pco.

pco.

user manual

edge 4.2 bi

pco.edge 4.2 bi UV

PCO asks you to carefully read this manual before using the

pco.edge camera system and follow the instructions.

In case of any questions or comments, contact us at PCO.

telephone +49 (0) 9441 2005 50

fax +49 (0) 9441 2005 20

email info@pco.de

postal address PCO AG

Donaupark 11

93309 Kelheim, Germany

The cover photo shows an exemplary PCO camera system.

The lens is sold separately.

Copyright © 2019 PCO AG (called PCO in the following text), Kelheim,

Germany. All rights reserved. PCO assumes no responsibility for errors or

omissions in these materials. These materials are provided as is without

warranty of any kind, either expressed or implied, including but not limited to,

the implied warranties of merchantability, fitness for a particular purpose, or

non-infringement. PCO further does not warrant the accuracy or

completeness of the information, text, graphics, links or other items

contained within these materials. PCO shall not be liable for any special,

indirect, incidental, or consequential damages, including without limitation,

lost revenues or lost profits, which may result from the use of these materials.

The information is subject to change without notice and does not represent a

commitment on the part of PCO in the future. PCO hereby authorizes you to

copy documents for non – commercial use within your organization only. In

consideration of this authorization, you agree that any copy of these

documents, which you make, shall retain all copyright and other proprietary

notices contained herein. Each individual document published by PCO may

contain other proprietary notices and copyright information relating to that

individual document. Nothing contained herein shall be construed as

conferring by implication or otherwise any license or right under any patent or

trademark of PCO or any third party. Except as expressly provided, above

nothing contained herein shall be construed as conferring any license or right

under any PCO copyright. Note that any product, process, or technology in

this document may be the subject of other intellectual property rights

reserved by PCO, and may not be licensed hereunder.

Released: July 2019 © PCO AG

pco.edge 4.2 bi (UV) user manual V1.00 © PCO AG, Germany

TABLE OF CONTENTS

TOP

TABLE OF CONTENTS

1. INTRODUCTION 4

1.1 INTENDED USE 4

1.2 CONVENTIONS 4

2. SAFETY INSTRUCTIONS 5

3. SYSTEM COMPONENTS 6

4. INSTALLATION 7

4.1 DRIVER 7

4.2 CAMWARE SOFTWARE 8

5. QUICK START 9

5.1 PREPARATION 9

5.2 START 9

5.3 FIRST IMAGE 10

6. ROLLING SHUTTER 11

7. CAMWARE 4 SOFTWARE 15

7.1 HARDWARE IO CONTROL 15

APPENDIX 17

A1 TECHNICAL DATA 18

A1.1 DATA SHEET 18

A1.2 MECHANICAL DIMENSIONS 19

A1.3 REAR PANEL 20

A2 HARDWARE MOUNTING 21

A2.1 USB CARD INSTALLATION 21

A2.2 CABLE MOUNTING 22

A2.3 DIRECT CAMERA MOUNTING 23

A3 F-MOUNT ADAPTER 24

A3.1 PCO F-MOUNT ADAPTER 24

A3.2 CHANGE FROM F-MOUNT TO C-MOUNT 25

A4 WATER COOLING OPTION PCO.AQUAMATIC II 26

A4.1 SYSTEM COMPONENTS 26

A4.2 FIRST TIME INSTALLATION 27

A4.3 OPERATION 28

A4.4 DIMENSIONS 29

A4.5 YOUR OWN COOLING SYSTEM 29

A5 CUSTOMER SERVICE 30

A5.1 SERVICE 30

A5.2 MAINTENANCE 30

A5.3 RECYCLING 30

A5.4 TROUBLE SHOOTING 31

A6 INDEX 32

ABOUT PCO 33

3

bold italics

Terms that can be found in the software pco.camware

Features

Heading within a chapter

A1.3

Bold chapter: hyperlink to a chapter

Numbers that help to find functions quickly

Notes that must be observed

1

1

1. INTRODUCTION

Advantages of the pco.edge 4.2 bi (UV)

Features

Innovations aren’t always about having that one big new idea. Unique

technology also comes from evolution, combining existing and new

technology. When our tried and trusted pco.edge series pools forces

with modern back illuminated (bi) sensor technology, the result is our

pco.edge 4.2 bi (UV).

The adjustable cooling system allows the use of air or water to cool

the sensor down to -25 °C. At this temperature, the dark current is

reduced to 0.2 e-/pixel/s.

According to your application you can choose an input window

specialized either for the UV or VIS range. High resolution and 6.5 x

6.5 μm² pixel size guarantees high-quality images with quantum

efficiency up to 95 %. The pco.edge 4.2 bi (UV) incorporates a

powerful USB 3.1 interface complementing its performance.

Main Features

1.1 INTENDED USE

1.2 CONVENTIONS

• Resolution: 2048 x 2048 pixels

• Superior quantum efficiency up to 95 %

• 26667:1 dynamic range

• lowest dark current (typ.) 0.2 e-/pixel/s

• USB 3.1 interface

This camera system is designed for use by technicians, engineers

and scientists. It is a scientific measuring instrument, which provides

images. The camera may only be used according to the instructions

of this manual. The disclosures and operating conditions in these

operating instructions installation must be respected. Unauthorized

modifications and changes of the device are forbidden for safety

reasons.

The following typographic conventions are used in this manual:

4

2 SAFETY

NOTICE

NOTICE

NOTICE

NOTICE

NOTICE

DANGER

WARNING

CAUTION

CAUTION

2. SAFETY INSTRUCTIONS

Read the safety instructions completely and follow them strictly.

DAMAGED POWER CABLE OR POWER PLUG

Danger to life due to electric shock.

Each time the camera is used, check the power cable for

damage.

ELECTRIC SHOCK WARNING DUE TO VOLTAGE PARTS INSIDE

Risk of injury due to electric shock.

Never slide any items through slits or holes into the camera.

MOISTURE

Risk of injury due to electric shock if moisture enters the camera.

To avoid the risk of water condensation, protect the camera

against extreme changes of ambient temperature.

TRIPPING HAZARD

Risk of injury from tripping over loose cables.

Never position the cable in a way that it could become a

tripping hazard.

