Page 1

HVAC Meter

PCE-360

INSTRUCTION MANUAL

TES ELECTRICAL ELECTRONIC CORP.

PCE Americas Inc.

711 Commerce Way

Suite 8

Jupiter

FL-33458

USA

From outside US: +1

Tel: (561) 320-9162

Fax: (561) 320-9176

info@pce-americas.com

www.pce-instruments.com/english

www.pce-instruments.com

PCE Instruments UK Ltd.

Units 12/13

Southpoint Business Park

Ensign way

Hampshire / Southampton

United Kingdom, SO31 4RF

From outside UK: +44

Tel: (0) 2380 98703 0

Fax: (0) 2380 98703 9

info@pce-instruments.com

Page 2

CONTENTS

Title Page

1. SAFETY INFORMATION ....................................................................................... 1

2. INTRODUCTION FEATURE .................................................................................. 4

3. SPECIFICATIONS ................................................................................................... 4

3-1 Environment Conditions ....................................................................................... 4

3-2 Safety Specifications ............................................................................................. 5

3-3 General Specification ............................................................................................ 5

3-4 Electrical Specification ......................................................................................... 7

4. PARTS & CONTROLS ......................................................................................... 10

4-1 Description of Parts & Co ntrol keys ................................................................... 10

4-2 Description of Display ........................................................................................ 14

5. OPERATING INSTRUCTION .............................................................................. 18

5-1 AC Current Adaptor ............................................................................................ 18

5-2 Single-Phase 2-Wire (1P2W) Power S ystem Measurement ............................... 20

5-3 Single-Phase 3-Wire (1P3W) Power S ystem Measurement ............................... 23

5-4 Three-Phase 3-Wire (3P3W2M) Power System Measurement ........................... 26

5-5 Three-Phase 3-Wire (3P3W3M) Power System Measurement ........................... 29

5-6 Three-Phase 4-Wire (3P4W) Power System Measurement ................................ 32

5-7 Only One Current I4 Measurement ..................................................................... 35

5-8 Manual Data Memory and Read Function Operation ......................................... 35

5-9 Auto Datalogging Function Operation ................................................................ 36

5-10 Phase Sequence Measurement .......................................................................... 37

5-11 Voltage, Current Waveform and Harmonic Analyzer ........................................ 38

5-12 Enable Auto Power Off Function ...................................................................... 38

6. MAINTENANCE .................................................................................................... 39

6-1 General Maintenance .......................................................................................... 39

6-2 Battery Replacement ........................................................................................... 39

7. SOFTWARE INSTALLATION and OPERATION ............................................. 39

※

Copyright © 2016 TES Electrical Electronic Corp. All rights reserved.

Page 3

1

1. SAFETY INFORMATION

This Instruction Manual provides information and warnings essential for operating

this meter in a safe manner and for maintaining it in safe operating condition. Before

using this meter, be sure to carefully read the following safety information.

DANGER

• During high voltage measurement, incorrect measurement procedures could

result in injury or death, as well as damage to the meter. Please read this

manual carefully and be sure that y ou understand i ts cont ents before us ing the

meter.

DANGER

• Do not use the meter or test leads if they look damaged.

• Use extreme caution when working around bare conductors or bus bars,

Accidental contact with the conductor could result in electric shock.

• To avoid damages to the met er , do not exceed the maximum limits of the input

values shown in the specifications.

• Use the meter only as specified in this manual, otherwise, the protection

provided by the meter may be impaired.

SAFETY SYMBOLS

• Caution refer to this manual before using the meter.

•

This symbol is affixed to the meter where the operator should consult

corresponding topics before using relevant functions of the meter.

•

This mark indicates explanation, which is particularly important that the

user should read before using the meter.

Dangerous voltages.

Meter is protected throughout by double insulation or reinforced insulation.

When servicing, use only specified replacement parts.

Comply with IEC61010-1, 2nd edition

Page 4

2

DANGER: Indicates that incorrect operation presents extreme danger of

accident resulting in death or serious injury to the user.

WARNING: Indicates that incorrect operation presents significant danger of

accident resulting in death or serious injury to the user.

CAUTION: Indicates that incorrect operation presents possibility of injury to

the user or damage to the meter.

NOTE: Denotes items of advice related to performance of the meter or to its

correct operation.

NOTES ON USE

In order to ensure safe operation and to obtain maximum performance from the

meter, observe the caution listed below.

Installation

CAUTION

• The meter is designed for indoor use and can be safely used at temperatures

ranging from 0℃ to 40℃.

• Do not store or use the meter where it will be exposed to direct sunlight, high

temperature, high hum idity, or condensation, if exposed to suc h conditions, the

meter may be damaged, the insulation ma y deteriorate, and the meter ma y no

longer satisfy its specifications.

• The meter does not construct to be waterpr oof or dus tproof, so do not us e it in

a very dusty environment or in one where will get wet.

• Do not use the unit where i t may be exposed to cor rosive or explosiv e gas. The

meter may be damaged, or may occur explosion.

Before use

WARNING

• To prevent electric shock, do not allow the m eter to become wet and do not use

the unit when your hands are wet.

• When working with live circuits, take all suitable precautions against

accidents, including the use of electrical safety gear such as rubber gloves,

rubber boots, and safety helmets.

Page 5

3

Connecting meter

WARNING

• To prevent electric shock, turn the power off before connecting the test leads

and then take measurements.

• In order to prevent electrical shock and short – circuit accidents, shut off the

power to the line to be measured before connecting the line to be measured to

the voltage input terminals.

CAUTION

• The measurement input and synchronizing input are not isolated from each

other. Connecting either one means that the other is exposed it is live, and

there is a danger of electric shock. To avoid electrical shock, connect both

terminals.

WARNING

To avoid electrical shock and / or meter damage, use caution when connecting

test leads to live components. The jaws of alligator clips can create a short

circuit between closely spaced live parts. Avoid making connections to feeder

conductors or bus bars at elevated potentials. Whenever, please make

connections to the output side of a circuit breaker as possible as you can, which

can provide better short circuit protection.

• Follow all legal requirements.

• Follow all instructions in the manuals.

• Obey posted instructions.

• Never assume that a circuit is de-energized, check it first.

• Always set up the measurement first, then connect the test leads to the circuit.

• Remove all test leads that are not in use.

• Make connections to the meter first, before connecting leads to a live circuit.

• Connect the ground lead first, then the voltage leads and the current probe,

Disconnect in reverse order.

• Route test leads carefully.

Page 6

4

2. INTRODUCTION FEATURE

The symptoms of poor power quality include intermittent lock-ups and resets,

corrupted data, premature equipment failure, over-heating of components for no

apparent cause, etc. The ultimate cost is in downtime, decreased productivity and

frustrated personnel.

Use power analyzer to power quality trouble shooting can help you keep your

power system up and running, troubleshoot problems quickly, improve power

efficient, manage energy costs, zero in on harmonics, optimize power system

performance, improve power quality and analyze system data to design optimal

upgrades.

• 10 display Easy-to-view LCD screen, and is capable of showing many power

quality parameters at the same time.

• 4 current probe including for measuring a neutral line current.

• Measures single-phase 2-wire, single-phase 3-wire, three-phase 3-wire and

three-phase 4-wire systems.

• All True-RMS sensing, V, A, KW, KVAR, KVA, PF, Θ , Hz, KWh, KVARh and

KVAh measurements.

• KW, KVA, KVAR Maximum/Minimum recording.

• Voltage and Current waveform THDF, THDR measurements.

