PCS 8275305 Service Manual

FOR SERVICE TECHNICIAN'S USE ONLY FOR SERVICE TECHNICIAN'S USE ONLY FOR SERVICE TECHNICIAN'S USE ONLY PAGE 1

PART NO. 8275305

NOTE: This sheet contains important

Technical Service Data

FOR SERVICE TECHNICIAN ONLY

DO NOT REMOVE OR DESTROY

PRECAUTIONS TO BE

OBSERVED BEFORE AND

DURING SERVICING OF

DISHWASHER

A. Even with the door open, there is line voltage at

several points in the console and belo w th e

tub. Therefore, be sure to disconnect the power

supply at the fuse box before replacing a

component.

B. Always check wiring harness and connectors

before any test procedures.

C. Disconnect power supply before touching the

circuit board or re-seating control connectors.

D. Voltage checks are made by inserting probes

beside wires on the connector with the AC power

source applied and the connector blocks plugged

in.

E. Resistance checks are made on components

with the wiring harness disconnected.

SPECIFICATIONS

Electrical Supply:

(Under load) 60 Hz, 120 V AC.

Supply Water Flow Rate:

To fill 1.9 liters (2 quarts) in 27 seconds,

120 PSI maximum, 20 PSI minimum.

Supply Water Temperature:

49° to 71° C (120° to 160° F) (Before

starting a cycle, run water from sink faucet

until hot.)

Water Charge:

8.3 liters (2.2 gallons) / fill approx.(Less for

IEC Normal and Water Miser/Low Energy

cycles)

Lower Spray Arm Rotation: 25 to 40 rpm.

Upper Spray Arm Rotation: 18 to 30 rpm.

REPAIR KITS

n

Vinyl Rack Patch Kit No .676453

n

Tine Tip Kit No.675679

OTHER CONTROL

FEATURES

CANCEL/DRAIN:

Terminates current active cycle and clears

cycle selections.Executes 2-minute drain

upon first selection if water is likely to be

left in sump.Subsequent selections toggle

between 2-minute drains and going to

standby.

CONTROL LOCK:

The Control Lock light is turned on and all

keys of the keyboard are disabled

whenever the Control Lock feature is

invoked by the customer.The Control Lock

feature (and light) can be turned on or off

by the customer at any time by holding

down the Air Dry option key for 4 seconds.

DELAY START:

Allows the customer to delay the start of a

cycle.Each press of the Delay key

increases the delay to the next available

Electrostatic Discharge (ESD)

Sensitive Electronics

ESD problems are present everywhere. ESD may

damage or weaken the electronic board.The new

board may appear to work well after repair

is finished, but failure may occur at a later date

due to ESD stress.

Use an anti-static wrist strap.Connect wrist

■

strap to green ground connection point or

unpainted metal in the appliance

-OR-

Touch your finger repeatedly to a green ground

connection point or unpainted metal in the

appliance.

Before removing the part from its package,

■

touch the anti-static bag to a green ground

connection point or unpainted metal in the

appliance.

Avoid touching electronic par ts or terminal

■

contacts; handle electronic board by edges only.

When repackaging failed electronic board in

■

anti-static bag, observe above instructions.

delay time selection and then back to no

delay.

n

For models with a Start key, the

delay will begin clocking down upon

selecting the Start key.

n

For models without a Start key, the

delay period will begin upon selecting

the Cycle key.

The cycle selected will begin automatically

upon completing the delay period.

ERROR MESSAGES

STUCK KEY:

If the control detects that a key is stuck in

the depressed position, dishwasher

operation will be suspended and the

control will flash the light for that key until

the condition is corrected. If a key without

a light is stuck/shorted or multiple keys are

stuck/shorted, the control will flash the

Rinse cycle key light.

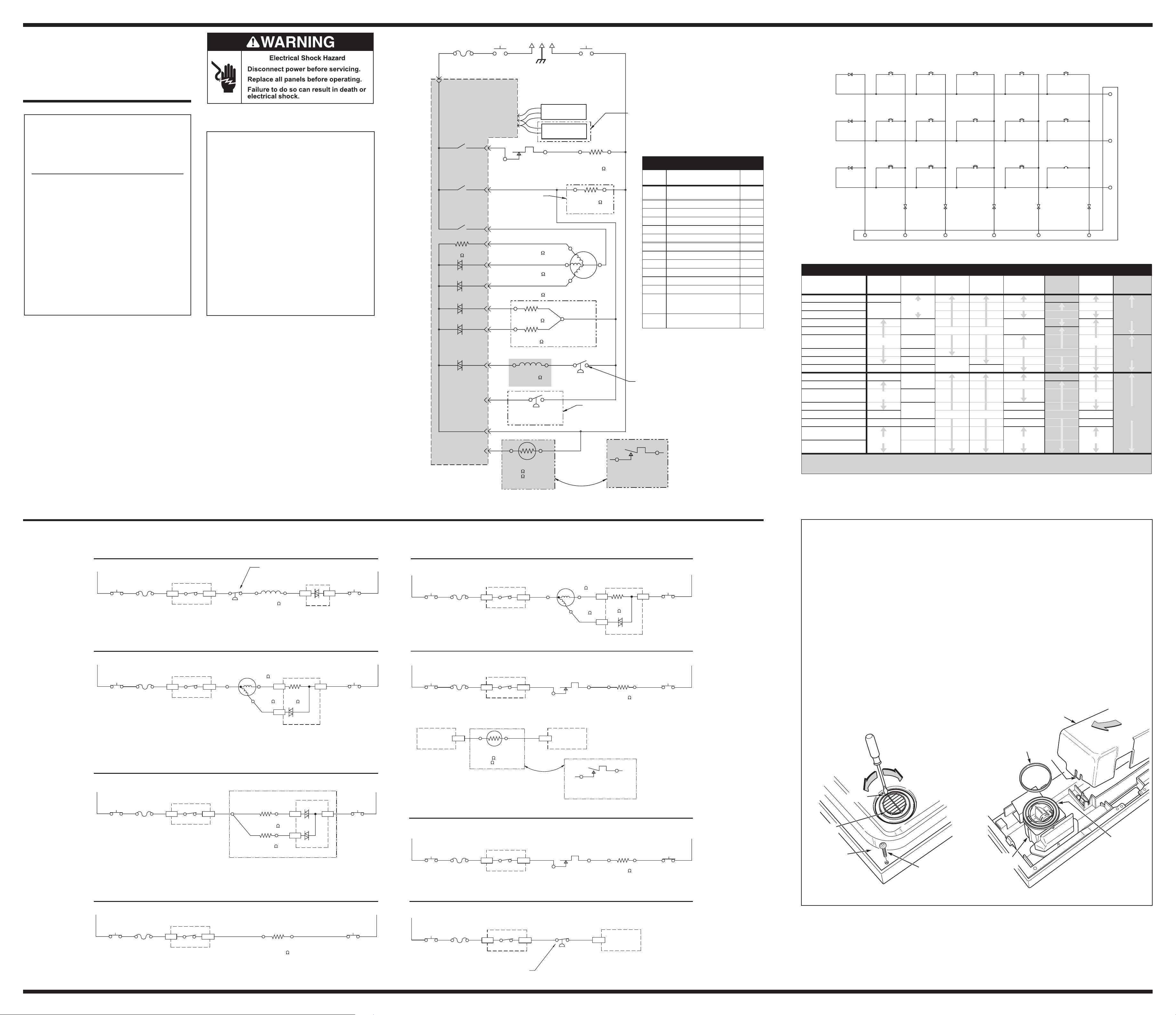

WIRING DIAGRAM

TCO

98°C (208°F)

T

SCHEMATIC SHOWN WITH DOOR

SWITCH AND ALL OTHER NORMALLY

OPEN CONTACTS OPEN.

