PCE Health and Fitness 5000H User Manual

© PCE Instruments

PCE-CT 5000H Coating Thickness Gauge

User Manual

User manuals in various languages (français,

italiano, español, português, nederlands, türk, polski,

русский, 中文) can be found by using our

product search on: www.pce-instruments.com

Last change: 6 September 2018

v1.0

English

© PCE Instruments

Contents

1 Safety notes ........................................................................................... 1

2 Introductions ......................................................................................... 2

2.1 Features ........................................................................................................................... 2

2.2 Application ....................................................................................................................... 2

2.3 Principle of Measurement ................................................................................................. 2

2.4 Delivery contents .............................................................................................................. 3

3 Device description ................................................................................ 3

4 Specifications ........................................................................................ 4

5 Use the Gauge ....................................................................................... 5

5.1 Replacing the Battery ....................................................................................................... 5

5.2 Basic Measurement Step ................................................................................................. 5

5.3 User Interface .................................................................................................................. 6

5.4 Measure Mode (Only Support Single Mode) ..................................................................... 7

5.5 Group Mode ..................................................................................................................... 7

5.6 Statistics .......................................................................................................................... 7

5.7 Probe Mode ..................................................................................................................... 8

5.8 Storage ................................................................................................ ............................ 8

5.9 Recall and Delete Readings ............................................................................................. 8

5.10 High and Low Limit Alarm................................................................................................. 9

5.11 Unit .................................................................................................................................10

5.12 Speed .............................................................................................................................10

5.13 Data Download................................................................................................................10

5.14 Auto Power off.................................................................................................................10

5.15 Measurement Accuracy ...................................................................................................11

6 Factors Affecting Measurement Accuracy ....................................... 11

7 Calibration ........................................................................................... 12

8 Troubleshooting .................................................................................. 14

9 Warranty ............................................................................................... 15

10 Disposal ............................................................................................... 15

© PCE Instruments

1

1 Safety notes

Please read this manual carefully and completely before you use the device for the first time. The

device may only be used by qualified personnel and repaired by PCE Instruments personnel.

Damage or injuries caused by non-observance of the manual are excluded from our liability and

not covered by our warranty.

• The device must only be used as described in this instruction manual. If used otherwise,

this can cause dangerous situations for the user and damage to the meter.

• The instrument may only be used if the environmental conditions (temperature, relative

humidity, …) are within the ranges stated in the technical specifications. Do not expose

the device to extreme temperatures, direct sunlight, extreme humidity or moisture.

• Do not expose the device to shocks or strong vibrations.

• The case should only be opened by qualified PCE Instruments personnel.

• Never use the instrument when your hands are wet.

• You must not make any technical changes to the device.

• The appliance should only be cleaned with a damp cloth. Use only pH-neutral cleaner,

no abrasives or solvents.

• The device must only be used with accessories from PCE Instruments or equivalent.

• Before each use, inspect the case for visible damage. If any damage is visible, do not

use the device.

• Do not use the instrument in explosive atmospheres.

• The measurement range as stated in the specifications must not be exceeded under

any circumstances.

• Non-observance of the safety notes can cause damage to the device and injuries to

the user.

We do not assume liability for printing errors or any other mistakes in this manual.

We expressly point to our general guarantee terms which can be found in our general terms of

business.

If you have any questions please contact PCE Instruments. The contact details can be found at

the end of this manual.

© PCE Instruments

2

2 Introductions

This compact gauge can be used for non-destructive coating thickness measurement of nonmagnetic coatings, e.g. paint, enamel, chrome on steel, and insulating coatings, e.g. paint and

anodizing coatings on non-ferrous metals.

