© PCE Instruments

PCE-USC 30

User Manual

User manuals in various languages (Deutsch,

français, italiano, español, português, nederlands,

türk, polski, русский, 中文) can be downloaded here:

www.pce-instruments.com

Last change: 6 January 2017

v1.0

English

© PCE Instruments

English

Contents

1 Safety notes ........................................................................................... 1

2 Specifications ........................................................................................ 2

2.1 Technical specifications ................................................................................................... 2

3 System description ............................................................................... 4

3.1 Device .............................................................................................................................. 4

3.2 Display and Side Panels .................................................................................................. 5

Rear panel of the flaw detector: ................................................................................................. 5

3.3 Function keys ..................................................................................................................11

4 Design of the Flaw Detector ............................................................... 14

4.1 Instrument Appearance ...................................................................................................14

4.2 Structural Scheme ...........................................................................................................15

4.3 Appearance of the Flaw Detector Screen ........................................................................16

Fig. 7 – Display Appearance after switching on the Flaw Detector ............................................16

4.4 Menu Structure................................................................................................................21

4.5 “TEST” Menu ..................................................................................................................22

4.6 Guidelines for Overload Processing ................................................................................33

4.7 "Conductivity" Mode ........................................................................................................34

4.8 “General Settings” Menu .................................................................................................38

4.9 View ................................................................................................................................40

4.10 “Memory” Menu ...............................................................................................................41

4.11 “Results” Menu ................................................................................................................42

4.12 “Settings” Menu ...............................................................................................................43

4.13 Set up of “Calibration” Menu ............................................................................................43

4.14 Communication with PC ..................................................................................................46

5 Labelling and Sealing ......................................................................... 52

5.1 The flaw detector labelling complies with the manufacturer’s set of documents and

includes: ...................................................................................................................................52

5.2 Labelling is made on the flaw detector casing by polygraphic technique. .........................52

5.3 Pattern approval mark is made on the flaw detector electronic unit by at least two seals

made on screws of casing cover. ..............................................................................................52

6 Composition and Delivery Set ........................................................... 53

© PCE Instruments

6.1 Basic delivery set consists of the following components: .................................................53

7 Setting-up procedures ........................................................................ 53

7.1 The flaw detector is operated by one operator who has a corresponding level of

qualification and has studied the present operation manual. .....................................................53

7.2 Before operating charge the battery of flaw detector (if required) governed by the passport

of automatic charging device. ...................................................................................................53

8 Instructions for Use ............................................................................ 54

8.1 Single Coil Probe ............................................................................................................54

8.2 Reflection, Differential Probe ...........................................................................................54

8.3 Rotation Probe ................................................................................................................55

9 Maintenance ........................................................................................ 56

9.1 The flaw detector maintenance includes the maintenance inspection, operating repair and

calibration. ................................................................................................................................56

9.2 Intervals between the maintenance inspections are set depending on the industrial

conditions, but no less than once per month. Connecting cable fixation, condition of controls and

indicators are checked during the maintenance inspection. ......................................................56

9.3 The maintenance inspection includes an external examination and is performed by

attending personnel before starting the flaw detector electronic unit operation. .........................56

9.4 Replacement of the battery pack. ....................................................................................56

10 Typical Failures and Troubleshooting .............................................. 58

10.1 The list of the most common and probable failures is given in Table 9. ...........................58

Table 9 – Typical failures and troubleshooting ..........................................................................58

11 Transportation and Storage ............................................................... 58

12 Warranty ............................................................................................... 58

13 Disposal ............................................................................................... 59

© PCE Instruments

1

English

Thank you for purchasing a PCE-USC 30 from PCE Instruments.

1 Safety notes

Please read this manual carefully and completely before you use the device

for the first time. The device may only be used by qualified personnel and

repaired by PCE Instruments personnel. Damage or injuries caused by nonobservance of the manual are excluded from our liability and not covered by

our warranty.

The device must only be used as described in this instruction

manual. If used otherwise, this can cause dangerous situations for

the user and damage to the meter.

The instrument may only be used if the environmental conditions

(temperature, relative humidity, …) are within the ranges stated in

the technical specifications. Do not expose the device to extreme

temperatures, direct sunlight, extreme humidity or moisture.

Do not expose the device to shocks or strong vibrations.

The case should only be opened by qualified PCE Instruments

personnel.

Never use the instrument when your hands are wet.

You must not make any technical changes to the device.

The appliance should only be cleaned with a damp cloth. Use only

pH-neutral cleaner, no abrasives or solvents.

The device must only be used with accessories from PCE

Instruments or equivalent.

Before each use, inspect the case for visible damage. If any damage

is visible, do not use the device.

Do not use the instrument in explosive atmospheres.

The measurement range as stated in the specifications must not be

exceeded under any circumstances.

In operation with the flaw detector, it is necessary to observe the

safety measures while charging the storage battery unit of the flaw

detector by means of automatic charger.

In operation with the flaw detector an operator should be governed

by the safety standards in effect at the enterprise.

Non-observance of the safety notes can cause damage to the

device and injuries to the user.

© PCE Instruments

2

English

We do not assume liability for printing errors or any other mistakes in this

manual.

We expressly point to our general guarantee terms which can be found in

our general terms of business.

If you have any questions, please, contact PCE Instruments. The contact

details can be found at the end of this manual.

Safety symbols

Safety-related instructions the non-observance of which can cause damage

to the device or personal injury carry a safety symbol.

Symbol

Designation / description

General warning sign. ATTENTION!

Non-observance can cause damage to the device and injuries

to the user.

2 Specifications

2.1 Technical specifications

Range of operating frequencies adjustment – from 10 Hz to 16

МHz.

Setup of the max. sampling frequency – 10 kHz.

Setup of the range of adjustment of ECP excitation signal voltage

(double amplitude) – from 0.5 to 6.0 V.

Preamplifier adjustment – from minus 6 to plus 40 dB with a step of

0,1; 1; 10 dB.

Gain adjustment – from 0 to 30 dB with a step of 0,1, 1 and 10 dB.

Horizontal gain adjustment – from -30 to 30 dB with a step of 0.1, 1

and 10 dB.

Vertical gain adjustment – from -30 to 30 dB with a step of 0.1, 1

and 10 dB.

© PCE Instruments

3

English

When displaying the signal in a complex plane it is possible to have

the following variants: а) the complex plane center is situated in the

center of display area; b) the complex plane center is situated in the

left upper corner; c) the complex plane center is situated in the right

upper corner; d) the complex plane center is situated in the left

bottom corner; e) the complex plane center is situated in the right

bottom corner; f) all frequencies and mixtures are displayed on the

same page (when operating in dual-frequency mode); g) manual

adjustment of the positioning of the center of the complex plane.

There is automatic LED and sound flaw alarm (ALARM) in the flaw

detector.

In processing of the testing results the flaw detector provides the

following options:

− changing of ECP signal phase (the range of signal turn – from 0°

to 360° with a step of 0.1°; 1°; 10°);

− filtering of ECP signal (there are 5 types of filters: Averaging,

Differential, Low-pass, High-pass, Bandpass);

− formation of a mix of two frequencies (for combining an operator

can select one of 4 algorithms: summation, subtraction, summation

with horizontal inversion, summation with vertical inversion).

Time of continuous operation of the flaw detector from fully charged

storage battery – no less than 8 hours.

Average mean time between failures – no less than 40000 hours.

Defined no-failure operating time – 4000 hours.

Total average service life – 10 years. The criterion of marginal state

of the flaw detector is economical inexpediency of restoration of its

performance by repair.

The flaw detector is powered from the in-built storage battery with

rated voltage of 12 V.

Weight of the flaw detector with a storage battery (without ECP set,

cables and casing) – no more than 0.9 kg.

Overall dimensions of the flaw detector – no more than 230 mm x

135 mm x 98 mm.

© PCE Instruments

4

English

3 System description

3.1 Device

User manual of PCE-USC 30 portable eddy current flaw detector (hereinafter

referred to as "Flaw detector"), is intended for the study of operation

principles of the flaw detector and its operating instructions, and includes the

information on application, specifications, operating principle and structure,

operating instruction, and also other information allowing a full-scale

implementation of flaw detector technical capabilities.

The flaw detector is intended for manual and mechanized testing by

eddy current method for the presence of surface and subsurface

defects, such as material discontinuity (cracks, laps, cissings, fine

cracks etc.), for conductivity and thickness measurement.

The flaw detector can be applied for the testing of products during

their manufacture and operation by NDT services and laboratories of

enterprises that provide the products quality control.

The parameters of testing objects, which limit the flaw detector

application area, are specified in regulatory documents for a specific

type of testing products and materials.

The flaw detector provides the possibility of connecting and

operating ECP of the following types:

- differential ECP;

- differential ECP, connected by the bridge circuit;

- differential transformer ECP with center-point earth;

- differential transformer ECP;

- single (parametric) ECP;

- single transformer ECP.

