Graphic AC Power Quality Analyzer

PCE-GPA 62

Users Manual

PCE Group

SYMBOLS showed on the clamp meter or in this manual:

Caution, risk of danger.

Refer to accompanying documents

Caution, risk of electric shock.

Double Insulation

Application around and removal from HAZARDOUS

LIVE conductors is permitted.

Earth (ground)

AC (Alternating Current)

DC (Direct Current)

Both direct and alternating current

Conforms to relevant European Union directives.

Do not dispose of this clamp meter as unsorted

municipal waste. Contact a qualified recycler for

disposal.

EN 61010-2-032

CAT III 600V

Pollution Degree 2

Overvoltage Category I (CAT I):

Equipment for connection to circuits in which measures are

taken to limit the transient overvoltages to an appropriate low level.

Overvoltage Category II (CAT II):

Energy-consuming equipment to be supplied from the fixed

installation.

Overvoltage Category III (CAT III):

Equipment in fixed installations.

SAFETY INFORMATION: (Read First Before Operation)

Please follow the following instructions carefully for safe operation.

■

NEVER use the clamp meter for Voltages higher than 600V.

■

DO NOT hold the clamp meter beyond its tactile barrier.

■

DO NOT use the clamp meter and accessories if they look

damaged.

■

USE CAUTION when working with high voltages.

■

USE CAUTION when measuring the voltages higher than

30VAC rms or 60VDC. These voltages pose a shock hazard.

■

USE EXTREME CAUTION when working around bare

conductors or bus bars.

■

ALWAYS use the clamp meter as the instructions in the manual.

WARNING: If the flexible tester is used in a manner

Not specified by the manufacturer, the protection

Pro vid e d by t he c l am p m ete r m ay b e imp aire d.

I

TABLE OF CONTENTS

I. FEATURES ................................................................................................................ 1

II. PANEL DESCRIPTION............................................................................................2

III. OPERATING INSTRUCTIONS ..............................................................................4

III.1 Setup................................................................................................................... 4

III.2 Measurement of RMS value, THD-F and Harmonics of ACV .......................13

III.3 Measurement of RMS value, THD-F and Harmonics of ACA .......................16

III.4 Waveforms of ACV and ACA with Phase Angle (φ)........................................19

III.4.1 Waveform of ACV with Peak Value..........................................................20

III.4.2 Waveform of ACA with Peak Value .......................................................... 21

III.5 Measurement of Single Phase AC Power Quality..........................................22

III.5.1 True Power (W) and Power Factor (PF)..................................................23

III.5.2 Apparent Power (VA, KVA) and Reactive Power (VAR, KVAR) ............. 23

III.5.3 Maximum Demand (KW and KVA)..........................................................24

III.5.4. Energy (KWh, PFh, KVARh, and KVAh).................................................24

III.5.5 Phasor Diagram........................................................................................24

III.5.6 RMS values of Voltage and Current.........................................................25

III.6 Measurement of Balanced 3 Phase AC Power Quality .................................26

III.6.1 AC Watt (W) and Power Factor (PF)........................................................27

III.6.2 Apparent Power (VA, KVA) and Reactive Power (VAR, KVAR) ............. 27

III.6.3 Maximum Demand (KW and KVA)..........................................................27

III.6.4 Energy (KWh, PFh, KVARh, and KVAh).................................................. 28

III.6.5. Phasor Diagram ....................................................................................... 28

III.6.6. RMS values of Voltage and Current........................................................ 28

IV. DATALOGGING OF VOLTAGE (RMS VALUE) AND HARMONICS...............29

IV.1 Scheduled Datalogging ...............................................................................29

IV.2 Immediate Datalogging................................................................................32

V. DATALOGGING OF CURRENT (RMS VALUE) AND HARMONICS...............33

V.1 Scheduled Datalogging ................................................................................ 33

V.2 Immediate Datalogging.................................................................................35

II

VI. DATALOGGING OF VOLTAGE AND CURRENT WAVEFORMS...................36

VI.1 Datalogging of both Voltage and Current Waveforms...............................36

VI.2 Datalogging of Voltage Waveform..............................................................37

VI.3 Datalogging of Current Waveform..............................................................38

