Page 1

PCS 4LHD/4LHDX APPLICATION GUIDE

Ph: 1.804.227.3023 | www.powertraincontrolsolutions.com

Page 2

FORWARD

All information contained in this booklet is based on the latest data available at the time of publication approval. The right

is reserved to make product or publication changes, at any time without notice. Be sure to regularly check for the latest

version, which will be posted on the following website.

https://www.powertraincontrolsolutions.com/latest/documents/

Password: pcs4LHDapp

No part of any PCS publication may be reproduced, stored in any retrieval system, or transmitted in any form by any

means, including but not limited to electronic, mechanical, photocopying, recording, or otherwise without the prior written

permission of Powertrain Control Solutions. This includes all text, illustrations, tables, and charts.

Any comments, questions, requests or to supply updated publication information should be forwarded Powertrain Control

Solutions.

PREFACE

This manual assists the reader in the applications of the 4LHD/4LHDX transmission to vehicle systems. It gives an

overview of the transmission characteristics, as well as focusing on the interface systems between the transmission and

vehicle. The performance of the transmission is dependent on the vehicle design and integration of the interface systems.

This manual is divided into three sections:

Section 1 Transmission Specications and Attributes: Includes guidelines that describe the transmission’s

internal features, external features, performance limitations, and functionality options.

Section 2 Transmission to Vehicle Interfaces: Denes the transmission integration subsystem characteristics,

options, limitations, and integration requirements.

Section 3 Production Line Procedures: Describes transmission installation and transmission handling methods.

Adhering to the requirements set forth in this document is imperative to proper transmission system operation.

All dimensions and values in this manual are for reference only. Refer to the appropriate transmission installation detail

drawing(s) for denitive information.

For more detailed information on the Transmission Control Module (TCM), calibration process, and diagnostic procedures

refer to your TCM manual, as an example the PCS TCM2600 Manual.

For more detailed information on transmission maintenance, diagnostic, and troubleshooting procedures please refer to

the latest version of the PCS 4LHD/4LHDX Technician’s Guide.

Additional information for PCS provided kits and their part numbers are available in the latest version of the PCS OEM

Parts Catalog.

Powertrain Control Solutions

10511 Old Ridge Rd.

Ashland, VA 23005

+1 (804) 227-3023

support@ptcs.us

Page 3

Table of Contents

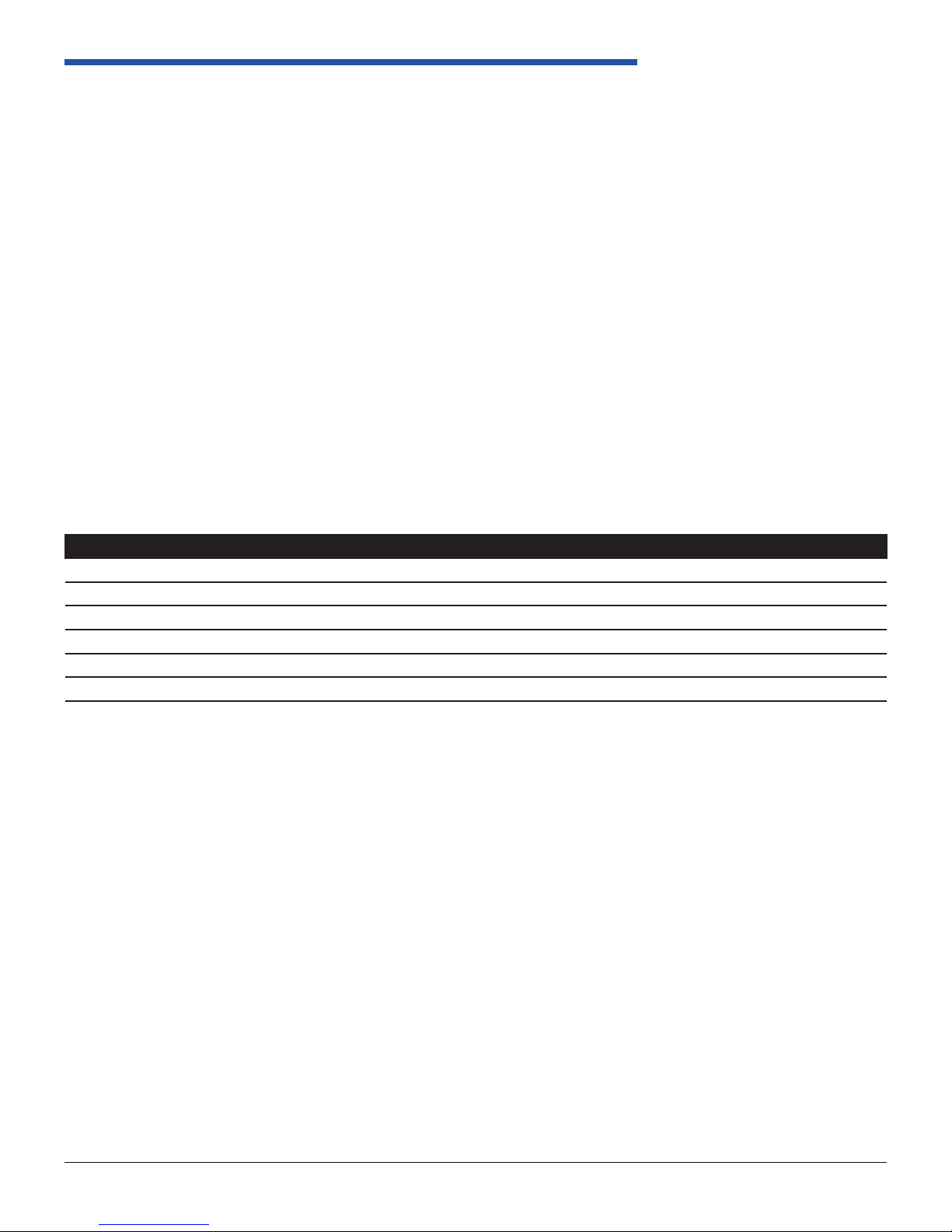

Section 1: Transmission Specications and Attributes ...................................................................................................................................... 1 - 18

Section 1.1 General Description .................................................................................................................................................................. 1 - 4

Section 1.1.1 Identication ................................................................................................................................................................2

Section 1.1.2 Feature Locations .......................................................................................................................................................3

Section 1.1.3 Gear Ratios .................................................................................................................................................................4

Section 1.2 Physical Specications ............................................................................................................................................................. 4 - 7

Section 1.2.1 Mass Properties ..........................................................................................................................................................4

Section 1.2.2 Driveline Lengths ........................................................................................................................................................5

Section 1.2.3 Center of Gravity ................................................................................................................................................... 6 - 7

Section 1.2.4 Inertia Properties .........................................................................................................................................................7

Section 1.2.4 Gross Vehicle Weight (GVW) ......................................................................................................................................7

Section 1.3 Maximum Performance Limitations .........................................................................................................................................8 - 11

Section 1.3.1 Torque Limitations .......................................................................................................................................................8

Section 1.3.2 RPM Limitations ..........................................................................................................................................................9

Section 1.3.3 Acceleration Limitations ..............................................................................................................................................9

Section 1.3.4 Temperature Limitations ............................................................................................................................................10

Section 1.3.5 Grade Limitations ......................................................................................................................................................11

Section 1.4 Valvebody Features and Specifcations ........................................................................................................................................12

Section 1.4.1 Abuse Protection .......................................................................................................................................................12

Section 1.4.2 Neutral Idle ................................................................................................................................................................12

Section 1.4.3 Electronic Range ........................................................................................................................................................12

Section 1.4.4 Inching Mode .............................................................................................................................................................12

Section 1.5 Electrical Specications ........................................................................................................................................................ 13 - 18

Section 1.5.1 Solenoids .......................................................................................................................................................... 13 - 16

Section 1.5.2 Internal Wiring ................................................................................................................................................... 17 - 18

Section 2: Transmission to Vehicle Interfaces .................................................................................................................................................... 19 - 69

Section 2.1 Transmission Input ............................................................................................................................................................... 19 - 30

Section 2.1.1 Torque Converters ............................................................................................................................................. 19 - 23

Section 2.1.2 Flexplate ....................................................................................................................................................................24

Section 2.1.3 Flywheel Interface .....................................................................................................................................................25

Section 2.1.4 Bellhousing to Flywheel Housing Interface ....................................................................................................... 26 - 30

Section 2.2 Transmission Output ............................................................................................................................................................ 31 - 39

Section 2.2.1 Lubrication and Sealing .............................................................................................................................................31

Section 2.2.2 Output Shaft Requirements ............................................................................................................................... 31 - 32

Section 2.2.3 Extension Housings .......................................................................................................................................... 32 - 39

Section 2.3 Transmission Cooling .......................................................................................................................................................... 40 - 52

Section 2.3.1 Cooling System Overview .........................................................................................................................................40

Section 2.3.2 Cooler Requirements .................................................................................................................................................41

Section 2.3.3 Cooler Lines ...................................................................................................................................................... 41 - 42

Section 2.3.4 Dipstick ......................................................................................................................................................................43

Section 2.3.5 Overow Vent ............................................................................................................................................................44

Page 4

Table of Contents

Section 2.3.6 Fluid Capacity ...........................................................................................................................................................45

Section 2.3.7 Check Fluid Level .............................................................................................................................................. 45 - 47

Section 2.3.8 Fluid Change ..................................................................................................................................................... 48 - 52

Section 2.4 Transmission Shift Lever ..................................................................................................................................................... 53 - 60

Section 2.4.1 Shaft Specs ...............................................................................................................................................................54

Section 2.4.2 Lever Specs ....................................................................................................................................................... 55 - 58

Section 2.4.3 Electronic Range ................................................................................................................................................ 59 - 60

Section 2.5 TCM Interface ....................................................................................................................................................................... 61 - 67

Section 2.5.1 TCM Overview .................................................................................................................................................. 61 - 62

Section 2.5.2 Vehicle Electrical Interface and Diagnostics ...................................................................................................... 63 - 66

Section 2.5.3 Harness Overview .....................................................................................................................................................67

Section 2.6 Throttle Position Sensor ....................................................................................................................................................... 68 - 69

Section 3: Production Line Procedures ............................................................................................................................................................... 70 - 73

Section 3.1 Assembly Procedures ........................................................................................................................................................... 70 - 71

Section 3.1.1 Storage Requirements ..............................................................................................................................................70

Section 3.1.2 Handling Requirements .............................................................................................................................................70

Section 3.1.3 Assembly Requirements ...........................................................................................................................................71

Section 3.2 End-of-Line Inspection Procedures ..................................................................................................................................... 72 - 73

Section 3.2.1 Pre-Start Checks .......................................................................................................................................................72

Section 3.2.2 Stationary Engine-Off Checks ...................................................................................................................................72

Section 3.2.3 Stationary Engine-Running Checks ...........................................................................................................................73

Section 3.2.4 Test Drive ..................................................................................................................................................................73

Section 3.2.5 Post Drive Check ......................................................................................................................................................73

Revision History

03-09-2016 - REV 1.0: Original Release

05-11-2016 - REV 1.1: Addition of torque specications for extension housing, line pressure tap tting, cooler lines, and bellhousing.

