Page 1

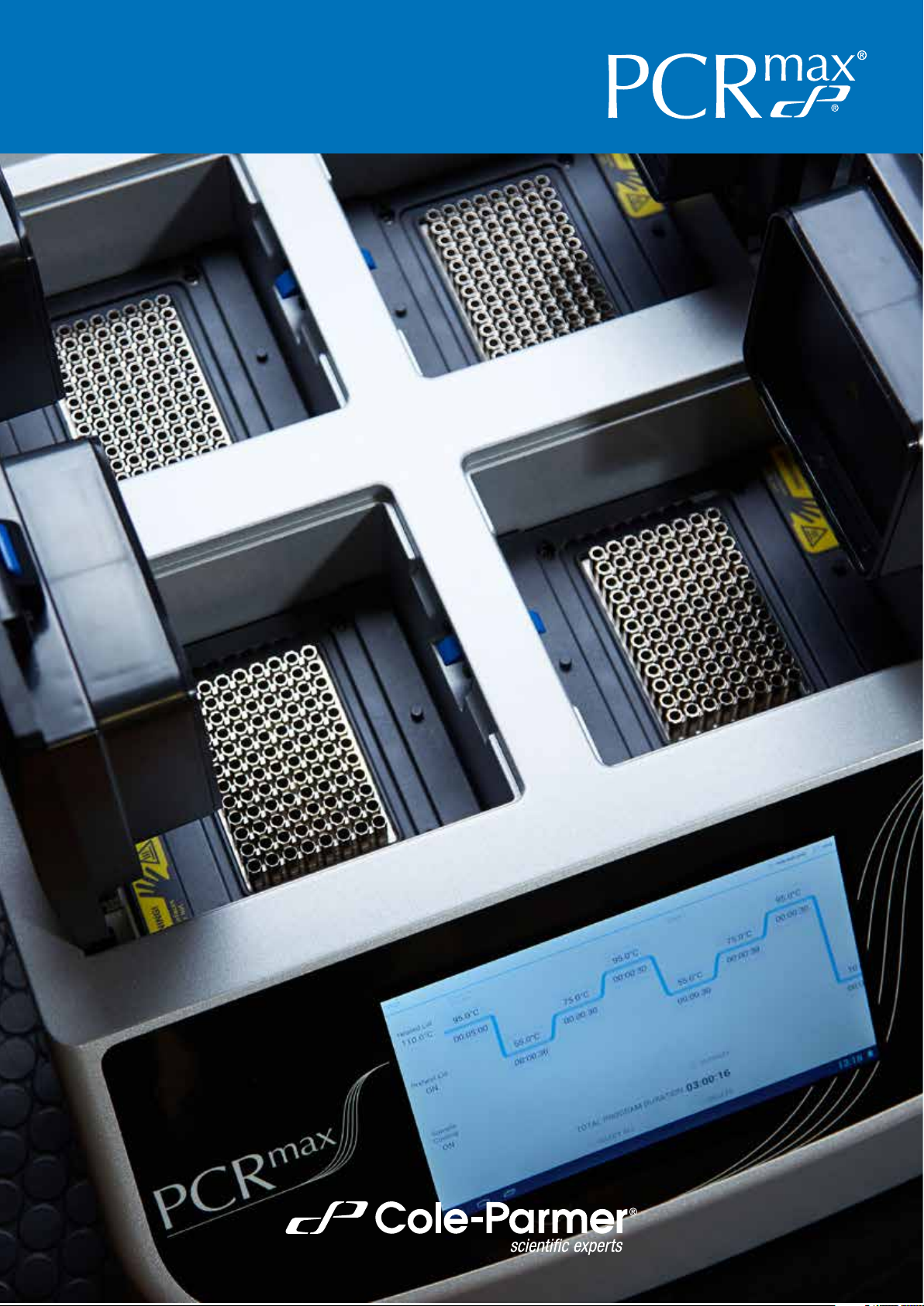

PCRmax Alpha Cycler 1,2 and 4

Operation Manual

PCRmax rev 10

Page 2

Contents

Introduction 4

Alpha Cycler configurations 4

Before Use 5

Unpacking 5

Fuse removal and replace 5

Safety Information 8

Consignes de sécurité 10

Sicherheitsinformationen 12

Informazioni sulla sicurezza 14

Información de seguridad 16

Contact Information 18

Alpha Cycler specification 19

Installation and operation 21

Installation 21

Operation 22

General software features 23

Introduction 23

Basic Android commands and data/text input 24

Template programs 25

Gradient 26

Creating user Profiles 27

Creating a new user account 27

To log in as an existing user 27

Logging out 27

Changing a user password 27

Creating USB Login 28

Programming 29

Using the Program Wizard 29

Manual program entry 33

Adding a stage 33

Editing step parameters 35

Adding a gradient step 35

Adding a temperature or time increment or decrement 36

Deleting a step or stage 37

Saving the program 38

Running a Program 41

Running a program from the short cut list 41

Running a program from the instrument memory 42

Viewing a running program 42

QR code and Alpha Track App 46

Stopping a program 48

Pausing a program 49

2

Page 3

Contents

Using the File Manager 50

Search for a file 50

Reports 51

Deleting a program or report from the File Manager 52

Copying and transferring Programs and reports 53

Copying a program to a USB memory stick 53

Transferring a program from a USB memory stick to the Alpha Cycler 53

Instrument settings and defaults 54

Preferences 54

Instrument settings 55

Temperature log 55

Auto-restart 55

Date and time 56

Program defaults 56

Updating the Alpha Cycler software 59

Procedure 59

Technical support and servicing 60

Replacing blocks 60

Additional information 61

User maintenance 61

Fault Finding 61

Fuses 61

Insulation testing 61

3

Page 4

Introduction

The Alpha Cycler thermal cyclers are standalone systems with flexible block options (96 or 384 well

formats being available). The range includes both a single block, the AC-1, a dual block variant, the AC-2

and a quad block variant, the AC-4.

The Alpha Cyclers range of block options allow for use of the most commonly used consumables including

0.2ml x 96 well plates, 0.2ml tubes, 0.2ml strip tubes and 384 well plates.

All combinations of base unit and block include a gradient feature, manually adjustable heated lid and

programming features such as touchdown, active sample cooling, advanced reporting and health check

options as standard to allow for most applications to be performed easily.

ALPHA CYCLER CONFIGURATIONS

The Alpha Cycler systems can be configured with any combination of 96 or 384 well format blocks in the

AC-1, AC-2 and AC-4 chassis, see below.

Part code Configuration

AC196 96 well

AC1384 384 well

AC296 2 x 96 well

AC2196 1 x 96 / 1 x 384 well

AC2384 2 x 384 well

AC496 4 x 96 well

AC4384 4 x 384 well

AC4296 2 x 96 / 2 x 384 well

AC4396 3 x 96 / 1 x 384 well

AC4196 1 x 96 / 3 x 384 well

4

Page 5

Before use

Before using the Alpha Cycler please ensure you have read this manual carefully. If there is any doubt

relating to the proper use of this equipment, please contact your local distributor or Cole-Parmer Ltd via

the website: www.coleparmer.com or email CPtechsupport@coleparmer.com.

UNPACKING

When unpacking the unit please ensure that the following have been removed from the packaging:

Alpha Cycler with block(s).

Mains cables (UK, EU, China and US).

USB stick containing operator’s manual and default protocols.

AC-4 2x 15A Fuse which must be changed in certain territories and power supplies, see below.

AC-2 2x 12.5A Fuse which must be changed in certain territories and power supplies, see below.

The user is advised to keep the original packaging in case the instrument ever needs to be returned

for service or repair. Cole-Parmer Ltd accepts no responsibility for damage incurred unless the unit is

correctly packed and transported in its original packaging.

IMPORTANT NOTE:

IF USING THE AC-2 / AC-4 AT 120V, BEFORE THE UNIT IS

CONNECTED TO THE MAINS AND SWITCHED ON FOR THE FIRST

TIME REPLACE THE FUSES.

FOR AC4 REPLACE 8A FUSES WITH 15A ANTI-SURGE FUSES.

FOR AC2 REPLACE 5A FUSES WITH 12.5A ANTI-SURGE FUSES.

THE FUSE HOLDERS ARE LOCATED BESIDE THE POWER SWITCH OF THE UNIT.

IF THE AC-4 IS INTENDED TO BE USED IN AUSTRALIA THE UNIT MUST BE A FIXED INSTALLATION

AND CONNECTED DIRECTLY TO THE MAINS.

FUSE REMOVAL AND REPLACE

The anti-surge fuses are located on the right side of the system towards the rear, beside the power

switch.

• Unscrew the fuse cover, using a flat head screwdriver or similar, and remove the fuse holder.

• Pop out the two fuses that the system is shipped with and replace with AC-2 (12.5A) or AC-4 (15A).

THIS MUST BE COMPLETED BEFORE CONNECTING THE SYSTEM TO THE LIVE MAIN AND POWERING

UP THE UNIT.

NOTE:

A 250mm air space should be kept free at each side of the AC-2 / AC-4 unit (left and right). If two AC-2

/ AC-4 units have to be positioned next to one another, a total of 500mm should be free between both

units. If the systems have to be wracked the shelves should be 600mm apart from each other vertically,

this promotes the correct airflow and heat distribution from the units. As air flow with the AC-2 / AC-4

is in thought the front of the unit and out the sides, caution should be taken to not block the path of

air in and out of the unit.

5

Page 6

Before use

REMARQUE IMPORTANTE :

EN CAS D’UTILISATION DES MODÈLES AC-2 OU AC-4 SOUS UNE TENSION DE 120

V, REMPLACEZ LES FUSIBLES AVANT DE BRANCHER L’APPAREIL À L’ALIMENTATION

SECTEUR ET DE LE METTRE SOUS TENSION POUR LA PREMIÈRE FOIS.

POUR LE MODÈLE AC-4, REMPLACEZ LES FUSIBLES 8 A PAR DES FUSIBLES

TEMPORISÉS 15 A.