VII. DATALOGGING OF TRANSIENT DETECTION ..............................................39

VIII. DATALOGGING OF AC POWER .....................................................................44

VIII.1 Scheduled Datalogging.............................................................................44

VIII.2 Immediate Datalogging .............................................................................46

IX. CLEAR DATA MEMORY......................................................................................47

X. RS-232 INTERFACE PROTOCOL.......................................................................47

XI. SPECIFICATIONS (23°°°°C±5°°°°C)............................................................................48

XII. BATTERY REPLACEMENT...............................................................................52

XIII. MAINTENANCE & CLEANING.........................................................................54

1

I. FEATURES

a. Power Quality Analysis for Single and Balanced Three Phase System.

b. Harmonic Analysis of Voltage and Current (1 to 50th order).

c. True RMS measurement of V with 0.5% of reading basic accuracy.

d. True RMS measurement of A with 1% of reading basic accuracy

e. Graphic Waveform of Voltage and Current

f. Graphic Phasor Diagram

g. Transient Detection and Logging of Swell, Dip, and Outage.

h. Fast peak function (39µs for 50 Hz, 33µs for 60Hz).

i. Active (W, KW, HP), reactive (VAR, KVAR) and apparent (VA, KVA) power

j. Power factor (PF), phase angle (Φ), and energy (WH, KWH, KVARH, PFH).

k. Measurement of balanced 3Φ Power Quality.

l. Programmable VT ratio from 1 to 3000.

m. Hold functions.

n. Auto power off function in 15 minutes (selectable).

o. Datalogging and Download to a PC.

p. Optical isolated USB data connection.

q. Unlimited datalogging facility on a PC.