Page 5

SECTION 1

TRANSMISSION SPECIFICATION

AND ATTRIBUTES

Page 6

Powertrain Control Solutions

CASE

ASSEMBLY

REVERSE

INPUT CLUTCH

INPUT CLUTCH

HOUSING

OVERRUN

CLUTCH

FORWARD

CLUTCH

FORWARD

SPRAG CL

ASSEMBLY

3-4

CLUTCH

INPUT

PLANETARY

GEARSET

LO AND

REVERSE

CLUTCH

TORQUE

CONVERTER

ASSEMBLY

STATOR

ROLLER

CLUTCH

PUMP

ASSEMBLY

LO ROLLER

CLUTCH

ASSEMBLY

REACTION

PLANETARY

GEARSET

TURBINE

SHAFT

2-4

BAND

ASSEMBLY

INSIDE

DETENT LEVER

MANUAL

SHAFT

CONTROL VALVE

ASSEMBLY

PARKING LOCK

ACTUATOR ASSEMBLY

OUTPUT

SHAFT

PARKING

PAWL

SPEED

SENSOR

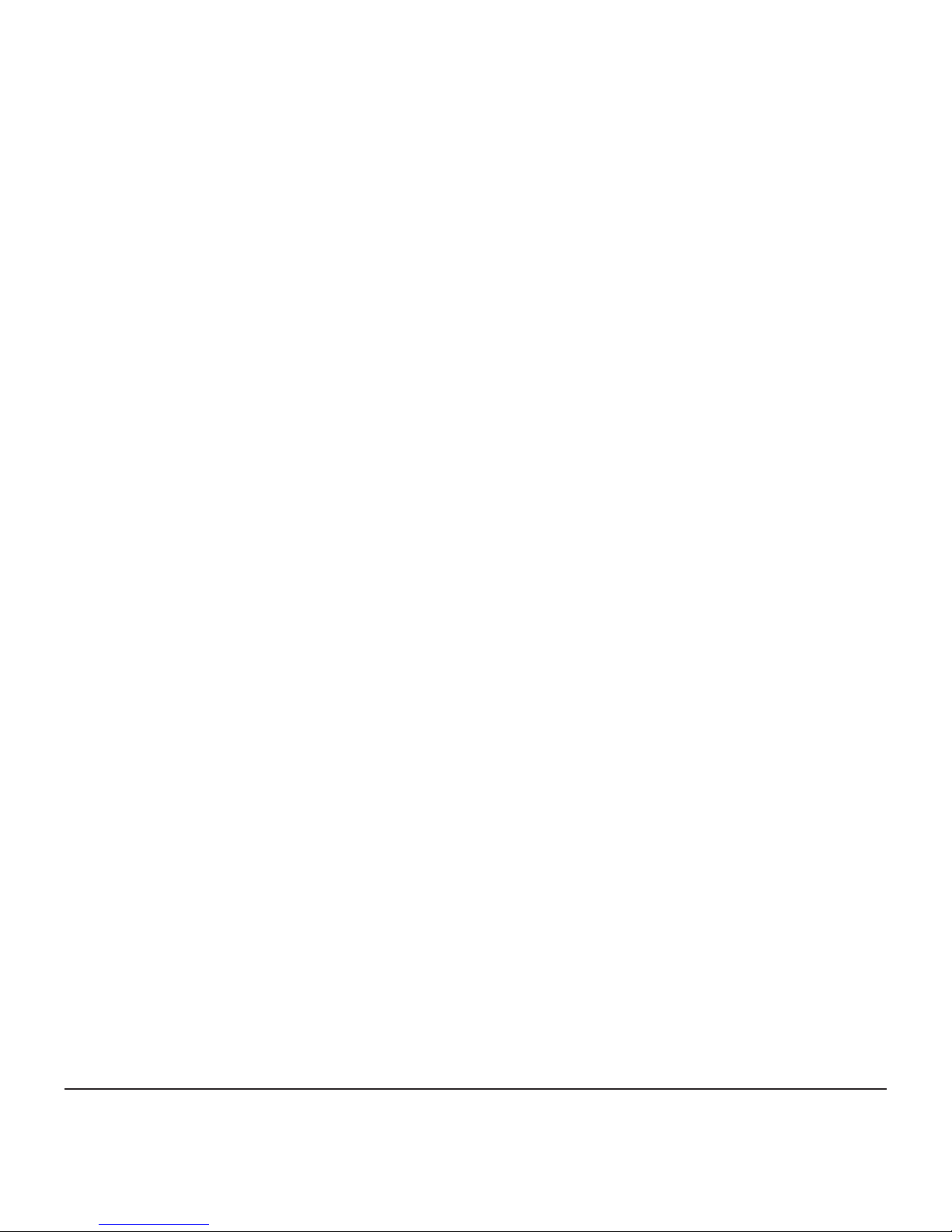

Section 1. Transmission Specications and Attributes

1.1 General Description

The 4LHD/4LHDX is a fully automatic, electronically controlled, RWD/4WD transmission. It consists primarily of a three

element hydraulic torque converter with a converter clutch, two planetary gear sets, various clutches, an oil pump, and

a control valve body. There are four forward driving gear ranges in addition to neutral, reverse, and park. The torque

converter clutch is available in 2nd, 3rd, and 4th (overdrive) gear. Park range is available in applications that do not

exceed the GVW ratings provided in Section 1.2.5. The mass of a complete system package is estimated to be between

87-113 kg (192-250 lb). This does not include cooler lines, radiator, uid within the external cooling system, shifter cable,

shifter bracket assembly, rear transmission mount isolator, external sensors (such as TPS), and otherwise anything else

vehicle specic not included in Section 1.2.1.

Figure 1.1-1

Abuse

Protection

Solenoid

Abuse

Protection

Solenoid

Page 1

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 7

4LHD/4LHDX Application Manual

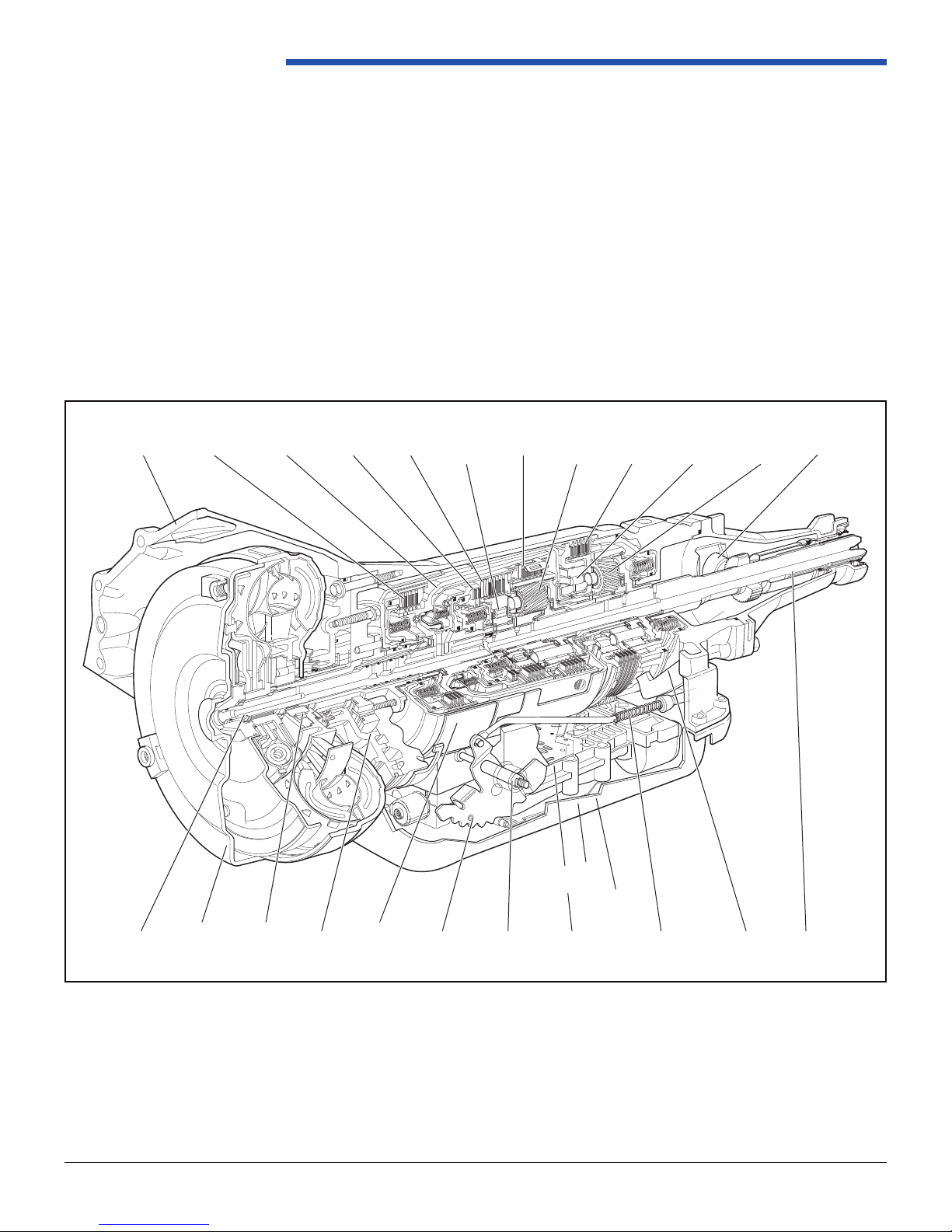

4.4. Transmission and Vehicle Identification

4.4.1. VIN

The following procedure is recommended for VIN operation. Typical locations are shown

in Figure 4.4.1-1.

1. Scan bar-code on transmission.

2. Place etcher on transmission in designsted GMPT approved VIN number area or

use hand stamp and imprint VIN number into transmission in designated GMPT

approved area.

1.1.1 Identication

The transmission nameplate is used to identify the transmission model as well as build date and manufacturing site. A

typical nameplate is shown and dened in Figure 1.1.1-2.

