SD card real time data recorder, RS232/USB

4 Channels

Vibration Analyzer

PCE-VM 5000

Y

our purchase of this

4 C H A NNEL S

VIBRATION METER

with SD CARD DAT

A

RECORDER marks a

step forward for you

into the field o

f

precision

measurement.

A

lthough this METER

is a complex and

delicate instrument,

its durable structure

will allow many years

of use if proper

operating techniques

are developed. Please

read the following

instructions carefully

and always keep this

manual within easy

reach.

OPERATION MANUAL

PCE Americas Inc.

711 Commerce Way

Suite 8

Jupiter

FL-33458

USA

From outside US: +1

Tel: (561) 320-9162

Fax: (561) 320-9176

info@pce-americas.com

www.pce-instruments.com/english

www.pce-instruments.com

PCE Instruments UK Ltd.

Units 12/13

Southpoint Business Park

Ensign way

Hampshire / Southampton

United Kingdom, SO31 4RF

From outside UK: +44

Tel: (0) 2380 98703 0

Fax: (0) 2380 98703 9

info@pce-instruments.com

TABLE OF CONTENTS

1. FEATURES........................................................................ 1

2. SPECIFICATIONS.............................................................. 2

3. FRONT PANEL DESCRIPTION.............................................9

4. MEASURING PROCEDURE.................................................. 11

4-1 Preparation................................................................. 11

4-2 Unit selection ( Acc./Velocity/Displacement

selection )...................................................................

.

12

4-3 Function selection ......................................................

.

14

4-4 Zero adjustment, Max hold reset procedures................. 15

4-5 Data Hold...................................................................

.

16

4-6 Data Record ( Max./ Min. reading )...............................16

4-7 LCD Backlight ON/OFF................................................. 16

5. DATALOGGER................................................................... 17

5-1 Preparation before execute datalogger function.............17

5-2 Auto Datalogger ( Set sampling time 1 second ).......≧ 18

5-3 Manual Datalogger ( Set sampling time = 0 second )....19

5-4 Check time information................................................ 19

5-5 Check sampling time information..................................20

5-6 SD Card Data structure................................................ 20

6. Saving data from the SD card to the computer....................22

7. ADVANCED SETTING.........................................................23

7-1 Set clock time ( Year/Month/Date,

Hour/Minute/ Second ).............................................. 23

7-2 Set sampling time .......................................................24

7-3 Auto power OFF management ..................................... 24

7-4 Set beep Sound ON/OFF.............................................. 24

7-5 Decimal point of SD card setting...................................25

7-6 SD memory card format...............................................25

7-7 Set Metric/Imperial unit...............................................

.

26

8. POWER SUPPLY from DC ADAPTER.................................... 26

9. BATTERY REPLACEMENT................................................... 27

10. SYSTEM RESET............................................................... 27

11. RS232 PC serial interface................................................. 27

12. CLASSIFICATION RANGES............................................... 29

13. SENSITIVITY RELATIVE according ISO 2954..................... 30

14. PATENT.......................................................................... 31

1. FEATURES

* 4 channels vibration recorder, use SD card to save the

4 channels' data along with time information, paperless.

* Applications for industrial vibration monitoring :

All industrial machinery vibrates. The level of vibration is

a useful guide to machine condition. Poor balance,

misalignment & looseness of the structure will cause the

vibration level increase, it is a sure sign that the

maintenance is needed.

* Channels no. : 4 channels ( CH1 to CH4 )

vibration measurement.

* Frequency range 10 Hz - 1 kHz, sensitivity relative meet

ISO 2954.

* Professional vibration meter supply with vibration sensor

& magnetic base, full set.

* Metric & Imperial display unit

* Acceleration, Velocity, Displacement measurement.

* RMS, Max hold, Peak value measurement.

* Max. Hold reset button, Zero button.

* Wide frequency range.

* Data hold button to freeze the desired reading.

* Memory function to record maximum and minimum

reading with recall.

* Separate vibration probe with magnetic base, easy operation.

* Real time SD memory card Datalogger, it Built-in Clock

and Calendar, real time data recorder , sampling time set

from 1 second to 3600 seconds.

* Manual datalogger is available ( set the sampling

time to 0 ), during execute the manual datalogger

function, it can set the different position ( location ) No.

( position 1 to position 99 ).

1

* Innovation and easy operation, computer is not need

to setup extra software, after execute datalogger, just

take away the SD card from the meter and plug in the

SD card into the computer, it can down load the all the

measured value with the time information (

year/month/date/ hour/minute/second ) to the Excel

directly, then user can make the further data or graphic

analysis by themselves.

* SD card capacity : 1 GB to 16 GB.

* LCD with green light backlight, easy reading.

* Can default auto power off or manual power off.

* Data hold, record max. and min. reading.

* Microcomputer circuit, high accuracy.

* Power by UM3/AA ( 1.5 V ) x 8 batteries or DC 9V adapter.

* RS232/USB PC COMPUTER interface.

* Include 1 PC vibration sensor, VB-83.

* Extra vibration sensor, VB-83 can be ordered.

