pixelfly

pixelfly qe

Operating Instructions

pco.

imaging

Safety Instructions 3

Safety Instructions

For your own safety and in order to guarantee a safe operation

of the camera, please read carefully the following information

prior to using the device.

" Never operate the camera at places where water or dust

might penetrate.

" Place the camera on a sufficiently stable basis.

Shocks like e.g. dropping the camera onto the floor, might

cause serious damage to the device. Therefore exclusively

the tripod attachment at the bottom side should be used for

mounting the camera.

" The camera is not be qualified for X-Ray applications and

can be damaged. Our warranty does not cover damaged

cameras caused by X-Ray applications.

" For applications with laser or plasma light please note that

the CCD sensor can be destroyed thermically or physically

with too much laser energy. Single pixels or the readout register and therefore the complete sensor can be destroyed.

The warranty does not cover damaged sensors by too much

laser light / laser energy.

" Always unplug the camera before cleaning it. Do not use

cleaning liquids or sprays. Instead, use a dry, soft duster.

" Never insert any objects through the device's slots. The ap-

plied voltage inside the camera can cause short-circuits or

electrical shocks.

" The slots in the camera housing are needed for ventilation.

In order to guarantee a proper operation and to prevent

overheating of the camera, these slots must always be kept

free.

" Make sure that the connecting cable is in good condition and

that the link to the socket does not represent an obstacle.

" Detach the camera and contact the customer service in the

following cases:

# When cable or plug are damaged or worn-out.

# When water or other liquids have soaked into the device.

# When the device is not properly working although you fol-

lowed all instructions of the user's manual.

# When the camera fell to the floor or the housing has been

damaged.

# When the device shows apparent deviations of normal

operation.

!PCO 2006

pixelfly

Contents 5

Contents

1. Installation and Powering Up

1.1 Computer ...............................................................................7

System Requirements .............................................................7

Graphic Setup .........................................................................7

Installing the PCI-Board ..........................................................8

1.2 Installation of the Hardware Driver......................................9

Installation under Windows 9x/ME/2000/XP ...........................9

Installation under Windows NT................................................9

Installation under Linux ...........................................................9

1.3 Installation of the Software ‚CamWare’.............................10

1.4 Camera and PCI-Board .......................................................11

Serial Data Transfer ..............................................................11

Lens Mount............................................................................12

Filter Installation ....................................................................12

1.5 Powering Up ........................................................................12

2. Functional Principle

2.1 Block Diagram and Internal Data Stream..............................13

2.2 Color Definition Algorithm......................................................16

2.3 Operating several Cameras from one Computer ..................17

3. Timing

3.1 pixelfly VGA / HiRes / Scientific r.......................................18

Async Mode...........................................................................18

Video Mode ...........................................................................19

DoubleShutter Mode .............................................................20

3.2 pixelfly qe.............................................................................21

Async Mode...........................................................................21

Video Modee .........................................................................22

DoubleShutter Mod ...............................................................23

4. Trigger Control

Internal Triggering .................................................................24

External Triggering ................................................................24

LED on the PCI-Board...........................................................25

!PCO 2006

pixelfly

6 Contents

5. Front-End Processor

Front-End Processor .............................................................26

6. Software

Application Software CamWare ............................................27

Plug-Ins .................................................................................27

Software Development Kit (SDK) ..........................................27

Drivers ...................................................................................27

7. Servicing, Maintenance and Cleaning

Instructions

Servicing, Maintenance and Cleaning Instructions ...............28

Cleaning Method for the Optical Part ....................................28

8. Appendix

Customer Service.................................................................. 29

Warranty................................................................................ 29

CE-Certification .....................................................................29

Dimensions and Weight (VGA, SVGA – long version) ..........30

Dimensions and Weight (QE – long version) ........................32

Dimensions and Weight (VGA, QE – short version)..............34

System Data.......................................................................... 36

Spectral Response ................................................................37

Operating Instructions pixelfly

Version 03/2006

Subject to change without prior notice!

Copyright by PCO, 2006

!PCO 2006

pixelfly

1. Installation and Powering Up 7

1. Installation and Powering Up

The pixelfly imaging system consists of camera and PCI-Board.

To get the system working properly, follow the instructions.

1.1 Computer

System Requirements The PCI-Board should be installed in a computer with following

characteristics:

" PCI-Bus with PCI-Chip Version 2.1 or higher

" Intel Processor, Pentium or AMD

" 128 MB RAM

" Possible Operating Systems

" Microsoft Windows 95 Version 4.00.950b or higher

" Microsoft Windows 98 or 98SE

" Windows ME

" Microsoft Windows NT 4.0 Workstation

" Microsoft Windows 2000 Workstation

" Microsoft XP

" Linux Kernel 2.2, preferable SuSE 6.3 or newer

In case of working with Linux, please contact PCO.

Graphic Board For best display of images on the monitor we recommend the

use of highest performance boards with at least 4MB RAM,

preferable with AGP Bus architecture.

Graphic Setup The camera generates 12 Bit (4096 grey levels). For display on

the PC Monitor 8 Bit (256 grey levels) respectively 3x8 Bit in

true color (16,7 millions colors) are generated.

In general, several graphic setups are possible. We recommend the setting with 24 or 32 Bit with 16.7 million colors.

In the 256-Color-Modus twenty colors are used by Windows for

internal purposes. This modus allows to display a maximum of

236 grey levels. Therefore only 7 bit (128 grey levels) are used

for black/white display.

Some graphic boards use in principle 6 bit for the 256-ColorModus, i. e. not more than 64 grey levels can be displayed on

the monitor.

!PCO 2006

pixelfly

8 1. Installation and Powering Up

Installing the PCI-Board

Caution! Before touching the PCI-Board make sure you have not accu-

mulated static charges. A discharge may destroy the sensitive

electronics and voids any guarantee.