The evaluation of resistance of the flaw detector and ECP

functioning quality to the impact of electromagnetic interferences of

"В" criterion according to

© PCE Instruments

5

English

3.2 Display and Side Panels

Rear panel of the flaw detector:

1 – Ethernet port for connecting a communication cable to PC;

2 – USB port for updating the flaw detector software and recording the

testing

results on the external Flash-Card

Fig. 1 – PCE-USC 30 Rear Panel

© PCE Instruments

6

English

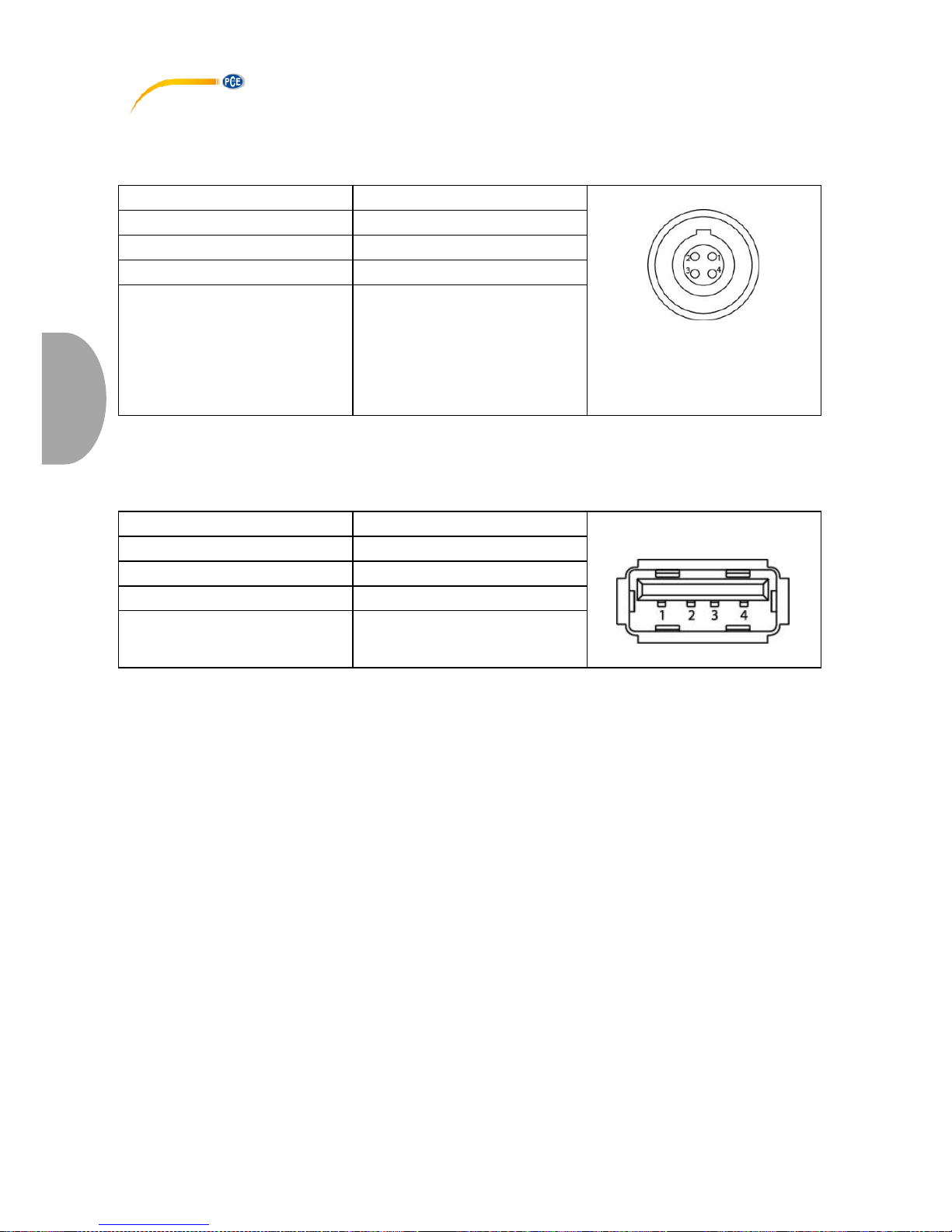

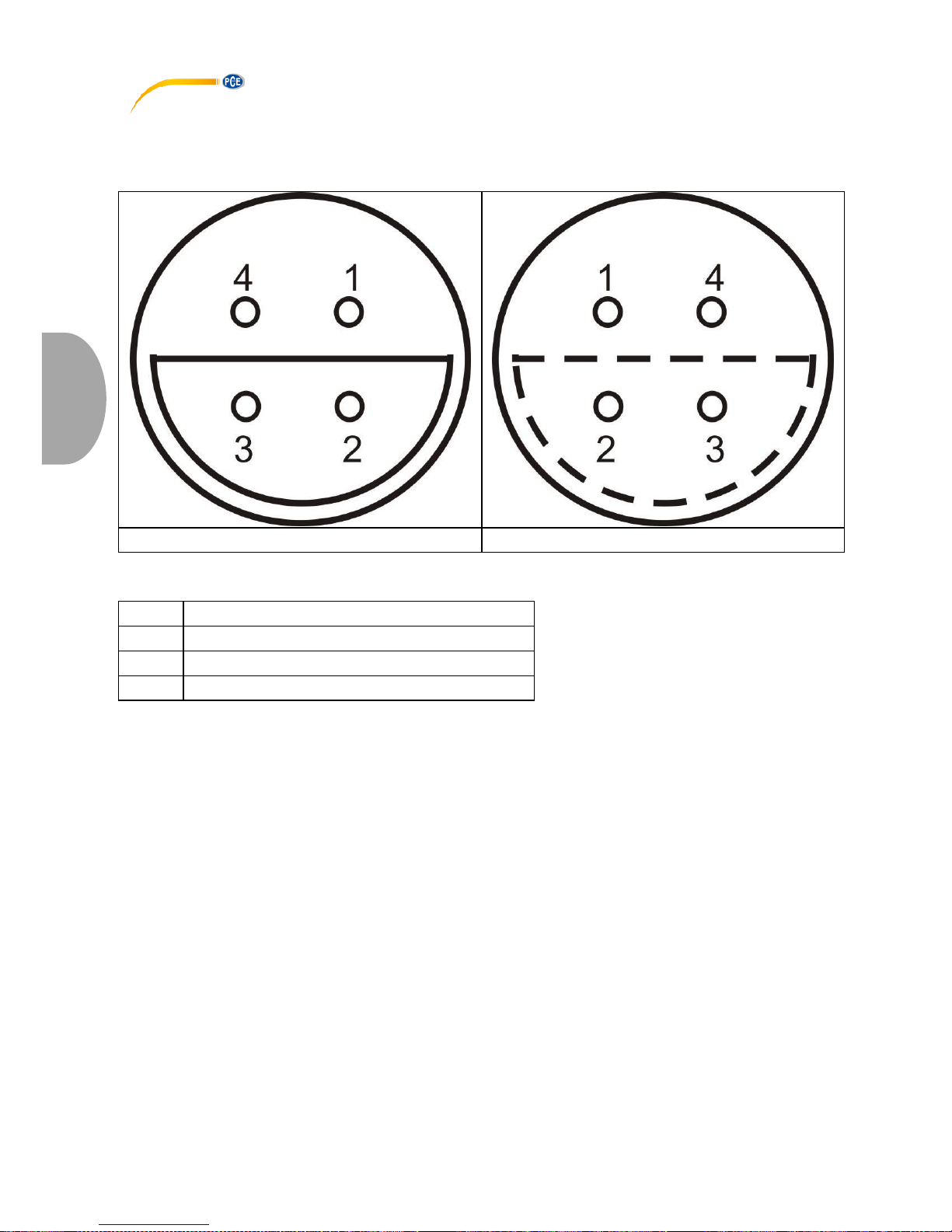

Table 1 – Description of connector for the instrument connection to

the PC Ethernet port

Contact

Description

Ethernet

ERA.0S.304.CLL

(front view)

1

Data of transmitter «+»

2

Data of transmitter «–»

3

Data of receiver «+»

4

Data of receiver «–»

Table 2 – Description of connector for the instrument connection to

the PC USB port

Contact

Signal

USB type A (front

view)

1 +5 V

2

Data -

3

Data +

4

Common

© PCE Instruments

7

English

Front Panel

Fig. 2 – PCE-USC 30 Front Panel

© PCE Instruments

8

English

Left side panel of the flaw detector:

1 - LEMO jack for headphones with microphone connection;

2 - Charger connector;

3 - Switching On/Off the instrument.

Fig. 3 – PCE-USC 30 Left Side Panel

Table 3 – Description of LEMO jack for headphones with microphone

connection

Cont.

Signal

EGG.0B.304.CLL

(front view)

1

Input signal from the

microphone

2

Right audio output

3

Common

4

Left audio output

© PCE Instruments

9

English

Table 4 – Description of charger connector

Cont.

Signal

EGG.1B.304.CLL

(front view)

1

Charging device -

2

Not used

3

Charging device +

4

Sync signal output

Right side panel of the flaw detector:

1 – Single coil (parametric) eddy current probe (ECP) connector;

2 - Universal connector for eddy current probe (ECP) and eddy current rotary

scanner;

3 - Encoder (Enc) connector

Fig. 4 – PCE-USC 30 Right Side

© PCE Instruments

10

English

Table 5 – Description of single coil (parametric) eddy current probe

(ECP) connector

Cont.