Located on

top side of

transmission

Behind TCM

bracket on

LH side

Figure 1.1.1-1 Transmission I.D. Nameplate Locations

Figure 1.1.1-2 Transmission I.D. Nameplate Features

Page 2

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 8

Powertrain Control Solutions

ATTACHMENT

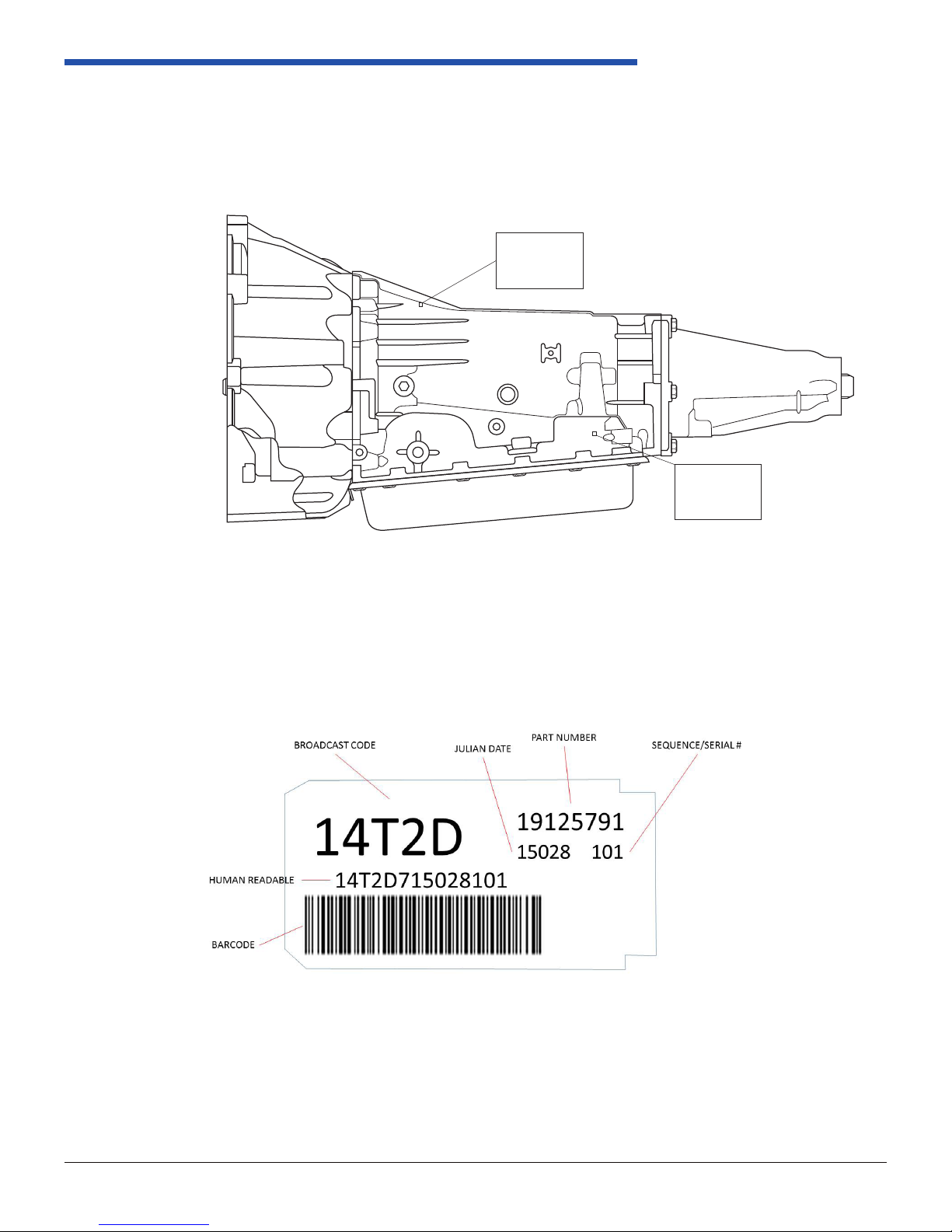

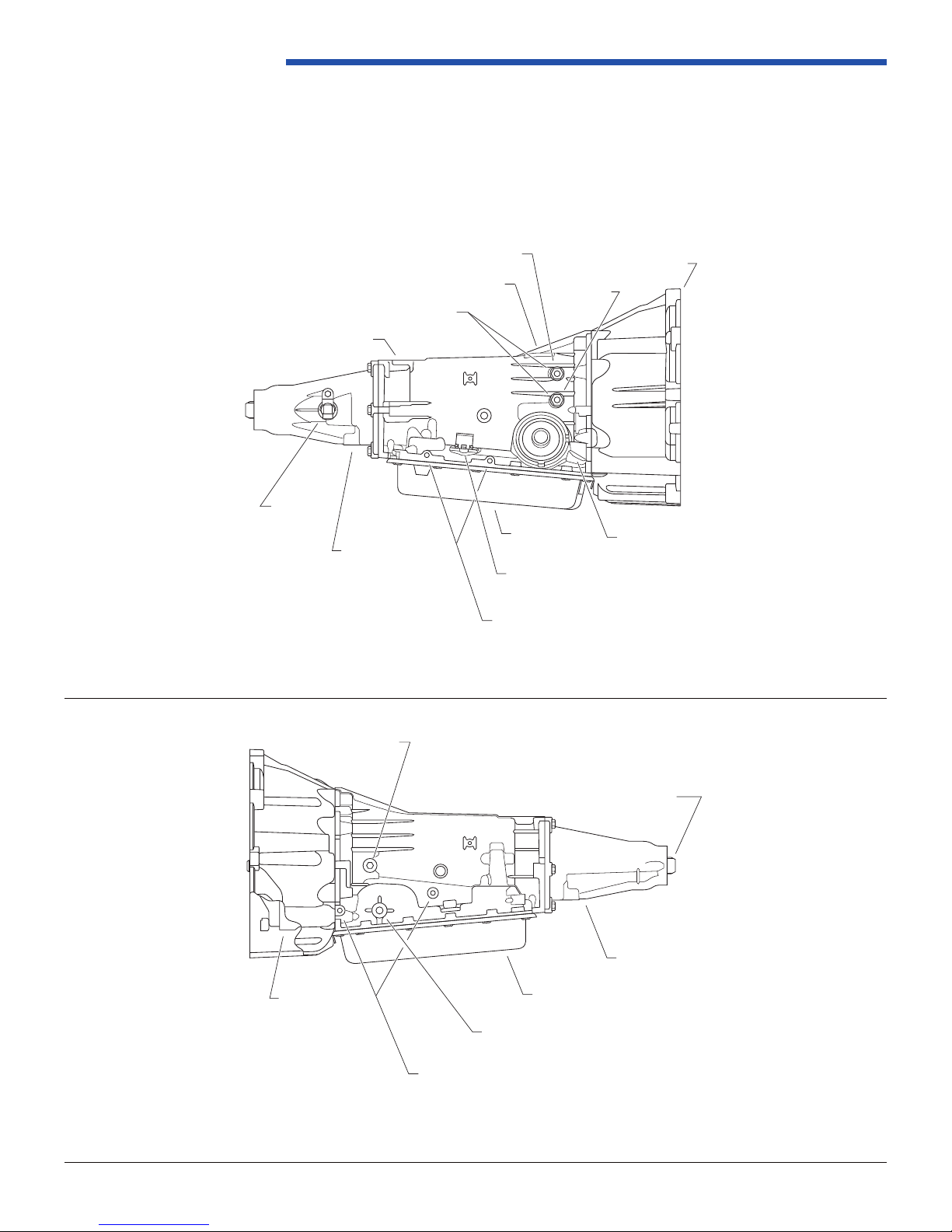

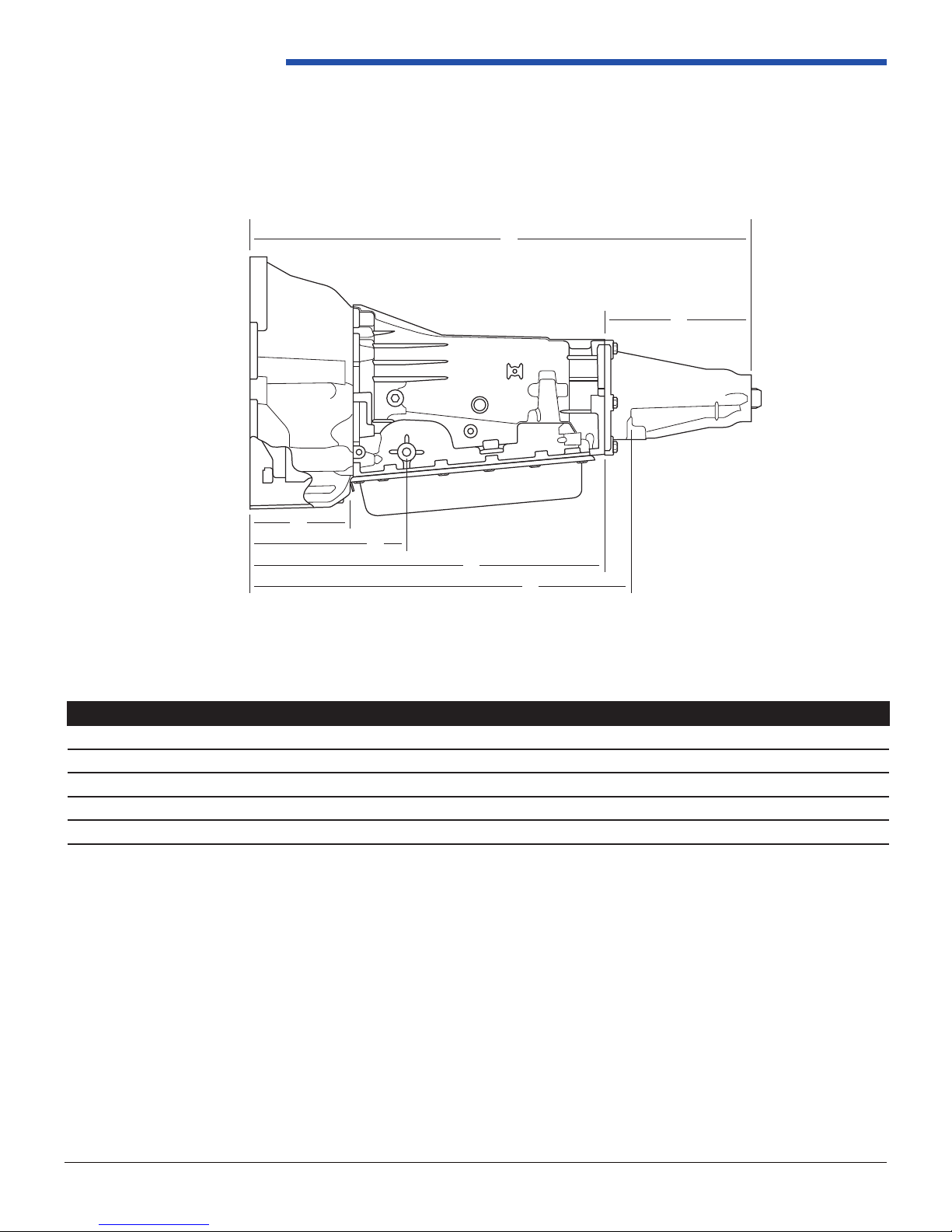

1.1.2 Feature Location Illustrations

The following gures show all external components and their locations on the transmission case. Manual shaft, uid

level screw, vent cap, output vehicle speed sensor, bottom pan, electrical pass-through connector, cooler line attachment

interface and powertrain mount boss provisions are shown in these diagrams.

FLARE OR QUICK CONNECT

TRANSMISSION CASE

➤

➤

SPEED

SENSOR

VEHICLE

MOUNTING PAD

FROM COOLER

AIR BREATHER (VENT)

➤

➤

➤

➤

TO COOLER

➤

➤

➤

➤

➤

TRANSMISSION

OIL PAN

TRANSMISSION CONTROL

CONNECTOR

HEAT SHIELD LOCATION (S)

ENGINE FACE

➤

➤

➤

FILL TUBE

HOLE

Figure 1.1.2-1: PCS 4LHD/4LHDX with GM GEN III Bellhousing and 2WD Extension Housing (Right Side View)

Page 3

LINE

PRESSURE

TAP

OUTPUT

SHAFT

➤

➤

TORQUE

CONVERTER

➤

➤

➤

➤

➤

TRANSMISSION OIL PAN

TRANSMISSION SHIFT LEVER

(MANUAL SHAFT)

ATTACHMENT BOSSES FOR

EXTERNAL POSITION SWITCH

➤

CASE

EXTENSION

Figure 1.1.2-2: PCS 4LHD/4LHDX with GM GEN III Bellhousing and 2WD Extension Housing (Left Side View)

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 9

1.1.3 Gear Ratios

Gear Ratio

1st 3.059:1

2nd 1.625:1

3rd 1.000:1

4th 0.696:1

Reverse 2.294:1

1.2 Physical Specications

1.2.1 Mass Properties

Transmission Mass As Installed

4LHD/4LHDX 75 kg (165 lbs)*

* This can vary +/- 3kg (6.6lbs) based on torque converter and output shaft

4LHD/4LHDX Application Manual

Bellhousing Mass As Installed

GM Gen III 4.9 kg (10.8 lbs)

C6 Replacement 5.2 kg (11.5 lbs)

SAE3 5.2 kg (11.5 lbs)

SAE4 4.5 kg (9.9 lbs)

SAE5 7.3 kg (16.1 lbs)

Extension Housing Mass As Installed

GM 2WD 1.8 kg (4.0 lbs)

GM 4WD 2.4 kg (5.3 lbs)

PCS Parking Brake 10.2 kg (22.5 lbs)*

C6 Replacement 4.3 kg (10.1 lbs)**

* Mass measured without drive shaft ange

** Mass measured without C6 brake housing and drum brakes

Accessory Mass As Installed

Transmission Harness 0.7 kg (1.6 lbs)*

Dipstick Kit 0.4 kg (0.9 lbs)

Heat Shield Kit 0.4 kg (0.9 lbs)

Controller (TCM) 0.3 kg (0.7 lbs)

TCU Bracket Kit 0.5 kg (1.1 lbs)

Overow Vent Kit 0.2 kg (0.5 lbs)

Flexplate Kit 1.8 kg (4.0 lbs)

Flywheel Adapter 8.8 kg (19.4 lbs)**

* This can vary +/- 0.3kg (0.7lbs) based on vehicle application

** This can vary +/- 4.0kg (8.8lbs) based on ywheel application

Page 4

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 10

Powertrain Control Solutions

1.2.2 Driveline Lengths

For an example, the following dimensions are based on the GM 2WD extension housing. For other extension housing

lengths, reference Section 2.2.3.

➤

D

➤

TRANSMISSION ASM.

(TWO-PIECE CASE)

2WD

➤

➤

➤

➤

Figure 1.2.2-1: PCS 4LHD/4LHDX with GM GEN III Bellhousing and 2WD Extension Housing Dimensions

➤

A

➤

B

E

C

➤

➤

➤

F

➤

Type DIM (mm) A B C D E F

GM GEN III Bell 176.3 259.2 618.0 794.3 568.0 226.3

C-6 Bell 142.3 225.2 584.0 760.3 534.0 266.3

SAE 3 Bell 189.0 271.9 630.7 807.0 580.7 266.3

SAE 4 Bell 189.0 271.9 630.7 807.0 580.7 266.3

SAE 5 Bell 189.0 271.9 630.7 807.0 580.7 266.3

A = Bellhousing Length

B = Engine Face to Manual Shaft Distance (C = Engine Face to Vehicle Mount Distance)

C = Engine Face to Vehicle Mount Distance

D = Overall Length (Engine Face to Rear Face of Extension)

E = Length of Case Dimension

F = Length of Extension Housing

Page 5

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 11

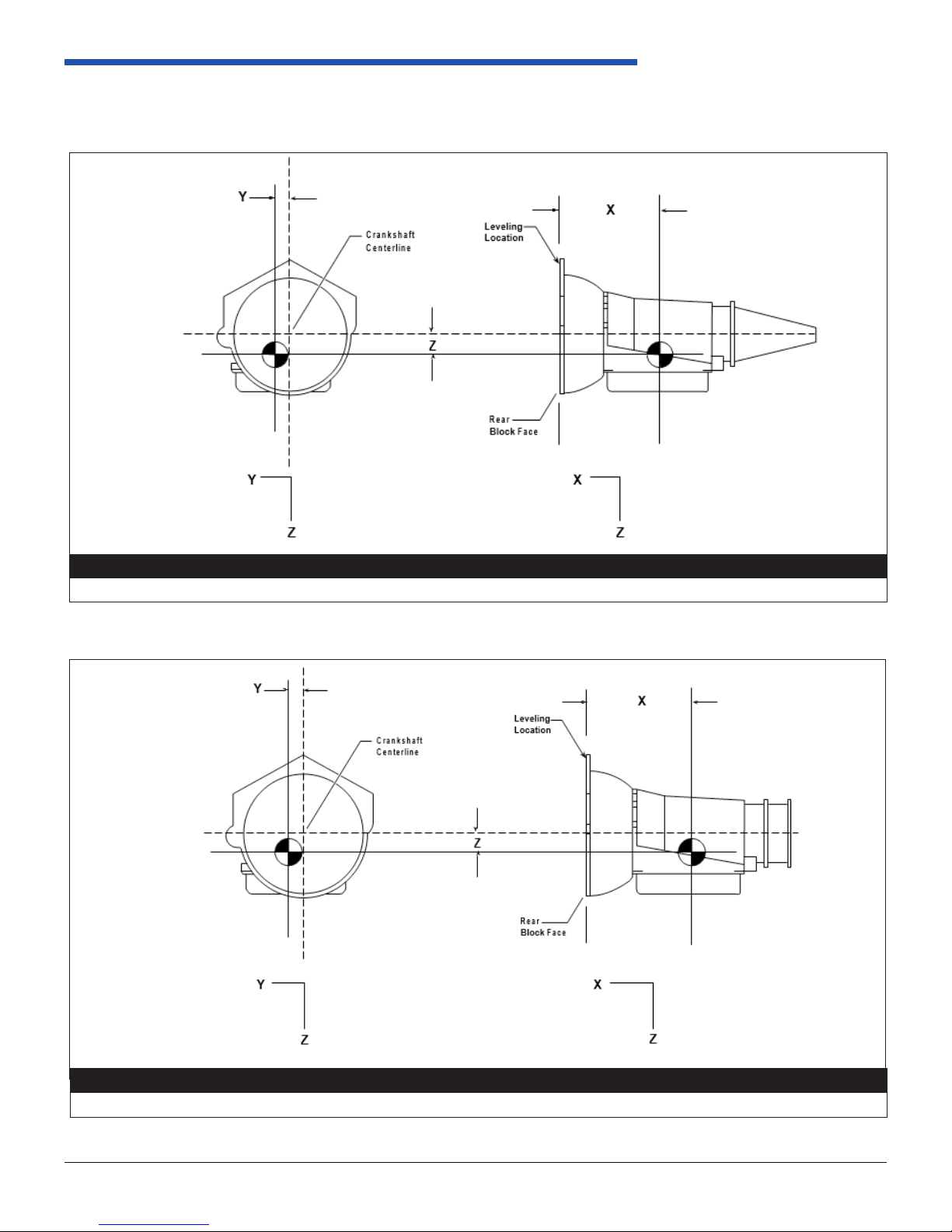

1.2.3 Center of Gravity

4LHD/4LHDX Application Manual

Object Weight X Y Z

83.9 kg (185.00 lb) -253 mm (-9.96 in) 3 mm (.12 in) 17 mm (.67 in)

Figure 1.2.3-1 4LHD/4LHDX with 2WD Extension Housing

Object Weight X Y Z

85.28 kg (188.00 lb) -251 mm (-9.90 in)

Figure 1.2.3-2 4LHD/4LHDX with 4WD Extension Housing

Page 6

10 mm (.40 in) 18 mm (.70 in)

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 12

Powertrain Control Solutions

1.2.3 Center of Gravity Cont’d

Approximate location of CG; actual location will depend on transmission model. Contact PCS if actual is desired.

258 mm Torque Converter

2WD 4WD

X -253 mm -251 mm

Y 3 mm 10 mm

Z 17 mm 18 mm

1.2.4 Inertia Properties

Approximate location of CG; actual location will depend on transmission model. Contact PCS if actual is desired.

Rotational Inertia

lxx = 0.94 kg-m

lyy = 2.93 kg-m

lzz = 2.99 kg-m

2

2

2

Approximate values, dependent on transmission model.

