PCE Health and Fitness PCE-A-315 Instruction Manual

PCE Americas Inc.

711 Commerce Way

Suite 8

Jupiter

FL-33458

USA

From outside US: +1

Tel: (561) 320-9162

Fax: (561) 320-9176

info@pce-americas.com

www.pce-instruments.com/english

www.pce-instruments.com

PCE Instruments UK Ltd.

Unit 11

Southpoint Business Park

Ensign way

Hampshire / Southampton

United Kingdom, SO31 4RF

From outside UK: +44

Tel: (0) 2380 98703 0

Fax: (0) 2380 98703 9

info@industrial-needs.com

Grain Moisture Analyzer

PCE-A-315

INSTRUCTION MANUAL

Contents

2/29

Contents

GENERAL SAFETY RECOMMENDATIONS .............................................................. 3

1. GENERAL INFORMATION ..................................................................................... 4

2. SPECIFICATIONS................................................................................................... 6

3. PRINCIPLE OF OPERATION ................................................................................. 7

4. WORKING WITH CONTROL PANEL...................................................................... 8

4.1. CONNECTIONS .................................................................................................... 8

4.2. SELECTING PRODUCT AND PERFORMING MOISTURE MEASUREMENTS ..................... 10

4.3. TREND VIEW ..................................................................................................... 13

4.4. ENTERING CORRECTIONS AND PARAMETERS ....................................................... 15

4.5. VIEWING ARCHIVE DATA ..................................................................................... 23

4.6. SETTING TIME AND DATE .................................................................................... 24

5. INSTALLATION ..................................................................................................... 25

6. TROUBLESHOOTING .......................................................................................... 27

7. DIMENSIONAL DRAWING ................................................................................... 29

General safety recommendations

3/29

General safety recommendations

The product is designed for industrial use. Installation and service must

be carried only out by trained and authorized personnel and according

to valid standards.

Before making any electrical connections, ensure that power supply

voltage and frequency meet the specifications provided on the labels of

devices and in this manual.

Incorrect connection may cause damage to the device. When installing,

always refer to relevant safety regulations.

Before carrying out any welding work near the device, make sure that

the device is disconnected from the power supply.

Do not use the device with damaged insulation of cables. In the case of

damage to the cable, disconnect the device from the power supply and

contact manufacturer or local dealer for cable replacement.

In case of device malfunction do not attempt to disassemble and repair

the device. Please, contact manufacturer or local dealer for repair.

Take precautions when mounting the equipment by using appropriate lift

gear, platforms and tools.

General information

4/29

1. General information

The system of online moisture content measurement is designed for continuous

measurement of current moisture content of grain products, oil or leguminous crops

and other products at inlet and outlet of continuous flow grain dryers.

fig 1. System of online moisture content measurement

The system can be used for measuring moisture content of the following products:

Grain:

- wheat

- barley

- oats

- triticale

- rye

- corn

- buckwheat

- millet

- sorghum

- rice

Oil crops:

- rape

- sunflower

- jojoba

Leguminous

crops:

- peas

- lupine

- soybean

Other:

- seaweed

- coffee

The system of online moisture content measurement consists of two А315 microwave moisture sensors and control panel (fig. 1). One moisture sensor is installed

at the inlet of dryer and another is at the outlet of dryer. If grain drying complex has

two drying shafts, one moisture sensors can be installed at the outlet of each shaft.

Control panel is installed at the operator station and intended for monitoring of

input and output flow moisture. Information about grain moisture and temperature is

displayed in digital form and in the form of charts (trends).

General information

5/29

Control panel allows adjusting scaling settings of two moisture content current

loop outputs for use in automation systems, storing correction coefficients for measured moisture content of every product, time-averaging of measurement results and

other functions described in this manual.

Specifications

6/29

2. Specifications

Sensor type .................................................................. microwave;

Measuring mode ........................................................... continuous;

Measuring range .......................................................... 5 – 40%;

Moisture content measurement error (up to 18%) ........ ±0.5% max;

Moisture content measurement error (18-40%) ........... ±1% max;

Product temperature ..................................................... +5ºС – +55ºС;

Ambient temperature ................................................... 0ºС – +55ºС;

IP rating ....................................................................... IP65;

Communication protocol ............................................... RS-485;

Cable length between sensor and control panel .......... up to 100 m;

Analog output ............................................................... 4-20 or 0-24 mA;

Analog output loading capability .................................. 400 Ω max;

Sensor weight ............................................................... 6.5 kg;

Control panel weight ..................................................... 4.5 kg;

Control panel power supply .......................................... 100-240VAC / 50-60Hz;

Sensor power supply .................................................... 24VDC.

