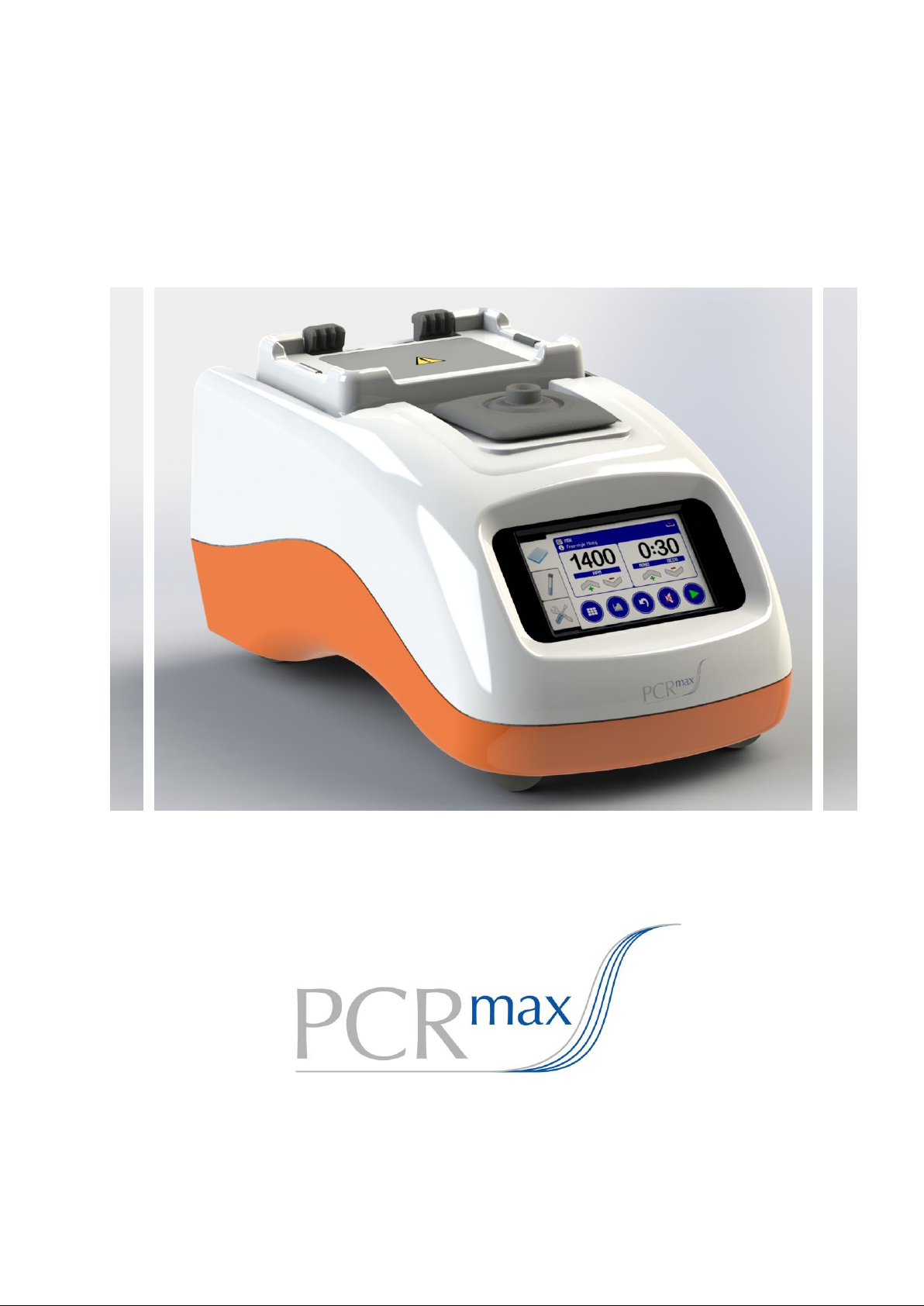

Page 1

Combination Vortex and Plate Shaker

13204-31

Instructions for Use

Page 2

Combination Shaker

Instructions for Use

2

Contents

1 Symbols Used in this Instruction Manual ......................................................... 4

2 Safety Precautions and Limitations of Use ...................................................... 5

3 Regulatory Limitations of Use .......................................................................... 9

4 Unit Description ............................................................................................. 10

5 Unit Installation .............................................................................................. 12

6 Unit Operation ................................................................................................ 13

6.1 Overview of Operating Controls ..................................................................... 13

6.2 Unit Shutdown Procedure .............................................................................. 16

6.3 Shaking Plates and Tubes ............................................................................. 17

6.3.1 Shaking with Free-style Parameters .............................................................. 18

6.3.2 Pre-defined Shaking Programs ...................................................................... 22

6.3.3 Using PCR Plates in the PCR Adapter Block (Type 1) .................................. 24

6.3.4 Using Micro Tubes in the Tube Adapter Blocks (Type 1, 2 and 3) ................ 24

6.3.5 User-defined Mixing Programs ...................................................................... 24

6.4 Vortexing Tubes ............................................................................................. 25

6.4.1 General Tube Vortexing ................................................................................. 25

6.4.2 Batch Vortexing of Tubes ................................ Error! Bookmark not defined.

6.4.3 User-defined Vortexing Programs ................................................................. 28

7 Advanced Set-up Features ............................................................................ 30

7.1 Shaker Program Tools ................................................................................... 30

7.1.1 Favorite Programs List ................................................................................... 31

7.1.2 Creating a New User-defined Program .......................................................... 32

7.1.3 Changing the Program ID, Info, Adapter Type and Parameters .................... 33

7.1.4 Deleting a User-defined Program .................................................................. 34

7.2 Profiled Mixing Programs ............................................................................... 35

7.3 Vortexer Program Tools ................................................................................. 39

7.4 User Preferences and Options ...................................................................... 40

7.4.1 Beeper and Button Click Volume ................................................................... 41

7.4.2 LCD Backlight Brightness Level .................................................................... 41

7.4.3 Cooling Fan Operating Mode ......................................................................... 41

7.4.4 Program Set-up Protection Mode .................................................................. 41

7.4.5 Vortexer Auto-start Mode ............................................................................... 42

7.4.6 Standby Mode ................................................................................................ 42

8 Maintenance and Servicing............................................................................ 43

8.1 Replacing the Unit Fuse ................................................................................ 43

8.2 Routine Cleaning and Inspection ................................................................... 44

8.3 Decontamination Procedure .......................................................................... 45

8.4 Transportation and Storage ........................................................................... 46

8.5 Product Disposal ............................................................................................ 46

9 Troubleshooting ............................................................................................. 47

10 Warranty and Returns .................................................................................... 49

11 Technical Specifications ................................................................................ 50

12 Glossary of Terms and Abbreviations ............................................................ 51

Page 3

Combination Shaker

Instructions for Use

3

Figures

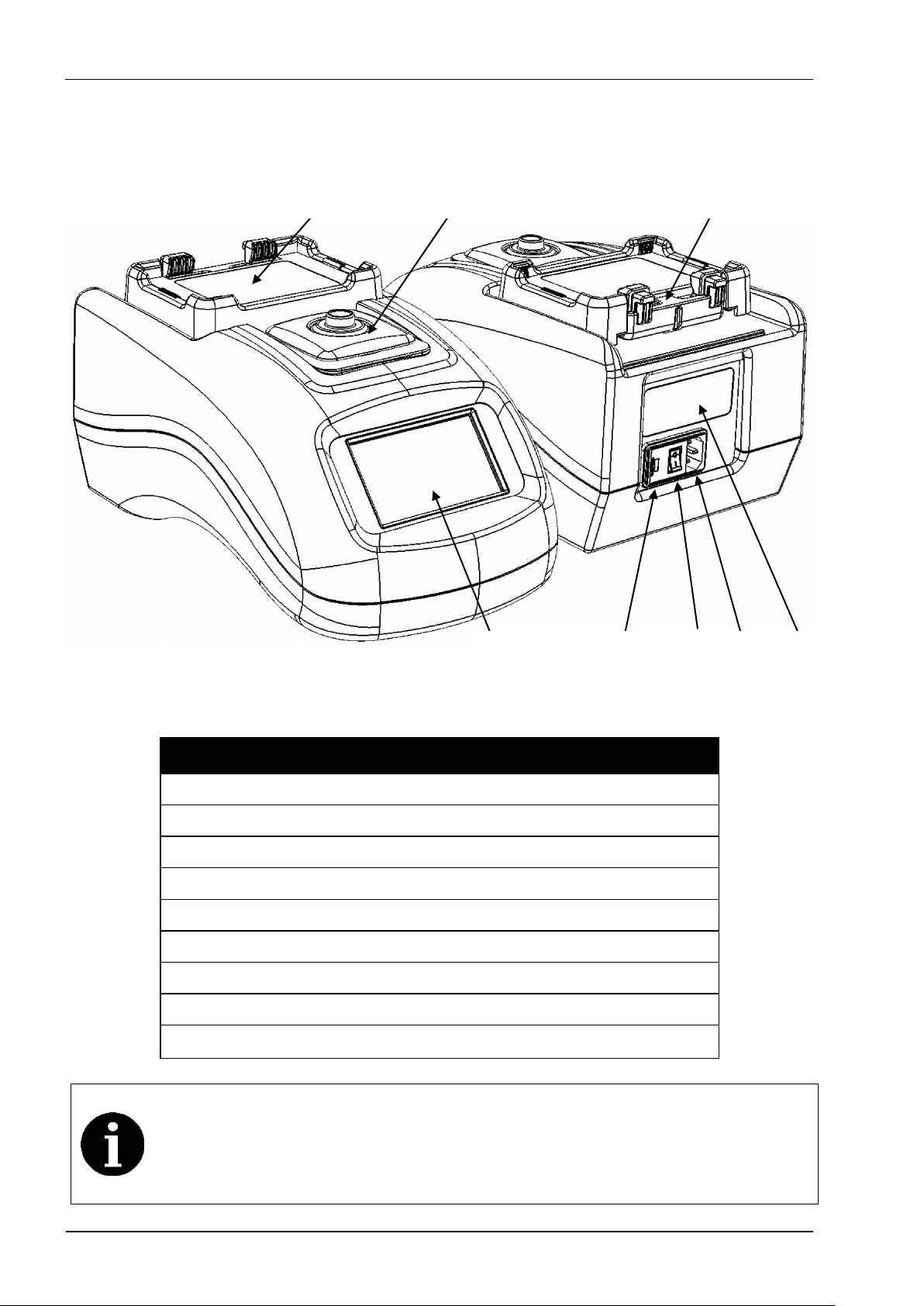

Figure 1: Front and Rear Unit Views ....................................................................... 10