Reference: SAE Engine Coordinate System or gures found in Section 1.2.3-1

Rotational Inertia

1st gear 0.0547 kg-m

2nd gear 0.039616 kg-m

3rd gear 0.02553 kg-m

4th gear 0.06692 kg-m

Referred to the input shaft of the transmission without torque converter, transfer case, or parking brake.

2

2

2

2

1.2.5 Gross Vehicle Weight

GVW

3,900 kg (8,600 lb) maximum*

*This gure is limited by the strength of the parking pawl. If other parking mechanisms are utilized, and the transmission is not shifted into park, higher

GVWs are possible. Contact PCS for vehicle calculations in this case.

Page 7

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 13

1.3 Maximum Performance Limitations

1.3.1 Torque Limitations

Engine Input Torque

4LHD with 258 MM Converter - 340 Nm (250 lb-ft) Maximum

4LHDX with 300 MM Converter - 542 Nm (400 lfb-ft) Maximum

Gearbox Input Torque

4LHD with 258 MM Converter - 660 Nm (487 lb-ft) Maximum

4LHDX with 300 MM Converter - 1057 Nm (780 lb-ft) Maximum

Torque Converter Capacity - Speed

258 mm: 7,000 RPM @ 690 kPa (100 psi), 6500 RPM @ 1020 kPa (150 psi)

300 mm: 7,000 RPM @ 900 kPa (130 psi)

Torque Converter Capacity - Input Torque

258 mm: 340 Nm (250 lb-ft)

300 mm: 542 Nm (400 lb-ft)

4LHD/4LHDX Application Manual

Torque Converter Capacity - Stall Power

258 mm: 79.1 kW (106 hp)

300 mm: 124.6 kW (167 hp)

NOTE: Values @ 690 kPa (100 psi), increase limit by 0.75 kW/14 kPa (1 hp/psi), not to exceed 1020 kPa (150 psi).

To calculate stall power:

(engine stall speed) x (engine torque at stall)

9546

Torque Converter Capacity - Turbine Torque

258 mm: 632 Nm (392 lb-ft)

300 mm: 943 Nm (696 lb-ft)

NOTE: Must verify adequate spline engagement. Reference Section 2.1.1.

Calculated: (engine torque) x (converter ratio)

Torque Converter Capacity - Stator Torque

258 mm: 340 Nm (250 lb-ft)

300 mm: 542 Nm (400 lb-ft)

Calculated: (engine torque) x [ (converter ratio) - 1 ]

Torque Converter Capacity - Max TCC Apply Pressure

258 mm: 930 kPa (135 psi)

300 mm: 862 kPa (125 psi)

Minimum pressure, all operating conditions 415 kPa (60 psi).

Page 8

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 14

Powertrain Control Solutions

1.3.2 RPM Limitations

Maximum Speed in Park and Neutral

Maximum engine speed cannot exceed 4,000 RPM when the transmission is in park or neutral.

Maximum Shift Speed

The maximum shift speed allowed is application dependent. Note: These maximum shift speeds are dependent on

nal drive ratio, torque converter stall torque ratio, and the engine torque curve prole. Consult with Powertrain Control

Solutions for application specic maximum shift speeds.

Minimum Engine Idle Speed

600 RPM when ATF is above 115˚C (240˚F)

550 RPM when ATF is 0˚C to 115˚C (32˚F to 240˚F)

700 RPM when ATF is below 0˚C (32˚F)

Minimum TCC Apply

Minimum TCC apply speeds are dictated by powertrain and chassis response in the following ranges at normal operating

temperatures.

Engine Engine RPM (Light Throttle) Engine RPM (Heavy Throttle)

All 1000 1800

Maximum Output Speed

Maximum output speed is 7,200 RPM.

Maximum Vehicle Speed

Maximum vehicle speed is dependent on nal drive ratio, torque converter ratio and engine torque curve prole. Powertrain

Control Solutions must be consulted for application specic maximum speeds.

1.3.3 Acceleration Limitations

The 4LHD/4LHDX automatic transmission has been tested for longitudinal and lateral acceleration capability in vehicles

under the following maneuvers at the entire temperature range:

W.O.T. acceleration on level road. Panic stop from 30 mph followed by W.O.T. acceleration.

Longitudinal

Lateral

Gradual stop from 30 mph followed by W.O.T. acceleration.

Right turn at 20 mph with W.O.T. acceleration. Left turn at 20 mph with W.O.T. acceleration. Right

turn panic stop from 20 mph. Left turn panic stop from 20 mph. Continuous right turn at 60 ft turning

radius. Continuous left turn at 60 ft turning radius.

*W.O.T = Wide Open Throttle

Page 9

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 15

4LHD/4LHDX Application Manual

1.3.4 Temperature Limitations

Functional Range: -40˚C to 55˚C (-40˚F to 131˚F)

Dened as the ambient range where the vehicle will function without causing transmission operational concerns or thermal

distress in adequately cooled installations.

Underbody Temperature

Life of the transmission gaskets, seals and connectors is affected by elevated temperatures. Airow around the

transmission and the proximity to heat sources such as catalytic converter or exhaust system inuence the temperature

build up at the transmission surface. It should be noted that shift cable systems are also sensitive to heat, and should be

routed to avoid extreme temperatures.

Temperatures shall be monitored during testing to ensure appropriate temperature levels. A thermal packaging study is

recommended to verify all underbody temperatures.

Component Skin Temperature Limits

The following maximum temperatures are based on released component materials. These temperatures must not be

exceeded during test.

Exposed Area Maximum Continuous Maximum Excursion

External Seals 138°C (280°F) 150°C (302°F)

Oil Pan Gasket 138°C (280°F) 150°C (302°F)

Trans. Based on Non Metallic Connectors 138°C (280°F) 138°C (280°F)

Trans. Electrical Terminals 135°C (275°F) 135°C (275°F)

Trans. Wiring Harness 125°C (257°F) 125°C (257°F)

Controller (TCM) 105°C (221° F) 125°C (257°F)

* Reference Section 2.3 for cooler requirements and transmission sump operating temperatures.

Page 10

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 16

Powertrain Control Solutions

Heat Shield

Shown in Figure 1.3.4-1 is an available heat shield that protects the gasket, connector, and accumulator from common

exhaust positions. Consult with PCS if this is necessary or adequate for your application.

Figure 1.3.4-1: Heat Shield Exploded View

1.3.5 Grade Limitations

Maximum Grade for Hydraulic Operation

This transmission is validated to operate on longitudinal and lateral slopes of up to 30% (16.7 degree grade) without

detrimental effect on the operation of the hydraulic system at normal working temperature. Consult with Powertrain

Control Solutions if the proposed application exceeds these values.

Maximum Grade for Park System

There is a maximum grade capability of 30% (16.7 degree grade) for park pawl engagement with both the park mechanism

engaged and the parking brake on.

Page 11

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 17

4LHD/4LHDX Application Manual

1.4 Valve body Features and Specications

The following are valve body options. When ordering from PCS, you must specify your desired valve body conguration.

1.4.1 Abuse Protection

Often times the operator causes the most damage to the transmission, reducing the service life and causing

costly repairs and downtime. The PCS 4LHD/4LHD-X abuse protection valve body protects the transmission by

locking out reverse engagement until the vehicle is stopped and the engine is at idle. It also prevents “neutral

drops” by only engaging the forward gears when the engine is at idle.

1.4.2 Neutral Idle

As an option, the PCS valve body can disengage the forward gears when the vehicle is stopped and the brake

pedal is pressed. By reducing the number of rotating components during idle, fuel consumption can be reduced

especially for vehicles that spend a lot of time idling in gear. With the forward gears disengaged, the reduced

brake force required to hold the vehicle, especially in high gear reduction drivelines, can signicantly improve the

drivability of the vehicle from the operator’s perspective.

1.4.3 Electronic Range (Option)

This allows you to eliminate the shift cable and shift the transmission electronically with a push button or a

movement of a lever. Driver inputs can be validated based on vehicle modes and conditions so the vehicle is

operated within standard operating protocols. Also eliminate transmission failures due to the shift cable not

adjusted properly. Reference Section 2.4.3 for external setup.

1.4.4 Inching Mode (Option)

The PCS inching valve body allows the operator to move the vehicle forward or backward in small increments

from an operator’s panel remotely mounted on the vehicle. This greatly reduces time when connecting to trailers

or other equipment and makes the operation more efcient for one person.

Page 12

Figure 1.4-1: PCS Valve Body Explosion View

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 18

Powertrain Control Solutions

1.5 Electrical Specications

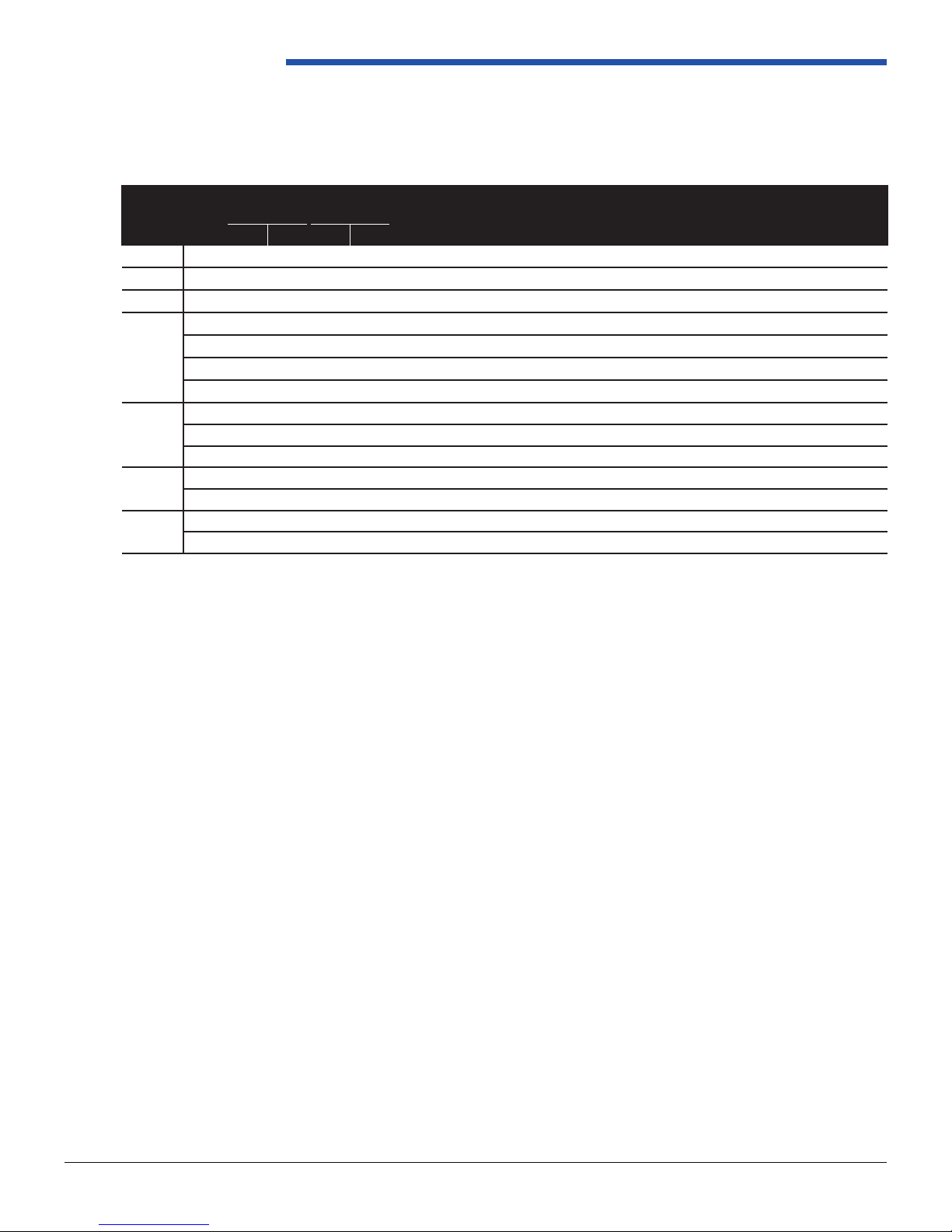

1.5.1 Solenoids

Shift

Range Gear

Park

Reverse

Neutral

OD

D

2

1

1. Shift solenoid state is a function of vehicle speed and may change if vehicle speed increases.

2. Manual Second - First gear is electronically prevented under normal operating conditions.

3. Solenoid state will be opposite shown during abuse protection

2nd OFF ON ON 3OFF Applied Applied Holding

2nd OFF ON ON 3OFF Applied Applied Holding

1st 2ON ON ON 3OFF Applied Applied Holding Holding

2nd OFF ON ON 3OFF Applied Applied Applied Holding

2nd OFF ON ON 3OFF Applied Applied Applied Holding

Solenoid

1-2 2-3 FWD REV

ON 1ON 1OFF OFF Applied

ON 1ON 1ON ON

ON 1ON 1ON ON

1st ON ON ON 3OFF Applied Holding Holding

3rd OFF OFF ON 3OFF Applied Holding Applied

4th ON OFF ON 3OFF Applied Applied Applied

1st ON ON ON 3OFF Applied Holding Holding

3rd OFF OFF ON 3OFF Applied Applied Holding Applied

1st ON ON ON 3OFF Applied Applied Holding Holding Applied

Abuse

Solenoid

Reverse

2-4

Band

3

Input

Clutch

Applied Applied

Overrun

Clutch

Forward

Clutch

Forward

Sprag CL.

Assembly

3-4

Clutch

LO/

Roller

Clutch

LO/REV

Clutch

Shift Solenoids

The two identical shift solenoids are two port, on/off solenoids (normally on) that are used to control the shift

change events.

• The shift solenoid coil resistance should be 20-40 ohms at 20.0 +/- 5.0°C.

• The shift solenoid current ow should not exceed 0.75 Amps.

• The shift solenoid energizes at 7.5 volts or more.