Principle of operation

7/29

3. Principle of operation

The principle of sensor A315 operation is based on the considerable difference

of the permittivity of dry substances and water at ultra-high frequencies (UHF).

The feature and important advantage of A315 moisture content sensor is that

due to simultaneous measurement of resonant frequency and amplitude of the resonance and special processing algorithm, moisture content measurements become

practically independent of product bulk density.

The sensing element is based on a ring resonator. The resonator has a cavity

formed by a PTFE tube for grain flow. Interaction of grain flow with resonator field inside the tube influences parameters of the resonator. Temperature sensors in measuring channel allow automatic correction of measured value of moisture content from

the grain temperature.

Electronics of the sensor consists of two units – UHF module and data processing module that control frequency response of measurement resonator, provide

necessary calculations and transfer of data to control panel via RS-485 interface.

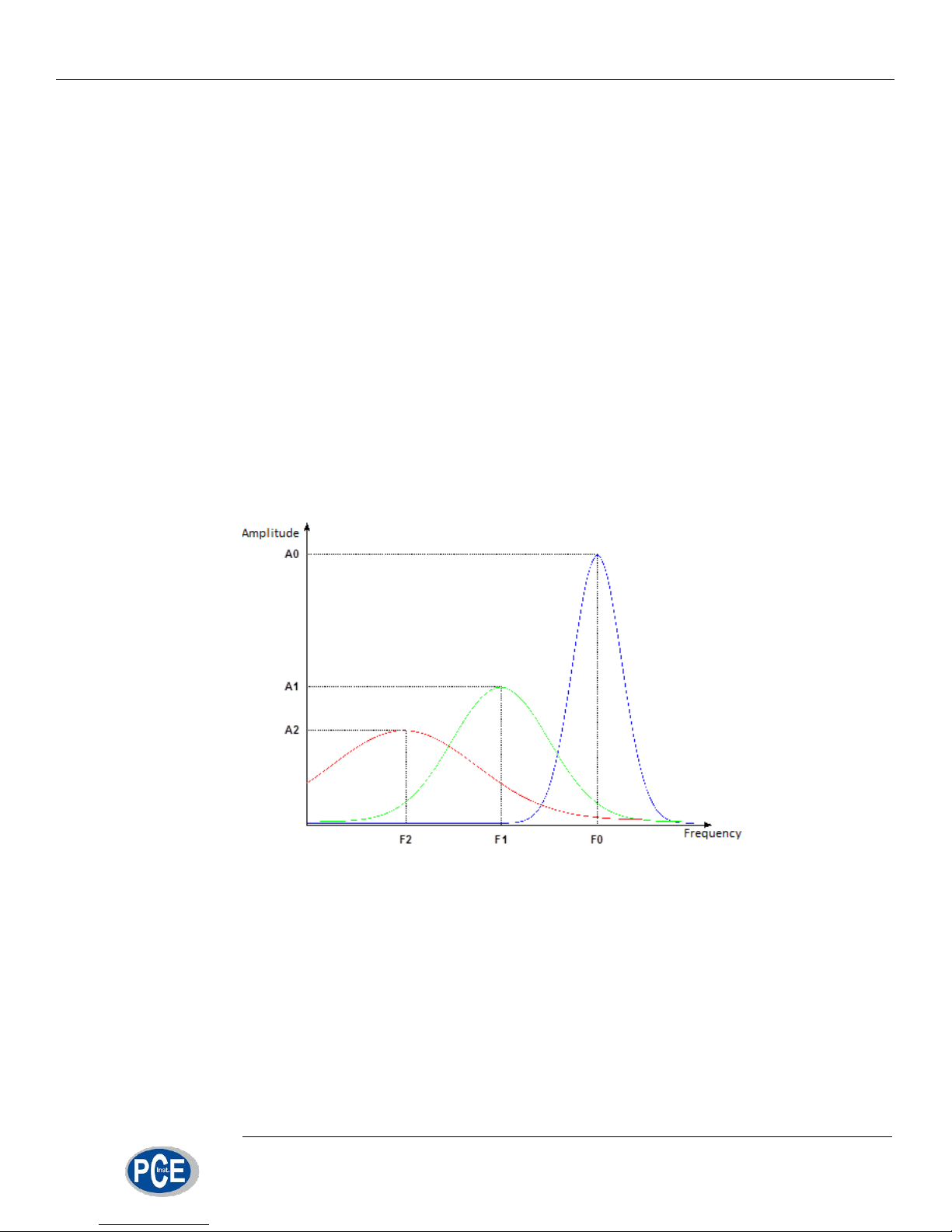

fig 2. Principle of operation

When the measuring channel is empty, the resonator has resonant frequency

F0 and amplitude A

0

(fig. 2). When the channel is filled with grain with certain mois-

ture content, the resonant frequency and amplitude decrease to F

1

and А1 respective-

ly. With the increase of moisture content in measured product, resonant frequency

and amplitude decrease even more (F

2

and А2). Simultaneous measurement of resonant frequency and amplitude allows determining moisture content independently of

grain density.