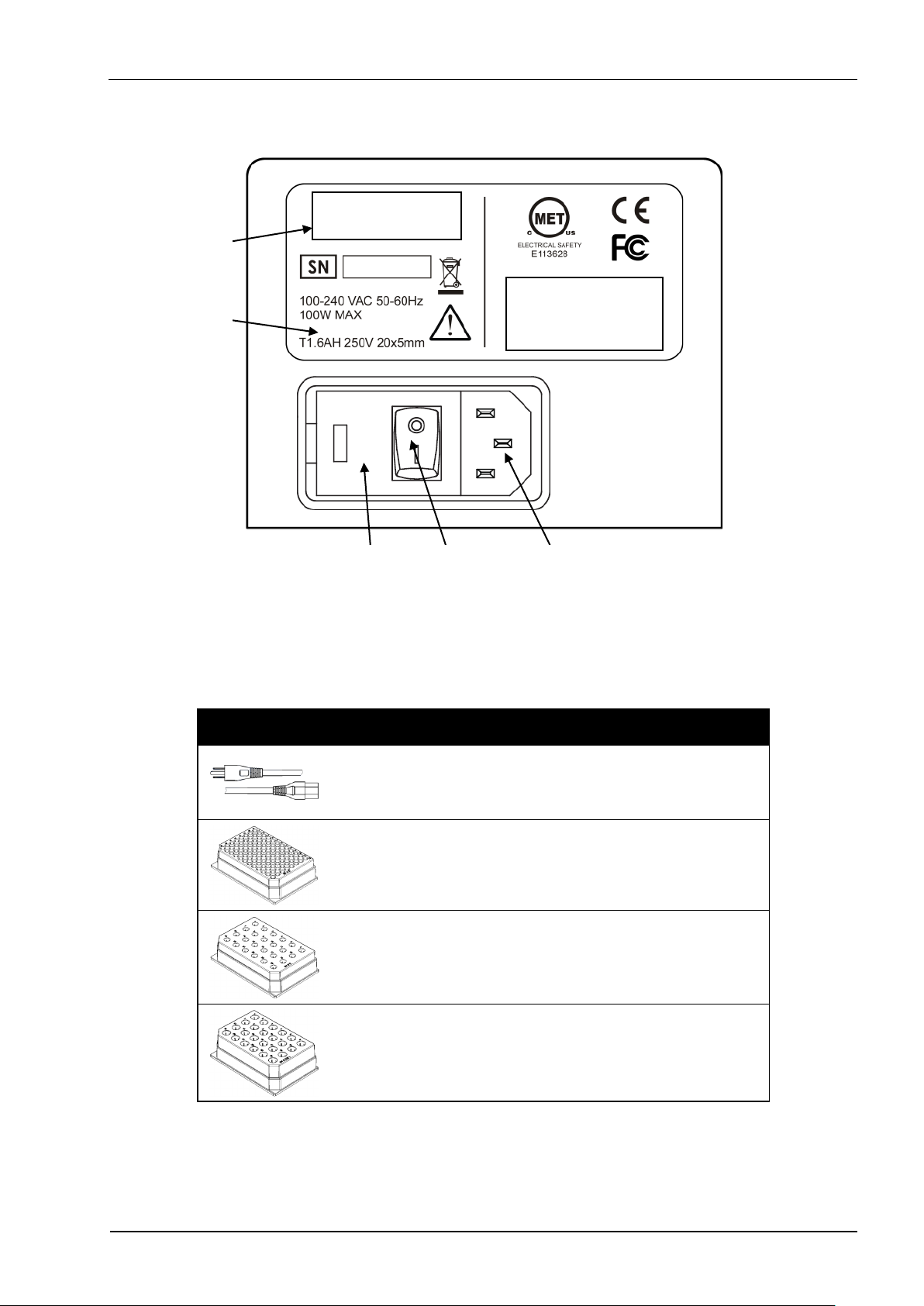

Figure 2: Unit Label and Mains Power Inlet ............................................................. 11

Tables

Table 1: Advisory Symbol Meanings.......................................................................... 4

Table 2: Key for Figure 1 and Figure 2 .................................................................... 10

Table 3: Unit Accessories ........................................................................................ 11

Table 4: Page Selection Tabs .................................................................................. 13

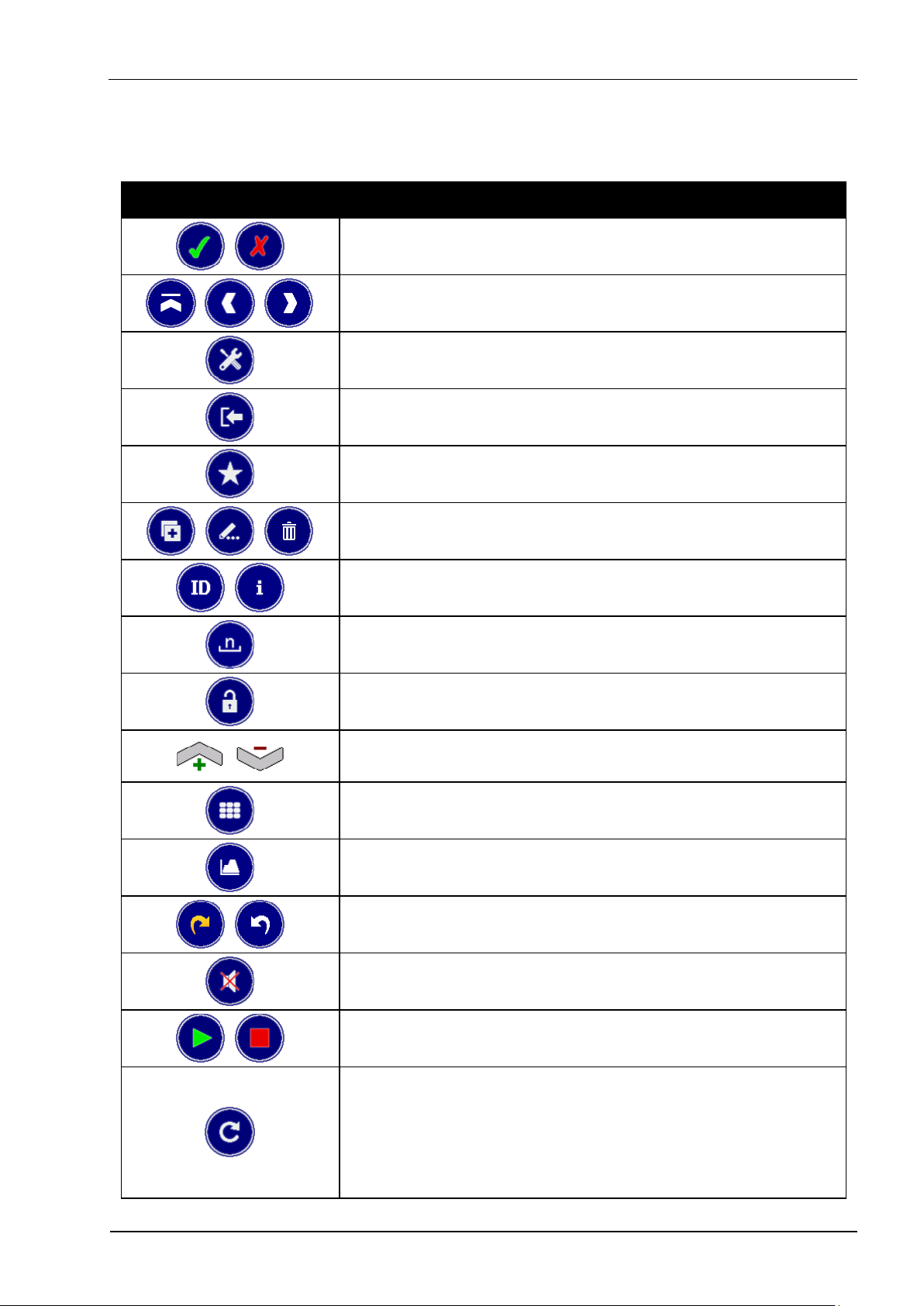

Table 5: Button Quick Reference ............................................................................. 15

Table 6: Menu Structure and Button Presses .......................................................... 16

Table 7: Supported Plate and Tube Types .............................................................. 17

Table 8: Pre-defined Mixing Programs .................................................................... 22

Table 9: Supported Vortexer Tube Types ................................................................ 25

Table 10: Program Tools Options ............................................................................ 31

Table 11: Program Editing Functions ...................................................................... 33

Table 12: Program Profile Step Parameters ............................................................ 35

Table 13: Program Profiling Functions .................................................................... 37

Table 14: Profile Editing Functions .......................................................................... 39

Table 15: User Preferences and Options ................................................................ 40

Table 16: Protected Function Buttons ..................................................................... 42

Table 17: Troubleshooting Tips ............................................................................... 47

Table 18: Unit Error Codes ...................................................................................... 48

Page 4

Combination Shaker

Instructions for Use

4

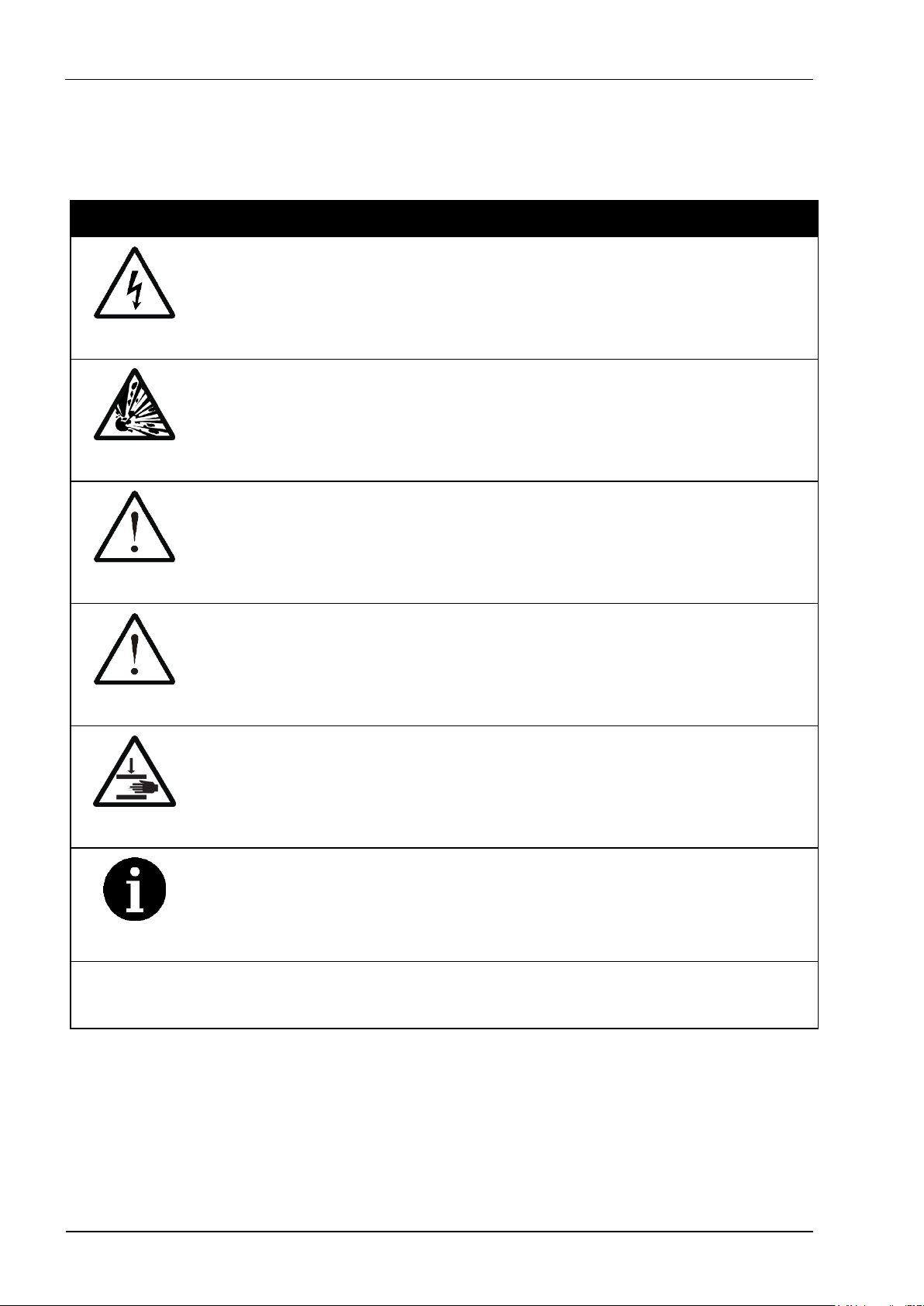

1 Symbols Used in this Instruction Manual

The following advisory symbols are used in this manual.

