Page 1

1 2

PCE-PCM 3 Digital Clamp Meter

1. Safety information ............................................. 3

1.1 Preparation ............................................. 3

1.2 Use ......................................................... 4

1.3 Mark........................................................ 5

1.4 Maintenance ........................................... 5

2. Description ........................................................ 6

2.1 Name of parts ......................................... 7

2.2 Descriptions of switch, button and input

jack ............................................................... 8

2.3 LCD display .......................................... 10

3. Specification.................................................... 11

3.1 General ................................................. 12

3.2 Technical specifications ........................ 12

3.2.1 Alternating current ..................... 13

3.2.2 Inrush current ............................ 13

3.2.3 DC voltage ................................ 13

3.2.4 AC voltage ................................. 14

3.2.5 Frequency ................................. 14

3.2.6 Duty ratio ................................... 16

PCE Americas Inc.

1201 Jupiter Park Drive

Suite 8

Jupiter

FL-33458

USA

From outside US: +1

Tel: (561) 320-9162

Fax: (561) 320-9176

info@pce-americas.com

PCE Instruments UK Ltd.

Unit 11

Southpoint Business Park

Ensign way

Hampshire / Southampton

United Kingdom, SO31 4RF

From outside UK: +44

Tel: (0) 2380 98703 0

Fax: (0) 2380 98703 9

info@pce-instruments.co.uk

www.pce-instruments.com/english

www.pce-instruments.com

Page 2

3 4

3.2.7. Resistance ................................ 16

3.2.8 Circuit continuity test ................. 17

3.2.9. Capacitance .............................. 17

3.2.10 Diode test ................................ 17

3.2.11 Single-phase active power ....... 18

3.2.12 Single-phase apparent power .. 18

3.2.13 Single-phase reactive power ... 19

3.2.14 Power factor ............................ 19

3.2.15 Harmonics measurement......... 19

4 Operation Guide ............................................... 19

4.1 Reading holding .................................... 19

4.2 Manual range ........................................ 20

4.3 Switchover of frequency and duty ratio . 20

4.4 Selection of maximum/minimum value

measurement .............................................. 21

4.5 Function switching ................................ 21

4.6 Measurement of relative value .............. 22

4.7 LINK measurement ............................... 22

4.9 ▼function .............................................. 23

4.10 ▲function ........................................... 23

4.11 INRUSH measurement ....................... 24

4.12 Back-light and clamp lighting .............. 24

4.13 Automatic shutdown............................ 25

4.14. Measurement preparation .................. 25

4.15 AC current measurement .................... 25

4.16. Voltage measurement ........................ 27

4.17 Measuring frequency and duty ratio.... 28

4.18 Resistance measurement ................... 31

4.19 Diode test ........................................... 32

4.20 Circuit continuity test........................... 33

4.21 Capacitance measurement ................. 34

4.22 Measurement of inrush current ........... 35

4.23 NCV measurement ............................. 36

4.24 Active power measurement ................ 37

4.25 Apparent power measurement ............ 39

4.26 Power factor measurement ................. 41

4.27 Phase angle measurement ................. 42

4.28 Harmonics measurement (voltage signal)

Page 3

5 6

.................................................................... 44

4.29 Harmonics measurement (current signal)

.................................................................... 46

5 Maintenance ..................................................... 47

5.1 Battery replacement .............................. 47

5.2 Probe replacement ................................ 48

6 Attachments ..................................................... 48

1. Safety information

Warning

Please pay special attention when using this

meter, improper use may result in electric

shock or damage to the meter. Please follow

the common safety rules, and fully comply

with the safety precautions specified in the

user manual.

To make full use of the meter, and ensure safe

operation, please read carefully and follow the

application methods in this specification.

This meter conforms to GB/T 13978-92: Generic

Specification for Digital Multi-meters, GB4793.11995 (IEC-61010-1, IEC-61010-2-032): Safety

Requirements of Electronic Measuring Instrument.

It causes secondary pollution, and the over-voltage

standard is CAT IV 600 V and CAT III 1,000 V.

Please abide by the safe operation guidance to

ensure the safety use of the meter. Appropriate use

and protection of the meter will bring you

satisfactory service.

1.1 Preparation

1.1.1 The users must comply with the following

safety regulations when using the meter:

- General electric shock protection

- Prevent the misuse of the meter

1.1.2 After receiving the meter, check whether it is

damaged in the transportation.

Page 4

7 8

1.1.3 Check and verify whether the meter is

damaged after being stored and shipped in poor

condition.

1.1.4 The probe must be in good condition. Check

whether the insulation of the probe is broken and

the metal wire of the conductor is exposed before

using.

1.1.5 The probe provided with the meter can ensure

the safe use, and it must be replaced with the same

probe or the probe of the same grade, if necessary.

1.2 Use

1.2.1 You must use the meter according to

requirements of correct functions and measuring

range.

1.2.2 Do not exceed the indicated value of

protection scope of each measuring range during

the measurement.

1.2.3 Do not touch the top of the probe when the

meter is connected for measuring the circuit.

1.2.4 During the measurement, if the measured

voltage is higher than 60V DC or 30 V AC (effective

value), you should keep your fingers behind the

probe protector all the time.

1.2.5 Do not measure the voltage when the AC

voltage between the measuring terminal and the

ground is greater than 750 V.

1.2.6 Select the highest range of the manual range

if you don't know the measured value in advance.

1.2.7 Remove the probe from the measured circuit

before rotating the change-over switch to change

the measuring function.