HUMIDITY, DUST OR RADIATION

NOTICE

Humidity, dust or X-rays could damage the camera.

Never operate the camera in humid or dusty environments

or in places with high levels of x-ray radiation.

JOLT & VIBRATION

To avoid damaging the camera it must be firmly mounted and

protected against strong shocks or vibrations.

Use the camera's mounting threads to secure it.

LENS MOUNTING

Screw in the lens gently to avoid thread damage.

To protect the lens connector thread from damage, use

minimal force when attaching a lens to the camera.

LIQUIDS DAMAGE CAMERA

If liquids have penetrated the device.

Switch the camera off immediately, detach it from power and

contact PCO's customer support.

DAMAGED CAMERA HOUSING

If the camera has been dropped or the camera body is damaged.

Switch the camera off immediately, detach it from power and

contact PCO's customer support.

IF CAMERA IS NOT WORKING PROPERLY

In case all actions following this manual to get the camera working

properly were unsuccessful.

Switch the camera off immediately, detach it from power and

contact PCO's customer support.

INSTRUCTIONS

5

• Power connector

Mounting Thread

USB 3.1 Cable

Power Supply & Power Cord

3. SYSTEM COMPONENTS

The camera system includes the following parts.

Camera

• F-mount / C-mount optical connection

• For standard C-mount / F-mount lenses and adapters

Rear Panel

• USB 3.1 Type C connector

• LED indicates camera status (see A1.3)

• SMA connectors

Serial Number Tag

• 1x 1/4"- 20 UNC

• USB Type A / USB Type C screwable cable

• Length 3 m

USB 3.0 / 3.1 Gen1 Interface Card

• 2x USB Type A socket

• PCI Express x1 V2.0

• Output: 24 VDC / 36W / 1.5A

• Connector: Lemo FGG.0B

• Voltage input: 115 VAC - 230 VAC; IEC 60320 C14 plug

• Power cord IEC 60320 C13

Digital Camera Tools (USB flash drive content)

• pco.camware: software for camera control & image acquisition

• Camera driver & tools

• Software Development Kit (SDK) & demo programs in C and C++

6

4 INSTALLATION

• Intel® Core™ i7

• Full-HD resolution display

• RAM > 8 GB DDR3

• USB 3.1 Gen1

• Windows 7 or higher

3

4

3 4 1

2

1

2

4. INSTALLATION

You find all necessary files on the accompanying USB flash drive.

You may also download the latest versions of our software, camera

driver and third party software drivers from our Website

(www.pco.de).

Minimum System Requirements:

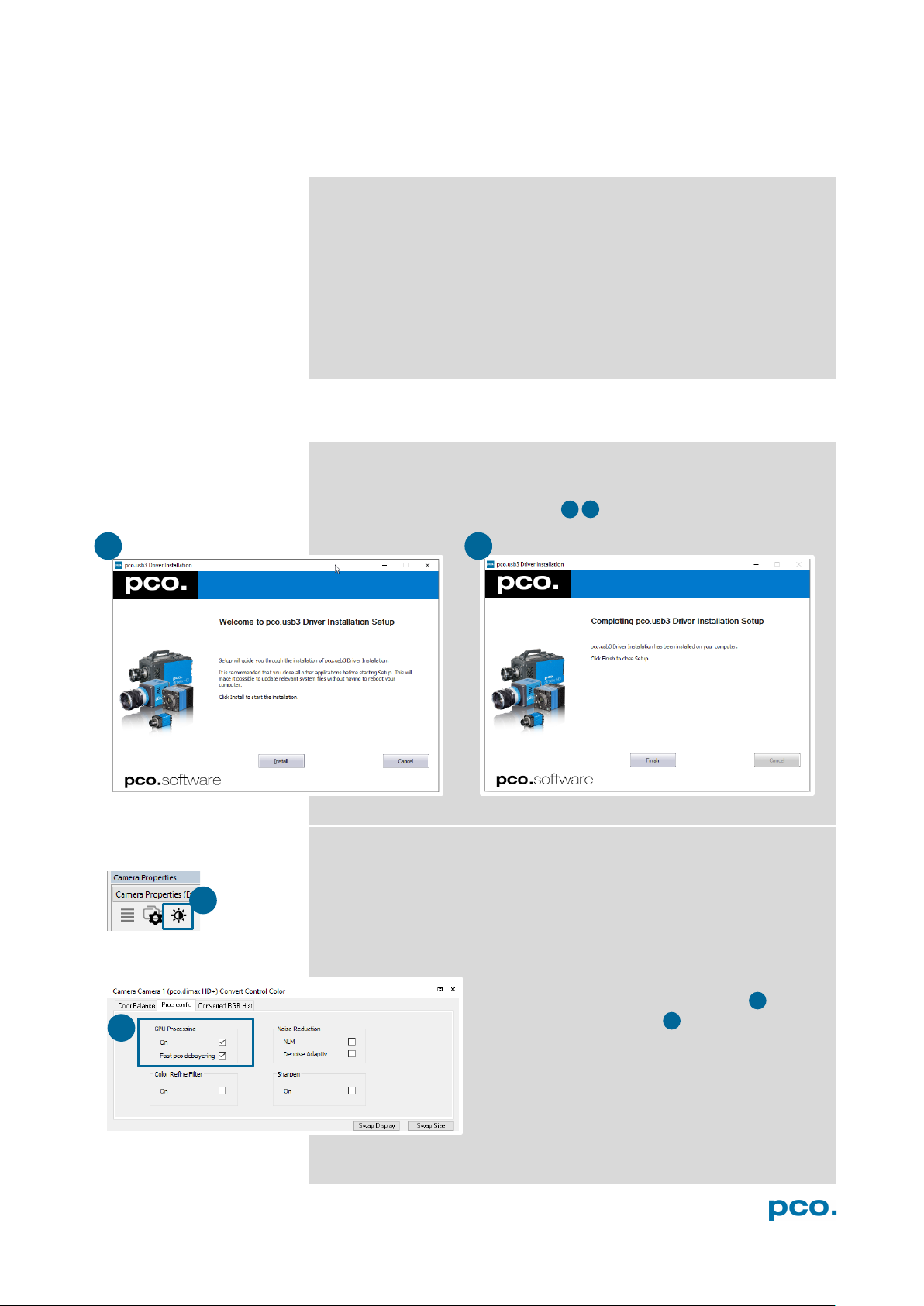

4.1 DRIVER

Install PCO USB 3.0/3.1 Driver

Always install the latest USB driver version. After these two screens

the driver is completely installed.