POUR LE MODÈLE AC-2, REMPLACEZ LES FUSIBLES 5 A PAR DES FUSIBLES

TEMPORISÉS 12,5 A.

LES PORTE-FUSIBLES SONT SITUÉS À CÔTÉ DU BOUTON MARCHE/ARRÊT DE

L’APPAREIL.

En cas d’utilisation du modèle AC-4 en Australie, l’appareil doit être installée de manière fixe

et définitive, et directement connectée à l’alimentation secteur.

Retrait et remplacement des fusibles

Les fusibles temporisés sont situés du côté droit en partie arrière de l’appareil, à côté du bouton marche/arrêt.

• Dévissez le couvercle des fusibles à l’aide d’un tournevis plat ou d’un outil similaire, puis retirez le

porte-fusibles.

• Retirez les deux fusibles déjà présents dans l’appareil et remplacez-les par des fusibles de 12,5 A (AC-2)

ou de 15 A (AC-4).

LES FUSIBLES DOIVENT ÊTRE REMPLACÉS AVANT LE BRANCHEMENT DE L’APPAREIL À L’ALIMENTATION

SECTEUR ET SA MISE SOUS TENSION.

WICHTIGER HINWEIS:

WENN SIE DEN AC-2 / AC-4 BEI 120 V VERWENDEN, TAUSCHEN SIE DIE SICHERUNGEN

AUS, BEVOR DAS GERÄT AN DIE STROMVERSORGUNG ANGESCHLOSSEN UND

DAS ERSTE MAL ANGESCHALTEN WIRD.

BEIM AC4 ERSETZEN SIE DIE 8-A-SICHERUNGEN MIT TRÄGEN 15-A-SICHERUNGEN.

BEIM AC2 ERSETZEN SIE DIE 5-A-SICHERUNGEN MIT TRÄGEN 12,5-A-SICHERUNGEN.

DIE SICHERUNGSFASSUNGEN BEFINDEN SICH NEBEN DEM NETZSCHALTER DES

GERÄTS.

Wenn der AC-4 für die Verwendung in Australien vorgesehen ist, muss das Gerät fest installiert

und direkt mit der Stromversorgung verbunden werden.

Entfernen und Austauschen einer Sicherung

Die trägen Sicherungen befinden sich nach hinten gerichtet auf der rechten Seite des Systems, neben

dem Netzschalter.

• Schrauben Sie die Sicherungsabdeckung mit einem Flachschraubenzieher oder Ähnlichem ab und

entfernen Sie die Sicherungsfassung.

• Ziehen Sie die zwei Sicherungen heraus, die im Lieferumfang des Systems enthalten sind, und

ersetzen Sie sie mit AC-2 (12,5 A) oder AC-4 (15 A).

DIESER SCHRITT MUSS ABGESCHLOSSEN SEIN, BEVOR DAS SYSTEM MIT DER SPANNUNGSVERSORGUNG

VERBUNDEN UND DAS GERÄT ANGESCHALTEN WIRD.

6

Page 7

Before use

NOTA IMPORTANTE:

SE SI UTILIZZA L’AC-2 / L’AC-4 A 120 V, PRIMA CHE L’UNITÀ SIA COLLEGATA

ALL’ALIMENTAZIONE DI RETE E ACCESA PER LA PRIMA VOLTA, SOSTITUIRE I

FUSIBILI.

PER L’AC4 SOSTITUIRE I FUSIBILI DA 8 A CON I FUSIBILI RITARDATI DA 15 A.

PER L’AC2 SOSTITUIRE I FUSIBILI DA 5 A CON FUSIBILI RITARDATI DA 12,5 A.

I PORTAFUSIBILI SONO SITUATI VICINO ALL’INTERRUTTORE DI ALIMENTAZIONE

DELL’UNITÀ.

Se l’ac-4 viene utilizzato in australia, l’unità deve essere collegata direttamente e in modo

permanente all’alimentazione di rete.

Rimozione e sostituzione dei fusibili

I fusibili ritardati sono situati sul lato destro del sistema verso il retro, accanto all’interruttore di alimentazione.

• Svitare il coprifusibile, usando un giravite a testa piatta o simile, e rimuovere il portafusibile.

• Estrarre i due fusibili con cui viene fornito il sistema e sostituirli con AC-2 (12,5 A) o AC-4 (15 A).

QUESTA OPERAZIONE DEVE ESSERE COMPLETATA PRIMA DI COLLEGARE IL SISTEMA ALLA RETE E DI

ACCENDERE L’UNITÀ.

NOTA IMPORTANTE:

SI UTILIZA EL AC-2 / AC-4 A 120 V, ANTES DE CONECTAR LA UNIDAD A LA RED Y

ENCENDERLA POR PRIMERA VEZ, SUSTITUYA LOS FUSIBLES.

PARA EL AC4 SUSTITUYA LOS FUSIBLES DE 8 A POR FUSIBLES PROTECTORES DE

SOBRETENSIÓN DE 15 A.

PARA EL AC4 SUSTITUYA LOS FUSIBLES DE 5A POR FUSIBLES PROTECTORES DE

SOBRETENSIÓN DE 12,5A.

LOS SOPORTES DE LOS FUSIBLES SE ENCUENTRAN AL LADO DEL INTERRUPTOR DE

ALIMENTACIÓN DE LA UNIDAD.

Si el AC-4 se va a usar en Australia, la unidad debe ser una instalación fija y estar directamente

conectada a la red.

Retirada y sustitución de los fusibles

Los fusibles protectores de sobretensión están situados en el lado derecho del sistema tocando a la parte

trasera, al lado del interruptor de alimentación.

• Destornille la tapa de los fusibles con un destornillador de punta plana o similar, y retire el soporte

del fusible.

• Saque los dos fusibles con los que se suministra el sistema y sustitúyalos por AC-2 (12,5 A) o AC-4 (15 A).

ESTO DEBE REALIZARSE ANTES DE CONECTAR EL SISTEMA A LA RED ELÉCTRICA Y ENCENDER LA UNIDAD.

7

Page 8

Safety information

Please read all the information in this manual before using the Alpha Cycler.

WARNING

HIGH TEMPERATURES ARE DANGEROUS: they can cause serious burns to operators and ignite combustible

material. Users should be aware of the following potential hazards:

• USE CARE AND WEAR PROTECTIVE GLOVES TO PROTECT HANDS.

• DO NOT use combustible substances near hot objects.

• DO NOT operate the instrument in the vicinity of inflammable liquids or gases.

• DO NOT place any liquid directly into the instrument.

• DO NOT touch the heated lid when system is running or within 10 minutes of the

system completing a run.

• DO NOT touch the block when the system is running or within 10 minutes of the system

completing a run.

OPERATOR SAFETY

All operators of PCRmax equipment must have available the relevant literature needed to ensure their

safety. It is important that only suitably trained personnel operate this equipment, in accordance with the

instructions contained in this manual and with general safety standards and procedures. If the equipment

is used in a manner not specified by Cole-Parmer Ltd. the protection provided by the equipment to the

operator may be impaired.

All PCRmax instruments are designed to conform to international safety requirements and are fitted with

an over-temperature cut-out. If a safety problem should be encountered, switch off the unit at the mains

socket and remove the plug from the electricity supply.

INSTALLATION

The instrument should be carried using both hands. Never move or carry the instrument when in use or

connected to the mains electricity supply.

The AC-2 / AC-4 have a weight of 30kgs / 47kgs respectively; it is advised that two people lift and carry

the AC-2, and three people lift the AC-4.

1. All PCRmax instruments are supplied with a power cable; this may be integral or plug-in.

2. Before connecting the instrument to the mains electricity supply, check the voltage

against the rating plate (located on the back of the unit). Please note that the unit

must be earthed to ensure proper electrical safety.

3. The units are rated to operate at: for the AC-1 100-230V, 50/60Hz and for the AC-2 / AC-4 100230V 50/60Hz.

4. Do not allow the Alpha Cycler to overhang the bench.

5. Ensure the bench for the AC-2 / AC-4 can withstand 30kgs / 47kg of weight.

6. Place the unit on a suitable flat and level bench or in a fume cupboard if required, ensuring that the

air inlet and outlet vents on the underside and rear are free from obstruction.

7. Ensure that the feet of the instrument do not overhang the side of the bench.

8. Plug the mains cable into the socket on the back (side in AC-2 / AC-4) of the instrument.

9. Switch on the instrument using the switch located on the back (side in AC-2 / AC-4 of the unit.

8

Page 9

REPLACEMENT CABLE

Should the mains lead need replacement, a cable of 1.5 mm2 of harmonized code H05VV-F 3G connected

to an IEC320 plug should be used. IF IN DOUBT CONSULT A QUALIFIED ELECTRICIAN.

ENVIRONMENTAL CONDITIONS

The Alpha Cycler is designed operate under the following conditions:

• Indoor use

• Ambient temperature range +5°C to +35°C

• Altitude to 2000m

• Relative humidity not exceeding 80%

• Mains supply fluctuations not exceeding 10%

• Over voltage category II IEC 60364-4-443

• Pollution degree 2

Note: The control specifications are quoted at an ambient temperature of 20°C ±2°C.

The instrument has been tested for radio frequency interference and is certified under EN61326.

WARRANTY

Cole-Parmer Ltd warrants this instrument to be free from defects in material and workmanship, when

used under normal laboratory conditions for two (2) years. In the event of a justified claim, Cole-Parmer

Ltd will replace any defective component or replace the unit free of charge. This warranty does not

apply if damage is caused by fire, accident, misuse, neglect, incorrect adjustment or repair, damage by

incorrect installation, adaption, modification, fitting of non-approved parts or repair by unauthorised

personnel. Cole-Parmer Ltd liability is limited to the cost of repair or replacement of the product and

excludes in particular, indirect and consequential loss, damage, costs or expenses, including but not

limited to wasted time, materials and expenditure or loss of use, profit, production, revenue, expected

savings or goodwill. To make a claim please contact the supplier of the instrument. This warranty is in

addition to, and does not affect any statutory rights.