1.2.8 Do not perform the live line measurement for

the resistance, capacitance, diodes and circuit

continuity.

Page 5

9 10

1.2.9 Do not connect the meter to the voltage source

during the current, resistance, capacitance, diodes

and circuit continuity test.

1.2.10 Do not measure the capacitance before the

capacitor is fully discharged.

1.2.11 Do not use this meter near the explosive gas,

steam or dust.

1.2.12 In case of any abnormality or fault, please

stop using the meter.

1.2.13 Do not use this meter, unless the bottom

case and the battery cover are fully fastened in situ.

1.2.14 Do not store or use this meter in direct

sunlight, high temperature, or high humidity.

1.3 Mark

Note (See the operation manual for the important

safety information)

It can be used for dangerous energized

conductors.

Double insulation protection (CAT II)

CAT III complies with the over-voltage

(installation) class III of IEC-61010-1, and the

pollution level 2 refers to the level of the pulse

withstand voltage protectionprovided.

Conform to the European Union (EU) Standard

Grounding

1.4 Maintenance

1.4.1 Do not try to open the bottom case of the

meter for adjustment or repair. These operations

can only be performed by the technicians who

understand the meter and the shock hazard

adequately.

Page 6

11 12

1.4.2 Please remove the probe from the measured

circuit before opening the bottom case or the battery

cover of the meter.

1.4.3 In order to avoid the electric shock caused by

the incorrect reading, when the meter displays "

"replace the battery immediately.

1.4.4 Use wet cloth and mild detergent to clean the

meter, and do not use the abrasive or solvent.

1.4.5 Turn off the power of meter when you don't

use it, rotate the range switch to the OFF gear.

1.4.6 Take off the battery to prevent the damage to

the meter, if you do not use it for a long time.

2. Description

- PCE-PCM 3 single-phase clamp-type harmonic

power meter is hand-type intelligent power

measuring meter, which combines the digital

multimeter and power measurement with Bluetooth

function. The range switch with one-handed

performance is convenient for the measurement,

and this meter can perform the functions of overload

protection and low battery indicator.

- The meter can be used for the measurement of the

alternating current, alternating voltage, direct

voltage, frequency, duty ratio, resistance and

capacitance and circuit continuity, diode test, noncontact voltage detection, as well as the

measurement of the active power, reactive power,

apparent power, power factor, harmonics

measurement and phase angle measurement.

- The meter supports the auto range and manual

range.

Page 7

13 14

- The meter supports reading holding.

- The meter supports maximum measurement.

- The meter supports minimum measurement.

- The meter supports relative measurement.

- The meter supports Bluetooth.

- The meter supports data storage.

- The meter supports back-light and clamp lamp.

- The meter supports automatic shutdown.

- The meter supports low voltage indicator.