2

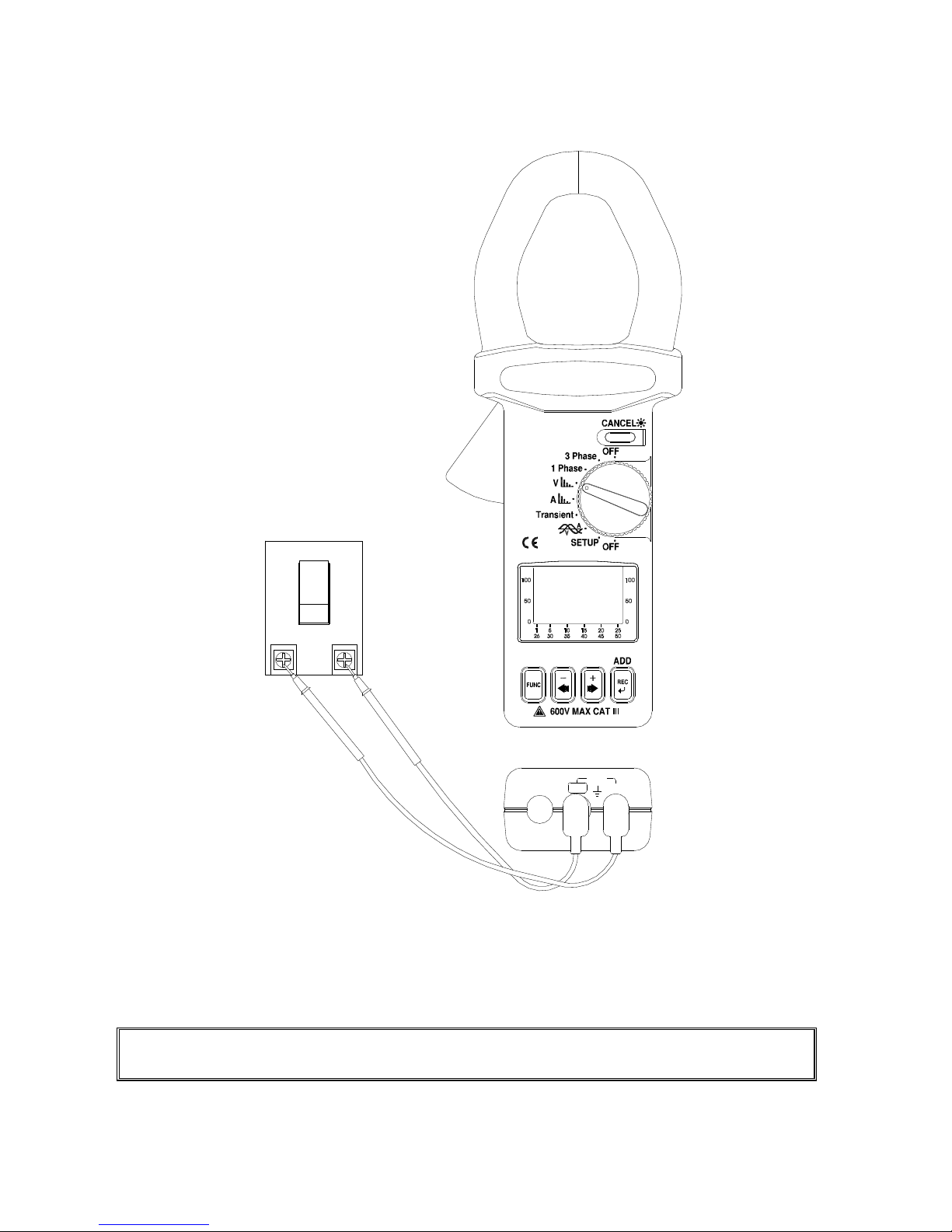

II. PANEL DESCRIPTION

600V

COM

V

L1

L3

1. Jaw Assembly

2. Trigger

Press the trigger to open the jaw assembly.

3. HOLD/CANCEL/BACK LIGHT

Press this button to HOLD the display in LCD, or turn the backlight on or off.

It is also used to delete harmonics in the harmonics configuration

4. Rotary Switch

Select setup, measurement of current, voltage, transient detection, or power.

Turn the unit on or off.

5. LCD

This is a dot matrix LCD with backlight.

3

6. + ►

Button

. Increment value by 1

. Move the reference axis up

. Move the line cursor right to previous harmonics

. Page up to next transient events

7. REC

Press this button to start Datalogging. Press again to stop. Holding the button and

turning the power on will clear the data memory.

It is also used to add harmonics in the harmonics configuration.

8. - ◄ Button

. Decrement value by 1

. Move the reference axis down

. Move the line cursor left to next harmonics

. Page down to next transient events

9. FUNC Button

Press this button to select different display.

10. V Input Terminal

This terminal is used as input for voltage.

11. COM Terminal

This terminal is used as common voltage reference input.

12. RS-232 window and Battery Cover

4

III. OPERATING INSTRUCTIONS

III.1 Setup

Move the rotary switch to the SETUP position. Users should setup the parameters

of the meter before use.

5

CURRENT TIME

: There is a calendar clock inside the meter. Users should

setup the correct time.

HOUR

MINUTE

SAMPLE: Setup the sampling interval in seconds for Datalogging.

START TIME: schedule when to start datalogging

6

HOUR

MINUTE

STOP TIME: schedule when to stop datalogging

HOUR

7

MINUTE

VT: set the ratio of voltage transformer, normally 1.

V (reading) = Voltage * VT

MD: set the time interval form maximum demand in minutes (1 to 60 minutes),

normally 15.

8

HZ:

set the operating frequency to 50Hz, 60Hz, or Auto.

AUTO POWER OFF: enable (1) or disable (0) auto-power-off function.

TRANSIENT REFERENCE: set the nominal voltage and threshold (%) for

transient capture.

NOMINAL VOLTAGE

9

TOLERANCE

10

HARMONICS CONFIGURATION:

select the harmonics to be logged.

NOTE: The unit will adjust the sampling time according to the amount of

harmonics to be logged

11

WAVEFORM CONFIGURATION:

set the points to be logged for each cycle of

the waveform. There are four options, 32, 64, 128, and 256.

NOTE: The unit will adjust the sampling time according to the processing time

required to log waveform.

DATE: set the date of the internal calendar clock.

YEAR

12

MONTH

DAY

13

III.2 Measurement of RMS value, THD-F and Harmonics of ACV

L3

L1

V

COM

600V

Voltage:

a. Set the rotary switch at V position.

b. Insert the test leads into the input jack. Connect the test prods of the test

leads in PARALLEL to the circuit to be measured.

NOTE: If the peak value of the input AC voltage is greater than the maximum

value of the range, then symbol of OL will be displayed.

14

%THD-F: Total Harmonic Distortion with respect to Fundamental frequency

%THD-F = (√(V22+ V32 + … +V492+ V502)) / V1) * 100

Where,

V1: magnitude at the nominal frequency (eg.50 or 60 Hz)

V2: magnitude at the second harmonics

…

V50: magnitude at the 50-th harmonics.

