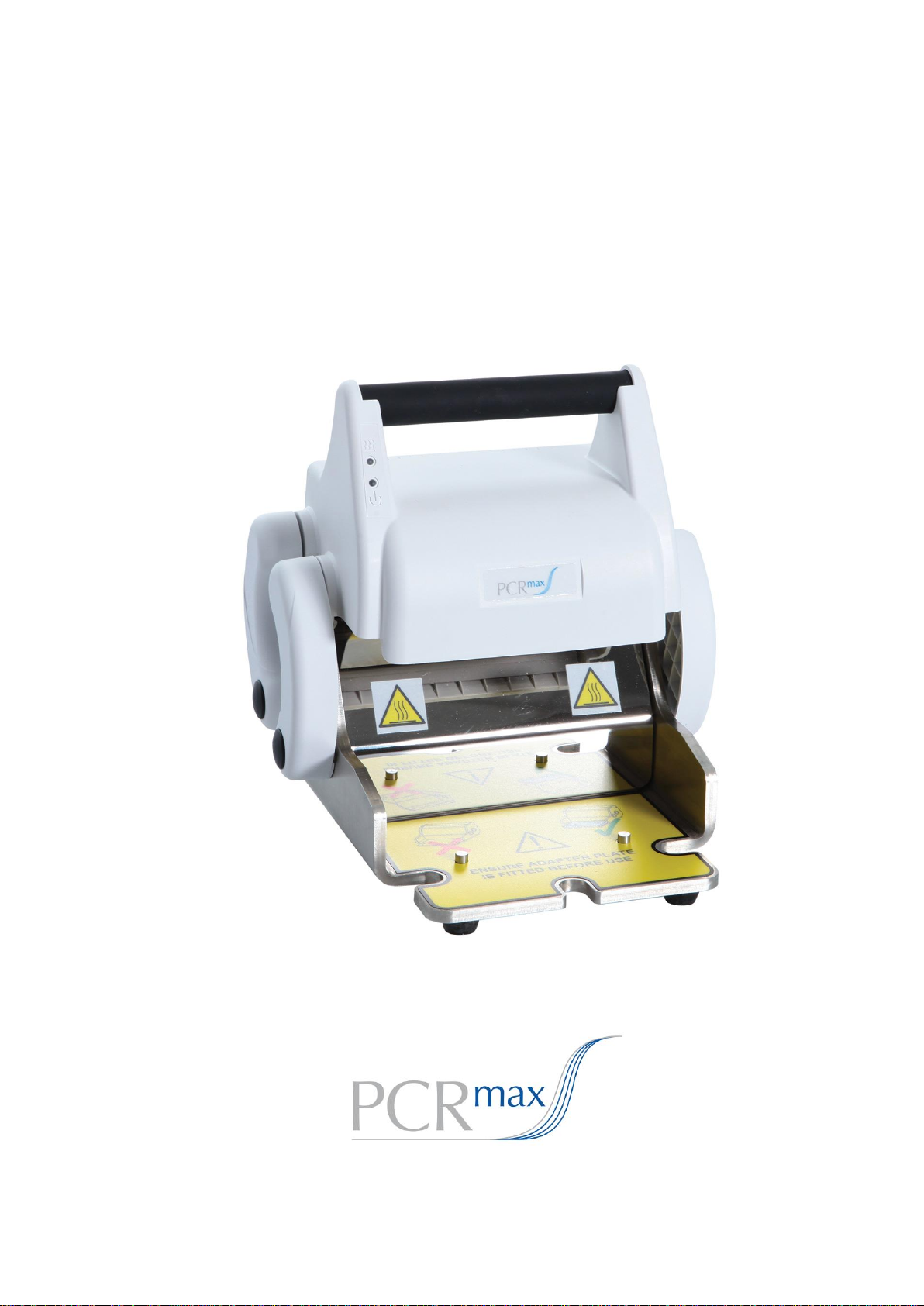

Page 1

Mini Microplate Heat Sealer, Fixed Temperature

13204-11

Instructions for Use

Page 2

Mini Microplate Heat Sealer

Instructions for Use

2

Contents

1 Symbols Used in this Instruction Manual ......................................................... 3

2 Safety Precautions and Limitations of Use ...................................................... 4

3 Regulatory Limitations of Use .......................................................................... 8

4 Unit Description ............................................................................................... 9

5 Unit Installation .............................................................................................. 11

6 Unit Operation ................................................................................................ 13

6.1 Status Indicator LEDs .................................................................................... 13

6.2 Performing a Sealing Operation .................................................................... 14

7 Maintenance and Servicing............................................................................ 15

7.1 Replacing the Unit Fuse ................................................................................ 15

7.2 Over Temperature Safety Cut-out ................................................................. 16

7.3 Routine Cleaning and Inspection ................................................................... 16

7.4 Decontamination Procedure .......................................................................... 17

7.5 Transportation and Storage ........................................................................... 18

7.6 Product Disposal ............................................................................................ 18

8 Warranty and Returns .................................................................................... 19

9 Technical Specifications ................................................................................ 20

10 Glossary of Terms and Abbreviations ............................................................ 21

Tables

Table 1: Advisory Symbol Meanings ......................................................................... 3

Table 2: Unit Features ............................................................................................... 9

Table 3: Plate and Adapter Types ........................................................................... 10

Table 4: Recommended Film and Foil Types .......................................................... 10

Table 5: Mains Voltage Selection ............................................................................ 11

Table 6: Status Indicator LEDs ................................................................................ 13