Signal

Lemo ERA.00.250CLL

1

Parametric ECP

2

Common for parametric ECP

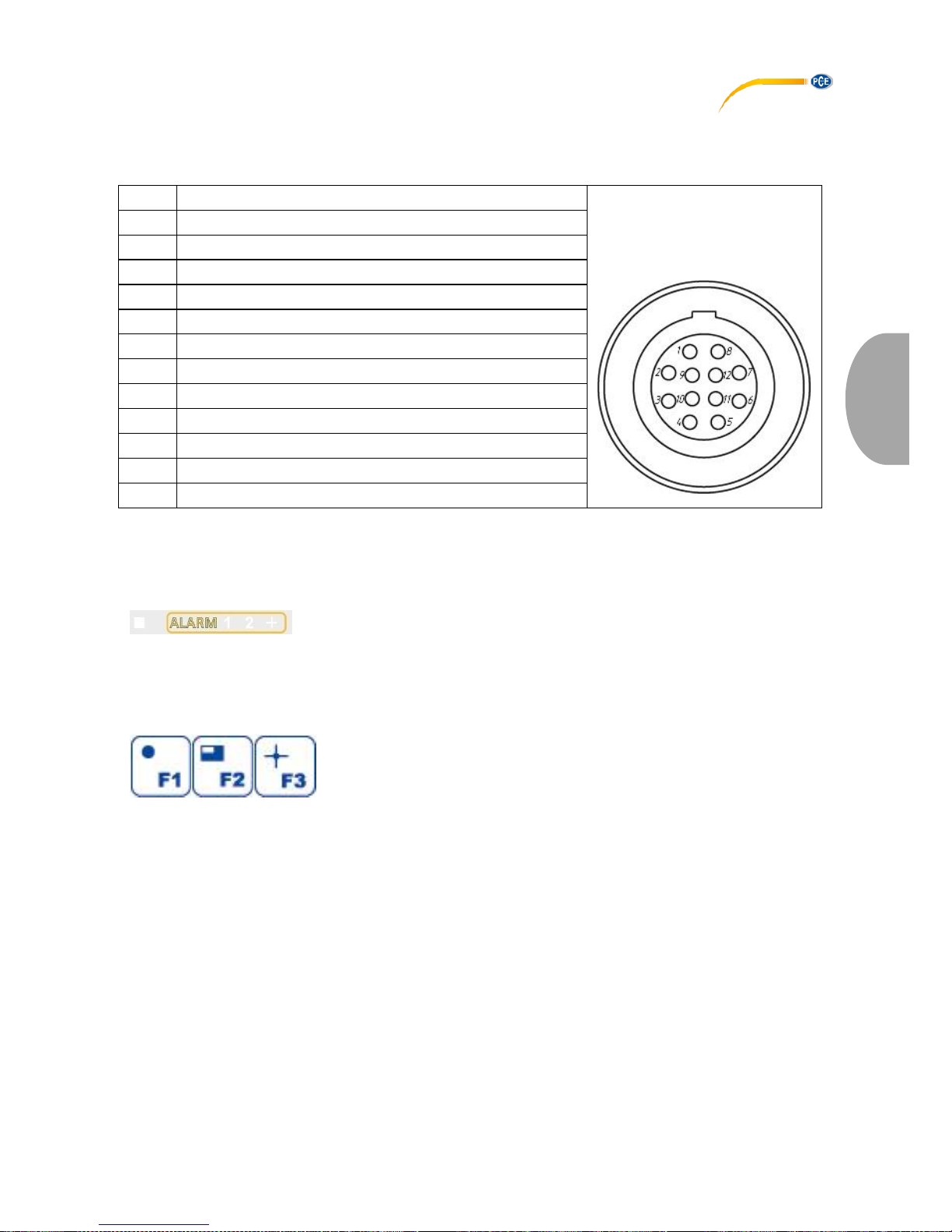

Table 6 – description of encoder (Enc) connector

Cont.

Signal

Lemo

EGG.1B.308CLL

(front view)

1

Positive signal input "A"

2

Power "+5V"

3

Negative signal input "Z"

4

Positive signal input "Z"

5

Negative signal input "B"

6

Positive signal input "B"

7

Negative signal input "A"

8

Common

© PCE Instruments

11

English

Table 7 – Description of connector for eddy current probe (ECP)

and eddy current rotary scanner

Pin

Signal

Lemo

EGG.2B.312CLL

(front view)

1

Gen Ret

2

Gen Out

3

+12V Battery

4

Motor -

5

Motor +

6

Gnd

7

Dif Input 1

8

Dif Input 2

9

Synchro Input

10

Motor On

11

Rotary On

12

Alarm LED

3.3 Function keys

Automatic flaw alarm by the first and second frequencies,

respectively, and by the mix of the 1st and 2nd frequencies, as well as

overloading alarm square. If ALARM triggers during testing, the signal

amplitude and phase are automatically measured and the signal is evaluated

by the calibration curve.

Function keys

Respectively:

"F1 Balancing", "F2 Full-screen mode", "F3 Centering"– in "TEST" menu;

"F1 Import data", "F2 Export data "– in “MEMORY” menu;

"F1 Load", "F2 Create/ Save","F3 Delete"– in "RESULTS"/"SETTINGS"

submenu;

"F1 An" (An - amplitude noise) – in "VIEW" menu;

"F2 OK” save calibration curve – in "CALIBRATION" menu.

© PCE Instruments

12

English

Key

Function

- automatically puts a displayed signal from lift-off (or from

any interference) in horizontal position;

- in the mode of name editing – selects a digit/letter

- changes the parameter variation step;

- in the mode of name editing – selects a digit/letter

- increases the selected parameter;

- in the mode of name editing – selects a digit/letter

- changes the frequency;

- in the mode of name editing – selects a digit/letter

- moves up through the menu;

- in the mode of name editing – selects a digit/letter

- decreases the selected parameter;

- in the mode of name editing – selects a digit/letter

- cancels the selection;

- in the mode of name editing – selects a digit/letter;

- pressing the key results in displaying the firmware version

in "SETTINGS" menu;

- delete point in “CALIBRATION" menu;

- freeze the display in the test menu

- moves down through the menu;

- in the mode of name editing – selects a digit/letter

- confirms the selection;

- in the mode of name editing – selects a digit/letter;

- pressing the key in "TEST" menu results in saving of

current setup as a default one (if the current item is above

the ALARM item);

- add point in “CALIBRATION" menu

- quick access to "TEST" menu

- quick access to "SETTINGS" menu

© PCE Instruments

13

English

- quick access to "VIEW" menu

- quick access to "MEMORY" menu;

- confirms the saving of the entered name of the file or

folder while operating in "MEMORY" menu

- quick access to "CALIBRATION" menu

- automatically sets the parameters of single coil

(parametric) ECP with switched On Single input;

- sets the number of rounds while operating with eddy

current rotary scanner

- switches On/Off the instrument

© PCE Instruments

14

English

4 Design of the Flaw Detector

4.1 Instrument Appearance

Fig. PCE-USC 30 eddy current flaw detector

© PCE Instruments

15

English

4.2 Structural Scheme

Structural scheme of the flaw detector.

Fig. 6 – Structural Scheme of the Flaw Detector

Structurally, the flaw detector consists of:

a) casing and cover plate with the membrane keypad, indicators of ALARM

and overloading, Ethernet port for connection to PC, USB port for external

flash-card connection, charger connector, headphones and microphone;

b) connector, ECP connector;

c) TFT display;

d) processor and memory boards;

e) analog board;

f) battery.

© PCE Instruments

16

English

4.3 Appearance of the Flaw Detector Screen

Fig. 7 – Display Appearance after switching on the Flaw Detector

Working filed in the testing mode is divided in 3 areas of signal reflection and

display area title:

Working field (display areas – complex plane, time charts);

Bottom horizontal field (data line);

Navigation menu:

o FREQ – test frequency;

o PRE AMP – preamplifier gain;

o GAIN – main gain;

o H GAIN – horizontal gain;

o V GAIN – vertical gain;

o DRIVE – probe drive level;

o PHASE – phase adjustment;

o FILTER – filter type;

o POSITION – spot position;

© PCE Instruments

17

English

o GRID – grid;

o AXIS – axis;

o ALARM – short cut to ALARM Setting;

o SWEEP – number of points in a screen scan;

o PROBE – type of connector;

o RPM – rounds per minute for the eddy current rotary scanner;

o ROT PRESENT– type of connected rotary eddy current scanner.

The flaw detector displays two time charts of time dependence of signal

and eddy current signal which is displayed in a complex plane for the

selected

frequency.

1 – Navigation menu

2 – Time charts

3 – ALARM frame

4 – Eddy current signal

5 - Signal display area

© PCE Instruments

18

English

6 - Parameters of the measured signal (A – amplitude in “Volts”, P – phase

in “degrees”, D – equivalent depth of flaw in “mm” or conductivity in

“MSm/m”), T - current value of a receive circuit parameters (“…/” – load of

the input circuit before the balancing; “…/” non-balance of the input circuit;

“…” – the current value of the input circuit expressed in % from the maximum

possible), F- sampling frequency

7 - Frequency number

8 - Battery life indicator

9 - Temporary memory indicator of the flaw detector

10 - Digital overload indicators for receiving circuit

11 - digital trigger indicators of ALARM levels for the first, second and mix of

frequencies respectively (from left to right)

Fig. 8 – The Flaw Detector Interface

Note – Parameter "T: …/…/... %" shows:

1) The value of a signal amplitude at the input of the receiving circuit

expressed in % from the maximum possible,

2) Input circuit is not balanced, after performing the balancing in %;

3) Current value of the load of the input circuit expressed in % from the

maximum possible.

The most suitable option is one in which the two parameters do not

exceed, or exceed but not significantly the 50%. Operation in mode, in

which one of the parameters exceeded the threshold of 90% is

unacceptable and requires the adjustment of flaw detector parameters.

Lighting of a left overload indicator (pos. 10, Fig. 8) – indicates that

unacceptably large amplitude signal came to the input of the receiving

circuit.

The flaw detector electronic unit displays the signal in the complex plane that

allows to foil defects by waveform analysis (Fig. 9):

© PCE Instruments

19

English

Fig. 9 – Display of signal in the complex plane (XY)

Fig. 10 – Mix of two frequencies (MIX)

The flaw detector has the mechanism of automatic flaw alarm (ALARM). It is

provided for the creation of up to 4 "frames" (threshold levels) of alarm for

each frequency and mix (examples of threshold levels see Figure 14, 15, 16,

17). These frames together with the signal form an event (for example, the

threshold level exceeding by the signal). An operator is able to adjust the

reaction to an event. Reaction to an event can be the following:

− LEDs illuminating on the instrument panel;

− or LEDs illuminating and sound alarm.

"ALARM" menu setup

This menu allows setting of ALARM (automatic flaw alarm). There is a

possibility to setup ALARM for each frequency and mix. ALARM itself is the

response of flaw detector to the event occurring at crossing or non-crossing

of alarm frame (threshold level) by a signal. All in all one alarm frame can be

activated for each frequency.

© PCE Instruments

20

English

Frame setup is carried out in special item of ALARM settings - from

"TEST" menu. To change the type of the alarm frame operator should press

or key on “ALARM” position (if the icon is displayed, the

frames are switched off). To enter in alarm frame setup operator should

press key.

Note. An operator is offered to set up the frame according to the

frequency, he plans to work with.

Automatic measurement of the signal amplitude and phase provides a

possibility to evaluate the defect size in analyzing the data. The measured

values of the voltage phase or amplitude are required for estimating the

defect size in conformity with the selected calibration curve. Such curve

compares the parameters of signal amplitude or phase with the defect

parameters in millimeters or percent from the wall thickness. The flaw

detector interface allows calibration curves plotting both by the phase and

amplitude.