• Harmonic Analysis to the 63th order.

• Phase sequence indicator function.

• Backlight display function.

• Manual Data Memory and Read (50 sets).

• Data logging (micro SD CARD 4GB).

• USB optical interface with three phase voltage / current waveform display and

harmonic analysis.

• Easy-to-use key operation.

• Light weight and portable design.

3. SPECIFICATIONS

3-1 Environm ent Conditions:

Altitude up to 2000 meters

Indoor use only

Relatively humidity 80% max.

Operation ambient 0 ~ 40℃

Page 7

5

3-2 Safety Specificat i ons

Category Rating: 1000V Measurement Category III, Pollution Degree 2.

: IEC 61010-1 2nd Edition

CAT III: Measurement category in which measurements performed in the

building installation.

Safety Characteristics:

Current Clamps, Model TES AC3600, to be used only with the Three-Phase

Power Analyzer , Model TES-3600N.

This manual contains i nformati on and warning t hat m ust be foll owed by the user

to ensure safe operation and to keep the meter and its accessories in a safe

condition.

Use of this meter and its accessories in a manner not specified by the

manufacturer may impair the protection provided by the equipment.

Equipment operation, the responsible body shall be made aware that, if the

equipment is used in a manner not specified by the manufacturer, the protection

provided by the probe assembly may be impaired.

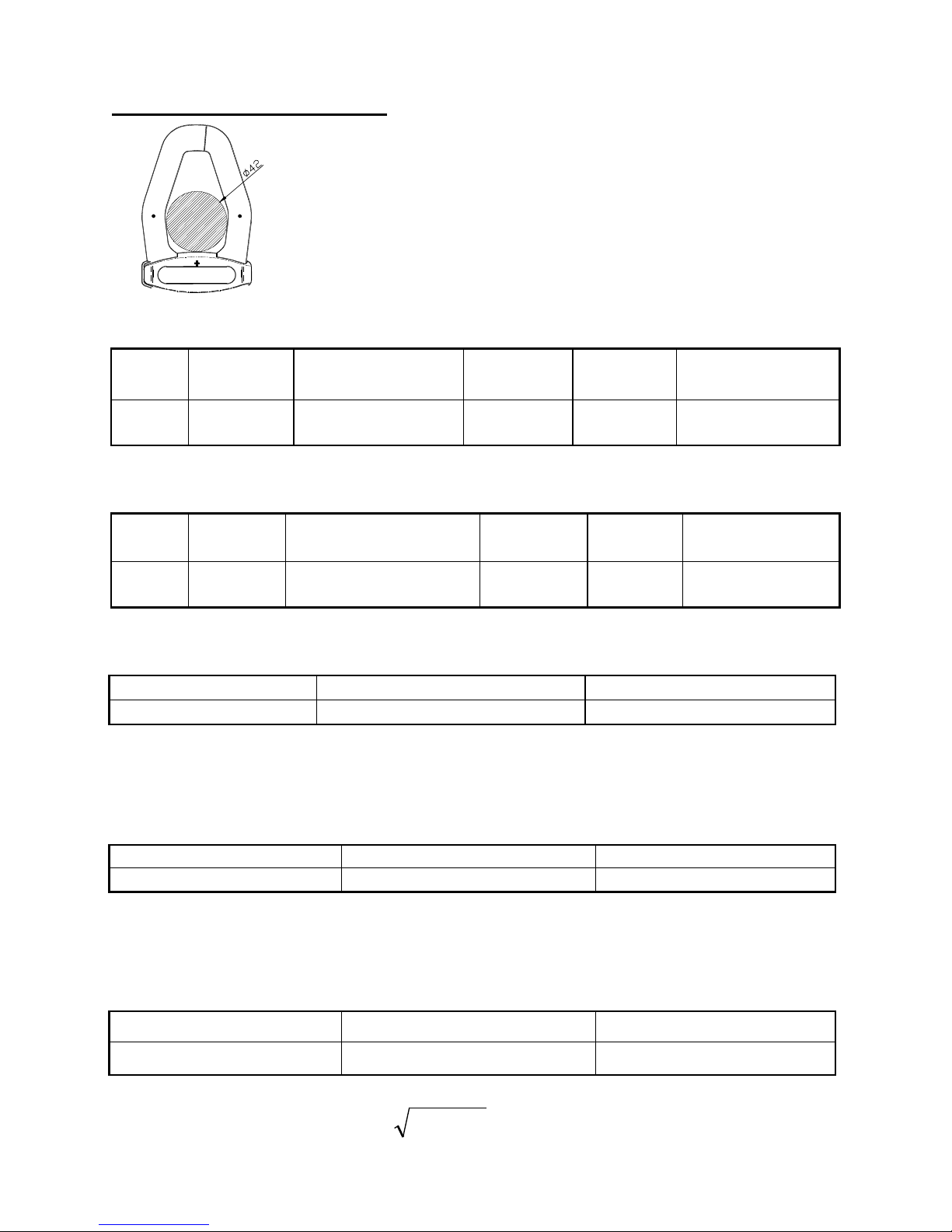

3-3 General Specifi cat ion

• Maxim um v oltage betw een volt age input ter mina ls and earth gr ound: 100 0 Vrms

• Maximum rated working voltage for current input: 0.35 Vrms

• Maximum current for current probe: 1000 Arms

• Numerical 10 display: 10 display 4 digit LCD maximum reading 9999.

• Battery life: approx. 50 hours.

• Auto power off: approx. 30 minutes.

• Low battery indication: The

BT

is displayed when the battery voltage drops

below the operating voltage.

• Backlight display time: Auto off approx. 30 seconds.

• Sampling rate : Approx. 1 time per 1 seconds (Digital display).

• Harmonic analyzer: 1 ~ 63th order.

• Manual data memory and read capacity: 50 sets.

• Data logger capacity: micro SD CARD 4GB (Maximum 99 blocks).

• Current probe jaw opening diameter: Cablesψ40mm.

• Operating temperature: 0°C to 40°C

• Operating humidity: Maximum relative humidity of 80% for temperatures up to

31

°C decrease linearly to 50% relative humidity at 40°C

(non-condensed).

Page 8

6

• Temperature coefficient: 0.1 × (specified accuracy) / °C (<18 or >28°C)

• Storage temperature and humidity: -10°C to 60°C / R.H. < 70% non-condensed.

• Dimensions: Meter → 235(L)×117(W)×54(H)mm.

Current probe → 193(L)×88(W)×40(H)mm.

• Weight: Meter including battery → approx. 730g

Current probe → approx. 333g

• Accessories:

1. TES 3600 AC CURRENT ADAPTOR x 4pcs

Category Rating: CAT III 600V per IEC61010-1, Pollutio n Degree2.

: IEC 61010-1 2nd Edition and IEC61010-2-032

Input: AC 1000A maximum.

Output: 0.35mV/A

2. Voltage test lead x 4pcs

Model no: TL 202I

Manufacturer: Hong Kai Co., Ltd.

Category Rating: CAT III, 1000V, AC 10A Max.

3. Alligator clip x 4pcs

Model no: FC-A23

Manufacturer: Fu Chyi Enterprise CO., Ltd.

Category Rating: CAT III, 1000V, AC 10A Max.

4. AC Adaptor (IN-OUT Isolated type, Input 120V AC 60Hz

Model: MW35-1200300

Input: 120V AC 60Hz 6.1W

Output: 12V DC 300mA

Manufacturer: MAW WOEI Enterprise CO., Ltd.