This manual has been prepared for the convenience of Cole-Parmer’s customers and nothing in

this manual shall be taken as a warranty, condition or representation concerning the description,

merchantability, fitness for purpose or otherwise of the unit or components.

Notwithstanding the description and specification(s) of the instruments contained in the operator’s

manual, Cole-Parmer Ltd reserves the right to make such changes as it sees fit to the instruments or to

any of the components.

9

Page 10

Consignes de sécurité

Veuillez lire toutes les informations contenues dans ce manuel avant d’utiliser l’appareil Alpha Cycler.

AVERTISSEMENT

LES TEMPÉRATURES ÉLEVÉES SONT DANGEREUSES : elles peuvent être à l’origine de graves brûlures

et enflammer les matériaux combustibles. Les utilisateurs doivent tenir compte des dangers potentiels

suivants :

• FAITES PREUVE DE PRUDENCE ET PORTEZ DES GANTS DE PROTECTION.

• N’UTILISEZ PAS de substances combustibles à proximité d’objets chauds.

• N’UTILISEZ PAS l’appareil à proximité de gaz ou de liquides inflammables.

• NE PLACEZ AUCUN liquide directement dans l’appareil.

• NE TOUCHEZ PAS le couvercle chauffant lorsque le système est en marche ou dans les

10 minutes qui suivent son utilisation.

• NE TOUCHEZ PAS le bloc lorsque le système est en marche ou dans les 10 minutes qui

suivent son utilisation.

SÉCURITÉ DE L’UTILISATEUR

Tous les utilisateurs de matériel Cole-Parmer Ltd doivent avoir accès aux documents pertinents concernant

leur sécurité. Il est important que seul le personnel ayant suivi une formation adéquate utilise ce matériel,

conformément aux instructions figurant dans ce manuel, ainsi qu’aux normes et aux procédures de

sécurité de base. Dans le cas d’une utilisation du matériel selon une procédure non spécifiée par ColeParmer Ltd., la protection intégrée à l’appareil est susceptible d’être compromise.

Tous les appareils Cole-Parmer Ltd sont conçus de manière à répondre aux exigences de sécurité

internationales et sont équipés d’un coupe-circuit de surchauffe. En cas de problème de sécurité, éteignez

l’appareil au niveau du connecteur d’alimentation et débranchez son cordon de l’alimentation secteur.

INSTALLATION

Transportez l’appareil à l’aide des deux mains. Ne déplacez et ne transportez jamais l’appareil en cours

d’utilisation ou lorsqu’il est relié à l’alimentation électrique secteur.

Les modèles AC-2 et AC-4 pèsent respectivement 30 kg et 47 kg. Il est recommandé de faire appel à

deux personnes pour soulever et transporter l’AC-2 et de faire appel à trois personnes pour soulever et

transporter l’AC-4.

1. Tous les appareils Cole-Parmer Ltd sont fournis avec un cordon d’alimentation. Celui-ci peut être

intégré ou amovible.

2. Avant de relier l’appareil à l’alimentation, assurez-vous que la tension correspond à la

tension indiquée sur la plaque signalétique (située à l’arrière de l’appareil).

Veuillez noter que l’appareil doit être relié à la terre pour assurer une

sécurité électrique adéquate.

3. L’appareil est conçu pour fonctionner avec les alimentations suivantes : 100-230 V, 50/60 Hz pour le

modèle AC-1 et 100-230 V, 50/60 Hz pour les modèles AC-2 et AC-4.

4. L‘appareil Alpha Cycler ne doit pas dépasser hors des limites de la paillase.

5. Assurez-vous que la paillasse utilisée pour les modèles AC-2 et AC-4 est capable de supporter un poids

de 30 kg / 47 kg.

10

6. Placez l’appareil sur une paillasse plane et horizontale adaptée ou dans une hotte, le cas échéant, en

veillant à ce que les entrées et sorties d’air des faces inférieure et arrière soient libres de toute obstruction.

7. Assurez-vous que les pieds de l’appareil ne dépassent pas des bords de la paillasse.

8. Branchez le cordon d’alimentation au connecteur situé à l’arrière de l’appareil. Le connecteur

d’alimentation des modèles AC-2 / AC-4 est situé sur le côté de l’appareil.

9. Allumez l’appareil à l’aide du bouton marche/arrêt situé à l’arrière. Le bouton marche/arrêt des modèles

AC-2 / AC-4 se trouve sur le côté de l’appareil.

Page 11

CÂBLE DE REMPLACEMENT

Lorsque le cordon d’alimentation doit être remplacé, utilisez un câble constitué de conducteurs d’1,5

mm2 de type H05VV-F 3G harmonisé, connecté à une fiche IEC320. EN CAS DE DOUTE, CONSULTEZ

UN ÉLECTRICIEN QUALIFIÉ.

CONDITIONS D’UTILISATION

L’appareil Alpha Cycler est conçu pour fonctionner dans les conditions suivantes :

• Utilisation en intérieur

• Température ambiante comprise entre +5 °C et +35°C

• Altitude jusqu’à 2 000 m

• Humidité relative ne dépassant pas 80 %

• Variations d’intensité de l’alimentation secteur ne dépassant pas 10 %

• Catégorie de surtension II CEI 60364-4-443

• Degré de pollution 2

REMARQUE : les caractéristiques de contrôle sont indiquées pour une température ambiante de 20 °C

± 2 °C.

L’appareil a fait l’objet de tests d’interférences radioélectriques et a reçu une certification EN61326.

GARANTIE

Cole-Parmer Ltd France garantit cet appareil contre tout défaut de pièces et de fabrication, dans des

conditions d’utilisation normale en laboratoire, pour une période de deux (2) ans. En cas de réclamation

dûment justifiée, Cole-Parmer Ltd France s’engage à remplacer gratuitement la pièce défectueuse ou

l’appareil. Cette garantie ne s’applique pas en cas de dommages provoqués par un incendie, un accident,

une utilisation inappropriée, une négligence, un réglage incorrect, une réparation inadéquate, une

installation, une adaptation ou une modification inappropriée, l’installation de pièces non approuvées

ou la réalisation de réparations par un personnel non autorisé. La responsabilité de Cole-Parmer Ltd

France se limite au coût de réparation ou de remplacement de l’appareil et exclut en particulier les

pertes indirectes ou consécutives, les coûts ou dépenses et dommages, incluant, sans s’y limiter, les

pertes de temps, de matériaux et de dépenses, les pertes de jouissance, de profit, de production, de

revenus, d’économies prévues ou de clientèle. Pour toute réclamation, veuillez contacter le fournisseur

de l’appareil. Cette garantie s’ajoute à vos droits prévus par la lois, sans les modifier.

Ce manuel est fourni aux clients de Cole-Parmer Ltd pour des raisons de commodité et rien dans ce

document ne doit être considéré comme une garantie, une condition ou une déclaration quant à la

description, la qualité marchande, l’adéquation ou autre de l’appareil ou de ses composants.

Nonobstant la description et les caractéristiques des appareils figurant dans le manuel d’utilisation,

Cole-Parmer Ltd se réserve le droit d’apporter toutes les modifications jugées nécessaires à l’appareil ou

à ses composants.

11

Page 12

Sicherheitsinformationen

Bitte lesen Sie vor der Verwendung dieses Alpha Cycler alle Informationen in diesem Handbuch.

WARNUNG

HOHE TEMPERATUREN SIND GEFÄHRLICH: Sie können zu schweren Verbrennungen des Bedieners führen

und brennbare Materialien entzünden. Die Benutzer sollten die folgenden möglichen Gefahren kennen:

• SEIEN SIE AUFMERKSAM UND TRAGEN SIE SCHUTZHANDSCHUHE, UM IHRE HÄNDE

ZU SCHÜTZEN.

• Verwenden Sie KEINE brennbaren Stoffe in der Nähe heißer Objekte.

• Bedienen Sie das Gerät NICHT in der Nähe brennbarer Flüssigkeiten oder Gase.

• Füllen Sie KEINE Flüssigkeiten direkt in das Gerät.

• Berühren Sie den beheizten Deckel NICHT während des Betriebs des Systems oder

innerhalb von 10 Minuten nach Betrieb des Geräts.

• Berühren Sie den Block NICHT während des Betriebs des Systems oder innerhalb von 10

Minuten nach Betrieb des Geräts.

BEDIENERSICHERHEIT

Alle Bediener von Cole-Parmer Ltd-Geräten müssen Zugang zu den Dokumenten haben, die für die

Gewährleistung der Sicherheit relevant sind. Es ist wichtig, dass nur entsprechend geschultes Personal

diese Ausrüstung gemäß den Anweisungen in dieser Gebrauchsanweisung und den allgemeinen

Sicherheitsstandards und -verfahren bedient. Wenn die Ausrüstung auf eine nicht von Cole-Parmer Ltd.

spezifizierte Weise verwendet wird, kann der Schutz des Bedieners beeinträchtigt werden.

Alle Cole-Parmer Ltd-Geräte erfüllen internationale Sicherheitsanforderungen und sind mit einem

Übertemperatur-Ausschalter ausgestattet. Sollte ein Sicherheitsproblem auftreten, schalten Sie das Gerät

an der Netzsteckdose aus und entfernen Sie den Stecker aus der Stromversorgung.

INSTALLATION

Das Gerät sollte mit beiden Händen getragen werden. Transportieren Sie das Gerät unter keinen

Umständen, wenn es in Betrieb ist, oder während das Gerät noch am Netz angeschlossen ist.

Die Geräte AC-2 / AC-4 haben ein Gewicht von 30 kg bzw. 47 kg. Es wird empfohlen, dass der AC-2 von

zwei Personen und der AC-4 von drei Personen getragen wird.

1. Im Lieferumfang aller Cole-Parmer Ltd-Geräte ist ein Stromkabel enthalten. Dies ist entweder integriert

oder eine steckbare Kabelverbindung.

2. Bevor Sie das Gerät mit der Stromversorgung verbinden, überprüfen Sie die

Spannung mit dem Typenschild (auf der Rückseite des Geräts). Bitte beachten

Sie, dass das Gerät geerdet sein muss, um eine einwandfreie elektrische

Sicherheit zu gewährleisten.