The flaw detector connectors for the eddy current probes connection (see

Fig. 4) provide the possibility of ECP connection of various constructions

(see Fig. 11):

differential ECP, connection by the bridge circuit;

single transformer ECP;

differential ECP, connection by the bridge circuit;

differential transformer ECP with center-point ground;

single (parametric) ECP;

differential transformer ECP.

© PCE Instruments

21

English

Fig.11 – Circuits of probe connection

4.4 Menu Structure

Fig. 12 – Menu Structure

© PCE Instruments

22

English

Navigation of the menu map described below is performed with the help of

the following keys:

The instrument menu is divided in five inserts: "TEST", "SETTINGS", "VIEW",

"MEMORY", "CALIBRATION", the first and the fourth ones are also divided in

submenus.

4.5 “TEST” Menu

"Test" menu is displayed immediately after switching On the instrument (see

Figure13) and contains main settings an operator will need to set during

operation.

Fig.13 – “TEST” menu

In this menu, an operator can set (change) the settings of the selected

frequency, the values of operating frequency, gain and preamplifier,

generator voltage, initial phase of signal, filter type and its parameter, input

type, general scale and independently to axles, position of complex plane

center as well as set up ALARM and general flaw detector parameters.

© PCE Instruments

23

English

Moving through the vertical menu of the electronic unit parameters is carried

out by , keys. In order to change the value of any parameter one

should use , keys. A step of parameter variations can be changed

by multiple pressing of key.

© PCE Instruments

24

English

Quick selection to "TEST", "SETTINGS", "VIEW", "MEMORY",

"CALIBRATION" inserts is carried out by pressing

keys.

"Hot keys" which are operated by "F1", "F2", "F3" function keys are situated

on the keypad of the flaw detector:

− F1 (Balancing)1 – to balance the signal (place it in the screen center) and

clear the flaw detector screen;

− F2 (Full-screen mode) – the complex plane and time chart is maximized to

fill the entire screen.

− F3 (Clearing) – clear the flaw detector screen;

“Balancing” – it is hardware compensation of input signal. It is carried out

by summation of input signal with reference signal of the same amplitude but

opposite in phase. Current procedure is conducted after preamplifier

according to radio signal (before signal detecting). Balancing algorithm is

iterative and takes some time. The procedure is necessary for ECP nonbalance voltage compensation. After the balancing of flaw detector the

centering is carried out automatically.

Balancing should be applied in case if:

− ECP type was changed;

− One of following parameters was changed: ECP frequency, gain

coefficient, preamplification coefficient, ECP excitation voltage;

− Testing object was changed;

− The auto-adjustment of ECP was activated (if Single input was used).

Clearing should be used if persistence is switched off.

1. “ F, Hz"- operating frequency of probe2; varied in the range

from 10 Hz to 16 MHz with a step of 1, 10, 100, 1000, 10000,

100000, 1000000, 10000000 Hz.

Here you adjust the test frequency of the probe that is connected to the

instrument. The frequency depends on the probe you use and the

application at hand. You can select the frequency between 10 Hz and 16

MHz.

1

Balancing of the flaw detector is required after the ECP operating frequency

was set or changed. Also, the balancing should be carried out after the ECP

replacement. If the flaw detector was once balanced and its operating

frequencies were not changed, it is possible to carry out centring.

2

Operating frequency of probe is selected from the rage of frequencies

indicated in the registration certificate for the given ECP.

© PCE Instruments

25

English

2. “ PRE AMP” - preamplifier for amplifying the probe voltage;

varied in the range from -6 to 40 dB with a step of 0,1, 1, 10 dB.

To adapt the eddy current probe that is to be used, you can adjust

the preamplification in 0.1; 1; 6; 10 dB steps between 0dB and 40dB.

Please avoid a preamplification overload because it may tamper with the

results of the measurement. The overload is indicated by the amber light

of the ALARM-LED.

3. " GAIN" - gain for amplifying the probe voltage; varied in the

range from 0 to 30 dB with a step of 0,1; 1; 10 dB.

Here you adjust the signal amplitude for the best possible display of the

eddy current signal by moving the probe across a reference defect while

slowly increasing the gain. You can adjust the gain between 0 dB and 30

dB. The display shows the overall gain simultaneously for X and Ycoordinates.

4. " H GAIN" – horizontal gain for amplifying the probe voltage;

varied in the range from 0 to 30 dB with a step of 0,1; 1; 10 dB.

5. " V GAIN dB" – vertical gain for amplifying the probe voltage;

varied in the range from 0 to 30 dB with a step of 0,1; 1; 10 dB. This

item is often used to set up single coil probe for visual increase of

angle between lift-off signal and signal from defect.

6. " DRIVE" - ECP excitation voltage3; it is possible to set specified

values of 0.5; 1; 2; 4; 6 V (double amplitude value). The maximum

voltage for single coil probe is 2V. The maximum voltage for other

types of probes is limited by 6V. High voltage is used for subsurface

defects detection.

7. " PHASE" - signal phase change (signal turn) – from 0 to 360˚

with a step of 0.1˚, 1˚, 10˚.

3

ECP exciting voltage is selected from the range indicated in the

registration certificate for the given ECP.

© PCE Instruments

26

English

8. " FILTER" - Filter type: Averaging, Differential, Low-pass, High-

pass, Bandpass;

Filters setup is carried out for the channel Frequency 1 and

Frequency 2.

Averaging Filter

Switching on of the averaging filter "Avrg" sets a number of points N

to be averaged from 2 to 127 points with a step of 1, 10, 100 points.

Can be used when working with high gains and scales to reduce

noise signal by smoothing it.

Differential Filter

Switching on of a differential filter “Diff” activates its settings, where L

– filter depth, set in the range from 2 to 127 units with a step of 1, 10,

100.

Low-Pass Filter

Switching on of a low-pass filter activates the field for setting up the

frequency LF from 1 to 4000 Hz with a step of 1, 10, 100, 1000 Hz.

The frequencies from 0 Hz to the set value of Hz are allowed.

The low-pass filter is used to reduce the noise respectively highfrequency non-essential signal components by displaying only those

signals whose alternating frequency is lower (i. e. slower) than the

frequency of the selected low-pass filter. Since electronic noise is

usually caused by high- frequency signals, the noise on the screen is

lower, if the frequency of the low-pass filter is set low, too.

The low-pass filter is used for static applications (usually with handheld probes).

It is important that the low-pass filter is not too low, because defect

signals are not displayed anymore, if you move the probe across the

crack at a speed that is too high with regards to the filter frequency.

If for example you move the probe very slowly across the crack, then

the dot slowly tracks the full defect signal at a low-pass frequency of

10 Hz. If, one the other hand, you move the probe across the crack

more quickly at the same low-pass frequency, you will see only a

small amplitude on the screen. This happens because the frequency

of the signals is now too high for the low-pass filter frequency you

selected.

If, however, you increase the low-pass filter frequency, the full

amplitude of the defect signal is displayed, i. e. the higher the test

speed the higher the frequency of the low-pass filter to be selected.

Since differential probes generate a dual signal that changes more

quickly than that of an absolute probe at the same speed, you

© PCE Instruments

27

English

should select a higher low-pass frequency for differential probes

than for absolute probes. Thus the minimum low-pass frequency to

be selected for a particular application depends on the test speed

and the coil system of the probe you use.

The easiest way to determine the minimum low-pass frequency is

probably by trial and error.

High-Pass Filter

Switching on of a high-pass filter activates the field for setting up the

frequency HF from 1 to 5000 Hz with a step of 1, 10, 100, 1000 Hz.

The frequencies from the set value of Hz to F

sampling

/2 Hz (where

F

sampling

– sampling frequency) are allowed.

If you use a high-pass filter, the signal dot always returns to the

selected compensation point, if the probe is not moved relative to the

surface of the test specimen. This can be likened to an „automatic

reset". Thus, if you move the probe across materials with varying

electric conductivity, the signal dot briefly moves to a position on the

screen that varies depending on the material; the dot then returns to

the selected compensation point.

The filters are intended to improve the signal/noise ratio and/or

supress undesired signals so that the signal evaluation and test

sensitivity are optimized. The noise can be “electronic” (caused by

the instrument or the probe), or it can be caused by other factors

such as scanning rough surfaces. You can easily identify electronic

noise by the so-called “fuzzy” signal image instead of a steady dot.

This happens frequently, if you carry out inspections with low

frequencies or high gain. The filter frequency does not depend on

the alternating frequency of the current that flows through the coils,

but on how frequently the test signals change. If for example you

move a probe across a crack, the frequency depends on how fast

you do so. The high-pass filter is designed so that only those signals

whose frequency is greater than that of the high-pass filter are

depicted by deflecting the signal dot. If the high-pass fil filter is active

the signal dot on the screen remains on the compensation point.

Bandpass

Switching on of a bandpass filter activates its settings:

Carrier frequency F is set from 1 to 5000 Hz with a step of 1; 10;

100; 1000 Hz;

© PCE Instruments

28

English

F ≤

Fsampling

2

where Fsampling – frequency is set in "SETTINGS" (sampling frequency);

WF bandpass is set from 1 to 5000 Hz with a step of 1; 10; 100; 1000 Hz.

You can use the bandpass-function to adjust both the high pass and the low

pass. This is very helpful when you want to quickly determine the frequency

band for the best possible defect display - especially for rotor applications or

inspections of rotating parts.

Note. Only one filter can be set in the frequency selected by an

operator. Activation of the other filter makes the earlier selected filter inactive

within the set frequency.

9. " " - selection of the position of complex plane centre. Can be set

in the following positions: - complex plane centre, - in the right

centre of the screen, - in the right upper corner, - in the upper

centre of the screen, - in the left upper corner, - in the left

centre of the screen, - in the left bottom corner, - in the bottom

centre of the screen, - in the right bottom corner, - per-

channel display when operating in double frequency mode.

10. " Grid"– variants of marking for the complex plane: " "– square,

" " – radial, " " – Off.

11. " Axis"– activates coordinate axes.

12. " ALARM" – activation and setting of frames (threshold levels).

Types of frames: - frames are switched off, - circle frame type,

- threshold frame type, - sector frame type, - cut-off frame

type.