• The shift solenoid de-energizes at 1.0 volts or less.

TCC Enable Solenoid

The TCC Enable Solenoid is a two port, on/off solenoid (normally on) that is used to apply and release pressure

to the Torque Converter Clutch.

• The TCC Enable Solenoid coil resistance should be 20-40 ohms at 20.0 +/- 5.0°C.

• The TCC Enable Solenoid current should not exceed 1.5 Amps.

TCC Control Solenoid

The TCC Control Solenoid is a three port (normally closed) device used to control the apply and release pressure

of the Torque Converter Clutch. Adujsting this in the TCU Calibration changes the shift rmness of the Torque

Converter Clutch.

• The TCC Control Solenoid operates at a xed frequency (negative duty cycle) of 32 Hz.

• The TCC Control Solenoid coil resistance should be 10.0 - 11.5 Ohms when measured at 20.0 +/- 5.0°C.

Page 13

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 19

4LHD/4LHDX Application Manual

➤

TIME

VOLTS

12

0

1 CYCLE = 1/292.5 SECOND

➤

➤

40%

60%

➤

➤

➤

➤

➤

(ON)

PRESSURE CONTROL SOLENOID VALVE POSITIVE DUTY CYCLE

PRESSURE CONTROL SOLENOID VALVE

➤

➤

➤

➤

➤

➤

➤

➤ ➤ ➤

➤

➤ ➤ ➤

➤

➤

➤

➤

➤

➤ ➤ ➤ ➤

➤

➤

➤

➤

➤

➤

➤

PUSH

ROD

FRAMESPRING

SPOOL

VALVE

ACTUATOR

FEED

LIMIT

FLUID

TORQUE

SIGNAL

FLUID

COIL

ASSEMBLY

EXHAUST ARMATURE

DAMPER

SPRING

FLUID

SCREENS

SPOOL

VALVE

SPRING

VARIABLE

BLEED

ORIFICE

SPOOL

VALVE

SLEEVE

PLNGR

54

54

54

21

CNTRL

PRESS

SHIFT

20

21

9

54

54

54

54 54

SHIFT

PRESSURE CONTROL

SOLENOID VALVE

(SLS) (340)

1111

11

FLUID PRESSURE

TEST HOLE PLUG (334)

SHIFT PRESSURE CONTROL SOLENOID VALVE (SLS)

EXHAUST

EXHAUST

CONNECTOR

COIL

ASSEMBLY

SPOOL

VALVE

SPRING

PLUNGER

PRESSURE

SUPPLY

(SOLENOID

MODULATOR)

PRESSURE

CONTROL

(SHIFT

CONTROL)

VALVE

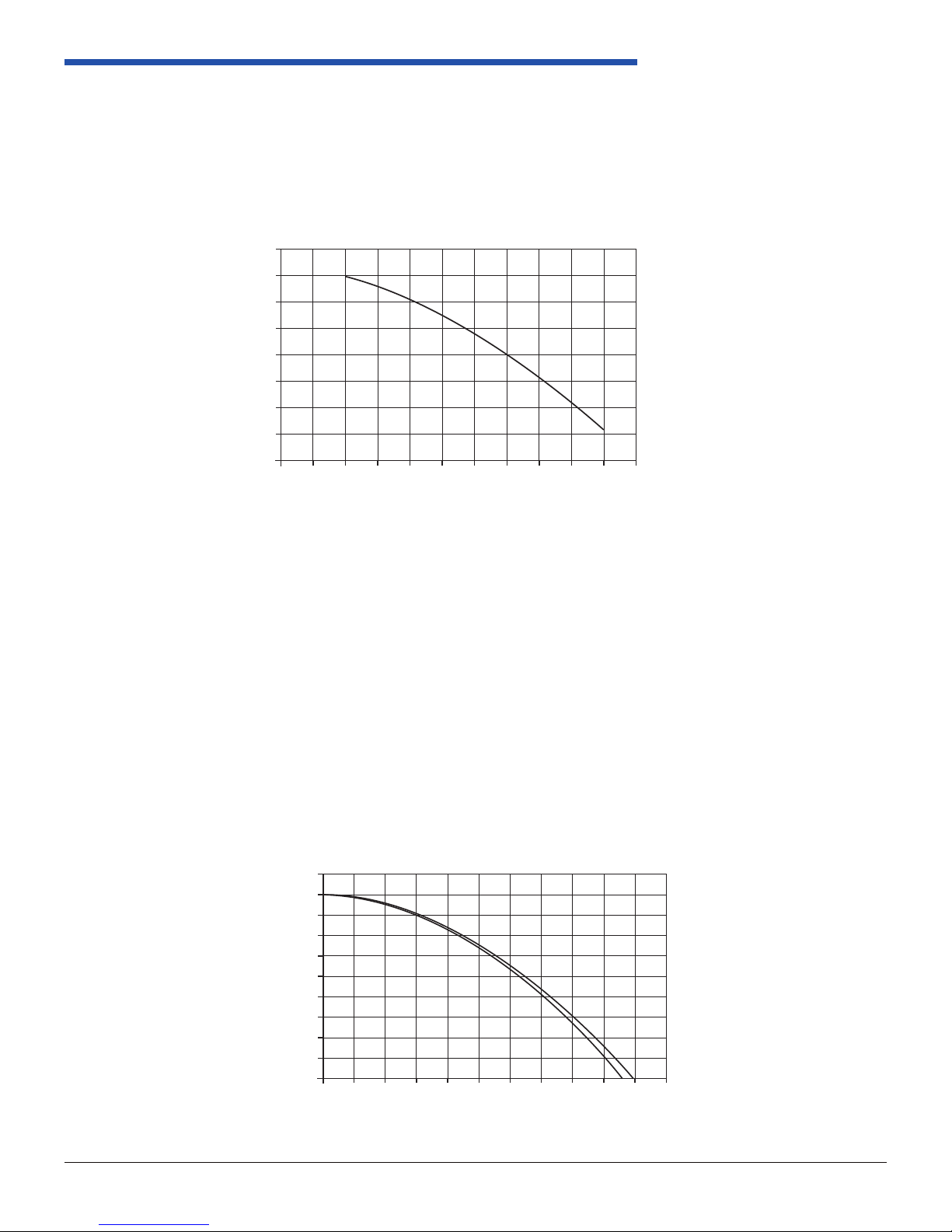

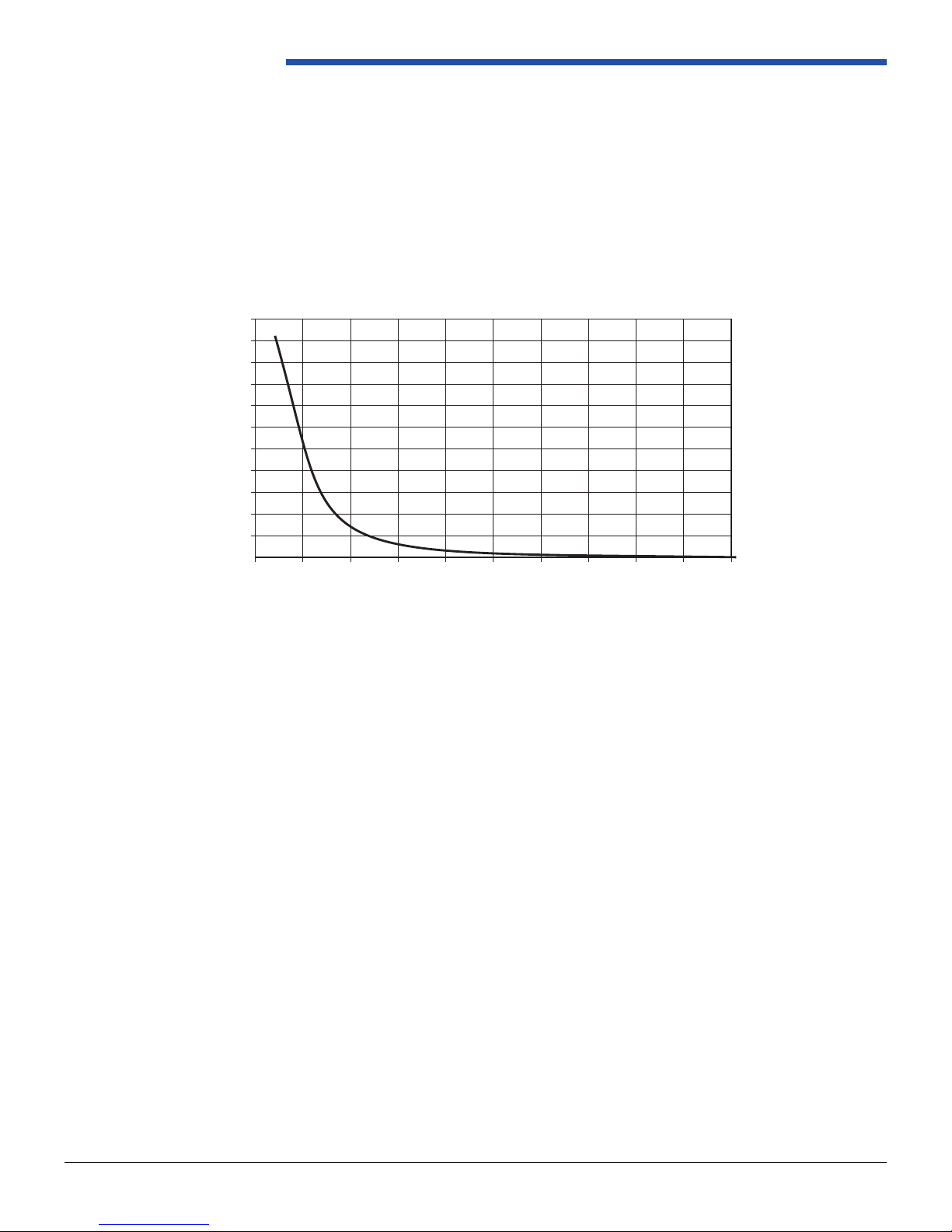

Abuse Protection Solenoid (Non-Electronic Range)

The identical Forward/Reverse Abuse Protection Solenoids (Non-ER) three port linear pressure control solenoids

(normally open).

• The Non-ER Forward/Reverse solenoids coil resistance is 5.0-5.6 ohms at 25.0 +/- 1.0°C.

• The Non-ER Forward/Reverse solenoids operate at a xed frequency of 300Hz.

160

140

120

100

80

60

Abuse Protection Solenoid (Electronic Range)

The two identical ER Forward/Reverse Abuse Protection solenoids are three port PWM (Pulse Width Modulation)

solenoids (normally closed).

• The ER Forward/Reverse solenoids operate at a xed frequency (negative duty cycle) of 32 Hz.

• The ER Forward/Reverse solenoids coil resistance should be 10.4-10.8 Ohms when measured at 20.0 +/- 5.0°C

• The ER Forward/Reverse solenoids coil resistance should be approximately 16 Ohms when measured at 150 +/-

5.0°C.

Pressure Control Solenoid

The Pressure Control Solenoid is a three port electronic pressure regulator used to control line pressure. When the

solenoid is off, line pressure is unrestricted from the line pressure pump. When the solenoid is on, line pressure is

restricted to the values shown in the chart. A line pressure tap is available. The torque rating for this tting is 8 lb*ft / 11

N*m. Reference Figure 2.4.6.1-3.

• The Pressure Control Solenoid operates at a xed frequency of 292.5 Hz.

• The Pressure Control Solenoid coil resistance is 3.5-4.6 Ohms at 20.0 +/- 5.0°C.

40

CONTROL PRESSURE (PSI)

20

0

0.0

Figure 1.5.1-1: Abuse Protection Solenoid Valve Current Flow

100

90

80

70

60

0.1 0.2 0.3 0.4

50

40

30

20

CONTROL PRESSURE (PSI)

10

0

0.0

Figure 1.5.1-2: Pressure Control Solenoid Valve Current Flow

INPUT CURRENT (AMP)

0.1 0.2 0.3 0.4

0.60.5 0.7 0.8 0.9

0.60.5 0.7 0.8 0.9

INPUT CURRENT (AMP)

1.0 1.1

1.0 1.1

Page 14

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 20

TEMPERATURE SENSOR

VEHICLE SPEED SENSOR

FIGURE A: CONDITIONED SIGNAL

OUTPUT VOLTS

LOW SPEED

➤

5.0

HIGH SPEED

TIME

-50 -30 -10 10 30 50 70 90 110 130 150

110

100

90

80

70

60

50

40

30

20

10

0

Sensor Resistance (K ohms)

Temperature C

SENSOR RESISTANCE VS. TEMPERATURE

CONNECTOR RESISTOR

TRANSMISSION

FLUID PRESSURE

MANUAL VALVE

POSITION SWITCH

ASSEMBLY (69)

ELECTRICAL

CONNECTOR

MAGNETIC PICKUP

TRANSMISSION FLUID TEMPERATURE (TFT) SENSOR

The temperature sensor is a negative temperature coefficient

thermistor (temperature sensitive resistor) that provides

information to the PCM regar ding transmission fluid

temperature. The temperature sensor is a part of the

transmission fluid pressure (TFP) manual valve position switch

assembly which is attached to the control valve body and

submersed in fluid in the transmission bottom pan. The

internal electrical resistance of the sensor varies in relation to

the operating temperature of the transmission fluid (see chart).

The PCM sends a 5 volt reference signal to the temperature

sensor and measures the voltage drop in the circuit. A lower

fluid temperature creates a higher resistance in the temperature

sensor, thereby measuring a higher voltage signal.

The PCM measures this voltage as another input to help

control TCC apply and line pressure. The PCM inhibits

TCC

apply until transmission fluid temperature reaches

approximately 29°C (84° F). Also, when fluid temperatures

exceed 135° C (275°F), the PCM commands TCC apply at

all times in Fourth gear, as opposed to having a scheduled

apply. Applying the TCC reduces fluid temperatures created

by the fluid coupling in the converter.

pickup on the VSS. Whenever the vehicle is moving, the

VSS produces an AC voltage proportional to vehicle speed.

