PCS VC-MP Instruction Manual

MODEL VC-MP

MICROPROCESSOR-BASED

MODULAR HOT-RUNNER

TEMPERATURE CONTROLLER

INSTRUCTION MANUAL

SAFETY WARNING

WARNING!

READ THIS MANUAL BEFORE

OPERATING EQUIPMENT!

The high voltage req uired to operate this temperat ure

controller and the high temperatures created by its

operation can cause serious injury or death, and

presents a potential fire hazard.

Installation and oper ati on o f this equi pment should only

be performed by qualified i ndividuals and all direction s

should be carefull y followed. Caution should be tak en

to guarantee that only the rated voltage is applied to

this unit and appro priate lim iting contr ol devices s hou ld

be used for safe operation.

DISCONNECT THE MAIN POWER FROM

THE CONTROL SYSTEM BEFORE

SERVICING!

Hazardous voltage is present on the inside of the

controller and mainframe system.

Standard safety procedures should be followed.

Additionally, the following guidelines will help prevent

personal injury and product damage:

• Do not apply a voltage greater than that

specified on the product nameplates.

• Do not operate controllers or mainframe

systems without appropriate supply ground

connections.

• Do not insert or remove controllers into

mainframe systems with power applied.

• Do not operate any controller or mainframe

system without all covers i n place and prop erly

secured.

• Do not operate this product when wet or in a

damp environment.

• Do not operate this product in an explosive

atmosphere.

PCS Company VC-MP 15 Amp Hot Runner Controller Document No.: ED-1503-MN-006-A

User’s Manual October 18, 2016

Page 1 of 15

Note on EMC compliance:

Due to the processing of small analog voltages

(thermocouple input) this controller is susceptible to

interface caused by radiated electromagnetic fields.

Although steps have been taken to reduce upsets

caused by EMI, strong signals may cause degradatio n

of instrument accuracy. User intervention is not

required to reset the controller under these

circumstances. The c ontr oller will automatically recover

following the removal of the interfering signal.

If continuous upsets are recognized remove the

interfering signal from the process. If this is not

possible consult the manufacturer for assistance with

solving specific EMI interference problems.

INTRODUCTION

This manual combines graphical representation of

displays with explanatory dialogue to help the user

acquaint themselves with the controller features.

Should further clarific ation be required do not hesitat e

to contact your nearest sales representative or

distributor for assistance.

KEY FEATURES

The VC-MP modular temperature controller offers

many user-friendly featur es that enabl e novice users to

quickly become productive. These same features are

key for veteran molders who des ire f luent integr ation o f

the VC-MP into applications where upgrade or

replacement is necessary.

• The VC-MP controllers are physically and

electrically compatible with all †D-M-E® GSeries®, Smart Series® and similar style

mainframe control systems.

• Large, highly visible LED display for process

temperature, load current (amps), power

output and diagnostic (fault) codes.

• Three digit rotary push button switch for

setpoint temperature and manual percent of

power output.

• Diagnostic (Fault) Code reference label

supplied with every controller provides

convenient descriptions of the VC-MP

diagnostic codes.

• Symbolic mode and condition indicators

combined with displayed mnemonics

(abbreviations) clearly state operating modes

or alarm conditions.

• Reliable, sealed polycarbonate face panel

graphic with 2-key tactile in terface. The sealed

construction protects the keys and circuitry

from debris that typically leads to component

failure.

• The front panel graphics are printed on the

underside of the polycarbonate face insuring

that controls will be recognizable even after

many years of service.

• Time tested and prov en electronics f or reliable

performance.

• Automatic (closed loop) and Manual (open

loop) modes of control.

• Load current (Amps) monitor mode.

• Industry standard t ype “J” Thermocouple inp ut

(default) or selectable type “K” Thermocouple

input.

• Fully automatic, adaptiv e tuning of PID (three-

term) control variables providing smooth

adaptation to any runnerles s mold tem perature

control application with no user inter vent ion.

• Automatic slow-start temperature ramp at

start-up to ensure wet heater bake out,

prolonging heater life.

• Wet heater ground fault detection at start-up

that limits or disables power to avoid

destructive short circuits.

• View (monitor) display of output power (%)

available when in Automatic control mode.

• View (monitor) display of load current (amps)

available when in Autom atic or Manual control

mode.