3376359

P8

ELECTRONIC CONTROL

*

8528806

(TRIACS AND RELAYS SHOWN)

N.O.

K2

N.O.

K3

N.O.

K1

SENSE RESISTOR

<1

P6

P9

P10

P3

P5

Q6

P4

Q5

P2-3

Q1

P2-4

Q2

P2-5

Q3

P2-1

P7

P2-2

LINE 120 V 60HZ

BKT

BK

DOOR SWITCH

3369325

P1

W-R

N.C.

HI-LIMIT THERMOSTAT

OPENS 77°C – 83°C (171°F – 181°F)

G

USER INTERFACE

NUMERIC DISPLAY

3371618

BU-BK

USED ONLY ON

SOME MODELS,

OTHERWISE OPEN

(SEE TABLE)

R-BK

BU

MAIN WINDING

2.0 – 3.4

GY

DRAIN WINDING

4.2 – 7.0

Y

WASHWINDING

4.2 – 7.0

O-BK

DETERGENT

LBU

BR

O-GY

(W)

W-V

GY-O

600 – 1800

RINSE AID

600 – 1800

FILL VAL VE

*

695 – 995

(SEE TABLE)

N.O.

PRESSURE SWITCH

(SOIL SENSOR)

3380871

T

THERMISTOR

*

47 – 53K @ 25°C/77°F

12 – 13K @ 60°C/140°F

9743158

N.O.N.O.

W

DOOR SWITCH

3369325

(SEE TABLE)

(SEE TABLE)

OR

HEATER

800/500W PTC

15 – 30

8519830

(ASSEMBLY)

VENT ACTUATOR ASM.

600 – 1800

9742770

BU

GY

Y

PUMP & MOTOR

ASSEMBLY

(SEE TABLE)

DUALWAX

MOTOR

3374501

N.O.

BR-W

OVERFILL SW.

3369067

USED ONLY ON

SOME MODELS,

OTHERWISE OPEN

(SEE TABLE)

(W)

W-V

WATER

TEMPERATURE SENSOR

DEPENDS ON MODEL

(SEE TABLE)

W-VW

W-V

W-V

BU-BK

BU-BK

BU-BK

N.O.

OPERATINGTHERMOSTAT

*

CLOSES 57°C – 63°C

(135°F – 145°F)

USED ONLY ON

SOME MODELS,

OTHERWISE OPEN

(SEE TABLE)

ELECTRONIC CONTROL CONNECTOR PINS

PIN

NUMBER

P1

P2-1 Pressure Switch (Soil Sense) O-GY

P2-2 Thermistor/Thermostat GY-O

P2-3 Detergent Dispenser O-BK

P2-4 Rinse Aid Dispenser LBU

P2-5 Fill Valve BR

P3 Motor Main Winding BU

P4 Motor Aux Winding - Wash Y

P5 Motor Aux Winding - Drain GY

P6 Switched L1 to Heater W-R

P7 AC Neutral W-V

P8 L1 T

P9

P10

FLOAT (IN

NORMAL POSITION)

CLOSES SWITCH

3378083

DESCRIPTION

Ribbon Cable to

User Interface

Switched L1 to Vent,

Fill Valve, Dual Dispenser,

& Pressure Switch

Switched L1 to

Motor Common

WIRE

COLOR

—

BU-BK

R-BK

USER INTERFACE SWITCH MATRIX

Note: Switches may not appear on all models, ID’s vary by model.

Note: Names of cycles vary by model. See Model Specific Cycle Name Key on the other side.

ID01

D6

ID02

D7

ID03

D8

WIRING DIAGRAM AND MODEL SPECIFIC ELECTRICAL COMPONENTS KEY

MODEL

NUMBER

1782x

1x63x

1x65x (Energy Star)

1x68x

1x71x

1x73x, 1X76X

1x75x

1682x, 1582x

1x83x

DP940

DU940, DU945, IKU586

DU941

DU600

DU943

DU948

DU950, DU951, DUL200

DU960PWK, DU620

SW3

CYCLE 5 SANI RINSE

SW2

CYCLE 6

SW1

CYCLE 7

P1-1 P1-4P1-2

WIRING

HARNESS

8275395

8275394

8275391

8275392 3384549 9742770

8275395

8275394

8275391 N/A N/A 3385007 8283345 3380871

8275394 8269521 3385002 N/A

8275391

*

INTERFACE

3384833 or

3384551 or

3384552 or

8269362 or

8269362 or

8269358 or

DENOTES ENERGY EFFICIENT COMPONENTS.DO NOT SUBSTITUTE.

SW6

SW5

HIGH TEMP

WASH

SW4

CYCLE 1

D1

USER

3385147

3385148

3385149

3385150 3385007 8283346

3384406

8269364

8269509

8269364

8269509

8269508

D2

P1-3

NUMERIC

DISPLAY

N/A N/A

3383825

SW9

DELAY

SW8

CYCLE 4

SW7

CYCLE 3

ACTUATOR

ASSEMBLY

VENT

START

(WHERE

APPLICABLE)

SW11

CANCEL

SW10

AIR DRY

D3

PUMP & MOTOR

ASSEMBLY

3385004

3385006

3385002

3385373

3385007 3380871

SCOUR/SCRUB

D4

P1-5

FILL VALVE

8274220

8283345

8274220

SW15SW12

HIGH TEMP

SW14

CYCLE 2

ID00

D9

*

P1-11

P1-12

P1-13

D5

P1-6

PRESSURE

SWITCH

N/A

3380871

N/A

WATER

*

TEMPERATURE

SENSOR

3378083

(Thermostat)

9743158

(Thermistor)

9743158

(Thermistor)

DISHWASHER CIRCUITS

The following individual circuits are for use in diagnosis. Before starting diagnosis, check the line voltage and check for blown fuses.

FILL

L1

BK T

DOOR

SWITCH

WASH / RINSE

L1

BK T

DOOR

SWITCH

T

TCO

98°C (208°F)

T

TCO

98°C (208°F)

N.O.

P8

K3 RELAY

ELECTRONIC CONTROL

N.O.

P8

K1 RELAY

ELECTRONIC CONTROL

DISPENSER (DETERGENT & RINSE AID)

L1

BK T T

DOOR

SWITCH

TCO

98°C (208°F)

N.O.

P8

K3 RELAY

ELECTRONIC CONTROL

P9

P10

P9

N.O.

BU-BK

OVERFILLSW.