When change the VB-83, it is not necessary to make

calibration again.

2. SPECIFICATIONS

2-1 General Specifications

Circuit Custom one-chip of microprocessor LSI

circuit.

Display LCD size : 82 mm x 61 mm.

* with green color backlight.

Channels 4 channels :

CH1, CH2, CH3, CH4.

Measurement Velocity, Acceleration, Displacement

2

Function

Acceleration, Velocity :

RMS, Peak, Max Hold.

Displacement :

p-p ( peak-peak ), Max Hold p-p.

Unit

Measurement Metric Imperial

Acceleration meter/s^2, g ft/s^2,

Velocity mm/s, cm/s inch/s

Displacement mm inch

Frequency 10 Hz to 1 KHz

range

* Sensitivity relative during the

the frequency range meet ISO 2954

Refer to table 1, page 30.

Circuit Exclusive microcomputer circuit.

Peak

Acceleration, Velocity :

Measurement To measure and update the peak

value.

Displacement :

To measure and update the peak to

peak ( p-p ) value.

Max Hold

Acceleration, Velocity :

Measurement To measure and update the max. peak

value.

Displacement :

To measure and update the max.

peak to peak ( p-p ) value.

Zero Button Under Acceleration ( RMS ) measurement,

sensor motionless , press two Buttons

( 3-5, 3-7, Fig. 1 ) >3 seconds.

Max. Hold Reset Under Max. hold measurement, press

Button two Buttons ( 3-5, 3-7, Fig. 1 ) >3

seconds.

3

Datalogger Auto 1 second to 3600 seconds

Sampling Time

@ Sampling time can set to 1 second,

Setting range

but memory data may loss.

Manual Push the data logger button

once will save data one time.

@ Set the sampling time to

0 second.

@ Manual mode, can also select the

1 to 99 position ( Location ) no.

Data error no. 0.1 % no. of total saved data typically.≦

Memory Card SD memory card 1 GB to 16 GB.

Advanced * Set clock time ( Year/Month/Date,

setting Hour/Minute/ Second )

* Set sampling time

* Auto power OFF management

* Set beep Sound ON/OFF

* Decimal point of SD card setting

* SD memory card Format

* Set Metric/Imperial unit

Data Hold Freeze the display reading.

* Only available for the RMS function.

Memory Recall Maximum & Minimum value.

* Only available for the RMS function.

Data Output RS 232/USB PC computer interface.

* Connect the optional RS232 cable

UPCB-02 will get the RS232 plug.

* Connect the optional USB cable

USB-01 will get the USB plug.

Sampling Time Approx. 1 second.

of Display

Operating 0 to 50 .℃

Temperature Less than 85% R.H.

and Humidity

4

Power Supply

*

A

Alkaline or heavy duty DC 1.5 V battery

( UM3, AA ) x 8 PCs, or equivalent.

*

A

DC 9V adapter input. ( AC/DC power

adapter is optional ).

Power Current Normal operation ( w/o SD card save

data and LCD Backlight is OFF) :

Approx. DC 12 mA.

When SD card save the data and LCD

Backlight is OFF) :

Approx. DC 35 mA.

Weight

Meter :

515 g/ 1.13 LB.

Probe with cable and magnetic base :

99 g/0,22 LB

Dimension

Meter :

203 x 76 x 38 mm

Vibration sensor probe:

Round 16 mm Dia. x 37 mm.

Cable length : 1.2 meter.

Accessories * Instruction manual....................... 1 PC

Included * Vibration sensor set, VB-83 with

cable........................................... 1 PC

* Magnetic base..............................1 PC

* Carrying case ( CA-08 )................

.

1 PC

Optional * Vibration sensor set, VB-83 with cable.

Accessories * SD Card ( 2 G ).

* AC to DC 9V adapter.

* USB cable, USB-01.

* RS232 cable, UPCB-02.

*

Data Acquisition software,SW-U801-WIN.

5

2-2 Electrical Specifications (23± 5 )℃

Acceleration ( RMS, Peak, Max Hold )

Unit m/s^2

Range 0.5 to 199.9 m/s^2

Resolution 0.1 m/s^2

Accuracy ± ( 5 % + 2 d ) reading

@ 160 Hz, 80 Hz, 23 ± 5 ℃

Calibration 50 m/S^2 ( 160 Hz )

Point

Unit g

@ 1 g = 9.8 m/s^2

Range 0.05 to 20.39 G

Resolution 0.01 G

Accuracy ± ( 5 % + 2 d ) reading

@ 160 Hz, 80 Hz, 23 ± 5 ℃

Calibration 50 m/S^2 ( 160 Hz )

Point

Unit ft/s^2

Range 2 to 656 ft/s^2

Resolution 1 ft/s^2

Accuracy ± ( 5 % + 2 d ) reading

@ 160 Hz, 80 Hz, 23 ± 5 ℃

Calibration 50 m/S^2 ( 160 Hz )

Point

Remark :

RMS : To measure the true RMS value.

Peak : To measure and update the peak value.

Max. Hold : To measure and update the max. peak value.