NVIDIA Cuda Driver

Only relevant if an NVIDIA graphics card is used! GPU Processing is

only working with NVIDIA graphics cards.

Update your NVIDIA driver for pco.camware. In case of an old driver

version GPU Processing is not working. Therefore image processing

is slow.

Check if GPU Processing is activated by having

a look into the Proc config settings in the

Convert Control window (see pco.camware

manual).

If GPU Processing is disabled and greyed out,

update your NVIDIA driver.

7

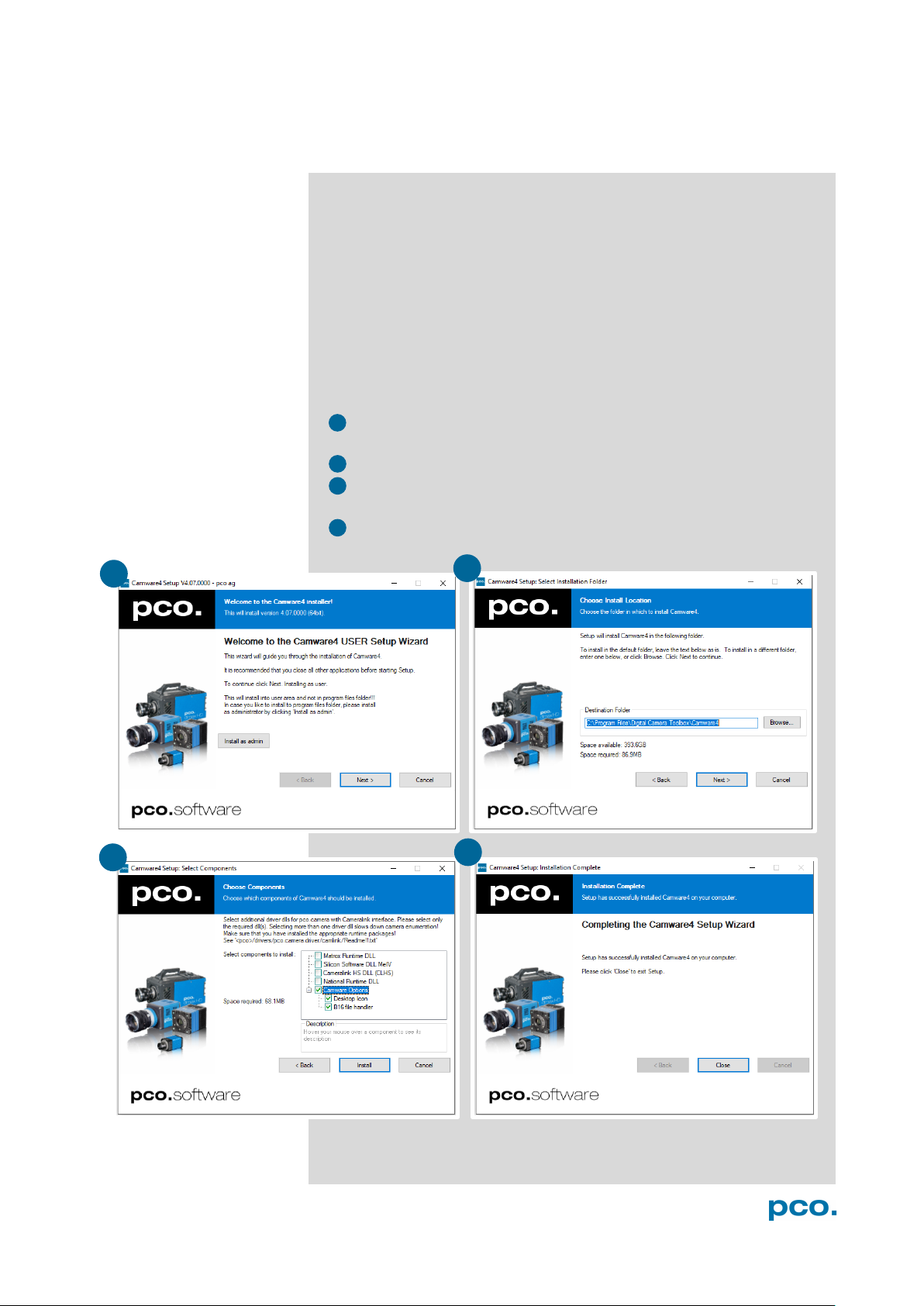

1 2 3

4

1

1

2

3

4

4.2 CAMWARE SOFTWARE

The pco.camware application software enables to control every

camera parameter or setting. Images can be displayed on a monitor

and may be downloaded and stored. The USB flash drive contains

the installation files for the software for latest Windows operating

systems in 32 & 64 bit.

After a successful installation, you find the program file Digital

Camera Toolbox in your program directory and a pco.camware 32 /

64 button on your desktop.

To uninstall the pco.camware program, use the software feature

under Windows’ system control.

Follow the Installation Wizard

• Install as admin to install to program folder, otherwise it is

installed only to user folder

• Choose install directory

• Choose components: select additional drivers (not recommended

for pco.edge 4.2 bi (UV))

• After the next two screens installation is complete

8

5 QUICK

5. QUICK START

5.1 PREPARATION

START

In order to get familiar with your new camera and software it might be

helpful, if you first aim at an object that is easy to focus and that can

be seen at standard light conditions.