Page 3

Mini Microplate Heat Sealer

Instructions for Use

3

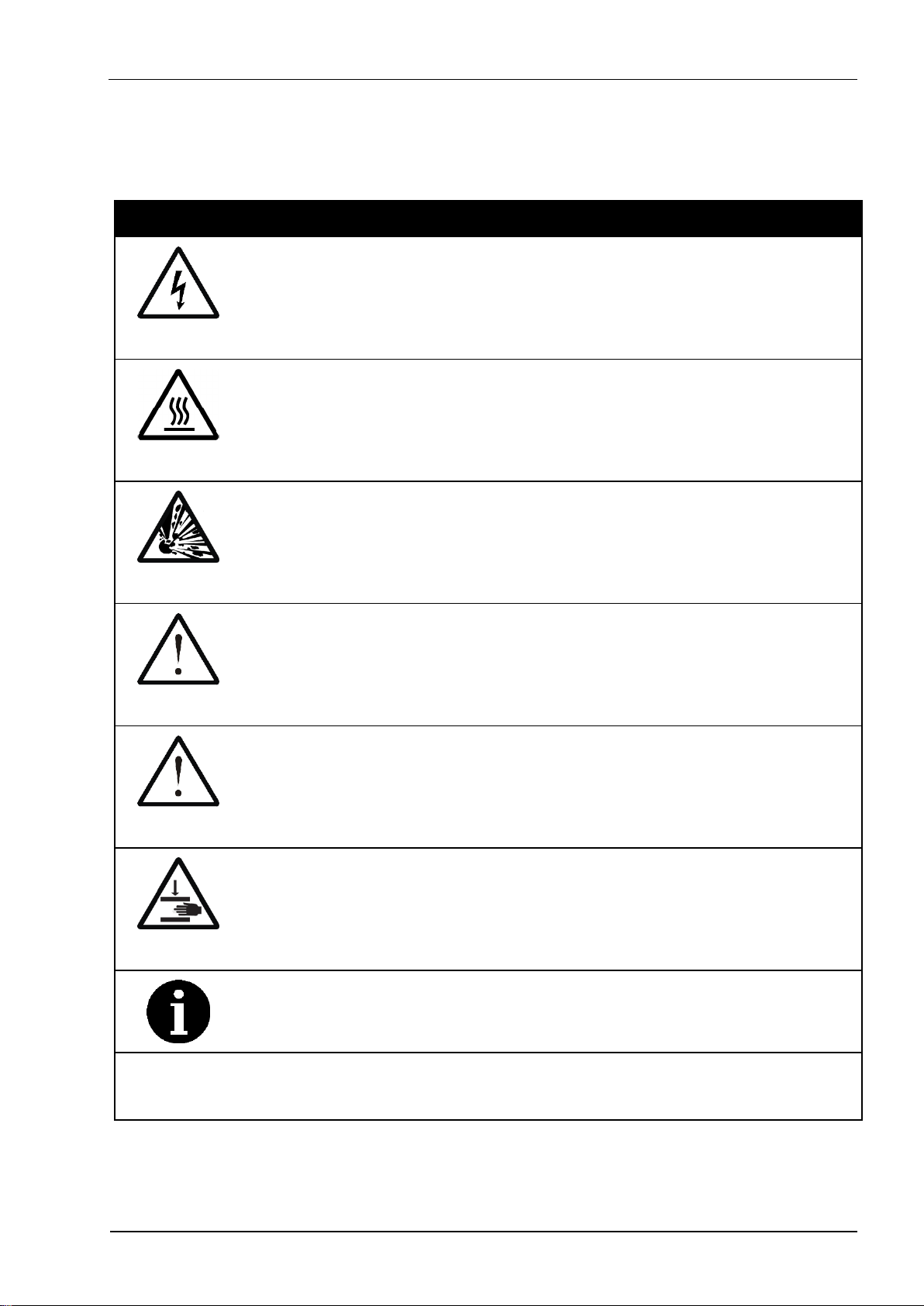

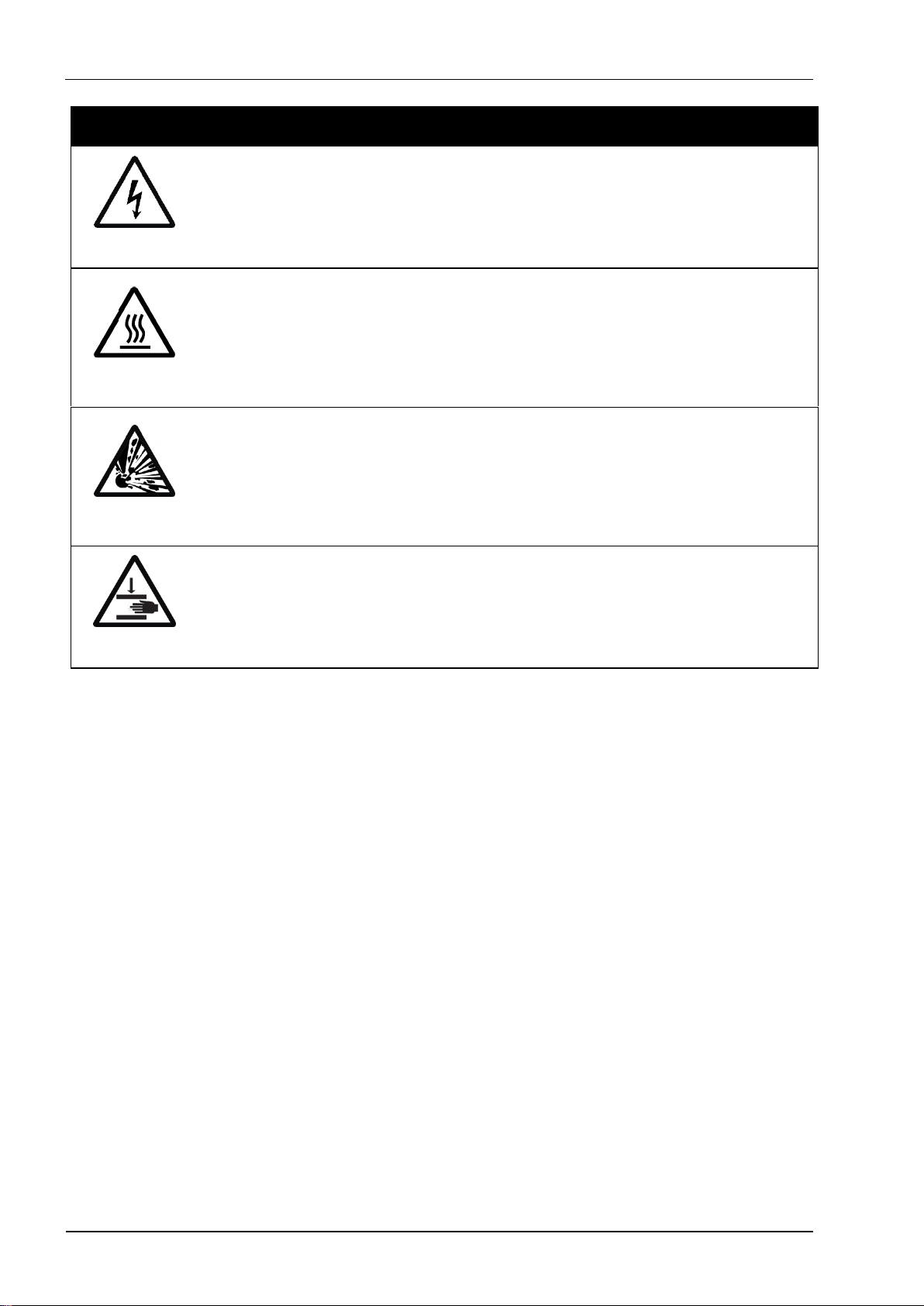

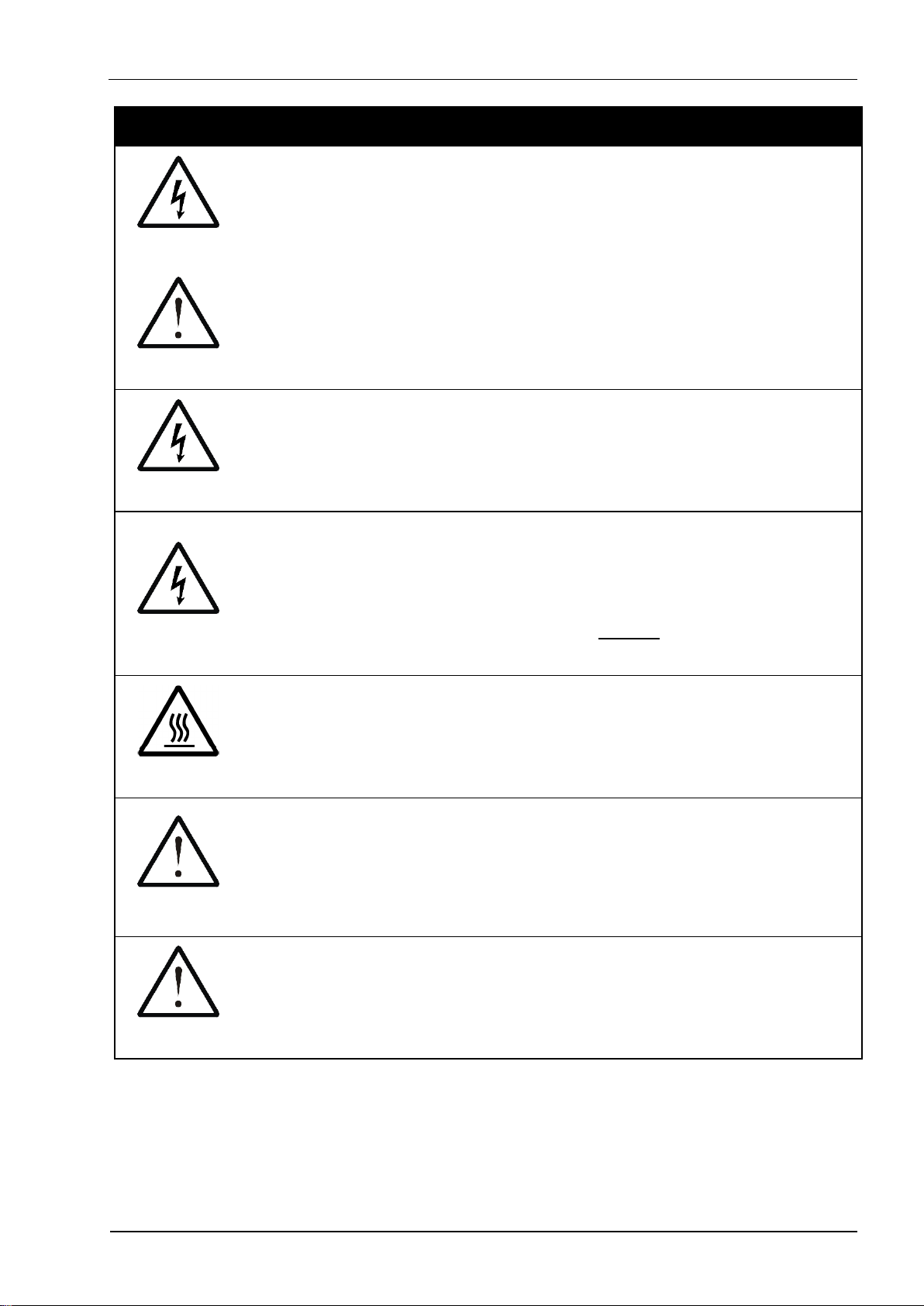

1 Symbols Used in this Instruction Manual

The following advisory symbols are used in this manual.

Table 1: Advisory Symbol Meanings

DANGER

Indicates a Risk of Electric Shock which could, if not avoided,

result in serve injury or death.

