Page 1

76433 Issue 2

www.pclairtechnology.com

D90/91/92/93 Tyre Inflator Quick Start Manual

Safety Guidelines

This manual contains information that is very important to know

and understand. This information is provided for safety and to

prevent equipment problems. To help recognise this information,

observe the following symbols.

Danger indicates an imminently hazardous

situation which if not avoided WILL result

in death or serious injury.

Warning indicates a potentially hazardous

situation which if not avoided, COULD

result in death or serious injury.

Caution indicates a potentially minor or

moderate injury.

Notice indicates important information,

that if not followed, may cause damage to

equipment.

Unpacking

After unpacking the unit, inspect carefully for any damage that

may have occurred during transit.

Do not operate unit if damaged during

shipping, handling or use.

General Safety Information

The operator of this product must take the necessary precautions

to prevent the level of danger indicated by these symbols. The

operator is required to read and understand this instruction

manual and all safety warnings, labels etc.

Any employer allowing the use of this product in their field of work

must distribute this instruction manual to all users. The employer

must also ensure all users read, understand and follow the

instructions as described in the manual, safety warnings, labels,

etc.

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

Purchased airtower may not be representative of the image shown

Read and understand all safety warnings

and instructions before operating this

product. Failure to read and follow all

safety warnings may result in serious

personnel injury or death. Property

damage and/or product damage may also

occur if all warnings are not followed.

1. Do not expose the product to flammable gases,

vapours or fumes

2. Do not store flammable gases in or near this product

3. Never use flammable or toxic solvents to clean the

product or any of the unit's parts

4. Never remove or alter any safety warning labels, tags,

etc. located or provided with product.

5. Follow all directions for maintenance.

The use of other than genuine PCL

replacement parts may result in reduced

equipment performance. Repairs must be

performed by authorised repair personnel,

otherwise the warranty will be void.

PART NUMBER

SERIAL NUMBER

Page 2

PCL D90 series Tyre Inflator

www.pclairtechnology.com

General Specifications

D90 and D91

Max inlet supply: 218 psi / 15 bar / 1500 kPa

Recommended supply : 10 psi / 0.7 bar / 70 kPa

above the max set pressure of Inflator

D92 and D93 optional internal 7 or 10 bar compressor

Max operating pressure : 145 psi / 10 bar / 1000kPa (10 bar)

Max operating pressure : 80 psi / 5-50 bar / 550kPa (7 bar)

Min operating pressure: 4 psi / 0.3 bar / 30 kPa

Display resolution: 1 psi / 0.1 bar / 10 kPa

Units of measurement: psi / bar / kPa / kg/cm

Electrical Installation

In order to provide a trouble free operation it is necessary to

connect the power supply from the main switchboard with a MAX

3amp fuse/RCB protection device. This must be grounded.

The circuit breaker should be marked as the disconnecting device

for the equipment.

Inside installations

Use 3 pin connecting plugs or 2 pin + Earth with the Earth Ground

wire installed on electrical infrastructure. This must be grounded.

Outdoor installations

The unit must be connected to an earth conductor or conducting

metal work (metal pipe conduit or sheathing) which has

equipotential bonding to the main Earthing point of the installation.

The unit is designed to run with the earth connection installed.

"According to Class 1 - Basic insulation in conjunction with

protective Earthing"

Air installation

For models D90 and D91 only

The compressor producing the air should have the necessary

water and dirt filtration, to minimise accumulation of debris at the

inflator line filter strainer.

For efficient tyre inflation, ensure that the air supply is 10 psi, 0.7

bar or 70kPa above the intended maximum inflation range.