3. Die Geräte werden bei 100-230 V und 50/60 Hz (AC-1) bzw. 100-230 V und 50/60 Hz (AC-2 / AC-4)

betrieben.

12

4. Der Alpha Cycler darf nicht über die Tischkante hinausragen.

5. Stellen Sie sicher, dass der Tisch für den AC-2 / AC-4 einem Gewicht von 30 kg bzw. 47 kg standhalten

kann.

6. Positionieren Sie das Gerät auf einem geeigneten flachen und ebenen Tisch oder ggf. in einen

Abzugsschrank, sodass gewährleistet wird, dass die Öffnungen für den Lufteinlass und -auslass auf der

Unterseite und auf der Rückseite frei sind.

Page 13

7. Stellen Sie sicher, dass der Fuß des Geräts nicht über die Tischkante hinausragt.

8. Stecken Sie das Stromkabel in die Anschlussdose auf der Rückseite des Geräts. An den Geräten AC-2

und AC-4 befindet sich die Dose an der Seite des Geräts.

9. Schalten Sie das Gerät mit dem Schalter auf der Rückseite des Geräts an. An den Geräten AC-2 und

AC-4 befindet sich der Schalter an der Seite des Geräts.

ERSATZKABEL

Bei einem eventuellen Austausch des Netzkabels wird ein Kabel vom Typ H05VV-F 3G mit 1,5 mm²

Adernquerschnitt und Europastecker (IEC 320) benötigt. IM ZWEIFEL EINEN QUALIFIZIERTEN

ELEKTRIKER ZU RATE ZIEHEN.

UMGEBUNGSBEDINGUNGEN

Der Alpha Cycler kann unter den folgenden Bedingungen arbeiten:

• Verwendung in Innenräumen

• Umgebungstemperatur zwischen +5°C und +35°C

• Höhenlage bis zu 2000 m

• Relative Luftfeuchtigkeit maximal 80 %

• Netzspannungsschwankungen maximal 10 %

• Überspannungskategorie II IEC 60364-4-443

• Verschmutzungsgrad 2

Hinweis: Die Steuerspezifikationen sind mit einer Umgebungstemperatur von 20°C ±2°C angegeben.

Das Gerät wurde auf Funkfrequenzstörungen getestet und gemäß EN61326 zertifiziert.

Garantie

Cole-Parmer Ltd. garantiert, dass dieses Gerät frei von Material- und Herstellungsfehlern ist. Bei Einsatz

unter normalen Laborbedingungen wird eine Garantie von zwei (2) Jahren gewährt. Im Falle eines

berechtigten Anspruchs wird Cole-Parmer Ltd das fehlerhafte Teil oder das gesamte Gerät kostenlos

austauschen. Diese Garantie gilt jedoch nicht, wenn der Schaden durch Feuer, Unfall, unsachgemäße

Verwendung, Nachlässigkeit, falsche Einstellung oder Reparatur, falsche Installation, Anpassung oder

Modifikation sowie durch das Anbringen von nicht genehmigten Teilen oder durch eine Reparatur

von dazu nicht autorisiertem Personal verursacht wurde. Die Haftung von Cole-Parmer Ltd. ist auf die

Reparatur- oder Austauschkosten des Produkts begrenzt und schließt insbesondere direkte und indirekte

Verluste, Schäden, Kosten oder Aufwände aus, einschließlich unter anderem verschwendete Zeit,

Materialien und Aufwendungen oder der Ausfall der Nutzung, Gewinne, Produktion, des Umsatzes,

erwarteter Einsparungen oder Firmenwerte. Um Ansprüche geltend zu machen, wenden Sie sich bitte

an den Lieferanten dieses Geräts. Diese Garantie gilt als Ergänzung und beeinflusst keinerlei gesetzliche

Ansprüche.

Diese Gebrauchsanweisung soll die Verwendung durch die Kunden von Cole-Parmer Ltd erleichtern und

kein Abschnitt in dieser Gebrauchsanweisung gilt als Garantie, Bedingung oder Erklärung hinsichtlich

der Beschreibung, Marktgängigkeit, Gebrauchstauglichkeit oder in anderer Weise des Geräts der

Komponenten.

Unbeschadet der in der Bedienungsanleitung enthaltenen Beschreibung und Spezifikation(en) der Geräte

behält sich Cole-Parmer Ltd das Recht vor, solche Änderungen an den Geräten oder den Komponenten

nach eigenem Ermessen vorzunehmen.

13

Page 14

Informazioni sulla sicurezza

Si prega di leggere tutte le informazioni contenute in questo manuale prima di utilizzare l’Alpha Cycler.

AVVERTENZA

LE TEMPERATURE ELEVATE SONO PERICOLOSE: possono provocare bruciature gravi agli operatori

e causare l’accensione di materiale combustibile. Gli utenti devono essere a conoscenza dei seguenti

pericoli potenziali:

• PRESTARE ATTENZIONE E INDOSSARE GUANTI PER PROTEGGERE LE MANI.

• NON usare sostanze combustibili in prossimità di oggetti caldi.

• NON mettere in funzione lo strumento in prossimità di liquidi o gas infiammabili.

• NON collocare alcun tipo di liquido direttamente nello strumento.

• NON toccare il coperchio riscaldato quando il sistema è in funzione o nei 10 minuti

successivi al completamento di un ciclo.

• NON toccare il blocco quando il sistema è in funzione o nei 10 minuti successivi al

completamento di un ciclo.

SICUREZZA DELL’OPERATORE

Gli operatori di attrezzature Cole-Parmer Ltd devono avere a disposizione la documentazione necessaria

a garantire la loro incolumità. È importante che solo personale adeguatamente addestrato utilizzi questo

apparecchio, in conformità con le istruzioni contenute in questo manuale e con le normative e procedure

generali di sicurezza. Se l’apparecchio è utilizzato in modo non conforme a quanto specificato da ColeParmer Ltd. la protezione offerta all’operatore potrebbe risultare compromessa.

Tutti gli strumenti Cole-Parmer Ltd sono progettati in conformità con i requisiti internazionali di sicurezza

e sono equipaggiati con un dispositivo di interruzione anti surriscaldamento. Se si dovesse verificare

qualche problema di sicurezza, disconnettere la presa di corrente e rimuovere la spina.

INSTALLAZIONE

Questo strumento deve essere trasportato usando entrambe le mani. Non spostare né trasportare lo

strumento quando è in funzione o collegato all’alimentazione di rete.

L’AC-2 e l’AC-4 hanno un peso rispettivamente di 30 kg e 47 kg; si consiglia di far sollevare e trasportare

l’AC-2 da due persone e di far sollevare e trasportare l’AC-4 da tre persone

1. Tutti gli strumenti Cole-Parmer Ltd sono forniti con un cavo di alimentazione; questo può essere

incorporato o da collegare.

2. Prima di collegare lo strumento all’alimentazione elettrica di rete, controllare la

tensione confrontandola con la targhetta riportante i valori nominali (situata

sul retro dell’unità). Notare che occorre che l’unità sia messa a terra al fine di

garantire la corretta sicurezza elettrica.

3. Le unità sono stimate per funzionare a: per l’AC-1 100-230 V, 50/60 Hz e per l’AC-2 / AC-4 100-230

V 50/60 Hz.

4. Evitare che l’Alpha Cycler sporga dal banco.

14

5. Assicurarsi che il banco per l’AC-2 e l’AC-4 possa sostenere rispettivamente 30 kg e 47 kg di peso.

6. Collocare l’unità su un banco sufficientemente piano o in una cappa aspirante se necessario, assicurando

che le bocchette di ingresso e di uscita sul lato inferiore e posteriore siano libere da ostruzioni.

7. Assicurarsi che i piedini dello strumento non sporgano dal lato del banco.

8. Inserire il cavo di alimentazione nella presa sul retro dello strumento. Per l’AC-2 e l’AC-4 la presa di

ingresso è sul lato dello strumento.

9. Accendere lo strumento usando l’interruttore situato sul retro dello strumento. Per l’AC-2 e l’AC-4

l’interruttore è sul lato dello strumento.

Page 15

Cavo di ricambio

Qualora occorra sostituire il cavo di rete, si dovrà utilizzare un cavo di 1,5 mm2 armonizzato H05VV-F 3G,

collegato ad una spina IEC320. IN CASO DI DUBBI, RIVOLGERSI A UN ELETTRICISTA QUALIFICATO.

Condizioni ambientali

L’Alpha Cycler è progettato per operare nelle seguenti condizioni:

• uso interno

• temperatura ambiente compresa tra +5°C e +35°C

• altitudine massima 2000 m

• umidità relativa non superiore all’80%

• oscillazioni dell’alimentazione di rete non superiori al 10%

• categoria di sovratensione II IEC 60364-4-443

• grado di inquinamento 2

Nota: le specifiche di controllo sono indicate per una temperatura ambiente di 20°C ± 2°C.

Lo strumento è stato collaudato per interferenze da radiofrequenze ed è certificato secondo la norma

EN61326.

Garanzia

Cole-Parmer Ltd garantisce questo strumento da difetti di materiali e fabbricazione per un periodo

di due (2) anni, se utilizzato in normali condizioni di laboratorio. In caso di reclamo giustificato, ColeParmer Ltd. sostituirà gratuitamente qualsiasi componente difettoso o l’intera unità. Questa garanzia

non copre i danni provocati da incendi, incidenti, uso non conforme, negligenza, errori di regolazione o di

riparazione, danni dovuti a installazioni, adattamenti e modifiche non corretti, montaggio di componenti

non approvati o riparazioni effettuate da personale non autorizzato. La responsabilità di Cole-Parmer Ltd

è limitata al costo della riparazione o della sostituzione del prodotto ed esclude in particolare qualsiasi

perdita indiretta o secondaria, danno, costo o spesa, ivi inclusi, a titolo di esempio e in modo non

esaustivo, perdite di tempo, materiali e spese oppure perdite di utilizzo, profitto, produzione, ricavo,

risparmio atteso o avviamento. Per usufruire della garanzia, contattare il fornitore dello strumento.