Working with control panel

8/29

4. Working with control panel

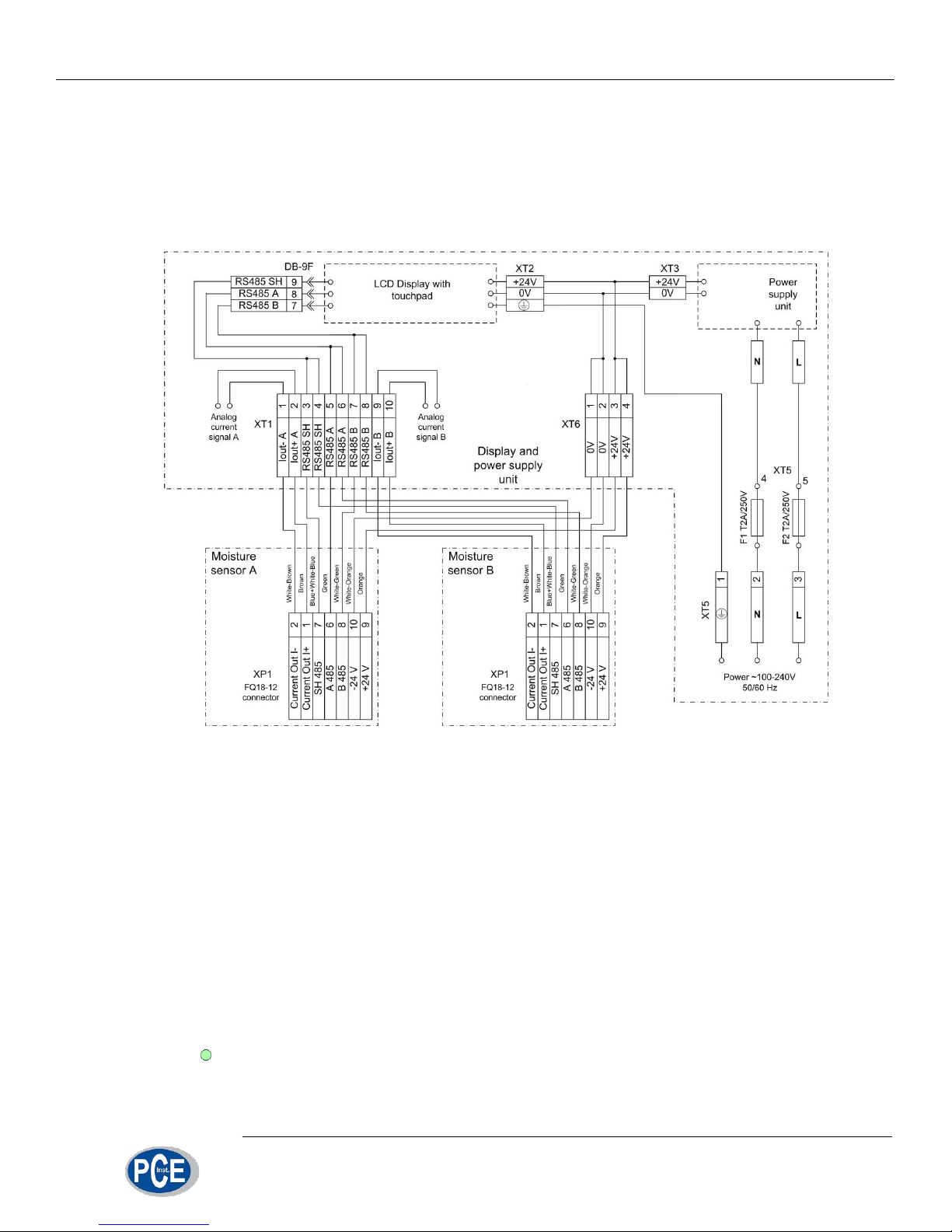

4.1. Connections

Control unit is designed to work with two A315 grain moisture content sensors.