• Anti-arc (high voltage) protection circuit to

prevent electrical damage if the controller is

accidentally installed or removed from the

mainframe with power appl ied. (Circuit ma y be

disabled).

• Automatic T/C Fault Hold transfer to manual

control mode (enabled at fac tory). Provides for

uninterrupted load power upon loss of

thermocouple signal.

• Full diagnostic software to inform operator of

fault conditions.

• Shorted Thermocouple diagnostic allows for

user selectable (DIP switch) sample times,

giving the operator greater flexibility to tailor

the VC-MP diagnostic to the unique thermal

weight and response characteristics of a

variety of control applications. (Light or heav y

loads).

• Over and under temperature indication with

communications output to activate external

control intervention or audible and/or visual

alarm. Output compatibilit y with †D-M-E® TAS

accessory alarm modules.

• Compliant with WEEE and RoHS

requirements.

PCS Company VC-MP 15 Amp Hot Runner Controller Document No.: ED-1503-MN-006-A

User’s Manual October 18, 2016

Page 2 of 15

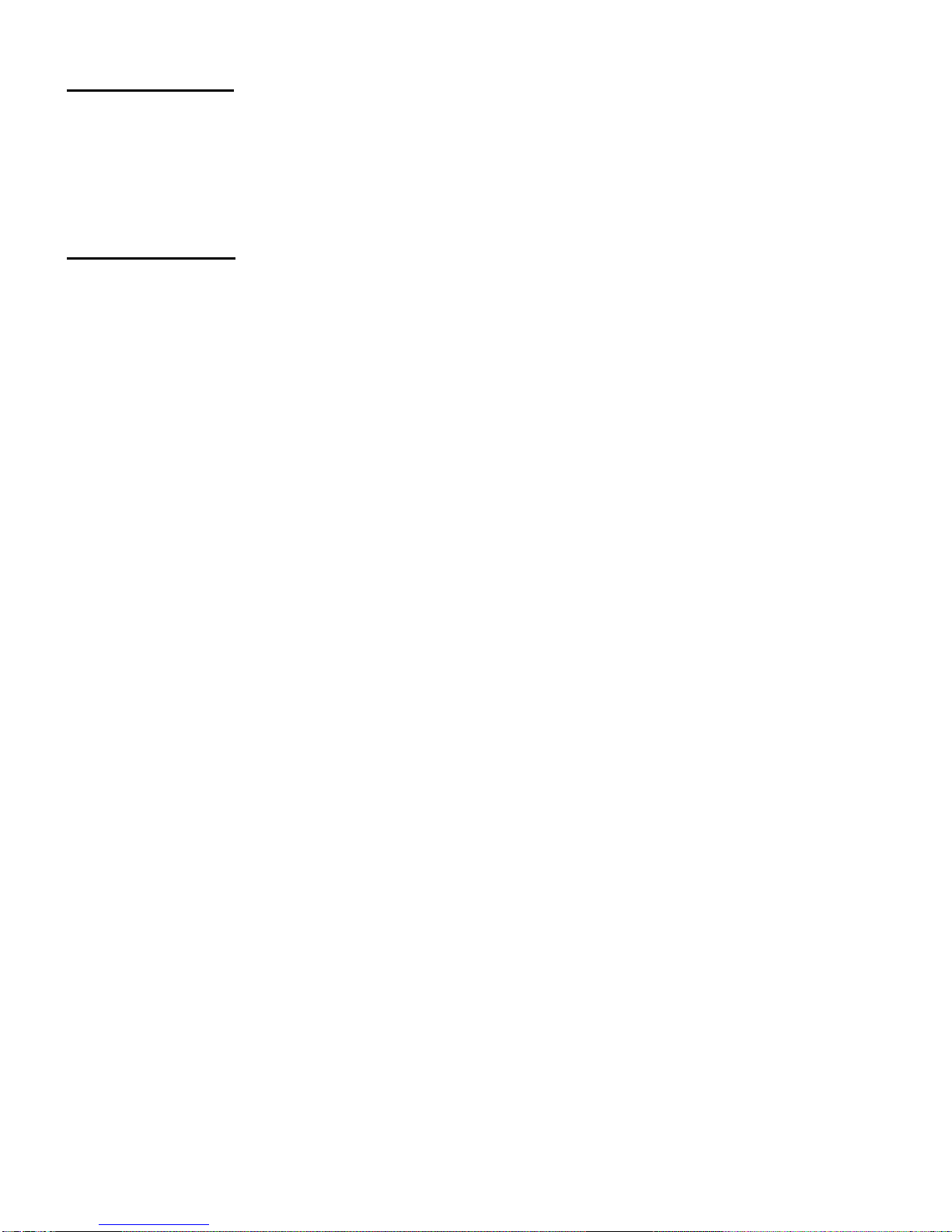

CONTROLSCONTROLS

CONTROLS

CONTROLSCONTROLS

1. Power Switch -Both sides of the AC line, fuse protected

2. Digital Display:

Process T emperature Display (Default)

Diagnostics (Fault Codes)

Load Current (Amps) Display

AMPS DISPLAYAMPS DISPLAY

AMPS DISPLAY

AMPS DISPLAYAMPS DISPLAY

(%) Percent of Power Display (In Auto)

POWER DISPLAYPOWER DISPLAY

POWER DISPLAY

POWER DISPLAYPOWER DISPLAY

3. Setpoint Temperature / % Power Push Button Input

4. Automatic / Manual Control Mode Select

5. View Control (Display Process Temp, Amps or % Power)

6. Plastic Retention / Locking Device

2

3

7

2

5

0

10

INDICAINDICA

INDICA

INDICAINDICA

7. Automatic (Closed Loop) Control Mode Indication

8. Start-Up Power Ramp Indication (W et heater bake-out)

9. Load Power Indication

10. Manual (Open Loop) Control Mode Indication

1 1. Thermocouple Fault Indication (Also LED code below)

12. Output Fault Indication (Also LED code below)

13. Fahrenheit T emperature Mode Indication