Questa garanzia è in aggiunta ai diritti di legge e non ha alcun effetto su di essi.

Il presente manuale è stato preparato ad uso dei clienti di Cole-Parmer Ltd e niente di quanto in esso

contenuto costituisce garanzia, condizione o rappresentanza riguardo la descrizione, la commerciabilità,

l’idoneità allo scopo o altro dell’unità o dei componenti.

Nonostante la descrizione e le specifiche dello strumento contenute nel manuale dell’operatore,

Cole-Parmer Ltd si riserva il diritto di apportare le modifiche ritenute opportune agli strumenti o a

qualsiasi loro componente.

15

Page 16

Información de seguridad

Lea toda la información incluida en este manual antes de usar el Alpha Cycler.

ADVERTENCIA

LAS TEMPERATURAS ELEVADAS SON PELIGROSAS: pueden causar quemaduras graves a los operarios

y prender fuego aL material combustible. Los usuarios deberían ser conscientes de los posibles peligros

indicados a continuación:

• TENGA CUIDADO Y USE GUANTES PROTECTORES PARA PROTEGER LAS MANOS.

• NO utilice sustancias combustibles cerca de objetos calientes.

• NO utilice el instrumento cerca de líquidos o gases inflamables.

• NO coloque ningún líquido directamente en el instrumento.

• NO toque el bloque cuando el sistema esté funcionando o durante los 10 minutos

siguientes a la finalización de la serie por parte del sistema.

• NO toque el bloque cuando el sistema esté funcionando o durante los 10 minutos

siguientes a la finalización de la serie por parte del sistema.

SEGURIDAD DEL OPERARIO

Todos los operarios del equipo Cole-Parmer Ltd deben tener a su disposición la bibliografía pertinente

necesaria para garantizar su seguridad. Es importante que este equipo solo sea usado por personal

debidamente formado, de acuerdo con las instrucciones contenidas en este manual y con las normas

y procedimientos de seguridad generales. Si se usa el equipo de una manera no especificada por ColeParmer Ltd. la protección que el equipo proporciona al operario puede resultar alterada.

Todos los instrumentos de Cole-Parmer Ltd han sido diseñados para ajustarse a los requisitos de seguridad

internacionales y están equipados con un cortacircuitos por sobretemperatura. Si se produce un problema

de seguridad, desconecte la unidad de la toma de red y desenchúfela del suministro eléctrico.

INSTALACIÓN

El instrumento debería transportarse con las dos manos. No mueva ni transporte nunca el instrumento

cuando esté en funcionamiento o conectado al suministro eléctrico.

Los AC-2 / AC-4 tienen un peso de 30 kg / 47 kg respectivamente; se recomienda emplear a dos

personas para levantar y transportar el AC-2, y tres personas para el AC-4.

1. Todos los instrumentos de Cole-Parmer Ltd son suministrados con un cable de alimentación; puede

estar integrado o ser enchufable.

2. Antes de conectar el instrumento a la red de suministro eléctrico, compruebe la

tensión que figura en la placa de especificaciones (situada en la parte trasera

de la unidad). No olvide que para garantizar la seguridad eléctrica apropiada,

es imprescindible que la unidad esté conectada a tierra.

3. Las unidades están clasificadas para funcionar a: para el AC-1 100-230 V, 50/60 Hz, y para el AC-2 y

AC-4 100-230 V, 50/60 Hz

4. No permita que el Alpha Cycler sobresalga de la mesa de trabajo.

16

5. Asegúrese de que la mesa de trabajo para el AC-2 / AC-4 pueda soportar 30 kg / 47 kg de peso.

6. Coloque la unidad sobre una mesa de trabajo plana y nivelada adecuada o en una campana extractora

si es necesario, y compruebe que la entrada de aire y los respiraderos de salida situados en la parte

inferior y la parte posterior no estén obstruidos.

7. Asegúrese de que las patas del instrumento no sobresalen por los lados de la mesa de trabajo.

Page 17

8. Conecte el cable de red en la toma de la parte trasera del instrumento. Para el AC-2 / AC- 4 la toma

de entrada se encuentra en un lado del instrumento.

9. Encienda el instrumento usando el interruptor ubicado en la parte trasera del instrumento. Para el

AC-2 / AC- 4 el interruptor está un lado del instrumento.

CABLE DE SUSTITUCIÓN

En caso de que sea necesario sustituir el cable de alimentación, utilice un cable de 1,5 mm2 de código

armonizado H05VV-F 3G conectado a un enchufe IEC320. EN CASO DE DUDA, PÓNGASE EN

CONTACTO CON UN ELECTRICISTA CUALIFICADO.

CONDICIONES AMBIENTALES

El Alpha Cycler ha sido diseñado para funcionar en las siguientes condiciones:

• Uso interior

• Intervalo de temperatura ambiente +5 °C a +35°C

• Altitud máxima de 2 000 m

• Humedad relativa no superior al 80%

• Fluctuaciones de corriente no superiores al 10%

• Categoría de sobrevoltaje II IEC 60364-4-443

• Grado de contaminación 2

Nota: Las especificaciones de control se indican a una temperatura ambiente de 20°C ±2°C.

El instrumento ha sido sometido a las pruebas de interferencia por radiofrecuencia y está certificado

según la norma EN61326.

GARANTÍA

Cole-Parmer Ltd. garantiza que este equipo se encuentra libre de defectos de material o de fábrica,

siempre que se utilice en condiciones normales de laboratorio, durante un plazo de dos (2) años. Si la

reclamación es justificada, Cole-Parmer Ltd sustituirá cualquier componente defectuoso o cambiará

la unidad gratuitamente. Esta garantía no se aplicará si el daño ha sido causado por un incendio,

accidente, mal uso, negligencia, ajuste o reparación incorrecta, daños por una instalación incorrecta,

adaptación, modificación, montaje de piezas no aprobadas o reparación por personal no autorizado. La

responsabilidad de Cole-Parmer Ltd se limita al coste de reparación o sustitución del producto y excluye

en particular, pérdidas, daños, costes o gastos indirectos y emergentes, incluidos aunque no limitados a

tiempo perdido, materiales y desembolso o pérdida de uso, beneficios, producción, ingresos, ahorros o

crédito mercantil esperados. Para realizar una reclamación, póngase en contacto con el proveedor del

instrumento. Esta garantía es además de los derechos legales y no les afecta en absoluto.

Este manual se ha elaborado para comodidad de los clientes de Cole-Parmer Ltd y nada de lo que

figura en este manual debe interpretarse como garantía, condición o declaración relacionadas con la

descripción, comerciabilidad, adecuación al propósito u otro de la unidad o los componentes.

No obstante, la descripción y las especificaciones de los instrumentos contenidas en el manual

del operador, Cole-Parmer Ltd se reserva el derecho a realizar los cambios que considere apropiados

para los instrumentos o para cualquiera de los componentes.

17

Page 18

Contact Information

For technical, sales or servicing information, contact your local PCRmax distributor or Cole-Parmer Ltd

directly at:

Cole-Parmer Ltd

Beacon Road

Stone

Staffordshire

ST15 0SA

UK

Tel: +44 (0)1785 812121

Fax: +44 (0)1785 810405

Technical Support email: CPtechsupport@coleparmer.com

Sales email: cpenquiries@coleparmer.com

Web: www.coleparmer.com

18

Page 19

Alpha Cycler Specification

Temperature

Block temperature range 4°C (10°C during cycling) to 100°C

Block uniformity (at 55°C) ≤±0.3°C

Temperature accuracy (at 55°C) ≤±0.25°C

Gradient availability Between 10°C and 100°C

Maximum gradient 29°C on a 96 well block and 19°C on a 384 well block

Minimum gradient 1°C

Column uniformity with a 10°C gradient ≤±0.3°C

Final store 4°C to 100°C

Temperature set point adjustment 0.1°C

Heating/Cooling Rate

Maximum heating rate 3.4°C/s

Minimum heating rate 0.1°C/s

Maximum cooling rate 1.0ºC/s

Minimum cooling rate 0.1ºC/s

Heated lid

Selectable heated lid temperature 35 to 115°C or off

Lid uniformity ±5°C

Pre-heat lid Yes

Warm up time from ambient <2 min

Over-temperature cut-out Yes

Regulated heated lid pressure Manually adjustable

The heated lid is only operational if the block temperature is set above 35°C. Above figures are quoted

at an ambient temperature of 20°C ±2°C

Programming

Program interface 10” and 7” HD touch screen

Operation system Android

Maximum number of programs stored 1000

Maximum number of stages per program 25

Maximum number of steps 10

Maximum number of cycles per stage 99

Programmable ramp rate Yes, 0.1°C/s steps

Maximum hold time 4h 59m 59s

Minimum hold time 1s

Program Wizard Yes

Active sample cooling Yes, 4°C

Advanced reporting options Yes

Touchdown Yes

19

Page 20

Incremented/decremented temperature Yes

Incremented/decremented time Yes

Pause facility Yes

Program naming Alpha numeric plus symbols

Password protection Yes

Keyword selection Yes

Run completion time Yes

Auto resume on power failure Yes, always, never or user-defined

Oligonucleotide Tm calculator Yes, based on the Nearest-Neighbour method

Software updates Free of charge from www.coleparmer.com

Communication ports

USB port on the front of the AC-1 Connection for USB memory stick

USB port on side of the AC-2 / AC-4 Connection for USB memory stick

Type B USB port on rear of unit For Internal use only.

Dimensions

AC-1 AC-2 AC-4

Height (mm) 330 330 330

Width (mm) 260 535 535

Length (mm) 430 470 700

Weight (kg) 10 30 47

1

Power

AC-1 AC-2 AC-4

Voltage 100-230V, 50/60Hz 100-230V, 50/60Hz 100-230V, 50/60Hz

Power 425W 900W 1,600W

Fuse ratings 220V: 5 Amp x 2 220V: 8 Amp x 2

120V: 12.5 Amp x 2 120V: 15 Amp x 2

1

Breslauer, K.J.; Frank, R.; Blocker, H. and Marky, L.A. (1986) Proc. Natl. Acad. Sci. USA 83,

pp 3746-3750.

