PCS 4000 User Manual

USER GUIDE

™

PCS 4000

SINGLE WELL CONTROLLER

Contents

Basic Operations ............................................................. 2

Controller’s Faceplate .................................................... 2

Turning the Controller On and Off ..................................3

Status Display ................................................................3

Units of Measurement ...................................................3

Operating the A-Valve and B-Valve Manually ................ 3

Reading Reports and Program Functions ..................... 3

Setting Program Functions ............................................3

Report and Program Function Reference .....................4

Reports .......................................................................... 4

Program Functions ........................................................4

Controller Reports ........................................................... 5

How Pressure Operation Works ..................................... 7

Calibrating the Transducers ...........................................8

Calibrate Transducers Wired to the Controller............... 8

Calibrate Transducers Reporting Wireless to the

Controller ....................................................................... 8

Turn off a Transducer ..................................................... 8

Creating a Pressure-Operation Plunger Program ........ 9

Pressure-Operation Selection Functions ....................... 9

Pressure-Operation Control Functions .......................... 9

Features for Opening the A-Valve ................................ 11

Features for Closing the A-Valve ................................. 12

Features for Special Circumstances ............................ 12

Sales-Line Safeguard Features .................................... 13

Using Pressure Operation to Intermit a Well without a

Plunger ...........................................................................14

Pressure-Operation Selection Functions ..................... 14

Pressure-Operation Control Functions ........................ 14

Features for Opening the A-Valve ................................ 14

Features for Closing the A-Valve ................................. 14

Features for Special Circumstances ............................ 14

Sales-Line Safeguard Features .................................... 14

Troubleshooting ............................................................. 15

Controller Display Problems ........................................ 15

Program Cycle Problems ............................................. 16

Solenoid (Shift Valve) Problems ................................... 19

Transducer Problems ................................................... 19

Preventive Maintenance ...............................................19

PCS 4000 SINGLE WELL CONTROLLER

©2008 Production Control Services, Inc. ProductionControlServices.com

USER GUIDE

Current

well status

Time remaining

in hrs.:min.:sec.

When A-valve is closed:

- Casing pressure

- Tubing pressure

- Line pressure

When A-valve is open:

- Casing pressure

- Flow rate

- Line pressure

Opens A-valve

Closes A-valve and

B-valve

Used with other keys

to access functions that

control B-valve.

Example: B ON opens

B-valve

Clears current entry

and backspaces

Sets program functions

Reads reports

and function

values

Power

On/Off

Local operator input (LOI)

serial port for connection

to laptop computer

PRODUCTION CONTROL SERVICES, INC.

1-800-619-2241

PCSplungerlift.com

THIS PCS CONTROLLER IS MANUFACTURED BY PCS, INC © 1998

PATENT NO.6,196,324 B1

OPERATING INSTRUCTIONS

READ B 30: Serial Number

Read CE: Version Number

MANUAL VALVE CONTROL

ON Open A Valve (Sales)

OFF Close A & B Valves

B ON Open B Valve (Vent)

PROGRAM AND READ SETTINGS

PROGRAM Press: SET, Function Key

READ Press: READ, Function Key

ON A Valve Open Time

OFF Close Time

B ON B Valve Open Time

#00 Battery And Solar Conditions

#02 A Valve Delay (Sales) Time

#03 Mandatory Shut In Time

#05 Plunger Fall Time

#08 Delay Close Time

Sensor Status (On or Off)

#09 Auxillary Close Delay

(On = No Delay or Off = Close Delay)

#11 Controller Operating Mode

Differential Open Pressure

#12 Casing-Tubing or Casing-Line

#13 Casing PSI Increase (Casing Dip) Close

#14 High Line Pressure Close

#15 Low Line Pressure Close

#16

Activate and Calibrate Trans #1/Casing

#17

Activate and Calibrate Trans #2/Tubing

#18 Activate and Calibrate Trans #3/Line

#20 Casing Drop Pressure

#21 Casing Peak Build Time

#24 Load Factor

#26 Equalize Time / C Valve

#90 Scan / Set Entire Program

B VALVE SETTINGS

B-0 A Valve Closed When B is Open (Yes or No)