14. Celsius T emperature Mode Indication

TT

ORSORS

T

ORS

TT

ORSORS

8

9

13

4

5

1

6

11

12

14

www.pcs-company.com

800-521-0546

PCS Company VC-MP 15 Amp Hot Runner Controller

User’s Manual

Figure 1

Controls & Indicator Placement

Document No.: ED-1503-MN-006

September 26, 2016

SPECIFICATIONS

0

2

5

Dimensions ……..………. 2.0” Wd X 7.0” Hg X 7.8” Lg

(51mm X 178mm X 198mm)

Weight …………….……………………. 1.25lb (0.57Kg)

Operating Temp. Range …. 32° to 120°F (0° to50° C)

Control Method:

Automatic Mode ……. Full Scale Auto-Tuning

PID (3-Term)

Manual Mode ……………..…. User Selectable

0% to 99% Output Power

Temperature Reset ……….. To Within ±1°F (±0.55°C)

Of Setpoint

Power Response Time ………………………… 250mS

Control Accuracy (In Auto Mode) .… ±1°F (±0.55°C)

** Dependant On Total Thermal System **

Slow Start Mode …… From Ambient to 212°F (100°C)

Low Power Application Temperature Ramp

ELECTRICAL POWER SPECIFICATIONS

Operating / Input Voltage …………… 230 VAC ±10%

(Optional 115 VAC ± 10%)

Frequency ………………...…… 50 / 60 Hz (Automatic)

Power Consumption ……..…. < 3 Watts (N.I.C. Load)

DC Power Supplies ……………. Internally Generated,

Regulated with Temperature Compensation

Circuit Protection .. Dual Fast-Acting Fuse Type ABC

Over-Voltage Protection via MOV

Circuit Isolation …..……… Transformer, > 2500 Volts

Triac Optically Coupled

INPUT SPECIFICATIONS

Sensor Type ………………….. Type “J” Thermocouple

Selectable Type “K” (Grounded or Ungrounded)

Sampling Rate ………………………………….. 250mS

Temperature Range ……... 32° to 999°F (0° to 537°C)

Temperature Accuracy ……….… ±0.3% of Full Scale

Temperature Repeatability …..… ±0.1% of Full Scale

Cold Junction Compensation ….... Automatic Across

Operating Temperature Range

Input Impedance …………………..…… 22 Meg Ohms

Input Protection …… Diode Clamp & Fusible Resistor

Input Isolation ………...…… Via Control Circuit Power

Supply Transformer

Current (Amps) Sensor Type ……...…… Transformer

Current (Amps) Range ………...……… 0-15 Amperes

Current (Amps) Accuracy / Resolution …... 0.1 Amp

OUTPUT SPECIFICATIONS

Output Voltage ……….. 240 VAC (Optional 120 VAC)