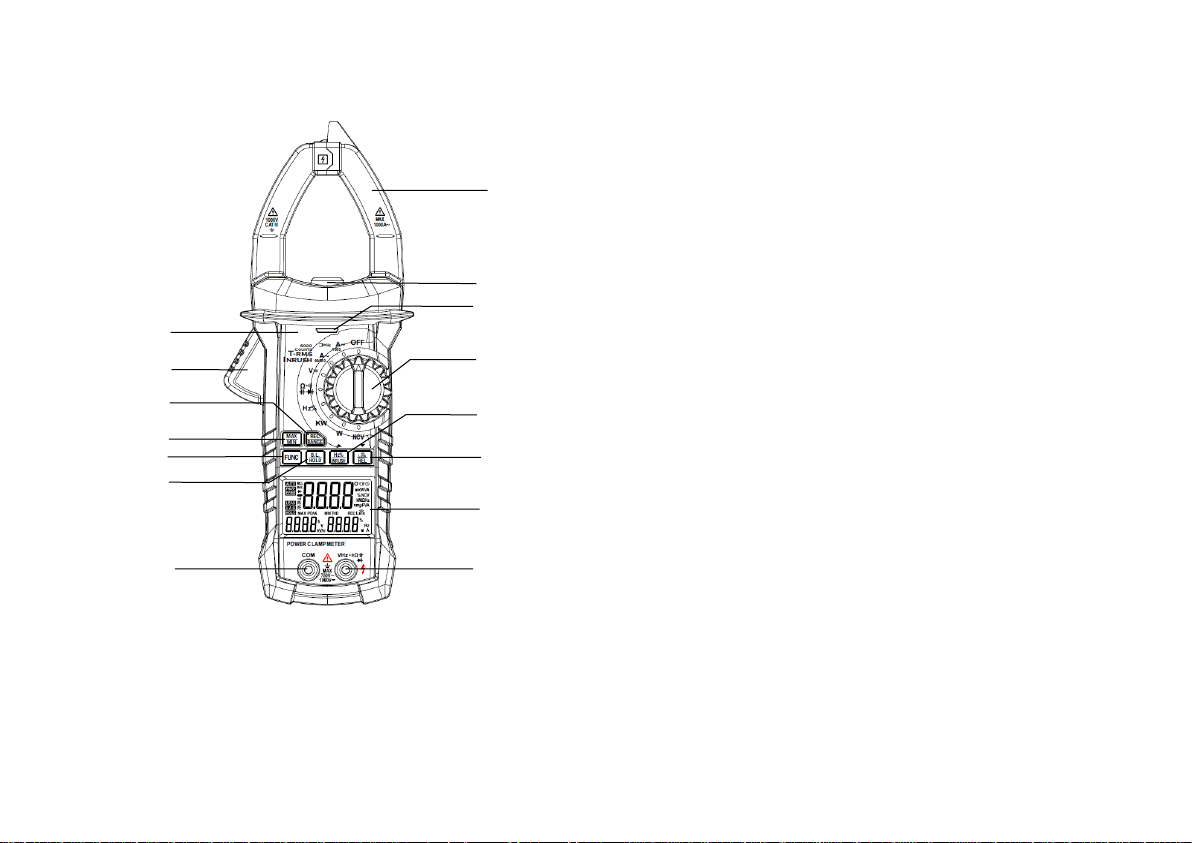

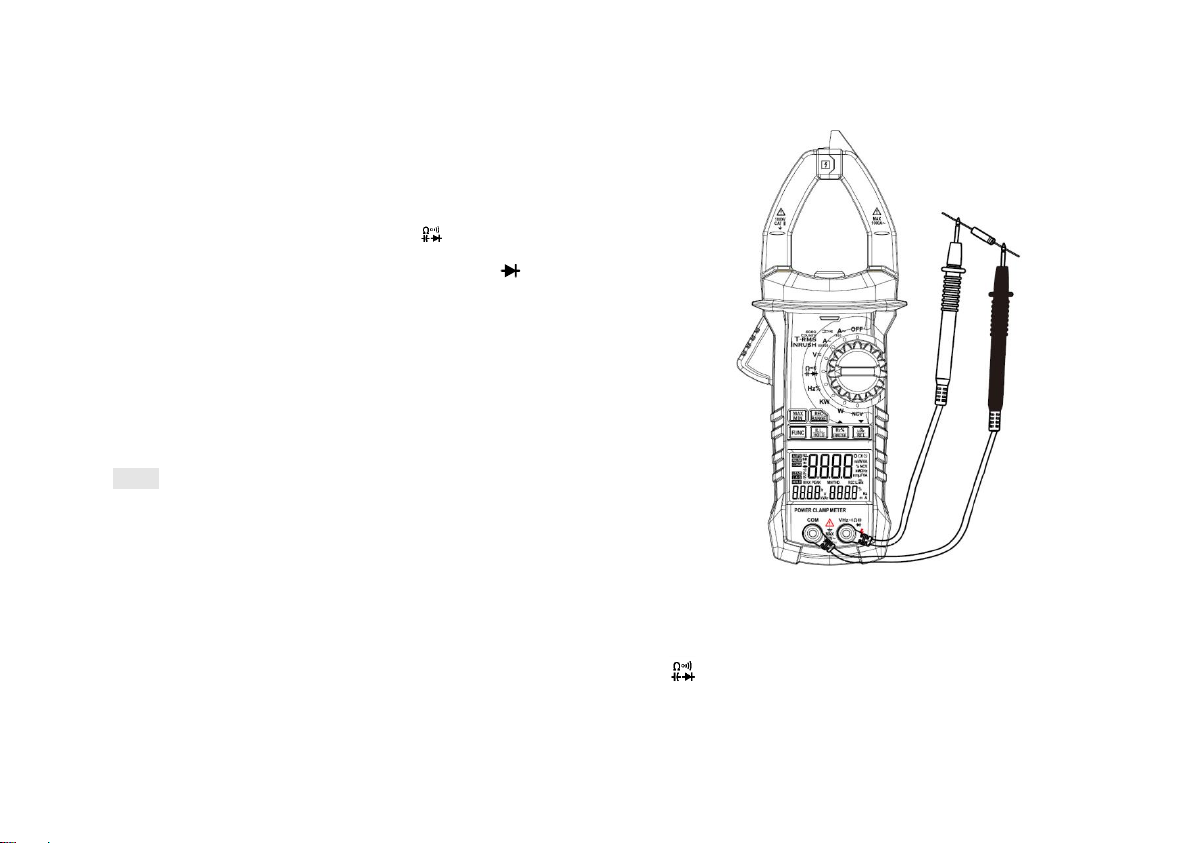

2.1 Name of parts

(1) Current clamp: for current measurement.

(2) Clamp lamp

(3) Faceplate

(4) Trigger

(5) Button for data storage and switch of auto and

manual range

(6) Button for maximum/minimum selection

(7) Button for function switch

(8) Button for reading holding/back-light

(9) Button for frequency and duty ratio

measurement, inrush current and up

(10) Button for Bluetooth function, relative

measurement and down

(11) Change-over switch

(12) NCV indicator light

(13) LCD display

(14) Input jack of resistance, capacitance, voltage,

frequency, diode and continuity.

(15) Jack of common terminal

Page 8

15 16

2.2 Descriptions of switch, button and input jack

FUNC button: for switching the measurement

function.

B.L/HOLD button: the readings will be held by the

short press, and the back-light will be turned on by

long press. The back-light and clamp lamp will be

turned on at the same time by pressing the

B.L/HOLD button in the current gear and in the

power gear on the current interface.

REC/RANGE button: short press for switching

between auto and manual range mode, and long

press for data storage.

1

2

3

4

5 6 7

8 9 10

11

12

13

14

15

Page 9

17 18

LINK/REL/▼ button

1)Long press for validating Bluetooth in all gears.

2)Short-press in the harmonic measurement

interface at KW and W gears to scroll down, and to

switch between the 1st harmonic and 20th harmonic.

At the KW and W gears, short-press the function key

in the maximum/minimum value measurement

interface to scroll down, and switch and display the

maximum/minimum value.

3)Short press on alternating current, AC/DC

voltage and capacitance for relative value

measurement mode.