AC Adaptor (IN-OUT Isolated type, Input 230V AC 50Hz

Model: MWD48-1200300GS

Input: 230V AC 50Hz

Output: 12V DC 300mA

Manufacturer: MAW WOEI Enterprise CO., Ltd.

5. Battery 1.5V “AA” × 8

6. Instruction manual × 1

7. PC software CD-R × 1

8. Carrying case × 1

Page 9

7

9. Optical USB interface × 1

3-4 Electrical Speci f i cat ion

Accuracy: ±(% of reading + number of digits) at 18 ℃ to

28 ℃ ( 64℉ to 82℉ ) wi th r %.

The current error is specified within the largest circle which

can be drawn inside the jaw.

AC Voltage Trms measurement (V):

Range Resolution

Accuracy

Input

impedance

Overload

protection

Nominal power

system frequency

999.9V

0.1V

±

(0.3%rdg±10dgts)

(>10V)

2M

Ω

1000Vrms 45Hz ~ 66Hz

•

Display item: RMS voltage value for each channel.

AC Current Trms Measurement (A):

Range Resolution

Accuracy

(including current probe)

Current

probe output

Overload

protection

Nominal power

system frequency

999.9A 0.1A

±

(0.5%rdg±15dgts)

(>3A)

0.35mV/A 1000Arms 45Hz ~ 66Hz

•

Display item: RMS current value for each channel.

Active Power measurement P (KW):

Range

Resolution

Accuracy

999.9KW

0.1KW

±

1.0%rdg±20dgts

•

Display items: Active power of each channel and its sum of multiple channels.

•

Polarity display: For influx (consumption) No symbol, For outflow

(regenerative) “ - ”.

Apparent Power measurement S (KVA):

Range

Resolution

Accuracy

999.9KVA

0.1KVA

±

1.0%rdg±20dgts

•

Measurement method: Calculate from RMS voltage U and RMS current I.

•

Display item: Apparent power of each channel and its su m of multiple channels.

•

Polarity display: No polarity.

Reactive Power measurement Q (KVAR):

Range

Resolution

Accuracy

999.9KVAR

0.1KVAR

±

1.0%rdg±20dgts

•

Measurement method: Calculate from apparent power S and active power P,

Q=

S P

2 2

−

.

Page 10

8

•

Display item: Reactive power of each channel and its sum of multiple channels.

•

Polarity display: For phase lag (LAG: current is slower than voltage): “-”

For lead phase (LEAD: current is faster than voltage):

No symbol.

Power Factor measurement (COSψ):

Range

Resolution

Calculated Accuracy

-1 ~ +1

0.001

±

10dgt

•

Measurement method: Calculate from apparent power S and active power P,

PF = COSψ=

P S/

•

Display item: Power factor of each channel and its sum of multiple channels.

Phase angle measurement (ψ):

Range

Resolution

Calculated Accuracy

+180° ~ 0° ~ -180° 0.1°

±

15dgt

•

Measurement method: Calculate from power factor COSψ,ψ= COS

-1

PF.

•

Display item: Phase angle of each channel and its sum of multiple channels.

•

Polarity display: For phase lag (LAG: current is slower than voltage): “-”.

For phase lead (LEAD: current is faster than voltage):

No symbol.

Frequency measurement (Hz):

Range

Resolution

Accuracy

Measurement source

60HZ

0.1Hz

±

0.1%rdg±2dgt

Voltage U1 > 10V

•

Measurable input range: > 10V

Three Phase Sequence Detection:

Input vo ltage range

Normal phase indication

Reverse phase indication

Measurement source

3P > 10V

U1, U2 and U3

Active Power Energy measurement (KWh):

Range

Resolution

Active power

accuracy

Timer interval

Timer Accuracy

9.999KWh

0.001KWh

±

1.0%rdg±20dgt

1 sec

±50ppm (25℃, 77℉)

99.99KWh

0.01KWh

999.9KWh

0.1KWh

9.999MWh

0.001MWh

30.59MWh

0.01MWh

•

Measurement display: Display all active power consumption energy (sum of

absolute values).

Page 11

9

Apparent Power Energy measurement (KVAh):

Range

Resolution

Apparen t power

accuracy

Timer interval

Timer Accuracy

9.999KVAh

0.001KVAh

±

1.0%rdg±20dgt

1 sec

±50ppm (25°C, 77°F)

99.99KVAh

0.01KVAh

999.9KVAh

0.1KVAh

9.999MVAh

0.001MVAh

30.59MVAh

0.01MVAh

•

Measurement display: Display all apparent power energy (sum of absolute

values).

Reactive Power Energy measurement (Kvarh):

Range

Resolution

Reactive power

accuracy

Timer interval

Timer Accuracy

9.999Kvarh 0.001Kvarh

±

1.0%rdg±20dgt

1 sec ±50ppm (25°C, 77°F)

99.99Kvarh 0.01Kvarh

999.9Kvarh 0.1Kvarh

9.999Mvarh 0.001Mvarh

30.59Mvarh 0.01Mvarh

•

Measurement display: Display all reactive power consumption (sum of

absolute values).

Harmonic measurement

Order

Accuracy

Harmonic Source

1 ~ 63

±

3%THD

U1, U2, U3 > 10V

I1, I2, I3 > 3A

Waveform (use only PC on line displayed)

Select phase A, B or C.

Select Voltage and current waveform output.

Page 12

10

4. PARTS & CONTROLS

4-1 Description of P ar t s & Control keys

MAG.

Q

U12 Y- M

-h

NO.

P

S

U23 D-h

U31 m-s

I3

I1

I4

I2

N

¢»

U1

U2 U3

Page 13

11

1. Input for voltage terminals (U1, U2, U3, N).

2. Input for current probe jacks (I1, I2, I3, I4).

3. Plug for external AC adaptor power supply input.

4. Optical interface output.

5. LCD display.

6. WIRING key: Select the type of electrical system under test, press “WIRING”

key to select 1P2W (To measure single-phase two-wire power

lines), 1P3W (To measure single-phase three-wire power lines),

3P3W2M (To measure three-phase three-wire power line without

neutral, using the two power meter method, use this when

measuring three-phase power with 2-current probe measurement

only.), 3P3W3M (To measure three-phase three-wire power line

without neutral, using the three power meter method, use this

when measuring three-phase power with 3-current probe

measurement only .) and 3P4W (To m easure three-phase four-wire

power lines with neutral) electrical system in cycles.

7.

key: Phase sequence detection function key. In a 3P4W mode, press and

hold down this key, it will display phase detection results as follows:

Normal phase

Reverse phase

8. HOLD key: Data hold function key, press “HOLD” key to hold data, the

“HOLD” annunciator is displayed, press “HOLD” key again to

exit Hold function.

9. key: Backlight function key, press key to turn on and off of backlight.

The backlight will switch off automatically after 30 seconds.

10. MAX key: Active power (P), reactive power (Q), and apparent power (S)

Maximum / Minimum recording measurement.

In the power measurement screen mode, press “ POWER ” key to

select (P1, Q1, S1), (P2, Q2, S2), (P3, Q3, S3) or (Pt, Qt, St) which one

measured value to do the maximum/minimum recording measurement.

Press “MAX” key to enter this mode, the “REC” mark is displayed.

Press “MAX” key to cycle through the

a). Maximum reading the “ REC MAX ” mark is displayed.

Press key to cycle through the

Maximum reading for Active power (“P” ma rk is blinking) with its Q, S, V,

Page 14

12

A reading and its PF, Θ , Hz, I4 reading by press “PFΘ” and “Hz I4” keys.