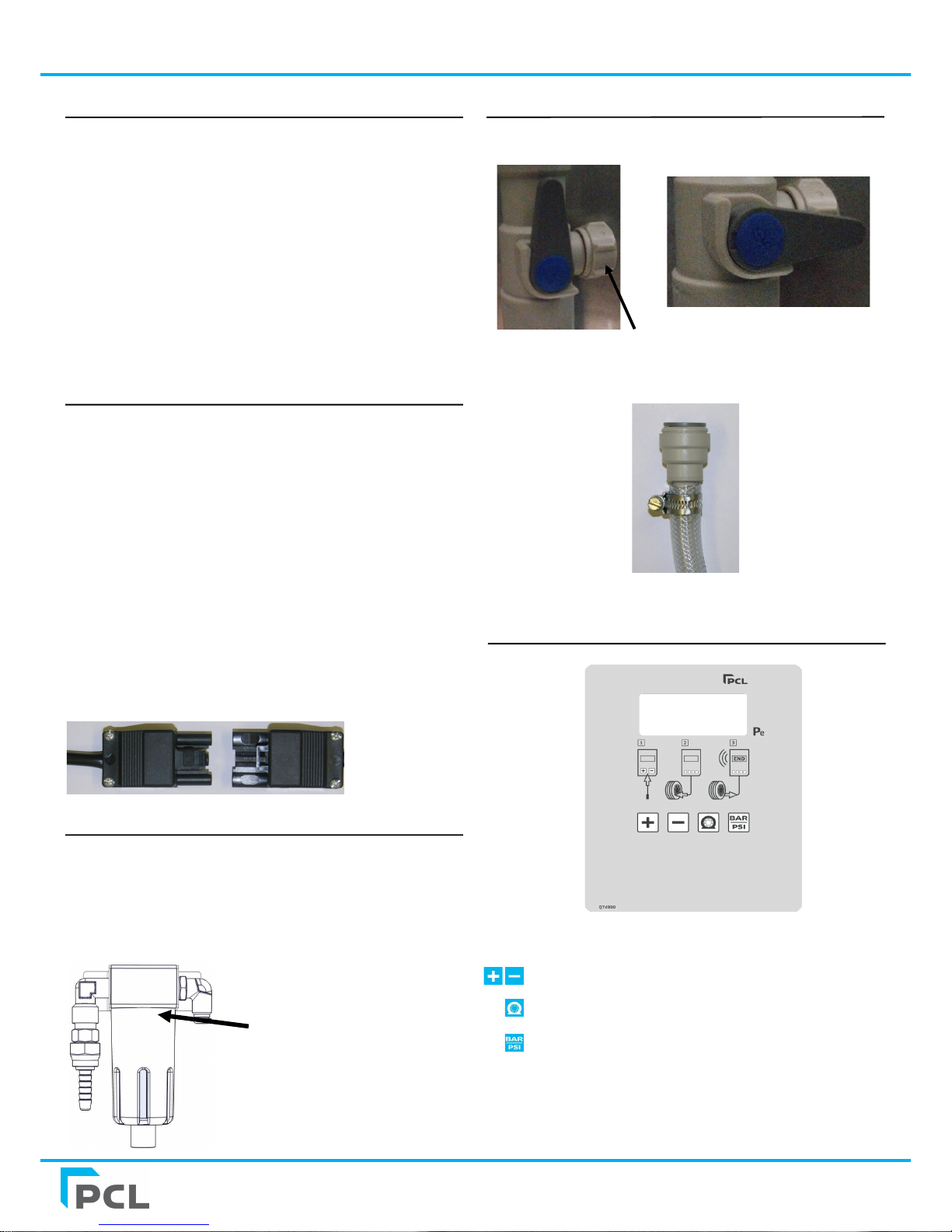

Air supply port

R1/4

Electrical supply

ST-18 Socket

Control Panel

Key Legend

Increase or decrease to set pressure

Start flat tyre inflation

Switch pressure unit

Note:

Key legend above is for standard PCL decal, symbols used may

vary by individual part number but functionality remains the same

Water installation (optional)

For models D91 and D93 ensure that 15mm piping is available to

connect to the water supply port.

Water supply port

(where fitted) 15mm

tubing/pipe

Stop valve

On position

Stop valve

Off position

Double check valve

(anti syphon)

Page 3

PCL D90 series Tyre Inflator

www.pclairtechnology.com

Start-up

1. Turn on power supply via the isolator switch.

2. Display will show all LCD digits check

3. Display will show the current Firmware version number e.g.

'3.2.1'

4. Display will show Program model variant '300' ( psi default)

or '302' (bar default)

5. Display will show the application, 'Std'

6. After 10 seconds the display will show 'PCL'

7. The unit will then display the set default pressure

Do not connect the hose to the tyre during start-up or E5

will show

Standard Operation

Inflation and deflation

1. Set desired pressure, by touching either or

2. Connect the hose to the tyre.

3. Automatic inflation will commence to the set pressure,

periodically stopping to display the pressure of the tyre.

4. If the pressure in the tyre is below 3 psi, 0.2 bar or 20 kPa,

the process will not commence until is touched.

5. When the Set pressure is reached, the buzzer will sound

and the display will show 'END' with the final pressure.

6. Remove the hose from tyre.

7. For selection of alternative pressure unit touch .

For adjustments to Inflators parameters

please refer to your Distributor or PCL.

This unit is not suitable for the filling of

bicycle tyres with a standard (Presta,

Woods) bicycle valves and adapters. Over

fill of the tyre is possible!

User Inspection mode

It is possible to set the inflator to act as a pressure gauge.

The display resolution is changed and can be used to reference the

inflator against a calibrated pressure source. The inflator automatic

cycle is inhibited.