6

Velocity ( RMS, Peak, Max Hold )

Unit mm/s

Range 0.5 to 199.9 mm/s

Resolution 0. 1 mm/s

Accuracy ± ( 5 % + 2 d ) reading

@ 160 Hz, 80 Hz, 23 ± 5 ℃

Calibration 50 mm/s ( 160 Hz )

Point

Unit cm/s

Range 0.05 to 19.99 cm/s

Resolution 0. 01 cm/s

Accuracy ± ( 5 % + 2 d ) reading

@ 160 Hz, 80 Hz, 23 ± 5 ℃

Calibration 50 mm/s ( 160 Hz )

Point

Unit inch/s

Range 0.02 to 7.87 inch/s

Resolution 0.01 inch/s

Accuracy ± ( 5 % + 2 d ) reading

@ 160 Hz, 80 Hz, 23 ± 5 ℃

Calibration 50 mm/s ( 160 Hz )

Point

Remark :

RMS : To measure the true RMS value.

Peak : To measure and update the peak value.

Max. Hold : To measure and update the max. peak value.

7

Displacement ( p-p, Max Hold p-p )

Unit mm

Range 1.999 mm

Resolution 0.001 mm

Accuracy ± ( 5 % + 2 d ) reading

@ 160 Hz, 80 Hz, 23 ± 5 ℃

Calibration 0.141 mm ( 160 Hz )

Point

Unit inch

Range 0.078 inch

Resolution 0.001 inch

Accuracy ± ( 5 % + 2 d ) reading

@ 160 Hz, 80 Hz, 23 ± 5 ℃

Calibration 0.141 mm ( 160 Hz )

Point

Remark :

p-p :

To measure the Peak to Peak value.

Max. Hold p-p :

To measure and update the max. Peak to Peak value.

@ Above specification tests under the environment RF Field Strength

less than 3 V/M & frequency less than 30 MHz only.

8

3. FRONT PANEL DESCRIPTION

Fig. 1

9

3-1 Display

3-2 Power Button ( Backlight Button )

3-3 Hold Button

3-4 REC Button

3-5 ACC/VEL/DISP Button ( Button ) ▲

3-6 SET Button ( Time Button )

3-7 FUNCTION Button ( Button )▼

3-8 LOG Button ( ENTER Button )

3-9A CH1 VB-83 Input Socket

3-9B CH2 VB-83 Input Socket

3-9C CH3 VB-83 Input Socket

3-9D CH4 VB-83 Input Socket

3-10 SD Card Socket

3-11 RS-232 Output Terminal

3-12 Reset Button

3-13 DC 9V Power Adapter Input Socket

3-14 Battery Compartment/Cover

3-15 Battery Cover Screws

3-16 Stand

3-17 Magnetic Base

3-18 Vibration Sensor

3-19 Input Socket of Vibration Sensor

3-20 Mini Plug of Cable

3-21 Sensor Cable

3-22 Cable BNC Plug

3-23 BNC Socket of VB-83 module

3-24 Plug of VB-83 module

10

4. MEASURING PROCEDURE

4-1 Preparation

1)Install the vibration sensor set

The complete vibration set are :

1. Vibration Sensor, 3-18, Fig 2

2. Sensor Cable, 3-21, Fig. 2

3 VB-83 module, 3-24, Fig. 2

* Plug in the " Cable BNC Plug "

( 3-22, Fig. 2 ) to the " BNC

Socket of VB-83 module "

( 3-23, Fig. 2 ).

* Plug in the " Mini plug of cable "

( 3-20, Fig. 2 ) to the " Input

socket of vibration sensor " (

3-19, Fig. 2 ).

Plug in the " Plug of VB-83

module " ( 3-24, Fig. 2 ) to the "

CH1 VB-83 Input Socket "

( 3-9A, Fig. 1 ). If you have extra

vibration sensor set, then Plug

in to the " CH2/CH3/CH4 VB-83

Input Socket " ( 3-9B, 3-9C, 3-9D Fig. 2

Fig. 1 )

Remark

:

Extra vibration sensor set, VB-83 can be ordered.

When change the VB-83, it is not necessary to make

calibration again due to the vibration detail calibration

information already save into the " VB-83 module "

(

3-24, Fig. 2

)

11

2)1)Power on the meter by pressing the " Power button "

( 3-2, Fig. 1 ) > 3 seconds continuously.

* After already power on the meter, pressing the

" Power button " > 3 seconds continuously will

turn off the meter.

The " Display " ( 3-1, Fig. 1 ) will show the 4 channels

vibration value ( CH1, CH2, CH3, CH4 ) at the same time.

If some channels not plug in the VB-83 Vibraion set,

then the corresponding cahannel Display will show

" - - - - ".

Remark :

1.

If the surface material of measuring article is not

the ferrous material, hold the vibration sensor by

hand & touch the sensor to the surface of the

measuring article,

*

If the surface material of measuring article is the

ferrous material, connect " Vibration sensor " (

3-18, Fig. 2 ) with the " Magnetic base " ( 3-17, Fig.