Insert the PCI-Board in a free PCI-slot of your computer and

screw the bow onto the PC housing.

Make sure the board does not touch any electrical conducting

parts (housing, other boards, wires or chillers)

It is essential to use a master PCI-slot. Some computers require additional enabling of PCI-slot mastering on BIOS level.

!PCO 2006

pixelfly

1. Installation and Powering Up 9

1.2 Installation of the Hardware Driver

You can operate the camera with Windows9x/ME/2000/NT or

Linux.

Installation under Windows 9x/ME/2000/XP

New-Installation of the hardware driver

If you have Windows9x/ME/2000/XP installed, the computer

should automatically recognize the new hardware (PCI-Board)

and request you to insert a disk with the manufacturer's drivers.

For installation please read the actual information in the readme.txt file on the enclosed CD.

Updating the hardware driver

For updating an existing driver, please download the newest

driver version from the internet under

For installation please read the actual information in the readme.txt file which will be download automatically with the

driver.

In case the downloaded drivers are compressed you have to

decompress them with a suitable program (e.g. ZIP program).

Installation under Windows NT

Installation of the Hardware Driver

If you install the camera under Windows NT, you need the

rights of the administrator. Please login as administrator.

For installation please read the actual information in the readme.txt file on the enclosed CD or after downloading from

internet.

Installation under Linux

The Linux driver is on the enclosed CD or can be downloaded

from internet under

In case the downloaded drivers are compressed you have to

decompress them with a suitable program (e.g. ZIP program,

TAR program).

Detailed instructions for installation you will find in the readme

file.

http://www.pco.de.

http://www.pco.de.

!PCO 2006

pixelfly

10 1. Installation and Powering Up

1.3 Installation of the Software „CamWare“

CamWare is a 32 Bit Windows application. With CamWare all

camera parameters can be set. The images can be displayed

on the monitor and saved on hard disk. For detailed information

please see the separate manual ‚CamWare’.

You will find the software CamWare on the enclosed CD. The

newest version can also be downloaded from the internet under

http://www.pco.de.

Installation from CD In case the CD will not start automatically, please start it manu-

ally by double click starter.exe.

Please select your camera and the software ‘CamWare’:

Installation from Internet Download CamWare from the Internet to a free selected direc-

tory. The downloaded file must be decompressed with a suitable program (e.g. ZIP program) Start the installation with

setup.exe.

The newest information how to install CamWare can be found

in the readme.txt file.

To install CamWare under Windows 2000, Windows NT or

Windows XP you need administration rights.

Remark After successful installation the computer has to be restarted.

The installation program transfers all necessary DLL and OLE

files to the respective Windows, checking automatically for existing older versions and replacing them by new ones.

Windows’95 carries out all „registry“-entries.

If the program is to be deleted from the computer, a proper deinstallation is carried out in

TART - SETUP - SYSTEM CONTROL - SOFTWARE

S

After successful installation you will have the new directory

‘Digital Camera Toolbox’. CamWare and some additional useful

tools will be installed to this directory.

Hotline In case you have problems during installation, call our hotline

(see „Customer Service“).

!PCO 2006

pixelfly

1. Installation and Powering Up 11

1.4 Camera and PCI-Board

Before Powering Up, make the connection between camera

head and PCI-Board.

In case of not using the enclosed cable, please note:

" Pleas use only Ethernet cables, where all 8 lines are con-

nected (4x twisted pair).

" The cable quality must be at least category 5, 5+ or higher

" minimum cable length: 2m

" maximum cable length: 12.5m

Remark The connectors and cable are identical with Ethernet cables but

there is no Ethernet protocol!