This AC signal is sent to the digital ratio adaptor converter

(DRAC) where it is converted to a direct current (DC) square

wave form. The DC signal is then sent to the PCM and

interpreted as vehicle speed. As vehicle speed increases and

more rotor teeth pass by the magnetic pickup on the VSS in

a given time frame, the frequency of the DC signal sent to

the PCM increases. The PCM interprets this increase in

frequency as an increase in vehicle speed (see Figure A).

Note: On f

our wheel drive (4WD) applications the VSS is

located on the transfer case.

Vehicle Speed Sensor Circuit Low will set DTC P0502 and the

PCM will command the following default actions:

• Freeze shift adapts.

• Maximum line pressure.

• Calculate A/T OSS from A/T ISS sensor output.

• DTC P0502 stores in PCM history.

TFT Sensor Circuit Range/Performance will set DTC P0711

and the PCM will command the following default actions:

• Freeze shift adapts.

• Defaults the TFT to 140°C (284°F) for shift

scheduling (hot mode pattern).

• DTC P0711 stores in PCM history.

Powertrain Control Solutions

Transmission Fluid Temperature Sensor

• The Transmission Fluid Temperature Sensor is a negative temperature coefcient temperature sensitive resistor that

drops an input 5V signal to the values shown below.

• The Transmission Fluid Temperature Sensor voltage range is 5.0-0.0V DC.

Internal Mode Switch (IMS)

The internal mode switch (IMS) is a sliding contact switch attached to the manual shift shaft inside the transmission. The

ve inputs to the TCM from the transmission manual shift shaft switch assembly indicate the transmission gear selector

lever position. Refer to this pinout in Figure 1.5.2-2.

Transmission Input Speed Sensor (TISS)

Mounted within the pump, the Transmission Input Speed Sensor (TISS) contains an AC-coupled Hall-effect chip that

switches in response to changing differential magnetic elds created by rotating ferrous targets and requires a constant

supply voltage between 4.0 and 26.5 volts to operate. The signal is induced by a 15 tooth spline on the turbine shaft

(a.k.a. input shaft).

Page 15

Figure 1.5.1-3: Sensor Resistance vs. Temperature

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 21

4LHD/4LHDX Application Manual

Output Speed Sensor (VSS)

The Output Speed Sensor (also known as Vehicle Speed Sensor) is a variable reluctance magnetic pickup which receives

a sin wave from a speed gear on the output shaft and generates a square wave output. The sensor requires a two wire

connector from the Extension Housing to the TCM.

• The output speed sensor coil resistance is 1850-2250 ohms at 25.0 +/- 1.0°C.

• The maximum output speed sensor inductance is 2000 mH at 1000 Hz with 50 mA applied.

• The speed sensor will produce a minimum voltage (loaded) of 0.25 V peak positive and 0.25 negative at minimum

speed of 100 RPM.

• The speed sensor will produce a maximum voltage (loaded) of 100 V peak positive and 100 negative at a maximum

speed of 7200 RPM.

• All available GM and PCS extension housings use a symmetrical 40 tooth speed gear on the output shaft, resulting in

40 pulses per revolution to the TCM.

NEGATIVE TERMINAL

POSITIVE TERMINAL

➤

➤

Figure 1.5.1-4: Speed Sensor Connector

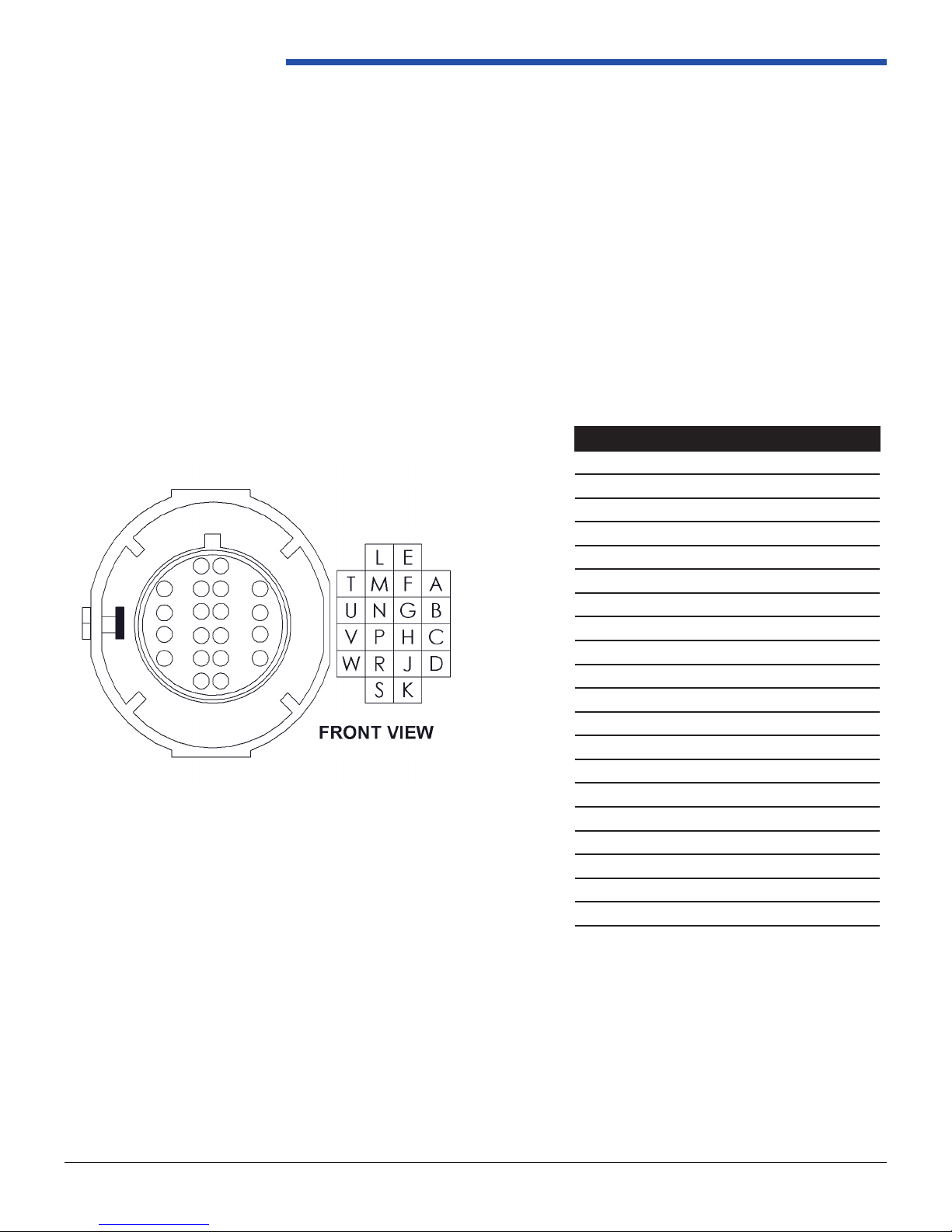

Pass-Thru Connector

The transmission to vehicle electrical interface is a 20 pin connector used to mate the internal and external harnesses of

the transmission. Use the alignment key to ensure proper installation. Reference Figure 1.5.2-1.

• The pass-thru connector envinromental temperature shall not exceed -40 to 135°C at any time. Proper shielding is

required. Reference Section 1.3.4 for temperature details.

Page 16

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 22

Powertrain Control Solutions

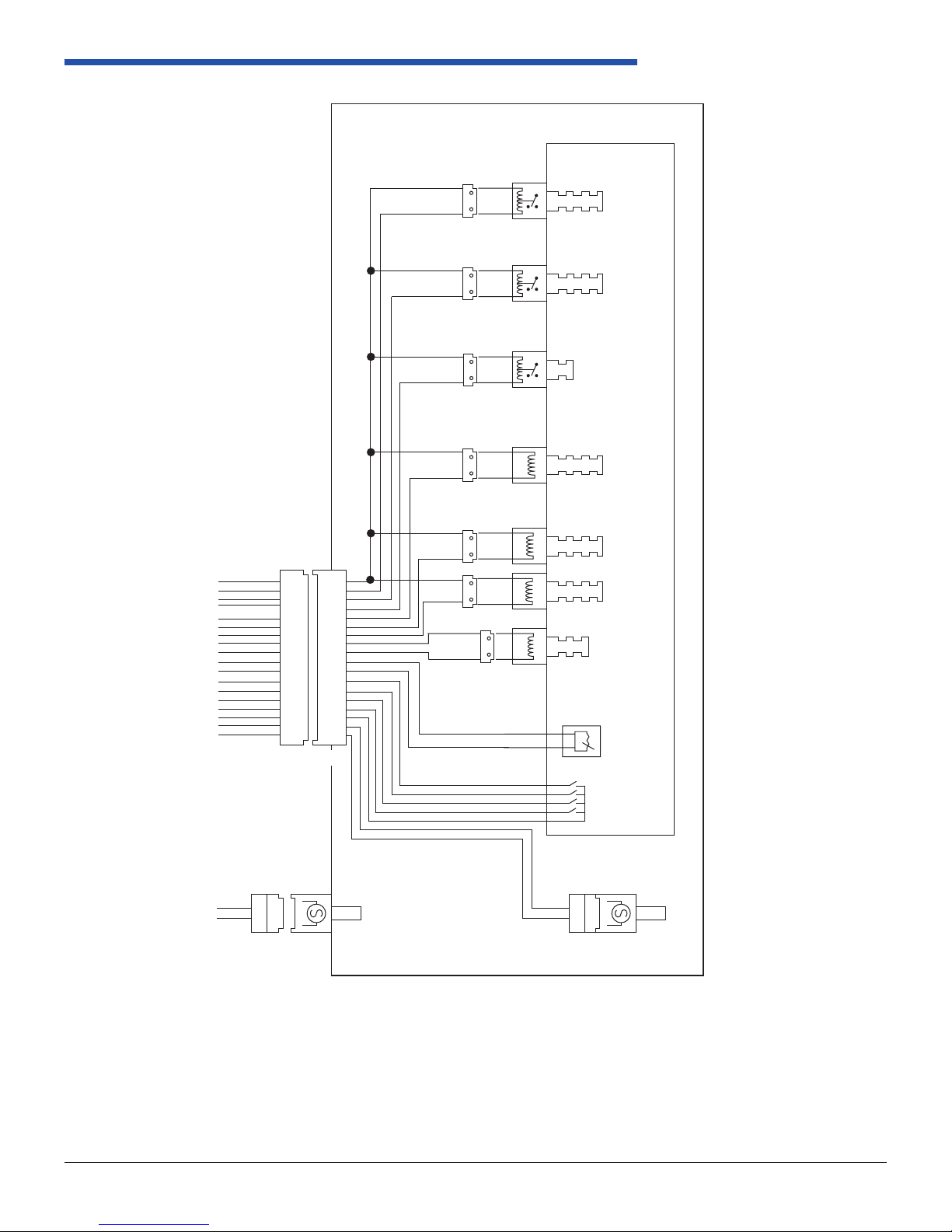

1.5.2 Internal Wiring

Unless otherwise specied, electrical components operating range shall be 8.0 to 18.0 VDC. It is recommended that

the transmission controls solenoids are not engaged without the engine running. Transmission electrical components

should be fused separately from other vehicle components.

Electrical Connections

Two connections must be made to the transmission to interface with the TCM. The connections are for the transmission

control connector and the output speed sensor. Figures 1.5.2-1 and 1.5.2-2 shows the internal system schematic.

CAV Function

A Shift SOL ‘A’

B Shift SOL ‘B’

C Line Pressure +

D Line Pressure -

E Switched +12V

F IMS A

G IMS C

H IMS B

J IMS P

K Turbine Speed +

L Trans Temp Sensor

M Trans Temp Sensor Ground

N IMS Ground

P

TCM Connector

R Forward Clutch SOL

S Reverse Clutch SOL

T TCC SOL

U TCC PWM

V Turbine Speed

W Neutral Safety

Page 17

Figure 1.5.2-1: TCM Connector and Terminal Locations

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 23

TRANSMISSION

VALVE BODY

SHIFT

SOLENOID A

SHIFT

SOLENOID B

TCC ENABLE

SOLENOID

(ON/OFF)

TCC CONTROL

PWM SOLENOID

4LHD/4LHDX Application Manual

VEHICLE

CONNECTOR

FORWARD

CLUTCH

SOLENOID

E

A

B

T

D

M

G

H

J

N

K

V

E

A

B

T

U UU

R

S

C

D

L

M

F

G

H

S1

S2

A

B

E

A

B

T

RR

SS

CC

D

LL

M

FF

G

H

J

J

N

N

K

K

V

V

PRESSURE

CONTROL

SOLENOID

P1

‰

‰

OUTPUT

SPEED

SENSOR

TURBINE

SPEED

SENSOR

➤

A

C

B

P

Internal

Mode

Switch

REVERSE

CLUTCH

SOLENOID

TEMP

SENSOR

‰

‰

Page 18

Figure 1.5.2-2: Transmission Electrical Schematic

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 24

SECTION 2

TRANSMISSION TO VEHICLE

INTERFACES

Page 25

Powertrain Control Solutions

Section 2 Transmission to Vehicle Interfaces

2.1 Transmission Input

2.1.1 Torque Converters

Power input and torque multiplication are accomplished by the transmission torque converter. Converters are

available with a variety of internal components that offer torque ratios up to 1.95 to 2.1 (Refer to Section 2.2.4).

A spring damper smooths out torsional variation when the converter clutch is locked. The correct choice of

components will result in a package that provides an optimum level of fuel economy, performance, and driveability.

We offer two torque converters, 258mm and 300mm. The 258mm torque converter is used in SAE4/SAE5

applications while the 300mm torque converter is used in SAE3 and GM 3.0L/4.3L applications.