R-BK

BU-BK

PUMP

&MOTOR

ASSEMBLY

FLOAT (IN NORMAL POSITION)

CLOSES SWITCH

BR-W

FILLVALVE

695 - 995

MAIN WINDING

2.0 - 3.4

BU

P3 P7

WASH

WINDING

4.2-7.0

Y

P4

ELECTRONIC CONTROL

DUALWAX MOTOR

O-BK

DETERGENT

600 - 1800

LBU

RINSE AID

600 - 1800

BR

P2-5

Q3 TRIAC

ELECTRONIC CONTROL

SENSE

RESISTOR

<1

Q5 TRIAC

Q1 TRIAC

P2-3

P2-4

Q2 TRIAC

ELECTRONIC CONTROL

P7

P7

W-V

W-V

W-V

DOOR

SWITCH

DOOR

SWITCH

DOOR

SWITCH

W

W

N

W

ARTICULATED VENT ASSEMBLY &

ELECTRONICS COVER REMOVAL

1. Disconnect electrical power from dishwasher.

N

N

DRAIN

L1

BK T

DOOR

SWITCH

WATER HEATING

L1

BK T

DOOR

SWITCH

TCO

98°C (208°F)

TCO

98°C (208°F)

MAIN WINDING

N.C.

2.0-3.4

DRAIN

WINDING

4.2-7.0

BU

P3 P7

SENSE

RESISTOR

<1

GY

P5

Q6 TRIAC

ELECTRONIC CONTROL

OR

HEATER

15 - 35

800/500W PTC

N.O.

T

P8

K1 RELAY

ELECTRONIC CONTROL

PUMP IS ALSO WASHINGDURING WATER HEATING PERIODS (SEE WASH/RINSE)

N.O.

T

P8

K2 RELAY

ELECTRONIC CONTROL

P10

P6

R-BK

PUMP

&MOTOR

ASSEMBLY

W-R

HI-LIMIT THERMOSTAT

OPENS 77°C - 83°C

(171°F -181°F)

W-V

W-V

DOOR

SWITCH

DOOR

SWITCH

N

W

N

W

2. Refer to Figure 1.Open dishwasher door and insert

the end of a screwdriver into the notch in the vent

louver .Push counter-clockwise to rotate louver

approximately 1/8 turn to release it. Remove louver

and set aside for later reinstallation.

3. Remove eight (8) screws around perimeter of the

inner door panel and remove panel.See Figure 1.

4. To remove the vent assembly, refer to Figure 2 and

disconnect two (2) electrical harness wire leads

from wax motor terminals.Lift out the vent

assembly, retaining the seal ring for later

reinstallation.

5. To access electronic controls, press in on snap tab

at end of electronics cover to release, then lift cover

up at tab end as you slide cover out.See Figure 2.

ARTICULATED VENT ASSEMBLY &

ELECTRONICS COVER REINSTALLATION

1. Reinstall electronics cover by sliding it into position

above controls and pressing down till snap tab holds

it in place.(Figure 2 shows cover removal.)

2. Reinstall the vent assembly. Refer to Figure 2 and

reconnect two (2) electrical harness wire leads to

the wax motor terminals.Place seal ring in seal ring

groove of vent assembly, and lower vent assembly

into place.

3. Reinstall inner door panel. Align it in place over the

vent assembly, and reinstall eight (8) screws around

the inner door panel perimeter.See Figure 1.

4. Align vent louver over vent assembly, and tur n

louver clockwise by hand to engage vent assembly.

5. Insert the end of a screwdriver into the notch in the

vent louver. Push clockwise to rotate louver

approximately 1/8 turn to lock it in position.See

Figure 1.

6. Reconnect electrical power to dishwasher.

Electronics

Cover

ELECTRONIC

HEAT DRY

L1

CONTROL

P2-2

GY-O

T

THERMISTOR

47-53K @25°C/77°F

12-13K @60°C/140°F

(W)

W-V

P7

WATER

TEMPERATURE SENSOR

DEPENDS ON MODEL

(SEETABLE)

ELECTRONIC

CONTROL

GY-O

N.O.

OPERATING THERMOSTAT

CLOSES 57°C - 63°C

(135°F -145°F)

(W)

W-V

Seal

Counter-Clockwise

Ring

Clockwise

to Lock

Snap

Tab

to Release

Notch

Vent

N

Louver

Harness Wire

Leads Location

BK T

DOOR

SWITCH

TCO

98°C (208°F)

N.O.

T

P8

K2 RELAY

ELECTRONIC CONTROL

P6

W-R

N.C.

HI-LIMIT THERMOSTAT

OPENS 77°C - 83°C

(171°F -181°F)

OR

HEATER

15 - 35

800/500W PTC

W-V

DOOR

SWITCH

W

Inner

Door Panel

Vent

Assembly

(8)

InnerDoorPanel

Screws

VENT

L1

BK T

DOOR

SWITCH

Figure 1

(USED ONLY ON SOME MODELS, OTHERWISE OPEN. SEE TABLE)

N.O.

P8

K3 RELAY

ELECTRONIC CONTROL

P9

BU-BK

TCO

98°C (208°F)

T

VENT

ACTUATOR

600 - 1800

DOOR

SWITCH

N

WW-V

SOIL SENSING

L1

BK T

DOOR

SWITCH

98°C (208°F)

FOR SERVICE TECHNICIAN'S USE ONLY FOR SERVICE TECHNICIAN'S USE ONLY FOR SERVICE TECHNICIAN'S USE ONLY

(USED ONLY ON SOME MODELS, OTHERWISE OPEN. SEE TABLE)

PUMP IS ALSO WASHING DURING SENSING PERIODS (SEEWASH / RINSE)

TCO

N.O.

T

P8

K3 RELAY

ELECTRONIC CONTROL

SWITCH CLOSES WHEN

SIGNIFICANT SOILS

ACCUMULATE IN PUMP

P9

BU-BK

N.O.

PRESSURE

SWITCH

(SOIL SENSOR)

O-GY

P2-1

ELECTRONIC

CONTROL

MANUFACTURED UNDER ONE OR MORE OF THE

FOLLOWING UNITED STATES PATENTS:

4,319,598

4,319,599

4,350,306

4,418,868

4,449,765

4,559,959

4,693,526

4,732,323

DES314,256 DES320,489 DES393,333 DES391,696

4,732,431

4,746,177

4,753,570

4,758,057

4,765,697

4,776,620

4,802,934

4,805,647

4,822,241

4,834,125

4,848,382

4,927,033

4,991,611

5,005,740

5,018,550

5,031,649

OTHER PATENTS PENDING

5,031,651

5,033,659

5,039,828

5,069,360

5,158,346

5,165,433

5,165,435

5,202,582

5,330,102

5,474,378

5,637,938

5,881,906

5,882,739

5,900,070

Figure 2

MANUFACTURED UNDER ONE OR

MORE OF THE FOLLOWING

CANADIAN PATENTS:

1,278,461

1,288,666

1,288,667

1,288,688

2,001,663

2,017,386

2,022,831

OTHER PATENTS PENDING

DES67168

2,033,506

2,049,828

2,053,752

2,058,213

2,075,251

2,115,475

FOR SERVICE TECHNICIAN'S USE ONLY FOR SERVICE TECHNICIAN'S USE ONLY FOR SERVICE TECHNICIAN'S USE ONLY PAGE 2

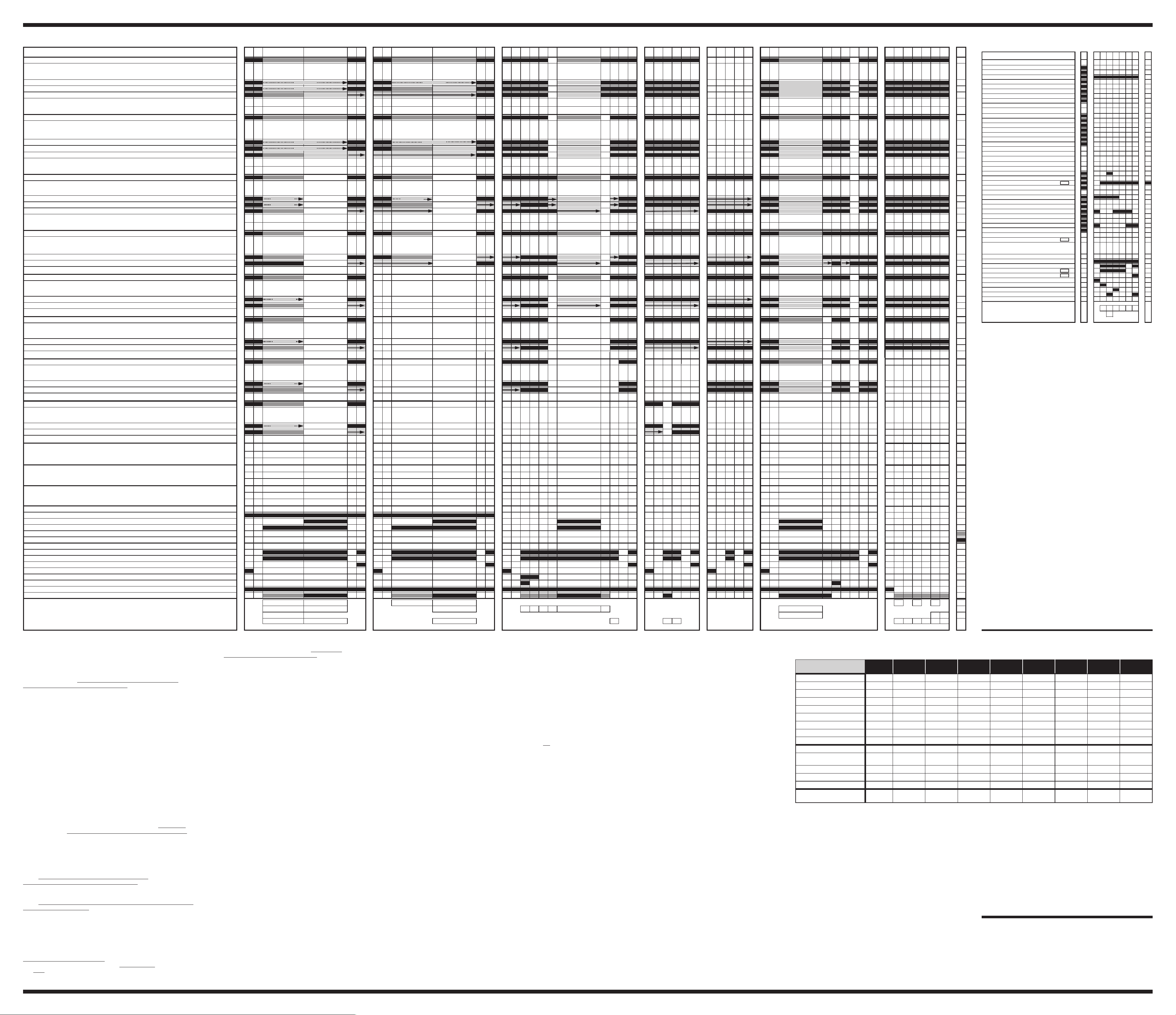

COMMON CYCLE TIME CHART

INTERVAL

CYCLE 1

INTERVAL TIME (min:sec)

HIGH SOIL 85 - 97 : 00 w/o Th.Holds soil sensed soil sensed

MEDIUM SOIL 91 - 97 : 00 w/o Th.Holds soil sensed

LOW SOIL OR NON-SENSOR MODEL 87 : 00 w/o Th.Holds [135°F/57°C]

NUMERIC CYCLE TIME DISPLAY NOTE 5 85 83 83 83 83 83 81 79 79

Special Adjustments for Hi Temp Scrub/Scour (Note 14) -->

CYCLE 2

INTERVAL TIME (min:sec)

HIGH SOIL 80 - 92 : 00 w/o Th.Holds soil sensed soil sensed

MEDIUM SOIL 86 - 92 : 00 w/o Th.Holds soil sensed

LOW SOIL OR NON-SENSOR MODEL 82 : 00 w/o Th.Holds [135°F/57°C]

NUMERIC CYCLE TIME DISPLAY NOTE 5 80 78 78 78 78 78 76 74 74

Special Adjustments for Hi Temp Scrub/Scour (Note 14) -->

CYCLE 3 (a)

INTERVAL TIME (min:sec)

HIGH SOIL 78 - 90 : 00 w/o Th.Holds soil sensed soil sensed

MEDIUM SOIL 80 - 86 : 00 w/o Th.Holds soil sensed

LOW SOIL OR NON-SENSOR MODEL 71 : 30 w/o Th.Holds

NUMERIC CYCLE TIME DISPLAY NOTE 5 78 76 76 76 76 74 72 72

Special Adjustmentsfor Low Soil/Non-Sensor version (Note 5) -->

CYCLE 3 (b)

INTERVAL TIME (min:sec)

"MEDIUM SOIL" - invoked by options only - see Notes 14 & 17 87 : 50 w/o Th.Holds

ANY SOIL (This cycle is for certain NON-SENSOR MODELS only) 84 : 10 w/oTh.Holds

NUMERIC CYCLE TIME DISPLAY (N/A, this cycle is for NON-DISPLAYMODELS only)

CYCLE 4

INTERVAL TIME (min:sec)

MEDIUM SOIL 71 - 75 : 50 w/o Th.Holds soil sensed

LOW SOIL OR NON-SENSOR MODEL 61 : 20 w/o Th.Holds

NUMERIC CYCLE TIME DISPLAY NOTE 5 72 70 70 70 70

CYCLE 5

INTERVAL TIME (min:sec)

MEDIUM SOIL 68 - 72 : 00 w/o Th.Holds soil sensed

LOW SOIL OR NON-SENSOR MODEL 57 : 30 w/o Th.Holds

NUMERIC CYCLE TIME DISPLAY NOTE 5 68 66 66 66 66

NUMERIC CYCLE TIME DISPLAY NOTE 5 68 66 66 66 66

CYCLE 6

INTERVAL TIME (min:sec)

MEDIUM SOIL 25 - 29 : 30 w/o Th.Holds soil sensed

LOW SOIL OR NON-SENSOR MODEL 25 : 30 w/o Th.Holds

NUMERIC CYCLE TIME DISPLAY NOTE 5 26 24 24 24 24

CYCLE 7

INTERVAL TIME (min:sec)

MEDIUM SOIL 10 - 14 : 00 (no Th.Holds) soil sensed

LOW SOIL OR NON-SENSOR MODEL 10 : 00 (no Th.Holds)

NUMERIC CYCLE TIME DISPLAY NOTE 5 10 8 8 8 8

CYCLE PROGRESSION INDICATORS

CYCLE 1, CYCLE 2, & CYCLE 3 W2 W2 W2

(W1=WASHING,R1=RINSING, D1=DRYING)

CYCLE PROGRESSION INDICATORS

CYCLE 4, CYCLE 5, & CYCLE 6

(W1=WASHING,R1=RINSING, D1=DRYING)

CYCLE PROGRESSION INDICATORS

CYCLE 7

(W1=WASHING,R1=RINSING, D1=DRYING)

NOTES 1,14,15,16,17

NOTES 1,14,15,16,17

NOTES 1,14,15,16,17

.