DANGER

Indicates a Burn Hazard which could, if not avoided, result in

serve injury or death.

DANGER

Indicates a Risk of Explosion which could, if not avoided,

result in serve injury or death.

WARNING

Indicates a hazardous situation which could, if not avoided,

result in serve injury or death; or severely damage the unit.

CAUTION

Indicates a hazardous situation which could, if not avoided,

result in minor or moderate injury; or degrade or impair the

functionality of the unit.

CAUTION

Indicates a Risk of Crush hazard due to moving parts which

could, if not avoided, result in minor or moderate injury.

Advisory note or other useful information.

NN

Refer to “section NN” for more details.

Page 4

Mini Microplate Heat Sealer

Instructions for Use

4

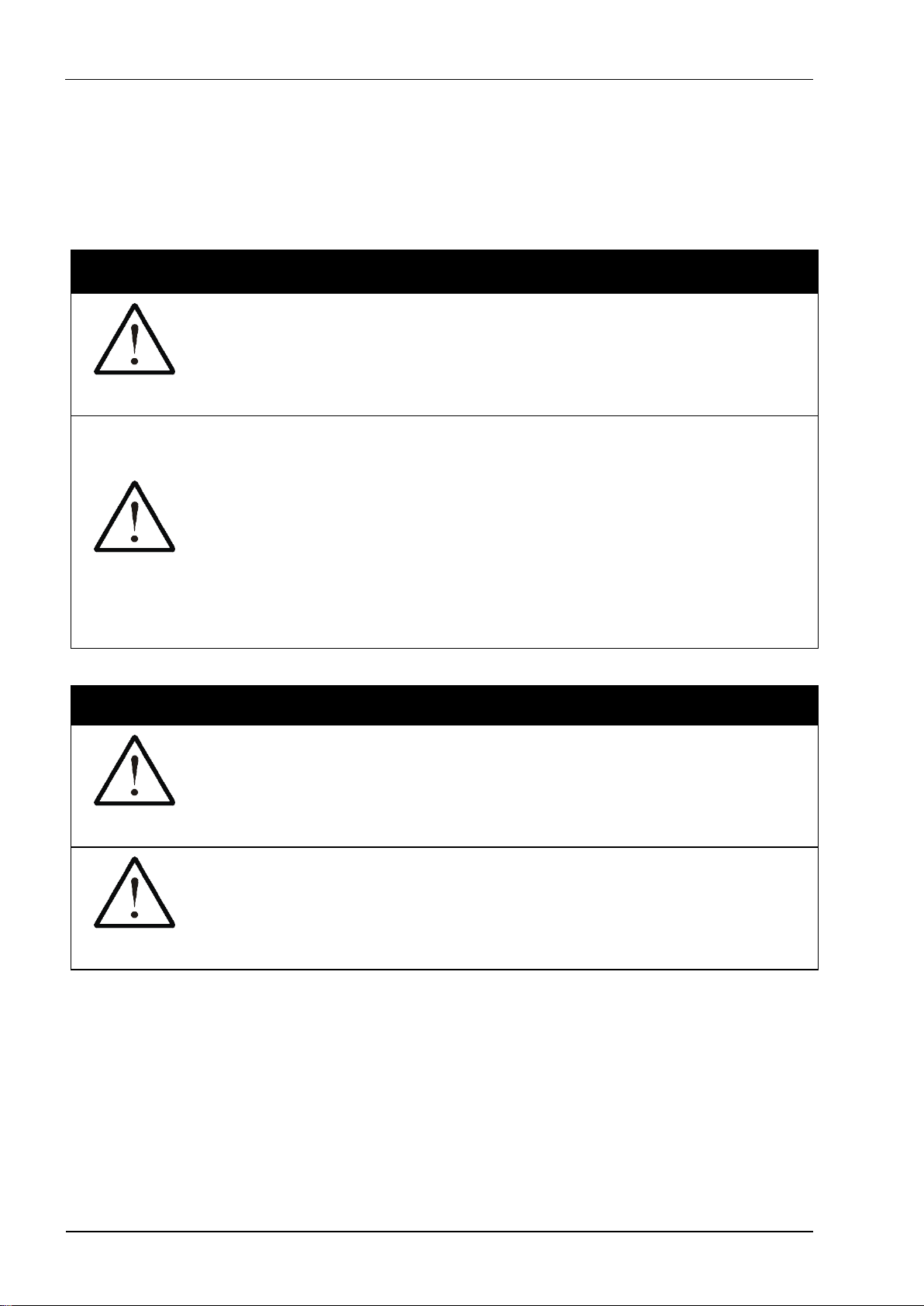

2 Safety Precautions and Limitations of Use

It is essential that all users of this equipment have fully read and understood

the following safety precautions and limitations of use before installing or

operating the Mini Microplate Heat Sealer unit.

IMPORTANT

WARNING

The protection provided by this equipment may be impaired if

it is not used in a manner described in this manual.

WARNING

It is essential that the user of this equipment is aware of the

potential hazards associated with the unit and its accessories.

All operators should be familiar with the safety precautions

and warnings given in these instructions before attempting to

operate the unit.

Improper use of this unit or its accessories may impair their

functionality and invalidate the manufacturer’s warranty.

Unit Handling Precautions

CAUTION

Care should be taken not to drop the unit or subject it to rough

physical handling, both during normal use and during

transportation and storage.

WARNING

The unit should be held by the handle when being lifted or

moved. Do not lift the unit by any other part of the casework.

Care should be taken when lifting due to the unit’s weight.

Page 5

Mini Microplate Heat Sealer

Instructions for Use

5

Unit Installation and Operating Environment

DANGER

WARNING

The Mini Microplate Heat Sealer unit is designed for indoor

laboratory use only.