Load Power ……… 3600 Watts; 15 Amps @ 240 VAC

1800 Watts; 15 Amps @ 120 VAC

Power Disconnect ……...….. 16A Double Pole Switch

Power Output Control Device ……………..…… Triac

(Solid State – Not Mechanical)

Overload Protection ….……… Dual Fast-Acting Fuse

Type ABC

Power Line Isolation ……...… Triac Optically Coupled

CONTROLS AND INDICATORS

Process Temperature Display ……….....

Setpoint Temperature / Manual Power ...

Power Output (%) Display …………….…

Amps (Load Current) Display ……..……

Control Mode Selection ….……….……...……

Display Output Power (%) & Amps ……….…..

Automatic Mode Indication ……..…………..….

Closed Loop LED Indicator

Manual Mode Indication ………………….……..

Open Loop LED Indicator

Slow Start Mode Indication …………………….

LED Indicator

Load Power Indicator ……………………………

LED Indicator

DIAGNOSTICS

Diagnostics are fully automatic and require no operator

intervention.

Over Temperature Indication

LED Display with Accessory Alarm Output

(+30°F/+17°C)

Under Temperature Indication (-30°F/-17°C)

LED Display with Accessory Alarm Output

Open T/C Indication ……………………

LED Display with Accessory Alarm Output

Reverse T/C Indication …………..……

LED Display with Accessory Alarm Output

Shorted T/C Indication ………………..

LED Display with Accessory Alarm Output

Shorted Output Indication ……………

LED Display with Accessory Alarm Output

Open Output Indication ……………….

LED Display with Accessory Alarm Output

Ground Fault Indication ……..………..