NOTES 1,14,15,16,17

NOTES 1,11,15,16,17

NOTES 1,10,11,16

NOTE 1

NOTE 1

NOTE 9

NOTE 9

NOTE 9

50 49 48 47 46 45 44 43 42

SOIL SENSE

(default6:00 max)

2:00

0:05

SOIL SENSE

(default6:00 max)

2:00

0:05

SOIL SENSE

(default6:00 max)

2:00

0:05

SOIL SENSE

(default6:00 max)

1:55

0:05

SOIL SENSE

(default4:00 max)

1.55

0:05

SOIL SENSE

(default4:00 max)

2:00

0:05

SOIL SENSE

(default4:00 max)

2:00

0:05

SOIL SENSE

(default4:00 max)

2:00

0:05

W1 W1 W1 W1 W1 W1 W1 W1 W1

W1 W1 W1 W1 W1

R1 R1 R1 R1 R1

PERIOD 1 PERIOD 2

PRE-WASH / PRE-RINSE PRE-RINSE

THERMAL H OLD

& SOIL SENSE

(default25:00 max)

THERMAL H OLD

& SOIL SENSE

(default25:00 max)

0:05

0:05

0:05

0:05

0:05

0:05

0:05

0:05

2:00

2:00

2:00

2:00

2:00

2:00

2:00

2:00

2:00

2:00

2:00

2:00

SOIL SENSE

(default6:00 max)

0:05

SOIL SENSE

(default6:00 max)

0:05

SOIL SENSE

(default6:00 max)

0:05

SOIL SENSE

(default6:00 max)

0:05

soil sensed [ ]140°F/60°C

soil sensed [ ]140°F/60°C [140°F/60°C]

STATUS INDICATORS

ADD-A-DISH (turns on for CYCLES 1, 2, and 3 ONLY)

WATER HEATING NOTE 6

SENSING NOTE 7

SANITIZED NOTE 8

CLEAN NOTE 8

OUTPUT LOADS

MOTOR

WASH NOTE 12

DRAIN NOTE12

FILL

DETERGENT DISPENSER

RINSE AID (DET/R.A.) DISPENSER

VENT

HEATER NOTES 4,10,11,14,15,16

1, 2 2 2

4, 11 3

17

14 14

NOTES

PERIOD 3 PERIOD 4 (a) PERIOD 4 (b) PERIOD 5

MAIN WASH RINSE PURGE FINAL RINSE

41 40 39 38 37 36 35 34 33 32 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8

THERMAL H OLD

& SOIL SENSE

(default20:00 max)

[135°F/57°C] [ ]140°F/60°C

79 79 79 77 75 75 75 73 67 67 62 62 62 60 58 58 52 46 46 42 42 42 42 41 40 32 32

THERMAL H OLD

& SOIL SENSE

(default20:00 max)

[135°F/57°C] [ ]140°F/60°C [1 ]40°F/60°C

74 74 74 72 70 70 70 68 62 62 62 62 60 58 58 52 46 46 44 42 42 42 41 40 32 32

W1 W1 W1 W1 W1 W1 W1 W1 W1 W1 W1 W1 W1 W1 R1 R1 R1 R1 R1 R1 R1 R1 R1 R1 R1 R1 R1 R1 R1 R1 R1 R1 R1 R1

W2 W2 W2 W2 W2 W2 W2 W2 W2 W2 W2 W2 W2 W2 R2 R2 R2 R2 R2 R2 R2 R2 R2

2

3 444434 3

14 14 14 14

NOTES NOTES NOTES NOTES NOTES

0:05

2:00

2:00

0:05

0:05

1:55

0:05

2:00

2:00

0:05

0:05

1:55

0:05

2:00

2:00

0:05

0:05

1:55

72 72 70 68 68 68 66 -- 62 -- 62 62 60 58 58 52 46 46 -- -- -- -- -- 44 42 42 42 41 40 32 32

66 59 -- 50 48 48 -- -- -- -- -- -- 46 46 46 45 45 44

0:05

2:00

1:45

0:05

0:05

1:55

2:00

0:05

0:05

1:55

68 66 66 66 64 60 60 58 58 56 54 54 48 46 46 46 46 45 45 45 44 42 42 42 41 40 32 32

2:00

0:05

0:05

1:55

64 62 62 62 60 56 54 54 52 50 50 44 42 42 42 42 42 41 41 40 38 38 38 37 32 32 30

64 62 62 62 60 56 54 54 52 50 50 44 42 42 42 42 42 41 41 40 38 38 38 37 32 32 30

2:00

0:05

0:05

1:55

22 20 20 20 18 12 12 10 10 10 9 9 6 6 6 6 5 2 2

W3 W3 W3 W3 W3 W3 W3 W3 W3 W3 W3 R3 R3 R3 R3 R3 R3

W1 W1 W1 W1 W1 W1 W1 W1 R1 R1 R1 R1 R1 R1 R1 R1 R1 R1 R1 R1 R1 R1 R1 R1 R1 R1 R1

W2 W2 W2 W2 W2 W2 W2 W2 R2 R2 R2 R2 R2 R2 R2 R2

W3 W3 W3 W3 R3 R3 R3 R3 R3

6:00

6:00

4:00

4:00

4:00

4:00

6:00

4:00

2:00

THERMAL H OLD

(default20:00 Max)

[]140°F/60°C

THERMAL H OLD

(default20:00 Max)

[]140°F/60°C []140°F/60°C

THERMAL H OLD

(default30:00 Max)

[]140°F/60°C []140°F/60°C

[]140°F/60°C []140°F/60°C

THERMAL H OLD

(default30:00 Max)

[]140°F/60°C []140°F/60°C

THERMAL H OLD

(default30:00 Max)

[]140°F/60°C []140°F/60°C

5:00

0:05

2:00

2:00

0:05

2:00

2:00

2:00

2:00

2:00

2:00

0:05

0:05

0:05

0:05

0:05

0:05

6:00

6:00

6:00

6:00

6:00

6:00

0:00

62 52 52 50 48 48 48 46

0:05

2:00

0:00

62 52 52 50 48 48 48 46

2:00

0:05

2:00

0:05

2:00

16:30

2:00

0:05

2:00

2:00

0:05

2:00

0:05

2:00

64 422

R1 R1 R1 R1 R1

R2 R2 R2 R2 R2

6:00

6:00

6:00

6:00

2:00

2:00

2:00

0:05

0:05

0:05

0:05

0:05

0:05

0:05

R3 R3

2:00

2:00

2:00

2:00

2:00

2:00

2:00

0:25

0:45

0:25

0:25

0:25

0:05

0:05

0:05

0:05

0:05

0:05

0:30

0:05

0:05

0:05

0:05

0:05

0:05

0:05

0:05

1:00

1:00

1:00

1:00

1:00

(anti-bac 40:00 max)

2:00

0:05

anti-bac [155°F/68°C]

(default25:00 Max)

2:00

0:05

(default30:00 Max)

2:00

0:05

(default30:00 Max)

1:45

0:05

(default40:00 Max)

1:55

0:05

(default15:00 Max)