20

Page 21

Installation and operation

See also the Safety Information sections on pages 5 to 15.

Front view

1. Heated lid pressure knob

2. Lid release.

3. Android HD touchscreen interface

4. USB port for memory stick.

Rear view

1. Mains cable inlet.

2. On/Off rocker switch

2

1

1

2

3

3

4

4

Note: On the AC-2 / AC-4 the mains cable inlet,

On/Off rocker switch and USB port are situated

on the side of the instrument for easier access.

INSTALLATION

1. Place the unit on a suitable flat and level bench, ensuring that the air inlet vents on the sides are free

from obstruction, as per the guidelines in the Safety Information sections.

Note: Ensure a 250mm gap to the side of the AC-2 / AC-4 power lead to allow disconnect of the

electrical supply from the chassis if required, 100mm is sufficient for AC-1.

2. Note that block removal can only be performed by a qualified service engineer.

3. Plug the mains cable into the mains cable inlet of the unit.

4. Connect to the mains electricity supply with the plug provided or one wired correctly for the supply.

Switch the power ON using the switch located on the rear (AC-1) or side (AC-2 / AC-4) of the unit.

The front display will then light up.

NOTE:

A 250mm air space should be kept free at each side of the AC-2 / AC-4 unit (left and right). If two AC-2

/ AC-4 units have to be positioned next to one another, a total of 500mm should be free between both

units. If the systems have to be wracked the shelves should be 600mm apart from each other vertically,

this promotes the correct airflow and heat distribution from the units. As air flow with the AC-2 / AC-4

is in thought the front of the unit and out the sides, caution should be taken to not block the path of

air in and out of the unit.

1

2

21

Page 22

OPERATION

1. Release the heated lid by pressing the blue

circular button located towards the front edge

of the lid. The lid is sprung and should open to

around 45 degrees with little assistance. To close

the lid, lower the lid onto the block and press

until you hear a click.

2. Place the samples in the block. If individual tubes

or strip tubes are being used, space these out

evenly across the block to equalise the pressure

from the heated lid.

3. The heated lid has a rotating knob to adjust

the lid pressure on the samples, allowing for a

variety of consumables to be used. To adjust the

pressure:

a. Rotate the knob anti-clockwise to raise the lid to

the highest position.

b. Place the samples in the block and close the lid.

c. Rotate the knob clockwise until resistance is felt

then give a further quarter of a turn; this will

give the correct pressure. Do not over-tighten.

4. Once the pressure has been set it should not need

to be adjusted unless a different consumable is

used. Good standard practice is to check the

pressure of the heated lid is adjusted correctly

every time the system is run.

5. Keep fingers clear of rear hinged part of the lid

while opening or closing.

22

Page 23

General software features

INTRODUCTION

The Alpha Cycler software is aimed at being consistent with all the instruments in the PCRmax range.

The common themes of simplicity and performance are echoed in all PCRmax thermal cyclers. The

software will boot automatically when the system is switched on.

The Alpha Cycler software allows the user to quickly and easily create thermal cycling programs using

a simple and clear touch screen format. The software is structured into six modules which are accessed

from the Home Screen. The Home Screen has the following buttons and associated features.

• Run a program allows the user to run an existing program, selecting from templates or programs

saved on the unit.

• New program allows the user to manually build a custom thermal cycling program.

• Program wizard allows the user to automatically generate a protocol based on primer sequences,

Tm’s and template size.

• Edit program gives access to the File Manager and allows the user to search for programs and

reports stored on the unit and to edit existing programs.

• Block status allows the user to monitor the progress of the program running on one or more of

the blocks.

• Settings allows the user to define default states of the system e.g. temperatures for cycling steps,

language and response to power outages etc.

The Recent Programs panel displays the most recent protocols which have been run on the system.

Note: The Recent Programs panel will allow users to quickly access and run common programs without

the need to navigate the File Manager.

23

Page 24

BASIC ANDROID COMMANDS AND DATA/TEXT INPUT

The Alpha Cycler system interface is Android based and as such responds and operates similarly to other

Android devices.

The standard Android navigation bar is located at the bottom of all Alpha Cycler screens:

• Back: This will take you back to the previous page. Repeatedly press this button to go back multiple

screens.

• Home: This will take you back to the Home Screen for the Alpha Cycler.

• Recent: This will allow you to toggle between recent pages you have open. End users can also close

open pages by swiping the windows left or right, as you would normally with Android interfaces.

Note: If you have opened multiple pages, for example you been in settings, started writing a protocol

and had a protocol running, selecting the recent button allows you to easily toggle between these open

pages.

When users are required to input data, either an Android keyboard will open in the screen or a scrolling wheel

may appear (the scrolling wheel is used more for defining values such as number of cycles and time).

Example keyboard

24

Example time wheel during step duration input

Page 25

TEMPLATE PROGRAMS

To help with programming, a number of program templates are provided on the USB memory stick

supplied with the system. These are available to copy and edit or can be run directly without changes.

Details of the installed program templates are given below.

Instrument and program defaults

Parameter Gradient 50 to 60 deg. 3 Step Template RT PCR Template

Heated Lid 110°C 110°C 110°C

Heated lid before program On On On

Sample cooling On On On

Polymerase activation 95°C, 05m00s 95°C, 05m00s 95°C, 05m00s

Final extension 72°C, 05m00s 72°C, 05m00s 72°C, 07m00s

Final store 10°C for infinite time 10°C for infinite time 10°C for infinite

time

Thermal cycling conditions

Parameter Gradient 50 to 60 deg. 3 Step Template RT PCR Template

Stage 1

Number of cycles 35 35 1

Step 1 95°C, 00m30s 95°C, 00m30s 45°C, 40m00s

Step 2 50 to 60°C, 00m30s 56°C, 00m30s 95°C, 05m00s

Step 3 72°C, 00m30s 72°C, 00m30s

Stage 2

Number of cycles 40

Step 1 95°C, 01m00s

Step 2 55°C, 00m50s

Step 3 72°C, 01m00s

Note: There is also an Ice Bucket program which is a simple temperature hold at 4°C: the heated lid is

switched off and the polymerase activation and final extension functions are disabled.

25

Page 26

GRADIENT

The gradient feature of the Alpha Cycler can be useful in optimising the annealing conditions for

reactions. A gradient can be set around a temperature in any step of a program. The set temperature

is the temperature in the middle columns and the range around the set point defines the gradient’s

minimum and maximum temperatures, see diagram below.

The maximum temperature gradient range which can be set is 29°C (depending on block type) and the

minimum is 1°C; within the temperature range of 10°C and 100°C. Examples are given in the table below:

Gradient Set temperature Lowest temperature Highest temperature

(°C) (°C) Column 1 (°C) Column 12 (°C)

10 55 50 60

15 55 47.5 62.5

29 55 40.5 69.5

To program a gradient step see section Manual program entry.

The red circles in the below diagram illustrate the A1 well position of each block in an AC4.

26

FRONT

Page 27

Creating user profiles

The Alpha Cycler system allows for individual user profiles to be created, simplifying file management

and controlling access to certain programs.

CREATING A NEW USER ACCOUNT

• To create a new user account tap the LOGIN button located at the top of the Home Screen.

• Select Create an account.

• Complete the details: User name, Password and Re-enter password.

• Tap on Create Account to save the profile.

Note: Programs written by a logged in user will only be available to that user unless the user chooses to

share these programs with everyone; see the programming section.

TO LOG IN AS AN EXISTING USER

• Select LOGIN from the top of the Home Screen.

• Select Log in from the login screen.

• Log in with your user-specific name and password.

• Tap on Log in.

Note: Each Alpha Cycler has a administration level user accessed by logging in with the following:

Username: admin - Password: admin

LOGGING OUT

To log out simply tap the user name on the Home Screen and select Log out.

CHANGING A USER PASSWORD

To change a password, while logged in, tap the user name button on the Home Screen and select

Change Password from the login screen.

• Type in your current password.

• Type in a new password.

• Re-enter the new password.

• Tap on Change Password to confirm.

27

Page 28

Creating USB Login

The Alpha Cycler system allows for individual user profiles to be created, simplifying file management

and controlling access to certain programs.

CREATING A USB LOGIN

• To create a USB LOGIN device click on the login button located at the top of the home screen.

• LOGIN with existing account.

• Return to the login screen

• Insert a USB drive and click Authorize USB drive.

28

Note: Any USB drive can be authorised as the users login device. When logging in via USB all specified

user defaults will be carried forward and applied. Removing the USB drive will logout the user.

• To log in with the authorised USB drive, simply insert the authorised / USB into the Alpha Cycler

• When a program is started from a logged in user and the user then logs out the running program

can only be interrupted or stopped by inputting the specific users login details.

• Removing the USB drive will automatically log the user out.

Page 29

Programming

This section gives instructions for the two methods of programming the Alpha Cycler systems. The first

method uses the Program Wizard to automatically generate a program based on a few user defined

parameters. The second method is accessed through the New program button from the Home Screen

and allows the user to control every element of the program.

Note: When programming an Alpha Cycler protocols are built with a steps and stages structure.

Individual steps can be created and a collection of those steps make up a stage. Stages have a number of

cycles applied to them and all steps in a stage will cycle the specified number of times before progressing

to the next stage. Protocols can have multiple stages comprising multiple temperature steps.

USING THE PROGRAM WIZARD

The Program wizard allows users to automatically generate a protocol based upon the following

criteria:

• Primer Sequence or Tm’s

• Length of amplicon

• Template source (bacterial, eukaryote or plasmid)

• Special considerations

Special considerations has a series of options which accommodate for the use of hot start Taq polymerases,

adjusts the temperatures based upon the amplicons A/T and G/C bias and will allow for the user to add

a touchdown PCR stage as a means of improving specificity.

