Page 1

EB Technology for Narrow Web Systems

Web/Press Width

Up to 400 mm

Press Speed

Up to 100 mpm (30 kGy dose)

EB Voltage Range

90 to 180 kV

Electron Beam (EB) technology has been used in commercial printing and converting

applications for more than 25 years. It has been proven to be safe, reliable and effective. EB

systems harness the power of electrons to provide efficient curing of inks, coatings and

adhesives with little or no substrate heating.

Traditionally EB systems have been an option available only to large or complex web setups.

This is no longer the case: the innovative minds at PCT Engineered Systems have created an

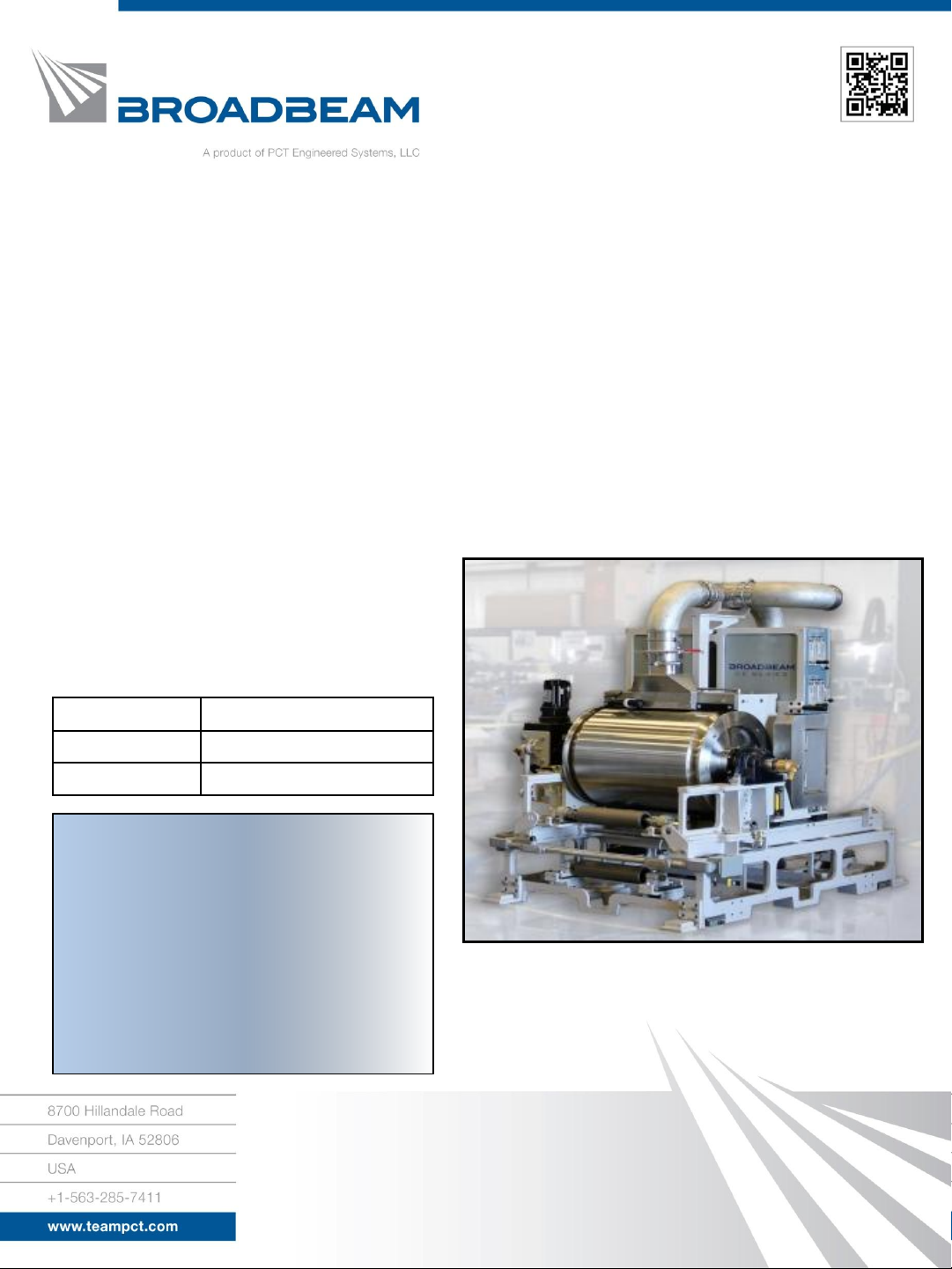

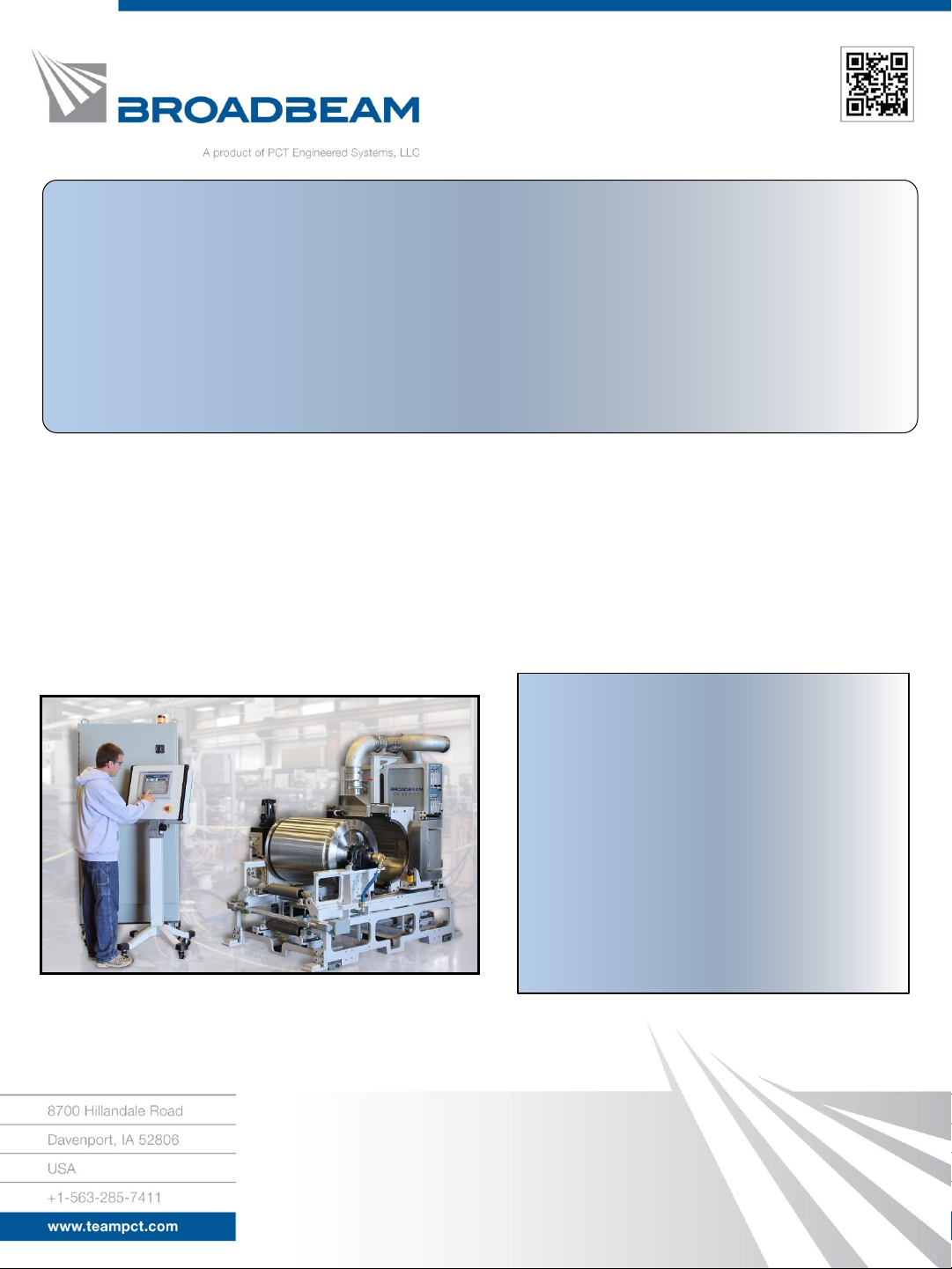

EB system that is superbly suited for narrow web installations. By combining the compact

footprint of a Comet E-beam emitter with PCT’s patented Integrated Shield Roll, the resulting

solution extends several powerful benefits of EB to narrow web printers, including:

• Stable Web Support

• Web Temperature Control

• Inerting Volume Minimization

• Easy Access

• Small Footprint

Narrow Web EB System Specifications

Air, heat-set and ultraviolet (UV) curing

technologies have long been the only

available solutions for narrow web

printing systems.

With the introduction of EB technology

as a viable solution in such settings,

companies need to reevaluate their

alternatives for optimizing their evolving

printing operations.

Narrow Web System Electron Beam Processor

© 2012 PCT Engineered Systems LLC. All Rights Reserved

Page 2

Is EB Curing Right For Your Business?

Situations where EB curing provides the most impactful results include:

• The curing of thick and/or high density ink layers is needed

• Supplemental curing of UV inks is required

• Food products or materials must be packaged with no potential for

photoinitiator migration

• Adhesive lamination is a component of the printing/curing process

• Cold foil transfer is a component of the printing/curing process

EB offers several advantages over UV:

• Needs no photoinitiator in printing inks, coatings or adhesives

• More effectively penetrates opaque inks and substrates

• Provides higher conversion

• Offers more consistent output

• Requires far less energy

• Delivers a much cooler curing process

Specific Applications That Achieve

Benefit From EB Include:

• Higher Density White and Black Inks

• Film Label Applications

• Laminations

• Heavier Rotary Screen Applications

• Specialty Inks

• Scratch Off

• Metallic

• Magnetic

• Phosphorescent/fluorescent

• Identity/Security

Can EB Technology improve the performance of YOUR business? Call us for a free consultation!

© 2012 PCT Engineered Systems LLC. All Rights Reserved

Loading...

Loading...