Hz%/INRUSH/▲button

1) Short press on alternating current, alternating

voltage and HZ% gear for the switch among

alternating current or alternating voltage, frequency

and duty ratio.

2) Short-press on the harmonic measurement

interface at KW and W gears to scroll up, and switch

between the 1st harmonic and 20th harmonic. At the

KW and W gears, short-press the function key in the

maximum/minimum value measurement interface to

scroll up, and switch and display the

maximum/minimum value.

3) Long press on the alternating current gear for

switching to the measurement mode of inrush

current.

MAX/MIN button: for the switch between the

maximum/minimum measurement.

OFF gear: for power off.

Page 10

19 20

INPUT jack: input terminal of voltage, resistance,

frequency, duty ratio, capacitance, diode and circuit

continuity.

COM jack: common terminal of voltage, resistance,

frequency, duty ratio, capacitance, diode and circuit

continuity.

Change-over switch: for selection of functions and

ranges.

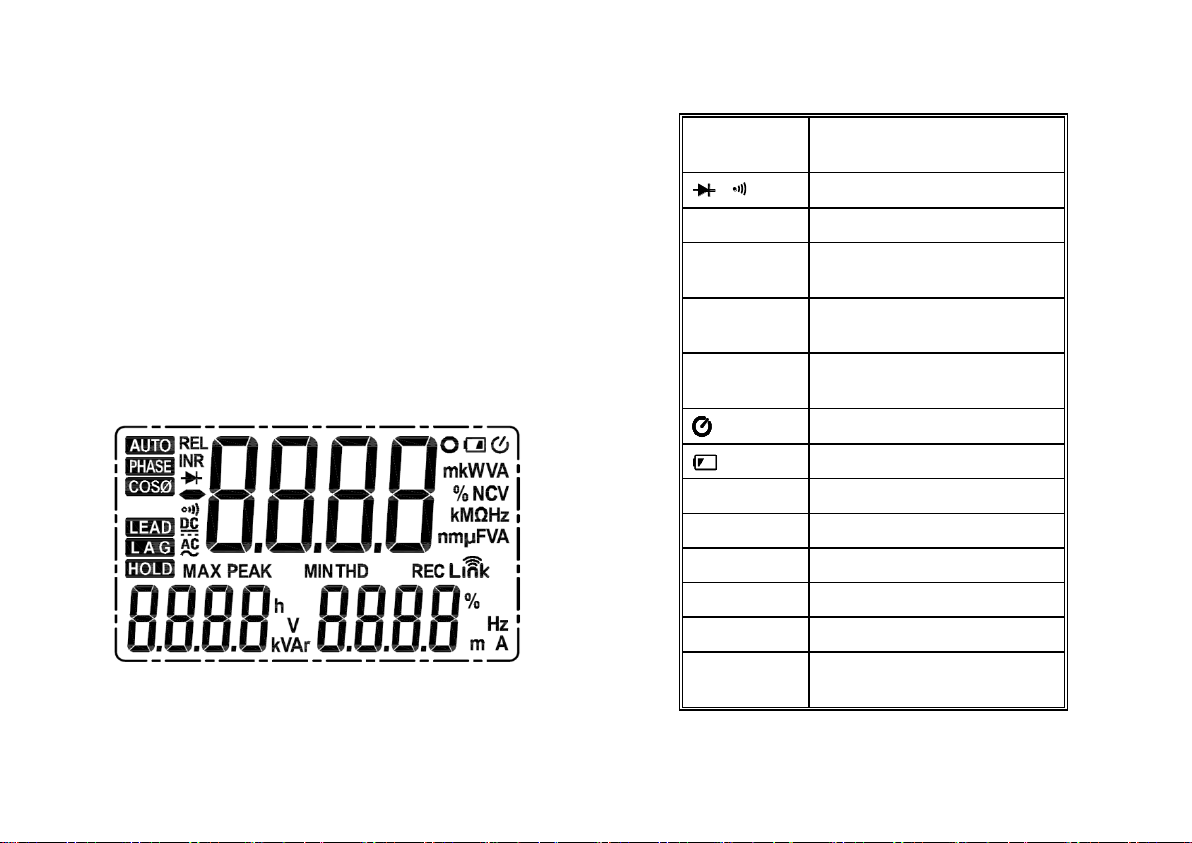

2.3 LCD display

AC, DC

Alternating current/Direct

current

.

Diode and continuity

AUTO

Auto range mode

MAX

Status of maximum

measurement

MIN

Status of minimum

measurement

REL

Status of relative

measurement

Status of automatic shutdown

LOW BATTERY

HOLD

Status of reading holding

HZ

Frequency measurement

%

Percentage (duty ratio)

mV, V

Millivolt, volt (voltage)

A

Ampere (electric current)

nF,μF, mF

Nano farad, microfarad and

millifarad

Page 11

21 22

Ω, kΩ, MΩ

Ohm, kilo-ohm and megohm

(resistance)

Hz, kHz,

MHZ

Hertz, kilohertz and

megahertz (frequency)

NCV

Non-contact voltage

detection

W, KW

Watt and kilowatt (active

power)

VA, KVA

Unit of apparent power

Var, KVAr

Reactive power

o

Phase angle

PEAK

Peak value measurement

THD

Total harmonic distortion

H01F

Total harmonic distortion F

(relative to fundamental

wave)

H01r

Total harmonic distortion r

(relative to actual effective

value)

COSФ

Power factor

Phase

Phase

INR

Status of inrush current

measurement

REC

Data recorder

Bluetooth function

LEAD

Leading phase angle

LAG

Lagging phase angle

h

Hour (time unit)

Negative sign

3. Specification

Recalibrate the meter under the conditions of

18°C~28°C and the relative humidity less than 75%,

with the calibration cycle of 1 year.