2 ). Put the whole unit ( Vibration sensor &

Magnetic base ) to the surface of measuring article.

*

Please do not use the finger or hand to touch the

the " Sensor cable " ( 3-21, Fig. 1 ).

4-2 Unit selection ( Acc./Velocity/Displacement

selection )

Select the desired display unit by pressing the

" ACC/VEL/DISP Button " ( 3-5, Fig. 1 ) > 3 seconds (

not release the button ), the Display will show the

following units according Acceleration / Velocity /

Displacement in sequence.

12

Measurement Unit

Acceleration

Metric unit

m/s^2, g

* LCD show " ACC "

Imperial unit

ft/s^2

Velocity

Metric unit

mm/s, cm/s

* LCD show " VEL. "

Imperial unit

inch/s

Displacement

Metric unit

mm

* LCD show " DISP p-p"

Imperial unit

inch.

ACC m/s^2

ACC g Metric

unit

VEL mm/s

VEL cm/s

DISP p-p mm

--------------------------------------------------------------------

ACC ft/s^2

Imperial

VEL inch/s unit

DISP p-p inch.

Remark :

1. For the Acceleration measurement, the Display will

show the indicator " ACC "

2. For the Velocity measurement, the Display will show

the indicator " VEL. "

3. For the Displacement measurement, the Display will

show the indicator " DISP p-p "

4. For general applications of industrial vibration

monitoring, select " Velocity " or " Acceleration " typically.

5. After select the unit will be saved into the circuit with default.

13

4-3 Function selection

Select the desired function ( RMS, Peak, Max HOLD )

by pressing the " Function Button " ( 3-7, Fig. 1 ).

continuously ( not release the button ), until the

Display will show the desiring function ( RMS, Max

HOLD, Peak ) , then release the " Function

Button " ( 3-7, Fig. 1 ).

Remarks :

1. RMS measurement is intend to measure and

root means square ( RMS ) value.

a. Available for Acceleration, Velocity only

When the select to the unit of Acceleration or Velocity,

b. The Display will show the indicator " RMS ".

c. Typically, for Acceleration and Velocity measurement

always select the RMS measurement.

2. Max HOLD measurement is intend to measure and

update the max. peak value.

a. Available for Acceleration, Velocity, Displacement

measurement.

b. The Display will show the indicator " Max HOLD ".

3. Peak measurement is intend to measure the

peak vibration value.

a. Available for Acceleration, Velocity measurement only.

b. The Display will show the indicator " Peak ".

4. After select the Function will be saved into the circuit with

default.

14

4-4 Zero adjustment, Max hold reset procedures

Zero adjustment procedures

Due to drift of environment temperature value, battery

power change, meter used for a long time or other

reasons. The display value may exist not zero value ( few

digits ) in case of no signal into the " Vibration Sensor ".

General speaking those not zero value will not effect the

measurement typically. However if intend to make the

precision measurement, the following zero adjustment

procedures should be executed as :

1)Vibration sensor set, VB-83 is ready, connect the " Plug of

VB-83 module " ( 3-24, Fig. 1 ) to the " CH1, CH2,

CH3, CH4 VB-83 Input Socket " ( 3-9A, B, C, D, Fig. 1 ).

2)Select the measurement to the " Acceleration "

3)Keep the vibration sensor motionless, no signal into

the vibration sensor.

4)Under Acc./Velocity/Displacement measurement if press the

" Button " ( 3-5, Fig. 1 ) and " Button " ( 3-7, Fig. 1 )▲▼

together > 3 seconds, then the " CH1 " symbol will flasing.

* Press the " SET Button " ( 3-6, Fig. 1 ) to select the

channel no. ( CH2, CH3, CH4 ), after the exact

channel is selected, the channel no. will flashing .

Press " Enter Button " ( 3-8, Fig. 1 ) to let the display reach

zero value according the selected channle no. ( flashing ).

5)The zero adjustment can be execute only

the display value show the no. less than 10 digits.

Max hold reset procedures

Under execute the Max Hold function if press the " ▲

Button " ( 3-5, Fig. 1 ) and " Button " ( 3-7, Fig. 1 )▼

together > 3 seconds, then the " CH1 " symbol will flasing.

15

* Press the " SET Button " ( 3-6, Fig. 1 ) to select the

channel no. ( CH2, CH3, CH4 ), after the exact

channel is selected, the channel no. will flashing .

Press " Enter Button " ( 3-8, Fig. 1 ) to clear the existing

Max hold value according the selected channle no. ( flashing ).

4-5 Data Hold

During the measurement, press the " Hold Button " ( 3-3,

Fig. 1 ) once will hold the measured value & the LCD will

display a " HOLD " symbol.

Press the " Hold Button " once again will release the data

hold function.

4-6 Data Record ( Max., Min. reading )

1)The data record function records the maximum and

minimum readings. Press the " REC Button " ( 3-4,

Fig. 1 ) once to start the Data Record function and

there will be a " REC " symbol on the display.