LED Display with Accessory Alarm Output

PCS Company VC-MP 15 Amp Hot Runner Controller Document No.: ED-1503-MN-006-A

User’s Manual October 18, 2016

Page 3 of 15

INSPECTION

NOT USED

NOT USED

or

Sho T/C LONG

ACTIVATE

SW4

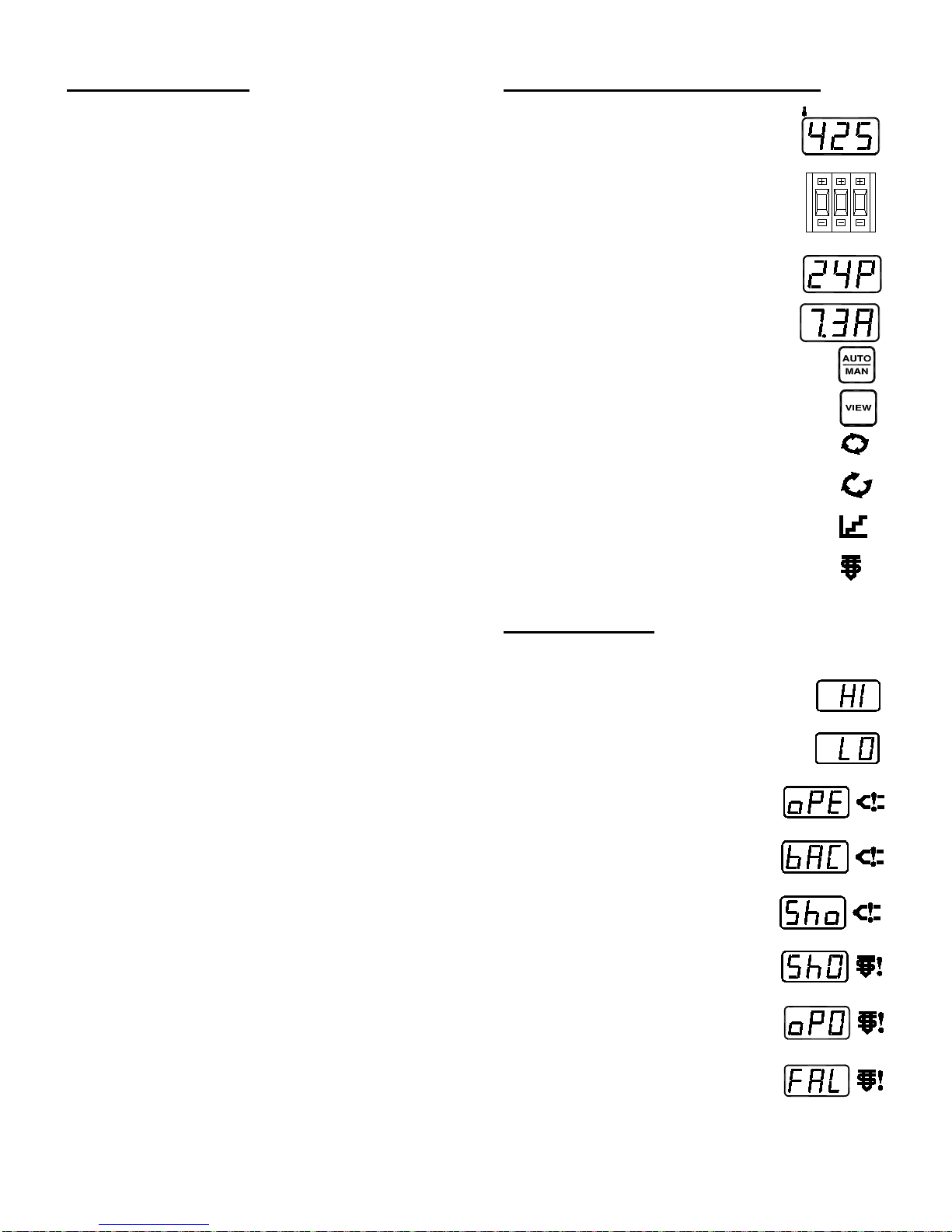

DIP SWITCHES

AUTO T/C HOLD

°F or °C SCALE

NOT USED

TYPE "J" or "K" T/C

Sho T/C **OFF**

USER SELECTABLE OPTIONS

oPO **OFF**

After removing the VC-MP tem perature controller from

the shipping container im mediately inspect the unit for

damage resulting f rom mishandling in shippi ng. I ns pe ct

for loose components and mechanical damage such as

bent sheet metal, marred front panel screen, etc.

Remove the spare ABC15 fuses and mainframe zone

edge connector contact (required for anti-arc circuit)

and save them for later use.

Note: If the unit appears damaged or the container

is missing components, contact your sales

representative immediately! Use or modification of

the controller or its packaging will decrease the

likelihood of freight claim reimbursement.