15

NOTE: Frequency (Hz) is displayed in the second page (Harmonics order 25th to

50th order).

16

III.3 Measurement of RMS value, THD-F and Harmonics of ACA

a. Set the rotary switch at A position.

b. Clamp on to the conductor, and read the data from LCD display.

WARNING: Make sure that all the test leads are disconnected from the meter's

terminals for current measurement.

17

%THD-F: Total Harmonic Distortion with respect to Fundamental frequency

%THD-F = (√(V22+ V32 + … +V492+ V502)) / V1) * 100

Where,

V1: magnitude at the nominal frequency (eg.50 or 60 Hz)

V2: magnitude at the second harmonics

…

V50: magnitude at the 50-th harmonics.

18

NOTE: Frequency (Hz) is displayed in the second page (Harmonics order 25th to

50th order).

19

III.4 Waveforms of ACV and ACA with Phase Angle

((((φφφφ

)

20

When users set the rotary switch at waveform position, the unit will display both

voltage and current waveform with phase angle.

Users can press the +►or -◄ buttons to move the 0 reference axis of current up or

down. So the waveforms of voltage and current can be easily distinguished as in the

following figure.

III.4.1 Waveform of ACV with Peak Value

Press the FUNC button to select display of voltage waveform with RMS value and

peak value

21

III.4.2 Waveform of ACA with Peak Value

Press the FUNC button to select display of current waveform with RMS value and

peak value

22

III.5 Measurement of Single Phase AC Power Quality

NOTE: If the peak value of the input AC current or AC voltage is greater than the

maximum value of the range, then symbol of OL will be displayed.

NOTE: If the VT ratio is not 1, the readings

of shown in LCD is equal to the W, VA,

and VAR values measured by the tester multiplied by VT ratio (W

LCD

= W × V

T,

VA

LCD

= VA × VT, VAR

LCD

= VAR × VT, WH

LCD

= WH × VT).

--

+

+

--

+

L

3

L

1

V

C

O

M

6

0

0

V

a. Set the rotary switch at the 1 Phase position

b. Connect the test leads to the voltage source in parallel with the load.

c. Clamp on one of the wire to the load. The current should flow from the front of

the tester to the side of the battery cover

d. Press FUNC to select following display.

23

III.5.1 True Power (W) and Power Factor (PF)

III.5.2 Apparent Power (VA, KVA) and Reactive Power (VAR, KVAR)

24

III.5.3 Maximum Demand (KW and KVA)

WARNING: Must disable auto-power-off for this measurement.

III.5.4. Energy (KWh, PFh, KVARh, and KVAh)

WARNING: Must disable auto-power-off for this measurement.

III.5.5 Phasor Diagram

25

III.5.6 RMS values of Voltage and Current

26

III.6 Measurement of Balanced 3 Phase AC Power Quality

L1

L3

L1

L2

L3

+

6

0

0

V

C

O

M

V

L

1

L

3

a. Set the rotary switch at the 3 Phase position

b. Connect the test leads to the voltage source in parallel with the load.

c. Clamp on one of the wire to the load. The current should flow from the

front of the tester to the side of the battery cover

d. Press

3φ

button for balanced

3φ

system measurement.

e. Press the FUNC button to select following displays

27

III.6.1 AC Watt (W) and Power Factor (PF)

III.6.2 Apparent Power (VA, KVA) and Reactive Power (VAR, KVAR)

III.6.3 Maximum Demand (KW and KVA)

WARNING: Must disable auto-power-off for this measurement.

28

III.6.4 Energy (KWh, PFh, KVARh, and KVAh)

WARNING: Must disable auto-power-off for this measurement.

III.6.5. Phasor Diagram

III.6.6. RMS values of Voltage and Current

29

IV. DATALOGGING OF VOLTAGE (RMS VALUE) AND HARMONICS

IV.1 Scheduled Datalogging

Set the rotary switch at the V position and press the REC button ONCE.

If users see the following display and press the REC button, the true RMS value of

voltage and selected harmonics set in the configuration will be logged at specified

sampling interval.

The START TIME and STOP TIME is set in the SETUP.