The acceptable operating temperature range is 18ºC to 30ºC,

with a relative humidity of 20% to 80% non-condensing, at a

maximum altitude of 2200m above sea level.

If the unit is stored in conditions outside of these ranges, it

must be left to stand unpowered until it has acclimatised to

within these environmental limits before being powered.

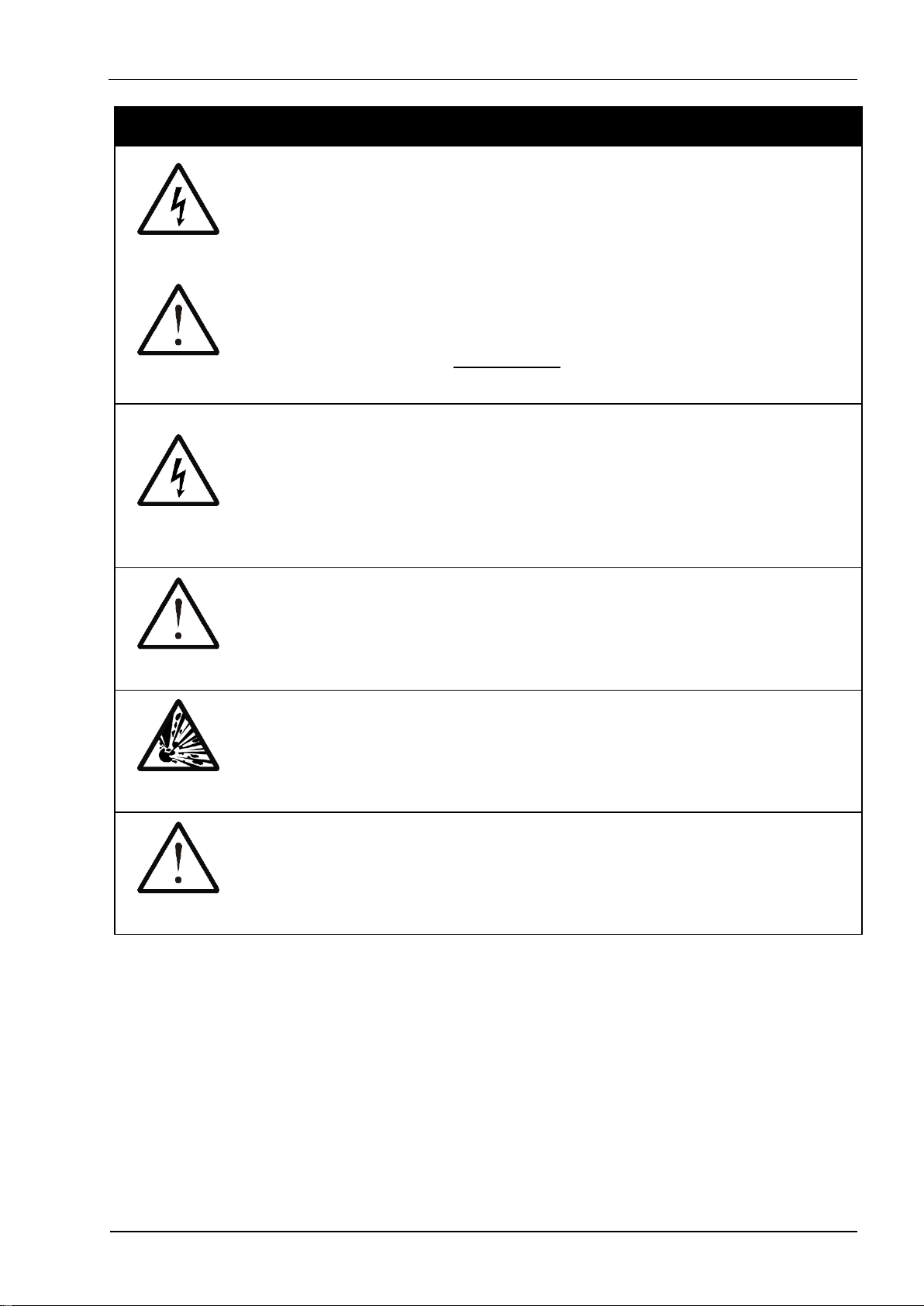

DANGER

Use only the AC mains power cord provided with the unit or as

specified in section 9.

The unit must be connected to a suitably earthed mains

supply, with appropriate earth-leakage and over-current

protection.

WARNING

Always ensure that the mains power connector is securely

inserted into the rear of the unit, and any excess power cord

does not pose a potential trip or pull hazard.

DANGER

Do not operate the unit in any area which is, or has been, or is

thought to have been exposed to explosive or flammable

gases, vapours or liquids.

WARNING

The unit must be installed and operated on a solid, stable and

level working surface.

Page 6

Mini Microplate Heat Sealer

Instructions for Use

6

General Operating Precautions

DANGER

Ensure that the power is switched off at both the AC mains

supply outlet and at the back of the unit before inserting or

removing the mains power cord.

DANGER

The heater plate reaches a temperature of 170ºC and will

remain hot for a considerable time after being turned off.

Extreme care must be taken not to touch the heater plate as it

will cause a serve burn injury.

DANGER

The unit is intended for use with plates containing biological

samples only.

Never use the unit to seal any explosive, volatile or highly

reactive substances or chemicals.

CAUTION

There is a possible finger crush hazard due to the moving

parts of the handle and plate carrier.

Care should be taken when operating the handle.

Page 7

Mini Microplate Heat Sealer

Instructions for Use

7

Unit Maintenance and Serviceability

DANGER

WARNING

There are no user or operator serviceable parts inside the

unit.

Do not remove the unit casework.

Removal of the unit's casework will void the manufacturer’s

warranty and may expose the user to a Risk of Electric Shock

resulting in serious injury or death.