• Computer is turned on

• Installation is finished (see chapter 4)

• An appropriate lens is attached (remove cap) or the camera is

attached properly to the microscope, spectrograph or other

scientific device

• Camera is connected to the PC

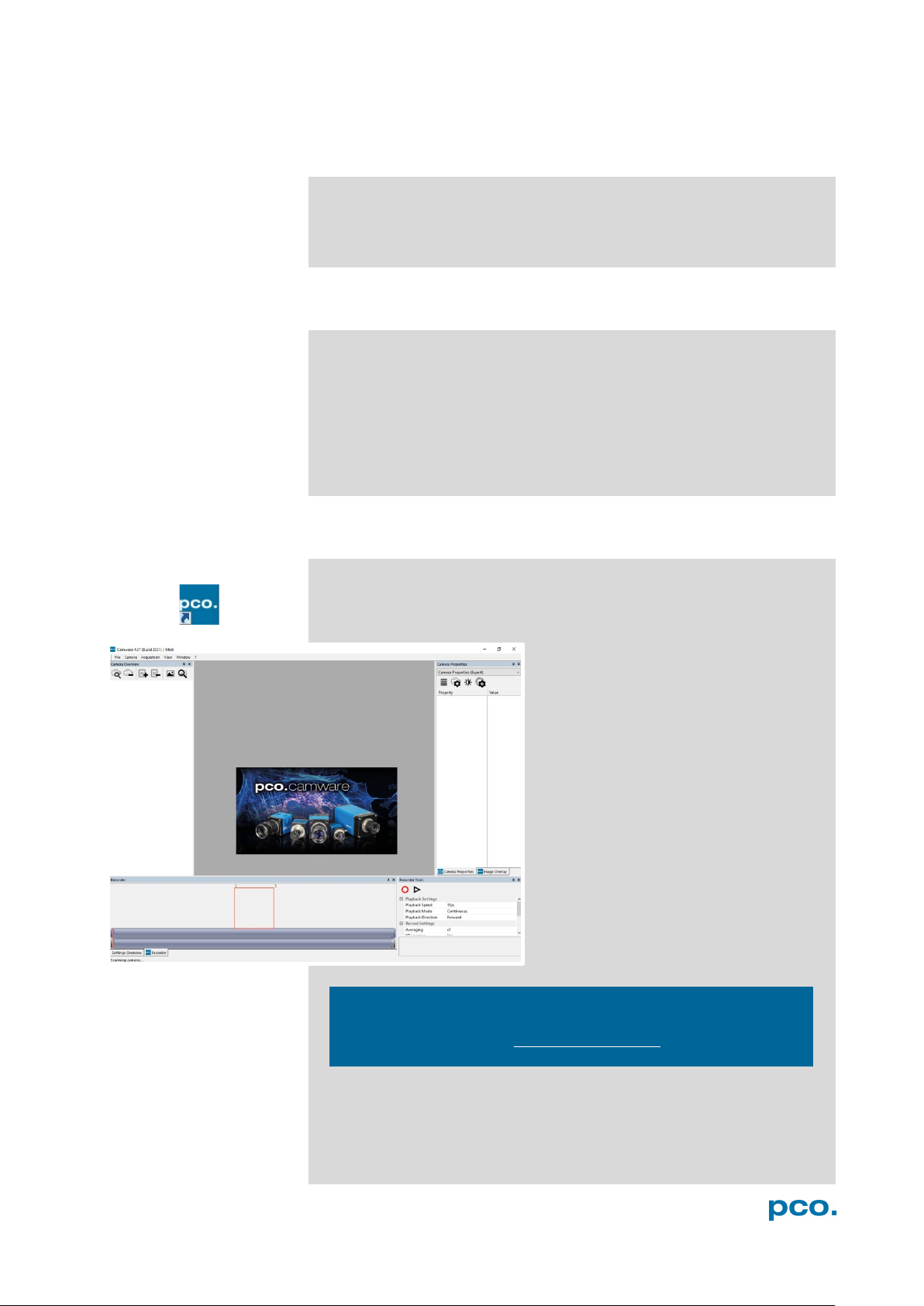

5.2 START

Start pco.camware and the graphical user interface starts up:

NOTE

Always install latest pco.camware version to be able to use full

function of your camera (www.pco.de/support

).

9

7

6

2

2

4 5 6

7

3

4 5 1

1

3

5.3 FIRST IMAGE

Follow the Instructions

• pco.camware must be started

• A View Window is shown automatically or open a new one

• Start Live Preview

• Right-click in the view window & apply Continuous Auto Range

• You may adjust Exposure time , aperture and focus of the

mounted lens

• Now you should clearly see the object in the window

To change Exposure time (e.g. the

image is still either too dark or too

bright) and to record and save

images, see pco.camware manual

for detailed information.

NOTE

Live preview: useful for fast and easy camera adjustment and

focusing.

10

6 ROLLING

pco.edge 4.2 bi (UV)

NOTE

exposure and

delay time can be

adjusted in steps of

6. ROLLING SHUTTER

The pco.edge 4.2 bi (UV) uses the rolling shutter mode. In this mode

the pixel reset and exposure start is carried out line by line. Each line

has the same exposure time, but a different start and end of

exposure. Within one line, the exposure starts simultaneously for all

pixels.

The exposure time of each line starts with the corresponding reset of

the line. Then after a predefined time (exposure time), the exposure is

stopped. The light induced accumulated charge carriers of the pixels

in a line are recorded into memory in a low noise (readout) mode. This

way the content of the pixels is assembled in the memory to form the

complete image.

The diagram shows different signal timing settings (see chapter 7.1).

During Show common time of ‘All Lines’ the image sensor is

completely exposed to light. The labels Show time of ‘First Line’

and ‘Last Line’ are the setting for the first / last exposed line and

Show overall time of ‘All Lines’ for the entire exposure period.

There are two different timing cases for rolling shutter mode, which

are explained on the following pages:

• exposure time > sensor readout time

• exposure time < sensor readout time

Rolling Shutter General Timing Diagram

SHUTTER

The

one line time.

Timing

Camera Exposure time Delay time Line time

USB 3.1

11

10 μs … 20 s 0 … 5 s 12.174 μs

Exposure time > Sensor frame readout time

In case the required exposure time is longer than the frame readout

time, the image sensor is completely exposed to light for some time

(Show common time of ‘All Lines’ also see General Timing

Diagram). In case of a triggered flash illumination, this would be the

best moment to illuminate the image sensor. The hardware signal for

the time Show common time of ‘All Lines’ is available on connector

#4 (see 7.1).