Page 12

23 24

3.1 General

Auto range and manual range.

Full-scale overload protection.

Maximum allowable voltage between measured

end and the ground: 1,000 V DC or 750 V AC.

Working height: less than 2,000 m.

Displayer: LCD.

Maximum displayed value: 5999 dgt.

Polar indication: self-indicating, "-" means

negative polarity.

Over-range display: '0L' or '-0L'.

Sampling time: around 3 times/s.

Unit display: display the functions and the unit

of electric quantity.

Time of automatic shutdown: 30 minutes.

Power supply: DC power supply 9 V.

Type of battery: NEDA 1604 or 6F22.

Under-voltage indication of battery: LCD

display symbol.

Temperature coefficient: less than 0.1×degree

of accuracy/°C.

Working temperature: 18°C~28°C.

Storage temperature: -10°C~50°C.

Dimension: 238×92×50 mm.

Weight: around 420 g (including battery).

3.2 Technical specifications

Environmental temperature: 235°C relative

humidity: ≤ 75%

Page 13

25 26

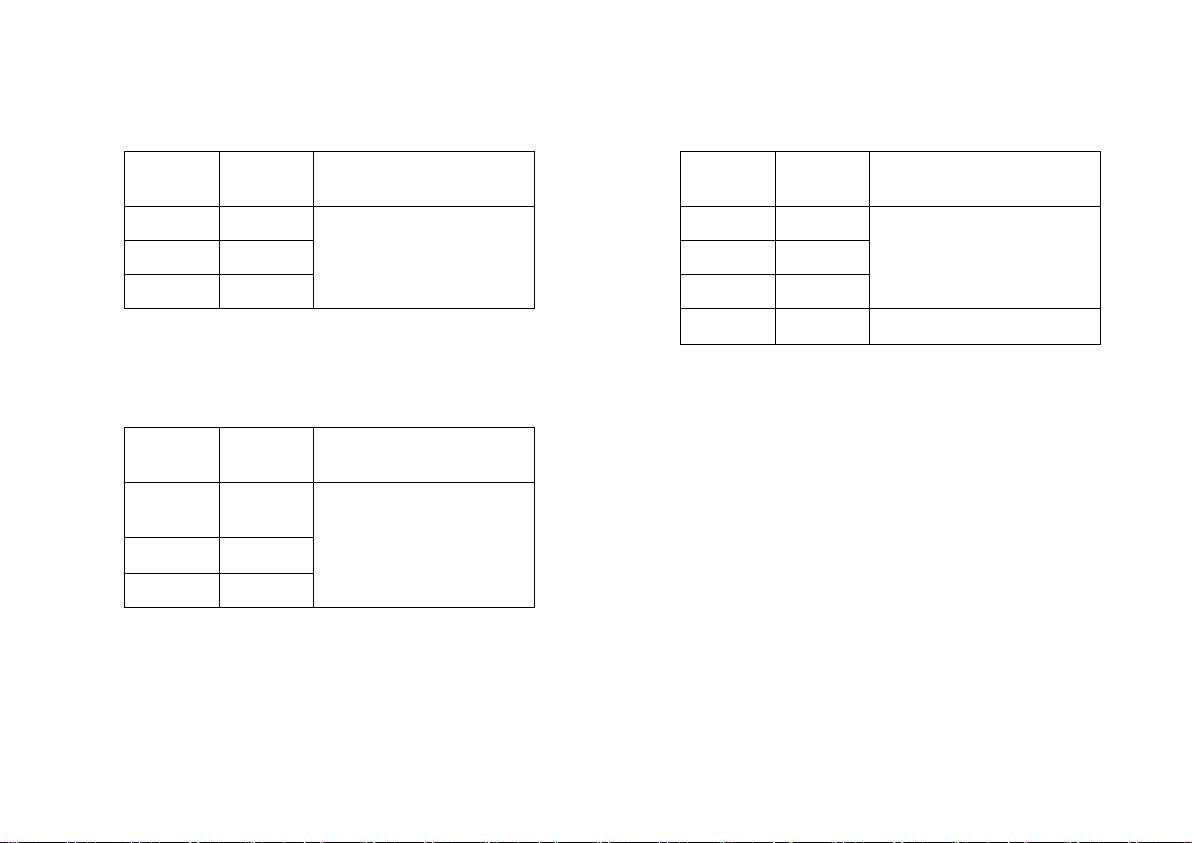

3.2.1 Alternating current

Range

Resolutio

n

Accuracy

60A

0.01A

(2.0% rdg+ 8 dgt)

600A

0.1A

1000A

1A

- Maximum input current: 1,000A AC

- Frequency range: 40~400 Hz

3.2.2 Inrush current

Range

Resolutio

n

Accuracy

60A

0.01A

< 60 A (for reference

only)

600A

0.1A

(5% rdg+ 60 dgt)

1000A

1A

Integral time: 100 ms; measurement range:

20~1,000 A; frequency range: 40~400 Hz

3.2.3 DC voltage

Range

Resoluti

on

Accuracy

6V

0.001V

(0.5% rdg+ 5 dgt)

60V

0.01V

600

0.1V

1000V

1V

(0.8% rdg+ 4 dgt)

- Input impedance: 10M

- Maximum input voltage: 750 V AC (effective value)

or 1,000 V DC.