To access:-

1. Touch and together

2. The unit will beep but the display will not change

3. Touch 5 times

(if this is not undertaken within 10 seconds, the Inflator

reverts back to normal Inflator mode)

4. Display will show the pressures to the minimum resolution:

psi = 0.1 / Bar = 0.01 / kPa = 1 / kg/cm = 0.01

5. Connect the hose to the tyre and the display will show the

pressure in the tyre

6. When complete, touch any button to return to the last set

mode.

Isolator switch

The isolator can be turned off by simply turning the

switch clockwise or anti-clockwise.

There is a 10amp fuse installed inside the isolator

switch.

Coin mech (Optional)

1. Use the keys provided to open the door.

2. Take the coin mech holder out from underneath the

coin mech and empty the contents.

3. Re-attach the holder and lock the doors.

Page 4

PCL D90 series Tyre Inflator

www.pclairtechnology.com

Template for mounting the airtower to the floor.

Page 5

PCL D90 series Tyre Inflator

www.pclairtechnology.com

Service/Maintenance

There is no requirement to service the following items:

1. Pressure Transducer

2. Electric Control Board

If these are faulty they can only be

replaced by a competent person.

Please refer to an Authorised

dealer.

Periodically

Check the hose.

Check the tyre connector.

Remove air input supply and tyre hose from the head.

Unscrew captive sintered filters from filter housings and

clean or replace.

Working safety instructions

Since the unit is not explosion-proof, the device should not be

installed in areas where explosions are possible. Consideration

must be given to the requirements relative to Hazardous Area

Standards for your region or country.

The unit is designed and built to the relevant basic health and

safety requirements of the EC.

This product can be dangerous if used

improperly. Children should not be

allowed to use this equipment, as

incorrect setting can allow tyre to be

over inflated and a subsequent tyre

burst/explosion can occur!

Each person who is involved with installation, start-up,

maintenance and the operation of the unit must read and

understand the complete operating manual.

The PCL tyre inflators are exclusively approved for the

dispensing of air/N2. Each use which doesn't follow this

purpose as well as modifications to the product will be

deemed to be improper use. The manufacturer is not

liable for damages caused by improper use, the risk lies

solely with the user.

Proper use of the product also implies the

observance of the manufacturers

instructions with regard to installation,

start-up, operation and maintenance.

All works concerning installation, start-up,

adjustment and maintenance must be

made by qualified staff. For the operation

of this tyre pressure inflator the local

safety and accident prevention rules must

be observed in all cases.

High Pressure air is stored within the

system.

When using N2P mode , locate this system

in a well ventilated area. Position the

system away from any heat source.

Do not exceed the maximum air input

pressure.

Do not operate this product if tired or

under the influence of medication, drugs

or alcohol.

To avoid the risk of personal injury,

especially to the eyes, face or skin DO

NOT direct the air/N2 stream at any

person.

Page 6

PCL D90 series Tyre Inflator

www.pclairtechnology.com

Problem Possible Cause Solution

No display No power connected Switch power on

No inflation process Tyre is below 3 psi

Faulty connector

Press flat tyre button

Replace faulty connector

Buzzer does not sound Buzzer volume has been turned off

Buzzer is damaged

Turn buzzer on or

Replace buzzer

Inflation process starts but does

not complete

Low or no supply pressure

Leaks exist

Check supply pressure

Confirm leaks do not exist

Supply pressure leaks out input Input and tyre hoses are incorrectly reversed Ensure input connection is to offset port, tyre

connection is central between input and exhaust

Inflating or deflating is very slow Check that mesh filters under input and output

port fittings are blocked

Clean and or replace mesh filters

Connector will not seal to the

tyre stems

Connector worn Replace connector

Connector leak while not

connected to tyres

Connector worn Replace connector

No power to display head Isolator fuse blown Replace 10 amp isolator fuse

E1 Unstable or insufficient supply pressure Check the supply pressure

E4 Small volume, caused inflator to check pressure

> 2bar / 29psi over target pressure

Check hose is not kinked or blocked, ensure a OPEN

END connector is installed

E5 Inflator started under pressure i.e. is connected

to tyre or a CLOSED END connector is being used

Remove hose from tyre and allow inflator to reset

Change connector to OPEN END type

E6 Pressure sensor drift out New sensor required - Refer to authorised repairer

E8 Pressure sensor disconnected from PCB or faulty New sensor required - Refer to authorised repairer

E9 Pressure sensor failure - high New sensor required - Refer to authorised repairer

E10 Under voltage Check power supply

E11 Over voltage Check power supply - Refer to authorised repairer

E12 Checksum corrupted New PCB required - Refer to authorised repairer

E13 Lost or corrupted calibration settings New PCB required - Refer to authorised repairer