Maximum reading for Reactive power (“Q” m ark is blinking) with its P , S, V,

A reading and its PF, Θ, Hz, I4 reading by press “

PF

Θ

” and “

Hz I4

” keys.

Maximum reading for Apparent power (“S” mark is blinking) with its P, Q, V,

A reading and its PF,

Θ

, Hz, I4 reading by press “

PF

Θ

” and “

Hz I4

” keys.

b). Minimum reading, the “ REC MIN ” mark is displayed.

Press key to cycle through the

Minimum reading for Active power (“P” mark is blinking) with its Q, S, V, A

reading and its PF, Θ, Hz, I4 reading by press “

PF

Θ

” and “

Hz I4

” keys.

Minimum reading for Reactive power (“Q” mark is blinking) with its P, S, V,

A reading and its PF, Θ, Hz, I4 reading by press “

PF

Θ

” and “

Hz I4

” keys.

Minimum reading for Apparent power (“S” mark is blinking) with i ts P, Q, V,

A reading and its PF,

Θ

, Hz, I4 reading by press “

PF

Θ

” and “

Hz I4

” keys.

c). Current reading, the “ REC ” mark is displayed.

Press “MAX” key for 3 seconds to exit this mode.

11. PF Θ key: Display measured power factor or phase angle value control key, the

“PF” or “

ψ

” annunciator is display ed.

12. THD key: Display measured voltage or current THDF, THDR value control

key.

THDF: Total Harmonic Distortion of a waveform is compared to its

Fundamental.

THDR: Total Harmonic Distortion of a waveform is compared to the

waveforms rms value.

Press “THD” key to enter the Voltage U1, U2 and U3 THDR and THDF

measurement mode, the “THDR” and “THDF” marks are displayed.

Press “THD” key again to enter the Current I1, I2 and I3 measurement

mode, the “THDR” and “THDF” marks are displayed.

Press “THD” key again to exit this mode.

13. Hz I4 key: Display measured frequency or I4 current probe value control key,

the “Hz” or “I4” annunciator is displayed.

14. SET key: Setting current date and time functi on key, press “SET” key to enter

current time setting mode and interval time setting mode for auto

datalogging use.

15 TIME key: Display current date and time control key, press and hold down

Page 15

13

“TIME” key display current data and time.

Press and hold down “TIME” key then press

key turn on the

meter , t he “

” mark appear, enter into auto power off func ti on.

16. ↵ keys:

In the harmonic measurement mode, press ↵ key t o select v ol tage or current

harmonic source. Press or key to select which source to be displayed.

Press or key to select harmonic order.

Sett ing current date and t ime, or recall manual data memory to read memory

data in cycles control keys.

17. START key: Start auto datalogging function.

18. STOP key: Stop auto datalogging function. Press “START” key to resume

recording in current data sets.

19. MEMORY key: Manual data memory control key. Press “MEMORY” key

each time to store one set current display reading into the

memory, the “M” annunciator and the memory address

number is displayed, total memory size is 50 sets.

20. READ key: Read manual memory data control key.

21.

POWER

key: Display measured power value control key, the “Pt123”,

“Qt123” and “St123” annunciators will be displayed in

cycles.

22. ENERGY key: Display total integrated power energy value control key, the

three “h” annunciators will be displayed.

23. KEY Lock key: Lock all the functions key, except

and keys, the

“LOCK” annunciator is displayed.

24.

key: Power on-off control key.

25.

M A G. key: Harmonic measurement control key.

Press “

M A G. ” key to enter the volt age and current waveform harm onic

measurement mode, the harmonic order number “Hd:XX” and its measured

value (V or A), harmonic ratio (%), P, Q, S, PF values are displayed.

Press or key to scroll the harmonic order from “Hd:01” to “Hd:63”.

Press ↵ key to scroll the voltage or current harmonic for display.

Press or key to scroll the U1, U2, U3 or I1, I2, I3 for display.

Press “

M A G. ” key again to exit this mode.

Page 16

14

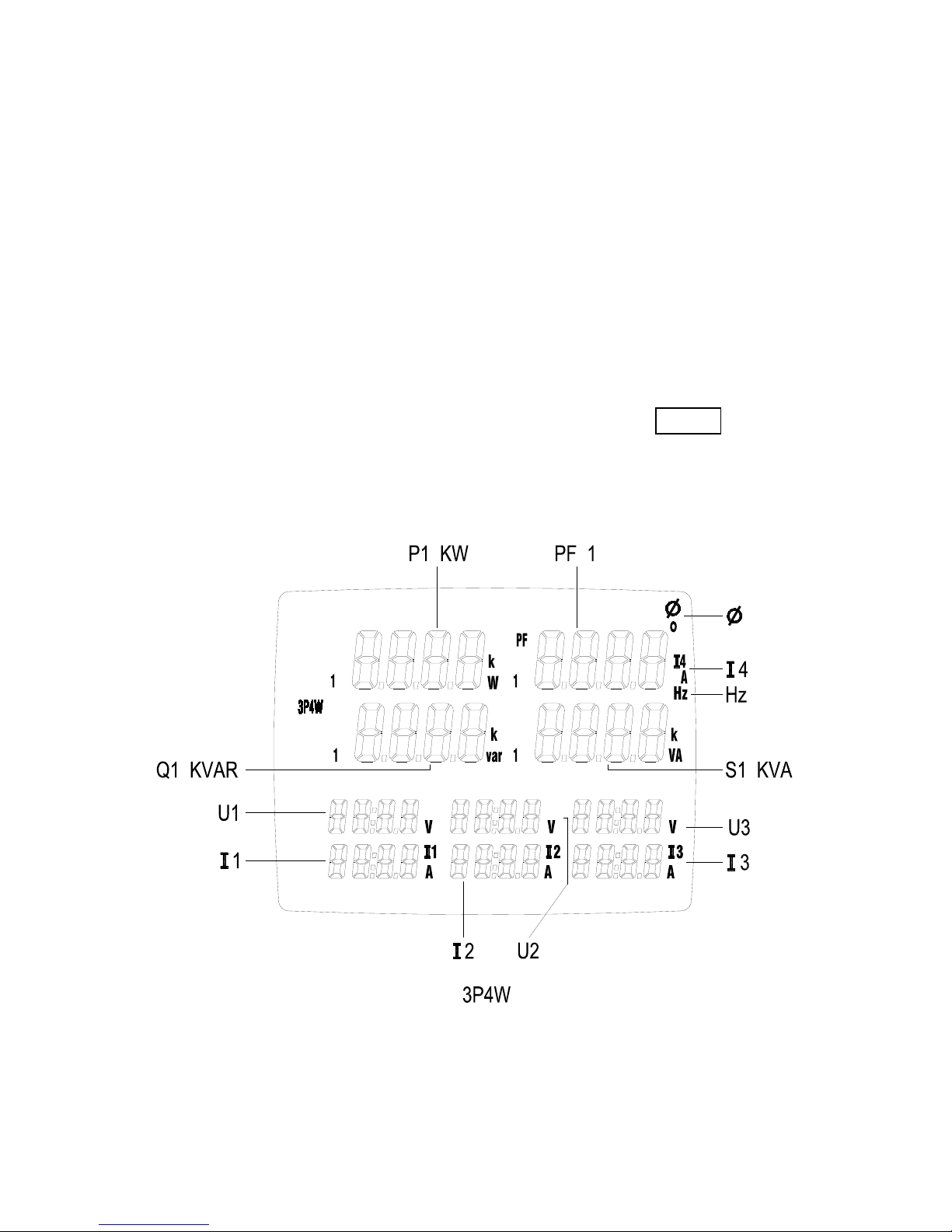

4-2 Description of Display

Q

P

4.11

4.10

4.1 4.2

4.3

4.4 4.5

4.7

4.6

4.9

4.8

S

4.17

4.18

4.19

4.20

4.16

4.13 4.14 4.15

4.21

4.22

4.12

U12 Y- M

U23 D-h

U3 m- s

4.32

4.334.33

4.46

4.45

4.44

4.43

4.42

4.41 4.40 4.39

4.38

4.37 4.36 4.35 4.34

4.23

4.24

4.25

4.26

4.27

4.28

4.29

4.30

4.31

4.1

: Auto power off indication.