Common Name K Factor ST/Ratio

258 146 1.95

300 114 2.1

300mm is used with SAE3, GM

3.0L & 4.3L applications

258mm is used with SAE4/SAE5

applications

Figure 2.1-1: Torque Converters

Page 19

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 26

Powertrain Control Solutions

4.2.4. Flexplate to Converter Connection

Converter piloting is provided by a counterbore in the end of the engine crankshaft, shown

in Figure 4.2.4-1. Axial movement of the converter is contained within this “floating pilot” to

ensure that thrust loads are not transferred to the crankshaft thrust bearing. Grease should

be applied to the pilot or bore to act as a lubricant and corrosion inhibitor. Care must be

taken to ensure that the converter pilot is seated properly in its bore.

During assembly to the engine, the transmission must be supported so that it is

horizontal, or with the bell housing slightly elevated. This will prevent the torque

converter from slipping out of engagement with the oil pump

shaft when the shipping

bracket is removed. The transmission case face must be squarely seated against the

engine face, with locating dowels fully engaged, before its attaching bolts are tightened.

After the case attachment is made, the converter must be moved to bring its lug surface

into contact with the flexplate (and to bring the pilot diameter into the crankshaft bore).

All bolts must be hand started to prevent cross threading. Moving the converter into

place before tightening its attaching bolts ensures that both the transmission to engine

and the converter to flexplate have been properly aligned and that the converter is free to

move in the crankshaft bore without loading the crankshaft bearings. The transmission to

engine attachment, and the converter to flexplate must NOT be drawn into position with

only one bolt tightened with a power gun.

The flexplate must be indexed for alignment to the converter attachment lugs. Access for

indexing the flexplate ring gear is available on some of the transmission case bell

housings adjacent to the starter pocket. In other cases, there is no access provision and

the flexplate is indexed via the engine crankshaft pulley.

A paint spot is applied to the front edge of the torque converter to indicate the lowest

mass location as measured during the converter balancing operation at the

manufacturing plant. The spot may be used to line up with any identified heavy spot on

the flexplate during assembly to the engine.

The following figures illustrates the converter bolt patterns and thread sizes. The choice

of bolt must consider factors such as thread engagement and clearances at the bolt head

and thread end. The threaded end must not bottom out against the converter cover. A

thread adhesive should be used to ensure durability.

Converter piloting is provided by a counter bore in the end of the engine crankshaft or ywheel adapter, shown in

Figure 2.1.1-2. Axial movement of the converter is contained within this “oating pilot” to ensure that thrust loads are

not transferred to the crankshaft thrust bearing. Grease should be applied to the pilot or bore to act as a lubricant and

corrosion inhibitor. Care must be taken to ensure that the converter pilot is seated properly in the engine crankshaft or

ywheel adapter bore.

During assembly to the engine, the transmission must be supported so that it is horizontal, or with the bell housing slightly

elevated. This will prevent the torque converter from slipping out of engagement with the oil pump shaft when the shipping

bracket is removed. The bellhousing face must be squarely seated against the engine face, with locating features fully

engaged, before its attaching bolts are tightened.

After the bellhousing attachment is made, check the converter pullout (Reference 2.1.3) and then move its lug surface

into contact with the explate (and to bring the pilot diameter into the crankshaft bore). All bolts must be hand started

to prevent cross threading. Moving the converter into place before tightening its attaching bolts ensures that both the

transmission to engine and the converter to explate have been properly aligned and that the converter is free to move in

the crankshaft bore without loading the crankshaft bearings. The transmission to engine attachment, and the converter to

explate must NOT be drawn into position with only one bolt tightened with a power gun.

The explate must be indexed for alignment to the converter attachment lugs. Access for indexing the explate ring gear

is available on some of the transmission bell housings adjacent to the starter pocket. In other cases, there is no access

provision and the explate is indexed via the engine crankshaft pulley.

A paint spot is applied to the front edge of the torque converter to indicate the lowest mass location as measured during

the converter balancing operation at the manufacturing plant. The spot may be used to line up with any identied heavy

spot on the explate during assembly to the engine.

The following gures illustrates the converter bolt patterns and thread sizes. The choice of bolt must consider factors such

as thread engagement and clearances at the bolt head and thread end. The threaded end must not bottom out against

the converter cover. A thread adhesive should be used to ensure durability.

➤

FLEXPLATE

END OF

ENGINE

CRANKSHAFT

➤

Page 20

➤

Figure 2.1.1-2: Torque Converter Pilot Arrangement

REV 1.1

TORQUE CONVERTER HUB

(CONVERTER PILOTING)

Ph: 804.227.3023

10511 Old Ridge Rd. Ashland, VA 23005

Page 27

4LHD/4LHDX Application Manual

Bellhousing Converter A B

GM LS

PCS SAE3 & SAE4

258 mm 36.7 mm (1.446”) 25.7 mm (1.012”)

300 mm 21.7 mm (0.854”) 10.7 mm (0.421”)

258 mm 49.4 mm (1.944”) 38.4 mm (1.512”)

300 mm 34.4 mm (1.354”) 23.4 mm (0.921”)

Dimension A: Rear face of engine to torque converter mounting lug.

Dimension B: Rear face of engine to explate.

The explate shown above is PCS part number TRN7007, reference Section 2.1.2 in this document or the PCS OEM

Parts Catalog for more information.

The dimensions provided indicate the installed depth of the torque converter. The tolerance is +/- 0.062”.

Every installation must have the converter pull-out measured and veried before the vehicle is operated. Improper torque

converter pull-out will result in transmission malfunction and/or damage.

To measure the Torque Converter Pull-Out:

1. Align and install the bellhousing/transmission assembly to the engine. Before tightening the bellhousing fasteners

completely, check to be sure converter rotates freely.

2. Once the bellhousing fasteners are torqued to specication, push the torque converter back into the transmission as

far as possible.

3. Using feeler gauges or calipers measure the gap between the explate mounting surface and the torque converter

mounting pads. If the gap distance is between .060” (1.5mm) and .187” (4.7mm) it is OK to bolt up the torque converter.

Reference Section 2.1.3 for a more detailed description of this verication process.

Page 21

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 28

Powertrain Control Solutions

258 mm CONVERTER LUG TO REAR FACE OF ENGINE

22.09mm ± 0.83

(ENGINE OFF)

SECTION A - A

➤

➤

ENGINE

BLOCK

300 mm CONVERTER LUG TO REAR FACE OF ENGINE

21.667mm±1.181

(ENGINE OFF)

3 HOLES

SECTION A - A

➤

➤

ENGINE

BLOCK

CONVERTER

PILOT

Ø43.234±

A

➤

➤

A

➤

➤

.016

.015

mm

➤

Figure 2.1.1-4 300 mm Torque Converter Attachment Features

281.0mm

➤

M10 x 1.5-6H THD THRU

CONVERTER

PILOT

Ø20.94 ± 0.02mm

A

➤

➤

A

➤

➤

Page 22

Ø 247.65mm

➤

➤

M10 x 1.5 - 6H THD THRU LUG

3 HOLES

Figure 2.1.1-5: 258 mm Torque Converter Attachment Features

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 29

4LHD/4LHDX Application Manual

Figure 2.1.1-6: C6 Torque Converter Attachment Features

Page 23

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 30

Powertrain Control Solutions

2.1.2 Flexplate

PCS uses a universal explate for our GM and SAE applications, while the C6 converter is designed for the stock C6

explate.

Page 24

Figure 2.1.2-1 GM Flexplate

Figure 2.1.2-2 C6 Flexplate

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 31

4LHD/4LHDX Application Manual

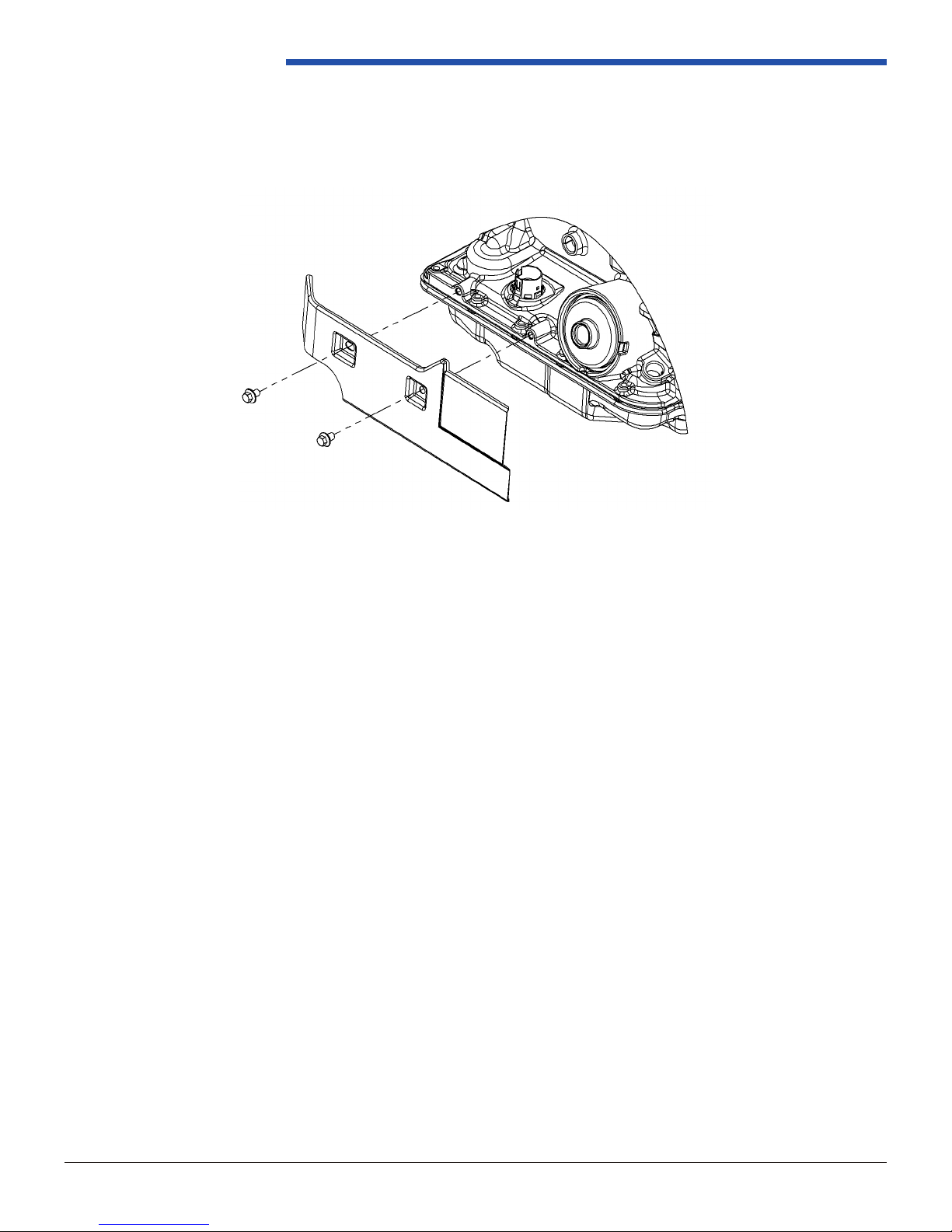

2.1.3 Flywheel Interface

Having the torque converter correctly spaced with the transmission pump is critical for optimal functionality and to prevent

permanent damage during installation/operation. To adapt to a wide variety of ywheels and bellhousing combinations,

PCS uses Flywheel Kits (a combination of Engine Spacers and Flywheel Adapters as shown in Figure 2.1.1-3) to mate

the 4LHD/4LHDX explate/torque converter with the engine’s ywheel. These parts must not be swapped between

different Flywheel Kits. After installation of the Flywheel Kit/explate to the engine and then installation of the transmission/

bellhousing to the engine, it is necessary to verify the “Torque Converter Pull Out” which can be measured by the distance

between the torque converter pad and the explate, referenced in Figure 2.1.1-3. This measurement only works if the

torque converter has been gently pushed into the transmission pump as far as possible, which should already be the case

for proper installation referenced in section 3.1.3. If the torque converter is removed from the transmission/pump for any

reason, reinsertion of the torque convert must be done gently and precisely. There are two tabs in the transmission pump

assembly, which must be correctly aligned and integrated with the corresponding slots on the torque converter pilot. If

this is not done properly, permanent damage to the transmission will result when the engine/transmission are assembled.

Reference the PCS OEM Parts Catalog for a current list of engine and ywheel applications, and PCS engineering for

new ones.

Flexplate

Engine Spacer

Flywheel Adapter

Figure 2.1.3-1 Example Flywheel Kit

Note: The explate kit is not included in the ywheel kit.

Page 25

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 32

Powertrain Control Solutions

2.1.4 Bellhousing to Flywheel Housing Interface

The conguration of the engine mounting face varies according to engine usage. The 4LHD/4LHDX currently supports

ve types of mounting faces. Contact PCS for an updated list. Figures 2.1.4-1 to 2.1.4-5 show these bellhousing

congurations. Dimensions are for reference only.

Reference section 3.1 for a discussion of assembly considerations that are critical to the alignment of the transmission

to the engine. These bellhousings have been factory installed to 51 lb*ft / 70 N*m, removing them without the instruction/

permission of PCS will damage the transmission and void your warranty.

Page 26

Figure 2.1.4-1: GM GEN III Bellhousing Front View

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 33

4LHD/4LHDX Application Manual

Page 27

Figure 2.1.4-2: PCS SAE3 Bellhousing Front View

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 34

Powertrain Control Solutions

Page 28

Figure 2.1.4-3: PCS SAE4 Bellhousing Front View

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 35

4LHD/4LHDX Application Manual

Figure 2.1.4-4 PCS SAE5 Bellhousing Adapter Front View

Page 29

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 36

Powertrain Control Solutions

Page 30

Figure 2.1.4-5: PCS C6 Bellhousing Front View

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 37

2.2 Transmission Output

2.2.1 Lubrication and Sealing

Referenced in Figure 2.2.1-1 is the lubrication system for all 4LHD/4LHDX extension housings. This system

ensures the spline engagement, rear bearings, and seals retain optimal functionality for the life of the transmission.

