+ Type k Temp., Pt 1000 ohm Temp.

IR Temp .

TACHOMETER

Model : PCE-T 260

PCE Americas Inc.

711 Commerce Way

Suite 8

Jupiter

FL-33458

USA

From outside US: +1

Tel: (561) 320-9162

Fax: (561) 320-9176

info@pce-americas.com

www.pce-instruments.com/english

www.pce-instruments.com

PCE Instruments UK Ltd.

Southpoint Business Park

Hampshire / Southampton

United Kingdom, SO31 4RF

From outside UK: +44

Tel: (0) 2380 98703 0

Fax: (0) 2380 98703 9

info@industrial-needs.com

Your purchase of this

TACHOMETER/

STROBOSCOPE Meter

marks a step forward for you

into the field of

precision measurement.

Although this METER is

a complex and delicate

instrument, its durable

structure will allow

many years of use if

proper operating

techniques are

developed. Please read

the following

instructions carefully

and always keep this

manual within easy

reach.

Units 12/13

Ensign way

OPERATION MANUAL

TABLE OF CONTENTS

1. FEATURES..............................................................................................................

2. SPECIFICATIONS..................................................................................................

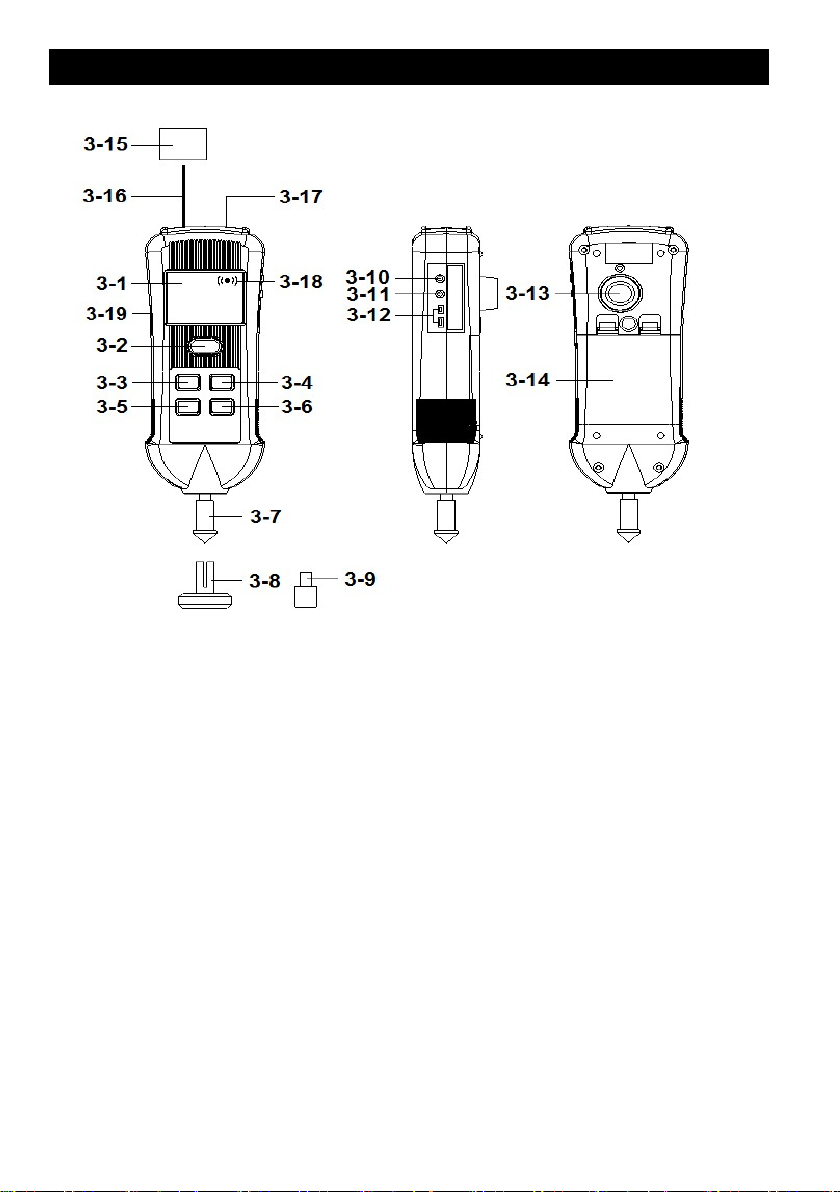

3. FRONT PANEL DESCRIPTION.............................................................................

3-1 Display ..........................................................................................................

