PCS BH60 Handpiece Instructions Manual

Instructions for

BH60 Handpiece

Item# 500-0224

Handling of the Motor Handpiece (SDE-BH60)

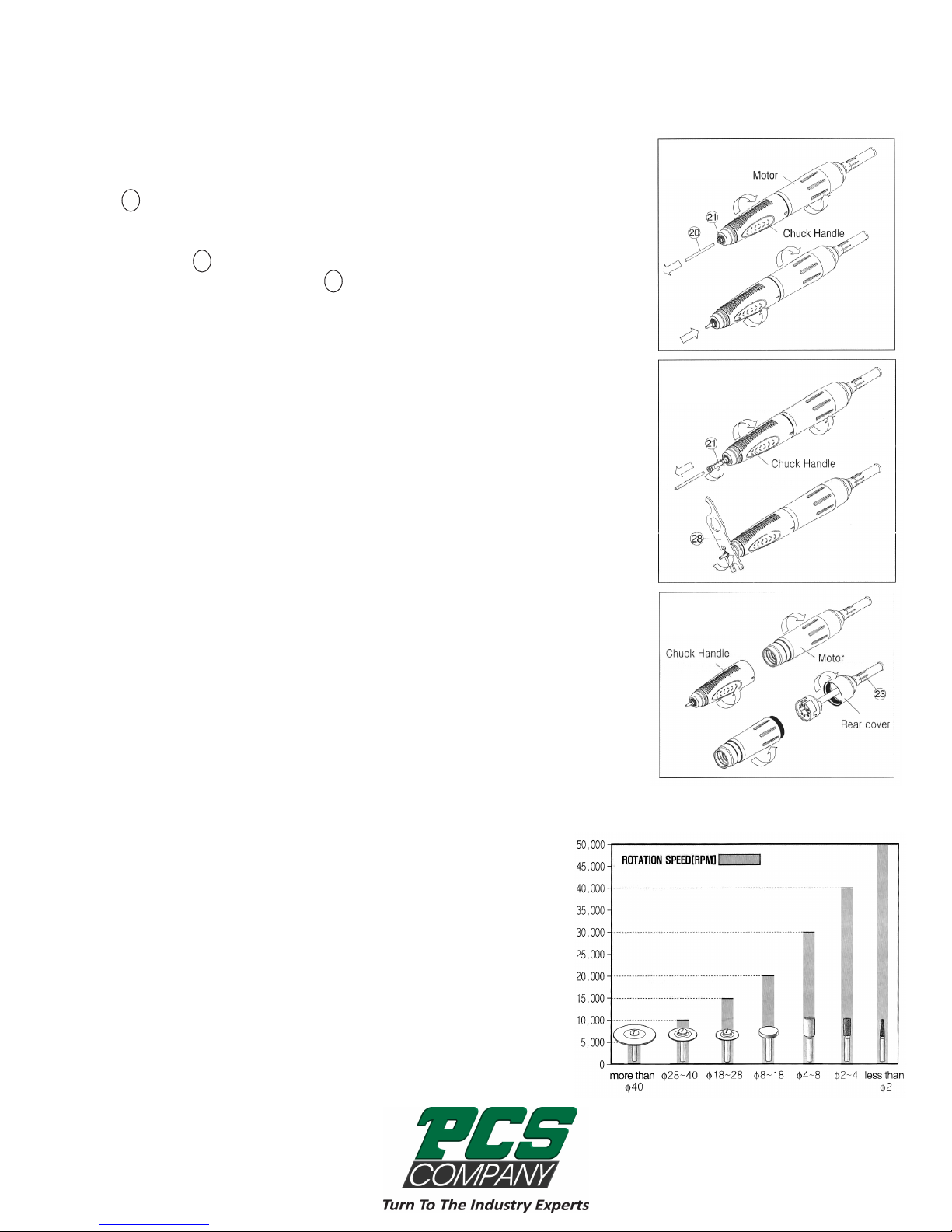

1. Insertion or Removal of Bur

The Bur 20 can be replaced by turning the Chuck Handle clockwise. After replacing the Bur, the

Chuck Handle must be turned counter-clockwise to be securely held. [Fig. 1]

2. How to mount and dismount the Collet Chuck

Turn the Collet Chuck 21 counter-clockwise while opened to dismount. If the Collet Chuck can

not be turned manually, use the Chuck Wrench 28 to dismount it. To mount the Collet Chuck, it is

required to first open the Chuck Handle and then insert the Collet Chuck and the Bur. [Fig. 2]

3. How to disassemble the Chuck Handle and the Motor

The Chuck Handle and the Motor are disassembled by continuously turning the Chuck Handle

counter clockwise. [Fig. 3]

CAUTION

s

- Use only recommended burs.