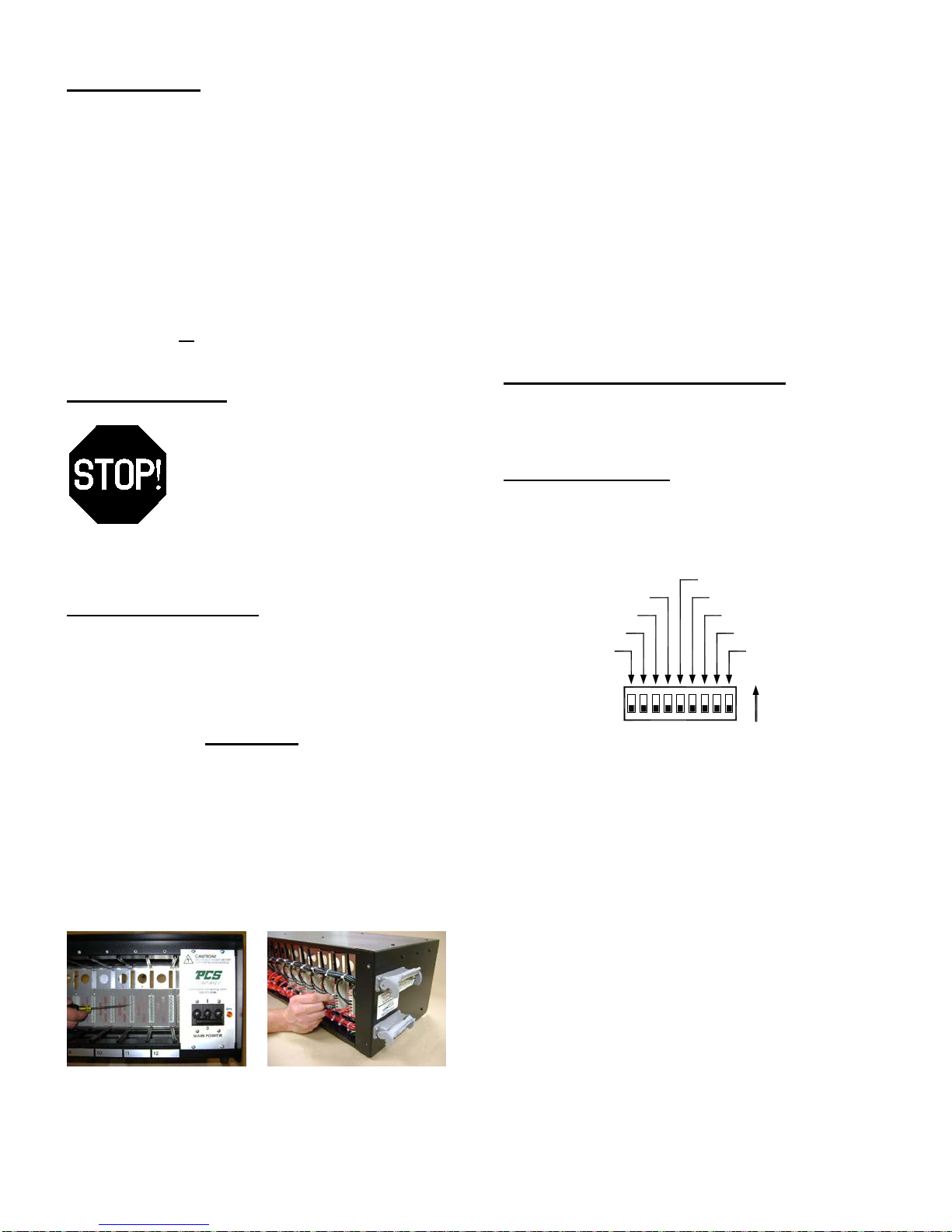

INSTALLATION

THIS VC-MP IS EQUIPPED WITH A

HIGH VOLTAGE ANTI-ARC CIRCUI T!

AND IS ENABLED – TO PREVENT

ELECTRICAL DAMAGE TO THE

CONTROLLER IF ACCIDENTALLY

REMOVED FROM THE MAINFRAME WITH

POWER APPLIED.

The controller WILL NOT apply power to

the load unless mainframe zone edge

connector contact #3 is installed.

Inspect each mainframe zone edge connector for the

required contact. If t he contact is not already installed

remove the mainframe rear cover (refer to

manufacturer instructions) and install the contact

supplied with the VC-MP. (Insure contact is locked in

the connector by gently pushing on it from the front.)

Step 1: Verify installation Step 2: If not, install

of contact. provided contact

PCS Company VC-MP 15 Amp Hot Runner Controller Document No.: ED-1503-MN-006-A

User’s Manual October 18, 2016

Page 4 of 15

Note that the contact itself completes the triac gate

(drive) circuit. No wiring, or wire connect ion, is require d

to the #3 edge connector contact.

The anti-arc circuit can be disabled by installing a

#22-28 AWG wire jum per into the printed circuit board

jumper position P5. (S oldering is required. See Fig. 2 ,

Component Layout.)

It is highly recommended that the anti-arc circuit

not be disabled in this manner! If the controller is

inadvertently instal led or removed from the m ainframe

under power it wil l suffer severe dam age, and possib ly

be destroyed. The user is encouraged to take

advantage of this protective feature.

ADVANCED FEATURES

USER SELECTABLE OPTIONS

Many of the advanced f eatur es of the VC-MP controller

must be user selected by setting the DIP switches

SW4 on the main printed ci rcuit boar d. ( Refer to Figure

2, Component Layout.)

Note the following SW4 Factory Default settings:

SW4:1: °F / °C Temperature Scale set °F

SW4:2: Auto T/C Hold set ON

SW4:3: Sho T/C Long Delay set OFF

SW4:4: Sho T/C **OFF** set OFF

SW4:5: Type “J” / “K” Thermocouple set Type “J”

SW4:6: Reserved for Future

SW4:7: oPO (Open Output) Disable set OFF

SW4:8: Reserved for Future

SW4:9: Reserved for Future

Enabling or disabling (on / off) any of these features

must be done before turning the controller power on

(reset). A detailed explan ation of these f eatures follows

below.

Loading...

Loading...