B-2 B Valve Display Time

B-4 B Valve Plunger and Valve Counts

B-7 B Valve Open and Close Times

B-8 Line Delay Times

PLUNGER HISTORY

History Press: READ, Function Key

Clear Totals Press: SET, Function Key, CE

#04 A Valve Plunger and Valve Counts

#06 Plunger Travel Times (Last 25) Avg. Run

#07 A Valve Open and Close Times

A & B Plunger and Valve Counts

#10 Plunger Travel Times (Last 25)

#19 Open and Close Times (Last 10)

CLOSE 0:00:00

C315 T250 L150

1 2 3

ON

4 5 6

OFF

7 8 9 B

READ

0

SET CE

POWER

ON/OFF

DISPLAY STATUS HRS:MIN:SEC

BasiC operations

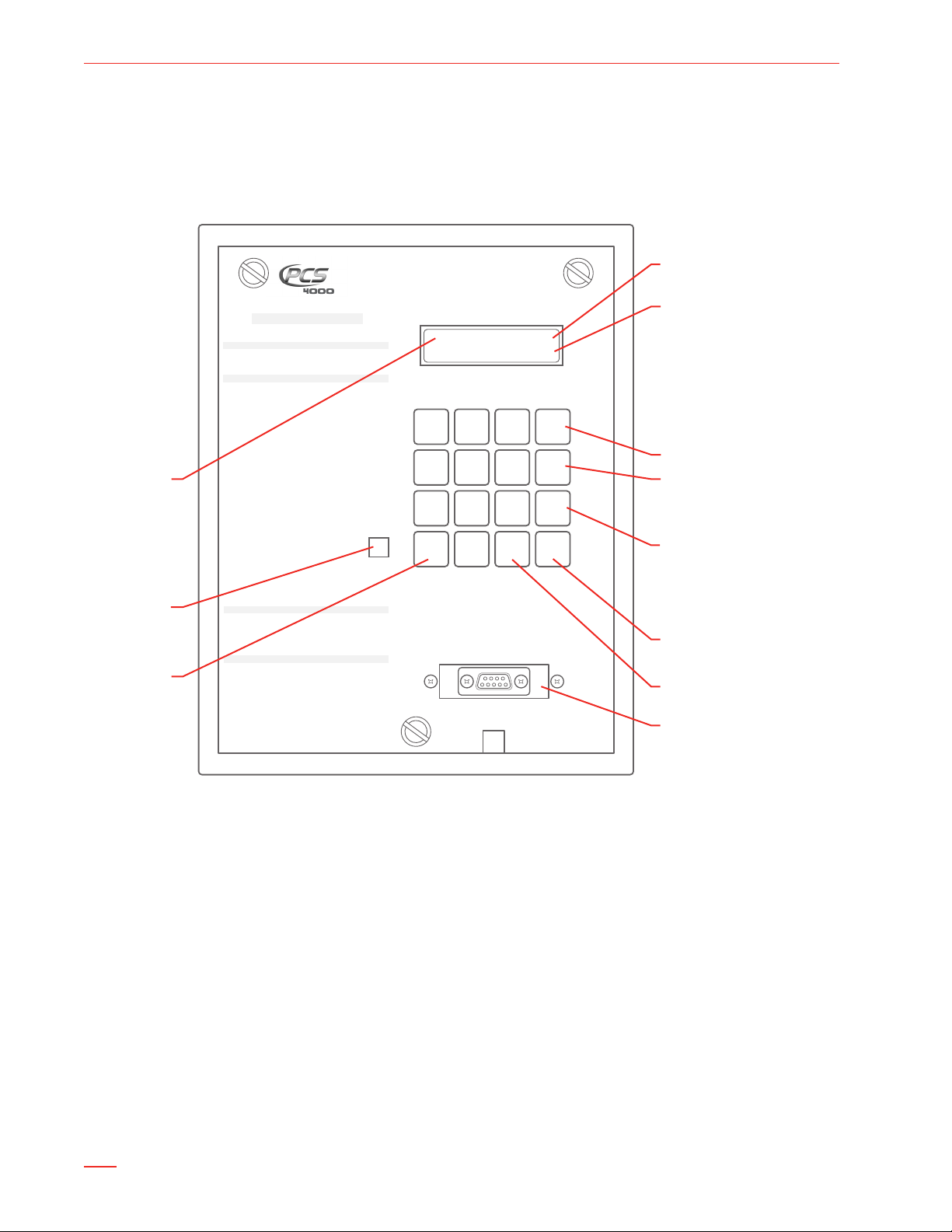

Controller’s Faceplate

Figure 1 shows the controller’s faceplate with the power on/off switch, status display, keypad, and serial port for local

operator input.

