Page 1

Converting Projects

Project Objective: Plant Wide Process Assessment & Automation Plan

Customer: Specialty Converter, Eastern U.S.

PCT provided:

• On site evaluation of all major process

equipment and material handling systems

• Interviews with production, maintenance,

engineering, and management staff

• Development of a plant wide automation

plan

• Recommendations for equipment and

process modifications

• Estimated costs and schedules to

complete modifications

Project Objective: Improve the Performance on Several Slitters

Customer: Midwest Location of Major Blown Film Producer

PCT provided:

• On site evaluation of the slitters in order to

take measurements, observe machine

operation, and gather drawings and

program files

• This evaluation considered input from

engineering, maintenance and operations

• Modifications to the slitter speed and

tension control logic as required

• Added taper tension control to improve

finished roll quality

• Minimized lay on bounce

• Optimized slitter for lock core winding

• Retrofit existing controls and drive to

modern equipment

• On site commissioning support for starting up and tuning the new control program

• On site support for initial production at which time PCT continued to refine the system tuning

© 2007 PCT Engineered Systems LLC. All Rights Reserved

Page 2

Project Objective: Upgrade Single-Layer Extruder to 7-Layer Extruder

Customer: Midwest Location of Major Blown Film Producer

PCT provided:

• Integrated system for control of the blending system,

vacuum pump, and extruder

• (7) multi-bay control enclosures including PLC,

drives, SSR’s and power distribution

• New operator stations

• Programming for the PLC, HMI, and drives

• Onsite commissioning and support

Project Objective: Supply of a Complete Electron Beam Process Line

Customer: South American Location of a Major Film Producer

PCT provided:

• Final design, fabrication, assembly and testing of turret

unwind, splicing station, chill roll stand and turret rewind

• Refurbishment, modification, assembly and testing of a

BroadBeam electron beam processor

• Integrated line control system including PLC’s, drives

and operator stations

• Shop testing of the entire line including training of

operators from the plant

• On site installation and commissioning support

Project Objective: Modify Slitter Mechanics to Improve Reliability

Customer: Midwest Location of Major Blown Film Producer

PCT provided:

• Engineering study to recommend mechanical

changes

• Created a pass line drawing from customer

drawings

• Simplified the pass line by removing several rolls

and developed alternate thread paths for the

system

• Replaced 4 rolls in the unwind section based on

engineering discoveries

• Replaced 3, high inertia, “billy rolls” with a single,

low inertia roll

• Modified upper fold board roll for load cell mounts

to provide appropriate tension feedback

• Replaced the nip roll mechanisms with driven Swrap rolls

© 2007 PCT Engineered Systems LLC. All Rights Reserved

Page 3

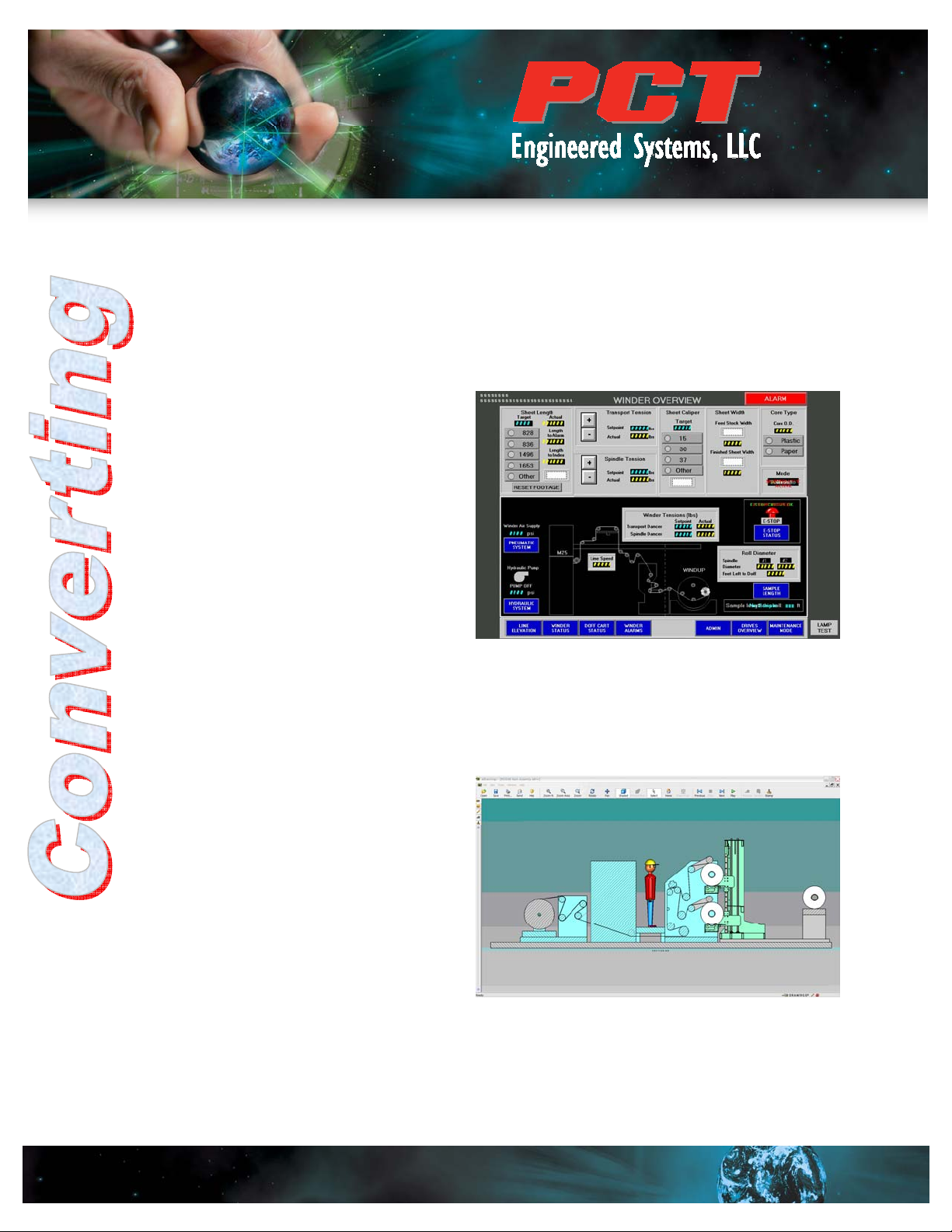

Project Objective: Upgrade Line Drives and Reeler Control Systems

Customer: Midwest Location of Major Blown Film Producer

PCT provided:

• Engineering study to recommend electrical and

mechanical changes to the winders on 5 blown film

lines

• Upgraded the winding control equipment which had

become increasingly difficult to maintain

• Upgraded the slack take up system power train and

control which was a safety concern

• Provided mechanical design of the new motor and

gearbox mountings

• Complete turnkey electrical change over and onsite

startup assistance

Project Objective: Support for a New High Performance Film Treating Line

Customer: Major Film Producer

PCT provided:

• Detailed sequence of operation document

• Complete OEM coordination for multiple pieces of machinery

• Detailed specifications for proposal solicitations for winder,

unwinder, and thermal control systems

• Integration of OEM machinery

• Design and programming of master line controller

• Development and programming of the line’s HMI system

including a “recipe” management function and integration with

the plant production data logging software

• Supply and population of a control house containing power

distribution and drive equipment

• Onsite control system checkout and product qualification

8700 Hillandale Road

Davenport, IA 52804

563.285.7411

FAX 563.285.7433

The Solutions Team

© 2007 PCT Engineered Systems LLC. All Rights Reserved

www.teampct.com

Loading...

Loading...