Table 1: Advisory Symbol Meanings

DANGER

Indicates a Risk of Electric Shock which could, if not avoided,

result in severe injury or death.

DANGER

Indicates a Risk of Explosion which could, if not avoided,

result in severe injury or death.

WARNING

Indicates a hazardous situation which could, if not avoided,

result in severe injury or death; or severely damage the unit.

CAUTION

Indicates a hazardous situation which could, if not avoided,

result in minor or moderate injury; or degrade or impair the

functionality of the unit.

CAUTION

Indicates a Risk of Crush hazard due to moving parts which

could, if not avoided, result in minor or moderate injury.

INFO

Advisory or other useful information.

NN

Refer to “section NN” for more details.

Page 5

Combination Shaker

Instructions for Use

5

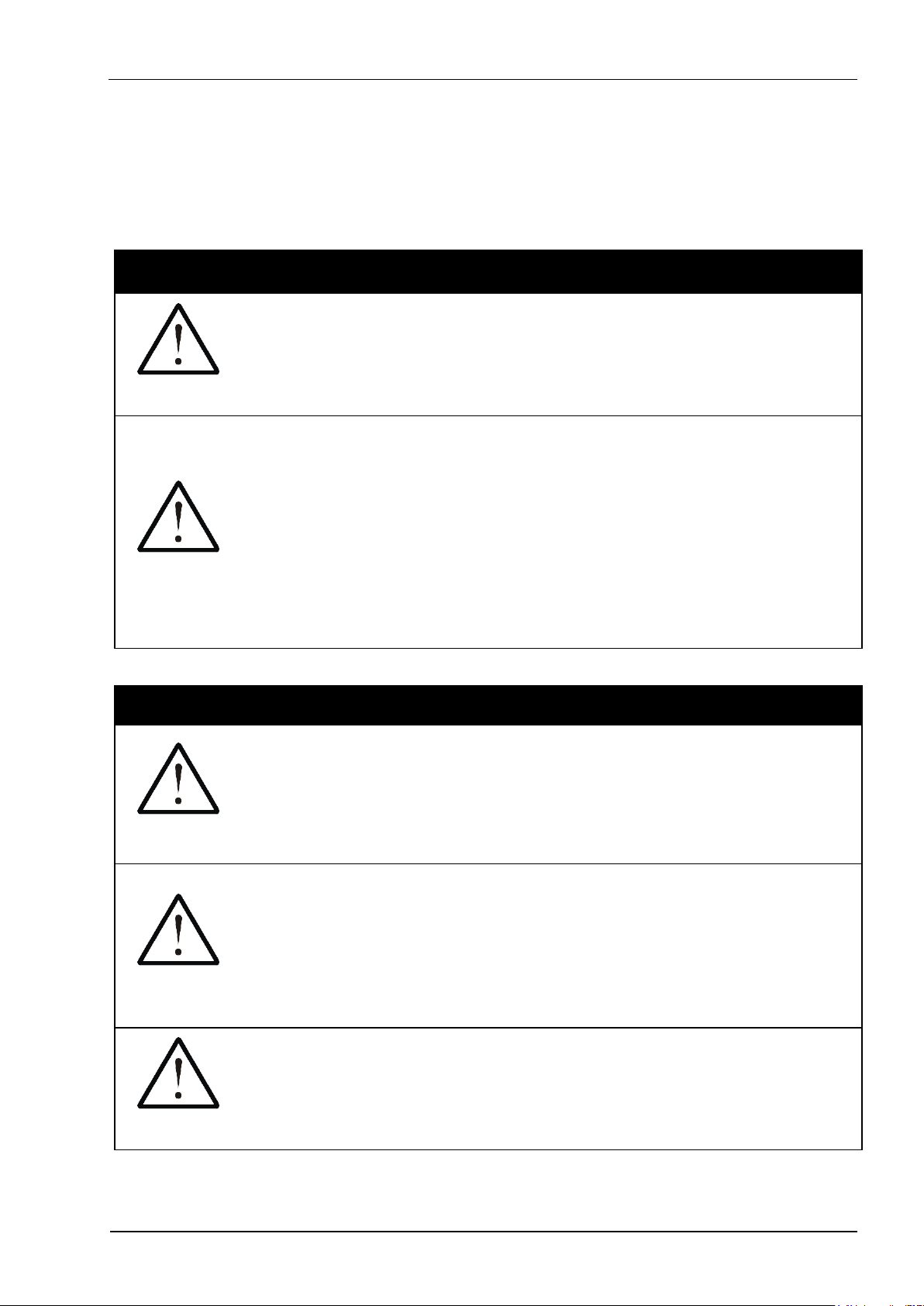

2 Safety Precautions and Limitations of Use

It is essential that all users of this equipment have fully read and understood

the following safety precautions and limitations of use before installing or

operating the Combination Shaker unit.

IMPORTANT

WARNING

The protection provided by this equipment may be impaired if

it is not used in a manner described in this manual.

WARNING

It is essential that the user of this equipment is aware of the

potential hazards associated with the unit and its accessories.

All operators should be familiar with the safety precautions

and warnings given in these instructions before attempting to

operate the unit.

Improper use of this unit or its accessories may impair their

functionality and invalidate the manufacturer’s warranty.

Unit Handling Precautions

CAUTION

Care should be taken not to drop the unit or subject it to rough

physical handling, both during normal use and during

transportation and storage.

Do not use the unit if it shows any signs of damage or wear.

WARNING

The unit should be held and supported in both hands when

lifting or moving. Do not lift the unit by the mixer or vortexer.

The base of the unit is cast from solid metal and is designed

to be heavy. Care should be taken to avoid trapping fingers

under unit when placing it down on a solid surface.

CAUTION

Care should be taken not to knock the LCD display.

Do not use excessive force when pressing the touchscreen

buttons or when cleaning it.

Page 6

Combination Shaker

Instructions for Use

6

Unit Installation and Operating Environment

DANGER

WARNING

The Combination Shaker unit is designed for indoor laboratory

use only.

The acceptable operating temperature range is 10ºC to 38ºC,

with a relative humidity of 20% to 85% non-condensing, at a

maximum altitude of 2000m above sea level.

If the unit is stored in conditions outside of these ranges, it

must be left to stand unpowered until it has acclimatised to

within these environmental limits before being powered.

DANGER

Use only the AC mains power cord provided with the unit or as

specified in section 11.

The unit must be connected to a suitably earthed mains

supply, with appropriate earth-leakage and over-current

protection.

WARNING

Always ensure that the mains power connector is securely

inserted into the rear of the unit, and any excess power cord

does not pose a potential trip or pull hazard.

DANGER

Do not operate the unit in any area which is, or has been, or is

thought to have been exposed to explosive or flammable

gases, vapours or liquids.

WARNING

The unit must be installed and operated on a solid, stable,

vibration-free and level working surface; ensuring that the

ventilation slots on the underside of the unit are not blocked.

CAUTION

The unit can create strong vibrations at high speeds which

may cause objects positioned near to it to move.

Do not place easily movable objects near the unit; or ensure

that such objects are appropriately secured.

Page 7

Combination Shaker

Instructions for Use

7

General Operating Precautions

DANGER

Ensure that the power is switched off at both the AC mains

supply outlet and at the back of the unit before inserting or

removing the mains power cord.

However, if a spillage occurs in or over the unit, always switch

the power off and unplug the power cord at the mains supply

outlet first, before attempting to deal with the spill.

DANGER

The unit is intended for use with aqueous solutions and

suspensions only.

Never use the unit to mix any explosive, volatile or highly

reactive substances or chemicals.

WARNING

To avoid liquid spills and possible cross-contamination of

samples, only use sealed plates and closed tubes when

mixing and vortexing.

WARNING

Injury can occur from flying plates and tubes if they are not

correctly inserted, or if the maximum recommended mixing

speed or total load weight is exceeded.

Always ensure that plates, adapter blocks and tubes are

correctly and securely inserted, and that plate dimensions

comply with the ANSI/SBS Standards for Microplates.

WARNING

Serious injury can occur from improper vortexing of tubes, and

tubes may be damaged, broken or destroyed.

Never vortex tubes made of glass or other fragile material.

WARNING

Injury or contamination can occur from sample material being

expelled from the plates or tubes whilst mixing and vortexing.

Only ever mix and vortex in sealed plates and closed tubes.

Always follow prescribed laboratory procedures and use

appropriate personal protective equipment (PPE, such as

gloves, clothing, goggles, etc) when handling samples.

Page 8

Combination Shaker

Instructions for Use

8

CAUTION

There is a possible finger crush hazard due to moving parts.

Do not remove or replace any consumables, tubes or Adapter

Blocks whilst the plate mixer is running.

Do not remove the vortexer pad when the unit is switched on.

Unit Maintenance and Serviceability

DANGER

WARNING

There are no user or operator serviceable parts inside the

unit.

Do not remove the unit casework.

Removal of the unit’s casework will void the manufacturer’s

warranty and may expose the user to a Risk of Electric Shock

resulting in serious injury or death.

DANGER

The externally accessible unit fuse will only blow under an

extreme internal fault condition. This fuse should only be

changed after the unit has been thoroughly inspected by a

qualified engineer. See section 8.1 for details.

DANGER

Always switch off the unit and disconnect the power cord

before performing any cleaning or decontamination procedure.

If liquid is spilt into or over the unit, switch off and disconnect

the power from the AC mains outlet before attempting to deal

with the spillage.

CAUTION

The use of harsh chemicals and cleaning agents may damage

the unit and degrade its performance.

Always follow the cleaning and decontamination procedures

specified in sections 8.2 and 8.3 of this instruction manual.

Page 9

Combination Shaker

Instructions for Use

9

3 Regulatory Limitations of Use

Declaration of Conformity

This product fulfils the essential requirements of the Low

Voltage Directive (LVD) 2006/95/EC and the EMC Directive

2004/108/EC, when installed and operated in accordance with

the instructions given in this manual.

The Combination Shaker unit has been type tested by TRaC

Global Ltd (UKAS accredited Testing Laboratory No 0026)

against the Safety and EMC Requirements listed below, and

issued Certificate Nos TRAC13SAF0012 and TRA-011466-38.

Safety and EMC Requirements

SAFETY

• EN 61010-1:2010, EN 61010-2-051:2003

• UL 61010-1:2001 2nd Edition (CAN C22.2 CSA 61010-1)

EMC

• EN 61326:2006, Class B

• FCC CFR 47 Parts 15.107 and 15.109, Class B

RoHS and WEEE Directive Compliance

This product is compliant with the requirements of the RoHS2

Directive 2011/65/EU for Electrical and Electronic Equipment.

Where applicable, the Combination Shaker unit should be

disposed of in accordance with the European Union WEEE

Directive 2002/96/EC on Waste Electrical and Electronic

Equipment.

Do not dispose of this product into unsorted municipal waste

or public landfill. Please refer to section 8.5 for details of how

to correctly dispose of this product.

The Combination Shaker unit is designed and manufactured under ISO 9001 by:

Integrated Technologies Limited

Viking House, Ellingham Way, Ashford, Kent, TN23 6NF

United Kingdom

Page 10

Combination Shaker

Instructions for Use

10

4 Unit Description

The combination vortex and shaker unit has the following features:

Figure 1: Front and Rear Unit Views

Table 2: Key for Figure 1 and Figure 2

LCD Touchscreen User Interface

6.1

Plate Shaker / Plate Holder

6.3

Plate Clamping Lever

6.3.2

Tube Vortexer

6.4

Unit Label and Serial Number

4

Mains Power Switch

5

Mains Power Inlet

5

External Fuse Access Cover

8.1

Mains Power and Fuse Ratings

11

The Combination Shaker has a unique automated plate clamping

lever () which allows plates and adapter blocks to be easily

inserted and removed from the plate holder () without disturbing

the samples.