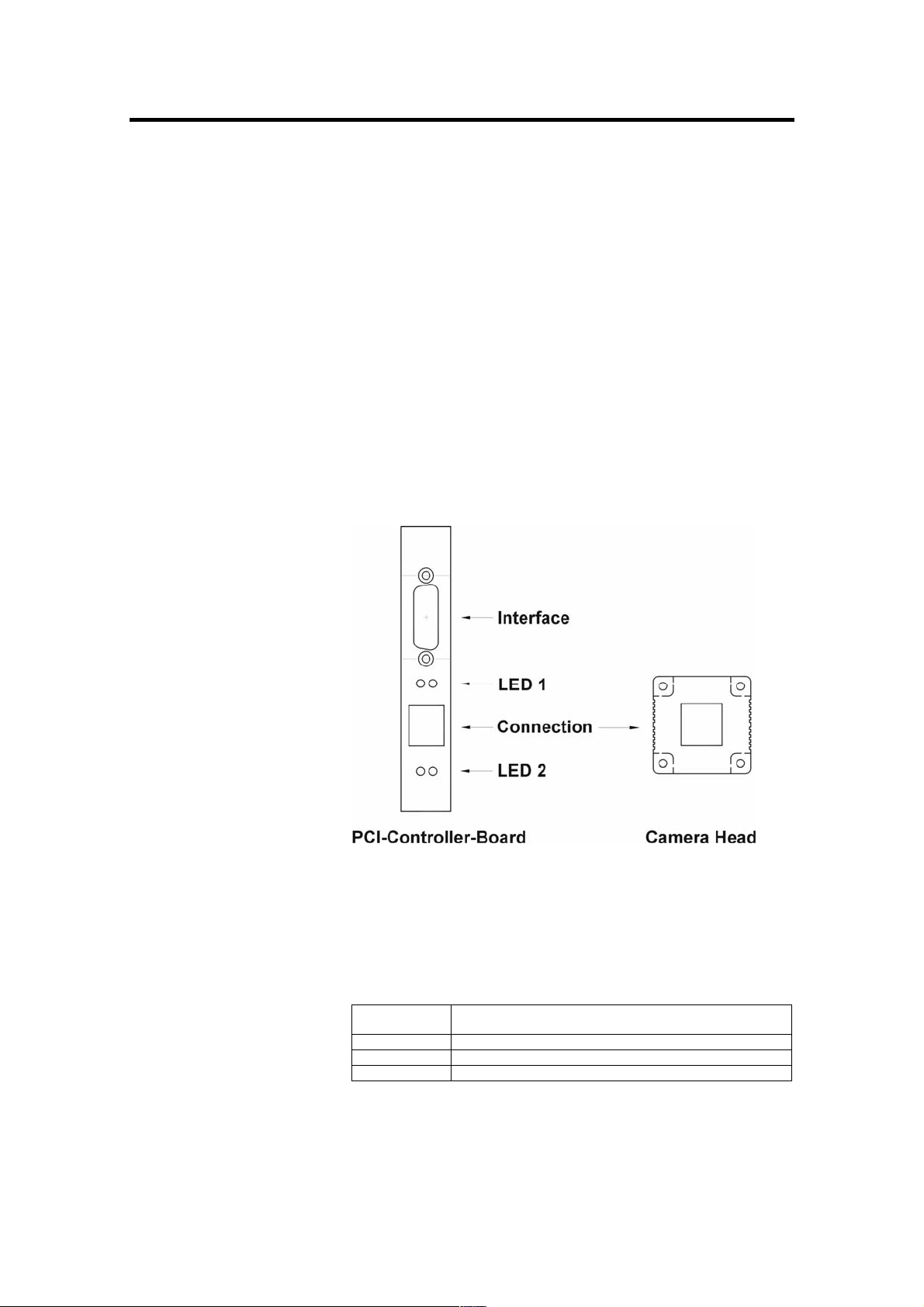

Standard and Compact PCI-Board

The front plates and connectors of the Standard and Compact

PCI-Boards are identical.

Frontplatten und Steckeranordnungen.

!PCO 2006

pixelfly

Interface 2 is the connection between camera head and PCIBoard.

The camera can be controlled via Interface 1 (e.g. external triggering, Front-End Processor, ...)

The LEDs show the operating states as follows:

LED 1 (green) control display when connection between camera head and

PCI-Board is ok

LED 1 (red) control display at data transfer

LED 2 (green) Power-On (blinking)

LED 2 (red) control display at external trigger input

12 1. Installation and Powering Up

Lens Mount pixelfly has a standard C-Mount with a back focal length of

17.52mm (Distance between front edge of C-Mount and CCDsensor).

Standard C-Mount lenses or other lenses with their respective

C-Mount adapter (e.g. photo camera lenses) can be used. The

maximum screw-in depth of a lens (or adapter) is 9.5mm.

Deeper screwing in could destroy the protecting window of the

camera (no warranty!).

The VGA and HiRes sensors have a 1/2“ format, the SVGA and

QE sensors a 2/3“. We recommend to use for all pixelfly Versions a 2/3“ or 1“ compatible lens. Cameras with high resolution

sensor should preferably be equipped with a high quality lens to

take advantage of the high resolution.

The cameras can be equipped optionally with a filter. This filter

will be placed at the C-Mount ring. In this case the maximum

screw-in depth is only 6mm instead of the 9.5mm.

Insert Filters Filters can be set in front of the CCD. You have to use a 24 mm

diameter filter.

In the C-mount screw there is a ring which can be screwed out.

Now the filter can be placed and the ring must be screwed in

again.

1.5 Powering Up

Check the following points:

" PCI-Board properly mounted

" Connection between camera and PCI-Board

" Lens mounted

Now start the program „CamWare“ from the directory

Programme – Digital Camera ToolBox.

For detailed information to CamWare please see the separate

manual ‚CamWare’.

!PCO 2006

pixelfly

2. Functional Principle 13

2. Functional Principle

The images, captured by the camera head, will be transferred

via a high speed data transfer to the PCI-Board in the computer. The data will be saved in the RAM of the computer where

the operator can decide what to do with them.

With the enclosed software ‚CamWare’ the camera can be controlled within the windows environment and the images can be

displayed on the monitor.

The Recorder function allows you to record image sequences

and display them as "movies".

The maximum memory space for the recorded images depends

solely on the RAM size of your computer.

When starting the program, the software automatically recognizes the camera type.

For detailed information to CamWare please see the separate

manual ‚CamWare’.

2.1 Block Diagram and Data Stream

Block Diagram In the following block diagram the structure of the complete

camera system is shown.

Lens

CCD

CCD Head

High speed data transfer

PCI-Interface-Board

External Trigger Input

!PCO 2006

pixelfly

14 2. Functional Principle

Internal Data Stream of black/white cameras

The PCI-Board gets the 12bit data from the camera and transfers it via PCI-Bus to a 16bit array (of the PC Memory). The

higher 4bits are set to zero. The 16bit data are automatically

converted in a 8bit array and accessed by the graphic board.

Depending on graphic board setup display on the monitor is effected in 8, 24 or 32 bit.

File Formats The command ‘Export’ stores 16bit or 8bit data on hard disk in

B16, TIFF, FITS, BMP, or ASCII format.

For further information see Chapter 2.3.

Display The camera which acquires always 12 bit images resolves with

4096 (2E12) grey levels between black and white, however the

monitor display of the image is always limited to 8 bit and therefore to 256 (2E8) grey levels.

The command ‘Convert Control’ allows to select a discretionary

range between 0 ... 4095 grey levels which is then displayed in

256 grey levels on the PC monitor.