2:00

0:05

(default40:00 Max)

2:00

0:05

THERMAL H OLD

(p&p 25:00 max)

p&p [140°F/60°C]

THERMAL H OLD

THERMAL H OLD

[]140°F/60°C

THERMAL H OLD

[]140°F/60°C

THERMAL H OLD

[]140°F/60°C

THERMAL H OLD

[130°F/54°C]

[130°F/54°C]

THERMAL H OLD

[]140°F/60°C

[]140°F/60°C

15

1:00

1:00

1:00

1:00

1:00

1:30

1:30

1:30

1:30

1:30

1:30

1:30

7:30

7:30

7:30

2:30

7:30

4:30

2:30

5:00

0:05

0:05

0:05

0:05

0:05

0:05

0:05

PERIOD 6

DRY

7654321 0

2:00

6:00

2:00

6:00

2:00

6:00

30 24 2 16 14 8 6

2:00

6:00

2:00

6:00

2:00

6:00

30 24 22 16 14 8 6

2:00

6:00

2:00

6:00

2:00

6:00

30 24 22 16 14 8 6

2:00

6:00

2:00

6:00

2:00

6:00

2:00

6:00

2:00

6:00

2:00

6:00

30 24 22 16 14 8 6

2:00

6:00

2:00

6:00

2:00

6:00

24 22 16 14 8 6

24 22 16 14 8 6

2:00

D1 D1 D1 D1 D1 D1 D1

D2 D2 D2 D2

D1 D1 D1 D1 D1 D1 D1

D2 D2 D2 D2

10 10 10 8

16 16 16 16 16 16

NOTES

15 15 15

2:00

2:00

2:00

2:00

2:00

2:00

6:00

6:00

6:00

6:00

6:00

6:00

DIAGNOSTICS CYCLE TIME CHART

INTERVAL

CYCLE BUTTON LIGHTS

POTS & PANS / ANTI-BACTERIA

HEAVY/POTSPANS

NORMAL/HEAVY

W. MISER

CHINA / LIGHT WASH

QUICK WASH / TIME SAVER

RINSE CYCLE/QUICK RINSE

CANCEL DRAIN

OPTION BUTTON LIGHTS

HI TEMP SCRUB/SCOUR

HI TEMPWASH

SANI RINSE

NO HEAT DRY / AIR DRY

DELAY 0-2 HR

DELAY 2-4 HR

DELAY 4-6 HR

STATUS LIGHTS

LOCKOUT

ADD-A-DISH

WATER HEATING

SENSING

CLEAN

SANI COMPLETE / SANITIZED

WASHING (W1)

W2

W3

RINSING (R1)

R2

R3

DRYING(D1)

D2

NUMERIC CYCLETIME DISPLAY

INTERVAL TIME (min:sec)

VENT (disp, fill, soil enable)

MOTOR

WASH DIRECTION

DRAIN DIRECTION

FILL

DETERGENT DISPENSER

RINSE AID DISPENSER

HEATER

NOTE 2

NOTE 1 88 14 12 10 10 8 8 6

NOTE 3

NOTE 3

8 7654321 0

S

T

A

N

D

B

Y

0:03

TH

2:00

2:00

2:00

0:05

222222

4

NOTES

2:00

6:00

RAPID ADVANCE SERVICE FEATURE AND

or

-

(above):

-

DIAGNOSTICS CYCLES

Pressing the following option keys in the sequence shown will either start

the Diagnostics Cycle or turn on the Rapid Advance feature for customer

selectable cycles:

HI TEMP WASH→AIR DRY→HI TEMP WASH→AIR DRY

HI TEMP SCRUB/SCOUR

If the sequence is entered after starting a cycle, the Rapid Advance

feature is turned on, which allows the operator to manually advance the

currently running cycle, interval by interval, by pressing the Pots & Pans

or Anti-Bacteria key.

If the above key sequence is entered with the dishwasher in Standby, the

Diagnostics Cycle is started. The operator can advance the cycle, interval

by interval, by pressing the Pots & Pans or Anti-Bacteria key.

(DIAGNOSTICS) NOTE 1 – Numeric Cycle Time Display

For models with time displays, the display shows the current cycle time

remaining in the Diagnostics Cycle (in minutes).

(DIAGNOSTICS) NOTE 2 – Thermostat/Thermistor

Detection

To help identify whether a thermostat or thermistor is installed in the

dishwasher, the clean light is only illuminated in intervals 1-6 of the

Diagnostics Cycle if a thermostat is installed. This determination is based

on the resistance detected on the temperature sensor line. Because the

resistance limits used by the control are close to the thermistor resistance

at room ambient, this indicator is only reliable if warm water is in the

dishwasher.

(DIAGNOSTICS) NOTE 3 – Wash and Drain Motor Phase

Windings

The wash and drain phase winding outputs are only “on” while the motor

is starting in the respective mode. Once the control has determined that

the motor started properly, the phase winding output is turned off".

(DIAGNOSTICS) NOTE 4 - Thermal Hold

The setpoint temperature for this thermal hold is 60°C/140°F and the

default time limit is 1 hour.

→

AIR DRY→HI TEMP SCRUB/SCOUR→AIR DRY

COMMON CYCLE TIME CHART NOTES

Common Cycle Time Chart describes the seven different cycles that are

available in the electronic control that is in the models on this Tech Sheet.

Each model uses some or all of these cycles but may call them different

names on the keypad. See the Model Specific Cycle Name Key to

identify the cycles and names for your model.

Note: there are 2 different cycles shown for Cycle 3 (Cycle 3a and 3b);

the control determines which Cycle 3 to use based on the model ID of the

user-interface it is hooked up to.

Note: the Final Rinse Thermal Hold temperature for Cycle 1 depends on

the model ID of the user interface it is hooked up to and whether it is a

model that needs an Anti-Bacteria cycle.

NOTE 1 - CYCLE MODIFICATIONS BASED ON SOIL LEVEL

The cycles all contain least one Soil Sense interval in the first Pre-Wash

and/or Pre-Rinse of the cycle (see Note 2 for a description of what

happens in a Soil Sense interval). The control determines the level of food

soil that is on the dishes based on what soil sensor (pressure switch)

inputs it receives during these Pre-Wash and/or Pre-Rinse Soil Sense

intervals and adjusts the cycle accordingly:

■

HIGH SOIL - Soil sensor tripped in intervals 48 or 47 and again in

intervals 42 or 41.

■

MEDIUM SOIL - Soil sensor tripped in intervals 48 or 47 but not in

intervals 42 or 41.

■

LOW SOIL - Soil sensor did not trip in intervals 48 or 47 (cycle skips

Sense intervals 42 & 41).

The control adjusts the remainder of the cycle for the soil level detected

by skipping certain intervals or portions of the cycle. The "solid arrows

on the Time Chart show which intervals are skipped for each Soil Level

(example: Cycle 1 skips intervals 46 through 41 when Low Soil is

detected).

All versions of a cycle are the same until the end of the Soil Sense

interval(s) in the Pre-Wash (intervals 48 & 47). If no soil is sensed in the

Pre-Wash, then the Low Soil version of the cycle is executed from that

point on.

Note: Non-Sensor models (without pressure switches)

always default to the Low Soil version of the cycle

never trip and thus

(unless modified by

customer selected Options). See Model Specific Electrical Components

Table to identify Non-Sensor models without pressure switches.