3-2 Power button..........................................................................................................

button..........................................................................................................

3-4 REC/DOUBLE button..........................................................................................................

button..........................................................................................................

3-6 Function button..........................................................................................................

3-7 RPM Adapter..........................................................................................................

3-8 Surface Speed Test Wheel..........................................................................................................

3-9 Funnel type rubber for RPM adapter..........................................................................................................

3-10 RS-232 Output Terminal..........................................................................................................

probe Terminal..........................................................................................................

3-12 Thermocouple(type k) probe Terminal..........................................................................................................

3-13 IR Thermometer..........................................................................................................

3-14 Battery Compartment/Cover..........................................................................................................

3-15 Reflecting Mark..........................................................................................................

3-16 Photo led light beam..........................................................................................................

3-17 Stroboscope flash light (red) indicator..........................................................................................................

3-18 Monitor indicator..........................................................................................................

3-19 DC 9V adapter socket..........................................................................................................

4. PHOTO TACHOMETER MEASURING PROCEDURE...........................................

5. CONTACT TACHOMETER MEASURING PROCEDURE......................................................................

6. STROBOSCOPE OPERATION PROCEDURE......................................................................

7. Type K Thermometer MEASURING PROCEDURE......................................................................

8. RTD Temperature MEASURING PROCEDURE......................................................................

9. Infrared Thermometer MEASURING PROCEDURE......................................................................

10. RECORD OPERATION PROCEDURE..................................................................................................................

11. ADVANCED SETTING ................................................................................................................

12. BATTERY REPLACEMENT.......................................................................................................

13. RS232 PC SERIAL INTERFACE....................................................................

3-3 HOLD/▲

3-5 UNIT/▼

3-11 Pt 1000Ω

1

2

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

7

8

9

10

11

11

12

13

14

14

1. FEATURES

* Multi-functions, one instrument combine Photo Tachometer

( RPM ) & Contact Tachometer ( RPM, m/min., ft/min.,in/min. ).

Stroboscope , Type K Thermometer, Pt 1000 Thermometer,

IR Thermometer .

* High intensity white light beam for photo tachometer,

safety and save the power energy.

* Wide measuring range from 0.5 to 99,999 RPM.

* 0.5 RPM resolution for the measured value < 1000

RPM.

* High precision with 0.05% accuracy.

* The last value, max. value, min. value will be stored

into the memory automatically & can be obtained by

pressing REC Button.

* Large LCD display

* High visible LCD display gives RPM reading exactly

with no guessing or errors & saves battery energy.

* This tachometer used the exclusive one chip

MICRO-COMPUTER LSI circuit & crystal time base,

offer the high accurate measurement & fast sampling

time.

* The use of durable, long lasting components, including

a strong, light weight ABS plastic housing, assures

almost maintenance free performance for many years.

* The housing cabinet has been carefully shaped to fit

comfortable in either hand.

1

2. SPECIFICATIONS

RPM adapter ( CONE )........................................

RPM adapter ( FUNNEL )..................................

Surface speed test wheel................................

......

..................................

..................................

2-1 General Specifications

Display

43 mm x 33 mm LCD, 5 digits.

5 digits with display unit.

Measurement

Operating Humidity Max. 80% RH.

Operating 0 to 50 ℃ ( 32 to 122 ℉ )

Temperature

Over Input Indication of "- - - - "

Indicater.