PCS 4000 SINGLE WELL CONTROLLER

Figure 1 – Controller’s Faceplate

2

USER GUIDE

PCS 4000 SINGLE WELL CONTROLLER

Turning the Controller On and Off

To turn the PCS 4000 Single Well Controller on or off,

insert a screw driver into the slot marked POWER ON/

OFF. See Figure 1.

Move the toggle switch to the left to turn the controller on.

Move the toggle switch to the right to turn the controller

off.

The plunger program does not run while the controller is

off. When you turn the controller on, it closes the A-valve

and starts counting down the FALL TIME (see step 1 on

page 7).

Status Display

After you turn the PCS 4000 Single Well Controller on, the

status display remains on. The controller never sleeps.

The rst line of the status display shows the current well

status and the time remaining.

When the A-valve is closed, the second line of the status

display shows the casing pressure, tubing pressure, and

sales line pressure.

Operating the A-Valve and B-Valve Manually

Open the A-Valve = ☛ ON

Press ON.

ON overrides all programmed functions such as FALL

TIME and MANDATORY SHUT-IN TIME.

ON does not override safeguard functions such as

LOW LINE CLOSE PRESSURE and HIGH LINE CLOSE

PRESSURE.

Open the B-Valve = ☛ B ON

Press B ON.

Close the A-Valve (and B-Valve if Used) = ☛ OFF

Press OFF.

OFF overrides all programmed functions such as OPEN

TIME and DELAY TIME (SALES).

Reading Reports and Program Functions

Read a Report or the Value of a Single Program Function

Press READ.1

Example:

CLOSE 0:00:00

C315 T250 L150

When the A-valve is open, the second line shows the

casing pressure, ow rate, and sales line pressure.

Example:

A-OPEN 0:14:22

C315 F123 L150

Units of Measurement

Time is in hours:minutes:seconds.

Example: 08:15:00

Pressure is in pounds per square inch (psi).

Example: 00100

Depending on the setting of the METRIC function (SET

33), the unit of measurement for ow rate is either

thousand cubic feet (mcf) or thousand cubic meters

(E3M3).

The status display shows:

READ:

Enter the number of the report or function you want to 2

display. Example: 10.

Read the Values of All Program Functions = ☛ READ 90

For a list of the program functions, see “READ 90

Program Function List” on page 4.

Setting Program Functions

Set a Single Program Function

Press SET.1

The status display shows:

SET:

Enter the number of the function you want to set. 2

Example: 05.

Enter the value for the function. See 3 “Units of

Measurement” on this page.

To exit the function without changing its value, press

CE.

Set All Program Functions = ☛ SET 90

For a list of the program functions, see “SET 90 Program

Function List” on page 4.

3

USER GUIDE

report and program FunCtion reFerenCe

The tables in this section cross-reference the reports and

program functions described in this User Guide.

Reports

Report READ Page

Software Version Report CE 6

Battery Status Report 00 6

Status of A-Valve when B-Valve Is Open B0 9

A-Valve and Plunger Counts History 04 5

B-Valve and Plunger Counts History B4 5

Plunger Travel Time History 06 5

A-Valve Total Time Report 07 5

B-Valve Total Time Report B7 5

Valve/Plunger Counts History, Total Time

Reports, and Plunger Travel Time History

Time Open and Closed History 19 6

Modbus Address Report 22 6

PCS 4000 SINGLE WELL CONTROLLER

Clearing Report Values

Program Function SET Display Name Page

Clearing Report

Values

Program Functions

READ 90 Program Function List

Press READ 90 to display the current times, pressures,

and ow rate values programmed for all functions listed in

the table on the right side of this page.

SET 90 Program Function List

Press SET 90 to program all functions listed in the table

on the right side of this page.

Additional Program Function

To program this function, press SET B 0.

To display its current value, press READ B 0.