Camera

PC

Monitor

PCI-Interface-Board Graphic Board

PCI-Bus

!PCO 2006

pixelfly

2. Functional Principle 15

Internal Data Stream of color cameras

The PCI-Board gets the 12bit data from the camera and transfers it via PCI-Bus to a 16bit array (of the PC memory). The

higher 4bits are set to zero. The 16 bit data are converted

automatically into a 3 x 8 bit array and accessed by the graphic

board. We recommend to display it in 32bits on the monitor.

File Formats The command ‘Export’ stores 16bit or 8bit data on hard disk in

B16, TIFF, FITS, BMP, or ASCII format.

For further information see Chapter 2.3.

Display The camera which acquires always 12 bit images resolves with

4096 (2E12) grey levels between black and white, however the

monitor display of the image is always limited to 8 bit and therefore to 256 (2E8) grey levels.

The command ‘Convert Control’ allows to select a discretionary

range between 0 ... 4095 grey levels which is then displayed in

256 grey levels on the PC monitor.

PC

Monitor

Camera

PCI-Interface-Board Graphic Board

PCI-Bus

!PCO 2006

pixelfly

16 2. Functional Principle

2.2 Color Definition Algorithm

Color sensors with RGB filter for the colors red, green and blue

are used for the color cameras. The CCD sensor records for

each pixel the light information as grey level with 12 Bit dynamic

(RX, GX, BX).

With the help of the camera control software, for each pixel the

12 Bit data is converted by interpolating into a 8 Bit triplet (P

, P

P

GREEN BLUE

).

For this interpolation following algorithm is applied:

Algorithm 1 This algorithm optimises the color resolution.

A red, green and blue part of the color for virtual pixels will be

calculated. These virtual pixels are placed between the original

pixels. In CamWare this algorithm is also called as ‘Smooth’.

" The first pixel on the top left side is always "red".

" Between the physical pixels, there are virtual pixels P

are computed with the algorithm described below.

Physical Pixel

R

1

G

2

R

3

G

4

RED

which

X

,

G

R

G

5

B

6

G

7

P

X

9

G

10

R

11

13

B

14

G

15

...

B

G

B

8

12

16

Virtual Pixel

...

Conversion algorithm for the new pixel P

:

X

P = ( 9 R + 3 R

RED 11 3

P = ( G

GREEN 7

P

BLUE 6

= ( 9 B

+ G )/2

+ 3 B8 + 3 B + B )/16

+ 3 R9 + R )/16

10

1

14 16

Algorithm 2 This algorithm optimises the spatial resolution. For each physi-

cal pixel, a color value (red, green and blue) is calculated, related to the corresponding neighbour pixel.

Example for Pixel

P = ( R

RED 1

P

P = B

= ( G

GREEN 2

BLUE 6

6

+ R3 + R9 + R )/4

+ G5 + G7 + G )/4

11

10

Example for Pixel

P = ( R

RED 3

P = G

GREEN 7

P = ( B

BLUE 6

7

+ R )/2

11

+ B )/2

8

!PCO 2006

pixelfly

2. Functional Principle 17

2.3 Operating several Cameras from one

Computer

Depending of the computer specification up to four cameras

can be used in one computer at the same time.

On the PCI-Board there is a FIFO memory (no full frame memory!). The incoming data must be transferred in real time to the

computer RAM.

With the 16 MHz versions (VGA 640 x 480 pixel and HiRes

1360 x 1024) the data transfer is 32 MB/s. For two cameras in

one computer you have 64 MB/s.

With the 20 MHz version (Scientific 1280 x 1024 pixel and QE

1392 x 1024) the data transfer is 40 MB/s, with two cameras 80

MB/s.

Please note that with synchronous triggering, maximum two

VGA cameras can be used. Cameras with higher resolution

(pixelfly Scientific, HiRes, qe) can cause conflicts.

The advantage of the FIFO memory (compared with a full frame

memory) is that you have no additional delay.

The disadvantage, that only two PCI-Boards can be used in one

computer at the same time, can be avoided by using CompactPCI CPUs in several computers which are connected by 100

MBit Ethernet cable.

!PCO 2006

pixelfly

18 3. Timing

3. Timing

3.1 pixelfly VGA / HiRes / Scientific

The pixelfly timing depends of the exposure mode

Async-, Video- and DoubleShutter modes are available.