- Always remove dirt before replacing a bur.

- After replacing a bur, make sure the Collet Chuck is securely held before running the Motor.

CAUTION

s

- DO NOT try to adjust the Chuck Handle while the motor is running to prevent the unit from being

damaged.

- When the Motor Handpiece is not is use, it is recommended that a bur is kept inserted in the Chuck.

- Always put the Motor Handpiece on the Handpiece Stand or Handpiece Holder while not in use.

Special care must be taken not to drop it on the floor.

- Thoroughly clean the Collet Chuck and Burs before reassembling. Clean at least once a week for

longer life.

- Special care must be taken so that the Chuck Handle and the Motor are free from dust and dirt

during disassembly.

- The spindle and the motor should be disassembled only by a qualified repair facility.

[Fig. 1]

[Fig. 2]

[Fig. 3]

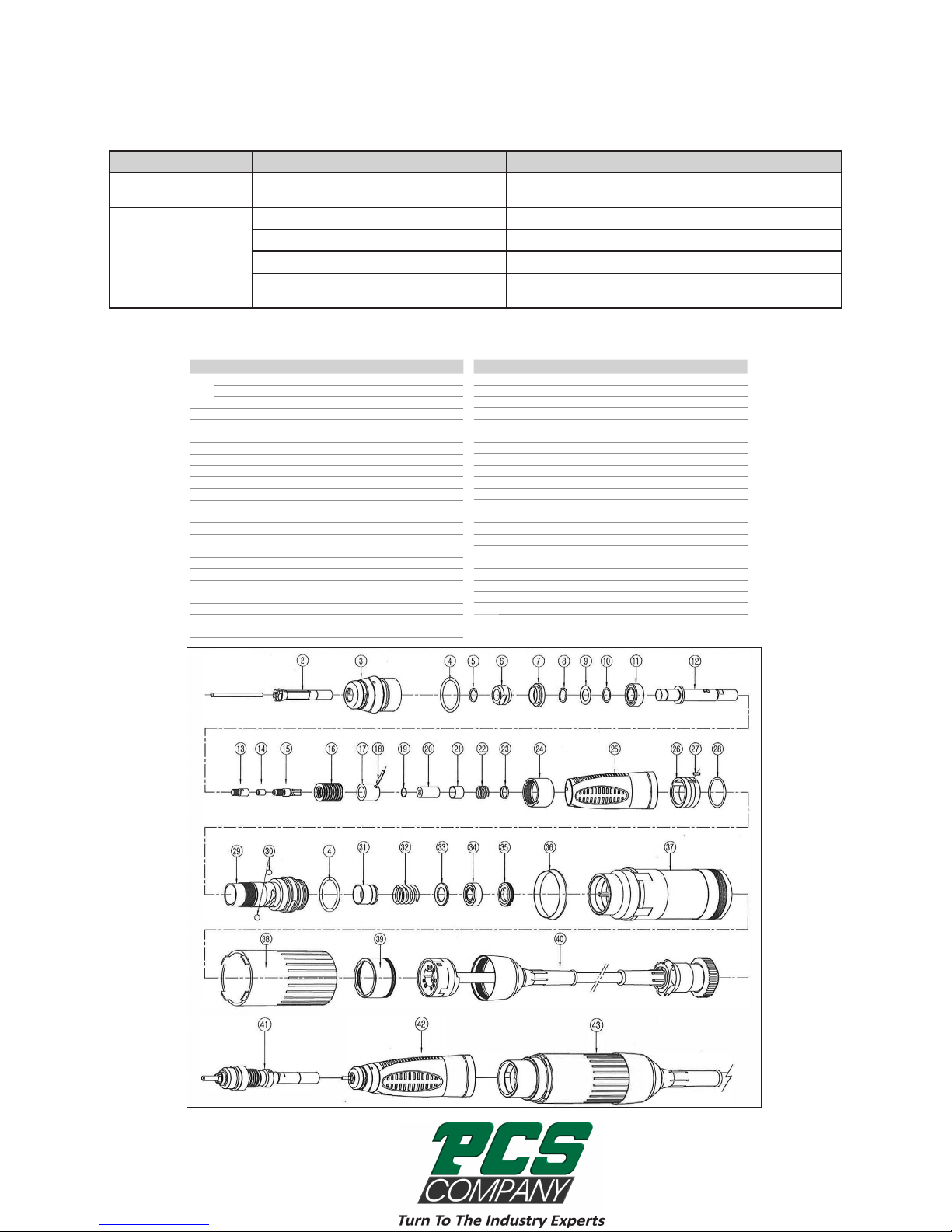

Allowable Rotation Speed

1. This chart is a general guide for the maximum rotation speed of conventional burs. The

allowable rotation speed can be slightly different, depending on bur materials or types.