NOTE: The true RMS value and the first harmonics are always logged.

30

31

When the REC button is pressed, users will see the following display.

Users always have 8 seconds to cancel Datalogging by pressing the HOLD button

for about 2 seconds. If users do not press HOLD/CANCEL button, the unit starts

Datalogging, and the LED next to the REC button starts blinking.

32

IV.2 Immediate Datalogging

Press the REC button TWICE

START TIME will be changed to next minute.

STOP TIME will be changed to current time tomorrow.

Please refer to HARMONICS CONFIGURATION of SETUP for selecting

harmonics.

33

V. DATALOGGING OF CURRENT (RMS VALUE) AND HARMONICS

V.1 Scheduled Datalogging

Set the rotary switch at the A position and press the REC button ONCE.

The true RMS value of current and selected harmonics set in the configuration will

be logged at specified sampling interval. The START TIME and STOP TIME is set

in the SETUP.

34

When the REC button is pressed, users will see the following display.

Users always have 8 seconds to cancel datalogging by pressing the HOLD button

for about 2 seconds. If users do not press HOLD/CANCEL button, the unit starts

datalogging, and the LED at the bottom starts blinking.

35

Please refer to HARMONICS CONFIGURATION of SETUP for selecting

harmonics.

NOTE: The true RMS value and the first harmonics are always logged.

V.2 Immediate Datalogging

Press the REC button TWICE, the unit start Datalogging in the next minute.

START TIME will be changed to next minute.

STOP TIME will be changed to current time tomorrow.

36

VI. DATALOGGING OF VOLTAGE AND CURRENT WAVEFORMS

VI.1 Datalogging of both Voltage and Current Waveforms

Set the rotary switch at the VA waveform, and press the FUNC to select

display of both voltage and current waveforms.

Press the REC button once to do scheduled Datalogging. Both voltage and

current waveforms will be logged.

NOTE: Users can specify how many points per cycle in the WAVEFORM

CONFIGURATION of SETUP.

37

VI.2 Datalogging of Voltage Waveform

Set the rotary switch at the VA waveform and press the FUNC to select display

of voltage waveform.

Press the REC button once to do scheduled Datalogging. Voltage waveform

will be logged.

NOTE: Users can specify how many points per cycle in the WAVEFORM

CONFIGURATION of SETUP.

38

VI.3 Datalogging of Current Waveform

Set the rotary switch at the VA waveform and press the FUNC to select

display of current waveform.

Press the REC button once to do scheduled Datalogging. Current waveform

will be logged.

NOTE: Users can specify how many points per cycle to be logged in the

WAVEFORM CONFIGURATION of SETUP.

39

VII. DATALOGGING OF TRANSIENT DETECTION

Set the rotary switch to the Transient position, the following display is shown.

It shows the reference voltage is AC 110.0V (TRANS REF), and the threshold is

5%. If the voltage exceeds 115.5V (SWELL) or is less than 104.5V (DIP), or is less

the 40.0V (OUTAGE), one transient event will be logged.

NOTE: Maximum 32000 events

40

Press the FUNC button to start transient detection.

41

After users press the FUNC button, the LCD will become blank and the LED at the

bottom starts to flash.

42

To stop transient detection and review events, press the FUNC button again. Press

the

+

►or -◄ buttons to review events.

43

44

VIII. DATALOGGING OF AC POWER

VIII.1 Scheduled Datalogging

Press the REC button ONCE

Users can press the REC button once to start scheduled datalogging. The START

TIME and STOP TIME is set in the SETUP.

45

When the REC button is pressed, users will see the following display.

Users always have 8 seconds to cancel Datalogging by pressing the HOLD button

for about 2 seconds. If users do not press HOLD/CANCEL button, the unit starts

Datalogging, and the LED next to the REC button starts blinking.

46

The unit will log 50,000 records of (Date/Time, VA, W, VAR, PF, KVAH, KWH,

KVARH, PFH, AD(VA), AD(W), MD(VA), MD(W), Phase, HP).

VIII.2 Immediate Datalogging

Press the REC button TWICE

START TIME will be changed to next minute.

STOP TIME will be changed to current time tomorrow.

47

IX. CLEAR DATA MEMORY

To clear the memory of data logger, hold the REC button and turn the power on.