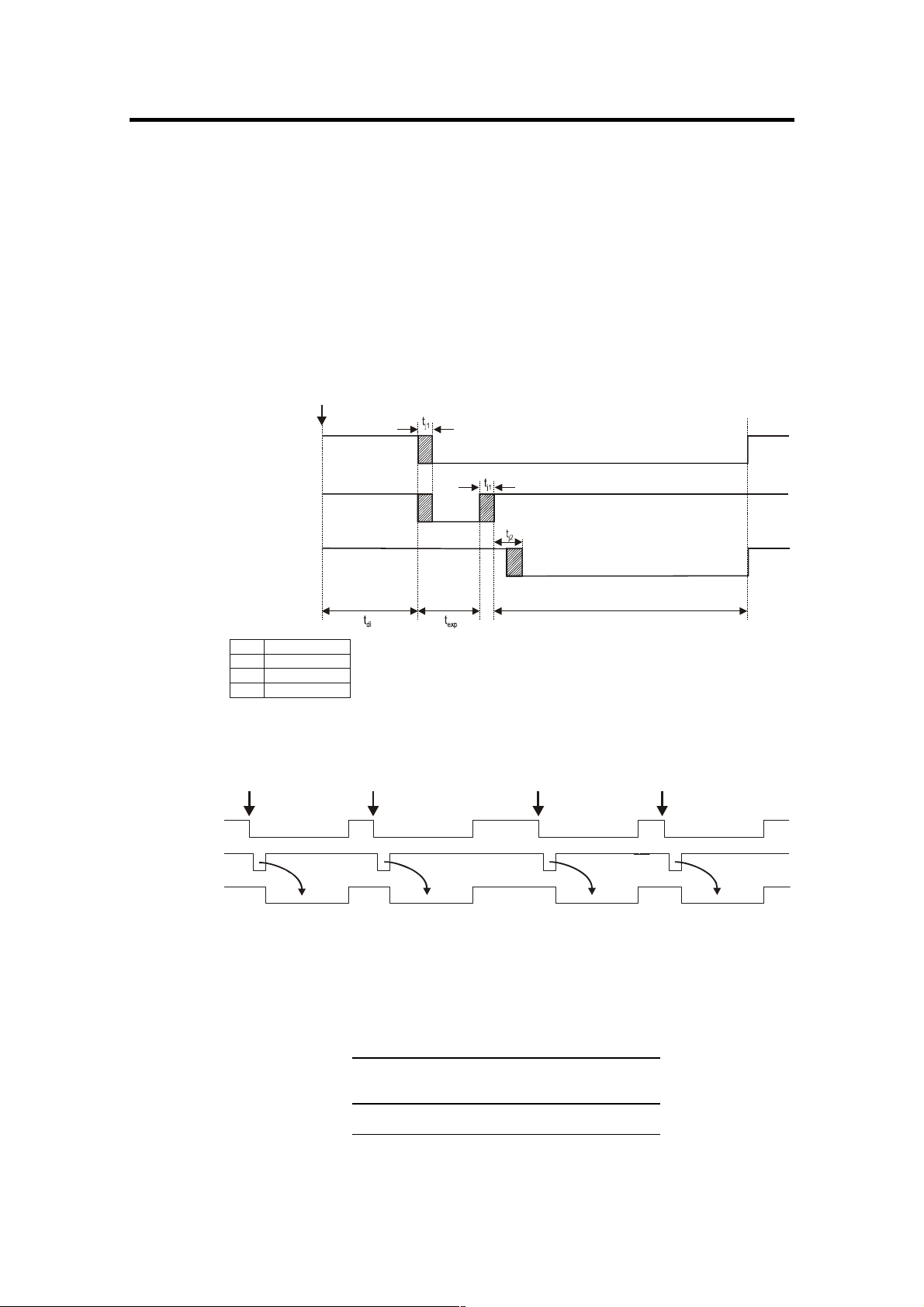

Async Mode

Each trigger (internal or external) generates an image.

The following signals /BUSY, /CCD-Exposure and /CCDReadout are at the 26-pin. HD-DSUB socket of the PCI-Board.

External Trigger

/ BUSY

/ CCD-Exposure

/ CCD-Readout

Exposure

Time

CCD Readout Time

timing n ot scale d

tdi 10...20µs

t

5µs...65ms

exp

tj1 0...5µs

tj2 300...700µs

Internal

Delay

Example for a external triggered sequence

/ BUSY

/ CCD-Exposure

/ CCD-Readout

CCD Readout Time The CCD readout time depends of the CCD sensor (VGA, Sci-

entifi, HiRes or UV) and of the selected binning:

VGA (200/205) V1-Binning: 19,8ms $ 0,5

V2-Binning 10,3ms $ 0,5

V4-Binning 5,6ms $ 0,5

VGA (210/215) V1-Binning: 24,8ms $ 0,5

V2-Binning 12,8ms $ 0,5

V4-Binning 6,8ms $ 0,5

Scientific V1-Binning 79,8ms $ 0,5

V2-Binning 40,3ms $ 0,5

HiRes / UV V1-Binning 104,0ms $ 0,5

V2-Binning 52,5ms $ 0,5

!PCO 2006

pixelfly

3. Timing 19

Video Mode

A trigger generates a complete imaging sequence.

The following signals /BUSY, /CCD-Exposure and /CCDReadout are at the 26-pin. HD-DSUB socket of the PCI-Board.

External Trigger

/ BUSY

/ CCD-Exposure

/ CCD-Readout

Intrinsic + System

Delay

Exposure Time < Readout Time

BUSY

CCD-Exposure

CCD-Readout

Exposure Time > Readout Time

BUSY

CCD-Exposure

CCD-Readout

CCD Readout Time The CCD readout time depends of the CCD sensor (VGA, Sci-

entifi, HiRes or UV) and of the selected binning:

VGA (200/205) V1-Binning: 19,8ms $ 0,5

V2-Binning 10,3ms $ 0,5

V4-Binning 5,6ms $ 0,5

VGA (210/215) V1-Binning: 24,8ms $ 0,5

V2-Binning 12,8ms $ 0,5

V4-Binning 6,8ms $ 0,5

Scientific V1-Binning 79,8ms $ 0,5

V2-Binning 40,3ms $ 0,5

HiRes / UV V1-Binning 104,0ms $ 0,5

V2-Binning 52,5ms $ 0,5

!PCO 2006

pixelfly

20 3. Timing

DoubleShutter Mode (only XD-Version)

Two separated full frame images with a short interframing time

can be captured. The length of the first exposure time will be

done by software input, the triggering either internally by software or by an external trigger signal. The exposure time of the

second image corresponds to the readout time of the first image. It depends of the used CCD sensor and binning mode.

During the interframing time td (dead time) no exposure should

be done

The following signals /BUSY, /CCD-Exposure and /CCDReadout are at the 26-pin. HD-DSUB socket of the PCI-Board.

External Trigger

/ BUSY

/ CCD-Exposure

/ CCD-Readout

Real exposure

on CCD sensor

tdi 10...20µs

t

5µs...65ms

exp1

tj1 0...5µs

tj2 300...700µs

tj3 0...3µs

td 2µs

Internal

Delay

t

can be set to 10µs...10ms by software.

exp1

Exposure

Image 1

Image 1

exposure time of image 2 (t

Exposure

Image 2

Readout Time 1 Readout Time 2

Image 2

) = readout time of image 1

exp2

timing n ot scaled

Example To set two laser pulses in a short time one after another (about

10µs), the following relation is valid. The timing of the first laser

pulse starts with the falling edge of /BUSY (respect. /CCDExposure). The first laser pulse must be set at the end of image

1, the second laser pulse at the beginning of image 2.