DANGER

Once installed, the externally accessible unit fuse will only

blow under a fault condition. This fuse should only be changed

after the unit has been thoroughly inspected by a qualified

engineer. See section 7.1 for details.

DANGER

Always switch off the unit and disconnect the power cord

before performing any cleaning or decontamination procedure.

If liquid is spilt into or over the unit, switch off and disconnect

the power from the AC mains outlet before attempting to deal

with the spillage.

CAUTION

Ensure that the heater plate has cooled down to room

temperature before performing any cleaning operation and

before moving or storing the unit.

CAUTION

The use of harsh chemicals and cleaning agents may damage

the unit and degrade its performance.

Always follow the cleaning and decontamination procedures

specified in sections 7.3 and 0 of this instruction manual.

CAUTION

Do not autoclave any part of the unit or its accessories.

Page 8

Mini Microplate Heat Sealer

Instructions for Use

8

3 Regulatory Limitations of Use

Declaration of Conformity

This product fulfils the essential requirements of the Low

Voltage Directive (LVD) 2006/95/EC and the EMC Directive

2004/108/EC, when installed and operated in accordance with

the instructions in this manual.

The Mini Microplate Heat Sealer unit has been type tested by

Trac Global (UKAS approved test facility and UK appointed

Notified Body) against the EMC Requirements listed below,

and issued Certificate No 6660/10 and 6661/10.

Safety and EMC Requirements

SAFETY

• EN 61010-1:2010, EN 61010-2-051:2003

• UL 61010-1:2001 2nd Edition (CAN C22.2 CSA 61010-1)

EMC

• EN 61326:2006, Class B

• FCC CFR 47 Parts 15.107 and 15.109, Class B

WEEE Directive Compliance

WEEE

Where applicable, the Mini Microplate Heat Sealer unit should

be disposed of in accordance with the European Union WEEE

Directive 2002/96/EC on Waste Electrical and Electronic

Equipment.

Do not dispose of this product into unsorted municipal waste

or public landfill. Please refer to section 7.6 for details of how

to correctly dispose of this product.

The Mini Microplate Heat Sealer unit is designed and manufactured under ISO 9001 by:

Integrated Technologies Limited

Viking House, Ellingham Way, Ashford, Kent, TN23 6NF

United Kingdom

Page 9

Mini Microplate Heat Sealer

Instructions for Use

9

4 Unit Description

The Mini Microplate Heat Sealer fixed temperature sealer provides a safe

and controlled method for sealing plastic sample plates to protect the

samples from evaporation and contamination during storage.

The unit has the following external features:

Table 2: Unit Features

Seal Activation Handle

6.2

Status Indicator LEDs

6.1

Heater Plate (Internal)

6.2

Adapter Plate Carrier

Table 3

Power Inlet, On/Off Switch and Fuse Holder

5

Mains Voltage Selector

5

Product Information Label

9

Page 10

Mini Microplate Heat Sealer

Instructions for Use

10

The Mini Microplate Heat Sealer unit is designed to be used with a range of

sample plates and consumables – some of which are listed below:

Table 3: Plate and Adapter Types

Adapter Type

Suitable Plate Types

Product Number 13204-13

96 Well Microtiter Plate

384 Well Microtiter Plate

PCR 96 Well Skirted Plate

Product Number 13204-15

PCR 96 Well Semi-skirted Plate

PCR 96 Well Unskirted Plate

Product Number 13204-17

Deep-well Plates

Plate Material Types

Polypropylene, Polyethylene or Polystyrene

Other specialty adapter plates may be available on request. Please contact

Cole-Parmer for details.

Table 4: Recommended Film and Foil Types

Films

Clear Polyester/Polypropylene Laminate

Clear Polymer

Thin Clear Polymer

Foils

Foil Polypropylene Laminate

Foil Laminate

Foil

A comprehensive range of clear films and foils are available. Please contact

Cole-Parmer for details.

Page 11

Mini Microplate Heat Sealer

Instructions for Use

11

5 Unit Installation

Before installing the Mini Microplate Heat Sealer unit, please check that the

delivery is complete and that the unit and any accessory parts are intact and

free from any signs of transportation damage. Also, ensure that all external

and internal packaging has been removed from the unit before installation.

Please retain all packaging for future transportation and storage of

the unit and its accessories.

The Mini Microplate Heat Sealer unit should be installed in a location which

meets the following requirements:

• Safe and suitable operating environment (see section 2)

• Solid, stable, level working surface

• At least 10cm clearance around the unit to adjacent objects and walls

• Earthed AC mains power connection (see section 9)

WARNING

Please also observe and abide by the Unit Installation and

Operating Environment safety precautions and preconditions

listed in section 2.

It is important the check that the Mains Voltage Selector switch on the rear of

the unit has been set to the correct position for the desired operating voltage,

and the correct value of fuse has been fitted (see Table 5).

Table 5: Mains Voltage Selection

Operating Voltage

110 to 120 VAC

220 to 230 VAC

Voltage Selection

See Section 4 for

switch location ()

on unit rear panel.

115

230

Fuse Rating

3.15AH

1.6AH

Page 12

Mini Microplate Heat Sealer

Instructions for Use

12

WARNING

Ensure that the correct fuse type has been fitted in the mains

inlet fuse holder for the desired voltage selector switch value.

See Table 5 for details.

▼

▲

1. Remove the AC plug from the power inlet module

2. Use a small flat bladed screwdriver to push the two

securing tabs inwards (highlighted in red) and pull

out the fuse holder

3. Fit the correct fuse in the lower position only

4. Push fuse holder back into mains inlet module

Install and test the Mini Microplate Heat Sealer unit using the following

procedure:

1) Place the unit on the suitably selected working surface (as specified

above).

2) Connect the unit to the AC mains power outlet using the mains

power cord supplied or as specified in section 9.

3) Switch the mains power on at supply outlet first, and then switch the

unit on using the power switch located at the rear of the unit.