It is critical that the extension housing is properly sealed from the environment and transfer case oil. Fluid enters

the cavity from both the oil jet and output shaft bearing, and drains to the oil pan through the return vent. PCS uses

a universal extension housing to transmission seal. The seal between the transmission case and the extension

housing is referenced in Figure 2.2.3-4. During transmission operation the return vent must not be plugged, as

this will cause the extension housing to ll with uid which can cause permanent damage. Contact PCS in the

case of applications requiring dry extension housings.

4LHD/4LHDX Application Manual

Page 31

Figure 2.2.1-1: Extension Housing Fluid Control

2.2.2 Output Shaft Requirements

Propshaft Alignment and Torsional Vibrations

The presence of universal joints in the propshaft will induce torsional vibrations in the driveline, due to the angles

at which the driveshafts operate. This can have a detrimental effect on component durability.

The chassis shall be designed to minimize the torsional vibration resulting from excessive driveshaft angle. Refer

to SAE Design Guideline AE-7: Universal Joint and Driveshaft Design. Excitations in the driveline, during any

continuously operating condition, shall not exceed:

Torsional excitation: 400 rad/s2

Inertia excitation: 1000 rad/s2

If a design approaches or exceeds these criteria, or if a design is considered at risk, a test shall be conducted to

ensure that the transmission is not compromised. This information can be found in the SAE Design Guide Line

AE-7: Universal Driveshaft Design.

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 38

Powertrain Control Solutions

Noise and Vibration

Special attention should be given to the following areas when developing a vehicle mounting system. Attachments to

these areas where the noise is generated will result in a direct noise path and could ultimately result in noise quality

concerns. In addition, mounts should not have the same excitation frequency at or near the natural vibrations of the

following components:

• Gears

• Bearings

• Converter

• Oil pump

2.2.3 Extension Housings

Typical vehicle mounting applications are shown in Figures 2.2.3-1 to 2.2.3-10. All four standard extension housings

available through PCS have integrated vehicle mounts. Any proposed boss locations and threaded fastener designs

must have PCS Engineering approval for load analysis. Mount loads should be supplied by the customer. For an updated

list of vehicle mount options reference the PCS OEM Parts Catalog. The factory torque rating for the six transmission to

extension housing bolts is 37 ft*lbs / 45 N*m. In addition, the speed sensor bolt in 2WD applications has a torque rating

of 8 lb*ft / 11 N*m.

A proper installation supports the transmission weight but must also:

• Avoid loading the internal components

• Allow for frame twist

• Absorb driveline torque

• To damp driveline shock forces

• Not exceed 200 lbs on transmission mount

GM 2WD Extension Housing

Used in rear wheel drive applications, this extension housing does not have a parking brake incorporated. When installed

properly the journal of the slip yoke provides a seal for the rear of the transmission. This is critical due to the lubrication

jet and return vent on the rear face of the 4LDH/4LHDX. The slip yoke features referenced in the table below are

required to ensure proper functionality and durability of the driveline system with respect to the transmission interface

subcomponents i.e., bushing and seal. There are many options available through Spicer and other manufacturers, as

each vehicle has different driveline lengths and power ratings. A common example is the Spicer 2-3-12411X from their

Slip Yoke Assemblies Catalog. Reference Figure 2.2.3-1 for transmission output interface.

Slip Yoke Details

Spline Type 27 Tooth (Involute)

Journal Diameter 38.176 - 38.151 mm (1.503 - 1.502 in)

Journal Surface Finish 0.25 - 0.50 μm (10 - 20 μin) Ra

NOTE: For the nishing procedure, Residual burrs produced by the turning, grinding and polishing operations to the slip yoke journal must be of a

favorable i.e., non-aggressive direction of lay to the journal rotational direction when the vehicle is in forward drive.

Page 32

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 39

4LHD/4LHDX Application Manual

2WD SPLINE DATA

Number of Teeth 27 Form Diameter 27.94 mm

Module 1.0583 mm Min Effective Tooth Thickness (Reference) 1.732 mm

Diameter Pitch 24.000 mm Max Effective Tooth Thickness 1.821 mm

Pressure Angle 30.0˚

Pitch Diameter

(Reference)

Base Diameter

(Reference)

28.575 mm

24.747 mm Measure Over Pins

Major Diameter 29.822-39.845 mm

Minor Diameter 27.00-27.20 mm Spline Length 115.5 mm

Min Actual Tooth

Thickness

Max Actual Tooth

Thickness

Pin Diameter

(Reference)

1.719 mm

1.795 mm

Min: 31.173 mm

Max: 31.051 mm

1.778 mm

SIDE VIEW

BOTTOM VIEW

SIDE VIEW

Page 33

Figure 2.2.3-1: GM 2WD Extension Housing

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 40

Powertrain Control Solutions

GM 4WD Extension Housing

Shown in Figures 2.2.3-2 and 2.2.3-3 is the PCS approved two speed electronic shifting transfer case. 2Hi, 4Hi, Neutral,

and 4Lo are controlled via an external PCS Transfer Case Module. The rear output shaft takes a GM 32 tooth female yoke,

while the front output shaft takes a GM 32 tooth make yoke. Reference the PCS OEM Parts Catalog for part numbers.

Page 34

Figure 2.2.3-2: GM 4WD Extension Housing

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 41

4LHD/4LHDX Application Manual

Page 35

Figure 2.2.3-3: GM 4WD Transfer Case

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 42

Powertrain Control Solutions

PCS Parking Brake

The PCS parking brake is a disk style brake that attaches to the 4LHD/4LHDX in rear wheel drive applications. It provides

a mechanical brake and also has an optional hydraulic brake that can be used for certain applications. It also can be

electronically controlled with the Parking Brake Module.

The caliper can be mounted in several different clocking orientations and is available with a left hand cable exit or a right

hand cable exit.

BOTTOM VIEW

Figure 2.2.3-4: PCS Parking Brake Explosion View

SIDE VIEW

Figure 2.2.3-5: PCS Parking Brake Dimensions

Page 36

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 43

4LHD/4LHDX Application Manual

Figure 2.2.3-6: PCS Parking Brake Feature Locations

The PCS Parking Brake is designed and manufactured to take a standard driveshaft ange yoke, dimensions shown in

Figure 2.2.3-8. A common example, shown in gure 2.2.3-7 is the Spicer 3-2-159. This is a parking brake only, not an

emergency brake. Max vehicle holding weight is dependant on nal gear ratio and tire size. Contact PCS for application

engineering.

BORE FOR

MALE FLANGE

Figure 2.2.3-7 Example Flange

Page 37

REV 1.1

Figure 2.2.3-8 Flange Yoke Bolt Circle

Ph: 804.227.3023

10511 Old Ridge Rd. Ashland, VA 23005

Page 44

Powertrain Control Solutions

PCS C6 Extension Housing

This replacement package holds all the same specications as the old Ford C6 w/ drum parking brake option. Shown in

Figures 2.2.3-9 to 2.2.3-10. This utilizes the original brake housing, drum, driveshaft yoke, and other hardware to correctly

seal and operate. Same as the original, our output shaft is an SAE10B spline. Reference SAE Standard J499 for full

spline detail.

Figure 2.2.3-9: PCS 4LHD/4LHDX with C6 Bellhousing and C6 Output

Page 38

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 45

4LHD/4LHDX Application Manual

Page 39

Figure 2.2.3-10: PCS C6 Extension Housing

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 46

Powertrain Control Solutions

2.3 Transmission Cooling

Transmission uid is heated primarily by the pumping action that occurs within the torque converter. Heat load varies,

depending on speed, grade, duty cycle, ambient temperature, etc. A method of heat dissipation must be provided in order

to maintain proper transmission temperature.

Cooling is accomplished by circulating the uid through a cooler that is external to the transmission. Incorporation of the

cooler within the radiator is recommended since this provides the added advantage of quick warm-up of the transmission

in cold climates. If the cooler is located in a radiator end tank, the inlet pipe should be at the lowest point of the cooler.

If an auxiliary cooler is used, it should be located in the return line to the transmission, and the system should incorporate

a bypass to allow lubrication ow under very low ambient temperature conditions. Adequate ow shall be veried by test.

NOTE: It is recommended for the transmission

cooler to ow IN at the cooler bottom port and

OUT at the cooler top port. This is recommended

not only so that heavy particles and sediment fall

to the bottom of the cooler instead of returning

to the transmission sump, but also allows any

trapped air in the system to rise and leave the

heat exchanger via the upper outlet tting.

2.3.1 Cooling System Overview

Automatic Transmission Fluid

Automatic transmission uid (ATF) is a complex lubricant that consists of a base oil and an additive package.

The additive package is designed to impart several desirable performance characteristics, above and beyond

those that the base oil could do alone. The performance of ATF’s are driven by the needs of the product and must

provide excellent uidity values for both low and high temperature transmission performance. Fill tubes, ll caps

and bottom pans should be accessible for repair without removing the transmission from the vehicle. In addition,

external seals should be accessible for serviceability.

Fluid Specication

The ATF to be used in any PCS 4LHD/4LHDX shall be Dexron® VI or equivalent. Transmission damage caused

by the use of improper uid will not be covered under warranty.

Page 40

Figure 2.3-1 Cooler System

REV 1.1

10511 Old Ridge Rd. Ashland, VA 23005

Ph: 804.227.3023

Page 47

4LHD/4LHDX Application Manual

3.2.1. Cooling

Transmission fluid is heated primarily by the pumping action that occurs within the torque

converter. Heat load varies, depending on speed, grade, duty cycle, ambient

temperature, etc. A method of heat dissipation must be provided in order to maintain

proper transmission temperature.

Cooling is accomplished by circulating the fluid through a cooler that is external to the

transmission. Incorporation of the cooler within the radiator is recommended since this

provides the added advantage of quick warm-up of the transmission in cold climates. If

the cooler is located in a radiator end tank, the inlet pipe should be at the lowest point of

the cooler.

If an auxiliary cooler is used, it should be located in the return line to the transmission,

and the system should incorporate a bypass to allow lubrication flow under very low

ambient temperature conditions. Adequate flow shall be verified by test.

3.2.1.1. Cooler Line Connection

Cooler lines connect the transmission to the radiator (cooler). Refer to Figure 3.2.1.1-1

for the position of the “to cooler” and “from cooler” connections.

Cooler lines should be as short, and with as few bends as possible. The largest

feasible pipe bore should be used. Routing should avoid external heat sources (such

as exhaust pipes, catalytic converters etc.), protect the pipe from road hazards and

provide for ease of installation and removal. The cooler lines should be adequately

supported along their length to prevent vibrations from generating noise or fatigue

distress, and to prevent noise transmission into the vehicle structure. The cooler

circuits should be capable of withstanding 2068 kPa (300 psi) and fluid temperatures

of 177˚C (350˚F).

2.3.2 Cooler Requirements

To provide proper operation and longevity, the cooling system must maintain the transmission sump temperature below

132°C (270°F) and stator temperature below 177°C (350°F) at all times. This is dened as a “never exceed” limit under

all operating conditions. Average sump temperature must not exceed 110°C (230°F). The cooler must be capable of 4-5

kW of heat rejection for light duty applications, and 8-10 kW for heavy use such as industrial vehicles, off road equipment,

military and ground support equipment.

2.3.3 Cooler Lines

Cooler Line Connection: Cooler lines connect the transmission to the radiator (cooler). Cooler lines should be as short,

and with as few bends as possible. The largest feasible pipe bore should be used. Routing should avoid external heat

sources (such as exhaust pipes, catalytic converters etc.), protect the pipe from road hazards and provide for ease of

installation and removal. The cooler lines should be adequately supported along their length to prevent vibrations from

generating noise or fatigue distress, and to prevent noise transmission into the vehicle structure.

Flow Requirements: The transmission cooler lines and the oil cooler must ow a minimum of 6 LPM at 345 kPa (50 psi)

and 11 LPM at 690 kPa (100 psi). The ow test shall be run with 93˚C (200˚F) ATF.

Pressure Requirements: Cooler line pressure under normal operation will be between 200 kPa (30 psi) and 1,000 kPa

(150 psi). The transmission may produce pressure of up to 2,086 kPa (300 psi) at the cooler line entrance. This pressure

may be observed on start up or if there is blockage in the transmission cooling system (cooler lines, oil cooler, return tting

at transmission). The lines and ttings must all be rated for a minimum of 300 psi.

Temperature Requirements: The cooler lines, cooler, and ttings shall be capable of withstanding uid temperatures of

177˚C (350˚F).

FROM COOLER

TO COOLER

➤

Page 41

Figure 2.3.3-1 Cooler Line Connection

REV 1.1

➤

Ph: 804.227.3023

10511 Old Ridge Rd. Ashland, VA 23005

Page 48

Powertrain Control Solutions

The cooler line interface exiting the case of the 4LHD/4LHDX is a #6 SAE Dash Size ORB (O-Ring Boss) for the hydraulic

tting. Reference gure 2.3.3-2 for dimensions and SAE J514 for more detailed specications.

SAE J514 Dimensions

SAE Dash Size 6

Nom Tube OD (mm) 9.52

Nom Tube OD (in) 0.375

Straight Thread Size 9/16-18

Nom Pipe Size 1/8

Figure 2.3.3-2: Cooler Output Dimensions

Cooler Line Installation

The following two sections provide the general guidelines for cooler line installation.

I. Flare Type Fittings

1. Remove shipping plugs from cooler lines and ttings. Plugs should be removed as late as possible to avoid damage

or contamination of the cooler lines and ttings.

2. Loose assemble the lines to the transmission and hand start nuts. Torque as specied, 28 lb*ft / 38 N*m. Over torquing

could distress the established thread lock of the connector in the transmission case.

3. Assure hoses/pipes are not kinked, crossed, twisted or grounded to any unspecied vehicle components. Due care

must be taken to prevent intentional movement of the cooler lines in the assembly process. Unnecessary vibration,