1. laser pulse = t

2. laser pulse = 1. laser pulse + t + (t

– t

exp1 j1

j1 d

+ t )

j3

CCD Readout Time The CCD readout time depends of the CCD sensor (VGA, Sci-

entifi, HiRes or UV) and of the selected binning:

VGA (200/205) V1-Binning: 19,8ms $ 0,5

V2-Binning 10,3ms $ 0,5

V4-Binning 5,6ms $ 0,5

VGA (210/215) V1-Binning: 24,8ms $ 0,5

V2-Binning 12,8ms $ 0,5

V4-Binning 6,8ms $ 0,5

Scientific V1-Binning 79,8ms $ 0,5

V2-Binning 40,3ms $ 0,5

HiRes / UV V1-Binning 104,0ms $ 0,5

V2-Binning 52,5ms $ 0,5

!PCO 2006

pixelfly

3. Timing 21

3.2 pixelfly qe

The pixelfly timing depends of the exposure mode.

Async-, Video- and DoubleShutter modes are available.

Async Mode

Each trigger (internal or external) generates an image.

The following signals /BUSY, /CCD-Exposure and /CCDReadout are at the 26-pin. HD-DSUB socket of the PCI-Board.

External Trigger

/ BUSY

/ CCD-Exposure

/ CCD-Readout

Exposure

Time

CCD Readout Time

timing n ot scale d

tdi 10...20µs

t

5µs...65ms

exp

tj1 0...5µs

tj2 300...700µs

Internal

Delay

Example for a external triggered sequence

/ BUSY

/ CCD-Exposure

/ CCD-Readout

CCD Readout Time The CCD readout time depends of the CCD sensor and of the

selected binning:

pixelfly qe V1-Binning 88,3ms $ 0,5

V2-Binning 44,8ms $ 0,5

!PCO 2006

pixelfly

22 3. Timing

Video Mode

A trigger generates a complete imaging sequence.

The following signals /BUSY, /CCD-Exposure and /CCDReadout are at the 26-pin. HD-DSUB socket of the PCI-Board.

External Trigger

/ BUSY

/ CCD-Exposure

/ CCD-Readout

Intrinsic + System

Delay

Exposure Time < Readout Time

BUSY

CCD-Exposure

CCD-Readout

Exposure Time > Readout Time

BUSY

CCD-Exposure

CCD-Readout

CCD Readout Time The CCD readout time depends of the CCD sensor and of the

selected binning:

pixelfly qe V1-Binning 88,3ms $ 0,5

V2-Binning 44,8ms $ 0,5

!PCO 2006

pixelfly

3. Timing 23

DoubleShutter Mode (only XD-Version)

Two separated full frame images with a short interframing time

can be captured. The length of the first exposure time will be

done by software input, the triggering either internally by software or by an external trigger signal. The exposure time of the

second image corresponds to the readout time of the first image. It depends of the used CCD sensor and binning mode.

During the interframing time td (dead time) no exposure should

be done

The following signals /BUSY, /CCD-Exposure and /CCDReadout are at the 26-pin. HD-DSUB socket of the PCI-Board.

External Trigger

/ BUSY

/ CCD-Exposure

/ CCD-Readout

Real exposure

on CCD sensor

tdi 10...20µs

t

5µs...65ms

exp1

tj1 0...5µs

tj2 300...700µs

tj3 0...3µs

td 2µs

Internal

Delay

t

can be set to 10µs...10ms by software.

exp1

Exposure

Image 1

Image 1

exposure time of image 2 (t ) = readout time of image 1

Exposure

Image 2

Readout Time 1 Readout Time 2

Image 2

exp2

timing n ot scaled

Example To set two laser pulses in a short time one after another (about

10µs), the following relation is valid. The timing of the first laser

pulse starts with the falling edge of /BUSY (respect. /CCDExposure). The first laser pulse must be set at the end of image

1, the second laser pulse at the beginning of image 2.

1. laser pulse = t

2. laser pulse = 1. laser pulse + t + (t

– t

exp1 j1

j1 d

+ t )

j3

CCD Readout Time The CCD readout time depends of the CCD sensor and of the

selected binning:

pixelfly qe V1-Binning 88,3ms $ 0,5

V2-Binning 44,8ms $ 0,5

!PCO 2006

pixelfly

24 4. Trigger Control

4. Trigger Control

The pixelfly can be triggered via the 26-pin. HD-DSUB socket at

the PCI-Board. Additional control signals are available.

The trigger control is generated by the Front-End-Processor

ORION (see chapter 5).

Pinning of the 26-pin. HD-DSUB socket at the PCI-Board:

Pin Name at

DSUB

1 OPTO IN 6 PD3 Trigger Input *

2 OPTO IN 5 PD2 **

3 OPTO IN 4 PB3 **

4 OPTO IN 3 PB2 **

5 OPTO IN 2 PB1 **

6 OPTO IN 1 PB0 **

7 HighSide 204 PC3 HighSide Driver

8 HighSide 104 PC7 HighSide Driver

9 HighSide 103 PC6 HighSide Driver

10 GND Ground for output signals

11 n.c.