Page 11

Combination Shaker

Instructions for Use

11

The unit label is located at the rear and provides general ratings information:

Figure 2: Unit Label and Mains Power Inlet

The unit is also supplied with the following accessories:

Table 3: Unit Accessories

Mains power cord (varies

according to country of use)

5

11

96 well PCR plate and 0.2ml tube

adapter block

6.3

6.3.3

24 well 0.5ml tube adapter block

6.3

6.3.4

24 well 1.5ml and 2.0ml tube

adapter block

6.3

6.3.4

Other optional accessories and specialty adapter blocks may be available on

request. Please contact Cole-Parmer for details.

Page 12

Combination Shaker

Instructions for Use

12

5 Unit Installation

Before installing the Combination Shaker unit, please check that the delivery

is complete (see Table 3) and that the unit and all accessory parts are intact

and free from any signs of transportation damage.

Please retain all packaging for future transportation and storage of

the unit and its accessories.

The Combination Shaker unit should be installed in a location which meets

the following requirements:

• Safe and suitable operating environment (see section 2)

• Solid, stable, vibration-free, level working surface

• At least 10cm clearance around the unit to adjacent objects and walls

• Earthed AC mains power connection (see section 11)

WARNING

Please also observe and abide by the Unit Installation and

Operating Environment safety precautions and preconditions

listed in section 2.

Install and test the Combination Shaker unit using the following procedure:

1. Place the Combination Shaker unit on the suitably selected working

surface (as specified above), ensuring that the ventilation slots on the

underside of the unit are not covered or blocked.

2. Connect the unit to the AC mains power outlet using the mains power

cord supplied (see section 4).

3. Switch the mains power on at supply outlet first, and then switch the

unit on using the power switch located at the rear of the unit.

4. Carry out a mixing test at the maximum required load and speed (using

the free-style MIX program described in section 6.3.1) to determine if

the grip between the unit and the working surface is sufficient to

prevent the unit from moving.

5. If the surface grip is sufficient, then the Combination Shaker unit should

not be moved from this installed position.

If the unit needs to be repositioned in the future, then the above installation

procedure should be repeated at the new location.

Page 13

Combination Shaker

Instructions for Use

13

6 Unit Operation

WARNING

Please ensure that you have read and fully understood all of

the Safety Precautions and Limitations of Use listed in

section 2 before attempting to operate the Combination

Shaker unit.

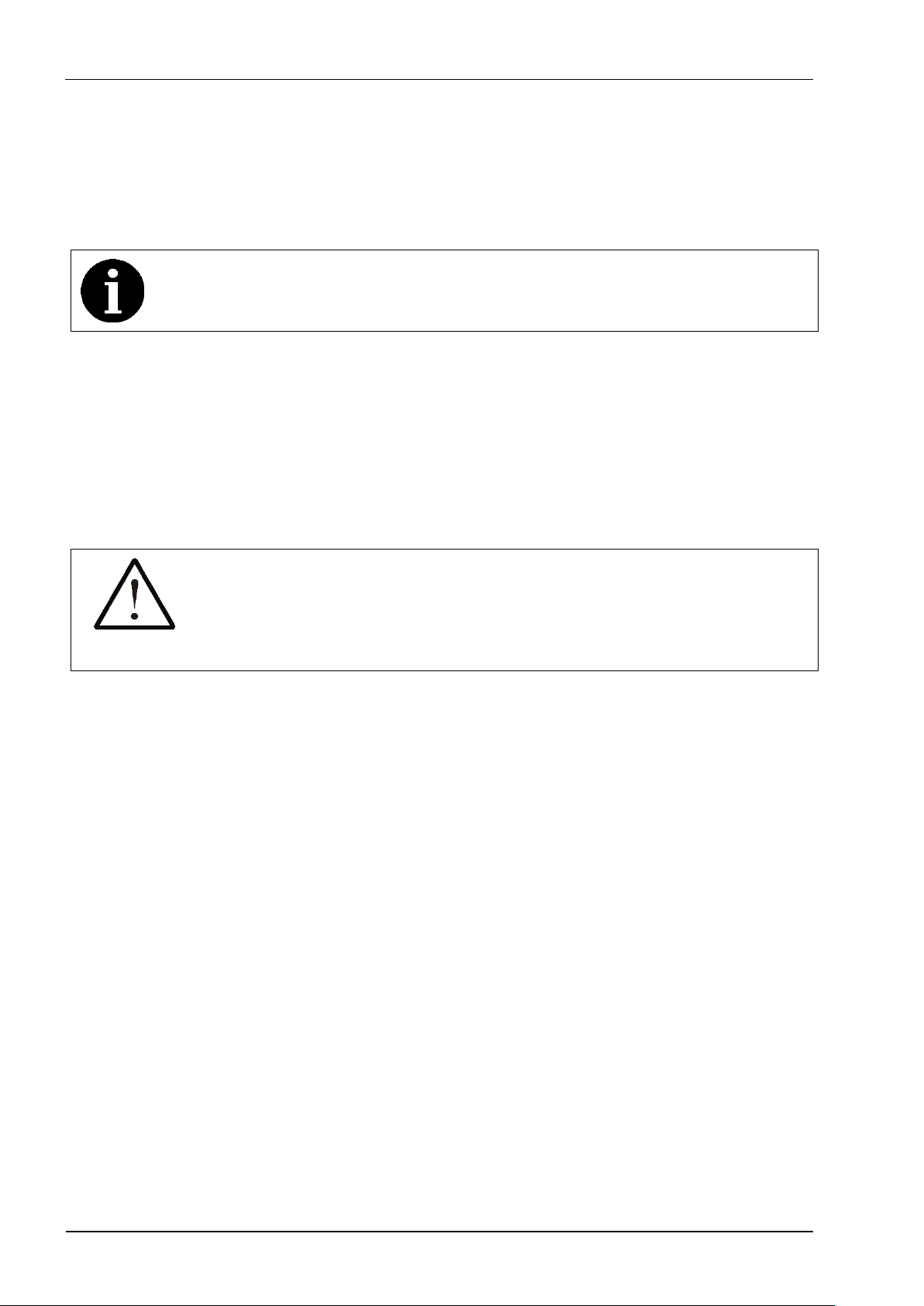

6.1 Overview of Operating Controls

The unit’s user interface consists of a color LCD touchscreen, with page

selection tabs down the left-hand side of the display and function buttons

along the bottom.

Page S

election

Tabs

Control and Status

Function and Option buttons

The Combination Shaker is designed to allow simultaneous operation of both

the plate shaker and tube vortexer, by providing easy mode switching using

the three page selection tabs shown in Table 4.

Table 4: Page Selection Tabs

Plate Shaker control and status

6.3

Tube Vortexer control and status

6.4

User Preferences and options

7.4

Page 14

Combination Shaker

Instructions for Use

14

The unit can store up to 200 shaking and vortexing programs (each with

different speed and time parameter settings) and is preloaded with eight

commonly used mixing programs.

The program selection grid on the Mixer and Vortexer pages can store up to

100 programs each, arranged as a 3x3 scrolling grid list.

Home

Previous

Next

Tools

Accept

Each program grid button shows the program’s ID and the assigned speed

and time parameters.

Program ID

Favourite

Pre-defined

Speed

Time

To load a program, use the Home button to jump to the top of the program

grid list or the Next and Previous buttons to scroll through the list to highlight

the desired program, and then press the Accept button.

The Tools button allows access to advanced program set-up functions,

including user-defined programs and profiled mixing programs.

Once the unit has been fully set-up, the program set-up functions

can be disabled to prevent accidental modifications. Refer to

section 7.4 for details.

Page 15

Combination Shaker

Instructions for Use

15

The user interface and controls are described in detail in sections 6.3, 6.4

and 7. Below is a quick reference guide to the main button functions.

Table 5: Button Quick Reference

Accept or Cancel option

Home, Previous or Next program

6.3.1

Program Tools menu

7.1

Exit to previous menu

Add/remove Favourite program

7.1.1

New, Edit or Delete program

7.1

Change program ID or Info

7.1.3

Change user program Adaptor type

7.1.3

Unlock program speed and time

7.1.3

Increase or Decrease setting

6.3.1

Show Program selection grid list

6.3.1

Mixer program Profile edit

7.2

Open or Close clamping mechanism

6.3.1

Mute audible sounder

6.3.1

Start and Stop mixing or vortexing

6.3.1

Vortexer Restart mode

Error!

Reference

source

not

found.

Page 16

Combination Shaker

Instructions for Use

16

The user preferences and set-up option buttons are detailed in section 7.4.

Page 17

Combination Shaker

Instructions for Use

17

Table 6 provides an overview of the button presses required to perform

certain common actions.

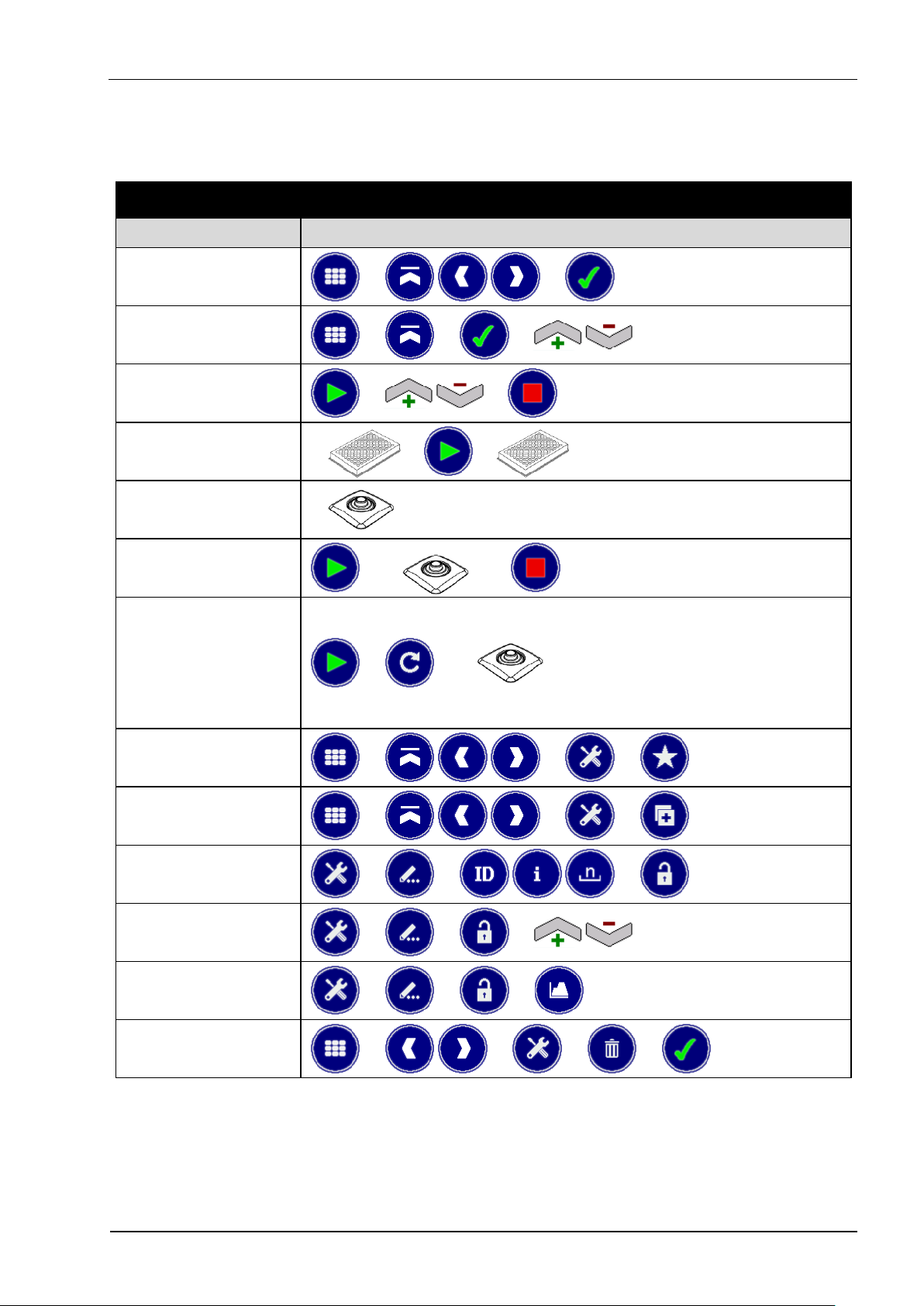

Table 6: Menu Structure and Button Presses

Action

Button Sequence

Load a

program

→ →

6.1

Load free-style

program

→ → →

6.3.1

Fine tune freestyle program

→ →

6.3.1

Plate or Tube

Shaking

→ →

6.3.1

Automatic Tube

Vortexing

6.4.1

Manual Tube

Vortexing

→

→

6.4.1

Batch Tube

Vortexing

→ →

Error!

