Page 1

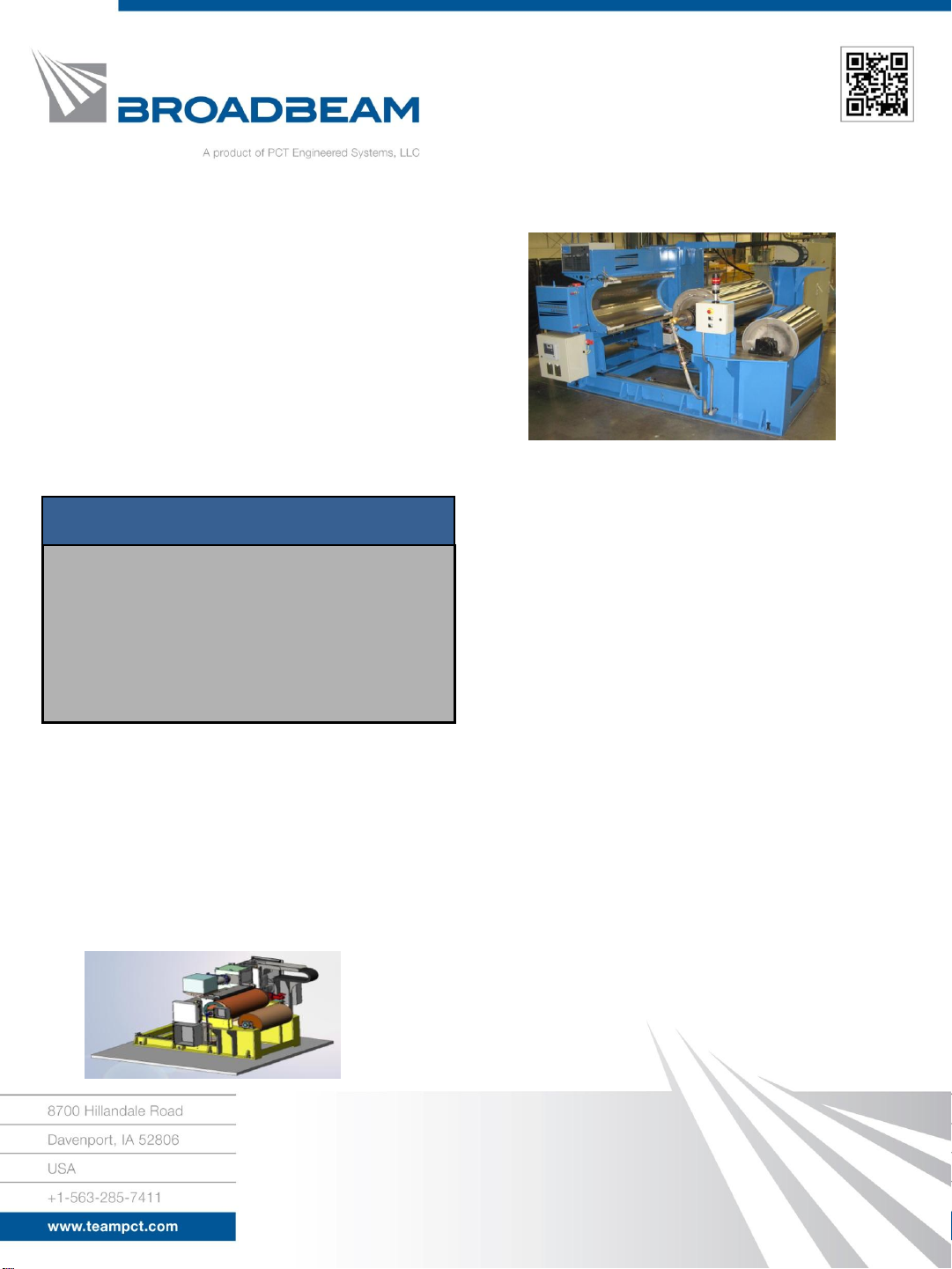

EB System for Coil Coating

Advantages for Coil Coating:

• Greatly Reduced Energy Consumption -

Uses less that 10% compared to convection

• Higher Throughput - Energy to cure at higher

line speeds

• “Green” Technology - Eliminates solvents

and significantly reduce emissions

• Very Compact - Reduced Floor Space

Technology Breakthrough

Congratulations on recognizing the many potential

advantages of harnessing the efficiency and

simplicity of EB curing for your coil coating line!

PCT is offering the first EB system designed

specifically for use in this application. This system

is positioned to provide a revolutionary advance in

the coil coating process. You will profit from

reduced operating costs and a dramatically

improved environmental footprint.

Designed for Coil Coating

The BroadBeam design includes specific features

for the production environment of a coil coating

line. The structure of the system is built to

withstand high strip tensions. An automated open

function allow stitches / welds to pass. We have

also ensured that the roll diameters are large

enough to avoid coil set in the metal.

Higher Throughput

Don’t let your drying oven limit your productivity.

With instantaneous EB curing you can significantly

increase the throughput of your line. The small size

of an EB system also opens the door to retrofitting

on existing lines.

Lower Power Consumption

Let us show you the energy savings you will realize

a BroadBeam on your coil coating line. The result is

typically less than 10% of what is required for a

conventional line using convection ovens. This

technology also produces less pollution providing

the ultimate “green” curing technology.

Easier Maintenance

Our patent-pending integral chill roll design

provides easy access to the roll surface for cleaning.

The window area is also easily accessible to

facilitate foil changes. Our standard remote

diagnostics allow for 24/7 monitoring by PCT’s

expert technicians.

Dependable Operation

PCT has been delivering solutions to our metals

customers since 1986. BroadBeam EB systems have

been in use for over 25 years.

© 2012 PCT Engineered Systems LLC. All Rights Reserved

Page 2

Voltage Range

90kV to 175kV

Standard Strip Widths

72” (1820 mm), 54” (1370 mm), 36” (910 mm)

Throughput

3 Mrads (30 kGy) @ 1312 FPM (400 MPM)

3940 Mrad FPM (12,000 kGy MPM)

Beam Direction

“Side fire” (Horizontal)

Reaction Chamber

Patented Integrated Shield Roll

Uniformity – Cross-web

+/- 8% Guaranteed

Nitrogen Inerting

< 200 ppm

Radiation Monitors

2 RadAlert sensors and controls included

Window

Solid copper with machined holes and internal cooling passages

Single window foil

High Voltage Power Supply

Digitally controlled, high frequency IGBT switching with integrated spark

management; Can be remotely mounted

Control

PC based HMI; Siemens PLC

Remote diagnostics standard

Utilities Required

Electric: 480 VAC @ 60 Hz / 400 VAC @ 50 Hz

Cooling Water: 100 psig (6.9 bar) 70 to 90 F (21 to 32 C)

Nitrogen: 100 psig (6.8 atm) to 150 psig (10.2 atm), filtered to 5 microns

Approximate Dimensions

36” Web: 87” (2199 mm) x 133” (3373 mm) x 122” (3104 mm)

52” Web: 87” (2199 mm) x 133” (3373 mm) x 138” (3510 mm)

72” Web: 87” (2199 mm) x 133” (3373 mm) x 158” (4013 mm)

BroadBeam LE Series Specifications

The TeamPCT Extra

There is even more to the LE Series than innovative equipment design. Like all BroadBeams the LE Series

is backed by the support of Team PCT. Our company is committed to complete customer satisfaction.

We strive to be responsive to our customers’ needs and we deliver professional service and support after

the sale.

© 2012 PCT Engineered Systems LLC. All Rights Reserved

Loading...

Loading...