This is an example timing diagram for Trigger Mode Auto

Sequence, SMA explanation see 7.1

Δt = 4.4 μs

12

6 ROLLING

SHUTTER

exposure stop & readout

reset & exposure start

band of simultaneous exposures

Exposure time < Sensor frame readout time

In case the required exposure time is shorter than the frame readout

time, the image is readout through an exposure band moving from

the top to the bottom of the sensor.

For example:

How can you calculate the band of simultaneous exposure lines at an

exposure time of 100μs (@ full resolution)?

Exposure time

Line time

This is an example timing diagram for Trigger Mode Auto

Sequence, SMA explanation see 7.1

= Number of simultaneous exposure lines

100 µs

12.174 µ

= 8,2 → 8 lines

13

t

Jitter

≤

t

Fixed system delay of rising edge

2x line time1

t

Programmable delay time

0 μs … 5 s

NOTE

can be a

The jitter t

jit

maximum of one line

time.

Details for External Exposure Start and External Exposure Control

The detailed timing for external trigger includes system delay times,

an adjustable additional delay time, and the jitter. Explanation for all

Trigger Modes see pco.camware manual.

Name Explanation Value

jit

rsys

delay

1

line time = 12.174 μs

For optimized synchronization (minimized jitter time) use the falling

edge of the line signal at the Status Expos output SMA #4 (see 7.1).

System time t

is depending on your camera settings and can be

rsys

read out from your camera, for further information see SDK manual

function PCO_GetImageTiming.

1 line time1

14

7 CAMWARE

1

2 3 4

1

2 3 4

1 2 3

4

7. CAMWARE SOFTWARE

This chapter contains only camera-specific additions to the

pco.camware manual. All main functions and explanations can be

found in the pco.camware manual.

7.1 HARDWARE IO CONTROL

Change setting are done via drop-down menu.

Exposure Trigger

If checked, a signal for External Exposure Start Trigger Mode

is accepted at the Exposure Trigger SMA input #1.

Exposure Trigger: On; Off

Signal Polarity: Rising; Falling

Aquire Enable

SOFTWARE

If checked, a signal for Acquire Mode is accepted at the Acquire

Enable SMA input #2.

Acquire Enable: On; Off

Signal Polarity: High; Low

Status Busy

If checked on, a signal indicating busy status is provided at the

Status Busy output. Once an acceptable trigger edge is received,

‘busy’ goes to status high. As soon as ‘busy’ goes low again, a new

trigger edge is accepted.

Status Busy: On; Off

Signal Polarity: High; Low

Status Expos / Status Line

If checked, a signal indicating exposure or line status is given at the

status output. Status Expos indicates the actual exposure window

for one frame. Use the falling edge of the Status Line signal for

optimized synchronization.

Detailed explanation for Signal timing see next page!

Select IO Signal: Status Expos; Status Line

Signal timing: Show time of ‘First Line’; Show common time of

‘All lines’; Show time of ‘Last line’; Show overall time of ‘All lines’

Status Expos: On; Off

Signal Polarity: High; Low

15

1 2 4

3 1 2

4

3

1

2

3

4

Enabling and Polarity of IO Signals

The polarity of the input and output signals indicating their active

states is selectable (positive or negative logic).

The polarity of level-sensitive signals can be set to High (positive

logic) or Low (negative logic).

The polarity of edge-sensitive signals can be set to Rising (positive

logic) or Falling (negative logic).

Detailed Explanation for Status Expos SMA #4 Signal Timing

Setting in pco.camware:

There are four different signal types selectable. The example timing

diagram shows all four different possibilities:

• Shows the exposure time of the first line

• Shows when all sensor lines are exposed

• Shows the exposure time of the last line

• Shows if any sensor line is integrating

16

APPENDIX

APPENDIX

A1 TECHNICAL DATA 18

A1.1 DATA SHEET 18

A1.2 MECHANICAL DIMENSIONS 19

A1.3 REAR PANEL 20

A2 HARDWARE MOUNTING 21

A2.1 USB CARD INSTALLATION 21

A2.2 CABLE MOUNTING 22

A2.3 DIRECT CAMERA MOUNTING 23

A3 F-MOUNT ADAPTER 24

A3.1 PCO F-MOUNT ADAPTER 24

A3.2 CHANGE FROM F-MOUNT TO C-MOUNT 25

A4 WATER COOLING OPTION PCO.AQUAMATIC II 26

A4.1 SYSTEM COMPONENTS 26

A4.2 FIRST TIME INSTALLATION 27

A4.3 OPERATION 28

A4.4 DIMENSIONS 29

A4.5 YOUR OWN COOLING SYSTEM 29

A5 CUSTOMER SERVICE 30

A5.1 SERVICE 30

A5.2 MAINTENANCE 30

A5.3 RECYCLING 30

A5.4 TROUBLE SHOOTING 31

A6 INDEX 32

ABOUT PCO 33

17

Image sensor

pco.edge 4.2 bi (UV)

Type of sensor

Customized sCMOS

Resolution (h x v)

2048 x 2048 pixel

Pixel size (h x v)

6.5 μm x 6.5 μm

Sensor format / diagonal

13.3 x 13.3 mm / 18.8 mm

Shutter mode

Rolling Shutter (RS)

MTF

76.9 lp/mm (theoretical)

Camera

Frame rate

40 fps @ full resolution

Exposure / shutter time

10 μs ... 20 s

Dynamic range A/D

16 bit

Binning (h x v)

1x1 ... 4x4

Cooling method

Adjustable: from -25°C to +20°C

Calibration setpoint: -10°C

Trigger input signals

Frame Trigger, Acquire (SMA connectors)

Trigger output signals

Exposure, Busy (SMA connectors)

Data interface

USB 3.1 Gen1

Timestamp

In image (1 μs resolution)

General

Power delivery

Power over USB 3.1 Gen1 Type-C and power

connector (24 VDC +/- 10%)

Power consumption

Typ. 4.5 W over USB 3.1 Gen 1 and

Weight

920 g

Operating temperature

+10°C ... +40°C

Operating humidity range

10% ... 80% (non-condensing)

Storing temperature

range

-10°C ... +60°C

Optical interface

F-mount, C-mount

CE / FCC certified

Yes

ROI step sizes

Horizontal steps

32 pixel steps

Vertical steps

8 pixel steps

Minimum ROI

64 x 16 pixels

A1 TECHNICAL DATA

A1.1 DATA SHEET

Peltier with forced air (fan) and water cooling.

typ. 10.0 W (max. 22.0 W) over power

connector

Subject to change, refer to current data sheet available on our website.