Power Supply

Power

Consumption

Weight

Dimension

1. Photo Tachometer. 2. Contact Tachometer

3. Stroboscope Tachometer. 4. Type K thermometer

5. P t 1000 Ω thermometer. 6. IR thermometer

UM3-AA X 4 ( DC 6 V battery ),DC Adapter (adapter is optional)

Approx. DC 42 mA

240g/0.53 LB (Meter only)

HWD 207 x 67 x 45 mm (8.15 x 2.63 x 1.77 inch).

Time base Quartz crystal.

Circuit Exclusive one-chip of microcomputer

LSI circuit.

Memory Last/Max./Min. value.

Accessories Hard carrying case ...................................... 1 PC.

Included Reflecting tape marks

( 600 mm )................................................... 1 PC.

1 PC.

1 PC.

1 PC.

Operation manual........................................ 1 PC.

2

2-2 Electrical Specification ( 23 ±5℃ )

Photo Tachometer

Measurement Photo Tachometer :

& Range 5 to 99,999 RPM.

Resolution RPM:

0.5 RPM ( < 1,000 RPM ).

1 RPM ( ≧1,000 RPM ).

Accuracy ±( 0.05% reading+ 1 digit ).

Photo 50 to 150 mm/2 to 6 inch. (typical

Tachometer max. 300 mm/12 inch, depending

detecting upon ambient light).

distance * Spec. of detecting distance are that

under the size of reflecting tape is

10 mm square & the measuring

RPM value is 1,800 RPM. The max.

& min. detecting distance may

change under different

environment, different reflecting

tape or the measuring RPM

beyond 1800 RPM.

Contact Tachometer

Measurement Contact Tachometer :

& Range 0.5 to 19,999 RPM.

Resolution CONTACT (RPM):

Accuracy ±( 0.05% reading+ 1 digit ).

NOTE: When using test wheel, accuracy can be affected as much as 0.5% of reading.

0.5 RPM (< 1000 RPM ).

1 RPM ( ≧ 1,000 RPM ).

SURFACE SPEED (m/min.):

0.05 m/min. ( < 100 m/min. ).

0.1 m/min. ( ≧100 m/min. ).

SURFACE SPEED (ft / min.):

0.1 ft / min. ( < 1,000 ft/min. ).

1 ft / min. (≧ 1,000 ft/min. ).

SURFACE SPEED (in./min.) :

0.1 in./ min. ( < 1000 in./min.).

1 in. /min. ( ≧ 1,000 in./min.).

3

Stroboscope Tachometer

Flash adjust 100 to 99990 RPM/FPM.

range * RPM : round per minute.

* FPM : flash per minute.

Resolution 0.1 RPM : 5 RPM :

< 1,000 RPM.

≧ 30,000 - 50,000 RPM

1 RPM : 10 RPM :

≧ 1,000 - 30000 RPM ≧ 50,000 - 99,990 RPM

Function Digital rotate knob,

buttons x 2 button, ÷ 2 button,

+ button, - button,

Accuracy ±(0.1 % reading+ 2d)

* Spec. tested under the environment

RF Field Strength less than 3 V/M &

frequency less than the 30 MHz only.

4

Type K thermometer

Sensor Resolution Range Accuracy

Type

Type K 0.1 ℃ -50.0 to 1300.0 ℃ ± ( 0.4 % reading+ 0.5 ℃ )

-50.1 to -100.0 ℃ ± ( 0.4 % reading+ 1 ℃ )

0.1 ℉ -58.0 to 2372.0 ℉ ± ( 0.4 % reading+ 1 ℉ )

-58.1 to -148.0 ℉ ± ( 0.4 % reading+ 1.8 ℉ )

P t 1000 Ω thermometer

Unit Range Resolution Accuracy

℃

℉ 14 to 158 ℉ 0.1 ℉ ± 2.2 ℉ reading

-10 to 70

℃

0.1

℃

± 1.2 ℃ reading

IR thermometer

Emissivity 0.95 fixed value

Spectral response 6 to 14 μm (wavelength)

Field of View D/S D/S =Approx. 3 : 1 ratio (D = distance, S =spot)

Unit Range Resolution Accuracy

℃

℉ -22 to 581 ℉ 0.5 ℉ ± 3 % reading or ± 5.4 ℉

Spec. is tested under the 20 cm dia. Black body, the measuring distance between the

sensing head and the target is 30 cm.