Note: High Temp Wash and High Temp/Power Scour options can override

Soil Sense interval decisions (see notes 14 and 17).

If the Soil Sensor trips in interval 48 or 47, then the control will execute

either the Medium or High Soil version of the cycle. Medium and High

Soil versions of the cycle are identical until the second set of Soil Sense

intervals in the Pre-Rinse (intervals 42 & 41), where High Soil versus

Medium soil can be determined. If soil is detected again in the Pre-Rinse,

then the High Soil version is executed; if not, then the Medium Soil

version is executed.

When a Soil Sensor trip is detected

control immediately ends the interval and skips directly to

and drain

intervals of the cycle (to clean the soil collection screens in the

during ANY Soil Sense interval, the

the next pause

"

pump) and then proceeds from there. The "dotted arrows" on the Time

Chart show this skip to drain upon sensing soil

(see Note 2).

The Time Chart shows a range of cycle time estimates for each Soil Level

version of the cycle (example: 85 - 97:00 minutes for Cycle 1 with High

Soil). The estimates do not include time spent in thermal hold intervals,

which varies. Even without thermal holds, there is still some variation in

cycle time because it depends on how long it takes for the soil sensor to

trip during the Soil Sense intervals.

NOTE 2 – SOIL SENSE INTERVALS

During Soil Sense intervals (48, 47, 42, and 41), cycle timing is

interrupted and the dishwasher continues to wash (& sometimes heat)

while it monitors the Pressure Switch (soil sensor) input. A “Sensing”

indicator (available on some models) will be turned on and the cycle time

displayed by models with numeric displays will be frozen until the end of

the Soil Sense interval (see Notes 5 & 6). The Soil Sense interval will

continue until a pressure switch (soil sensor) trip is detected or the default

maximum time limit specified for the Soil Sense interval expires. The de

fault time limit for each Soil Sense interval of each cycle is shown on the

Time Chart. If the default time limit expires, the Soil Sense interval ends,

normal operation and cycle timing resume, and the control proceeds with

a lower soil level version of the cycle (see Note 1). If a pressure switch

trip is detected, the control immediately ends the Soil Sense interval and

skips directly to the next pause and drain intervals of the cycle (per the

“dotted arrow” on the Time Chart) to clean out the soil collection screens

in the pump. Normal operation and timing resume and the control

proceeds with a higher soil level version of the cycle (see Note 1).

Note: Intervals 47 and 41 are Water Heating Thermal Hold intervals as

well as Soil Sense intervals (see Note 3 on Thermal Holds). The default

time limit for these intervals is longer to accommodate the Thermal Hold

aspect. If the Thermal Hold temperature setpoint is reached prior to

detecting a pressure switch trip in one of these intervals, then the interval

will end and the Soil Level determination will be the same as if the default

time limit for the Soil Sense interval expired (see Note 1). If a pressure

switch trip is detected before reaching temperature, the interval will end

and the control will skip directly to the next pause and drain interval like

all Soil Sense intervals.

Note: Models without pressure switches (soil sensors) never trip and

always run to the default time limit of the Soil Sense intervals.

Consequently they also always default to the Low Soil version of the cycle

(see Note 1). See Model Specifics Component Table to identify models

without pressure switches.

NOTE 3 – WATER HEATING THERMAL HOLD INTERVALS

During Water Heating Thermal Holds (intervals 47, 41, 32, & 14), cycle

timing is interrupted and the dishwasher continues washing while it heats

the water to the setpoint temperature specified on the Time Chart for the

Thermal Hold. The Water Heating and Sensing lights (available on most

models) are turned on and the cycle time displayed by models with

numeric displays is frozen during Thermal Hold intervals (see notes 5, 6,

& 7). The dishwasher will hold in this suspended, water heating mode until

the water reaches the temperature specified for the Thermal Hold or a

maximum default time limit for the Thermal Hold expires.The default

maximum time limit for each Thermal Hold interval of each cycle is shown

on the Time Chart. At the conclusion of the thermal hold, the control

resumes normal operation and timing and proceeds to the next interval

per the Time Chart.

NOTE 4 – THERMALLY CAPPED INTERVALS

Intervals 33-36 are heated wash intervals thermally capped at 60°C/140°F

for Cycles 3, 4, 5, and 6. Interval 31 is a heated wash interval thermally

capped at 66°C/150°F for Cycles 1 and 2. Interval 48 is only heated for

Cycles 4 and 5 and is thermally capped at 60°C/140°F. Anytime the thermal

cap temperature is exceeded during one of these intervals, the heater will

turn off, but the dishwasher will continue washing for the duration of the

interval.

NOTE 5 – NUMERIC CYCLE TIME DISPLAY

Models with numeric cycle time displays show time remaining in the cycle (in

minutes) or time remaining in a delay (in hours). The display should clock

down minute by minute during the cycle and hour by hour during delays.

The initial time displayed for each cycle is based on the worst case version

of the cycle (either High or Medium Soil). The time that will be on the

display at the beginning of each interval as you progress through the cycle

is shown on the Time Chart. The cycle time displayed does not

-

spent in Thermal Hold or Soil Sense intervals; the time display is frozen

during Soil Sense and Thermal Hold intervals due to their variable length.

As portions of the cycle are skipped for lighter soil loads, the time on the

display skips with it and will show the cycle time specified on the Time Chart

for that new point in the cycle (see Note 1). See the Model Specific

Electrical Components Table to identify models with numeric displays.

Note: The skips that occur in Cycle 3a for Low Soil conditions are such that

they require special adjustments to the time display for certain intervals of

the cycle; these are shown in a secondary display line on the Time Chart.

include time

1. The Thermal Hold in the Final Rinse (interval 14) fails to reach the

required 68°C/155°F before timing out on its default time limit.

2. The door is opened and/or power is interrupted between the end of

the Final Rinse Thermal Hold (interval 14) and the end of the cycle.

NOTE 9 – WASHING STATUS LED EXCEPTION

For the following models, the Washing LED is on in all W1 and R1 intervals

(not just W1): 1x63x, 1x65x, 1782x, 1x71x, 1x73x, and 1x75x.

NOTE 10 – PULSED HEAT DRY – CYCLE 5 ONLY

For Cycle 5, the heater is turned off in intervals 2, 4, and 6 of the dry

period.

NOTE 11 – HEATER ON FOR CYCLES 4 & 5 ONLY

The Hi Temp Scrub/Scour option may turn the heater on in interval 48 for

other cycles (see Note 14), but the heater is turned on as standard practice

in interval 48 for Cycles4&5only; and it is thermally capped at 60°C/140°F

(see Note 4).

NOTE 12 - WASH AND DRAIN MOTOR PHASE WINDINGS

The wash and drain phase winding outputs are only “on” while the motor

is starting in each of these respective directions. Once the control has

determined that the motor started properly, the phase winding output is

turned “off”.