2)With the " REC " symbol on the display :

a)Press the " REC Button " ( 3-4, Fig. 1 ) once, the

" REC MAX " symbol along with the maximum value

will appear on the display.

b)Press the " REC Button " ( 3-4, Fig. 1 ) again, the

" REC MIN " symbol along with the minimum value

will appear on the display.

c) Press the " REC Button " ( 3-4, Fig. 1 ) again,

the the " MIN " symbol will be appeared, LCD only

show the " REC " symbol, the meter start the Data

Record function again.

3)To exit the memory record function, just press the "

REC Button " ( 3-4, Fig. 1 ) > 3 seconds

continuously. The display will revert to the current

reading.

4-7 LCD Backlight ON/OFF

1)After power ON, the " LCD Backlight " will light

automatically. During the measurement, push the

" Backlight Button " ( 3-2, Fig. 1 ) once will turn

OFF the " LCD Backlight ".

2)Push the " Backlight Button " once again will turn

ON the " LCD Backlight " again.

16

5. DATALOGGE

R

5-1 Preparation before execute datalogger function

a. Insert the SD card

Prepare a " SD memory card " ( 1 G to 16 G, optional ),

insert the SD card into the " SD card socket " ( 3-10, Fig. 1).

The front panel of the SD card should face against the

the down case.

* It recommend use memory card's capacity is 4 GB.≦

b. SD card Format

If SD card just the first time use into the meter, it

recommend to make the " SD card Format " at first. ,

please refer chapter 7-6 ( page 25 ).

* It recommend strongly, do not use memory cards

that have been formatted by other meter or by

other installation ( such as camera... ). Reformat

the memory card with your meter.

* If the SD memory card exist the trouble during

format by the meter, use the Computer to

reformat again can fix the problem.

c. Time setting

If the meter is used at first time, it should to adjust the

clock time exactly, please refer chapter 7-1 ( page 23 ).

d. Decimal fo

r

The numerical data structure of SD card is

default used the " . " as the decimal, for

example "20.6" "1000.53" . But in certain

countries ( Europe ...) is used the " , " as the

decimal point, for example " 20, 6 "

"1000,53". Under such situation, it should

change the Decimal character at first, details

of setting the Decimal point, refer to Chapter

7-2, page 25.

17

5-2 Auto Datalogger ( Set sampling time 1 second )≧

a. Start the datalogger

Press the " LOG Button ( 3-8, Fig. 1 ) > 3 seconds

continuously, the lower LCD will show the " LOGGER "

indicator and flashing per sampling time, at the same

time the measuring data along the time information will

be saved into the memory circuit.

Remark :

*

How to set the sampling time, refer to Chapter 7-2,

page 24.

*

How to set the beeper sound is enable, refer to

Chapter 7-4, page 24.

b. Pause the datalogger

During execute the Datalogger function, if press the

" LOG Button " ( 3-8, Fig. 1 ) once will pause the

Datalogger function ( stop to save the measuring data

into the memory circuit temporally ). In the same time

the the " LOGGER " will be no flashing.

Remark :

If press the " LOG Button " ( 3-8, Fig. 1 ) once again

will execute the Datalogger again, the bottom text of

" LOOGER " will flashing.

c. Finish the Datalogger

During execute the Datalogger function, press the

" LOG Button ( 3-8, Fig. 1 ) > 3 seconds continuously

again will finish the Datalooger function, the " LOGGER "

indicator will be disappeared and finish the Datalogger.

function.

18

5-3 Manual Datalogger ( Set sampling time = 0

second )

a. Set sampling time is to 0 second

Press the " LOG Button ( 3-8, Fig. 1 ) once , the low LCD

will show the indicator " LOGGER ", then press the " LOG

Button " ( 3-8, Fig. 1 ) once, the bottom indicator "

LOGGER " will flashing once and Beeper will sound once,

at the same time the measuring data along the time

information will be saved into the memory circuit. The lower

Display will show the Position ( Location ) no. and saved

into the SD card too.

Remark :

During execute the Manual Datalogger, it can use the " ▲

Button " ( 3-5, Fig. 1) or " Button " ( 3-7, Fig. 1 ) to▼

set the measuring position ( 1 to 99, for example room 1

to room 99 ) to identify the measurement location , the

lower Display will show P x ( x = 1 to 99 ).

( x = 1 to 99 ).

b. Finish the Datalogger

During execute the Datalogger function, press the

" LOG Button ( 3-8, Fig. 1 ) > 3 seconds continuously

again will finish the Datalooger function, the " LOGGER "

indicator will be disappeared and finish the Datalogger.

function.

5-4 Check time information

During the normal measurement ( not execute the

Datalogger ), If press " Clock Button " ( 3-6, Fig. 1 ) )

once , the lower LCD display will present the time

information of Year/Month, Date/Hour, Minute/Second

and the Sampling time information in sequence.

19

5-5 SD Card Data structure

1) When the SD card is used into the meter, the SD card

When the first time, the SD card is used into the meter,

the SD card will generate a folder :

VBC01

2)If the first time to execute the Datalogger,

under the route VBC01\, will generate a new

file name VBC01001.XLS.