4.2

P : Harmonic active power measured display indicatio n.

P1: Phase 1 active power measured display indicator.

P2: Phase 2 active power measured display indicator.

P3: Phase 3 active power measured display indicator.

Pt: Total active power measured display indicator and total active energy

measured display indicator.

4.3

Display value of Active Power

4.4

HOLD

: Display hold mode.

4.5

REC MAX : Maximum recorded reading.

REC MIN : Minimum recorded reading.

REC : Recording mode indication and current reading.

Page 17

15

4.6

KW: Active Power Unit: or KWh, MWh, active energy unit.

4.7

Kvar: Reactive Power Unit or Kvarh, Mvarh reactive energy unit.

4.8

Display of reactive Power.

4.9

Q : Harmonic reactive power measured display indication.

Q1: Phase 1 reactive power measured display indicator.

Q2: Phase 2 reactive power measured display indicator.

Q3: Phase 3 reactive power measured display indicator.

Qt: To tal reactive power measured display indicator and total reactive energy

measured display indicator.

4.10

DATA No.

××

: Last manual datalogged memory address number indication

(01~50).

M : Manual datalogged indication, M displays one time store one sets data

into the memory.

R No.

××

: Recall manual datalogged address number indication, the memory

data displayed for read.

DATA M

××

: Auto datalogging indication, M disappears one time store one

sets data into the memory .

01 ~ 99: Maximum 99 memory blocks can be use.

FULL: Memory full indicat ion, if exceed 99 m emory blocks or

micro SD CARD is full used.

4.11

1P2W: Measure single-phase two-wire power line indicator.

1P3W: Measure single-phase three-wire power line indicator.

3P3W2M: Measure three-phase three-wire power line indicator.

3P3W3M: Measure three-phase three-wire power line using 3 power meter

indication.

3P4W: Measure three-phase four-wire power line indica tor.

4.12

PF : Harmonic power factor measured display.

PF1: Phase 1 power factor measured display.

PF2: Phase 2 power factor measured display.

PF3: Phase 3 power factor measured display.

PFt: Total power factor measured display.

4.13

Display value for Power Factor, Frequency & I4 current

4.14

LOCK : Keyboard lock indicator.

4.15

BT

: Low battery indicator.

4.16

O

: Phase angle unit.

ϕ: Phase angle display.

4.17

Indicates curre nt measurement from input “I 4”.

4.18

A: Unit of c urrent.

Page 18

16

4.19

Hz: Unit of frequency.

4.20

K VA : Apparent power unit or KVAh, MVAh: Apparent energy unit.

4.21

Display value of apparent power.

4.22

S : Harmonic apparent power measured display indication.

S1: Phase 1 apparent power measured display indicator.

S2: Phase 2 apparent power measured display indicator.

S3: Phase 3 apparent power measured display indicator.

St: T otal apparent power measured display indicator and total apparent ener gy

measured display indicator.

4.23

U1: Indicates the display of voltage on phase 1(U1), THDR %, THDF % or

Harmonic.

4.24

Y-M: Year and Month displa y indica tor

4.25

Display of Voltage, Date (Year: Month), THDR % or Harmonic order number

(Hd: 01 ~ Hd: 63)

4.26

U2: Indicates the display of voltage on phase 2(U2), THDR %, THDF % or

Harmonic.

4.27 D-h: Day and hour display indicator

4.28 Display of Voltage, Date (Day: hour) or THDR %.

4.29

Display of the rotary field direction

4.30

U3: Indi cates display of voltage on phase 3, THDR %, THDF % or Harmonic.

4.31 m-s: minutes and seconds display indicator

4.32 Display of Voltage, Time (minutes:second) or THDR %.

4.33

A, I3, %

: Units and indica tor for phase 3 current, THDR %, THDF % or Ha rmo nic.

4.34 1000A: Current ra nge indica tor

4.35 Display of current, time or THDF %

4.36

A, I2, %: Units and indicator for phase 2 current, THDR %, THDF % or

Harmonic.

4.37

Displa y of current, date/time or THDF %

4.38

1000V

: Voltage range indicator

4.39

A, I1, %: Units and indicator for phase 1 current, THDR %, THDF % or

Harmonic.

4.40 Display of current, date or THDF %

4.41 STOP: Indicates the stop time for e nergy calculation

4.42

THDF: Vo lta ge o r current Total Harmonic Distortion of a waveform to its

Fundamental indication.

4.43 INTV: Indicates the Auto data logging interval time setting

Page 19

17

4.44 STAR: Indica te s the start time for energy calculation

4.45

THDR: Volta ge or current Total Harmonic Distortion of a waveform to the

waveform RMS value indication.

4.46 TIME: Current data a nd time indicator.

Page 20

18

5. OPERATING INSTRUCTIO N

CAUTION

• If possible, before connecting the meter to the electrical equipment to be

tested, take off the electrical equipment’s power.

DANGER

• Voltage input connectors U1 to U3 are common for input connector N, each

input connectors are not insulated.

• Do not connect the unnecessary number of cords.

WARNING

• Always set up the measurement first, then connect the test leads to the circuit.

• Make connections to the instrument first, before connecting leads to a live

circuit.

• Connect the ground lead first, then the voltage leads and the current probe,

Disconnect in reverse order.

• Remove all test leads that are not in use.

※ U1 must be connected to voltage source during the measurement of U2, U3,

I1, I2 and I3, because U1 is the main signal source of the whole meter

measuring system. Otherwise you could not have any measurement from

U2, U3, I1, I2 and I3.

5-1 AC Current Adaptor

Safety Information

Read First: Safety Information

T o ensur e safe operation and service of the current clamp, follow these instructions:

• Read the operating instructions before use and follow all safety instructions.

• Use the Current Clamp only as specified in the operating instructions,

otherwise the clamp’s safety features may not protect you.

• Adhere to local and national safety codes. Individual protective equipment

must be used to prevent shock and arc blast injury where hazardous live

conductors are exposed.

• Do not hold the Current Clamp anywhere beyond the tactile barrier, see Figure 1.

Page 21

19

• Before each use, inspect the Current Clamp. Look for cracks or missing

portions of the clamp housing or output cable insulation. Also look for loose

or weakened components. Pay particular attention to the insulation

surrounding the jaws.

• Never use the clamp on a circuit with voltages higher than 600V CAT III.

• Use extreme cauti on when working aroun d bare conduct or or bus bars. Contact

with the conductor could result in electric shock.

• Use caution when worki ng wi th vol tages a bov e 60V or 30V ac. Su ch v ol tages

pose a shock hazard.

Warning

To avoid possible electric shock or personal injury:

• Before each use, inspect the Current Clamp. Look for cracks or missing

portions of the clamp housing and output cable insulating cover and for loose

or weakened components. Pay particular attention to the insulation

surrounding the clamp jaws.