18

A1 TECHNICAL DATA

NOTE

focal distance:

A1.2 MECHANICAL DIMENSIONS

C-Mount flange

17.52 mm

All dimensions given in millimeter.

2D and 3D technical drawings are available on our website

3D step files and further technical drawings are available on request.

19

Color

Description

Red / green continuous

Camera is booting

Green

Camera is ready for operation

Orange continuous

Arm camera / rec state off

Orange blinking

Recording on

Red continuous

Error

Input (1=Exposure Trigger; 2=Acquire Enable)

Type

Digital

Level

3.3 V LVTTL (5 V tolerant)

Coupling

DC

Impedance

1 kΩ

Slew rate

> 1 V/ms

Output (3=Status Busy; 4=Status Expos)

Type

Digital

Level

3.3 V LVTTL

Coupling

DC

LEMO socket ECG.0B.302.CLV

Pin1

Ground

Pin2

VCC 24 V DC (+10%)

3 1 4

2

1

4

3

2

5

6

Pin1

Pin2

5

6

A1.3 REAR PANEL

Status LEDs

(LED1: green / red; LED 2: orange)

Interface Connector

USB 3.1 plug Type-C screwable;

Power delivery for the camera over USB cable

SMA Inputs

(see chapter 7)

SMA Outputs

(see chapter 7)

Power Input

Appropiate Lemo plug: FGG.0B.302.CLAD52Z

Power Switch

20

A2 HARDWARE MOUNTING

1

1

3

2

2

3

WARNING

NOTE

operation, each

edge 4.2 bi

own USB host

A2 HARDWARE MOUNTING

Instructions how to mount the pco.edge 4.2 bi (UV) camera system.

A2.1 USB CARD INSTALLATION

An external USB 3.0 / 3.1 Gen1 host controller card comes along with

to each pco.edge 4.2 bi (UV) camera.

Hardware Installation

First shut down your computer and install the USB 3.0 / 3.1 Gen1

host controller card. Hardware installation must be performed by a

technician, because high voltages can occur on the device.

ELECTRIC SHOCK WARNING DUE TO VOLTAGE PARTS INSIDE

Risk of injury due to electrical shock.

Always pull the main plug before opening the computer.

Driver Installation Instructions

In multi-camera

pco.

camera needs its

controller card.

• If your current OS is Win 7 / 8 and the User Account Control is

• Within the provided installation files USB_HBA, open the folder

U3X4-PCIE4XE101, U3X4-PCIE1XE101, U3-PCIE1XG202.

• Open the subfolder Driver and run RENESAS-USB3-Host-Driver-

30230-setup.exe.

enabled, a dialog prompts whether you wish to start the setup:

accept with Yes.

• At first the installation is prepared.

• Secondly the software components are copied automatically.

• Finally the installation is completed and the Delock USB 3.0 / 3.1

Gen1 extension card can be used.

21

NOTICE

A2.2 CABLE MOUNTING

In order to ensure a proper function of the pco.edge 4.2 bi (UV), it is

necessary to secure the USB cable by the fixing screws.

The accompanying USB cable is screwable on both ends of the

cable.

The maximum torque for the screws is 0.1 Nm.

Screw Connection to the Camera (recommended)

• The screw threads of the camera are very sensitive due to the

• Plug the USB cable into the camera.

• Then attach the fittings to the threads by hand.

Screw Connection to the Computer (optional)

small size.

• Attach the cable to the USB card in the same way.

22

A2 HARDWARE MOUNTING

3 1 2

3 4 4 1 2

NOTICE

A2.3 DIRECT CAMERA MOUNTING

The hardware design allows to mount the camera very close to an

optical setup (e.g. a microscope) without F- or C-mount adapter but

with the help of a rubber ring.

This allows to reduce the distance from the focal plane of the sensor

to the adaption plate to only 6.18 mm.

Contact us, if you need the rubber ring. The ring is not included in the

standard package of the camera:

O-ring D 55 x 1.5 material number: 10305100011

The rubber ring is essential for this direct adaption, as it is necessary

to block parasitic light.

Mounting Steps

First, the adapter containing the lens mount must be removed.

Completely unscrew the four cylinder head screws M4 x 8 and

remove the adapter.

As second step, place the rubber ring in the intended recess of the

camera.

Finally screw the camera to your optical setup by using the four M4

screw sockets .

Always make sure that the O-ring does not slip out of the recess!

23

Type 35mm F-Mount

• A012: SP 15-30mm F/2.8 Di VC USD

• F017: SP 90mm F/2.8 Di MACRO 1:1 VC USD

Type APS-C(H) F-Mount

•

• G005: SP AF 60mm F/2.0 Di II LD [IF] Macro 1:1

A3 F-MOUNT ADAPTER

A3.1 PCO F-MOUNT ADAPTER

Matching Lenses with Automatic Diaphragm

PCO's proprietary F-mount adapter for lenses

with automatic diaphragm. Sets manually the

lens aperture by turning the ring on the

adapter.

F-mount lenses

without automatic

diaphragm can be

fastened to the

camera's mount but

the aperture not

changed.

Adjust Back Focal Length

To adjust the back focal length (e.g. you

cannot focus to infinity or to the minimum

object distance of your lens), proceed as

follows:

Set the focus of your lens to infinity. Look at

an object in infinity and generate a sharp

image by turning the adapter. Use the

rearmost ring to fix the setting.

Nikon: all Nikkor lenses of type D and type G (not for type E, this one

is only electronic).

Zeiss: all ZEISS ZF.2 lenses (Otus, Milvus, Interlock, Distagon,

Planar).

Sigma: only lenses, which already have a manual diaphragm ring; all

other lenses have an aperture control lever, which does not spring

back, if you turn the aperture ring at the adapter.