After exist the Datalogger, then execute again,

the data will save to the VBC01001.XLS until

Data column reach to 30,000 columns, then

will generate a new file, for example VBC01002.XLS

3)Under the folder VBC01\, if the total files more

than 99 files, will generate anew route, such as

VBC02\ ........

4)The file's route structure :

VBC01\

VBC01001.XLS

VBC01002.XLS

.....................

VBC01099.XLS

VBC02\

VBC02001.XLS

VBC02002.XLS

.....................

VBC02099.XLS

VBCXX\

.....................

.....................

Remark :

XX : Max. value is 10.

20

6. Saving data from the SD card

to the computer ( EXCEL software )

1)After execute the Data Logger function, take away the

SD card out from the " SD card socket " ( 3-10, Fig. 1 ).

2)Plug in the SD card into the Computer's SD card slot

( if your computer build in this installation ) or

insert the SD card into the " SD card adapter ". then

connect the " SD card adapter " into the computer.

3)Power ON the computer and run the " EXCEL software ".

Down load the saving data file ( for example the file

name : VBC01001.XLS, VBC01002.XLS ) from the SD

card to the computer. The saving data will present into

the EXCEL software screen ( for example as following

EXCEL data screens ) , then user can use those EXCEL

data to make the further Data or Graphic analysis

usefully.

EXCEL data screen ( for example )

21

EXCEL graphic screen ( for example

)

7. ADVANCED SETTING

Under do not execute the Datalogger function,

press the " SET Button " ( 3-6, Fig. 1 ) continuously at

least 3 seconds will enter the " Advanced Setting " mode.

then press the " SET Button " (3-6, Fig. 1 ) once a while

in sequence to select the eight main function, the lower

display will show :

dAtE.....

.

Set clock time ( Year/Month/Date, Hour/Minute/

Second )

SP-t......Set sampling time

PoFF.....Auto power OFF management

bEEP....

.

Set beeper sound ON/OFF

dEC......

.

Set SD card Decimal character

Sd F..... SD memory card Format

unit......

.

Set Metric/Imperial unit

22

Remark :

During execute the " Advanced Setting " function, if

press " SET Button " ( 3-6, Fig. 1 ) > 3 seconds will exit

the " Advanced Setting " function, the LCD will return to

normal screen.

7-1 Set clock time ( Year/Month/Date,

Hour/Minute/ Second )

When the lower display show " dAtE "

1)Use the " Button " ( 3-5, Fig. 1 ) or " Button " ▲▼

( 3-7, Fig. 1 ) to adjust the value ( Setting start from

Year value ). After the desired value is set, press the

" Enter Button " ( 3-8, Fig. 1 ) once will going to

next value adjustment ( for example, first setting

value is Year then next to adjust Month, Date, Hour,

Minute, Second value ).

Remark :

The adjusted value will be flashed.

2)After set all the time value ( Year, Month, Date, Hour,

Minute, Second ), press the " ENETER Button " ( 3-8,

Fig. 1 ) once will save the time value.

Remark :

After the time value is setting, the internal clock will

run precisely even Power off if the battery is under

normal condition ( No low battery power ).

23

7-2 Set sampling time ( SecondS )

When the lower display show " SP-t "

1)Use the " Button " ( 3-5, Fig. 1 ) or " Button " (▲▼

3-7, Fig. 1 ) to adjust the value ( 0, 1, 2, 5, 10, 30,60,

120, 300, 600, 1800,3600 seconds ).

2)After the Sampling value is selected, press the

" Enter Button " ( 3-8, Fig. 1 ) will save the setting

function with default.

7-3 Auto power OFF management

When the lower display show " PoFF "

1)Use the " Button " ( 3-5, Fig. 1 ) or " Button " ▲▼

( 3-7, Fig. 1 ) to select the upper value to " yES " or

" no ".

yES - Auto Power Off management will enable.

no - Auto Power Off management will disable.

2)After select the upper text to " yES " or " no ", press the

" ENTER Button " ( 3-8, Fig. 1 ) will save the setting

function with default.

7-4 Set beeper sound ON/OFF

When the lower display show " bEEP "

1)Use the " Button " ( 3-5, Fig. 1 ) or " Button " ▲▼

( 3-7, Fig. 1 ) to select the upper value to " yES " or

" no ".

24

yES - Meter's beep sound will be ON with default.

no - Meter's beep sound will be OFF with default.

is power ON.

2)After select the upper text to " yES " or " no ", press the

" ENTER Button " ( 3-8, Fig. 1 ) will save the setting

function with default.

7-5 Decimal point of SD card setting

The numerical data structure of SD card is default used

the " . " as the decimal, for example "20.6" "1000.53" .

But in certain countries ( Europe ...) is used the " , " as

the decimal point, for example " 20,6 " "1000,53".

Under such situation, it should change the Decimal

character at first.

When the lower display show " dEC "

1)Use the " Button " ( 3-5, Fig. 1 ) or " Button " ▲▼

( 3-7, Fig. 1 ) to select the upper text to " USA " or

" Euro ".

USA - Use " . " as the Decimal point with default.