• Do not use a damaged Current Clamp. If a clamp is damaged, tape it shut to

prevent unintended operation.

Measurement Considerations

• Center the conductor inside the Current Clamp jaw.

• Make sure the clamp is perpendicular to the conductor.

• For optimal reading, make sure the conductor is positioned between the

alignment marks on the jaws of the Current Clamp.

Observe the following guidelines when making measurements :

• Avoid taking measurements close to other current carrying conductors.

Operation

To use the AC Current Adaptor, refer to “Measurement Considerations” and

Figure 1.

1. Connect the clamp cable to the instrument.

2. The arrow on the top of the clamp must face towards the load of the circuit.

3. Connect the current clamp jaws around the conductor to be measured.

Page 22

20

Warning

To avoid shock or personal injury, keep fingers behind the tactile barrier, see

Figure 1.

Load Direction Arrow

Alignment Marks

Tactile Barrier

Figure 1

5-2 Single-Phase 2-Wire (1P2W) Power System Measurement

Application :

Receptacle branch circuit Lighting loads

Troubleshooting electrical distribution system. Measuring current harmonic.

Measuring line rms voltage. Measuring power on single phase loads.

Measuring line rms current.

Measuring frequency.

Measuring vol tage harmonics.

Measuring current harmonics.

Measuring vol tage waveform (use PC ) .

Measuring current waveform (use PC)

Measuring the load on a transformer.

Recording the l oad on a transformer.

Page 23

21

A: Line, N: Neutral, G: Ground, Face the arrow toward the load.

U2

I3

I4

I1

I2

U1

Ⅲ

U3

1P2W Wiring Connection Diagram

1. Press

key to turn on the meter.

2. Press “WIRING” key to select the 1P2W electrical system under test, the

“1P2W” annunciator will be displayed.

3. Connect the voltage test leads and current probe to the meter.

Connect the black voltage test lead to the “N” terminal.

Connect the red voltage test lead to the “U1” terminal.

Connect the I1 current probe output plug to the “I1” jack.

If you want to measure ground leakage current, connect the I4 current probe

output plug to the “I4” jack.

4. Connect the vol tage test le ads and curre nt probe to t he ele ctrical equipm ent to be

tested.

CAUTION

• If possibl e, befor e conne cti ng the v ol tage test leads an d curr ent probe to

the electrical equipment to be tested, take off the electrical equipment’s

power.

Connect the black voltage test alligator to the Neutral Line “N”.

Connect the red voltage test alligator to the Line “A”.

Press I1 current probe trigger to open the jaw and fully enclose the Line “A”.

If you want to measure ground leakage current, press I4 current probe the

trigger to open the jaw and fully enclose the Ground Line “G”.

Page 24

22

5. Frequency (Hz), Phase Angle (Θ ), Ground Leakage Current (I4) and Power

Factor (PF) measurement :

Press “PFΘ” key to cycle shows the PF and Θ measured values.

Press “Hz I4” key to cycle shows the Hz and I4 measured values.

6. Voltage and Current THDR THDF measurement:

Please refer to section 4-1-12 “THD” key description.

7. Voltage and Current waveform harmonic measurement:

Please refer to section 4-1-25 “

M A G. ” key description.

8. Power Maximum/Mini mum mea s u r emen t :

Please refer to section 4-1-10 “MAX” key description.

9. Energy measurement:

Press “ENERGY” key, the “Pt”, “Qt”, “St” and “PFt” or “ψt” annunciator

and energy integrate start time are displayed. The energy integrate value and

the current time will be continuous accumulate.

a). KW displays KWh

b). KVAR displays KVARh

c). KVA displays KVAh

Press “STOP” key to stop ener gy accum ulated and the “HOLD” annunciator

is displayed.

Press ↵ key to exit the energy measurement.

Q

U1

P

S

Page 25

23

※

U1 must be connected to voltage source during the measurement of U2, U3,

I1, I2 and I3, because U1 is the main signal source of the whole meter

measuring system. Otherwise you could not have any measurement from

U2, U3, I1, I2 and I3.

5-3 Single-Phase 3-Wire (1P3W) Power System Measurement

Application: Same as 1P2W power system measurement.

A, B: Line, N: Neutral, G: Ground, Face the arrow toward the load.

I3 I4

I1 I2

N

U2U1

¢»

U3

1P3W Wiring Connection D iagram

1. Press

key to turn on the meter.

2. Press “WIRING” key to select the 1P3W electrical system under test, the

“1P3W” annunciator will be displayed.

3. Connect the voltage test leads and current probe to the meter.

Connect the black voltage test lead to the “N” terminal.

Connect the red voltage test lead to the “U1” terminal.

Page 26

24

Connect the yellow voltage test lead to the “U2” terminal.

Connect the I1 current probe output plug to the “I1” jack.

Connect the I2 current probe output plug to the “I2” jack.

If you want to measure ground leakage current, connect the I4 current probe

output plug to the “I4” jack.

4. Connect the vol tage test le ads and curre nt probe to t he elec trical equipm ent to be

tested.

CAUTION

• If possible, before connecting the voltage test leads and current probe to

the electrical equipment to be tested, take off the electrical equipment’s

power.

Connect the black voltage test alligator to the neutral line “N”.

Connect the red voltage test alligator to the line “A”.

Connect the yellow voltage test alligator to the line “B”.

Press I1 current probe trigger to open the jaw and fully enclose the Line “A”.

11

Press I2 current probe trigger to open the jaw and fully enclose the Line “B”.

12

If you want to measure ground leakage current, press I4 current probe trigger

to open the jaw and fully enclose the ground line “G”.

5. Press “

POWER

” key t o select (P1, Q1, S1, PF1), ( P2, Q2, S2, PF2) and (Pt,

Qt, St, PFt) measured values.

6. Frequency (Hz), Phase Angle (Θ ), Ground Leakage Current (I4) and Power

Factor (pF) measurement :

Press “PFΘ” key to cycle shows the PF and Θ measured values.

Press “Hz I4” key to cycle shows the Hz and I4 measured values.

7. Voltage and Current THDR THDF measurement:

Please refer to section 4-1-12 “THD” key description.

8. Voltage and Current waveform harmonic measurement:

Please refer to section 4-1-25 “

M A G. ” key description.

9. Power Maximum/Minim um measurem ent:

Please refer to section 4-1-10 “MAX” key description.

Page 27

25

10. Energy measurement:

Press “ENERGY” key, the “Pt”, “Qt”, “St” and “PFt” or “ψt” annunciator

and energy integrate start time are displayed. The energy integrate value and

the current time will be continuous accumulate.

a). KW displays KWh

b). KVAR displays KVARh

c). KVA displays KVAh

Press “STOP” key to stop energy accumulated and the “HOLD” annunciator

is displayed.

Press ↵ key to exit the energy measurement.

Q

U1

P

S

U2

Page 28

26

※

U1 must be connected to voltage source during the measurement of U2, U3,

I1, I2 and I3, because U1 is the main signal source of the whole meter

measuring system. Otherwise you could not have any measurement from

U2, U3, I1, I2 and I3.

5-4 Three-Phase 3-Wi r e (3P3W2M) Power System Measurement

Using 2 power meter method

Application :

Induction motors without adjustable speed drive.

Induction motors with adjustable speed drive.

Checking voltage u nbalance.

Checking current on phases.

Checking current and current unbalance.

Measuring frequency of motor current.

Measuring power in 3-phase balanced and

unbalanced system.