Reference

source

not

found.

Add favorite

program

→ → →

7.1.1

Create new

program

→ → →

7.1.2

Edit user-defined

program

→ → →

7.1.3

Change program

speed and time

→ → →

7.1.3

Edit profiled

program

→ → →

7.2

Delete userdefined program

→ → → →

7.1.4

Page 18

Combination Shaker

Instructions for Use

18

6.2 Unit Shutdown Procedure

After use, and before switch off the power to the unit, ensure that any plate or

adaptor block has been removed from the mixer plate holder, and then put

the unit into standby mode as described in section 7.4.6.

Page 19

Combination Shaker

Instructions for Use

19

6.3 Shaking Plates and Tubes

The shaker is designed to handle commonly used standard sample plates

and micro test tubes, as listed in Table 7.

Table 7: Supported Plate and Tube Types

Plate or Tube Type

Plate

Holder

Adapter Block Type

PCR 0.2 ml

0.5 ml

1.5 / 2.0 ml

x 1 2

3

MTP 96 and 384 Well

✓

DWP 96 and 384 Well

✓

Fully-skirted PCR Plate

✓

Semi-skirted PCR Plate

✓

Un-skirted PCR Plate

✓

PCR 0.2 ml Tubes

✓

0.5 ml Tubes

✓

1.5 ml Tubes

✓

2.0 ml Tubes

✓

CAUTION

All plates must conform to the ANSI/SBS Standard for

Microplates to ensure secure positioning in the plate holder.

The maximum permissible mixing speed for DWPs and

Adapter Blocks, or other plates over 80g, is 2000 RPM.

The Combination Shaker has eight pre-defined programs with recommended

mixing speeds and times to support the plate and tube types listed in Table 7.

Refer to section 6.3.2 and Table 8 for details.

The unit can also store over 90 user-defined mixing programs to easily

facilitate the use of other specific plates, sample types and fill volumes. See

section 6.3.5 for details.

Other specialist adapter blocks may be available on request.

Please contact your distributor with your specific requirements.

Page 20

Combination Shaker

Instructions for Use

20

6.3.1 Shaking with Free-style Parameters

The first program in the Mixer selection grid list is always the free-style MIX

program. This is a special program which allows the user to freely change the

mixing speed and time parameters to suit their immediate needs.

The shaker speed can be set between 200 RPM and 3000 RPM, and the

time between 5 seconds and 28 days.

Home

Previous

Next

Tools

Accept

To load the MIX program, select the Mixer page tab, then press the Home

button, followed by the Accept button.

→ → →

The plate clamping mechanism will automatically open, ready to accept the

plate or adapter block to be mixed.

Refer to section 6.3.2 for the use of the plate adapter blocks and

associated pre-defined shaking programs.

Page 21

Combination Shaker

Instructions for Use

21

The display now shows the current program parameters, which can be

manually changed using the Increase and Decrease buttons below the

speed and time values. Any changes are automatically saved in memory.

Programs

Profile

Clamp

Mute

Start

For the MIX program, the Increase and Decrease buttons are

always enabled to allow the speed and time parameters to be

freely changed, even when the mixer is running.

Place the plate or adapter block vertically down into the plate holder, making

sure it is sitting flat on the base of the holder.

WARNING

Injury can occur from flying plates and tubes if they are not

correctly inserted, or if the maximum recommended mixing

speed or total load weight is exceeded (see section 6.3).

Page 22

Combination Shaker

Instructions for Use

22

DANGER

Injury or contamination may also occur from sample material

being expelled from plates or tubes whilst mixing. Always use

sealed plates and closed tubes, and wear appropriate

Personal Protective Equipment (PPE).

Next press the Start button to begin the mixing process. The plate clamping

mechanism will automatically close to firmly grip the plate or adapter block

and the specified mixing program will be run.

The shaking timer will now count down each second until it reaches zero, or

the Stop button is pressed.

Stop

NOTE

The Combination Shaker unit has a vibration sensor which detects

if the mixer becomes unstable, and automatically decreases the

mixing speed (displaying the new RPM in red) to reduce the

vibration. If there is still too much vibration, mixing is aborted and

an E25 error displayed. See Table 18 for error code descriptions.

When shaking is complete, the unit beeps three times and the plate clamping

mechanism automatically opens so that the plate or adapter block can be

easily removed without disturbing the samples.

Page 23

Combination Shaker

Instructions for Use

23

The volume of the beeps at the end of mixing process can be

adjusted from the user Preferences page (see section 7.4.1) or

temporarily disabled by pressing the Mute button.

The display will return to the previous screen, ready to accept the next plate

to be mixed.

Pressing the Programs button will close the plate clamping mechanism and

return to the mixer program selection screen.

The Clamp button can be used to manually open and close the plate

clamping mechanism if required.

↔

Open

Close

NOTE

If the plate clamping mechanism is left open for longer than

5 minutes, it automatically closes to conserve energy. It can

be re-opened by simply pressing the Clamp open button.

Page 24

Combination Shaker

Instructions for Use

24

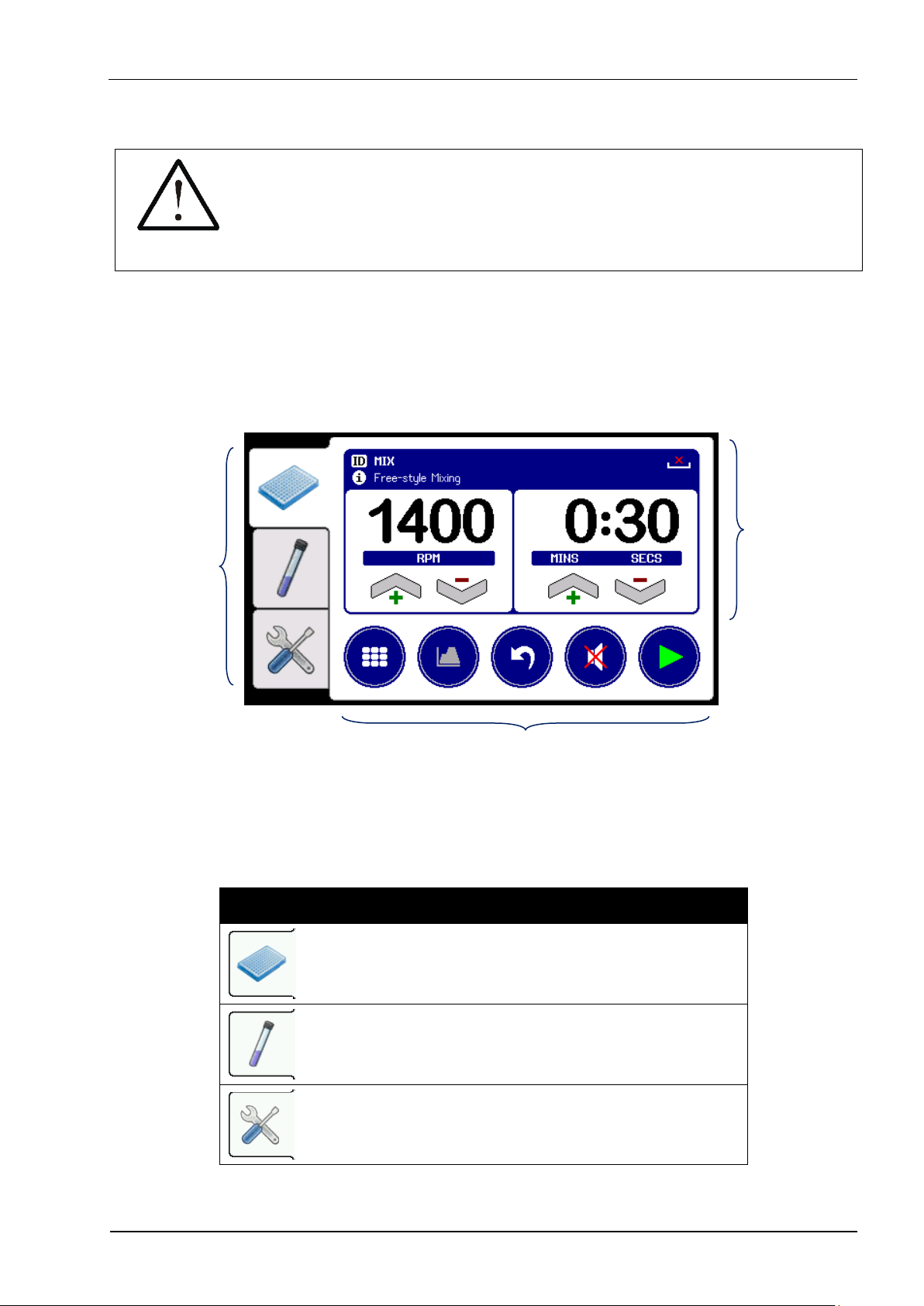

6.3.2 Pre-defined Shaking Programs

The unit has eight pre-defined shaking programs which support the

commonly used plates and micro test tubes listed in Table 7.

These programs are listed in Table 8, along with details of the pre-set

shaking speed and time parameters, the recommended well or tube fill level

and the required adaptor block type.

Table 8: Pre-defined Mixing Programs

Program

ID

Plate or Tube

Type

Speed

(RPM)

Time

(seconds)

Fill

Level

Adapter

Block

MTP-96

96 well MTP

1000

30

5 to 60%

x

DWP-96

96 well DWP

1650

30

5 to 50%

x

PCR-96

96 well PCR plate

0.2ml tubes or strips

1650

30

5 to 50%

1

MTP-384

384 well MTP

2000

15

10 to 60%

x

DWP-384

384 well DWP

2000

15

10 to 60%

x

PCR-384

384 well PCR plate

2600

15

10 to 50%

x

Micro 0.5

0.5ml micro tubes

1650

30

5 to 50%

2

Micro 1.5/2.0

1.5ml micro tubes

2.0ml micro tubes

1400

60

5 to 80%

3

Other shaking speeds and times can be selected using the freestyle MIX program (see section 6.3.1) or by creating a new userdefined program (see section 6.3.5 for details).

The procedure for shaking using a pre-defined program is similar to that

described in section 6.3.1 for the free-style MIX program.

First select the appropriate pre-defined program from the selection grid, and

then press the Accept button to load it.