Euro - Use " , " as the Decimal point with default.

2)After select the upper text to " USA " or " Euro ",

press the " ENTER Button " ( 3-8, Fig. 1 ) will save the

setting function with default.

7-6 SD memory card Format

When the lower display show " Sd F "

1)Use the " Button " ( 3-5, Fig. 1 ) or " Button " (▲▼

3-7, Fig. 1 ) to select the upper value to " yES " or

" no ".

25

yES - Intend to format the SD memory card

no - Not execute the SD memory card format

2)If select the upper to " yES ", press the " Enter Button

" ( 3-8, Fig. 1 ) once again, the Display will show text

" yES Enter " to confirm again, if make sure to do the

SD memory card format, then press " Enter Button "

once will format the SD memory clear all the existing

data that already saving into the SD card.

7-7 Set Metric/Imperial unit

When the lower display show " unit "

1)Use the " Button " ( 3-5, Fig. 1 ) or " Button " ▲▼

( 3-7, Fig. 1 ) to select the LCD symbol " m/s^2 "

or " ft/s^2 ".

m/s^2 - Meter will measure under " Metric " unit

f/s^2 - Meter will measure under " Imperial " unit

2)After select the symbol tp " m/s^2 " or " ft/s^2 ",

press '" ENTER Button " ( 3-8, Fig. 1 ) will save the setting

function with default.

8. POWER SUPPLY from DC

ADAPTER

The meter also can supply the power supply from the

DC 9V Power Adapter ( optional ). Insert the plug of

Power Adapter into " DC 9V Power Adapter Input Socket

" ( 3-13, Fig. 1 ). The meter will permanent power ON

when use the DC ADAPTER power supply ( The power

Button function is disable ).

26

9. BATTERY REPLACEMENT

1)When the left corner of LCD display show " ", it

is necessary to replace the battery. However, in-spec.

measurement may still be made for several hours after

low battery indicator appears before the instrument

become inaccurate.

2)Loose the screws of the " Battery Cover Screws " ( 3-15,

Fig. 1 ) and take away the " Battery Cover " ( 3-14, Fig. 1 )

from the instrument and remove the battery.

3)Replace with DC 1.5 V battery ( UM3, AA,

Alkaline/heavy duty ) x 8 PCs, and reinstate the cover.

4)Make sure the battery cover is secured after changing

the battery.

10. SYSTEM RESET

If the meter happen the troubles such as :

CPU system is hold ( for example, the key button can

not be operated... ).

Then make the system RESET will fix the problem.

The system RESET procedures will be either following

method :

During the power on, use a pin to press the " Reset

Button " ( 3-12, Fig. 1 ) once a while will reset the

circuit system.

11. RS232 PC SERIAL INTERFACE

The instrument has RS232 PC serial interface via a 3.5

mm terminal ( 3-11, Fig. 1 ).

27

The data output is a 16 digit stream which can be

utilized for user's specific application.

A RS232 lead with the following connection will be

required to link the instrument with the PC serial port.

Meter PC

(9W 'D" Connector)

Center Pin..........................Pin 4

(3.5 mm jack plug)

Ground/shield......................

.

Pin 2

2.2 K

resistor

Pin 5

The 16 digits data stream will be displayed in the

following format :

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

Each digit indicates the following status :

D15 Start Word

D14 4

D13 Function : CH1, CH2, CH3, CH4

When send the CH1 value, D13 = 1

When send the CH2 value, D13 = 2

When send the CH3 value, D13 = 3

W

h

en send the CH4 value, D13 = 4

D12, D11 Annunciator for Display

= 92 = 97

mm/s = 93 cm/s = 95 inch/s = 98

mm = 94 inch = 96 g = 57

D10 0

D9 Decimal Point(DP), position from right to the

left.

0 = No DP, 1= 1 DP, 2 = 2 DP, 3 = 3 DP

28

D8 to D1 Display reading, D1 = LSD, D8 = MSD

For example :