CAUTION

s

- Make sure not to exceed the maximum rotation speed specified by the manufacturer or

distributor for the bur being used.

- Large burs, even when operated below maximum rated speed, may begin to vibrate. Speed

should be reduced immediately to prevent damage to the bur, handpiece, or operator.

- Always use standard burs.

- Be sure to insert the Bur shank all the way, until it touches the back of the Collet Chuck.

Then tighten the Collet

gerous because vibration may cause it to come out.

Chuck. If the Bur is used while not inserted completely, it is very dan-

Instructions for

Handpiece

Model Name Weight Size

SDE-BH60 68g 60(W)x1

10(D)x45(H)

AC 100-120V 50/60 Hz

2.7kg 137(W)x232(D)x180(H)

Brushless Motor

AC 200-240V 50/60 Hz or Brush Motor

Control Unit

BH60 Handpiece

Item# 500-0224

Trouble Shooting

Trouble Check points Corrective actions

Motor Handpiece overheats

while in operation.

Motor Handpiece

vibrates excessively

and is unusually noisy.

The ball bearings are defective. Repair the Motor Handpiece.

Make sure that the Collet Chuck is free from dirt. Thoroughly clean the Collet Chuck.

The rotation speed is too high. Reduce the rotation speed. Refer to “Allowable rotation speed” chart.

Check if the bur shaft is straight or bent. Replace with new one.

Make sure that ball bearings are in good condition.

Repair the Motor Handpiece.

Parts List

NO. PARTS NAME ITEM #

Collet Chuck (Dia. 2.35 mm) 896-0417

2

Collet Chuck (Dia. 3.0 mm) 896-0418

Collet Chuck (Dia. 3.175 mm) 896-0419

3 BHS1 Nose Cap 896-0445

4 BH60 Nose Cap O-Ring 896-0446

5 BHS1 Chuck Housing C-Ring 896-0448

6 BHS1 Collar 896-0449

7 BHS1 B/R Stop Collar 896-0450

8 BHS1 814 Wave Washer 896-0451

9 BHS1 814 Washer2 896-0452

10 BHS1 814 Washer1 896-0453

11 BH60 Ball Bearing(814ZZ) 896-0454

12 BHS1 Chuck Housing 896-0455

13 BHS Connection Pin 896-0456

14 BH60N Spacer 896-0457

15 BH60 Joint Shaft 896-0458

16 BH60 Disc Spring 896-0459

17 BHK Spring Stopper 896-0460

18 BH60 Spring Pin 896-0461

19 ES6 Nosecone O-Ring 896-0462

20 BH80 Connector 896-0463

21 BH60 Spring Spacer 896-0464

22 BH60 Coil Spring1 896-0465

NO. PARTS NAME ITEM #

23 BH60 Spring Sheet 896-0466

24 BH60 Hand Cap Stopper 896-0467

25 BHK Hand Cap & Insert 896-0468

26 BH60 Set Ring 896-0469

27 BH60 Set Key 896-0470

28 BH60 Cam 0-Ring 896-0471

29 BHK Cam 896-0472

30 BH60 Ball 896-0473

31 BH60 Moving Housing 896-0474

32 BH60 Coil Spring2 896-0475

33 BH60 B/R Collar 896-0476

34 BH60 Ball Bearing(1360ZZ) 896-0404

35 BH60 B/R Stop Bolt 896-0477

36 BM40M Motor Case Ring Assembly

37 BM50M Motor Assembly

38 BM50M Motor Insert Assembly

39 BM50M Motor Case Cover Assembly

40 BH60 Motor Cord Assembly 896-0478

41 BHS1 Spindle Assembly 896-0479

42 BHS1 Assembly 896-0480

43 BM50M Motor Assembly 896-0481

– Collet Spanner & Wrench Set 896-0482

Loading...

Loading...