Page 1

Electron Beam Energy Transfer

The transfer of energy from the electron beam into material is specified completely by

four parameters:

Absorbed dose

Depth of penetration

Uniformity

Throughput

Absorbed Dose

Absorbed Dose is defined as the amount of energy deposited into a specified mass of material.

The unit of absorbed dose is the kilogray, defined as the number of joules (J) of energy

deposited into 1 kilogram of matter. An older, but frequently used unit, is the megarad (Mrad).

1kGy = 1kJ/kg

1Mrad = 10kGy = 10kJ/kg

At a fixed electron accelerating voltage, the dose is directly proportional to the electron beam

current. Typical values of the dose needed for practical applications are:

Drying/curing of inks and coatings 15-30 kGy

Crosslinking of plastic film 25-150 kGy

Sterilization of medical products 7.5-35 kGy

© 2012 PCT Engineered Systems LLC. All Rights Reserved

Page 2

Depth of Penetration

Dose Uniformity

Dose uniformity is a direct function of the electron beam uniformity. It is specified as a

percentage deviation from the average value, e.g. 20 kGy 10%. In general, BroadBeam

processors provide uniformity between 10% and 5%; many applications can tolerate

variations of 20% or more.

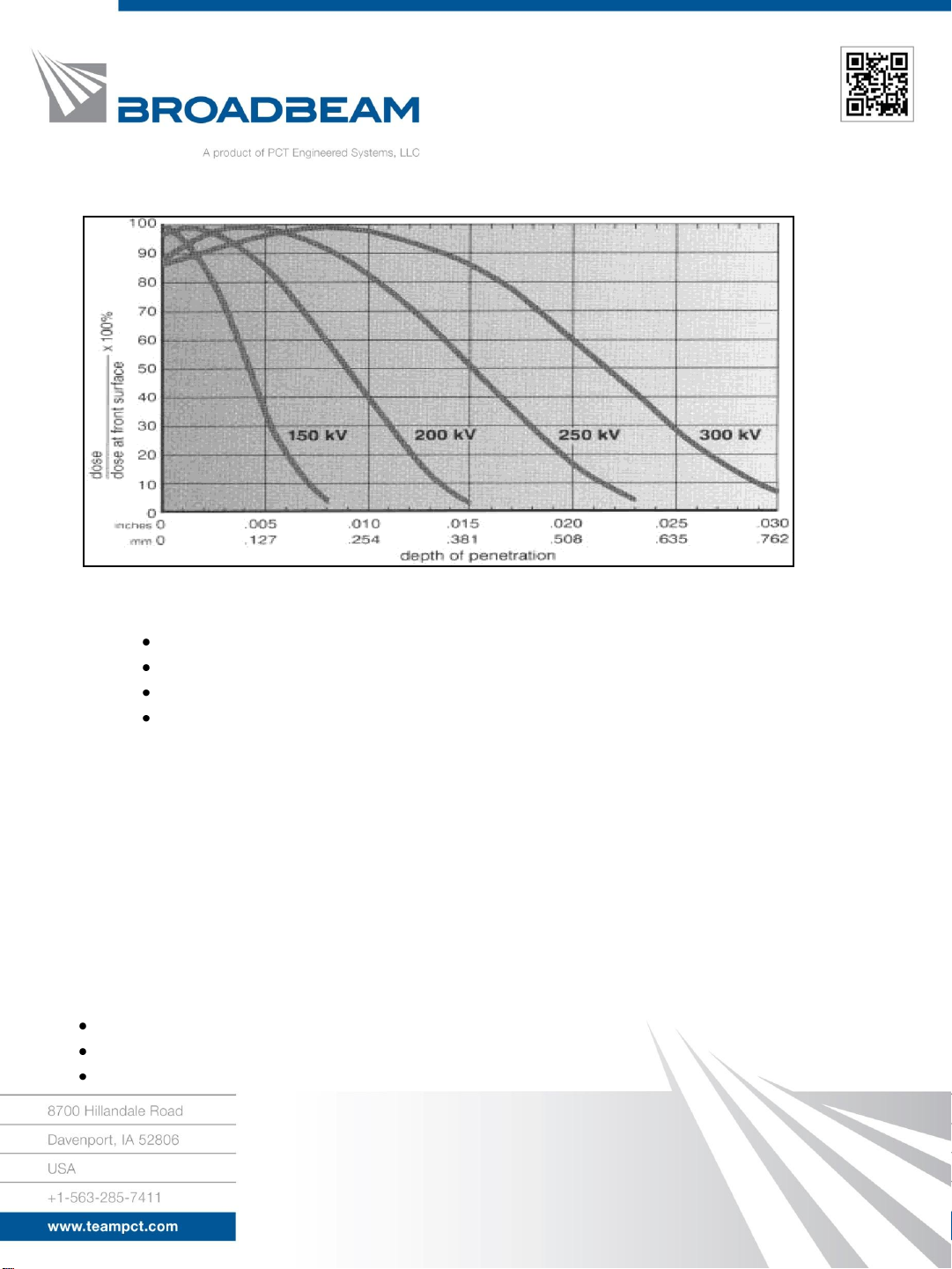

Penetrating power of the electron beam is related to the accelerating voltage and the density of

the processed material. Higher voltage causes deeper penetration, and denser material reduces

the depth of penetration. The Depth Dose Curves shown in the figure are convenient aids for

estimating the penetration depth. These curves relate the dose, normalized to the dose received

by the surface of the product, to the depth of penetration in a material with mass density equal

to that of water, i.e. p = I g/CM3. Penetration into materials of different density can be

estimated by multiplying the penetration depth, found from the normalized curves, by the ratio

of the density of water to the density of the material. For example, a 200kV beam will have a

50 percent dose point at 0.009 inches (.228 mm) in water and at 0.0045 inches (0.114 mm) in a

material twice as dense (p = 2 gm/cm3).

Throughput

Throughput is a measure of the energy deposition rate and relates directly to the amount of

material that can be processed within a given time interval. It is measured in kilogray-meters

per minute, abbreviated kGyMPM, megarad-feet per minute (MRFPM) or megarad-meters per

minute (MRMPM). A BroadBeam processor rated at 3,000 MRFPM can provide a dose of 3

Mrad when the web speed is 1,000 fpm, or 5 Mrad at 600 fpm, etc. The processor automatically

adjusts the beam intensity as the web speed changes so that the dose remains constant.

© 2012 PCT Engineered Systems LLC. All Rights Reserved

Loading...

Loading...