12 OPTO GND Trigger Ground

13 do not use

14 do not use

15 GND Ground for output signals

16 HighSide 202 PC1 HighSide Driver

17 HSSUP. Power Input for HighSide Driver

18 HighSide 102 PC5 HighSide Driver

19 I/O1 PD5 Blink Output (LED green)

20 I/O2 PD4 CCD Busy Output (LED red)

21 I/O3 PD0 CCD Exposure Output

22 I/O4 PD1 CCD Readout Output

23 HighSide 203 PC2 HighSide Driver

24 HighSide 201 PC0 HighSide Driver

25 GND Ground for output signals

26 HighSide 101 PC4 HighSide Driver

* Input Voltage according to the sticker on the PCI board

** 24V Input Voltage

Timing diagram of the three CCD signals (low level logic)

Name at Function

ORION

/CCD busy

/CCD exp

/CCD readout

Trigger Input Input, high active

A rising edge (TTL signal, 5V) starts a new exposure.

Trigger

!PCO 2006

pixelfly

Pin 1

R 111

+

10K

-

Pin 12

HCPL-0661

4. Trigger Control 25

Trigger Input Voltages

The trigger input voltage can be changed to +12V or +24V. For

details see Technical Manual of the pixelfly available at PCO on

request.

min. typ. max. R 111

Input 24V 10 V 24 V 40 V 3.3 kOhm

Input 12V 6 V 12 V 24 V 1.5 kOhm

Input 5V* 3 V 5 V 8 V 520 Ohm

* Factory preset.

Busy Output (LED) Output (low active) and red LED (parallel)

Output to low from staring the trigger till end of CCD readout

Blink LED Blinking LED (about 8 Hz) as power-on control.

CCD Exposure Output Output, low active

While exposing, this signal will be active low.

CCD Readout Output Output, low active

While reading out the CCD, this signal is low.

!PCO 2006

pixelfly

26 5. Front-End Processor

5. Front-End Processor

A Front-End processor (ORION) is placed on the PCI-Board.

This processor can be programmed by the end-user himself.

The external trigger input and some control signals will be handled by the processor.

This I/O controller can be used for individual tasks (e.g. microscopy control, error control, …).

To input signals there are optionally 8 high-side drivers available which can be controlled with maximum 1A each. These

drivers are short-circuit protected and therefore useful for industrial applications.

Furthermore there are three double opto-coupler available (Galvanic separated).

The Assembler Source Code of the ORION processor can be

found on the PCO Utility CD (ORION201.ASM, 8515DEF.INC).

An executable code (Intel-Hex) can be downloaded via the PCI

interface by a programming software (see SDK directory).

!PCO 2006

pixelfly

6. Software 27

6. Software

Application Software Shipment of the camera system includes the CamWare soft-

ware, a complete operation software for the camera allowing to

display and to save images.

For detailed information to CamWare please see the separate

manual ‚CamWare’.

Plug-Ins n case you are already working with an image processing or

image analysis software appropriate Plug-Ins may be installed.

Consequently camera control commands can be sent directly

from the image analysis software.

You will find more information about Plug-Ins on our website.

In case your software is not listed above, please contact PCO.

Software Development Kit In case you have written your own software or you wish to in-

clude the control software into already existing programs, the

camera control may be integrated as DLL file by using our Software Development Kit (SDK).

The following SDK’s with detailed manual are available:

" SDK for Windows 9x/ME/2000/NT

" SDK for Linux

The SDK can be found on the CD or can be downloaded from

Internet under

Drivers To work with the camera properly a Twain driver and the follow-

ing PCI-Board drivers are available:

" PCI-Board driver for Windows 9x/ME/2000/XP

" PCI-Board driver for Windows NT

" PCI-Board driver for Linux

The drivers can be found on the CD or can be downloaded from

Internet under

http://www.pco.de.

http://www.pco.de.

!PCO 2006

pixelfly

28 7. Servicing, Maintenance and Cleaning Instructions

7. Servicing, Maintenance and Cleaning

Instructions

Servicing, Maintenance and Cleaning Instructions

The camera is maintenance-free.

Factory settings make any inspection and servicing superfluous.

During use the camera should be protected from hard shocks

or strong vibrations.

Also should the camera be protected from high humidity and

temperature shocks. Avoid exposing to sunlight, since it heats

up the camera housing unnecessarily and prevents the cooling

from reaching its optimum operating temperature.

Keep apertures and slots free to allow air to circulate.

Objective lens or lens adapter should be screwed in gently.

Avoid forcing as it will damage the tread.

Use a soft and dry cloth to clean the housing.

Cleaning Method for the Optical Part

In principle every cleaning method bears the danger of damaging an optical surface.

Therefore clean only if it is strictly necessary.

As a first step use dry air to blow out dust particles. Avoid

strictly to wipe on a dry glass surface.

In case dirt cannot be removed by blowing, use special optical

cleaning fluids. Adequate fluids for optical surfaces are: pure

dehydrogenated alcohol, pure acetone or cleaning fluids available in photo shops. Use a soaked cotton tip and take care to

wipe only on glass surfaces, avoiding contact to metal surfaces,

e.g. C-Mount thread, otherwise microscopic dirt and metallic

chips are released, causing irreparable scratches on the glass

surface.

Never use aggressive cleaning substances, e.g. benzine, spirit,

nitro solvents, etc. commonly found in labs. Such substances

may destroy or damage the surface on which they are applied.

Hint The best is to avoid any dirt on optical parts, e.g. by replacing

immediately the black protection cap when removing the objective lens. Do not leave the camera’s optical input window open,

without lens or protecting cap.

Our warranty does not cover damaged optical surfaces caused

by improper cleaning methods.