Tamron: only some lenses provide automatic diaphragm (no

particular lens family):

• A007: SP 24-70mm F/2.8 Di VC USD

• A009: SP 70-200mm F/2.8 Di VC USD

• A011: SP 150-600mm F/5-6.3 Di VC USD

• F012: SP 35mm F/1.8 Di VC USD

• F013: SP 45mm F/1.8 Di VC USD

B001: SP AF 10-24mm F/3.5-4.5 Di II LD Aspherical [IF]

• B005: SP AF 17-50mm F/2.8 XR Di II VC LD Aspherical [IF]

24

A3 F-MOUNT ADAPTER

1

1

2 2 2 4 4

3

3

A3.2 CHANGE FROM F-MOUNT TO C-MOUNT

How to change the optical input from F-mount to C-mount.

MECHANICAL DAMAGE OF THE C-MOUNT RING

NOTICE

Tightening the hexagon socket setscrews too tight will permanently

damage the C-mount ring.

Use a torque wrench and select a maximum torque of 1 Nm

to tighten the hexagon socket setscrews.

Step 1: Remove F-mount adapter

Turn the black lock ring counterclockwise to loosen the F-mount

adapter and then unscrew it.

Step 2: Insert C-mount ring

Carefully screw the C-mount ring clockwise. The two hexagon

setscrews must be visible on the outside.

Step 3: Adjust flange focal distance

In order to reach the standard support dimension of C-mount (17.526

mm), screw in the C-mount ring so far that it protrudes outwards a

distance of 1.8 mm .

For fine adjustment use a suitable lens with large aperture.

Step 4: Fix the C-mount ring

To fix the C-mount ring, tighten both hexagon setscrews (1.5 mm

hex key) to a maximum torque of 1 Nm.

Limitations of C-mount Lenses

Keep in mind that C-mount lenses could cause shadings at the edges

of big sized sensors. Most C-mount lenses are able to illuminate a

maximum image circle of 11 mm (2/3”), 16 mm (1”) or 22 mm (4/3”)

diameter only. The pco.edge bi has a sensor diagonal of 18.8 mm, it

follows that you have to use the ROI function for a shade less image

while using the C-mount adapter with the two smaller C-mount

diameters.

25

Description

pco.aquamatic

connection tube 5m PVC 3541-01 PCO (Colder NS212 fittings)

power supply (1.2m cable length)

power cable

camera cable 5m (FGG-RG58-NC3MX)

Innovatec Protect IP 1l

NOTE

1

2

6

1 2 3 4 5

6

4

3

5

A4 WATER COOLING OPTION PCO.AQUAMATIC II

This is the re-cooling system for pco.edge cameras with watercooling.

A4.1 SYSTEM COMPONENTS

Normally no maintenance and almost no care is required. Only the

coolant’s level of the reservoir (water tank) should be checked from

time to time.

Only use Innovatec Protect IP for the pco.aquamatic! Do not use or

add any other coolant or normal water! If you need to add cooling

liquid in order to maintain the tank level, contact PCO for additional

supply.

The coolant will turn yellow after some hours of operation. This is

normal and no sign of wear or malfunction. The optimum pH-value is

between 8 and 9 (check this value if you are concerned about the

coolant’s quality).

The recommended service interval for the change of the coolant is

four years.

26

A4 WATER COOLING OPTION PCO.AQUAMATIC II

1

1 2 3 4 5

6

2

3

4

5

NOTE

The hose connectors are waterproof in not connected state.

system.

6

A4.2 FIRST TIME INSTALLATION

Take care to place the unit on a flat and firm surface. Do not cover

the cooling vents of the unit. Ensure free airflow around the

pco.aquamatic for maximum cooling performance. All tubes and

power cords need to run kink-free.

Before installation of the unit carefully read the Innovatek Protect

IP safety datasheet (see Innovatek Website

Follow Steps 1 – 6

1. Connect tubes to cooling unit and camera. The two arrows on the

housing of the cooling unit only indicate flow direction. Either

connection of the camera can be used for in or out.

2. Connect to power.

3. Open tank cover.

4. Turn power switch on (I).

• Slowly fill in the coolant while the unit is running. Refill as needed

to keep the level.

• While the cooling liquid flows back to the tank make sure all air

gets out of the system – this takes a few minutes (move hoses if

necessary).

).

outlet flow

inlet flow

The cooling liquid tank is full when liquid level is approximately 1-2

cm from the top of the tank. The integrated pump only works when

the pump chamber is completely filled. To ensure this Move hoses or

remove air by evacuating. Tank capacity is approximately 500 ml.

After steps 1 – 6 are completed successfully the system is ready for

operation.

Maybe they lose one drop of cooling liquid from time to time.

There is no need to empty the hoses while storing the camera

27

on

off

none

1Hz

flash

warning when temperature at 55 °C

(also if sensor is defect or missing)

2Hz

flash

fan speed

Temperature

Action

27°C

fan turns off

36°C

fan turns on

55°C

warning message

60°C

error message

NOTE

A4.3 OPERATION

First connect the power out of the cooling unit with the power in of

the pco.edge camera by using the PCO WAT camera cable.

The cooling unit provides two operation modes.

Operation Mode on: the cooling unit turns on and

provides permanently power to the camera. The

camera can be switchted on and off as needed.

Operation mode follow: the cooling unit turns on when

the camera is switched on and vice versa.

Error Codes

The coolant temperature sensor is located in the coolant tank.

If a warning level is passed, the Power LED blinks slowly and the

Error LED displays the error code. If a failure level is passed, the

Power LED blinks fast and the Error LED shows the error code.

Error / Failure

one short flash

one short flash failure when temperature at 60 °C

1Hz

flash

two short

flashes

(also if a high deviation of the standard value

is reached)

The camera has its own protection circuit and will shut down

Peltier cooling automatically when the electronics temperature

exceeds safety level. The camera itself will keep on running, but

sensor temperature will increase. (valid for air and water cooling!)

If the camera and the water cooler have a different power supply,

always first shut down camera and then the cooling system to

avoid damages.

28

A4 WATER COOLING OPTION PCO.AQUAMATIC II

A4.4 DIMENSIONS

All dimensions are given in millimeter.

Weight: 4kg (completely filled coolant tank)

A4.5 YOUR OWN COOLING SYSTEM

You are not obliged to purchase the pco.aquamatic system - you

may use your own water cooling device. A separate power supply will

be provided to every pco.edge camera with water connection. The

hardware of the pco.edge cameras with USB 3.1 interface is

designed to work with or without a water cooling system. A fan inside

the camera provides adequate cooling anyway.