Page 14

27 28

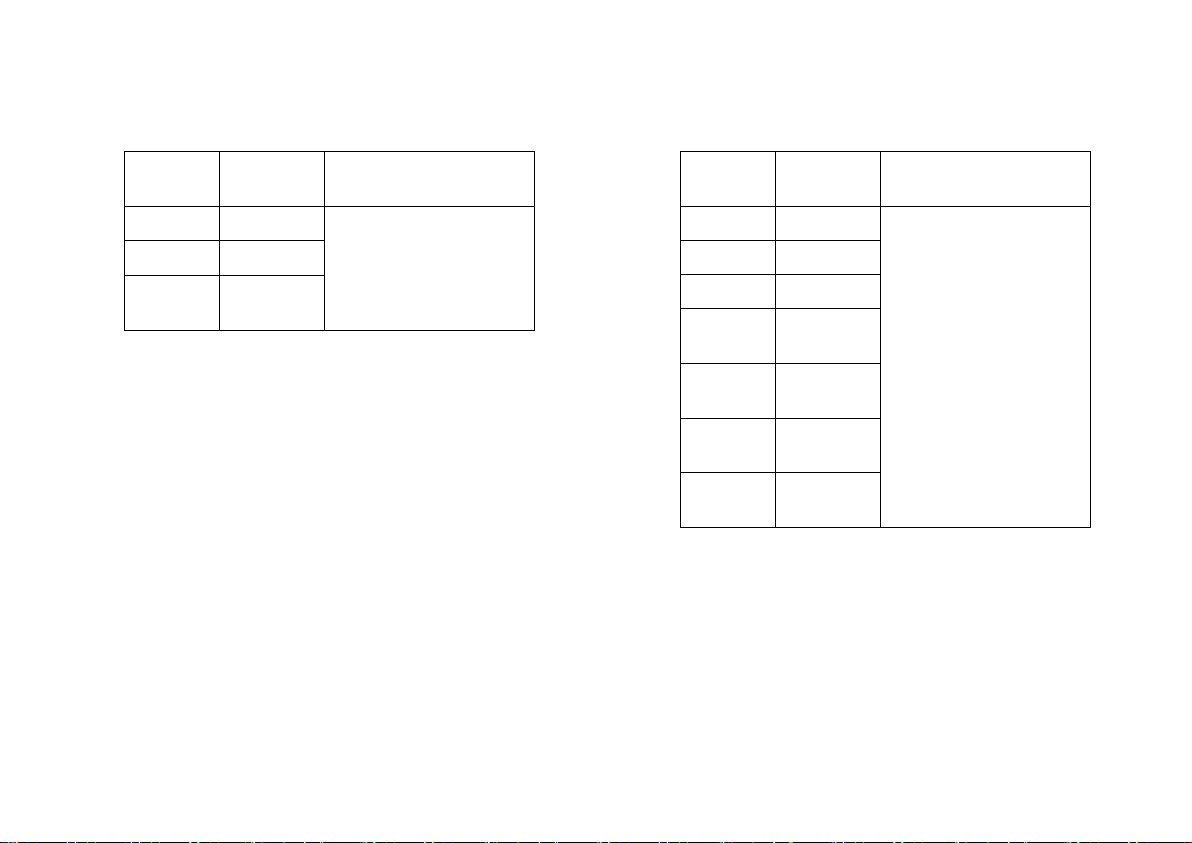

3.2.4 AC voltage

Range

Resoluti

on

Accuracy

6V

0.001V

(0.6% rdg+ 4 dgt)

60V

0.01V

600V

0.1V

750V

1V

(0.8% rdg+ 4 dgt)

- Input impedance: 10M

- Maximum input voltage: 750 V AC (effective

value) or 1,000 V DC.

- Frequency range: 40~400 Hz.

Note:

Under the small voltage range, there might be

reading on the meter before the probe is connected

to the measured circuit.

The above phenomenon is normal because the

meter has high sensitivity and it has no influence on

the actual measurement result.

3.2.5 Frequency

3.2.5.1 Frequency measurement with clamp (at

A gear):

Range

Resolutio

n

Accuracy

99.99Hz

0.01Hz

999.9Hz

0.1Hz

(1.5% rdg+ 5 dgt)

- Measurement range: 10 Hz~1 kHz

- Range of input signal: ≥ 20A AC (the input current

is increased with the measured frequency)

- Maximal input current: AC 1000 A (effective value)

Page 15

29 30

3.2.5.2 At V gear:

Range

Resolutio

n

Accuracy

99.99Hz

0.01Hz

999.9Hz

0.1Hz

(1.5% rdg+ 5 dgt)

9.999kH

z

0.001kHz

- Measurement range: 10 Hz~10kHz

- Range of input voltage: ≥ 1 V AC (effective value)

(the input voltage is increased with the measured

frequency)

- Input impedance: 10M

- Maximum input voltage: 750 V AC (effective

value)

3.2.5.3 At HZ/DUTY gear:

Range

Resolutio

n

Accuracy

9.999Hz

0.001Hz

(0.3% rdg+ 5 dgt)

99.99Hz

0.01Hz

999.9Hz

0.1Hz

9.999kH

z

0.001kHz

99.99KH

Z

0.01kHZ

999.9KH

Z

0.1KHZ

9.999M

HZ

0.001MH

Z

- Overload protection: 1,000 V DC or 750 V AC

(effective value)

- Range of input voltage: ≥ 2 V (the input voltage

is increased with the increase of the measured

frequency)

Page 16

31 32

3.2.6 Duty ratio

Range

Resolutio

n

Accuracy

0.1 - 99.9%

0.1%

(3.0%+3)

3.2.6.1 At A gear (from the clamp):

- Frequency response: 10 ~ 1 kHz.