!PCO 2006

pixelfly

8. Appendix 29

8. Appendix

Customer Service

Having a problem or a question about matters not handled in

these operating Instructions, we recommend to contact us :

... by Telephone 09441/2005-0

... by Fax 09441/2005-20

... by Email

... by Post PCO AG

support@pco.de

Donaupark 11

D-93309 Kelheim

Germany

" Serial number of the camera head

" Serial number of the PCI-Board

" Detailed description of the problem

" Experiment conditions

" Settings in the camera control software

" Technical data of the computer

Warranty

PCO grants a warranty by law for the pixelfly System (camera,

PCI-Board, FOL or coaxial cable, power supply). The warranty

period starts on day of delivery ex-factory. In case of defect

within the warranty period replacement or repair will be made

(at PCO’s discretion) free of charge. The device shall be returned on customer’s expenses to PCO, preferably in the original package.

PCO is not liable for consequential damages.

Before returning the camera, contact PCO via any of the Customer Services.

Pay attention to use a sufficient package if you have to send the

camera via mail (keep the original package).

The FOL cable connectors and the connectors of the camera

and PCI-Board must be protected with the protection caps.

Don’t forget to screw the C-Mount protection cap!

Attention Opening of the camera or improper handling (e.g. damage by

electrostatic charge, wrong cleaning method) voids the warranty.

CE-Certification

pixelfly complies with the requirements of the „EMC Directions

of the European Communities (089 / 336 / EWG)“ and therefore

bears the CE-Marking.

!PCO 2006

pixelfly

30 8. Appendix

Dimensions and Weight

pixelfly cameras are available in different housings. Please select the right version!

VGA, HiRes and Scientific versions (long housing)

Lateral view

Top view

Front View

!PCO 2006

pixelfly

8. Appendix 31

Rear View

Top View (bottom view incl. tripod)

!PCO 2006

pixelfly

Weight of the Camera Head: about 270g

32 8. Appendix

QE versions (long housing)

Lateral View

Top View

Front View

!PCO 2006

pixelfly

8. Appendix 33

Rear View

Top View (bottom view incl. tripod)

Weight of the Camera Head: about 290g

!PCO 2006

pixelfly

34 8. Appendix

VGA versions (short housing)

QE versions (short housing)

Lateral View

Top View

Front View

!PCO 2006

pixelfly

8. Appendix 35

Rear View

Top View (bottom view incl. tripod)

Weight of the Camera Head: about 280g

!PCO 2006

pixelfly

36 8. Appendix

System Data

CCD Sensor VGA (200 / 205) VGA (210 / 215) Scientific (230 / 235)

Number of Pixels 640 (H) x 480 (V) 640 (H) x 480 (V) 1280 (H) x 1024 (V)

Pixel Size 9.9µm x 9.9µm 9.9µm x 9.9µm 6.7µm x 6.7µm

Sensor Format 1/2“ 1/2“ 2/3“

Scan Area 6.3 x 4.8 mm 6.3 x 4.8 mm 8.6 x 6.9 mm

Full Well Capacity 30.000 e

Readout Noise 11…14 e

Scan Rate 20 MHz 16 MHz 20 MHz

Imaging Frequency …

… at binning mode 1 50 fps 40 fps 12,5 fps

… at binning mode 2 95 fps 76 fps 24 fps

… at binning mode 4 177 fps 140 fps not available

A/D Conversion Factor 6.5 e-/count 7 e-/count 4,5 e-/count

Spectral Range b/w 290 ... 1000 nm 290 ... 1000 nm 290 ... 1000 nm

Spectral Range color primary color, RGB primary color, RGB primary color, RGB

Anti Blooming > 1000 > 1000 > 1000

CCD Quality grade 0 grade 0 grade 0

Non-Linearity (Differential) < 2% < 2% < 2%

Binning Vertical factor 1, 2, 4 factor 1, 2, 4 factor 1, 2

Binning Horizontal factor 1, 2 factor 1, 2 factor 1, 2

CCD Sensor HiRes (220 / 225) QE (270 / 275)

Number of Pixels 1360 (H) x 1024 (V) 1392 (H) x 1024 (V)

Pixel Size 4.65µm x 4.65µm 6.45µm x 6.45µm

Sensor Format 1/2“ 2/3“

Scan Area 6.3 x 4.7 mm 9.0 x 6.6 mm

Full Well Capacity 13.000 e

Readout Noise 6…9 e

Scan Rate 16 MHz 20MHz

Imaging Frequency …

… at binning mode 1 9,5 fps 12 fps

… at binning mode 2 18 fps 23 fps

… at binning mode 4 not available not available

A/D Conversion Factor 3 e-/count 3.8 e-/count

Spectral Range b/w 290 ... 1000 nm 290 ... 1000 nm

Spectral Range color primary color, RGB primary color, RGB

Anti Blooming > 1000 > 400

CCD Quality grade 0 grade 0

Non-Linearity (Differential) < 2% < 2%

Binning Vertical factor 1, 2 factor 1, 2

Binning Horizontal factor 1, 2 factor 1, 2

Camera Head + PCI-Board

Power consumption 1 A at 5 V, 400mA at 12 V

PCI-Board about 10 W

Camera Head about 2,6 W …3,3 W

-

-

-

-

30.000 e

16 e

18.000 e

6…9 e

-

-

-

-

20.000 e

12 e

-

-

!PCO 2006

pixelfly

8. Appendix 37

Spectrale Response

(typical values)

pixelfly VGA

pixelfly Scientific

pixelfly HiRes

Scientific

VGA

HiRes

!PCO 2006

pixelfly

38 8. Appendix

pixelfly qe

low light mode

(= gain high)

standard mode

(= gain normal)

!PCO 2006

pixelfly

Dear Customer,

We hope this camera will be an always valuable tool for your scientific day in,

day out work.

Comments, suggestions or any new idea on our system are welcome.

We are at your disposal at any time, also after your buying of this camera.

Your PCO Team

pco.

imaging

PCO AG

Donaupark 11

D-93309 Kelheim

fon: +49 (0)9441 2005 0

fax: +49 (0)9441 2005 20

eMail: info@pco.de

www.pco.de

Loading...

Loading...