OPTION NOTES

MODEL

1x65x

1x63x, 1782x

1x68x

1x71x

1x73x

1x75x

1x76x

1582x, 1682x

1x83x

DP940

DU940, DU943, DU945, DU600,

IKU586

DU948

DU941, DU950, DU951, DUL200

DU620, DU960PWK

Engineering Software

Reference

MODEL SPECIFIC CYCLE NAME KEY

ENERGY

STAR

Yes — Pots/Pans — Heavy Wash Normal Wash Light Wash — Quick Rinse

No — Pots/Pans — Normal Wash Water Miser Light Wash — Quick Rinse

No — Pots/Pans — Normal Wash Water Miser Light Wash — Quick Rinse

No — Pots/Pans Normal Wash — Water Miser China Gentle — Quick Rinse

No — Pots/Pans Normal Wash — Water Miser China Gentle — Quick Rinse

No — Pots/Pans Normal Wash — — China Gentle Time Saver Quick Rinse

No — Pots/Pans Normal Wash — Water Miser China Gentle — Quick Rinse

No — Pots/Pans Normal Wash — — China Gentle Time Saver Quick Rinse

No Anti-Bac Pots/Pans Normal Wash — — China Gentle Time Saver Quick Rinse

Yes Pots&Pans — Heavy Wash — Normal Wash Light Wash — Rinse Only

Yes Pots&Pans — Heavy Wash — Normal Wash Light Wash — Rinse Only

Yes Anti-Bac Pots&Pans — — Normal Wash Light Wash Quick Wash Rinse Only

Yes Pots&Pans — Heavy Wash — Normal Wash Light Wash — Rinse Only

Yes Pots&Pans — Heavy Wash — Normal Wash Light Wash Quick Wash Rinse Only

Yes orNoPots&Pans or

CYCLE

1

Anti-Bac

CYCLE

2

Heavy

CYCLE

3 (a)

Normal

(STD)

CYCLE

3 (b)

Normal

(IEC)

CYCLE

4

CYCLE

5

CYCLE

6

CYCLE

Miser China Quick Wash Rinse Only

7

Note: The High Temp/Power Scour option makes time adjustments to Cycles

1 and 2 that require special display adjustments and they are shown in a

secondary display line on the Time Chart (see Note 14).

NOTE 6 - WATER HEATING (THERMAL HOLD) INDICATOR

The Water Heating indicator is turned on during all Thermal Hold intervals to

signal that cycle timing, status LED sequencing, and numeric cycle time

display countdown operations have been suspended or frozen while the

water is heated to the proper temperature (see note 3).

NOTE 7 - SENSING INDICATOR

The Sensing indicator is turned on during all Thermal Hold and Soil Sense

intervals to signal that cycle timing, status LED sequencing, and numeric cy

cle time display countdown operations have been suspended or frozen while

(temperature and/or soil) sensors are being monitored (see Notes 2 and 3).

NOTE 8 - ‘END-OF-CYCLE’ STATUS INDICATORS – CLEAN and

SANITIZED

Both end-of-cycle indicators (Clean and Sanitized) turn on at the end of a

cycle and turn off upon pressing any key or opening the door.

(A) Clean

Comes on at the end of every cycle except Cycle 7.

(B) Sanitized

Comes on at the end of all cycles completed with the Sani Rinse option

selected (see Note 15). If the Sani Rinse option is completed

successfully, the indicator is turned on steady at the end of the cycle.

If the Sani Rinse was unsuccessful (see below), the indicator will flash

½ second on, ½ second off, repeatedly, at the end of the cycle. The

Sani Rinse will be deemed unsuccessful (& flash the indicator) if:

NOTE 14 - HI TEMP SCOUR or SCRUB OPTION

The Hi Temp Scour or Scrub option is not allowed with cycles 4, 5, 6, or 7.

This option optimizes the selected cycle for tough soils by making the

following adjustments to the cycle:

(A) Cycles 1 and 2

■

Forces the cycle to execute at least the medium soil version of the cycle

(regardless of whether soil is sensed in Soil Sense interval 47 or not).

This is done because Non-Sensor models would not otherwise be able to

bump up to the medium soil version, and with Sensor models, the tough

soils may not always be removed soon enough to detect in the Pre-Wash/

-

Pre-Rinse Soil Sense intervals. The additional Rinse that comes with the

medium soil version also provides a solution for installations experiencing

spotting or filming trouble.

■

Turns the heater on in pre-wash Soil Sense interval 48 and thermally

caps the heater at 60°C/140°F (see Note 4).

■

Lengthens the default time limit for Soil Sense interval 48 to 16:00

minutes.

■

Increases the target temperature for Soil Sense/Thermal Hold intervals

47 and 41 from 57°C/135°F to 60°C/140°F.

■

Adds 10:00 minutes of wash time to the main wash at interval 30 and

compensates for the added cycle time by shortening rinse intervals 25

and 24 to 0:00 and 2:00 minutes respectively. The cycle time displayed

by models with numeric time displays in intervals 23-30 is adjusted

accordingly and shown on the secondary display line on the Time Chart.

(B) Cycle 3

■

Forces the cycle to execute at least the medium soil version of the cycle

(regardless of whether soil is sensed in Soil Sense interval 47 or not).

This is done because Non-Sensor models would not otherwise be able

to bump up to the medium soil version, and with Sensor models, the

tough soils may not always be removed soon enough to detect in the

Pre-Wash/Pre-Rinse Soil Sense intervals. The additional Rinse that

comes with the medium soil version also provides a solution for

installations experiencing spotting or filming trouble.

■

Turns the heater on in Pre-Wash Soil Sense interval 48 and thermally

caps the heater at 60°C/140°F (see Note 4).

NOTE 15 - SANI RINSE OPTION

The Sani Rinse option is not allowed with Cycles 5, 6, or 7. It is “built in”

and treated as an automatic option with Cycle 1 on models that call for

Cycle 1 to be an Anti-Bacteria cycle. The Sani Rinse option makes the

following adjustments to the cycle:

■

Changes the target temperature for the Final Rinse Thermal Hold

interval 14 from 60°C/140°F to 68°C/155°F and adds 15:00 minutes to

the default maximum time limit for the Thermal Hold.

■

Turns the heater off in intervals 1 and 2 of the Dry period of the cycle.

■

Invokes the Sanitized status indicator at the end of the cycle (see

Note 8).

NOTE 16 - AIR DRY OPTION

The Air Dry option is not allowed with Cycles 6 or 7 (which have no dry

period). This option turns the heater off in intervals 1-6 of the Dry period

of the cycle.

NOTE 17 - HI TEMP WASH OPTION

The Hi Temp Wash option is not allowed with Cycles 5, 6, or 7. It is “built

in” and treated as an automatic option with Cycles 1 and 2. This option

makes the following adjustments to the cycle to boost wash performance:

■

Forces Cycles 3 and 4 to execute at least the medium soil version of

the cycle (regardless of whether soil is sensed in Soil Sense interval 47

or not). This guarantees that the cycle will include the Main Wash

Thermal Hold at interval 32 (and thus assures the Main Wash will be

heated to 60°C/140°F for increased wash performance). It also

guarantees two full rinses after the Main Wash, which likewise

increases wash performance and also provides a solution for installa

tions experiencing spotting or filming trouble. Cycles 1 and 2 already

include a Main Wash Thermal Hold and two full rinses in all versions,

so this option is considered “built in” or automatic for these cycles.

PART NO. 8275305

NOTE: This sheet contains important

Technical Service Data

FOR SERVICE TECHNICIAN ONLY

DO NOT REMOVE OR DESTROY

-

FOR SERVICE TECHNICIAN'S USE ONLY FOR SERVICE TECHNICIAN'S USE ONLY FOR SERVICE TECHNICIAN'S USE ONLY

Loading...

Loading...