E16 Unit started under pressure Unit started when connected to a tyre or new sensor

required - Refer to authorised repairer

E17 Calibration settings corrupt Recalibrate unit - Refer to authorised repairer

E18 Runtime error New PCB required - Refer to authorised repairer

E19 Touch screen error New PCB required - Refer to authorised repairer

E20 - E23 Startup sequence error(s) New PCB required - Refer to authorised repairer

Trouble Shooting Guide/Error Messages

Page 7

PCL D90 series Tyre Inflator

www.pclairtechnology.com

PCL LIMITED WARRANTY

PCL warrants the components of each unit to which this Limited Warranty applies against defects in materials and workmanship for

a period of twelve (12) months from date of sale (as evidenced by bill of sale or equivalent) or for a period of eighteen (18) months

from date of shipment from PCL manufacturing facility (identifiable by the serial number and noted on original bill of lading from

the manufacturing facility), whichever period is shorter. During this warranty period and subject to the conditions set forth in this

statement, PCL will, at its option, repair or replace component parts that were defective at the time of shipment from PCL

manufacturing facility, subject, however, to the following specific EXCLUSIONS: hoses and connections.

Repair or replacement will not extend the warranty period.

Customer must give PCL timely notice of any warranty claim by contacting an authorized PCL service centre. Claims must be

accompanied by (1) evidence, by a bill of sale or equivalent, which clearly establishes date of purchase of the unit and (2) the

serial number, found on the unit. Customers must properly pack parts in their original or equivalent packaging, prepay shipping

charges, and insure the shipment or accept the risk for loss or damage in shipment. Return shipment to customer will be freight

collect unless otherwise agreed. For service at a customers location, customer will be charged the then prevailing service rates .

The Limited Warranty applies to PCL manufactured units only. Items listed in the applicable operators manual under routine

maintenance are not covered by this or any other warranty. Failure to complete maintenance as stated in any applicable

maintenance schedule will void the Limited Warranty. The Limited Warranty is expressly conditioned upon proper and normal use

and service of the unit and upon strict compliance by customer with all of PCL instructions and recommendations for installation,

operation and maintenance. The Limited Warranty does not apply to the unit or parts that are damaged or become defective due to

improper handling, maintenance, storage, use, or operation, and does not cover ordinary wear and tear, corrosion, or erosion.

THE LIMITED WARRANTY SET FORTH IN THIS STATEMENT CONSTITUTES PCL'S SOLE WARRANTY FOR THE UNIT AND

THE REMEDIES SET FORTH HEREIN CONSTITUTE CUSTOMERS SOLE REMEDIES FOR BREACH OF WARRANTY. THIS

LIMITED WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, IN FACT OR BY LAW,

INCLUDING WITHOUT LIMITING THE GENERALITY OF THE FOREGOING, ANY WARRANTY OR MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE.

Determination of the suitability of the unit for the use contemplated by the customer is the sole responsibility of the customer. PCL

shall not, under any circumstances, be liable in contract, tort or otherwise (including negligence and strict liability) for indirect,

special, incidental, or consequential damages, and PCL's total liability shall not exceed the net purchase price for the unit. PCL shall

be excused for delay or inability to perform obligations due to events beyond its reasonable control.

CUT HERE

Mail

Warranty Department

PCL

Holbrook Rise

Holbrook Industrial Estate

Sheffield

S20 3GE

United Kingdom

Warranty Registration

Please complete and mail this form to activate warranty

Or visit us at www.pclairtechnology.com

Name ________________________________________ Title __________

Company Name _______________________________________________

Type of Business ______________________________________________

Address _____________________________________________________

City ______________ County _______________ Post Code __________

Telephone ___________________________________________________

Part Number ____________________ Serial No _____________________

Purchased From _______________________________________________

Purchase Date __________________________

Page 8

Calibration Certificate

Each unit, before release, is checked and calibrated on test equipment that has accuracy

traceable to Druck pressure indicator S/N2329290.

The Druck unit is referenced to Certificate 0029346 issued by UKAS Laboratory No. 0221.

This accuracy exceeds BS EN 12645:2014 (MPE = 0.08 bar).

READING ACTUAL SET PRESSURE

1 BAR PSI KPA

2 BAR PSI KPA

PART NUMBER

SERIAL NUMBER

TESTED BY

DATE

Declaration of conformity

Note : The declaration of conformity is valid for units operating at 230V/50Hz.

2014/30/EC (EMC directive) confirmed by report No.10654/TR/1

2006/95/EC (LOW Voltage Directive)

National regulations of Germany (PTB), France (LNE), Spain (CEM) and Portugal (IPQ)

Mark McCaughey

Technical Director on behalf of PCL

Loading...

Loading...