2.1 Features

• 128* 128 dot matrix LCD display, standard menu operations;

• Two measure mode: single and continuous;

• Two group mode:direct(DIR) and general(GEN), readings will be lost when power off

in direct mode, and not be

• lost in general mode. Readings can be stored for each group;

• Zero point calibration and multi-point calibration(up to 4 points) for each group;

• User can recall, delete specified readings, or delete group readings;

• Statistics display: mean, minimum, maximum and standard deviation;

• Three probe mode:auto, magnetic and eddy current;

• User can set high or low limit alarm for each group;

• Power off automatically;

• USB interface to data transmission;

• Low battery and error indication ;

2.2 Application

This gauge is designed for non-destructive, fast and precise coating thickness measurement. The

principal applications lie in the field of corrosion protection. It is ideal for manufacturers and their

customers, for offices and specialist advisers, for paint shops and electroplaters, for the chemical,

automobile, ship building and aircraft industries and for heavy engineering. It is suitable for

laboratory, workshop and outdoor use.

2.3 Principle of Measurement

The coating thickness gauge work either on the magnetic induction principle or on the eddy

current principle, depending on the type of probe used. This gauge has internal F probe and N

probe.

F probe work on magnetic induction principle and should be used for non-magnetic coatings

such as aluminium, chrome, copper, zinc, paint and varnish, enamel, rubber etc., on an iron or

steel substrate; It is also suitable for alloyed and hardened magnetic steel (however, not

suitable for austenitic steel).

N Probe work on the eddy current principle and should be used for insulating coatings e. g.

paint, anodizing, ceramics, etc., on all non-ferrous metals such as aluminium, copper, zinc die

casting, brass etc. and on austenitic stainless steels.

© PCE Instruments

3

2.4 Delivery contents

1 x PCE-CT 5000H thickness gauge

2 x Zero calibration plates (ferrous and non-ferrous)