13. "SWEEP" – number of samplings displayed on time charts (see

Figure 8, pos. 4) - 256; 512; 1024; 2048; 4096; 8192; 16384, 32768

measurements.

14. "PROBE" – Connector type: "Refl", "Bridge", "Single".

15. "RPM" – rounds per minute for the eddy current rotary scanner.

Selected from the standard range: 600, 840, 1020, 1200, 1500,

1800, 2100, 2400, 2700, 3000.

16. "ROT" – type of connected rotary eddy current scanner SVR-02 or

MINI DRIVE.

17. "Mix type" – is selected for the frequencies mixing (setting is

available in double frequency mode), where: "+" – summation, "–" –

subtraction, "~X+" - summation with inversion in Х-direction, "~Y+" summation with inversion in Y-direction.

© PCE Instruments

29

English

If the mix type is "+", then:

XCi=X1i*M1+X2i*M2;

YCi=Y1i*M1+Y2i*M2.

If the mix type is "-», then:

XCi=X1i*M1-X2i*M2;

YCi=Y1i*M1-Y2i*M2.

If the mix type is «~Y+», then:

XCi=X1i*M1-X2i*M2;

YCi=Y1i*M1+Y2i*M2.

If the mix type is «~X+», then:

XCi=X1i*M1+X2i*M2;

YCi=Y1i*M1-Y2i*M2.

Where XCi, X1i, X2i – horizontal components of the mix of the 1st and 2nd

frequencies, respectively;

YCi, Y1i, Y2i – vertical components of the mix of the 1st and 2nd frequencies,

respectively;

M1, M2 – scales of the 1st and 2nd frequencies, respectively.

Threshold levels setup

Setup of "Circle" type frame

To set up circle type frame, operator should select "Type: " in special item

of settings ALARM – (see Figure 14).

Fig. 14 – Setup of “Type: “ threshold level

© PCE Instruments

30

English

"R:" parameter variation allows change the inner radius of threshold level.

Height parameter variation is carried out in the range from 0 to 32768 with a

step of 1, 10, 100, 1000, 10000 (see Fig.14).

Setup of "Threshold" type frame

To set up threshold type frame, operator should select "Type: " in special

item of settings ALARM – (see Fig. 15).

Fig. 15 – Setup of “Type: “ threshold level

"H:" parameter variation allows change the height of the threshold level.

Parameter variation is carried out in the range from 0 to 32768 with a step of

1, 10, 100, 1000, 10000 (see Fig. 15).

Setup of "Sector" type frame

To set up sector type frame, operator should select "Type: " in special

item of settings ALARM – (see Figure 16).

© PCE Instruments

31

English

Fig. 16 – Setup of “Type: “ threshold level

"R:" parameter variation allows change the inner radius of threshold

level. Height parameter variation is carried out in the range from 0 to 32768

with a step of 1; 10; 100; 1000; 10000 (see Fig. 16).

"W:" parameter variation allows change the width of threshold level.

Radius parameter variation is carried out in the range from 0 to 32768 with a

step of 1; 10; 100; 1000;10000 (see Fig. 16).

"α:" parameter variation allows change turning angle of threshold level

relative to the complex plane centre. Turn angle variation is carried out in the

range from 0˚ to 359˚ with a step of 1˚; 10˚; 100˚ (see Fig. 16).

"β" parameter variation allows change turning angle of threshold level.

Turn angle variation is carried out in the range from 0˚ to 180˚ with a step of

1˚; 10˚; 100˚ (see Fig. 16).

Select the frame polarity "Pol:", which makes the alarm trigger:

– the signal gets beyond the limits of the threshold level;

– the signal is within the limits of the threshold level.

If the symmetrical displaying of threshold level on the position “Symm:”

with , keys is required, this parameter can be activated.

© PCE Instruments

32

English

Setup of "Trapezium" type frame

To set up cut-off type frame, operator should select "Type: " in special

item of settings ALARM – (see Figure 17).

Fig. 17 – Threshold level setup "Type: "

"X1:" parameter variation allows to change the angle position of threshold

level in X1-direction. X1 parameter variation is carried out in the range from 32768 to 0 with a step of 1; 10; 100; 1000; 10000 (see Fig. 17).

"X2:" parameter variation allows to change the angle position of threshold

level in X2-direction. X2 parameter variation is carried out in the range from

0 to 32768 with a step of 1; 10; 100; 1000; 10000 (see Fig. 17).

"Y1:" parameter variation allows to change the angle position of threshold

level in Y1-direction. Y1 parameter variation is carried out in the range from 32768 to 32768 with a step of 1; 10; 100; 1000; 10000 (see Fig. 17).

"Y2:" parameter variation allows to change the angle position of threshold

level in Y2-direction. Y2 parameter variation is carried out in the range from

32768 to

- 32768 with a step of 1; 10; 100; 1000; 10000 (see Fig. 17).

Select the frame polarity "Pol:", which makes the alarm trigger:

– the signal gets beyond the limits of the threshold level

– the signal is within the limits of the threshold level.

© PCE Instruments

33

English

4.6 Guidelines for Overload Processing

4.6.1 For the Input – "Refl", "Bridge":

4.6.1.1 Reduce the probe drive;

4.6.1.2 Perform the probe balance by pressing key.

4.6.2 For the Input – "Single":

4.6.2.1 Choose the capacitor by pressing key

4.6.2.2 Perform the probe balance by pressing key;

4.6.2.3 If the recommendations specified in paras 4.6.2.1-4.6.2.2 didn`t resolve the

overload, then it is necessary to reduce the probe drive and repeat paras 4.6.2.1-

4.6.2.2.

Lightning of the right overload indicator (pos. 10, Fig. 8) – indicates the

general overload of the input of the receiving circuit. General overload may

include: overload by the input of the receiving circuit (exceeding the

maximum allowed signal amplitude at input of the receiving circuit), ADC

overload (exceeding the maximum allowed signal amplitude at ADC input).

4.6.3 For the input – "Refl", "Bridge" and "Single":

4.6.3.1 If the left indicator lights, then repeat the steps described for overload processing

for the left indicator (see above);

4.6.3.2 If the right indicator lights only, then it is required alternately reduce the “ PRE

AMP” and “ GAIN”. After each gain change it is required to press key.

© PCE Instruments

34

English

4.7 "Conductivity" Mode

Basics of Conductivity

The SI derived unit for conductivity is the Siemen per meter, but conductivity values are often

reported as % IACS. IACS is an acronym for International Annealed Copper Standard, which is

the material used to make traditional copper electrical wire. The conductivity of the annealed

copper is 5.8 x 107 S/m and copper is defined to be 100 % IACS at 20 °C. All other conductivity

values are related back to this conductivity of annealed copper.

Conductivities of metals at ambient temperature are typically in the range of 1 to 60

MegaSiemens per meter.

The PCE-USC 30 measures the conductivity of non-magnetic metals and alloys in the range 0.8

to 110.0 % IACS. It uses the Eddy Current technique for measuring the conductivity of materials

in % IACS, or MSiemens/meter.

It is important to understand that eddy current measurement is essentially a ‘skin’ effect.

The eddy current field intensity is greatest at the surface and decreases exponentially with

depth. The depth at which the field strength reduces to 1/e (37 %) of its surface value is referred

to as the ‘standard depth of penetration’. This depends primarily on the operating frequency and

the conductivity of the metal.

It is generally considered that materials of thickness greater than 3 standard depths of

penetration can be measured without any correction factors being required. For example, at 60

kHz this figure (the “effective depth of penetration”) is around 0.05” (1.25 mm) in Aluminium

Alloys (conductivity approximately 35 % IACS) and 0.32” (8 mm) in Titanium alloy, (conductivity

approximately 1% IACS). At 500 kHz the corresponding values are 0.02” (0.5 mm) and 0.11”

(2.8 mm).

Care must also be taken when measuring non-homogeneous materials, for example materials

which have been surface heat-treated, clad or plated, or where the surface is rough or corroded.

Measurements at different frequencies will give different results due to the different distribution

of energy within layers of different conductivity. Care must be taken to always measure such

materials at the same frequency (usually 60 kHz).

Setting up the device for measuring the conductivity and the thickness of nonconductive coatings

To use the PCE-USC 30 for Conductivity measurement requires the following:

- PCE-USC 30 flaw detector;

- Standard 60 kHz Probe (CP-13) and Cable (Lemo 12 - Lemo 04 Conductivity).

Conductivity standards of known value in a range from 0.59 MS/m (1.02 % IACS) to 63.8 MS/m

(110 % IACS). To connect the flaw detector with Cable and the eddy current probe CP-13 for

measuring the electrical conductivity.

Connect the flaw detector with cable and the eddy current probe CP-13 for measuring the

electrical conductivity.

ATTENTION! THE INSTRUMENT SETUP AND ELECTRIC CONDUCTIVITY

MEASUREMENT SHOULD BE CARRIED OUT AT AN AMBIENT AND TEST OBJECT

TEMPERATURE OF 20 ˚ С (68 ˚ F). BEFORE CARRYING OUT THE SETTING UP

PROCEDURE AND ELECTRIC CONDUCTIVITY MEASUREMENT, IT IS REQUIRED THAT

THE INSTRUMENT TO BE OPERATED AT LEAST OF 15 MINUTES AT A TEMPERATURE

OF 20 ˚ С (68 ˚ F).

© PCE Instruments

35

English

To press the button for entering the instrument menu «SETTINGS» and to choose «Test

mode» - «CONDUCTIVITY».

Fig.18 – “Conductivity” Test Mode

To press to enter the «TEST» menu. In the menu «TEST» under the position «Current

set», to choose by , buttons the appropriate setting for the measurement at a

specified frequency and to press the button to activate the settings. «CP13 – 60 kHz»;

«CP13 – 480 kHz».

Fig. 19 – Choosing and activating Settings “CP 13 – 60 KHZ”

After settings activation make calibration at standard samples

Note – For setting up procedure, use certified calibration blocks only.

© PCE Instruments

36

English

To determine the material by its conductivity the setting up samples should generate the range

of the conductivity, wherein the first sample value is lower and the second sample value is

higher than the conductivity of the material being measured.