• From the Home Screen select Program wizard.

The Program wizard consists of four steps which require user input in order to generate a suitable

protocol. The first step is to specify the melting temperature either from the primer sequences of from

the Tm values.

29

Page 30

• If selecting the primer sequences, tap “I’d like the melting temperatures calculated for me

from the primer sequences” to input the sequence of each primer.

• Tap on the line Primer Sequence 1; a keyboard will appear on the screen. Type in the sequence of

the first primer then tap on Next.

• Type in the sequence of the second primer then tap on Done. Primer sequences can be uploaded

direct from the root of a USB drive.

• To input your own primer Tm values, tap “I’d like to provide the melting temperatures myself”.

• Tap on the line Primer 1 (°C); a keyboard will appear on the screen. Type in the melting temperature

of the first primer then tap on Done.

• Type in the melting temperature of the second primer then tap on Done.

• After completing either step, tap NEXT PAGE at the top right of the screen to progress to the next

step. To go back, tap on PREVIOUS PAGE.

30

Page 31

The next step is to input the length of the PCR product in kb.

• Either tap the line next to Product length (Kb) to enter the size of the PCR product (in kb) or drag

the slider to the right or left to select the size.

Note: values of between 0-5kb are valid: all values below 0.5kb will be given an extension time of 30

seconds.

• Tap NEXT PAGE at the top right of the screen to progress to the next step. To go back, tap on

PREVIOUS PAGE.

The next step is to select the source of the DNA.

• Select one of the three options.

• Tap NEXT PAGE at the top right of the screen to progress to the next step. To go back, tap on

PREVIOUS PAGE.

Finally, use the check boxes to take into account any special considerations as listed on the final screen.

31

Page 32

• When finished, tap FINISH WIZARD at the top right of the screen.

Once you have completed the Program wizard, the final program will be displayed based upon the

answers/data given in the previous steps.

32

Note: all parameters of a Program wizard-generated program can be adjusted either before or after it

is saved. Ensure that heated lid is set how you wish it to be and add any special stages such as a final

extension or a store step at this point.

• To save the program, tap SAVE at the top right of the screen.

• Select whether the program will be available to Everyone or Just me (current logged-in user) and

assign a name.

• Tap Save.

Page 33

MANUAL PROGRAM ENTRY

The Alpha Cycler will also allow users to manually create a protocol by inputting the individual temperatures

and hold durations for each step. Where a temperature or hold time is visible/required the user will be

able to tap to select that step and either edit or input a time/temperature.

• From the Home Screen select New program.

The basic program will contain the defaults as set by the user in the Settings (see section on Settings).

A. Toggle on and off the Heated Lid.

B. Toggle on/off Preheat Lid.

C. Toggle on/off Sample Cooling before the run begins.

D. Add a new stage - adds a stage with one temperature step plus the option to add further

temperature steps within the same stage. The stage can be cycled up to 99 times.

E. Add a special step - including Touchdown, Final Extension and Final Store steps.

ADDING A STAGE

Tap on Add a new stage to create the first stage and step in the program. You will initially need to

define the parameters for the first temperature step:

33

Page 34

To change the step temperature, tap on the default temperature value and enter the desired value

followed by Done.

To change the steps hold temperature, click on the hold temperature and a window will open, scroll the

temperature in that window and select Change to update to the new hold temperature. To change step

hold time, the same applies but to the duration not temperature.

Note: Alpha Cycler Temperature steps carry an inherent hold time of 30 sec and temperature of 95˚C,

56˚C and 72˚C for a three step stage.

Tap Add stage to complete adding the first stage and step.

34

Page 35

Continue by adding further steps and stages as required in the same way.

Note: If a protocol has several stages it may appear to extend beyond the screen; simply swipe the screen

to the left or the right to view the whole protocol.

To adjust the number of cycles of a stage, tap on the cycle button at the bottom of each stage area; a

scrolling selector will appear. Select the desired number of cycles followed by Change.

As the program is written, the total duration of the protocol is displayed at the bottom of the programming

screen.

EDITING STEP PARAMETERS

To edit the parameters of a step e.g. the temperature, hold time, ramp rate etc. tap on the grey shaded

area of the step. The Change step parameters window (see below) will open. Make any changes to

the parameters then tap on Change to accept.

Note: The ramp rate (heating/cooling rate from the previous step to the current step) can be defined

between 0.1 ºC/sec up to 3 ºC/sec or MAX.

ADDING A GRADIENT STEP

Select the step on which you wish to add a gradient and tap on the grey shaded area. The Change

step parameters window will open. Toggle ON the parameter Gradient around step temperature.

Next, define the range of temperature you wish to run the gradient over. Tap on Change to accept the

changes.

The gradient and range will then be displayed within the program.

35

Page 36

Note: After running a gradient protocol to optimise a reaction, the program can be easily modified to

set the annealing temperature to that of the column in which the optimal reaction occurred. Simply tap

on the gradient step to edit it then select Convert to fixed temperature °C. A window showing the

actual temperature in each column of the block is displayed. Select the column which gave the optimal

reaction conditions to re-set the annealing temperature.

36

ADDING A TEMPERATURE OR TIME INCREMENT OR DECREMENT

Select the step on which you wish to add the increment or decrement and tap on the grey shaded area.

The Change step parameters window will open. Toggle ON the parameter Temperature change per

cycle or Time change per cycle as desired. Next, define the increment or decrement temperature or

time. Tap on Change to accept the changes.

Note: The maximum allowed temperature increment/decrement is between -10 °C and + 10°C/cycle

and the maximum time increment/decrement -30 seconds and +30 seconds/cycle. This will also be

dependent on the number of cycles in the stage and the limits of the thermal block.

Page 37

The temperature/time changes will be displayed with the program.

DELETING A STEP OR STAGE

To delete a step, tap in the area just below or above the step (not in the grey boxed area) so that the step

is highlighted. Multiple steps may be selected. Next, tap on DELETE at the bottom of the screen. The

step(s) will be deleted. To delete a complete stage, all steps within the stage must be deleted, this can

be done by highlighting the temperature steps, press the screen underneath the temperature step box

to highlight and then press DELETE.

Note: At the top of the screen there is an UNDO button to undo the last series of commands if a mistake

such as unintentionally deleting a step/stage is made.

SAVING THE PROGRAM

To complete writing a program and to store it to the cycler memory, tap SAVE on the top right corner of

the program window. The Save program window will appear.

37

Page 38

Define who will have access to the program:

• Everyone, meaning all users of the system will have access to this protocol, or

• Just me, meaning only the current logged-in user will have access.

Add a name for the program for future identification then tap on Save.

Programs can also be password protected. Click on the box marked “Protect the program from further

changes’ and assign a password. To alter the program the password must be known. Programs with

password protection can not be interrupted/stopped mid cycle without applying the password.

Note: The RUN AND SAVE button allows you to start the protocol from the programing screen without

the need to first save and then go into the File Manager to run the protocol. Run and save can be useful

for when you are modifying an existing protocol.

38

Page 39

Special steps

When writing a protocol there is an option to add a special step, these include:

• Polymerase Activation

• Touchdown

• Final Extension

• Final Store

Tap on Add a special step and the Add a special step or stage window will open.

Polymerase Activation allows for a one off temperature/time step to activate the polymerase, this step

will not cycle.

Touchdown stage allows users to generate a touchdown protocol which will change the temperature

uniformly across the entire block each cycle between two set temperatures (high to low) over a defined

number of cycles.

Define the starting (maximum) annealing temperature and the end (minimum) annealing temperature.

The temperature change per cycle will be equal to the difference in temperature between the maximum

and minimum divided by the number of cycles -1.

39

Page 40

Note: The software allows the user to either increment or decrement the time and/or temperature

of a step within a cycling stage. These features are used with applications such as touchdown PCR

where the annealing temperature is gradually decreased during the cycling process and long range PCR

amplification, where due to the size of the product, long annealing/extension times are required and the

extension time is increased by, for example, 15 to 20s per cycle during the final stages of the reaction.

Final extension allows users to add a final temperature step at the end of normal cycling.

Final store allows users to store the PCR reactions in the system at a set temperature until they are

ready to be taken out for further analysis. The default temperature is 10°C as this is suitable for storing

DNA for prolonged periods of time.

Note: Colder temperatures can be set, down to 4°C, but this is not essential for DNA work. It is advised

to never store RNA for prolonged periods in a thermal cycler, at 4°C or any temperature.

40

Page 41

Running a program

There are two main options for running a program; either selecting the program from the Home Screen

Recent Programs shortcut list or by searching through the system’s File Manager accessed through

either Run a program or Edit program.

RUNNING A PROGRAM FROM THE SHORTCUT LIST

When a program has been run on the Alpha Cycler it will appear in the Recent Programs list.

To re-run the same program, tap to select one of the programs from this list. The Pre-run screen will be

displayed.

The Pre-run Screen shows a graphical representation of the program allowing for a rapid check of the

temperature parameters. Any of the parameters can be edited at this point.

• Touch any stage or step to edit the program.

• Touch RUN AND SAVE to start the program. Note that this will over-write the existing program if

any edits have been made.

• Touch Back to return to the previous screen.

Note: With the AC-2 / AC-4 you will be asked at this point on which block(s) the program is to be run.

Any number of the available blocks can be selected. Select the required block(s) by tapping to display YES.

41

Page 42

Tapping on Run will send the program to the thermal cycler and it will begin automatically.

Note: AC-2 only has left/right block option.

RUNNING A PROGRAM FROM THE INSTRUMENT MEMORY

If the program required is not present in the Recent programs list it must be located using the File

Manager.

From the Home Screen, tap on Run a program to open the File Manager. Select the required program

by tapping to highlight it.

Note: With the AC-2 / AC-4 you will be asked on which block(s) the program is to be run. Any number

of the available blocks can be selected. Select the required block(s) by tapping to display YES.

Tapping on Run will send the program to the thermal cycler and it will begin automatically.

Note: This route of selecting a program does not allow you to view the thermal profile before it is run.