Program Function

Status of A-Valve

when B-Valve Is Open

10 ZERO ALL TOTALS 6

SET or

READ Display Name

B0 A OPEN W/ B VAL. 9

10 5

Page

Program Function

OPEN TIME ON A OPEN TIME 9

CLOSE TIME OFF CLOSE TIME 11

DELAY TIME (SALES) 02 A DELAY TIME 13

MANDATORY

SHUT-IN TIME

B OPEN TIME B ON B OPEN TIME 9

B DELAY TIME B2 B DELAY TIME 13

FALL TIME 05 FALL TIME 9

DELAY CLOSE TIME 08 DELAY CLOSE TIME 10

Sensor Operation 09 SENSOR?

A-Valve Location

(local or remote)

B-Valve Location

(local or remote)

C-Valve Location

(local or remote)

Operating Mode 11 1. TIME 2. T-L

DIFFERENTIAL

OPEN PRESSURE

DIFFERENTIAL

CLOSE PRESSURE

(DIP)

HIGH LINE CLOSE

PRESSURE

DELAY LINE CLOSE

TIME

LOW LINE CLOSE

PRESSURE

CASING DROP

PRESSURE

CASING PEAK TIME 21 CASING TIME 11

LOW FLOW RATE 23 MIN. FLOW RATE 12

LOAD FACTOR 24 LOAD FACTOR 11

CRITICAL FLOW K

FACTOR

EFM Device Setup 31 READ REMOTE

Flow Rate Unit of

Measurement

B LOW FLOW RATE 35 B LOW FLOW RATE 12

B LOW FLOW

DELAY TIME

SET or

READ Display Name

03 MAND. SHUT-IN 10

SET SENSOR

60 VALVE A LOCATION none

61 VALVE B LOCATION none

62 VALVE C LOCATION none

3. C-T 4. C-L

12 OPEN PRESSURE 9

13 CLOSE PRESSURE 10

14 HIGH LINE PRES. 13

B8 LINE DELAY TIME 13

15 LOW LINE PRES. 13

20 CASING DROP PRS. 12

25 TURNER CRIT

FLOW CONSTANT

FLOW

READ ACCUM

FLOW

SELECT EFM TYPE

33 METRIC 3

36 B LOW FLOW

DELAY

Page

9

9

12

9

12

4

Controller reports

Plunger Travel Time History = ☛ READ 06

This report provides information about the 25 most recent

plunger travel times. The rst display shows the number

of times the plunger surfaced and the average travel time.

Example:

GOOD RUNS: 25

AVE: 0:08:22

USER GUIDE

PCS 4000 SINGLE WELL CONTROLLER

Example:

A PLUNGER= 92

A VALVE = 96

In the example:

A VALVE = 96 shows that the A-valve opened 96 times.

A PLUNGER= 92 shows that the plunger arrived 92

times while the A-valve was open.

96–92=4. The plunger did not arrive 4 times while the

A-valve was open.

Use the READ button to scan through the report.

The next 25 displays show the 25 most recent plunger

travel times.

This example shows the most recent plunger run. The

plunger surfaced after 8 minutes and 15 seconds of

OPEN TIME.

LAST PLUNGER- 0

A 0:08:15

This example shows the 2nd most recent plunger run.

LAST PLUNGER- 1

A 0:08:15

This example shows the 25nd most recent plunger run.

LAST PLUNGER-24

A 0:08:15

This example shows the most recent plunger run. The

plunger surfaced after 10 minutes and 40 seconds of

OPEN TIME and B OPEN TIME.

LAST PLUNGER- 0

B 0:10:40

This example shows the most recent plunger run. The

CASING DROP PRESSURE was reached before the

plunger arrived.

LAST PLUNGER- 0

C 0:09:26

This example shows the most recent plunger run. The

plunger did not surface.

LAST PLUNGER- 0

NO PLUNGER

To exit the report at any display, press CE.

Valve/Plunger Counts History, Total Time Reports, and

Plunger Travel Time History = ☛ READ 10

This reporting option displays the 2 Valve and Plunger

Counts Histories (READ 04 and READ B4), the 2 Total

Time Reports (READ 07 and READ B7), and the Plunger

Travel Time History (READ 06). To display the next report,

press READ.

A-Valve and Plunger Counts History = ☛ READ 04

This report shows how many times the A-valve opened,

and how many times the plunger arrived while the A-valve

was open.

Note: If the well has a B-valve, this report shows 2 A-valve

counts for each B-valve count in the B-Valve and Plunger

Counts History. If the plunger did not arrive 4 times while

the A-valve was open, the plunger may have arrived up to

2 times while the B-valve was open.