-30 to 305

℃

0.5

℃

± 3 % reading or ± 3

℃

Spec. tested under the environment RF Field Strength less than 3 V/M &

frequency less than the 30 MHz only.

5

3. FRONT PANEL DESCRIPTION

Fig. 1

3-1 Display 3-12 Thermocouple(type k) probe Terminal

3-2 Power button 3-13 IR Thermometer.

3-3 HOLD/▲ button

3-4 REC/DOUBLE button 3-15 Reflecting Mark

3-5 UNIT/▼ button

3-6 Function button 3-17 Stroboscope flash light (red) indicator

3-7 RPM Adapter 3-18 Monitor indicator

3-8 Surface Speed Test Wheel 3-19 DC 9V adapter socket

3-9 Funnel type rubber for RPM adapter

3-10 RS-232 Output Terminal

3-11 Pt 1000Ω probe Terminal

3-14 Battery Compartment/Cover

3-16 Photo led light beam

6

4. PHOTO TACHOMETER

Release the "Measuring Button" when the reading

stabilizes (about 2 seconds).

MEASURING PROCEDURE

1) Power On the meter by short pressing the " Power

button " ( 3-2, Fig. 1 ) >1.5 seconds , the LCD will light.

2) Press the " Function button " ( 3-6, Fig. 1 ) (short push) in

sequence until to the " Photo RPM " function be

selected, in the same time the " Photo light beam " (

3-16, Fig. 1 ) will be generated.

3) Apply a " Reflecting mark " ( 3-15, Fig. 1 ) to the

object being measured. and align the " Photo light

beam " ( 3-16, Fig. 1 ) with the applied target. Verify

that the " Monitor Indicator " ( 3-18, Fig. 1 ) lights

when the target pass through the light beam.

Measuring consideration :

If the measured RPM values is very low ( for

example less than 50 RPM ), recommend to

attach more " Reflecting Marks " average to

the object. It will get the real RPM with high

resolution, precisely & fast sampling time

when divided the reading values by the no.

of the " Marks ".

7

5. CONTACT TACHOMETER

MEASURING PROCEDURE

5-1 RPM measurement

1) Power On the meter by short pressing the " Power

button " ( 3-2, Fig. 1 ) >1.5 seconds, the LCD will light.

2) Press the " Function button " ( 3-6, Fig. 1 ) (short push) in

sequence until to the " Contact RPM " function be

selected.

3) Lightly pressing the " RPM Adapter " ( 3-7, Fig. 1 )

against the center hole on the hole of the measured

rotating axis.

Measuring consideration :

Making the contact RPM measurement due to

different kind measured rotating axis, it may

changed the rubber for RPM adapter from "

CONE " type to " FUNNEL" type ( 3-9, Fig. 1 )

.

5-2 Surface Speed Measurement

1) Power On the meter by short pressing the " Power

button " ( 3-2, Fig. 1 ) >1.5 seconds , the LCD will light.

2) Short Press the " Function button " ( 3-6, Fig. 1 ) once

again and again until lcd display show the " touch " text,

then short press the " UNIT Button " to select the

Surface Speed Measurement unit m/min , " ft/min " or " in./min.".

3) Change the " RPM Adapter " instead of the " Surface

Speed Test Wheel " ( 3-8, Fig. 1 )

4) Simply attaching the surface speed test wheel to the

detector. approx. 2 sec. the display reading will be stabilizes.

8

6 STROBOSCOPE OPERATION PROCEDURES

6-1 STROBOSCOPE OPERATION

1) Power On the meter by short pressing the " Power

button " ( 3-2, Fig. 1 ) >1.5 seconds , the LCD will light.

2) Press the " Function button " ( 3-6, Fig. 1 ) (short push) in

sequence until to the " SCOPE RPM " function be

selected, in the same time the " Stroboscope flash light (red)

indicator " (3-17, Fig. 1 ) will be Light.