One of the sensors has address A, and the second one – address B.

fig 3. Wiring diagram

Control panel is supplied with two pre-wired cables (3 m each) for connecting

the sensors. This allows to quickly plug the sensors and check their operation before

installation on the grain dryer and to learn how to work with the control panel.

For installation on the grain dryer 7-terminal junction box should be mounted at

the distance of up to 3 m from a sensor and sensor cable should be connected to it.

Communication lines (4 twisted pairs) of the required length (up to 100 m) from each

junction box are wired to the operator station where control panel is installed. Connections should be performed according to wiring diagram shown in fig. 3.

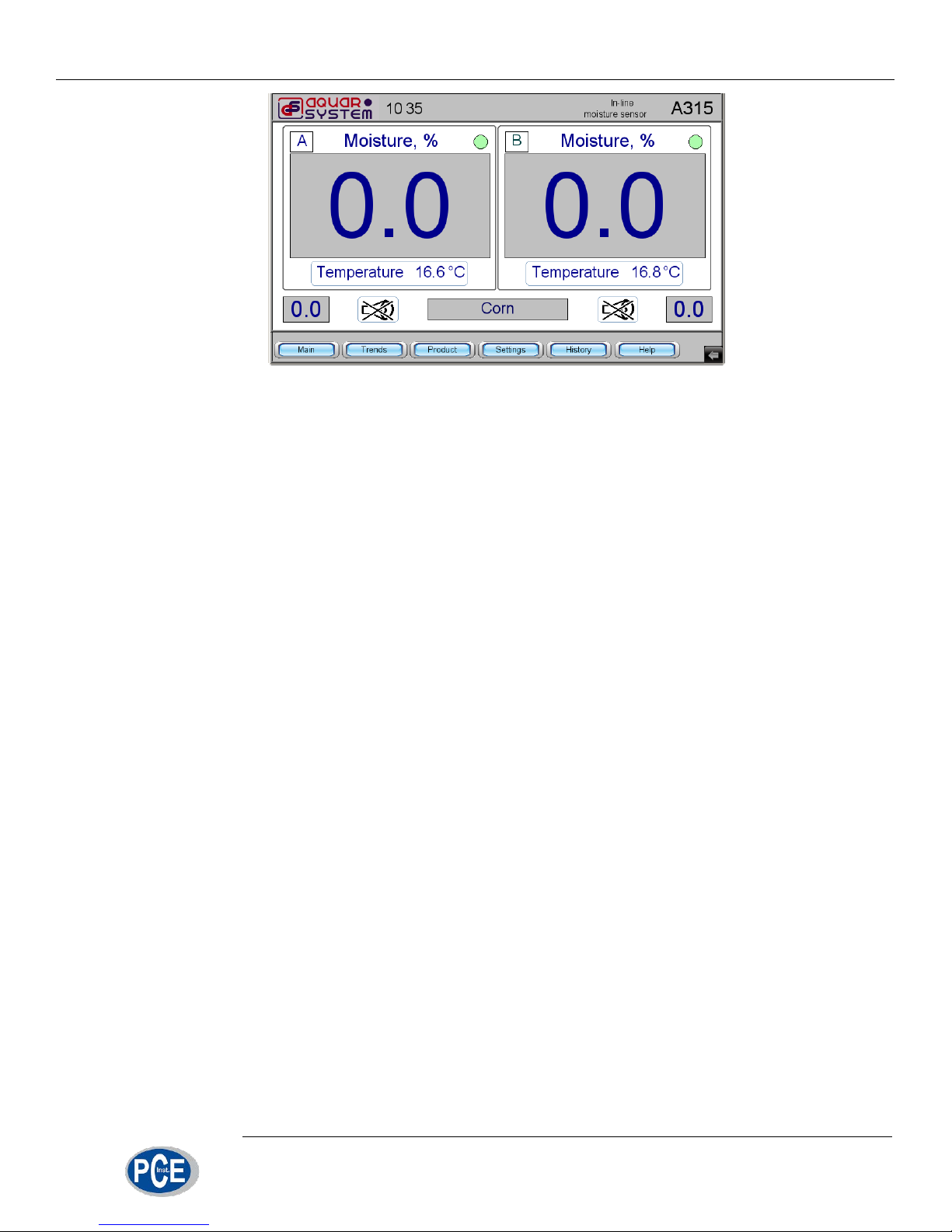

In order to check operation of measurement system place both sensors on a ta-

ble, connect the cables from control panel to sensors A and B and power up the con-

trol panel. After startup the display should look as shown in fig. 4. Two green indicators show that sensors are ready for measurements.

Working with control panel

9/29

fig 4. Control panel screen after system startup

Loading...

Loading...