5 x Calibration plates

2 x 1.5V AAA batteries

1 x USB cable

1 x PC-compatible software

1 x User manual

1 x Carrying case

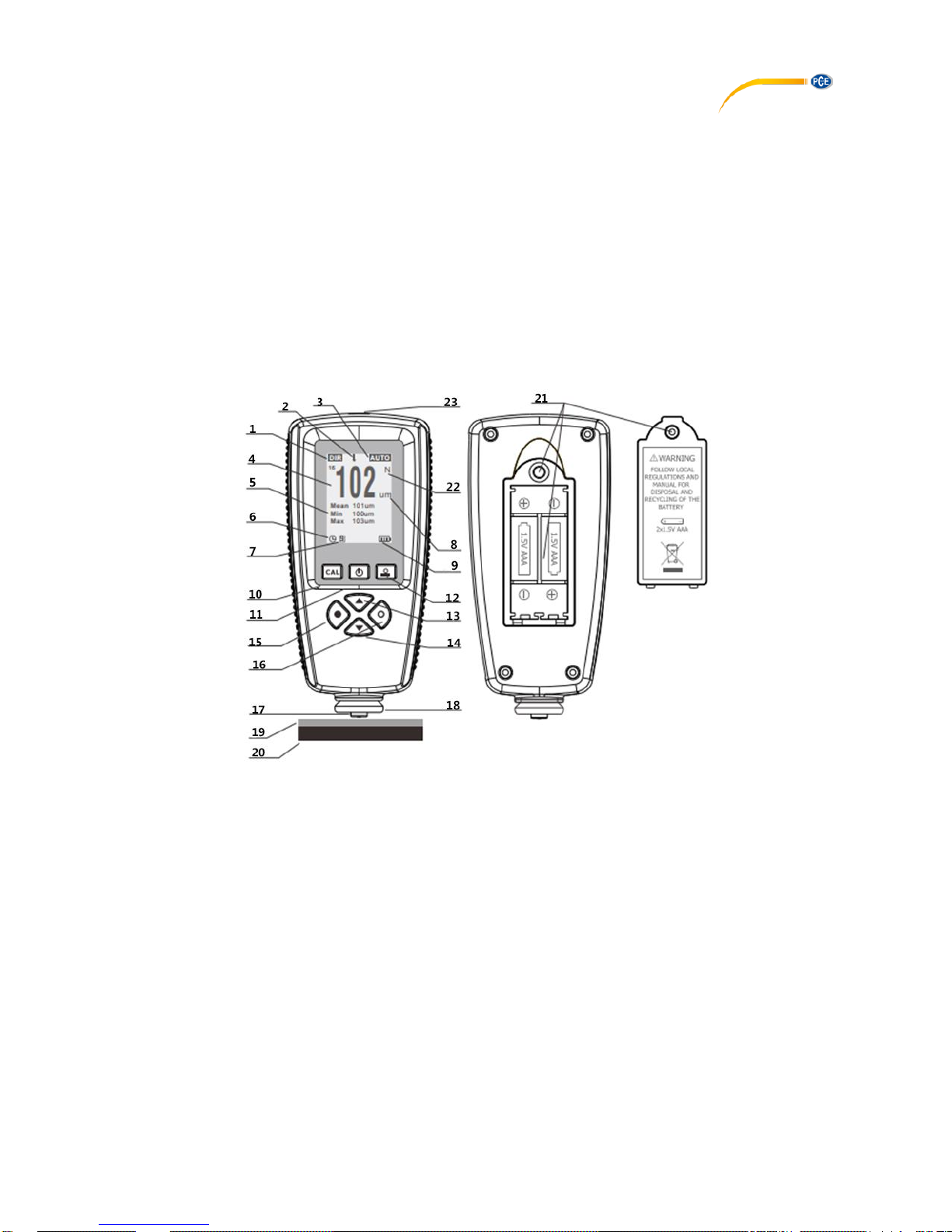

3 Device description

1. Measurement mode

2. High and low limit alarm

3. Probe mode: AUTO, MAG, EDDY

4. Measuring readings display

5. Statistics display (MIN/MAX/AVG)

6. Auto-power off indication

7. USB connecting indication

8. Measuring unit

9. Low battery indication

10. Calibration key

11. POWER on/off key

12. ZERO calibration key

13. UP key

14. DOWN key

15. LEFT key

16. RIGHT key

17. Probe

18. V groove

19. Standard foil

20. Substrate

21. Battery compartment

22. Material recognition (F: ferrous;N: non ferrous)

23. USB interface for PC connection

© PCE Instruments

4

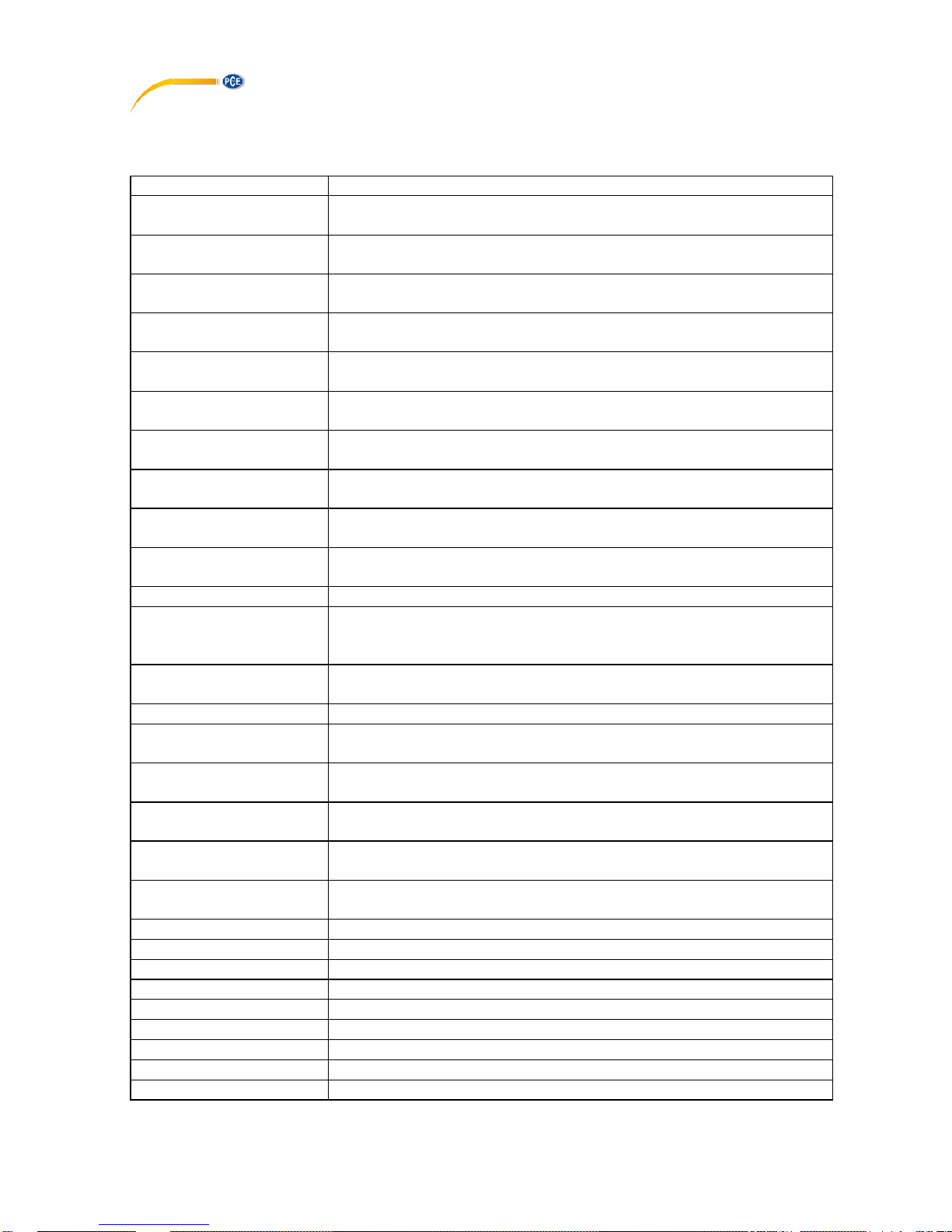

4 Specifications

Probe

Type F and Type N

Measuring range Type

F

0 ... 5000 μm / 0 ... 5 mm / 0 ... 196 mils

Measuring accuracy

Type F

± (2% + 1 μm)

Resolution Type F

0 ... 99.9 μm: 0.1 μm, 100 ... 999 μm: 1 μm

> 1000 μm: 0.01 mm

Measuring principle

Type F

Magnetic induction

Smallest thickness of

the base material

0.02 mm

Measuring range Type

N

0 ... 3000 μm / 0 ... 3 mm / 0 ... 118 mils

Measuring accuracy