3) The display will show " last measurement value " RPM ( FPM ),

last measurement value ,memo in the internal memory divice.

Use the " x 2 button(▲ button) " or " / 2 button(▼ button) " to adjust the

display value near the estimate setting signal's RPM

approximately.

*

Press and hold the " DOUBLE button " then Press " ▲ button "

once will double the display value.

For example, the display is " 100.0 " , Press and hold the

" DOUBLE button " then Press " ▲ button " once, the display will

change to " 200.0 ". Operation again, the display will change to "

400.0 ".....

*

Press and hold the " DOUBLE button " then Press " ▼ button "

once will divide the display value by two.

For example, the display is " 400.0 ", Press and hold the

" DOUBLE button " then Press " ▼ button " once , the display

will change to " 200.0 ". Operation again, the display will change

to " 100.0 ".....

6-2 Checking Speed (RPM/FPM)

1)

Use the " ▲+ button " ( 3-3, Fig. 1 ) , " ▼- button " ( 3-5,

Fig. 1 ) to adjust the exact display value.

*

Press the " ▲+ button " once will increase the display value.

*

Press the "▼ - button " once will decrease the display value.

*

Press and hold the " ▲+ button "or "▼ - button " will

fast increase or fast decrease the display value.

9

* If press the button once, the display value will

change with high resolution ( change just with 1

digit ).

* If press the button continuously, the display value will

change with low resolution ( change with more

digits ).

When checking the speed, care must be taken

to ensure that the strobe is flashing in unison

(one to one) with the object being monitored.

2) The Stroboscope will also stop motion at 2:1, 3:1, 4:1 et.,

this is normally referred to as harmonics. To ensure

unison, turn the dial until two images appear - this will

double the actual speed. Then lower the flashing rate

until a single and stationary image appears - this is the

actual true speed.

6-3 Checking Motion

For motion analysis, simply locate the actual speed as

mentioned above and use the " ▲ button " or "▼ button " to adjustment

slowly up or down. This will give a slow motion effect allowing complete

inspection.

7. Type K Thermometer

MEASURING PROCEDURE

1) Power On the meter by short pressing the " Power

button " ( 3-2, Fig. 1 ) >1.5 seconds, the LCD will light.

2) Press the " Function button " ( 3-6, Fig. 1 ) (short push) in

sequence until to the " TYPE k " function be

selected.

3) type k probe inserted into the thermocouple probe terminal

" thermocouple probe terminal " ( 3-12, Fig. 1 ).

4)

The display will show type k probe sensing temperature value.

10

8. RTD Temperature

Press and hold the IR thermometer test button " Power button " ( 3-2, Fig. 1 ).

MEASURING PROCEDURE

1) Power On the meter by short pressing the " Power

button " ( 3-2, Fig. 1 ) >1.5 seconds, the LCD will light.

2) Press the " Function button " ( 3-6, Fig. 1 ) (short push) , in

sequence until to the " P t " function be

selected.

3) TP-1000 probes are connected to the Pt 1000 Ω probe terminal

" ( 3-11, Fig. 1 ).

4)

The display will show TP-1000 probe sensing temperature value.

9. Infrared Thermometer

MEASURING PROCEDURE

NON-CONTACT TEMPERATURE MEASUREMENTS

1) Power On the meter by short pressing the "power

button " ( 3-2, Fig. 1 ) >1.5 seconds, the LCD will light.

2) Use the " Function button " ( 3-6, Fig. 1 )(short push), to select function ,

until to the " I r " function be selected.

3)

4)

Use the led light pointer to identify the exact spot to be measured.

5)

The area of the surface to be measured must be larger than the spot

size as determined by the distance to spot size specification.

6)

when test value stable then reless the IR thermometer test button

" Power button " ( 3-2, Fig. 1 ) .

7)

The display will show and hold the IR sensing temperture value.

11

10. RECORD OPERATION PROCEDURE

Data Record ( Max., Min. reading )

1) The data record function records the maximum and minimum readings.