4) Check that the unit is stable and safe by performing a trial sealing

operation, as described in section 6.2.

DANGER

If the unit has been stored in a cool environment, it must be

left to stand unplugged until it has acclimatized to the new

room temperature before being powered.

Page 13

Mini Microplate Heat Sealer

Instructions for Use

13

6 Unit Operation

WARNING

Please ensure that you have read and fully understood all the

Safety Precautions and Limitations of Use listed in section

2 before attempting to operate the Mini Microplate Heat Sealer

unit.

6.1 Status Indicator LEDs

The Mini Microplate Heat Sealer unit operators at a fixed sealing temperature

and requires no user set-up or controls. Hence, there are just two status

indicator LEDs on the front of the unit with the functions listed in Table 6.

Table 6: Status Indicator LEDs

Amber Heater Indicator

On or Off – Heater Plate is warming up

Flashing – Heater Plate at 170ºC ±2ºC

Green Power Indicator

On – Unit switched on

Off – Unit switched off (or no power)

When the unit is switched on, the green Power LED will illuminate and the

unit will automatically start heating to 170ºC. This is indicated by the amber

Heater LED being on.

Once the heater plate has reached the correct temperature to perform

sealing (within 2ºC of the 170ºC set-point) the Heater LED will start flashing,

and the Mini Microplate Heat Sealer is ready for use.

Page 14

Mini Microplate Heat Sealer

Instructions for Use

14

6.2 Performing a Sealing Operation

Various types of plastic sample plates may be loaded onto a plate carrier and

thermal sealed using a suitable foil or clear film. See section 4 for details.

A typical operating sequence is:

1) Switch the Mini Microplate Heat Sealer on

at the rear of the unit and allow sufficient

time for it to reach temperature (the

Heater LED will start flashing).

2) Using a suitable adapter plate (listed in

Table 3), load the sample plate onto the

plate carrier and add the sealing film on

top, the correct way up.

WARNING

Care should be taken not to touch the

surface of the heater plate whilst

loading the sample plate.

3) Grasp the handle with one or two hands,

as appropriate, and pull the handle

forward and down until the heater plate

contacts the sample plate.

CAUTION

Do not to apply more force to the

handle than is necessary to keep the

heater in contact with the sample.

4) When the required amount of time has

passed, return the handle to its upmost.

CAUTION

Leaving the handle down for too long

could damage the sample plate and

degrade the seal quality.

5) Remove the sealed plate from the unit and

review the seal integrity.

WARNING

The sample plate and film/foil may

remain hot for several seconds after

being removed from the unit.

The time taken to successfully seal a sample plate may vary with both plate

and film/foil type. For optimum seal integrity, the sealing time may need to be

adjusted empirically to achieve the desire seal quality.

Page 15

Mini Microplate Heat Sealer

Instructions for Use

15

7 Maintenance and Servicing

Although the Mini Microplate Heat Sealer unit does not require scheduled

maintenance or servicing, the operator should regularly clean and inspect the

unit for any detects, as described in section 7.3 below.

DANGER

WARNING

Please observe and comply with all the Unit Maintenance

and Serviceability precautions listed in section 2.

Never removed the unit casework. There are no user or

operator serviceable parts inside the unit.

Always switch off and unplug the unit before performing any

cleaning or disinfecting tasks.

For technical and service related enquiries, please contact Cole-Parmer.

7.1 Replacing the Unit Fuse

The unit fuse should only be replaced by a suitably qualified technician.

DANGER

The unit fuse will only blow as a result of an internal unit fault

or if the voltage selector switch has been incorrectly set (see

section 5). This fuse should only be changed after the unit has

been thoroughly inspected, and must be replaced with the

exact type specified in section 9.

Thoroughly inspect the unit for any signs of damage, loose components or

liquid spillage or ingress. If in doubt, please contact Cole-Parmer.

Page 16

Mini Microplate Heat Sealer

Instructions for Use

16

DANGER

The fuse holder is removed by disconnecting the mains cord

and then using a small flat bladed screwdriver to carefully

unclip and pull open the fuse holder (see section 5).

After replacing the fuse with the corrected rated one for the

operating voltage being used (see Table 5), push the fuse

holder firmly back into the inlet module.

The unit must be electrically safety tested for excess leakage

current before being repowered from the mains supply.

7.2 Overtemperature Safety Cut-out

The unit is fitted with a non-resettable thermal fuse which blows if the heater

plate temperature exceeds 195 ºC.

In the unlikely event of a fault condition, this fuse will permanently disable the

heater to protect the user and unit from injury and damage. If this occurs, the

Heater indicator will light but heater plate will remain cold and the Mini

Microplate Heat Sealer will need to be returned for repair.

7.3 Routine Cleaning and Inspection

The unit casework should be cleaned and inspected at regular intervals, and

whenever contamination or spillage occurs, as follows:

1. Switch off the unit and disconnect the power before performing any

inspection checks or cleaning.

2. Before cleaning, always inspect the unit casework, heater plate and

moving parts for any signs of wear, damage, cracks or other defects.

3. Clean the casework using a damp cloth soaked with a disinfectant

solution (such as Virkon), whilst wearing suitable PPE.

4. Carefully clean the heater plate surface to remove any debris or

sealing material.

5. Remove any debris or fluff from around or between the moving parts

of the handle mechanism.

6. Check and clean the adapter blocks.

DANGER

After cleaning, ensure that the unit is thoroughly dry,

especially around the mains power inlet, before reconnecting

the power cord and switching the unit on.

Page 17

Mini Microplate Heat Sealer

Instructions for Use

17

7.4 Decontamination Procedure

The unit and accessories should be decontaminated using the following

procedure before being stored or transported.

Certificate of Decontamination

We respect the health and safety of our clients and employees, and request

that any products or accessories being returned are decontaminated in

accordance with the procedure below.