Conductivity measurement tolerances are:

- ±0.5 % IACS [±0.3 MS/m] for the conductivity range from 0.9 % to 62 % IACS [0.5 to

36 MS/m];

- ±1.0 % IACS [±0.6 MS/m] for the conductivity range from 62 % to 110 %.

Tolerances for coating thickness measurement:

- ±1 mil [±0.0254 mm] for the thickness range 0-20 mil [0-0,508 mm].

Note – The narrower the range is, formed by the setting up samples, the more accurate

is the measurement.

Before beginning the calibration at the positions of Cond 1 (the lower conductivity value) and

Cond 2 (higher conductivity value) there must be set the values of the conductivity of the

samples, which will be calibrated, using the , buttons.

To set up the coatings thickness measurement there must be used the 20 mil [0.5 mm] film

thickness. Gap value is 20 mil [0.5 mm] to be set.

For beginning the calibration - to press the button and to follow the instructions displayed

on the screen of the flaw detector.

Hold the eddy current probe in the air at a considerable distance from metal objects and press

.

Set the eddy current probe on the sample with Cond 1 conductivity and press .

Figure 20 – Entering the conductivity value for the sample Cond 1

Set the eddy current probe on the sample with Cond 2 conductivity and press .

© PCE Instruments

37

English

Figure 21 – Entering the conductivity value for the sample Cond 2

To put on the sample with Cond 1 conductivity the gap element (20 mil [0.5 mm]), set the eddy

current probe on the sample and press .

Figure 22 – Entering the gap value for setting on the Cond 1 sample

After carrying out the setting up procedure, you can proceed with the measurement of electric

conductivity at real objects. During the operation it is required periodically to check the accuracy

of measurement of electric conductivity at calibration blocks.

In case, the value measured at calibration block differs from the nominal one and exceeds the

measurement tolerance, then it is required to reactivate the operating setup and perform the

adjustment at calibration blocks.

Note. In case, the ambient and test object temperature will be different from 20 ˚С (68˚

F), then the displayed value will be with an error.

© PCE Instruments

38

English

Setting up the threshold level in the mode of electric conductivity measurement

- set up the low value of electric conductivity Min;

- set up the high value of electric conductivity Max;

- set up the trigger logic for threshold level:

-light and sound ALARM shall be triggered, when the measured value of electric conductivity

gets into the middle of a selected range

Min – Max;

light and sound ALARM shall be triggered, when the measured value of electric conductivity

gets beyond the selected range

Min – Max.

Measuring Conductivity and Coating Thickness with the PCE-USC 30

Guidelines for successful operation:

- For accurate measurement of conductivity, the surface coating thickness should be

0.5 mm (0.020 inches).

- The surface to be measured should be flat, or of the same curvature as the calibration

standards. Where curved surfaces must be measured, additional error may be

introduced.

- Measurement close to edges and on thin materials may give erroneous results.

- Check on a known consistent material to establish the influence of these effects.

- The coating thickness measurement function does not require further calibration, it

should be accurate to better than 10 % of the displayed value on base materials

having a conductivity between approximately 1 % and 100 % IACS.

- The electric conductivity measurement should be carried out at an ambient and test

object temperature of 20 ˚ С (68 ˚ F).

4.8 “General Settings” Menu

When selecting "General settings" menu, the flaw detector displays the window with margins for

the flaw detector settings correction

Fig. 23 – “General Settings" menu

© PCE Instruments

39

English

An operator sets the following values in the corresponding menu lines:

- "Test mode" – test mode. Can be "Expert" and "Simple". In "Simple" mode the part of

operating settings is not displayed.

- "Max smp frequency" – measurement frequency for the "TEST" mode. Samplings frequency in

Hz (sampling frequency of ECP per 1 second) from 1 kHz to 10 kHz. If the value of the selected

frequency from a fixed number of measurement set a given operating frequency of ECP is not

supported, then the instrument will automatically determine the maximum possible frequency of

measurement.

- "Double frequency mode" – activated when there is a possibility to remove the interfering

factor by means of frequencies mixing.

- "Persistence" – time value, on the expiry of which all data on the flaw detector screen is

deleted (at the switched on "Persistence"), from (0.1 s, 0.5 s, 1 s, 2 s, 3 s, 4 s);

- "Сolor scheme" – 1. "Light" - for operation with faint outer lighting; 2. "Dark" - for operation with

intense outer lighting; 3. "Standard" – standard scheme.

- "Brightness" – display brightness in % - from 10 to 100 with a step of 10%;

- "Rounds"– the number of full turns of rotating ECP displayed in time chats.

- "Sound" – sound alarm if the ALARM triggers.

- "Language" - language selection.

- "TRIGGERING":

1) Internal – synchronization from inner generator;

2) Enc – synchronization from encoder;

Cenc (pulses/mm)4 – number of pulses per 1 mm generated by encoder – from 10 to10000

pulses/mm with a step of 1; 10; 100; 1000 pulses/mm;

- N meas/mm – number of measurements per 1 mm.

- "Input" – active connector for ECP – 1) Single (for single coil ECP), 2) Refl (for other ECP);

- "Date" – selection of current date (year, month, date);

- "Time" – selection of current time (hours, minutes, seconds)

4 Cenc value (pulses/mm) is indicated in the registration certificate for the scanning device

where an encoder (Enc) is used

© PCE Instruments

40

English

4.9 View

When entering "VIEW" menu, an operator is offered to view and analyze current testing results

as well as the saved results. In order to view the current testing results, it is necessary to press

key.

Fig. 24 – "VIEW" menu

Note. To view previously saved testing results, it is necessary to press key, choose

the "RESULTS" submenu and press key. Then, move the cursor to the certain result and

press key – "F1 Load". Then, an automatic enter in "VIEW" is carried out.

Position “Position” – moves the measurement cursor in the time chart.

Position “Width” – sets the width of the measuring cursor.

Position “Type” – the type of cursor measurement. Four types of measurement are available.

° Pk-Pk – the measurements are made between two points situated at the max. distance from

each other in cursor width.

° Cnt-Pk - the measurements are made between the cursor centre and the point situated at the

max. distance from the centre in cursor width.

° Cnt-K - the measurements are made between the centre and the cross point of cursor centre

signal.

° Vrt-M – vertical maximum - the measurements are made between two points situated at the

max. distance from each other in the cursor width in vertical projection.

Position “Measurer” – is intended for meter signal parameters displaying in complex plane.

Position “Scan” – is for changing the number of points in a strip chart. When moving the cursor

in the strip chart, the complex plane display is updated with the signal, which is located within

the cursor width. The values of amplitude in volts, phase in degrees and defect depth in

millimetres or percent are displayed in the information line.

© PCE Instruments

41

English

Note. The flaw detector has a feature, which allows the quick signal/noise ratio

measurement. In order to measure the ratio, first place the measuring cursor on defect free-area

in the strip chart and press – defect free area "F1 An" key, then move the centre of

measuring cursor to the signal peak from a defect. The result appears in the right bottom corner

of the flaw detector electronic unit at the "К= …" position, the measured signal/noise ratio will be

displayed.

In the view menu it is possible to estimate the saved or just taken data; carry out the

assessment of detected defects depth. By changing the position of measuring cursor, change

the cursor width in such way that the signal from defect stays within the cursor width. In this

case, the amplitude “A: ”, phase “P: ” and estimated defect size in millimetres or percent “D: ”

will be displayed in the flaw detector bottom information bar; the path data in mm will be

displayed in the top panel during the testing with ENC. By moving the cursor to the next signal

from defect, the data corresponding to the marked defect will be displayed on the screen.

The depth of the defect will be displayed only if the correct calibration curve is created!

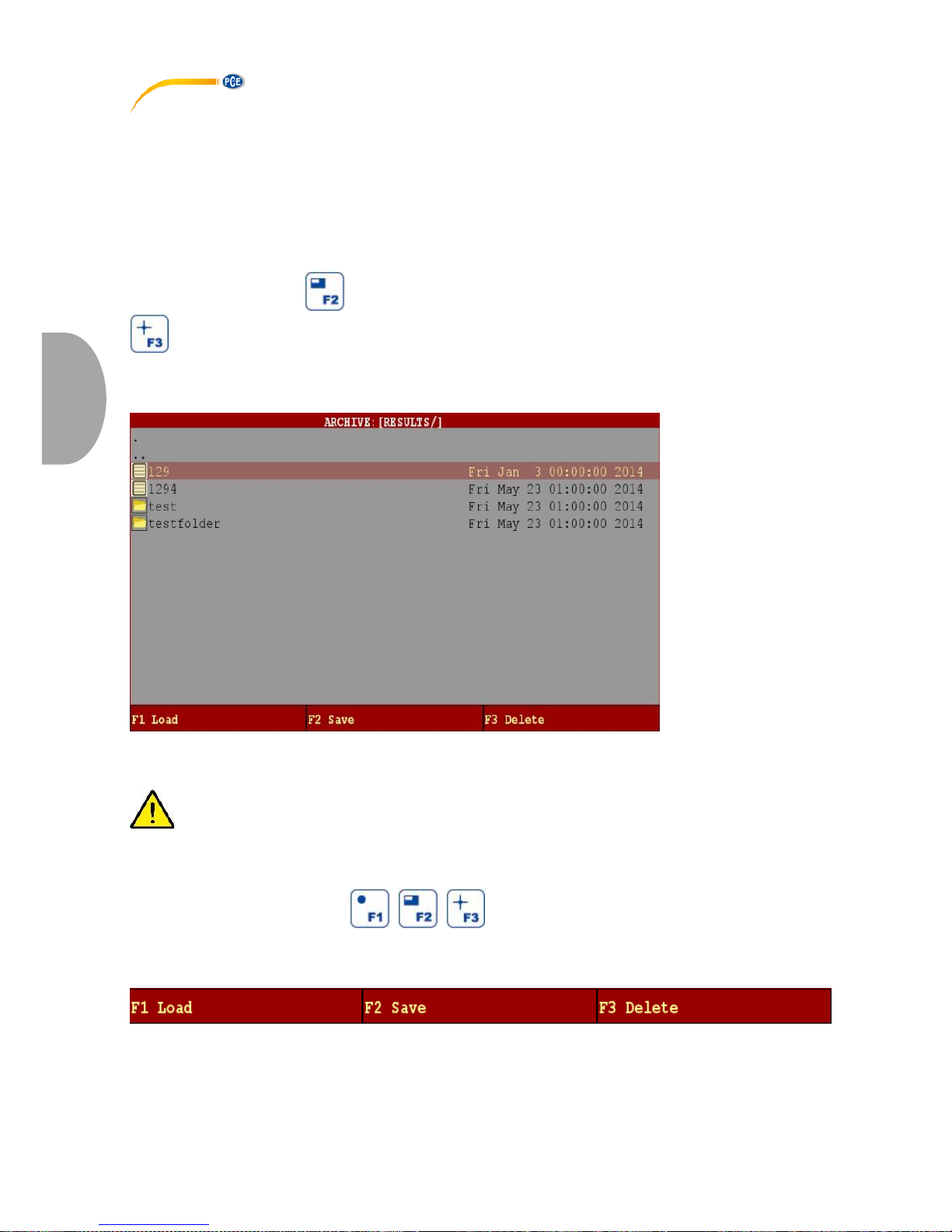

4.10 “Memory” Menu

In order to load/save testing results or device settings, it is necessary to press - key,