Measuring power factor of 3-phase motors.

Measuring vol tage harmonics (use PC).

Unbalance factor:

When the load of the specified phase becomes too heavy due to fluctuations in

loads connected to eac h p ow er li ne phases, or when ope ra ti ng on un ev en dev i ce,

the voltage and curr ent waveform s become dist orted, causing vol tage drops, the y

can cause voltage unbalance, reverse phase to neutral voltage, and harmonics

may cause accidents such as uneven motor rotation, circuit breaker trips, and

over load heating in the transformer.

A, B, C: Line, Face the arrow toward the load.

U2

I4

I3

N

I1

I2

U1

Ⅲ

U3

Page 29

27

3P3W2M Wiring Connection Diagram

1. Press

key to turn on the meter.

2. Press “WIRING” key to select the 3P3W2M electrical system under test, the

“3P3W2M” annunciator will be displayed.

3. Connect the voltage test leads and current probe to the meter.

Connect the black voltage test lead to the “N” terminal.

Connect the red voltage test lead to the “U1” terminal.

Connect the yellow voltage test lead to the “U2” terminal.

Connect the I1 current probe output plug to the “I1” jack.

Connect the I2 current probe output plug to the “I2” jack.

4. Connect the vol tage test le ads and curre nt probe to t he ele ctrical equipm ent to be

tested.

CAUTION

• If possible, before connecting the voltage test leads and current probe to

the electrical equipment to be tested, take off the electrical equipment’s

power.

Connect the black voltage test alligator to the line “B”.

Connect the red voltage test alligator to the line “A”.

Connect the yellow voltage test alligator to the line “C”.

Press I1 current probe trigger to open the jaw and fully enclose the Line “A”.

Press I2 current probe trigger to open the jaw and fully enclose the Line “C”.

5. Press “

POWER

” key to select (P1, Q1, S1, PF1), (P2, Q2, S2, PF2) and (Pt,

Qt, St, PFt) measured values.

6. Frequency (Hz), Phase Angle (Θ ) and Power Factor (pF) measurement:

Press “PFΘ” key to cycle shows the PF and Θ measured values.

Press “Hz I4” key show the Hz measured value.

7. Voltage and Current THDR THDF measurement:

Please refer to section 4-1-12 “THD” key description.

8. Voltage and Current waveform harmonic measurement:

Please refer to section 4-1-25 “

M A G. ” key description.

9. Power Maximum/Minimum measurement:

Page 30

28

Please refer to section 4-1-10 “MAX” key description.

10. Energy measurement:

Press “ENERGY” key, the “Pt”, “Qt”, “St” and “PFt” or “ψt” annunciator

and energy integrate start time are displayed. The energy integrate value and

the current time will be continuous accumulate.

a). KW displays KWh

b). KVAR displays KVARh

c). KVA displays KVAh

Press “STOP” key to stop ener gy accum ulated and the “HOLD” annunciator

is displayed.

Press ↵ key to exit the energy measurement.

Q

U1

P

S

U2

Page 31

29

5-5 Three-Phase 3-Wire (3P3W3M) Power System Measurement

Application : Same as 3P3W power system measurement.

A, B, C: Line, Face the arrow toward the load.

I4I3

I1 I2

N

U1 U2

¢»

U3

3P3W3M Wiring Connection Diagram

1. Press

key to turn on the meter.

2. Press “WIRING” key to select the 3P3W3M electrical system under test, the

“3P3W3M” annunciator will be displayed.

3. Connect the voltage test leads and current probe to the meter.

Connect the red voltage test lead to the “U1” terminal.

Connect the yellow voltage test lead to the “U2” terminal.

Connect the blue voltage test lead to the “U3” terminal.

Connect the I1 current probe output plug to the “I1” jack.

Connect the I2 current probe output plug to the “I2” jack.

Page 32

30

Connect the I3 current probe output plug to the “I3” jack.

4. Connect the vol tage test le ads and curre nt probe to t he elec trical equipm ent to be

tested.

CAUTION

• If possible, before connecting the voltage test leads and current probe to

the electrical equipment to be tested, take off the electrical equipment’s

power.

Connect the red voltage test alligator to the line “A”.

Connect the yellow voltage test alligator to the line “B”.

Connect the blue voltage test alligator to the line “C”.

Press I1 current probe trigger to open the jaw and fully enclose t he Line “ A”.

11

Press I2 current probe trigger to open the jaw and fully enclose the Line “B”.

12

Press I3 current probe trigger to open the jaw and fully enclose the Line “C”.

5. Press “

POWER

” key to select (P1, Q1, S1, PF1), (P2, Q2, S2, PF2), (P3,

Q3, S3, PF3) and (Pt, Qt, St, PFt) measured values.

6. Frequency (Hz), Phase Angle (Θ ) and Power Factor (pF) measurement:

Press “PFΘ” key to cycle shows the PF and Θ measured values.

Press “Hz I4” key show the Hz measured value.

7. Voltage and Current THDR THDF measurement:

Please refer to section 4-1-12 “THD” key description.

8. Voltage and Current waveform harmonic measurement:

Please refer to section 4-1-25 “

M A G. ” key description.

9. Power Maximum/Minim um measurem ent:

Please refer to section 4-1-10 “MAX” key description.

10. Energy measurement:

Press “ENERGY” key, the “Pt”, “Qt”, “St” and “PFt” or “ψt” annunciator

and energy integrate start time are displayed. The energy integrate value and

the current time will be continuous accumulate.

Page 33

31

a). KW displays KWh

b). KVAR displays KVARh

c). KVA displays KVAh

Press “STOP” key to stop energy accumulated and the “HOLD” annunciator

is displayed.

Press ↵ key to exit the energy measurement.

Q

U1

P

S

U2 U3

Page 34

32

5-6 Three-Pha se 4-Wire (3P4W) Power System Measurement

Application: Same as 3P3W power system measurement.

A, B, C: Line, N: Neutral, G: Ground, Face the arrow toward the load.

I4I3

I1 I2

N

U1 U2

¢»

U3

3P4W Wiring Connection Diagram

1. Press

key to turn on the meter.

2. Press “WIRING” key to select the 3P4W electrical system under test, the

“3P4W” annunciator will be displayed.

3. Connect the voltage test leads and current probe to the meter.

Connect the black voltage test lead to the “N” terminal.

Connect the red voltage test lead to the “U1” terminal.

Connect the yellow voltage test lead to the “U2” terminal.

Connect the blue voltage test lead to the “U3” terminal.

Connect the I1 current probe output plug to the “I1” jack.

Page 35

33

Connect the I2 current probe output plug to the “I2” jack.

Connect the I3 current probe output plug to the “I3” jack.

Connect the I4 current probe output plug to the “I4” jack.

4. Connect the vol tage test le ads and curre nt probe to t he elec trical equipm ent to be

tested.

CAUTION

• If possible, before connecting the voltage test leads and current probe to

the electrical equipment to be tested, take off the electrical equipment’s

power.

Connect the black voltage test alligator to the neutral line “N”.

Connect the red voltage test alligator to the line “A”.

11

Connect the yellow voltage test alligator to the line “B”.

12

Connect the blue voltage test alligator to the line “C”.

13

Press I1 current probe trigger to open the jaw and fully e nclose the Li ne “A”.

14

Press I2 current probe trigger to open the jaw and fully enclose the Line “B”.

15

Press I3 current probe trigger to open the jaw and fully enclose the Line “C”.

16

Press I4 current probe trigger to open the jaw and fully enclose neutral line “N”.