→ → →

Page 25

Combination Shaker

Instructions for Use

25

The plate clamping mechanism will automatically open to accept the plate or

adapter block to be shook.

Programs

Profile

Clamp

Mute

Start

The adapter block type is displayed in the top right-hand corner of

the status area, or as ‘x’ if none is required. Refer to sections 6.3.3

and 6.3.4 for details relating to the use of specific adaptor blocks.

For pre-defined programs, the Increase, Decrease and Profile

buttons are always disabled to prevent the program parameters

from being modified. Refer to section 7.1.2 for details of creating

user-defined variants of the pre-defined programs.

Place the plate or adapter block into the plate holder, making sure it is sitting

flat on the base of the holder, and then press the Start button to close the

clamping mechanism and begin the shaking process.

The shaking timer will count down each second until it reaches zero, or the

Stop button is pressed.

When shaking is complete, the unit beeps and the plate clamping mechanism

automatically opens so that the plate or adapter block can be removed.

The display will return to the previous screen, ready to accept the next plate

to be shook, or press the Programs button to close the clamping mechanism

and return to the program selection screen.

The clamping mechanism can be manually opened or closed by pressing the

Clamp button.

Page 26

Combination Shaker

Instructions for Use

26

6.3.3 Using PCR Plates in the PCR Adapter Block (Type 1)

1. Insert the semi-skirted or unskirted PCR plate into 96 well adapter block

(see Table 7), making sure that it is level with the top of the block and that

it is securely and fully inserted.

2. Insert the adapter block into the plate holder on the unit.

6.3.4 Using Micro Tubes in the Tube Adapter Blocks (Type 1, 2 and 3)

1. Select the appropriate adapter block for the tube being used from Table 7.

2. Insert the micro test tubes into the adapter block, ensuring that they are

securely and fully pushed down in the wells.

3. Insert the adapter block into the plate holder on the unit.

4. After shaking, remove the adapter block from the unit and then remove the

micro tubes as required.

6.3.5 User-defined Shaking Programs and Profiles

The unit can store over 90 user-defined shaking programs, which can be

created by copying an existing program and then changing the program ID

and the speed and time parameters as required. See section 7.1.2 for

details.

User-defined mixing programs can also consist of a series of individually

defined program steps, each with different shaking parameters and run in

succession to produce a complex profiled mixing sequence. Refer to section

7.2 for details.

Page 27

Combination Shaker

Instructions for Use

27

6.4 Vortexing Tubes

The Combination Shaker tube vortexer is designed to operate at the same

time as the plate shaker and supports the following tube types:

Table 9: Supported Vortexer Tube Types

Tube Types

Vortexing Pad

15 ml screw top (sealed) skirted and unskirted tubes

✓

20 ml screw top (sealed) skirted and unskirted tubes

✓

50 ml screw top (sealed) skirted and unskirted tubes

✓

Micro test tubes and PCR tubes (sealed)

✓

Other generic 5 ml to 100 ml screw top plastic tubes

✓

NEVER USE: Open topped tubes

NEVER USE: Glass tubes or other fragile materials

NEVER USE: Flasks or other flat bottomed vessels

WARNING

Serious injury can occur from improper vortexing of tubes.

Never vortex open-topped tubes. Always use sealed tubes.

Never vortex tubes made of glass or other fragile materials.

Not suitable for flasks or other flat bottomed vessels.

The Combination Shaker has no specific pre-defined vortexing programs, but

instead allows up to 99 user-defined programs to be created and stored.

The vortexer speed can be set between 700 RPM and 3500 RPM, and the

time between 2 seconds and 60 seconds.

6.4.1 General Tube Vortexing

When the unit is switched on it automatically loads the most recently used

vortexing program, making it instantly ready to accept tubes.

Page 28

Combination Shaker

Instructions for Use

28

NOTE

It is not necessary to have the Vortexer page displayed for the

loaded program to run in Automatic mode - the vortexer will

operate whenever the pad is depressed. See sections Error!

Reference source not found. and 7.4.5 for details of available

vortexing modes.

Initially only the general purpose VORTEX program is available on the unit,

which allows the user to freely change the vortexing speed and time settings.

→ → →

The Vortexer page displays the current program settings, which can be

manually changed using the Increase and Decrease buttons below the

speed and time values.

Programs

Mute

Start

To vortex a tube, simply press the tube down onto the center of the vortexer

pad and vortexing will automatically start at the programmed speed.

The timer will count down each second, and vortexing automatically stops

when the timer reaches zero or the tube is removed from the pad.

Page 29

Combination Shaker

Instructions for Use

29

NOTE

The Combination Shaker unit has a vibration sensor which detects

if the mixer or vortexer has become unstable. If vortexing

generates too much vibration it will be automatically stopped and

an E35 error will be displayed. See Table 18 for error code

descriptions.

Alternatively, the Start button can be pressed to manually set the vortexer

running until either the timer reaches zero or the Stop button is pressed.

The speed can be adjusted whilst the vortexer is running to optimize the

vortexing performance depending on the tube type, and sample type and

volume being used.

When the optimum speed and time parameters have been found

using the VORTEX program, a new user-defined program can be

created to store these settings, and then quickly reloaded when

next required. See sections 6.4.2 and 7.3 for details.

The unit clicks once to acknowledge when the tube has been pressed onto

the vortexer pad, and beeps once when the programmed time has elapsed.

The volume of the click and beep at the start and end of vortexing

can be adjusted from the user Preferences page (see section

7.4.1) or temporarily disabled by pressing the Mute button.

When processing large batches of tubes, it can be desirable to set the

vortexer running and then apply each tube in rapid succession. This is done

by first loading the appropriate vortexing program, then pressing the Start

button to set the vortexer running, and then the Restart button.

→ → → →

Page 30

Combination Shaker

Instructions for Use

30

Restart

Stop

The Restart button illuminates and the timer starts counting upwards from

zero instead. Now, each time a tube is pressed onto the vortexer pad (or the

Restart button is pressed) the timer will reset back to zero.

When the programmed time is reached the unit beeps once to indicate that

the tube can be removed. However, instead of stopping immediately, the

vortexer runs-on for a further 5 seconds (with the time displayed in red),

allowing extra time for the next tube to be placed on the vortexer.

TIP

Press the tube firmly down onto the vortexer pad to reset the timer,

then relax the tube pressure so that there is still sufficient contact

with the pad to maintain the vortexing action but without being

unduly strenuous on the user.

If desired, this mode can be permanently enabled for all vorexting

programs by selecting the vortexer auto-Restart mode in the user

Preferences page. See section 7.4.5 for details.

6.4.2 User-defined Vortexing Programs

The unit can store up to 99 user-defined vortexing programs, each of which

can be tailored to suit different tube types, sample solutions and fill volumes.

To define a new program, first determining the optimum vortexing parameters

using the general VORTEX program (see section 6.4.1).

→ → → →

→ →

→

Page 31

Combination Shaker

Instructions for Use

31

Then create a copy of these settings with a new program ID (see section

7.1.2 for details).

→ → → →

Program ID

→

The new program is now ready to be used whenever next required.

Page 32

Combination Shaker

Instructions for Use

32

7 Advanced Set-up Features

The Combination Shaker unit also provides a number of advanced features

which allow the user to optimise the unit’s performance to meet their

individual needs.

7.1 Shaker Program Tools

As well as the pre-defined shaking programs, the user can create variants of

the existing ones. This allows new programs to be developed and optimised

for the specific plate type, sample assay and fill volume being used.

Home

Previous

Next

Tools

Accept

From the Mixer program selection screen, highlight the program to be copied

or modified and then press the Tools button.

Exit

Favorite

New

Edit

Delete

The tools menu options are summarized in Table 10 and explained in detail

in the following sub-sections.

Page 33

Combination Shaker

Instructions for Use

33

Table 10: Program Tools Options

Exit to program selection screen

Add/remove program from Favorite list

7.1.1

Create a New copy of the selected program

7.1.2

Edit selected program details and parameters

7.1.3

Delete the selected program

7.1.4

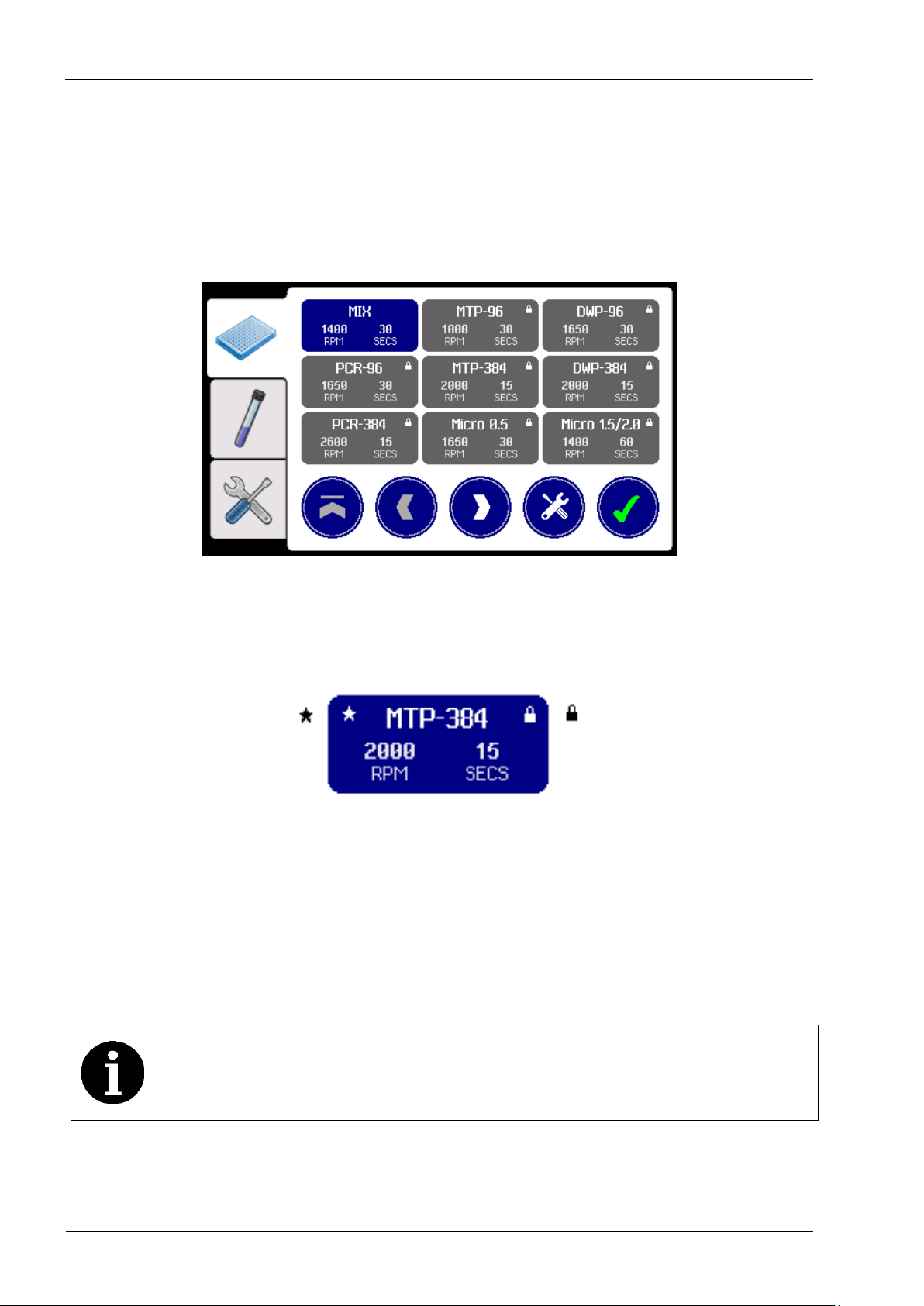

7.1.1 Favorite Programs List

Although the programs list can hold up to 100 pre-defined and user-defined

programs, typically only a small number of these will be regularly used.