choose submenu "RESULTS" or "SETTINGS" and press key. The flaw detector is capable

of storing of more than 1000 settings and up to 1000 testing results (depending on the

defectogram size) in the memory.

Fig. 20 – "RESULTS" menu

© PCE Instruments

42

English

4.11 “Results” Menu

The given menu allows storing and loading of the testing results.

In selecting "Results" menu the flaw detector displays the window with a list of results (Figure

26). The list of results contains catalogues (folders) and files. The catalogues are displayed in

the top part of the list (and are marked with the folders icon), the files – in the bottom part and

are numbered. The catalogues, in their turn, can comprise subdirectories and files.

A new catalogue is created by placing the cursor on the line with colon or on the existing

catalogue and pressing key ("F2 Create"). The existing catalogue is deleted by pressing

key ("F3 Delete").

Having placed the cursor on an empty string or on the existing file, function keys change their

function for the operation with files of results or settings.

Fig. 26 – "RESULTS" menu. List of catalogues and files

Note. To prevent an accidental deleting of catalogues with useful information, the flaw

detector has a protection, which allows only empty catalogues deleting. In order to delete the

catalogues, firstly you need to delete its contents.

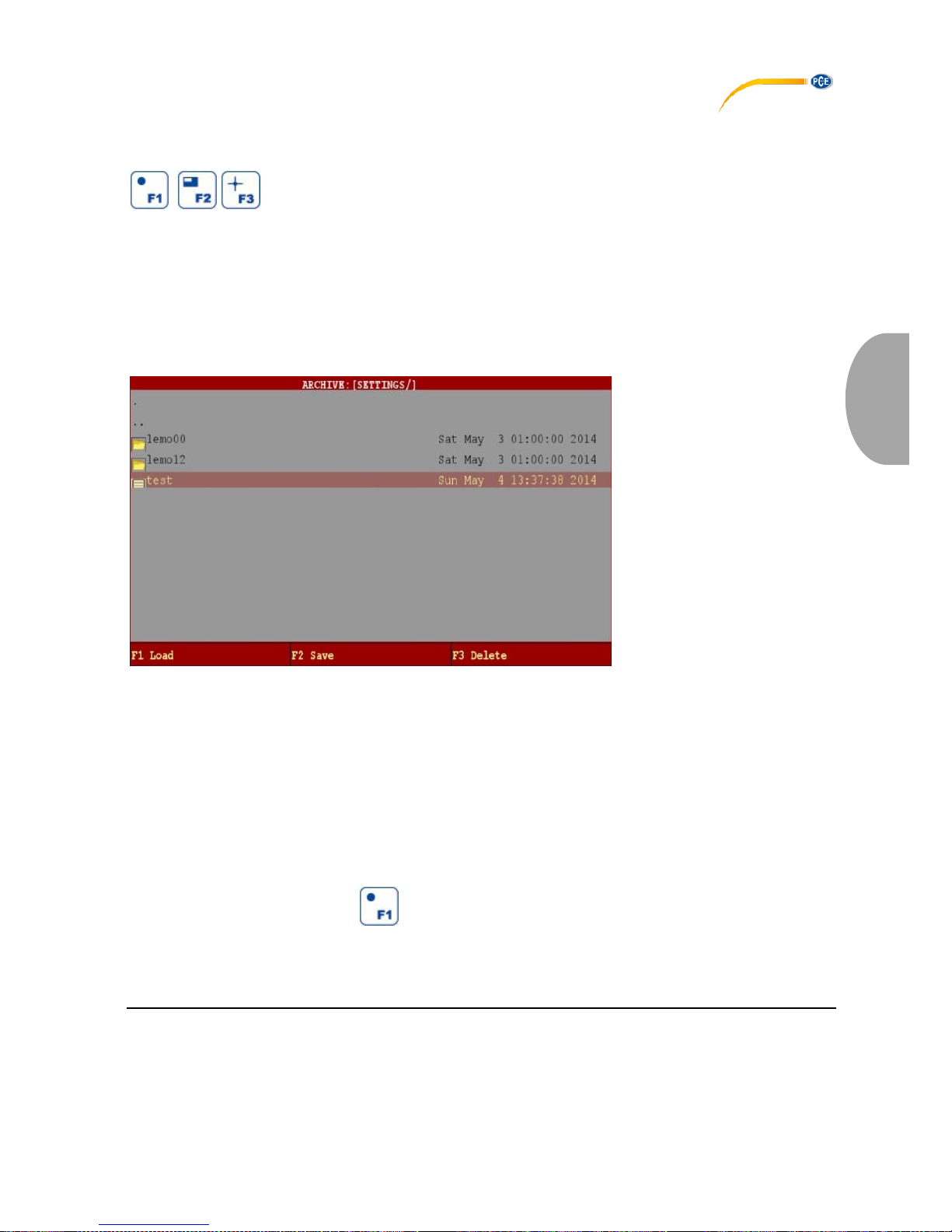

With the help of function keys , , – "F1 Load", "F2 Save",

"F3 Delete" (see Figure 27) – an operator can load the selected result (settings and data are

automatically loaded), save the current result and delete the selected result.

Fig. 27 - Operations with the testing results

© PCE Instruments

43

English

When loading the saved testing results, the setups which were used while the testing are set in

the instrument and the automatic transition (move) to "VIEW" menu is carried out.

When saving the results (and anywhere where it is necessary to enter the text information), "

, , " function keys delete the previous character – "backspc", move left – “move”

and cancel the information input – "cancel".

4.12 “Settings” Menu

When selecting "Settings" menu the flaw detector displays the window with a list of settings (see

Figure 23). The given menu allows the testing results saving and loading.

After a setups file loading, automatic enter in "Testing" menu is carried out.

Fig. 28 – "Settings" menu

4.13 Set up of “Calibration” Menu

The calibration curve plotting will be illustrated using the calibration block. To plot the calibration

curve, it is essential to set up all parameters of the flaw detector for operation with a specific

probe (i.e. select the ECP operating frequency from the range indicated in the registration

certificate, the required ECP exciting voltage, gain, scale) and take the calibration block (Ra

1.25).

In the "TEST" menu place the ECP on the flaw-free section before an artificial flaw with the

depth of 0.1 mm5 and press key (balancing). Pass all defects, having chosen such

scanning speed to have all signals from defects of regular shape (i.e. max symmetric relative to

the peak signal on time charts, see Figure 29).

The signals from the defect are not bound to stay only within the limits of one screen scan.

5

When operating with MDF probes, the mark on ECP case must coincide with the direction of

scanning trajectory.

© PCE Instruments

44

English

Fig. 29 – Appearance of defectogram for the calibration curve plotting

After the acquisition of defectogram, press key, for the quick transition to "CALIBRATION"

menu.

1 - Set a curve for evaluation of the defect depth (Amplitude, Phase);

2 - Select the units of defect measurement (mm, %);

3 - Calibration marker by the registered calibration blocks;

4 - Calibration block selection

5 - Position of the measuring cursor on the time chart;

6 - Width of the measuring cursor on the time chart;

7 - The type of the measuring cursor, see item 3.9

© PCE Instruments

45

English

Fig. 30 – "Calibration" menu

Note. After plotting the calibration curve, there is no point in changing the units of defects

measurements.

Before plotting the calibration curve, it is necessary to delete all points of previous calibration

curve by pressing key.

Select the type of measurement in the cursor "Type" – Pk-Pk. Move to the "Position: " menu

item and by the , and keys, position the central line of the cursor on the peak of

signal from the min defect. Move to the “Width:” menu item and increase the cursor width to

such an extent that only one friendly signal could get there, i.e. the signal from the defect (see

Figure 31). Having placed the cursor on a defect, press the key – add the calibration

curve point.

With the help of , keys, move to the "CURVE POINTS" – 1) and by , and

keys, set the depth of the first defect of the calibration curve, i.e.0.1 mm (see Fig. 31).

Then it is essential to perform similar operations for all other defects by setting corresponding

depth.

Fig. 31 – Plotting of the calibration curve

© PCE Instruments

46

English

Each newly added point of the calibration curve is assigned with a number (1), 2), 3) and so on).

The max number of the calibration curve points – 128.

Note. If calibration is carried out on any of the listed calibration blocks in pos. 4, Figure

30, then an operator can easily activate marker STD (pos.3, Fig. 30) and select an appropriate

type of the calibration block before adding of the calibration curve points. Then add in order,

starting with a minimum, all signals from defects of a given calibration block and the flaw

detector will automatically assign the wanted depth to the defects.

4.14 Communication with PC

The flaw detector in a set with "PCE-USC 30" software ensures communication mode with a PC

for the information input to the PC from the flaw detector memory (testing results, operating

setups) and the possibility to print out this information and to form a report.

