Page 1

Boiler & Furnace Control Solutions

PCT Engineered Systems’ Combustion Services Group can design a new combustion control system for your boiler or

furnace or re-engineer an existing system that is quietly costing you time and profit. Our team of professional engineers

will analyze the system and compile any data needed to insure the design meets the requirements of our clients as well

as industry standards. Our group has an extensive background including industrial boiler controls and most types of

furnaces, including ferrous and non-ferrous applications.

In addition to these services we can provide extensive on site training on proper operating procedures, system

inspections, and combustion safety awareness. Training we provide will be specifically matched to your company’s

requirements and will be performed at your facility.

Our Combustion Services Group, along with the entire PCT team will find the solutions you need to bring your system up

to date. Together we can increase your eqyuipment’s efficiency, provide a safer working environment and save lives.

Perform a thorough

inspection of your boiler or

furnace’s performance

including cold inspection,

survey of thermal distribution

and documentation of energy

efficiency.

Conduct required

checks of the safety interlocks.

Outline deficiencies and

propose changes to

procedures and equipment.

Supply construction crews

or assist in

supervising your crews

Develop the entire design

package necessary to modify

your existing combustion

system or build a new one if

required.

.

newest federal (OSHA) and other

regulations (NFPA

Conform your system to

).

Project management

throughout the installation

and start-up phase.

Provide system

documentation including

operating manuals with

shutdown procedures ,

operating screens,

maintenance instructions

and tuning parameters.

Purchase, preassemble or

fabricate custom equipment

including gas trains and

control panels.

Provide an initial report by

completing a comprehensive

system checklist.

Compile insurance provider

submittal

Train both maintenance and

operating personnel

packages.

.

Page 2

SAFETY

PROJECTS

MAINTENANCE

PROJECTS

NEW

CONSTRUCTION

UPGRADE

PROJECTS

PCT has completed

hundreds of Combustion

Safety Assessments for

boilers and both direct and

indirect fired process

furnaces.

As a result of these

assessments, we have

provided the design,

hardware installation

support, start-up support

documentation and training

needed to bring those

combustion systems into

compliance.

PCT has the capability to

evaluate a combustion

system and then recommend

repairs to improve

performance and

maintainability.

These projects have involved

repair or replacement of

controls, burners, flame

detectors, baffles, rails, coil

cars, floors, radiant tubes,

seals, door frames and

sometimes shell or insulation

repairs.

PCT has also supported the

construction of new furnaces

by writing unique customer

specifications or by working

with furnace manufacturers to

provide electrical/control

design, complete control

houses and installation/startup support.

We have also provided turnkey

project design and

management.

PCT has performed many

turnkey upgrades to industrial

process furnaces. These

include revisions from electric

to indirect gas fired, increases

in load capacity and improved

door designs.

We have also redesigned rail

and coil car arrangements for

reduced maintenance.

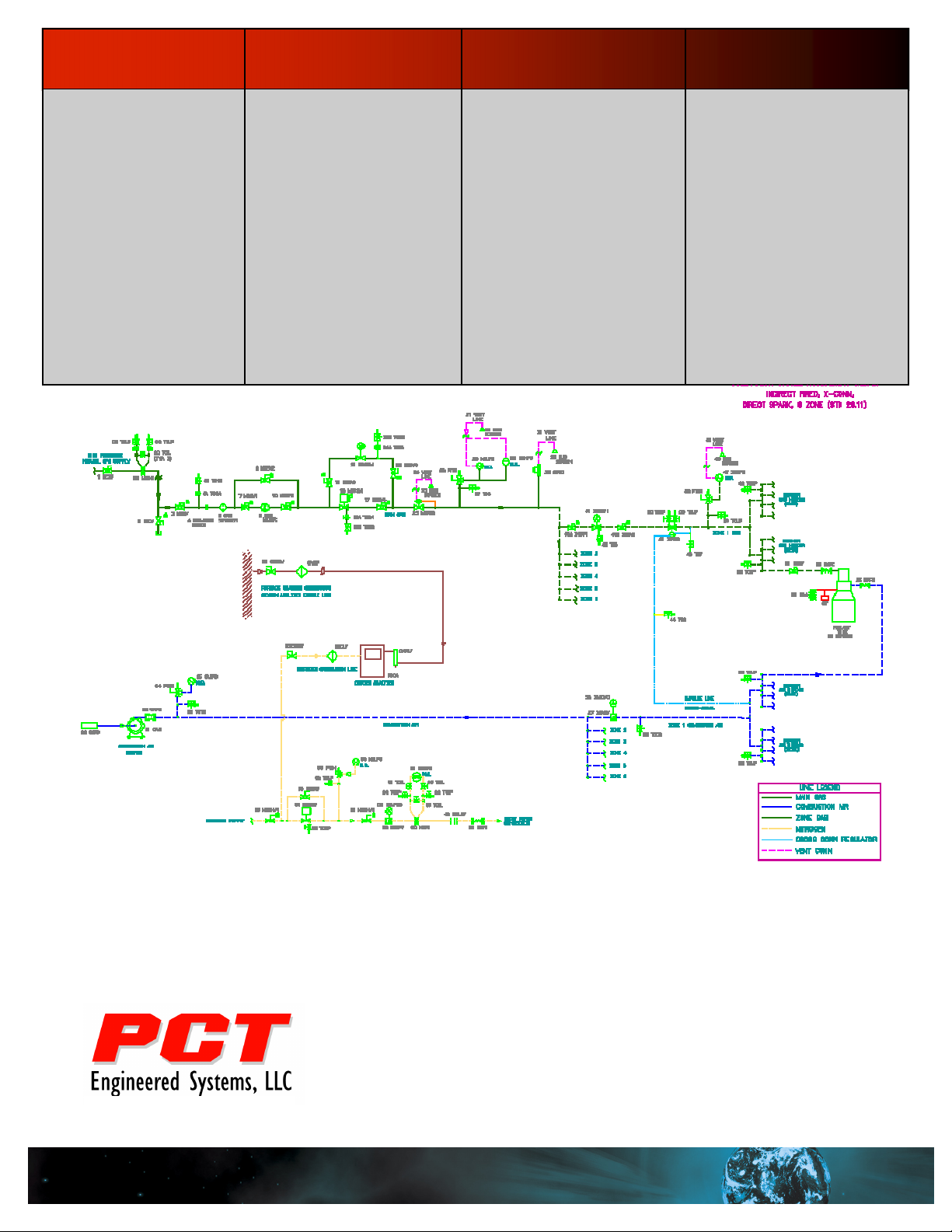

PCT’s design team will develop the entire package necessary to modify your existing system or build a new one if

required. A typical PCT design package includes: piping schematics and layouts; bills of materials for mechanical and

electrical equipment; wiring diagrams, electrical schematics and control panel layouts; PLC programming and MMI

screen development.

8700 Hillandale Road

Davenport, IA 52806

563.285.7411

FAX 563.285.7433

The Solutions Team

© 2009 PCT Engineered Systems LLC. All Rights Reserved

www.teampct.com

Loading...

Loading...