B-Valve and Plunger Counts History = ☛ READ B4

This report shows how many times the B-valve opened,

and how many times the plunger arrived while the B-valve

was open.

Example:

B PLUNGER= 2

B VALVE = 2

In the example:

B VALVE = 2 shows that the B-valve opened 2 times.

B PLUNGER= 2 shows that the plunger arrived 2 times

while the B-valve was open.

A-Valve Total Time Report = ☛ READ 07

This report shows 2 times of up to 999 hrs., 59 min., 59

sec. accumulated since the report was last cleared:

Total OPEN TIME and DELAY TIME (SALES).

Total time that the controller was closed. MANDATORY

SHUT-IN (if any), FALL TIME (if any), and CLOSE TIME

are accumulated under TOT CLS time.

Example:

A TOTAL 16:31:13

TOT CLS 8:12:45

B-Valve Total Time Report = ☛ READ B7

This report shows 2 times of up to 999 hrs., 59 min., 59

sec. accumulated since the report was last cleared:

Total B OPEN TIME.

Total time that the controller was closed. MANDATORY

SHUT-IN (if any), FALL TIME (if any), and CLOSE TIME

are accumulated under TOT CLS time.

Example:

B TOTAL 1:24:32

TOT CLS 8:12:45

5

USER GUIDE

Clearing Report Values = ☛ SET 10

The display shows:

ZERO ALL TOTALS

ON=YES OFF=NO

Press the ON button to clear all of the valve and plunger

counts (READ 04 and READ B4) and total times (READ 07

and READ B7).

This option does not clear the Plunger Travel Time History

(READ 06) and the Time Open and Closed History (READ

19). History information is always available.

Note: Press the OFF button to exit the Clearing Report

Values function without clearing any of the report values.

Time Open and Closed History = ☛ READ 19

This report provides information about the last 10 times

the A-valve was open, and the last 10 times the A-valve

was closed.

OPN-0 and CLS-0 show the most recent open and

close information.

OPN-1 and CLS-1 show the 2nd most recent open and

PCS 4000 SINGLE WELL CONTROLLER

close information.

OPN-9 and CLS-9 show the 10th most recent open

and close information.

Example:

OPN-0 O 00:20:00

CLS-0 C 00:15:00

OPN information shows:

How long the A-valve was open. Time Open includes:

OPEN TIME

DELAY TIME (SALES)

DELAY CLOSE TIME (if any)

Time Open does not include B OPEN TIME (if any).

A letter that explains why the A-valve closed:

F = low ow rate input or critical ow K value input

G = switch gauge input

H = high sales line pressure input

L = low sales line pressure input

M = manual close

O = open time ran out

S = increase in casing pressure input

U = drop in casing pressure input

Note: If the A-valve opens because a close input stops,

there is no letter. For example, the A-valve closes in

response to a close input caused by low or high sales line

pressure. When the sales line pressure returns to normal,

the A-valve opens. The CLS information does not include

a letter.

Operating Mode Report = ☛ READ 11

The controller’s operating mode:

TIME MODE (mode 1)

TUBING-LINE MODE (mode 2)

CASING-TUBING MODE (mode 3)

CASING-LINE MODE (mode 4)

For more information, see “How Pressure Operation

Works” on page 7.

Battery Status Report = ☛ READ 00

This report displays the current voltage of the battery and

the solar panel.

Example:

BATTERY = 7.00V

SOLAR = 9.24V

Sensor Status = ☛ READ 09

This report shows whether the sensor is ON or OFF.

Note: The sensor must be ON to read the sensor input.

When using the Time operating mode, you can set the

sensor to OFF. PCS recommends setting the sensor to off

only if you are not running a plunger.

Software Version Report = ☛ READ CE

This report displays the chip and software version

numbers.

Example: VERSION 138-41

Modbus Address Report = ☛ READ 22

This report displays the controller’s modbus address.

Example: MODBUS ADDR:005

Important! Do not change the modbus address.

CLS information shows:

How long the A-valve was closed

A letter that explains why the A-valve opened:

C = CLOSE TIME counted down to zero

D = differential open pressure input

M = manual open

R = load factor input

T = casing time input

6

Loading...

Loading...