An alternative way of accessing the File Manager is to go through Edit program. Using this route you

will be able to view the program in the Pre-run screen and make any changes before sending it to the

thermal cycler. Once you are satisfied the program is correct, tap RUN AND SAVE to start the program

as described above.

Note: With the AC-2 / AC-4 you can run any number of blocks simultaneously with the same program

or select different programs to run on each individual block.

VIEWING A RUNNING PROGRAM

Once the program has been started, the Home Screen will display information about which program is

running and how long it has left to run.

42

With the AC-1 this display is across the top of the screen. It shows the program name and end time.

Page 43

CREATING A FAVOURITE PROGRAM.

A program can become a favourite by pressing on the start icon in the Edit Programs menu or by

pressing the three stacked boxes icon while writing a program and selecting favourite as images below.

In Edit programs check the Star icon to Favourite a Program.

In New Program press the three stacked boxes icon and check Favourite to assign it as such.

NOTE: Favourite programs can then be visualised together on the home screen, see instrument setting

section for how to display Favourites on the home screen.

43

Page 44

There is also an option to display the countdown clock in full screen while the system is running. This

feature is only available in the AC-1 and is accessed by clicking on the four arrow icon in the status bar.

With the AC-2 / AC-4, status of each block is shown separately across the bottom of the screen.

To view the running program in more detail, from the Home Screen tap on Block status.

Note: With the AC-2 / AC-4, the status of all blocks will be displayed.

44

Page 45

To view an individual block, tap on the full screen icon close to program name. This will expand the run

screen of the selected block to fit the entire screen.

Note: If a protocol has several stages which extend beyond the screen; simply slide the screen to the left

or the right to view the protocol.

When a program is running the Track This Program button will appear. This button when pressed,

with create an on screen QR code which can then be scanned with the Alpha Track Mobile Device

Application. This can be downloaded free from the App store (Android and iOS).

When viewing an individual program there is the option to toggle between viewing the real time

temperature of the block and the program display.

To view the block temperature, tap on DISPLAY REAL-TIME TEMPERATURE at the top right of the screen.

Note: see settings too toggle between displaying the average temperature across the block or the actual

temperature recorded at the four temperature sensors.

When Real Time Temperature is selected the user is shown the current temperature of the block as

it progresses though the program. Approximately 5 minutes of temperature profile is shown on the

display.

To return to the program, tap on DISPLAY PROGRAM.

45

Page 46

QR code and Alpha Track App

Download the Alpha Track App from the iOS/Android App store and install it upon a device with a

camera function such as a mobile phone or tablet.

The Alpha Track App can be used to scan a QR code and inform the user about:

• Run time until completion, countdown clock

• User who started the run

• Serial number of the system being used (block for the AC-2 / AC-4)

• Health report on the system.

Upon first using the App you will be asked to provide an email address so you can be contacted by your

local service centre if the they find an error in the systems health report.

How to Use the Alpha Track App

To scan the QR code, start a program on the Alpha Cycler, ask it to display the QR code, see Pg42, launch

the Alpha Track App, click the QR code reader button, bottom right of the screen and position over the

displayed QR code such that the centre of the screen is positioned over the QR code.

46

Page 47

The countdown clock can be configured to alert the end user a specific time period before the run

completes and can be changed by selecting the running protocol and then selecting the time remaining

and setting that to what is required.

(Running Program) (instrument report)

When the system detects a fault the QR code will automatically contain that information and generate

an instrument report which is visible on the Alpha Track home screen the end user can select to send this

report to the Bibby Technical Team for review. Should the system require a visit/repair/further diagnostics

to be carried out the end user will be contacted using the details provided in the App.

NOTE: For the multiblock AC-2 / AC-4 systems one QR code can be scanned which represents all

running blocks. This is accessed through Block Status and then clicking on Track All Programs and

scanning the QR code displayed.

47

Page 48

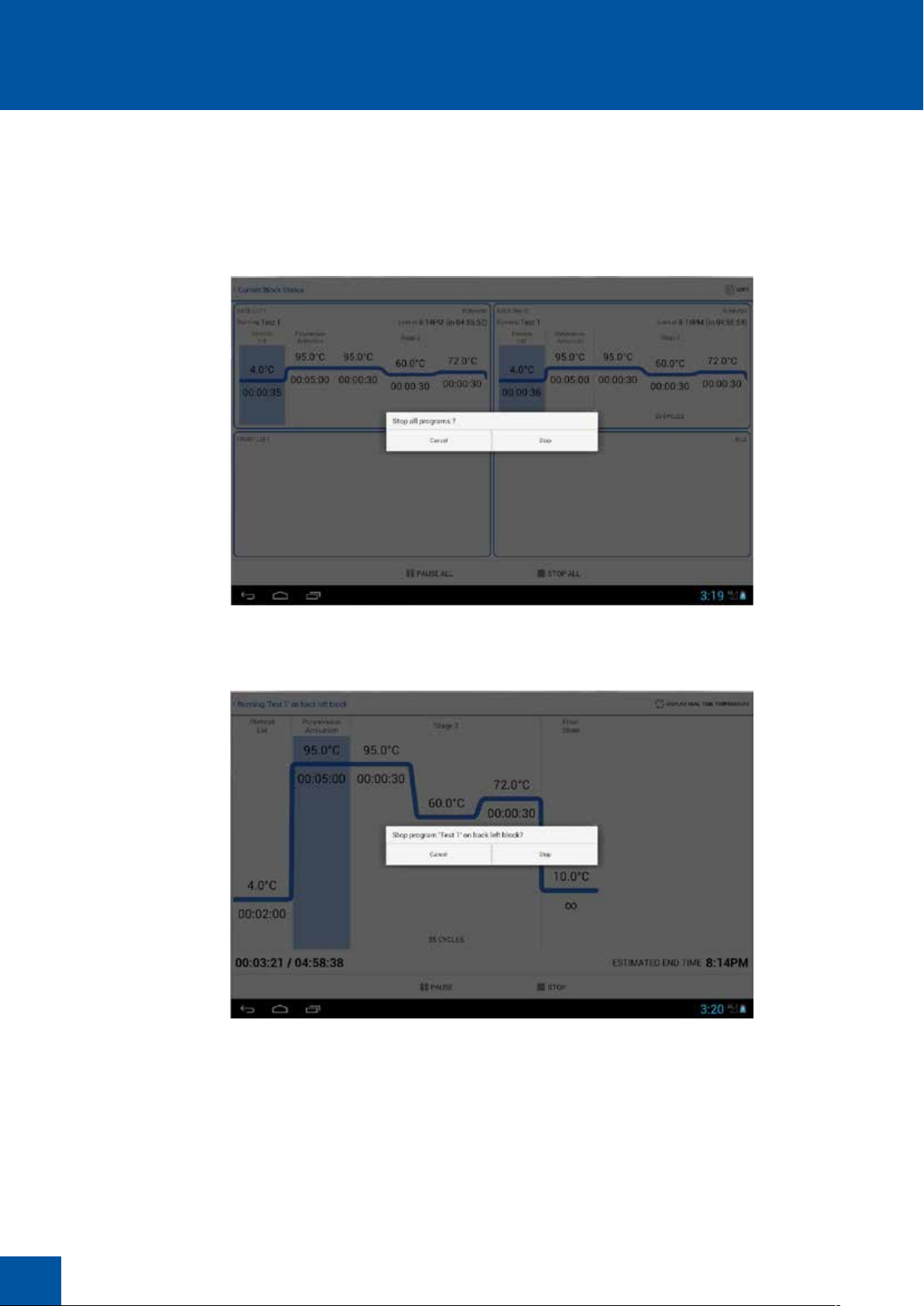

STOPPING A PROGRAM

When in the full screen display, tap STOP to stop the program. A prompt will ask you to confirm the

stop.

Note: For the AC-2 / AC-4 all active blocks can be stopped together from the block status screen.

To stop an individual program, first select the full screen display by tapping on the block area close to

program name to open up the full screen.

Alternatively, programs can be stopped from the Home Screen by tapping on the status bar. This will

open up the run screen.

48

Page 49

PAUSING A PROGRAM

A program can be paused in the same way as stopping a program. After a program has been paused, it

can be resumed by tapping on RESUME.

Note: It is possible to access all modules of the software while the unit is running a program. Simply use

the Return button or Home button at the bottom of the screen to access other areas of the software.

Program finished

When a program has completed, a Summary Report will be displayed on the screen.

• Click on OK to close the report.

Note: With the AC-2 / AC-4 a report will be presented for each individual block as each program

finishes.

49

Page 50

Using the File Manager

The File Manager is used to find and view programs and reports stored in the system memory or on an

external device such as a USB memory stick.

• To access the File Manager, tap on Edit program from the Home Screen.

• Touch PROGRAMS or REPORTS to view all those saved under the current profile (shown in the top

right of the screen).

• To view the files belonging to different profiles, tap the Profiles icon (head and shoulders of a

person) at the top right of the screen.

• Select whether to view the files available to Everyone or just the currently logged-in user.

50

Note: If a USB memory stick has been inserted into the USB port, A USB icon will also be visible at the

top right of the screen.

• To view files stored on the USB memory stick, tap on the USB icon.

SEARCH FOR A FILE

• Tap on the magnifying glass icon to enable a search for a particular program or report.

• Use the keypad to type in a keyword on which to search and then tap the magnifying glass symbol

on the keypad. Only programs or reports containing the search term will be shown.

• To cancel the search tap on the X symbol.

Page 51

REPORTS

Reports of runs performed on the Alpha Cycler are stored in the unit memory and can be accessed any

time.

• To view the report lists, from the File Manager select REPORTS.

• Select a program name. All reports for that program will be displayed in chronological order.

• Tap on a report from the list and the individual Summary Report will be displayed. Tap OK to exit.

Note: It is not possible to view the temperature log contained within the report on the Alpha Cycler

itself, it must first be copied to a USB memory stick then viewed on a PC using Excel®. The file will be

saved as a .csv file. See the directions given in the next section for copying files to a USB memory stick.