Type N

± (2% + 1 μm)

Resolution Type N

0 ... 99.9 μm: 0.1 μm, 100 ... 999 μm: 1 μm

> 1000 μm: 0.01 mm

Measuring principle

Type N

Eddy current

Smallest thickness of

the base material

0.05 mm

Calibration

One-point to four-point calibration, zero calibration

Data storage

Direct measurement (no measurement data storage), four data

groups (automatic measurement data storage of up to 2000

measured values)

Statistical functions

Number of measurements, average, minimum, maximum,

standard deviation

Measurement units

μm, mm, mils

Alarm

Alarm limits adjustable, alarm symbol is displayed when limits are

exceeded

Minimum radius of

curvature (convex)

5 mm / 0.2 in

Minimum radius of

curvature (concave)

25 mm / 1 in

Smallest measuring

surface

Diameter of 20 mm / 0.8 in

Maximum measuring

rate

2 x per second

Data interface

Data transfer via USB

Power supply

2 x 1.5V AAA batteries

Menu languages

German, English, Russian, Chinese

Operating conditions

0 ... 50°C / 32 ... 122°F, 20 ... 90% RH

Storage conditions

-10 ... 60°C / 14 ... 140°F

Standards

CE ROHS FCC

Dimensions

110 x 53 x 24 mm / 4.33 x 2.09 x 0.95 in

Material housing

ABS plastic

Weight

92 g / < 1 lb

Loading...

Loading...