In case you use an own water cooling system, make sure the liquid

you use to cool your camera is always ABOVE the dew point of the

ambient temperature. In order to avoid any occurance of

condensation, use a cooling liquid at room temperature.

• A liquid flow rate of 1–2 litres per minute is sufficient

• Always use Innovatec Protect IP cooling fluid or an equivalent

cooling fluid

29

NOTICE

CAUTION

NOTICE

NOTICE

NOTICE

A5 CUSTOMER SERVICE

A5.1 SERVICE

The camera is designed to operate with no need of special

adjustments or periodic inspections.

A5.2 MAINTENANCE

UNPLUG CAMERA BEFORE CLEANING

Risk of injury due to electric shock!

Unplug the camera from any power supply before cleaning it.

CLEANING

Use a soft, dry cloth for cleaning the camera.

Do not clean the input window unless it is absolutely

necessary (clean it with pressurized air).

Be careful and avoid scratches and damage to the input

window surface.

Do not use liquid cleaners or sprays.

LENS CLEANING

The lens is best cleaned with pressurized air or with liquid

cleaners such as pure alcohol or with special optical

cleaners that are available at high quality photo stores.

Use a cotton swab dipped in pure alcohol or optical cleaning

liquid and wipe only on the glass surface.

Do not get any cleaning liquid on the metallic parts such as

the lens thread, because tiny detached particles may scratch

the surface.

CLEANING LIQUIDS

Aggressive cleaning liquids can damage your camera.

Never use aggressive cleaning liquids such as gasoline,

acetone, spirits or nitro cleanser.

Every time the input window is cleaned, there is the

possibility of surface damage.

PROTECTIVE CAP

Always store the camera with the protective cap or with a lens

mounted to avoid dust and dirt on the input window.

A5.3 RECYCLING

If you want to dispose your camera, send it to PCO or take it to a

local recycling center.

The camera includes electronic devices, which can contain materials

harmful to the environment. These electronic devices must be

recycled.

30

A5 CUSTOMER SERVICE

1

1 2 2 3 3

A5.4 TROUBLE SHOOTING

Use pco.camware to create logfiles for the PCO support.

How to Create Logfiles

Enable Logging

? Help menu, select Logging and then Enable Logging

Open

The pco.camware will ask you to press YES to activate Logfiles after a

restart of the software.

Repeat Workflow

The workflow which produces the error must be repeated while

logging is enabled.

Support Mail (+Support File)

Open ? Help menu, select Support Mail (+Support File) and a

support file with all necessary files is created

The pco.camware opens a new email addressed to

support@pco.de

and send the mail to the PCO support.

Alternatively use the support form on our website:

http://www.pco.de/support/

To Speed up Your Request

, attach the Support File manually to this mail

and upload the support file.

Give us the following information:

• Describe your problem!

• Your application?

• Your camera:

o Type and version

o Serial number

• Your setup:

o Software version

o Operating system

o Processor and memory

o Graphics card

Firmware, Software and Driver Update

You will find all necessary software and drivers on the accompanying

USB storage device. For the latest versions check PCO website

31

.

Keyword

Chapter

Page

Camware installation

4.2

8

Cleaning

A5.1

30

Components camera system

3

6

Cuda Nvidia driver

4.1

7

Data sheet

A1.1

18

Dimensions

A1.2

19

Driver installation

4.1

7

F

A3

24

First Image

5.3

10

Hardware I/O Control

7.1

15

Input / Output possibilities

7.1

15

Installation 4 7

Live preview

5.3

10

Logfiles

A5.4

31

M

A5.2

30

Mounting

A2.2

22

R

A1.3

20

Recycling

A5.3

30

Rolling Shutter

6

11

Safety instructions

2

5

Support

A5

30

T

A5.4

31

USB card installation

A2.1

21

USB driver installation

4.1

7

Water Cooling

A4

26

NOTE:

always the starting

page of a chapter!

A6 INDEX

The mentioned page is

-Mount

aintenance

ear connections

rouble Shooting

32

ABOUT PCO

pco.

ABOUT PCO

pco.history

“PCO” stands for what we are: a Pioneer in Cameras and Optoelectronics. With 30 years of expert

knowledge and experience PCO has forged ahead to becoming a leading specialist and innovator

in digital imaging used in scientific and industrial applications such as life and physical science,

high-speed imaging and machine vision. However, the beginning of PCO’s story of success dates

back to the 1980s and a research project of the founder, Dr. Emil Ott, who was working at the

Technical University Munich for the Chair of Technical Electrophysics. While performing

measurements with intensified slow scan cameras, Dr. Ott realized that the existing standard did

not meet the sophisticated requirements of scientific applications – and so PCO came to life in

1987. With a small team of engineers Dr. Ott began to develop his first image intensified camera

followed by several variations on the original model, geared to overcoming all the existing flaws

and surpassing standards of the day. During these early years PCO developed a now well

established core of advance technologies used as the foundation to develop cutting edge

products.

In the early 1990s PCO expanded its business activities to the global market by successfully

establishing an international network of highly trained sales partners and customers. We entered

additional fields beyond traditional scientific research expanding the potential for our cameras’

applications in life science, automotive testing and even broadcasting. This step paved the way

for a wide range of innovative highlights:

As of 2017, PCO has three decades of technical know-how and expert knowledge in the

development and manufacturing of high-performing camera systems. In-house competence of all

significant technical disciplines and partnering with leading image sensors manufactures ensures

cutting edge sCMOS, CMOS and CCD technology for all PCO cameras.

pco.prospect

“If you want to do something special, particularly in the high end fields, you have to develop your

own image sensors. So we work with partner companies who develop tailored sensors made

especially for us. This is something we are doing continuously, so we’re already working on the

next generation of cameras that we will introduce in the coming years” – Dr. Emil Ott.

In PCO’s first 30 years, Dr. Emil Ott took a company that he started right after finishing university

and has built it into a major player in scientific and industrial cameras – and there’s plenty more to

come.

33

pco.

Loading...

Loading...