1. Decontamination Procedure

Thoroughly clean all outside surfaces of the product (including any

accessories, power cords, manuals, packaging, etc) with a damp cloth

soaked with suitable disinfectant solution (such as Virkon).

Allow to dry fully before packing.

2. Decontamination Declaration

Company Name:

Address:

Product Code:

13204-11

Serial Number:

Reason for Return:

Where Product Used:

Please tick the appropriate option(s) below:

I certify that I have decontaminated the product as per the above procedure.

Decontaminant Used:

I certify that the product has not been exposed to any chemical or biological materials.

Title:

Name:

Signature:

Date:

Telephone:

Email:

Page 18

Mini Microplate Heat Sealer

Instructions for Use

18

7.5 Transportation and Storage

The Mini Microplate Heat Sealer unit and its accessories should be

thoroughly decontaminated using the procedure detailed in section 0 before

being placed in its original packaging for transportation or storage.

WARNING

Refer to section 9 for the acceptable range of Storage and

Transportation environmental conditions.

Always ensure that the unit and accessories are completely

dry and free of any condensation before being packed.

7.6 Product Disposal

At end-of-life, this product must be disposed of in accordance with your local

authority regulations for the disposal of potentially hazardous waste and

electronic equipment.

The unit and its accessories should be decontaminated using the procedure

detailed in section 0 before disposal or shipping.

Do not dispose of this product into unsorted municipal waste

or public landfill.

Please contact Cole-Parmer for details of how to correctly dispose of this

product.

Page 19

Mini Microplate Heat Sealer

Instructions for Use

19

8 Warranty and Returns

Cole-Parmer warrants the Mini Microplate Heat Sealer product, when

purchased new and installed and operated in accordance with the

instructions of this manual, to be free from defects in materials and

workmanship, and will repair or replace, at their discretion, any unit or

accessory which exhibits such defects.

In no event will Cole-Parmer be liable for any indirect, incidental or

consequential damages resulting from any defect or warranty claim.

NOTE

Unspecified use or unauthorized modification of any part of the

Mini Microplate Heat Sealer unit or its accessories or the use or

attachment of any adapter or peripheral not supplied, specified or

sanctioned by Cole-Parmer will invalidate this warranty.

This warranty is provided to the original purchaser of the product for one year

from the date of purchase.

Under the terms of this warranty, the product must be returned in its original

packaging, transportation prepaid by the sender, with a copy of the Proof of

Purchase and a detailed description of the problem.

WARNING

The product must be decontaminated using the procedure

detailed in section 0 and a Certificate of Decontamination

supplied with any return. If the product is considered too

hazardous to be shipped, please contact Cole-Parmer for

further instructions.

Please contact Cole-Parmer to receive authorization to return the product.

Page 20

Mini Microplate Heat Sealer

Instructions for Use

20

9 Technical Specifications

Product Information

Name

Product Number

Mini Microplate Heat Sealer

13204-11

Accessories

Adapter plate, microtiter

Adapter plate, 96 well

Adapter plate, deep well

13204-13

13204-15

13204-17

Physical Unit Properties

Dimensions (W x D x H)

Weight (without adapter)

220 mm x 250 mm x 230 mm

4 kg

Mains Supply

Power Cord Rating

Inlet Module Type

Supply Voltage Selections

Supply Frequency Range

Power Consumption

Fuse Ratings and Sizes

IEC C13, 3-Core, 5A min

IEC C14, DPST, Single Fuse

115 110 to 120 VAC ±10%

230 220 to 230 VAC ±10%

50 to 60 Hz ±5%

350 W max

115 T3.15AH 250V 20x5mm

230 T1.6AH 250V 20x5mm

Operating Environment

Temperature Range

Relative Humidity Range

Maximum Operating Altitude

+18 to +30 C

20% to 80% non-condensing

2200 m above sea-level

Storage and Transportation

Temperature Range

Relative Humidity Range

-10 to +50 C

20% to 95% non-condensing

Sealing Parameters

Temperature Set-point

Temperature Accuracy

170 C (Non-adjustable)

±2 C

Page 21

Mini Microplate Heat Sealer

Instructions for Use

21

10 Glossary of Terms and Abbreviations

ANSI

American National Standards Institute

Deep-well Plate

Plate with an SBS footprint featuring 48, 96 or 384

wells with a larger volume than microplates

DWP

Deep-well plate

EMC

Electro-Magnetic Compatibility

Microtiter Plate

Plate with an SBS footprint featuring 24, 48, 96 or

384 wells

MTP

Microtiter plate

PCR

Polymerase Chain Reaction

PPE

Personal Protective Equipment

SBS

Society for Bio Molecular Screening

Semi-skirted PCR

Plate

PCR plate with an outer surrounding half edge

Skirted PCR Plate

PCR plate with an outer surrounding edge

Unskirted PCR Plate

PCR plate without an outer surrounding edge

Well

A single sample cavity in a Microtiter plate, PCR

plate or Deep-well plate

Page 22

Mini Microplate Heat Sealer

Instructions for Use

22

In the US

625 E. Bunker Court

Vernon Hills, IL 60061

Call toll-free 1-800-323-4340

Phone: 1-847-549-7600

Fax: 1-847-247-2929

www.coleparmer.com

In Canada

Call toll-free 1-800-363-5900

Phone: 1-514-355-6100

Fax: 1-514-355-7119

www.coleparmer.ca

In the United Kingdom

Free phone: 0500-345-300

Phone: 020-8574-7556

Fax: 020-8574-7543

www.coleparmer.co.uk

In India

Phone: 91-22-6716-2222

Fax: 91-22-6716-2211

www.coleparmer.in

International customers

Call 1-847-549-7600 to reach

our International Sales

Department or contact your

local dealer

Loading...

Loading...