4.14.1 Running the Program

To run the program it is required:

- to copy the files to the PC hard disk drive from the disk, that is included to the flaw detector

delivery set;

- run the file “.exe”.

4.14.2 Program Description

The operating window of the program includes the following areas (Fig. 32):

1 - main menu; 2 - tab panel; 3 - time diagrams area; 4 – signal display area (active area); 5 –

bottom status bar

Fig. 32 – Active window of PCE-USC 30 program

© PCE Instruments

47

English

4.14.2.1 Main Menu

Main menu bar includes the following menu items:

- File;

- Report.

"File" menu item includes the subitems:

Fig. 33

When selecting "Open" subitem, there appears a window for selection the path to the saved

testing results (by default the "RESULTS" folder is proposed, saved on the hard disk drive of PC

in the program directory of «PCE-USC 30»).

This file can be located in the flaw detector memory or also be stored on hard disk drive of PC

(if previously copied to the hard disk drive (4.14.3.2)). Double-click of the mouse left button

opens the file.

"Loading" subitem allows to view the files of all testing results saved in the flaw detector

memory and to copy them to the hard disk drive of PC (4.14.3.2).

When selecting "Device settings" subitem, there appears a window with the flaw detector

settings of the carried-out testing (Fig. 34).

Fig. 34 – “Flaw detector settings” window

© PCE Instruments

48

English

When selecting "Language" subitem, there appears a window for selecting the language of

program interface.

Fig. 35 – “Selecting the interface language” window

Note – Reload the program to change the interface language.

Select "Exit" subitem to finish the "PCE-USC 30" program.

When selecting "Report" item of the main menu, there appears a window for filling in the report

form of the testing carried out (Fig. 36).

Fig. 36 – Report form of a testing carried out

© PCE Instruments

49

English

After pressing button, there appears a window to preview the testing protocol.

There is an option to select between: weather to print out the setting parameters of the flaw

detector or not.

To abstain from printing out the flaw detector settings, put a tick in front of "Disable setting".

To print-out the testing protocol, press "Print" button in the upper part of a testing

protocol window.

To save the testing protocol in a «*.pdf» format, press button.

To exit the review mode of a testing protocol it is required to press button.

4.14.2.2 Tab Panel

Tab panel includes three tabs. Each tab corresponds to the selected frequency or to the mix of

frequencies (MIX): Frequency 1, Frequency 2, MIX.

Note - Frequency 2 and MIX are available for viewing only if the testing is carried out in a

two-frequency mode.

4.14.2.3 Time diagram area

Two diagrams of signal to time dependence are displayed in time diagram area (item 3, Fig. 32).

4.14.2.4 Signal display area (active area)

In the display area of eddy current signals is displayed the eddy current signal, which is

represented by an image in the complex plane for the frequency selected (item 4, Fig. 32). In

the active area are displayed the signals that come into the area covered by the measuring

cursor.

4.14.2.5 Bottom status bar

Fig. 37

"Duration of time sweeps" – sets the number of measurements to be displayed on time

sweeps. Duration of time sweep is measured in a range from 256 to 32768.

“Type of measurement” – allows to select the required type of cursor measurement from the

following list:

- Peak-Peak (the measurement is made between two points situated at the max. distance from

each other in cursor width);

- Vrt-M (vertical maximum – the measurement is made between two points situated at the max.

distance from each other in cursor width in vertical projection);

- Cnt-Pk (centre peak - the measurements is made between the cursor centre and the point

situated at the max. distance from the centre in cursor width);

- Cnt-K (centre cursor - the measurements is made between the centre and the cross point of

cursor centre signal);

© PCE Instruments

50

English

ENC (encoder) – displays the reference number by encoder when synchronizing from ENC.

Cursor position – displays the current vertical position of a measuring cursor in readings.

Fig. 38

To change the cursor position, it is required to place the "mouse" cursor onto the centre of a

measuring cursor (item 2, Fig. 38), and when there is a cursor, move the measuring cursor

to the required position by holding the left mouse button down.

- Cursor width – displays a set width of a measuring cursor (in readings).

To change the width of a measuring cursor, place the "mouse" cursor to the extreme position of

the measuring cursor (item 1, Fig. 38), and, when there is a cursor, set the required width of a

measuring cursor by holding the left mouse button down.

"Signal angle" – allows to change the signal phase:

- selects the step for signal phase change (from 0 to 90°);

- changing the signal phase with counter clockwise rotation considering the selected

step;

- changing the signal phase with clockwise rotation considering the selected step;

- restoring the initial signal phase.

Scale (HV) - simultaneous horizontal and vertical scaling of a signal image:

- scaling-up the signal image;

- scaling down the signal image;

- restoring the initial horizontal to vertical ratio.

Scale (H) – allows to adjust the horizontal scaling of a signal image:

- scaling-up the signal image horizontally;

- scaling down the signal image horizontally;

© PCE Instruments

51

English

- restoring the initial scale horizontally.

Scale (V) - allows to adjust a vertical scaling of a signal image:

- scaling-up the signal image vertically;

- scaling down the signal image vertically;

- restoring the initial scale vertically.

Signal parameters located in a measuring cursor are displayed in information area of a bottom

status bar:

− Amplitude (V);

− Phase (deg.);

− D (mm) - conditional defect depth;

− Аn (dB) - noise amplitude;

− S/N – measured value of signal to noise ratio.

Note – In order to measure the S/N ratio, place the measuring cursor on defect free-area

and press "An" key, then move the measuring cursor to the signal peak from the defect. The

measured signal/noise ratio will be displayed in the amplitude area.

4.14.3 Working with the program

4.14.3.1 Connecting the flaw detector to PC

Connect the flaw detector to PC using the USB connecting cable that is included to the flaw

detector delivery set.

Switch on the flaw detector by pressing the power On / Off button and hold it pressed until

a short beep sound is emitted.

Wait until the flaw detector is recognized on PC as a removable media (when the flaw detector

is recognized as a removable media, it is displayed on PC screen).

4.14.3.2 Saving the testing results from the flaw detector memory to PC

To save the testing results from the flaw detector memory to PC, connect the flaw detector to

PC using a USB cable (item 4.14.3.1). In the menu of «PCE-USC 30» program select the item

"Loading", and after, in the program window there are displayed the files of all the testing

results stored in the flaw detector memory. Then, the program window asks to select the files

that can be automatically copied to the selected location on the hard disk drive of PC.

© PCE Instruments

52

English

4.14.3.3 Viewing results of testing

Download «PCE-USC 30» program to PC.

In "File" item of the main menu choose the sub-item "Open".

In the window that appears, choose the path to removable media – the flaw detector memory or

the path where previously there was stored data on PC, move the cursor to the necessary file

with the testing results and click "Open".

After opening the file in the time diagrams window and in the active area of the program there is

displayed the stored defectogram and there is the possibility to view the testing results,

measurements of the signal parameters, as well as to make the report protocol followed by its

printing out.

Note - Viewing a list of data on the testing results from the flaw detector memory does

not store this data automatically in PC memory.

4.14.3.4 Printing out results of testing

To print out the testing results it is required:

- Select "Report" item in the main menu.

- Fill in the report form (Fig. 36).

- In the preview window of testing results click "Print" .

4.14.3.5 Disconnecting the flaw detector with PC

- Turn off the flaw detector by pressing the On / Off button .

- Disconnect the USB cable.

5 Labelling and Sealing

5.1 The flaw detector labelling complies with the manufacturer’s set of documents and

includes:

- manufacturer’s name and trade mark;

- name and designation of the flaw detector;

- year and quarter of manufacture;

- serial number;

- designation of specifications (TU);

- pattern approval mark.

Labelling is performed in English.

5.2 Labelling is made on the flaw detector casing by polygraphic technique.

5.3 Pattern approval mark is made on the flaw detector electronic unit by at least two seals

made on screws of casing cover.

© PCE Instruments

53

English

6 Composition and Delivery Set

6.1 Basic delivery set consists of the following components:

Table 8

Name and reference designation

Quantity

PCE-USC 30 electronic unit

SS340K09DA0 eddy current probe in protective case

Connection cable (Electronic unit/ECP)

Connection cable (PC/electronic unit)

Automatic charger Mascot

Calibration block SOP 2353.08 (Rz 40, D16T)

Case

Label for ECP

EC Probe CP13 (for conductivity measurement)

Cable Lemo12-Lemo04, 1200 mm

Documentations

Operation manual for ES.14327992.01.13 RE

Operation manual for Mascot

Passport for SOP 2353.08 PS (with roughness Rz 40,

material-D16T)

* Can be complemented with probes from the Appendix B.

** Quantity is according to ordered ECPs.

7 Setting-up procedures

7.1 The flaw detector is operated by one operator who has a corresponding level of

qualification and has studied the present operation manual.

7.2 Before operating charge the battery of flaw detector (if required) governed by the

passport of automatic charging device.

ATTENTION! WHEN CHARGING THE BATTERY, FLAW DETECTOR ELECTRONIC

UNIT MUST BE SWITCHED OFF.

© PCE Instruments

54

English

8 Instructions for Use

8.1 Single Coil Probe

1. Connect the ECP to the flaw detector using a connecting cable.

2. Set the ECP frequency in a range specified in the registration certificate for the ECP.

3. Set the ECP drive not more than 2 V.

4. Press key to select the capacity.

5. Place the ECP to the flaw-free area of a calibration block.

6. Press key to balance the ECP.

7. Put a signal from a lift-off in the horizontal plane. For this, it is necessary to decline the ECP

from the vertical axis at an angle of 15-45 ˚. While the vector end is deviated, press key. In

case, if the first attempt to put the signal from the lift-off horizontally failed it is necessary to

repeat the steps described above, or put the lift-off signal manually using the phase change (

parameter). The signal from a defect should be appeared in the first or second quadrant

of the complex plane.

8. By increasing the gain on preamplifier and amplifier you should maximize the

signal amplitude, but at the same time monitor behind parameters of the input circuit.

9. After changing any parameter that affects the absolute value of the signal it is necessary to

perform balancing by pressing key.

10. While testing aluminium alloys it is recommended to use the vertical gain " V GAIN" for