Press the " REC Button " ( 3-4, Fig.1 ) once to start the Data Record

function and there will be a " REC "Symbol indicator "

will be light.

2) With the " REC " Symbol is light on the display :

a) Press the " REC Button " ( 3-4, Fig. 1 ) once, the "

REC and MAX Symbol indicator will be light ,

and the maximum value will appear on the display.

b) Press the " REC Button " ( 3-4, Fig. 1 ) again, the

" REC and MIN " Symbol indicator will be light ,

and the minimum value will appear on the display.

c) To exit the memory record function, just press the

" REC " button for 1.5 seconds at least. The display will

revert to the current reading, Symbol indicator will be quenched

Remark :

At Infrared Thermometer and stroboscope function, the RECORD Function is disabled.

12

11. ADVANCED SETTING

press the " FUNCTION (SET) Button " ( 3-6, Fig. 1 ) continuously at

least Five seconds will enter the " Advanced Setting " mode. then

press the " FUNCTION (SET) Button " ( 3-6, Fig. 1 ) once a while in sequence

to select the two main function, the display will show :

POFF.......

t-CF.......

Remark:

wait eight seconds or short press " power button " to back measurement.

11-1 Auto power OFF management

When the lower display show " POFF "

1)

Use the " ▲ button " ( 3-3, Fig. 1 ) or " ▼ button " ( 3-5,Fig. 1 "

to select the upper text to " yES " or " no ".

yES - Auto Power Off management will enable.

no - Auto Power Off management will disable.

2) After select the text to " yES " or " no ", press the

" REC(Enter) Button " ( 3-4, Fig.1 ) will save the setting

function with default.

11-2 Select the Temp. unit to ℃ or

When the lower display show " t-CF "

Auto power OFF management

Select the Temp. unit to ℃ or ℉

℉

1)

Use the " ▲ button " ( 3-3, Fig. 1 ) or " ▼ button " ( 3-5,Fig. 1 "

to select the upper Display text to " C " or " F ".

C - Temperature unit is ℃

F - Temperature unit is ℉

2) After Display unit is selected to " C " or " F ", press the

" REC(Enter) Button " ( 3-4, Fig.1 ) will save the setting

function with default.

13

12. BATTERY REPLACEMENT

Center Pin............................................

Ground/shield...........................................

1) When the left corner of " Lobattery symbol " indicator

is light, it is necessary to replace the battery. However, in-spec.

measurement may still be made for several hours after

low battery indicator appears before the instrument

become inaccurate.

2) take away the " Battery Cover " ( 3-14, Fig. 1 )

from the instrument and remove the battery.

3) Replace with DC 1.5 V battery ( UM3, AA,

Alkaline/heavy duty ) x 4 PCs, and reinstate the cover.

4) Make sure the battery cover is secured after changing

the battery.

13. RS232 PC SERIAL INTERFACE

The instrument has RS232 PC serial interface via a 3.5

mm terminal ( 3-10, Fig. 1 ).

The data output is a 16 digit stream which can be

utilized for user's specific application.

A RS232 lead with the following connection will be

required to link the instrument with the PC serial port.

Meter PC

(3.5 mm jack plug)

(9W 'D" Connector)

Pin 4

Pin 2

2.2 K

resistor

Pin 5

14

The 16 digits data stream will be displayed in the

following format :

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

Each digit indicates the following status :

D15 Start Word

D14 4

D13 1

D12, D11 Annunciator for Display

ft/min = 11 inch/min = 28 m/min = 60

RPM = 27

D10 Polarity

0 = Positive 1 = Negative

D9 Decimal Point(DP), position from right to the

left

0 = No DP, 1= 1 DP, 2 = 2 DP, 3 = 3 DP

D8 to D1 Display reading, D1 = LSD, D8 = MSD

For example :

If the display reading is 1234, then D8 to

D1 is : 00001234

D0 End Word

℃ = 01 ℉ = 02

RS232 FORMAT : 9600, N, 8, 1

Baud rate 9600

Parity No parity

Data bit no. 8 Data bits

Stop bit 1 Stop bit

15

Loading...

Loading...