The following display will be shown in LCD. Users press the HOLD button to

confirm the clearance of memory. The unit is turned off after the memory is

cleared.

If users do not press the HOLD button in 8 seconds, the memory is not clear. This

timer could avoid users accidentally clear the memory.

X. RS-232 INTERFACE PROTOCOL

Baud Rate: 9600

Data Bits: 8

Stop Bit: 1

Parity: None

Format: ASCII

48

XI. SPECIFICATIONS (23°°°°C±5°°°°C)

AC Watt (50 or 60 Hz, PF 0.5 to 1.0, VT = 1, Voltage > 5V AC, Current > 5A AC

for A range, and continuous waveform)

Accuracy of Readings1 Range (0 to 1500A) Resolution

> 20 V and > 20A < 20V or < 20A

10.0 – 999.9 W 0.1W ±1% ±20dgts ±2% ±40dgts

1.000 – 9.999 KW 0.001 KW ±1% ±20dgts ±2% ±40dgts

10.00 – 99.99 KW 0.01 KW ±1% ±20dgts ±2% ±40dgts

100.0 – 999.9 KW 0.1 KW ±1% ±20dgts ±2% ±40dgts

1000 – 9999 KW 1 KW ±1% ±20dgts ±2% ±40dgts

1

For VT

≠≠≠≠

1, the accuracy in percentage is the same (±1%). But the additional

wattage should be multiplied by the VT ratio.

For example, ±0.2W becomes ±0.2W * VT ratio

AC Apparent Power (VA, from 0.000VA to 9999 KVA, PF 0.5 to 1)

Accuracy of Readings1 Range (0 to 1500A) Resolution

> 20 V and > 20A < 20V or < 20A

10.0 – 999.9 VA 0.1VA ±1% ±20dgts ±2% ±40dgts

1.000 – 9.999 KVA 0.001 KVA ±1% ±20dgts ±2% ±40dgts

10.00 – 99.99 KVA 0.01 KVA ±1% ±20dgts ±2% ±40dgts

100.0 – 999.9 KVA 0.1 KVA ±1% ±20dgts ±2% ±40dgts

1000 – 9999 KVA 1 KVA ±1% ±20dgts ±2% ±40dgts

1

For VT

≠≠≠≠

1, the accuracy in percentage is the same (±1%). But the additional

wattage should be multiplied by the VT ratio.

For example, ±0.2VA becomes ±0.2VA * VT ratio

AC Reactive Power (VAR, from 0.000 VAR to 9999 KVAR)

Accuracy of Readings1 Range (0 to 1500A) Resolution

> 20 V and > 20A < 20V or < 20A

10.0 – 999.9 VAR 0.1VAR ±2% ±30dgts ±3% ±40dgts

1.000 – 9.999 KVAR 0.001 KVAR ±2% ±30dgts ±3% ±40dgts

10.00 – 99.99 KVAR 0.01 KVAR ±2% ±30dgts ±3% ±40dgts

100.0 – 999.9 KVAR 0.1 KVAR ±2% ±30dgts ±3% ±40dgts

1000 – 9999 KVAR 1 KVAR ±2% ±30dgts ±3% ±40dgts

1

For VT

≠≠≠≠

1, the accuracy in percentage is the same (±2%). But the additional

49

wattage should be multiplied by the VT ratio.

For example, ±0.2VAR becomes ± 0.2VAR * VT ratio

Range of VT (Voltage Transformer) Ratio: 1 to 3000

AC Active Energy (WH, or KWH, from 0 WH to 999,999 KWH)

WH = W * Time (in hours)

AC Current (50 or 60 Hz, Auto Range, True RMS, Crest Factor < 4, Overload

Protection AC 2000A)

Range Resolution Accuracy of Readings

4.0 – 1500.0 A 0.01 A ±1.0% ± 5dgts

AC Voltage (50 or 60 Hz, Auto Range, True RMS, Crest Factor < 4, VT=1, Input

Impedance 10 MΩ, Overload Protection AC 800V)

Range Resolution Accuracy of Readings1

4.0 V – 600.0 V 0.1 V ±0.5% ± 5dgts

1

For VT

≠≠≠≠

1, the accuracy in percentage is the same (±0.5%). But the

additional digits should be multiplied by the VT ratio.