5. Press “

POWER

” key to select (P1, Q1, S1, PF1), (P2, Q2, S2, PF2), (P3,

Q3, S3, PF3) and (Pt, Qt, St, PFt) measured values.

6. Frequency (Hz), Phase Angle (Θ ), Neutral Line Current (I4) and Power Factor

(pF) measurement :

Press “PFΘ” key to cycle shows the PF and Θ measured values.

Press “Hz I4” key to cycle shows the Hz and I4 measured values.

7. Voltage and Current THDR THDF measurement:

Please refer to section 4-1-12 “THD” key description.

8. Voltage and Current waveform harmonic measurement:

Please refer to section 4-1-25 “

M A G. ” key description.

9. Power Maximum/Minim um measurem ent:

Page 36

34

Please refer to section 4-1-10 “MAX” key description.

10. Energy measurement:

Press “ENERGY” key, the “Pt”, “Qt”, “St” and “PFt” or “ψt” annunciator

and energy integrate start time are displayed. The energy integrate value and

the current time will be continuous accumulate.

a). KW displays KWh

b). KVAR displays KVARh

c). KVA displays KVAh

Press “STOP” key to stop energy accumulated and the “HOLD” annunciator

is displayed.

Press ↵ key to exit the energy measurement.

Q

U1

P

S

U2 U3

Page 37

35

5-7 Only One Cur r ent I4 Measurement

Application: Measurement any wire current independent of voltage, the

same as clamp meter application.

I3

I1

I4

I2

N

U1 U2¢»U3

1. Press

key to turn on the meter.

2. Press “I4” key.

3. Connect the I4 current probe output plug to the “I4” jack.

4. Press I4 current probe trigger to open the jaw and fully enclose desired measured

wire.

5. Read the I4 value.

5-8 Manual Data Mem ory and Read Function Operation

1. Clear Manual memory data:

Press

key to turn off the meter.

Press an d hold down the “MEMORY” key then press

key again to turn on

the meter and to enter clear m anual m em ory dat a mode, the “DATA M CLr 1

YES no” mark is displayed.

Page 38

36

Press or key to select “YES” or “no” then press ↵ key to confirm.

If select “YES”, the all manual memorized data is cleared.

2. Store Manual data to memory:

Press “MEMORY” key one time store one sets displayed data t o mem ory, the

“M” annunciator display one time and the stored memory address will be

displayed.

Maximum store memory capacity size is 50 sets.

3. Read the manual stored data:

Press “READ” key to enter the read mode, the “R” annunciator is displayed.

Press

key to read the memories data, the memories data address will be

displayed.

Press “READ” key to exit the read mode.

5-9 Auto Datal ogging Fu nction Operat i on

1. Clear SD Card memory data:

Press

key to turn off the meter.

Press an d hold down the “MEMORY” key then press

key again to turn on

the meter and to enter clear manual memory data mode, the “DATA M CLr 1

YES no” mark is displayed.

Press ↵ key to enter clear SD Card memory data mode, the “DATA M CLr 2

YES no” mark is displayed.

Press or key to select “YES” or “no” then press ↵ key to confirm.

If select “YES”, the all SD Card memorized data is cleared.

2. Store Auto datalogging data to memory:

Setting the current time and Auto datalogging interval time.

Press “SET” key to enter current time setting mode.

Press

keys to set actual current YEAR-month, DAY-hour,

minute-second.

Press ↵ key to enter auto datalogging interval time setting, the “INTV”

annunciator is displayed.

Press keys cycle select the interval time, you can select 5 seconds, 10

seconds, 30 seconds, 1 minute or 2 minutes.

Press ↵ key to exit TIME setting mode.

Page 39

37

Enter Auto datalogging mode.

Press “START” key to start Auto data logging, the “DATA M××” will be

displayed, the “M” annunciator, according to the interval time disappear one

time store one sets data into the memory.

Press “STOP” key to stop data record, press “START” ke y will resume data

record, but maximum can be divide to 99 memory blocks, the current block

number will be displayed ( 01 ~ 99).

When maximum block or maximum capacity is full, the “DATA FULL”

annunciator will be displayed, the data record is auto stopped.

Download data to PC

Please refer to the software manual (CD-ROM) to download the data.

5-10 Phase Sequence M easurem ent

1. Press

key to turn on the meter.

2. Press “WIRING” key to select 3P4W mode.

3. Connect the voltage test leads to the meter.

Connect the red voltage test lead to the “U1” terminal.

Connect the yellow voltage test lead to the “U2” terminal.

Connect the blue voltage test lead to the “U3” terminal.

4. Connect the voltage test leads to the electrical equipment to be tested.

CAUTION

• If possible, before connecting the voltage test leads and current probe to

the electrical equipment to be tested, take off the electrical equipment’s

power.

Connect the red voltage test alligator to the power line “A” phase.

Connect the yellow voltage test alligator to the power line “B” phase.

Connect the blue voltage test alligator to the power line “C” phase.

5. U1, U2 and U3 measured voltage must be greater than 30V, then press and hold

down “

” key. If connection wires is nor m al phase, t he “ ” annunciator

is displayed. If connection wires is reverse phase, the “

” annunciator is

Page 40

38

displayed. Release the “ ” key to exit this measurement.

5-11 Voltage, Current Waveform and Harmonic Analyzer

Application:

May device power sources now use semiconductor control devices and

harmonics occur because of distorted voltage or current wave forms.

When harmonic com ponents become t oo large, they can cause serious accidents,

such as transformer supplying seeming average loads are overheating, neutral

conductors in balanced circuit are overheating from exceesing loads, circuit

breakers are tripping for no apparent reason, overheating the motor or burning

out the reactor connected to the phase advance capacitor.

Please refer to software manual (CD-ROM) for waveform and harmonic

measurement.

5-12 Enable Auto Power Off Function

When enable auto power off function, the meter will automatically enter sleep

mode approx. 30 minutes to save power consumption.

1. Enable auto power off procedure:

Press

key to turn off the meter.

Press and hold d own “TIME” key, then press

key to

turn on the meter , t he

auto power function will be enabled, and the auto power off symbol “

”

will be appear.

2. Auto power off mode is disabled each time you turn on the meter and is

automatically disabled as the follow modes.

ENERGY function is active.

Auto datalogging function is active.

PC linked.

Page 41

39

6. MAINTENANCE

6-1 General Maintenanc e

1. Repairs or services that are not covered in t his manual should only be performed

by qualified personnel.

2. Clean the meter and accessories with a damp cloth and a mild soap. Do not use

abrasives, solvent, or alcohol. These may damage the text.

3. Additional to this it is recommended to open the jaws of the Current Clamp and

to wipe the magnetic pole pieces with a lightly oiled cloth. This in order to

avoid rust or corrosion to form on the magnetic poles.

6-2 Battery Replacem ent

WARNING

• T o AVOID electrical shock, remove the test l eads and current probe befor e

replacing the batteries.

1. As battery power is not sufficient, LCD will display

BT

annunciator, replace

new battery is required.

2. Disconnect all test leads and current probe from any power electrical source,

press

key to turn off the meter, and remove the test leads from the jacks.

3. The battery cover is secured to the bottom case by two screws. Using a screw

drive to remove the two screws from the bottom case.

4. Remove battery cover, take out the batteries and replace with new batteries.

(Please note battery polarity)

7. SOFTWARE INSTALLATION AND OPERATION

For the detailed instruction, please refer to the content of attached CD-ROM,

which has the complete instruction of software operation and relevant

information.

Loading...

Loading...