Thus, to help organise the full list, preferred programs can be added to a

favorites list, which always appears at the top of the program selection list.

To add a program to the favorites list, simply highlight it in the selection grid,

press the Tools button and then the Favorite button. The program is marked

with a symbol in the top corner and moved to the top of the list.

A program can be removed from the favorites list by repeating this process.

The order of the programs within the favorites list is determined by

the order in which they were created and cannot be individually

rearranged.

Page 34

Combination Shaker

Instructions for Use

34

7.1.2 Creating a New User-defined Program

The unit can hold up to 100 shaking programs, 91 of which can be created

and defined by the user.

To add a new program, highlight an existing program from the selection list

which best matches the new program requirements, then press the Tools

button followed by the New button.

→ → →

The New button is unavailable when Protected mode is enabled.

See selection 7.4.4 for details.

This will create a new copy of the selected program and pop-up the program

ID editing keyboard:

Shift

Delete

Cancel

Left

Right

Accept

Use the QWERTY keyboard to enter a new name (ID) for the program, then

press the Accept button.

Try to limit the program ID to about 10 characters, as longer

names are displayed truncated in the program selection grid.

The new program has now been created and saved to memory, and can be

further modified using the editing functions described in section 7.1.3.

Page 35

Combination Shaker

Instructions for Use

35

7.1.3 Changing the Program ID, Info, Adapter Type and Parameters

To modify an existing user-defined program, highlight the program in the

selection grid, then press the Tools button followed by the Edit button.

→ → →

The Edit button is unavailable when Protected mode is enabled.

See selection 7.4.4 for details.

The Edit menu provides four top-level program editing functions.

Exit

ID

Info

Adapter

Unlock

These editing functions allow the program ID, Info text and associated

Adaptor block type to be changed, as described in Table 11.

Table 11: Program Editing Functions

Exit program editing menu

Edit the program ID using QWERTY keyboard,

which can be between 1 and 20 characters long

7.1.2

Edit the optional program Info text, which can be

up to 50 characters

Change the Adapter block type, by stepping

through the block types: ‘x’ (none) then 1 to 9

6.3

Unlock the program to allow the speed and time

settings to be changed or a profile to be defined

7.2

Page 36

Combination Shaker

Instructions for Use

36

Pressing the Unlock button enables the speed and time Increase and

Decrease buttons, and the program Profile editor button.

Programs

Profile

Clamp

Mute

Start

Once Unlocked, the Increase and Decrease buttons can be used whilst the

shaker is running to fine tune the mixing performance for the particular plate

type, sample solution and fill volume being used. Any changes to these

parameters are automatically saved to memory for next time.

Pressing the Profile button brings up the advanced program profiling menu,

which allows a sequence of up to 20 mixing parameter steps (speeds and

times) to be defined. Refer to section 7.2 for details.

7.1.4 Deleting a User-defined Program

To permanently delete a user-defined program, highlight the program in the

selection grid, then press the Tools button followed by the Delete button.

→ → →

The Delete button is unavailable when Protected mode is

enabled. See selection 7.4.4 for details.

Page 37

Combination Shaker

Instructions for Use

37

Cancel

Accept

Next press the Accept button to confirm the deletion, or Cancel to exit.

7.2 Profiled Shaking Programs

The Combination Shaker can store up to 91 user-defined mixing programs,

each of which can consist of a sequence of up to 20 individual mixing steps.

For each mixing step, the user can specify the following parameters:

Table 12: Program Profile Step Parameters

Parameter

Purpose

Range

RPM

Mixing speed *Automatically limited to 2000 RPM

when the program specifies the use of an adapter block

200 to 3000*

RPM

TIME

Mixing step duration specified in days,

hours, minutes and/or seconds

5 seconds

to 28 days

RAMP

Time allowed to smoothly transition between

the previous speed and the new RPM value

0 to 99

seconds

Hence, an example profiled program could consist of the following three

steps:

1) 1000 RPM, 30 seconds, 5 second ramp

2) 2000 RPM, 60 seconds, 10 second ramp

3) 1600 RPM, 5 minutes, 5 second ramp

Page 38

Combination Shaker

Instructions for Use

38

When the program is run, the unit executes each profile step in the sequence

in turn, showing the overall progress on the profile chart.

For profiled programs, the speed and time cannot be adjusted

using the Increase and Decrease buttons. These parameters can

only be altered via the Profile button.

To create a new profiled program, first create a new program as described in

section 7.1.2 above.

Then from the program Tools menu, press the Edit button followed by the

Unlock button to enable the Profile button, and then press the Profile button

to display the profile editing screen.

→ → → → →

Exit

Up

Down

Modify

Switch

Page 39

Combination Shaker

Instructions for Use

39

The Profile button accesses the profile editing menu, which consists of two

sets of function buttons:

Set 1

Set 2

Exit

Up

Down

Modify

Switch

Cut

Copy

Paste

Test

These button functions are described in Table 13.

Table 13: Program Profiling Functions

Set 1

Exit profile editing menu

Move profile step cursor Up one line

Move profile step cursor Down one line

Modify profile step parameters at cursor position

Switch to menu functions Set 2

Set 2

Switch back to menu functions Set 1

Cut and remove profile step at cursor position

Copy profile step at cursor position

Paste cut/copied profile step above cursor position

Test run mixer profile step at cursor position

Press the Modify button to change the profile step parameters (listed in

Table 12), using the numeric keypad to enter each new value followed by the

Accept button.

Page 40

Combination Shaker

Instructions for Use

40

The Accept button is also used to skip over unmodified values. For instance,

to change just the RPM, MINS and SECS values:

1) Enter the new RPM value followed by Accept

2) Press the Accept button twice (skips DAYS and HRS)

3) Enter the new MINS value followed by Accept

4) Enter the new SECS value followed by Accept

5) Press Accept again (skips RAMP)

When all six values had been accepted, the new settings are saved and the

display returns to the previous profile editing screen.

To enter a new step at the end of the sequence, move the cursor Down to

the empty “...” line and press the Modify button. Enter the new step

parameters as required, and then press the Accept button until all six values

have been set.

Repeat this process for up to 20 profiles steps.

Page 41

Combination Shaker

Instructions for Use

41

The Cut, Copy and Paste functions can be used to delete, move and

duplicate profile steps, as illustrated in Table 14.

Table 14: Profile Editing Functions

Desired Action

Button Sequence

Modify step parameters at current cursor position

Modify

Add a new step at end of list

Down..., Modify

Delete step at cursor position

Cut

Move step at cursor to before new cursor position

Cut, Up/Down, Paste

Duplicate step at cursor position

Copy, Paste

Insert duplicate step before new cursor position

Copy, Up/Down, Paste

Insert new step before cursor position

Copy, Paste, Modify

7.3 Vortexer Program Tools

The Combination Shaker can store up to 99 user-defined vortexing programs,

allowing specific programs to be developed and optimized for different tube

types, sample solutions and fill volumes, as required.

Home

Previous

Next

Tools

Accept

The vortexer program Tools menu provides the same functions as the

shaker (Favorite, New, Edit and Delete), as described in section 7.1 and

listed in Table 10.

The Edit button allows user-defined vortexing programs to be modified via

the ID, Info and Unlock buttons, as described in section 7.1.3 and Table 11

(with the exception that there is no Adapter setting for the vortexer).

Likewise, the Unlock button enables the vortexing program speed and time

parameters to be changed via the Increase and Decrease buttons.

Page 42

Combination Shaker

Instructions for Use

42

7.4 User Preferences and Options

The user Preferences page provides several options for customizing the

unit’s behaviour, and shows the current settings state.

The available options are shown in Table 15 and described in the more detail

in the following sub-sections.

Table 15: User Preferences and Options

Beeper volume

Muted

Low

Medium

High

7.4.1

Touchscreen button

click volume

Disabled

Quiet

Loud

7.4.1

LCD backlight

brightness level

Dim

Normal

Bright

7.4.2

Cooling fan

operating mode

Off

Automatic

Continuous

7.4.3

Program set-up

protection mode

Disabled

Protected

7.4.4

Vortexer auto-start

mode

Manual

Automatic

Restart

7.4.5

Standby mode

Standby

7.4.6

Page 43

Combination Shaker

Instructions for Use

43

To change a setting, press the associated option button, then select the new

value, and press the Accept button to save the new setting.

Cancel

Accept

7.4.1 Beeper and Button Click Volume

The beeper is sounded at the end of each shaking or vortexing operation.

This volume can be adjusted to suit the ambient sound conditions, or muted.

The touchscreen button click volume can also be independently set or

permanently Disabled.

7.4.2 LCD Backlight Brightness Level

The LCD backlight brightness can be adjusted to suit different lighting

conditions.

7.4.3 Cooling Fan Operating Mode

The unit’s internal cooling fan draws air in from around the plate holder and

gently blows warm air out of the ventilation slots in the base of the unit.

It is recommended that the mode is set to Automatic, which operates the fan

only when required. However, if the unit is being used in a temperaturecontrolled chamber, it may be desirable to ensure consistent airflow by

setting the cooling fan to run Continuous or turning it Off completely.

7.4.4 Program Set-up Protection Mode

By default, the user is able to access all features and functions of the unit.

However, once the unit has been installed and fully set-up, it may be

desirable to disable these programming functions to protect against

accidental modification.

Page 44

Combination Shaker

Instructions for Use

44

Enabling Protected mode hides the following function buttons:

Table 16: Protected Function Buttons

New, Edit, Delete

Unlock, Profile

Modify, Cut, Copy , Paste

To regain access to these functions, simply Disable protected mode again.

7.4.5 Vortexer Auto-start Mode

Initially the vortexer is configured to Automatically start when the vortexer

pad is depressed, and stop when it is released. Alternatively, this feature can

be disabled for Manual start/stop operation.

If processing large batches of tubes, it may be desirable for the vortexer to

run-on after the tube has been removed. This auto-Restart mode can be

permanently enabled for all vortexer programs by using this set-up option; or

temporarily using the Restart button described in section Error! Reference

source not found..

7.4.6 Standby Mode

Before turning off the unit, it is recommended to put it into standby mode by

first removing any plate or adaptor block from the plate holder, and then

selecting the Standby option and pressing the Accept button.

→ → → →

Turn Power Off

NOTE

When the power to the unit is switched off or disconnected, the

LCD may remain illuminated for up to 5 seconds before going

blank.

Page 45

Combination Shaker

Instructions for Use

45

8 Maintenance and Servicing

Although the Combination Shaker unit does not require any scheduled

servicing, the operator should regularly clean the unit and inspect it for any

defects, as described in section 8.2 below.

DANGER

WARNING

Please observe and comply with all of the Unit Maintenance

and Serviceability precautions listed in section 2.

Never removed the unit casework. There are no user or

operator serviceable parts inside the unit.

Always switch off and unplug the unit before performing any

cleaning or disinfecting tasks.

For technical and service related inquiries, please contact Cole-Parmer.

8.1 Replacing the Unit Fuse

The unit fuse should only be replaced by a suitably qualified engineer.

DANGER

The unit fuse will only blow as a result of an internal unit fault.

This fuse should only be changed after the unit has been

thoroughly inspected by a qualified engineer, and must be

replaced with the exact type specified in section 11.

Thoroughly inspect the unit for any signs of damage, loose components or

liquid spillage or ingress. If in doubt, please contact Cole-Parmer.