For example, ±5digits becomes ± 5digits * VT ratio

Harmonics of AC Voltage in Percentage( 1 to 50th order, minimum voltage at 50

or 60 Hz > AC 80V. If the voltage is 0 at 50 or 60 Hz, all the percentage (%) display

is 0.)

Range Resolution Accuracy

1 – 20th 0.1% ±2%

21 – 50th 0.1% 4% of reading ±2.0%

Harmonics of AC Voltage in Magnitude (1 to 50th order, minimum voltage at 50 or

60 Hz > AC 80V, VT=1)

Range Resolution Accuracy

1 – 20th 0.1% ±2% ± 0.5V

21 – 50th 0.1% 4% of reading ±0.5V

50

Harmonics of AC Current in Percentage (1 to 50

th

order, minimum current at 50

or 60 Hz > 20 A. If the current is 0 at 50 or 60 Hz, all the percentage (%) display is 0.)

Range Resolution Accuracy

1 – 20th 0.1% ±2%

21 – 50th 0.1% 4% of reading ±2.0%

Harmonics of AC Current in Magnitude (1 to 50th order, minimum current at 50 or

60 Hz > 20A)

Range Resolution Accuracy

1 – 20th 0.1% ±2% of reading ±0.4A

21 – 50th 0.1% ±4% of reading ±0.4A

Power Factor (PF)

Accuracy Range Resolution

> 20V and > 20A < 20V or < 20A

0.000 – 1.000 0.001 ± 0.04 ±0.1

Phase Angle (Φ)

Range Resolution Accuracy

-180° to 180° 0.1° ± 1°

0° to 360° 0.1° ± 1°

Total Harmonic Distortion (THD-F with respect to the 50 or 60 Hz, min. value at 50

or 60 Hz > 80V and > 20 A, 1 to 50th Harmonics. If the voltage or current is 0 at 50 or

60 Hz, all the percentage (%) display is 0)

Range Resolution Accuracy

0.0 – 20% 0.1% ± 2%

20.1 – 100% 0.1% ± 6% of reading ± 1%

100.1 – 999.9 % 0.1% ± 10% of reading ± 1%

Peak Value of AC Voltage (peak value > 10V) or AC Current (peak value > 20A)

Range Sampling Time Accuracy of Reading

50 Hz 39 µs ± 5% ± 50 digits

60 Hz 33 µs ± 5% ± 50 digits

51

Frequency (RMS value > 20V) or ACA (RMS value > 30A)

Range Resolution Accuracy

46 – 65 0.1 ± 0.3Hz

Indoors Use

Conductor Size: 55mm (approx.), 65 x 24mm (bus bar)

Battery Type: two 1.5V SUM-3

Display: 128 X 64 dot matrix LCD with backlight

Range Selection: Auto

Overload Indication: OL

Power Consumption: 10 mA(approx.)

Auto-Power-Off: 15 minutes after power-on

Update Time: 2 times/second (display)

No. Of Samples per Period 512 (voltage or current)

256 (power)

Operating Temperature: -10°C to 50°C

Operating Humidity: less than 85% relative

Altitude: up to 2000M

Storage Temperature: -20°C to 60°C

Storage Humidity: less than 75% relative

Dimension: 271mm (L) x 112mm (W) x 46mm (H)

10.7" (L) x 4.4" (W) x 1.8" (H)

Weight: 647g / 22.8 oz (battery included)

Accessories: Test leads

Carrying bag x 1

Users manual x 1

Software users manual x 1

Software CD x 1

Batteries 1.5V x 2

Alligator clips

RS232 to USB bridge x 1

52

XII. BATTERY REPLACEMENT

When the battery voltage low is shown in LCD,

A. Turn the power off and remove the test leads from the box.

B. Remove the screw of the battery compartment.

C. Lift and remove the battery compartment.

D. Remove the old batteries

E. Press the FUNC button for 2 seconds to discharge.

F. Insert two new 1.5V SUM-3 batteries.

G. Replace the battery compartment and secure the screw.

53

54

XIII. MAINTENANCE & CLEANING

Servicing not covered in this manual should only be performed by qualified

personnel. Repairs should only be performed by qualified personnel.

Periodically wipe the case with a damp cloth and detergent; do not use abrasives or

solvents.

Address of Agent, Distributor, Importer, or Manufacturer

Loading...

Loading...