- Range of input current: ≥ 20 A AC (effective value)

-Maximal input current: AC 1,000 A

3.2.6.2 At V gear:

- Frequency response: 10 ~ 10kHz.

- Range of input voltage: 1 V AC.

- Input impedance: 10M

- Maximum input voltage: 750 V AC (effective

value)

3.2.6.3 At HZ/DUTY gear:

- Frequency response: 10 ~ 10MHz.

- Range of input voltage: ≥ 2V AC (effective value)

(the input voltage is increased with the measured

frequency)

- Maximum input voltage: 250V AC (effective value)

3.2.7. Resistance

Range

Resolution

Accuracy

600

0.1

(0.8% rdg+ 3 dgt)

6k

0.001k

60k

0.01k

600k

0.1k

6M

0.001M

(2% rdg+ 5 dgt)

60M

0.1M

- Open-circuit voltage: around 0.78 V

- Overload protection: 1,000 V DC or AC (effective

value)

Page 17

33 34

3.2.8 Circuit continuity test

Range

Resolut

ion

Function

600Ω

0.1

If the resistance of

measured circuit is less

than 50, the buzzer inside

the meter will send a sound.

- Open-circuit voltage: around 1.48V

- Overload protection: 1,000 V DC or 750 V AC

(effective value)

3.2.9. Capacitance

Range

Resolutio

n

Accuracy

9.999nF

0.001nF

(3.0% rdg+ 5 dgt)

99.99nF

0.01nF

999.9nF

0.1nF

9.999F

0.001F

99.99F

0.01F

(3.0% rdg+ 5 dgt)

999.9F

0.1F

9.999mF

0.001mF

99.99mF

0.01mF

- Overload protection: 1,000 V DC or 750 V AC

(effective value)

3.2.10 Diode test

Range

Resoluti

on

Function

3V

0.001V

Display the approximate

value of diode forward

voltage

Page 18

35 36

- DC forward current is around 1 mA

- DC reverse voltage is around 3.2 V

- Overload protection: 1,000 V DC or 750 V AC

(effective value)

3.2.11 Single-phase active power

Range

Resoluti

on

Accuracy

3W

0.01W

(3.0% rdg+ 5 dgt)

100W

0.1W

4000W

1W

10kW

0.01kW

100kW

0.1kW

750kW

1kW

Minimum input current: 1 mA, and minimum input

voltage: 1 V.

3.2.12 Single-phase apparent power

Range

Resoluti

on

Accuracy

3VA

0.01VA

(3.0% rdg+ 5 dgt)

(3.0% rdg+ 5 dgt)

100VA

0.1VA

4000VA

1VA

10kVA

0.01kVA

100kVA

0.1kVA

750kVA

1kVA

Minimum input current: 1 mA, and minimum input

voltage: 1 V.

Page 19

37 38

3.2.13 Single-phase reactive power

Range

Resoluti

on

Accuracy

3W

0.01W

(3.0% rdg+ 5 dgt)

100W

0.1W

4000W

1W

10kW

0.01kW

100kW

0.1kW

750kW

1kW

Minimum input current: 1 mA, and minimum input

voltage: 1 V.

3.2.14 Power factor

Range

Resolution

Accuracy

0.3 ~ 1

capacitive

0.001

(3.0% rdg+ 5

dgt)

0.3 ~ 1

inductive

0.001

Min. input current: 1 mA / min. input voltage: 1 V.

3.2.15 Harmonics measurement

Range

Accuracy of harmonic electrical

level

1

(3.0% rdg+ 10 dgt)

2-6

(3.5% rdg+ +10 dgt)

7-8

(4.5% rdg+ 10 dgt)

9-10

(5.0% rdg+ 10 dgt)

11-15

(7.0% rdg+ 10 dgt)

16-20

(10.0% rdg+ 10 dgt)

Minimum input current: 1 mA, and minimum input

voltage: 1 V.

4 Operation Guide

4.1 Reading holding

1) During the measurement, if the reading shall be

held, short-press the "HOLD/B.L" key to lock the

display value of the display, and short-press the

"HOLD/B.L" key to unlock the kept reading.

Page 20

39 40

4.2 Manual range

The RANGE key is used for setting the auto/manual

range, and this key can be activated through

triggering. Its startup default state is

auto range. Press the key once to switch to the

manual range. In the manual range mode, move the

meter to the next higher gear after pressing the key

once, and after moving to the highest gear, press

the key continuously to move the meter to the lowest

gear. Perform the cyclic operations in sequence. If

press the key for more than 2 s,

the meter will be switched to the state of auto range.

Note:

During the measurement of diode, continuity test,

capacitance, and frequency KW, W and NCV gear,

the manual range is unavailable.

4.3 Switchover of frequency and duty ratio

1) When the meter is at AC current gear, short-press

the "Hz/%/INRUSH/▲" key, the meter can be in Hz

measurement state to measure the frequency of

measured AC voltage and current signals. Then,

short-press the "Hz/%/INRUSH/▲" key again, the

meter will be in DUTY measurement state to

measure the duty ratio of measured voltage and

current signals. If the meter is in HZ/% gear, shortpress "Hz/%/INRUSH/▲" key to switch the meter to

the HZ and DUTY states circularly.