DANGER

The fuse holder is removed by disconnecting the mains power

cord and then using a flat bladed screwdriver to carefully pry

open the fuse access cover and ease out the fuse holder.

After replacing the fuse with an identically rated fuse (see

section 11), push the fuse holder firmly back into the inlet

module and close the access cover.

The unit must be electrically safety tested for excess leakage

current before being repowered from the mains supply.

Page 46

Combination Shaker

Instructions for Use

46

8.2 Routine Cleaning and Inspection

The unit casework should be cleaned and inspected at regular intervals, or

whenever contamination or spillage occurs, as follows:

1. Switch off the unit and disconnect the power cord before performing

any inspection checks or cleaning.

2. Before cleaning, always inspect the unit casework, plate holder and

rubber pads for any signs of wear, damage, cracks or other defects.

3. Wearing suitable PPE, clean the exterior casework using a damp

cloth or cotton bud soaked with a mild detergent or disinfectant

solution (such as Virkon®).

4. Clean the plate holder, paying particular attention to the inner mating

surfaces and the rubber pads of the holder and clamping

mechanism.

5. Remove any debris or fluff from around or between the moving parts

of the plate clamping mechanism.

6. Clean around the gap between the plate holder and casework to

remove any build-up of debris – avoiding pushing it into the unit.

7. Clean along the spill gutter strip at the rear of the unit.

8. Clean the vortexer pad and check there is no debris accumulating

between the pad and the casework. If need be, the vortexer pad can

be removed for cleaning by pulling it off in an upwards motion.

9. Check that the vortexer pad is evenly and firmly pushed down.

10. Clean around the LCD fascia and touchscreen, taking care to avoid

over wetting or pushing debris into bezel gap.

11. Check that the ventilation slots on the base of the unit are clear of

dust and fluff build-up.

12. Check and clean the adapter blocks. Replace the block if it becomes

damaged or no longer tightly grips the tubes.

DANGER

After cleaning, ensure that the unit is thoroughly dry,

especially around the mains power inlet, before reconnecting

the power cord and switching the unit on.

Do not operate the unit is it shows any signs of damage or

excessive wear.

Page 47

Combination Shaker

Instructions for Use

47

8.3 Decontamination Procedure

The unit and accessories should be decontaminated using the following

procedure before being stored or transported.

Certificate of Decontamination

We respect the health and safety of our clients and employees, and request

that any products or accessories being returned are decontaminated in

accordance with the procedure below.

1. Decontamination Procedure

Thoroughly clean all outside surfaces of the product (including any

accessories, power cords, manuals, packaging, etc) with a damp cloth

soaked with suitable disinfectant solution (such as Virkon).

Allow to dry fully before packing.

2. Decontamination Declaration

Company Name:

Address:

Product Code:

13204-31

Serial Number:

Reason For Return:

Where Product Used:

Please tick the appropriate option(s) below:

I certify that I have decontaminated the product as per the above procedure.

Decontaminant Used:

I certify that the product has not been exposed to any chemical or biological materials.

Title:

Name:

Signature:

Date:

Telephone:

Email:

Page 48

Combination Shaker

Instructions for Use

48

8.4 Transportation and Storage

The Combination Shaker unit and its accessories should be thoroughly

decontaminated using the procedure detailed in section 8.3 before being

placed in its original packaging for transportation or storage.

WARNING

Refer to section 11 for the acceptable range of Storage and

Transportation environmental conditions.

Always ensure that the unit and accessories are completely

dry and free of any condensation before being packed.

8.5 Product Disposal

At end-of-life, this product must be disposed of in accordance with your local

authority regulations for the disposal of potentially hazardous waste and

electronic equipment.

The unit and its accessories should be decontaminated using the procedure

detailed in section 8.3 before disposal or shipping.

Do not dispose of this product into unsorted municipal waste

or public landfill.

Please contact Cole-Parmer for details of how to correctly dispose of this

product.

Page 49

Combination Shaker

Instructions for Use

49

9 Troubleshooting

For technical enquiries, please contact Cole-Parmer

Table 17: Troubleshooting Tips

Unit Will Not Turn On

No power → Check power is switched on at wall outlet socket and rear of unit

5

Bad connection → Ensure power connector fully inserted into rear of unit

5

Unit fuse blown → Consult a qualified engineer

8.1

Unit Spuriously Resets or Restarts Automatically

Power connecter loose → Ensure connecter fully inserted at rear of unit

5

Supply brown-outs or black-outs → Power unit from a stable AC mains supply

11

Shaker Not Gripping Plate

Plate holder rubber pads dirty or worn → Inspect and clean pads

8.2

Shaker Will Not Run at Required Speed...

Unstable working surface → Ensure installed on solid, stable, level working surface

5

Load too heavy → Observe mixing restrictions listed in Table 7 and Table 8

6.3

Shaking Ineffective or Not As Expected

Shaking speed too slow → Increase mixing speed for optimum performance

6.3.1

Shaking time too short → Increase mixing time to ensure adequate mixing

6.3.1

Lid wetting or sample leakage → Reduce shaking speed or fill volume

6.3

Vortexer Does Not Operate When Pad Is Depressed

Vortexing program not loaded → Select and load appropriate vortexing program

6.4

Vortexer auto-start mode not enabled → Set vortexing mode to Auto or Restart

7.4.5

Vortexer pad worn or deformed → Replace vortexing pad

8.2

Vortexing Fails to Re-suspend Solutions

Vortexing speed too slow → Increase vortexing speed for optimum performance

6.4.1

Vortexing time too short → Increase vortexing time

6.4.1

Vortexer pad slippery or worn → Clean or replace vortexer pad

8.2

Insufficient contact pressure between tube and vortexer pad → Use Restart mode

Error!

Referen

ce

source

not

found.

Unsuitable tube type or shape → Refer to Table 9 for suggested tube types

6.4

Vortexer Stops Unexpectedly When Running

Page 50

Combination Shaker

Instructions for Use

50

Insufficient contact pressure between tube and vortexer pad → Use Restart mode

Error!

Referen

ce

source

not

found.

Inappropriate tube type being used → Refer to Table 9 for suggested tube types

6.4

Vortexer Starts Without Pad Being Depressed

Vortexer pad worn or deformed → Replace vortexing pad or use Manual mode

7.4.5

If the software detects a problem with the unit, it displays the following error

popup showing one of the error codes listed in Table 18.

If the problem persists, please contact Cole-Parmer for assistance, quoting

the error code and the 20-digit report code.

Table 18: Unit Error Codes

Code

Meaning

Suggested Remedy

E10

User Preferences

not set

Review option settings and adjust as

required

7.4

E20

E21

E22

Shaker

mechanism fault

Contact distributor for further

assistance

8

E23

E24

Shaker

overloaded or

jammed

Switch off unit and inspect plate

holder for obstructions

8.2

E25

Shaking load

unbalanced

Ensure unit correctly installed on

solid working surface

5

Ensure maximum speed and load

weight limits are observed

11

E30

E31

E32

Vortexer

mechanism fault

Contact distributor for further

assistance

8

Page 51

Combination Shaker

Instructions for Use

51

E33

E34

Vortexer

overloaded or

jammed

Switch off unit, remove vortexer pad

and inspect for any obstructions or

pad wear

8.2

E35

Vortexing too

unsteady

Check unit installation and vortexer

usage

6.4

E40

Plate clamping

mechanism fault

Contact distributor for further

assistance

8

All

others

Internal unit fault

Contact distributor for further

assistance

8

Page 52

Combination Shaker

Instructions for Use

52

10 Warranty and Returns

Cole-Parmer warrants the Combination Shaker with the instructions of this

manual, to be free from defects in materials and workmanship, and will repair

or replace, at their discretion, any unit or accessory which exhibits such

defects.

In no event will Cole-Parmer be liable for any indirect, incidental or

consequential damages resulting from any defect or warranty claim.

This warranty is provided to the original purchaser of the product for one year

from the date of purchase.

Under the terms of this warranty, the product must be returned in its original

packaging, transportation prepaid by the sender, with a copy of the Proof of

Purchase and a detailed description of the problem.

WARNING

The product must be decontaminated using the procedure

detailed in section 8.3 and a Certificate of Decontamination

supplied with any return. If the product is considered too

hazardous to be shipped, please contact Cole-Parmer for

further instructions.

Please contact Cole-Parmer to receive authorization to return the product.

Page 53

Combination Shaker

Instructions for Use

53

11 Technical Specifications

Physical Unit Properties

Dimensions (W x D x H)

Weight (without adapter)

190 mm x 350 mm x 200 mm

7 kg

Mains Supply

Power Cord Rating

Inlet Module Type

Supply Voltage Range

Supply Frequency Range

Power Consumption

Fuse Rating and Size

IEC C13, 3-Core, 5A min

IEC C14, DPST, Single Fuse

100 to 240 VAC ±10%

50 to 60 Hz ±5%

100 W max

T1.6AH 250V 20x5mm

Operating Environment

Temperature Range

Relative Humidity Range

Maximum Operating Altitude

+10 to +38 C

20% to 85% non-condensing

2000 m above sea-level

Storage and Transportation

Temperature Range

Relative Humidity Range

-10 to +50 C

20% to 95% non-condensing

Plate Shaker Rating

Eccentric Mixing Orbit

Total Maximum Load

Speed Range (0g to 80g load)

Speed Range (80g to 300g load)

Time Range

3 mm diameter

300 g

200 to 3000 RPM

200 to 2000 RPM

5 seconds to 28 days

Tube Vortexer Rating

Eccentric Vortexing Orbit

Speed Range

Time Range

3 mm diameter

700 to 3500 RPM

2 to 60 seconds

Page 54

Combination Shaker

Instructions for Use

54

12 Glossary of Terms and Abbreviations

ANSI

American National Standards Institute

Deep-well Plate

Plate with an SBS footprint featuring 48, 96 or 384

wells with a larger volume than microplates

DWP

Deep-well plate

EMC

Electro-Magnetic Compatibility

Incubate

Keeping an organism, cell or cell culture at the

optimum temperature for growth and development

Microtiter Plate

Plate with an SBS footprint featuring 24, 48, 96 or

384 wells

Mixing Load

All samples to be mixed located in their respective

tubes or plates

MTP

Microtiter plate

PCR

Polymerase Chain Reaction

Pellet

A small densely packed mass. Created, for

example, via the centrifugation of a suspension

PPE

Personal Protective Equipment

Resuspending

Dissolving a pellet by Vortexing in a liquid with the

material being redistributed in the liquid

RPM

Revolutions Per Minute

SBS

Society for Bio molecular Screening

Semi-skirted PCR

Plate

PCR plate with an outer surrounding half edge

Skirted PCR Plate

PCR plate with an outer surrounding edge

Unskirted PCR Plate

PCR plate without an outer surrounding edge

Vortexing

Strong whirling or spinning flow of liquid by manually

pressing a tube onto the Vortexing pad

Well

A single cavity in a Microtiter plate, PCR plate or

Deep-well plate

Page 55

Combination Shaker

Instructions for Use

55

In the US

625 E. Bunker Court

Vernon Hills, IL 60061

Call toll-free 1-800-323-4340

Phone: 1-847-549-7600

Fax: 1-847-247-2929

www.coleparmer.com

In Canada

Call toll-free 1-800-363-5900

Phone: 1-514-355-6100

Fax: 1-514-355-7119

www.coleparmer.ca

In the United Kingdom

Free phone: 0500-345-300

Phone: 020-8574-7556

Fax: 020-8574-7543

www.coleparmer.co.uk

In India

Phone: 91-22-6716-2222

Fax: 91-22-6716-2211

www.coleparmer.in

International customers

Call 1-847-549-7600 to reach

our International Sales

Department or contact your

local dealer

Loading...

Loading...