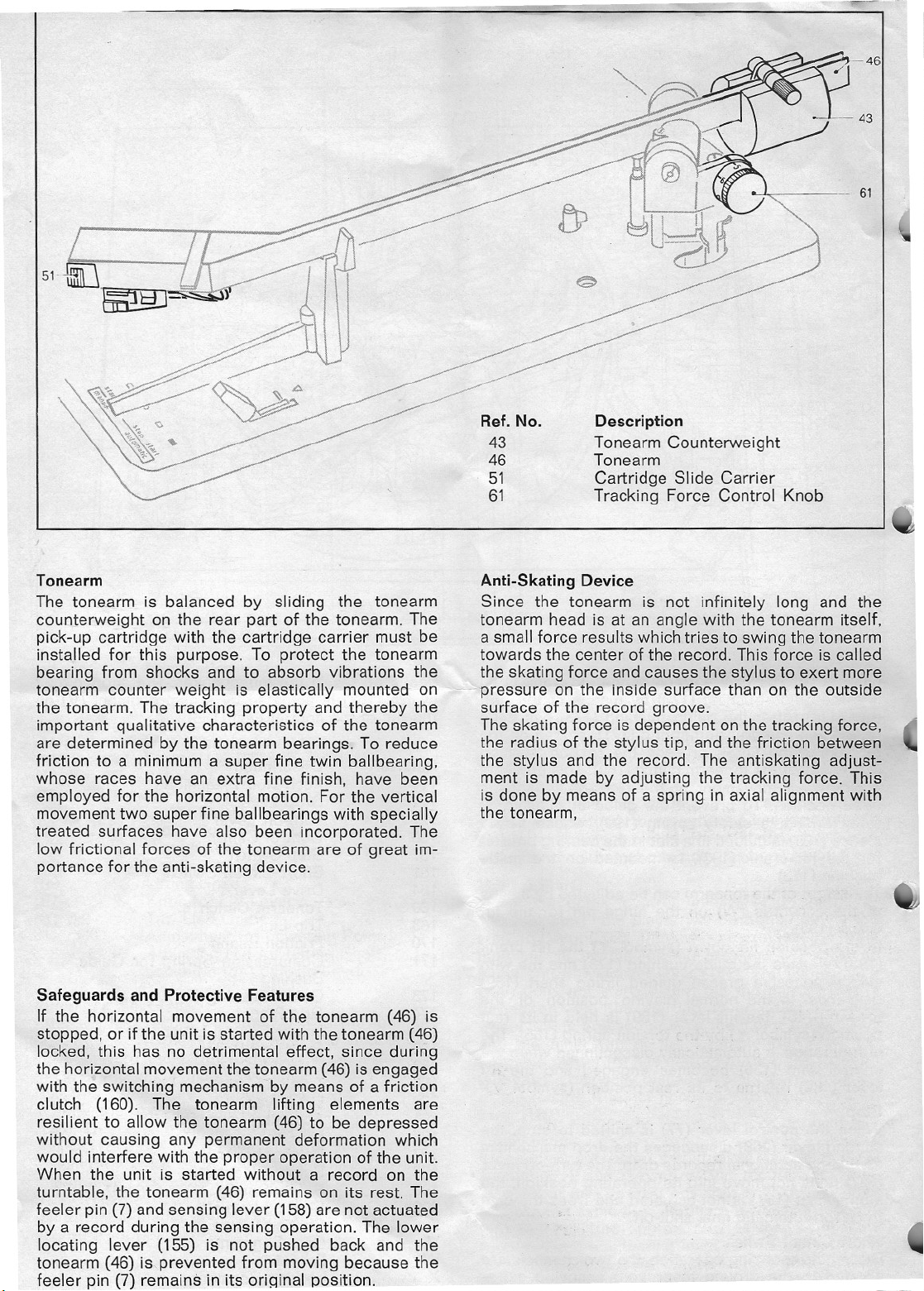

Tonearm

The tonearm is balanced by sliding the tonearm

counjerweight on the rear part of the tonearm. The

pick-up cartridge with the cartridge carrier must be

installed for this purpose. To protect the tonearm

bearing from shocks and to absorb vibrations the

tonearm counter weight is elastically mounted on

the tonearm. The tracking property and thereby the

important qualitative characteristics of the tonearm

are determined by the tonearm bearings. To reduce

friction to a minimum a super fine twin ballbearing,

whose races have an extra fine finish, have been

employed for the horizontal motion. For the vertical

movement two super fine ballbearings with specially

treated surfaces have also been incorporated. The

low frictional forces of the tonearm are of great im-

portance for the anti-skating device.

JY

~ ---

---

~

Ref. No.

43

46

51

61

Anti-Skating Device

Since the tonearm is not infinitely long and the

tonearm head is at an angle with the tonearm itself,

a smal Iforce results which tries to swing the tonearm

towards the center of the record. This force is called

the skating force and causes the stylus

~'pressure onPthe inside surface than on the outside

surface of the record groove.

The skating force is dependent on the tracking force,

the radius of the stylus tip, and the friction between

the stylus and the record. The antiskating adjwste

ment is made by adjusting the tracking force. This

is done by means of a spring in axial alignment with

the tonearm,

Description

Tonearm Counterweight

Tonearm

Cartridge Slide Carrier

Tracking Force Control Knob

to exert more

I1 Q

Q

I

I

~

Safeguards and Protective Features

If the horizontal movement of the tonearm

stopped, or if the unit is started with the tonearm

locked, this has no detrimental effect, since during

the horizontal movement the tonearm

with the switching mechanism""by means of a friction

clutch (160). The tonearm lifting elements are

resilient to allow the tonearm (46) to be depressed

without causing any permanent deformation which

would interfere with the proper operation of the unit.

When the unit is started without a record on the

turntable, the tonearm (46) remains on its rest. The

feeier pin (7) and sensing lever (158) are not actuated

by a record during the sensing operation. The lower

locating lever (155) is not pushed back and the

tonearm (46) is,prevented from moving because the

feeier pin (7) remains in its oriÇJinal position.

(46) is engaged

(46) is

(46)

~

~

-

Loading...

Loading...