If the display reading is 1234, then D8 to

D1 is : 00001234

D0 End Word

RS232 FORMAT : 9600, N, 8, 1

Baud rate 9600

Parity No parity

Data bit no. 8 Data bits

Stop bit 1 Stop bit

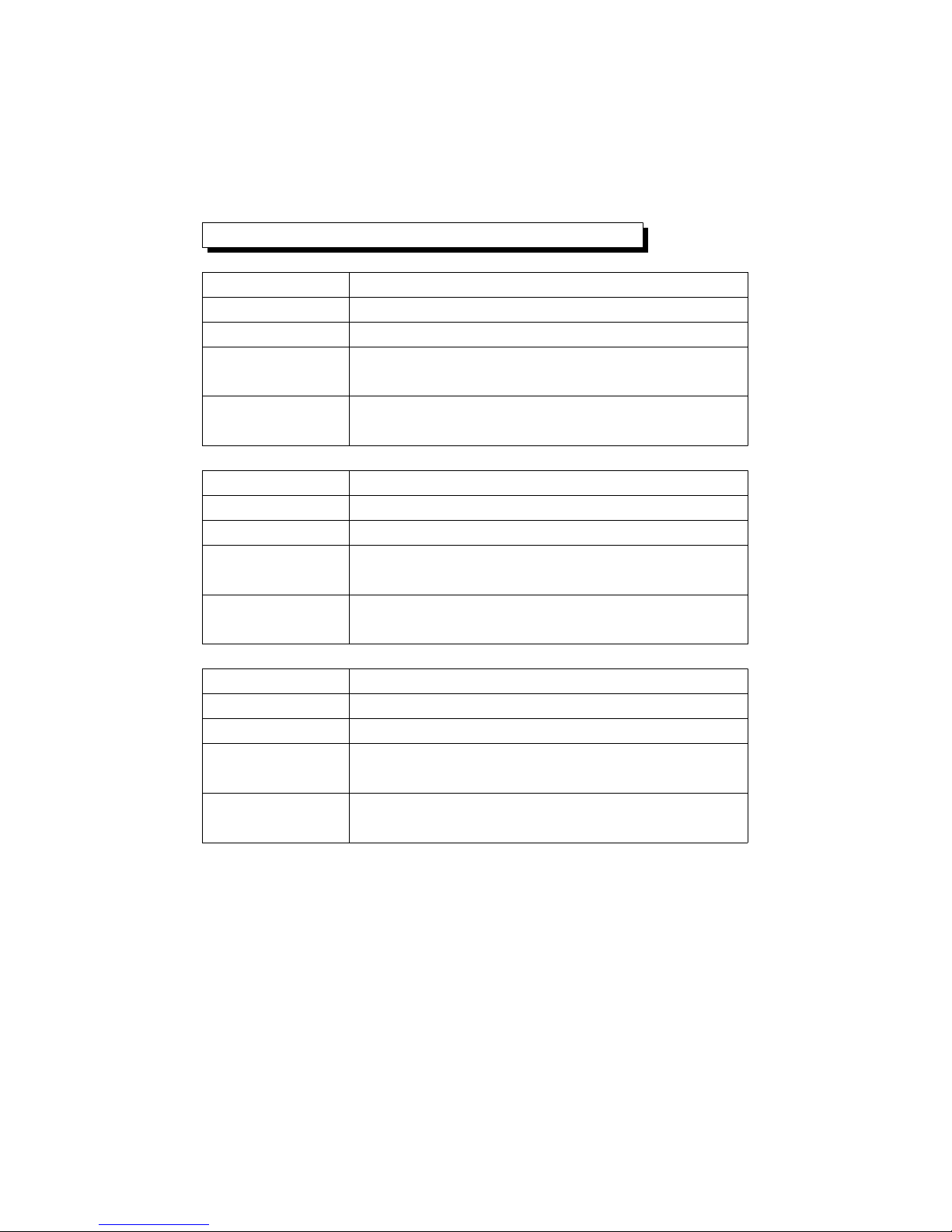

12. CLASSIFICATION RANGES

For the valuation of machines and equipment in the ISO

2372 and VDI 2056, four different kinds of machine groups

with four classification ranges and their limits for vibration

severity ( mm/s ) are determined.

The classifications for each machine group are specified as

follows :

Small machines, especially production electrical

motors of up to 15 KW ( Group K )

Good 0 to 0.71 mm/s

Acceptable 0.72 to 1.80 mm/s

Still permissible 1.81 to 4.5 mm/s

Dangerous > 4.5 mm/s

Medium sized machines, especially electrical

motors with 15 up to 75 KW output, without

special foundations ( Group M )

Good 0 to 1.12 mm/s

Acceptable 1.13 to 2.80 mm/s

Still permissible 2.81 to 7.1 mm/s

Dangerous > 7.1 mm/s

29

Large machines on heavy foundations ( Group G )

Good 0 to 1.80 mm/s

Acceptable 1.81 to 4.50 mm/s

Still permissible 4.51 to 11.2 mm/s

Dangerous > 11.2 mm/s

Largest machines and turbo machines with a

special foundations ( Group T ).

Good 0 to 2.80 mm/s

Acceptable 2.81 to 7.10 mm/s

Still permissible 7.11 to 18.0 mm/s

Dangerous > 18 mm/s

13. SENSITIVITY RELATIVE to the

reference sensitivity at 80 Hz ,

according ISO 2954

Frequency Normal Relative sensitivity

value Minimum Maximum

value value

10 Hz 1.0 0.8 1.1

20 Hz 1.0 0.9 1.1

40 Hz 1.0 0.9 1.1

80 Hz 1.0 1.0 1.0

160 Hz 1.0 0.9 1.1

500 Hz 1.0 0.9 1.1

1000 Hz 1.0 0.8 1.1

Table 1

30

14. PATENT

The meter ( SD card structure ) already

get patent or patent pending in following

countries :

Germany

JAPAN Nr. 20 2008 016 337.4

TAIWAN 3151214

M 358970

CHINA M 359043

ZL 2008 2 0189918.5

USA ZL 2008 2 0189917.0

Patent pending

31

Loading...

Loading...