2) If the meter is in AC current and AC/DC voltage

gear, short-press the "Hz/%/INRUSH/▲" key, the

meter will be in the voltage and current

measurement state.

Page 21

41 42

4.4 Selection of maximum/minimum value

measurement

1) Press the "MAX/MIN" key in the kW and W gear,

the interface will simultaneously display the

maximum and minimum values obtained after the

test for a period of time, and then press the ▲or

▼key on this interface to enter the interface

displaying the time of record. After that, the specific

time period of these maximum and minimum values

will be displayed.

2) When the meter is at AC current gear, AC/DC

voltage gear and resistance gear, press the

"MAX/MIN" to enter the MAX mode and measure

the maximum value all the time; press "MAX/MIN"

key once again to enter the state for measuring the

minimum value; and then press the "MAX/MIN" key

for the third time to exit the measurement mode of

maximum and minimum value.

Note:

1) The meter is in manual range mode under the

measurement states of max/min value.

4.5 Function switching

1) Long-press the FUNC key in the power

measurement interface to enter the power, voltage

and current measurement interface.

2) Short-press the FUNC key in the power

measurement interface to enter the active power,

apparent power, reactive power, power factor and

phase angle measurement interface.

3) When the meter is at power gear, short-press the

FUNC key in the voltage measurement interface to

enter the voltage effective value, harmonic,

harmonic distortion rate THD-R and harmonic

distortion rate THD-F measurement interface.

Page 22

43 44

4) When the meter is at power gear, short-press the

FUNC key in the current measurement interface to

enter the current effective value, harmonic,

harmonic distortion rate THD-R and harmonic

distortion rate THD-F measurement interface.

5) When the meter is at DC/AC gear, short-press the

FUNC key to switch between the DC voltage

measurement and AC voltage measurement

interface.

6) When the meter is at

resistance/diode/buzzer/capacitance gear, shortpress the FUNC key to switch among resistance,

diode, buzzer and capacitance measurement.

4.6 Measurement of relative value

1) Short-press the LINK/REL/▼ key at AC current,

AC/DC voltage and capacitance gears to enter the

relative value measurement mode and store the

current displaying value in memory as the reference

value. For the sequent measurement, the displayed

value is the difference value between the input value

and reference value, i.e. REL△ (current reading) =

input value - reference value.

2) This function of relative value measurement

only can be available in the manual measurement

mode.

4.7 LINK measurement

At any gear (excluding OFF gear), long-press

LINK/REL/▼ to turn on the Bluetooth of meter. Then

open the corresponding APP (iOS or Android) of the

meter through mobile phone or other equipment and

search the signal to link them. After the linking, the

APP will display the content displayed on meter in

Page 23

45 46

real time. Long-press the LINK/REL/▼ key once

again, the Bluetooth of meter will be turned off and

the meter will be disconnected from the APP.

4.8 REC function

The meter performs the functions of data recording

and Bluetooth data reading.

1) Data recording: the meter can save 1,000 pieces

of data records. Long-press REC/RANG key to

enable the meter to record data. The REC indicator

on LCD will be on, and the meter will store the

current measurement data at the rate of 3 times/s.

Long-press REC key again to exit the data

recording function. The meter also can exit the data

recording function when the 1,000 pieces of data

are recorded or a key operation or gear switching

operation is performed.

2) Data reading: the meter cannot support the direct

reading of stored data, and it only support the

reading of the stored data with the Bluetooth

function through a specific APP on the mobile phone.

4.9 ▼function

Short-press LINK/REL/▼ in the harmonic

measurement interface at KW and W gears to scroll

down, and to switch between the 1st harmonic and

20th harmonic. At the KW and W gears, short-press

the function key in the maximum/minimum value

measurement interface to scroll down, and switch

and display the maximum/minimum value.

4.10 ▲function

Short-press in the harmonic measurement interface

at KW and W gears to scroll up, and to switch

between the 1st harmonic and 20th harmonic. At the

KW and W gears, short-press the function key in the

maximum/minimum value measurement interface to

scroll up, and switch and display the

maximum/minimum value.

Page 24

47 48

4.11 INRUSH measurement

Long-press "Hz/%/INRUSH/▲" for more than 2 s at

AC current gear to enterthe inrush measurement

state.

4.12 Back-light and clamp lighting

1) During measurement, if the ambient light is too

dim to read, press

the "B.L/HOLD" for more than 2 s to turn on the

back-light, and the back-light will be off 20 s later.

2) In this period, press the "B.L/HOLD" key for 2 s

to turn off the back-light.

3) Turn on the back-light of the meter at the current

gear, and the clamp lamp will be on at the same time.

The luminous object of the back-light is LED with

high working current.

Although this meter is set with timing circuit (with

time of 30 s),

the service life of battery will be shortened with

frequent use of back-light.

Therefore, you shall minimize the use of back-light

as far as possible under the unnecessary conditions.

Note:

When the battery voltage ≤ 7.2 V, the display will

display the symbol of " "(under-voltage).

However,

if the back-light is used, when the battery voltage ≥

7.2 V, the battery voltage is reduced due to high

working current, the display may display the symbol

" "(when the symbol of " " is displayed, the

measurement accuracy cannot be guaranteed).

Under such circumstance, the battery will not be

replaced until the symbol " "is displayed without

back-light.

Page 25

49 50

4.13 Automatic shutdown

1) After startup, in case of no operation within 30

minutes, the meter will enter the dormant state and

shut down automatically for saving electric energy.

There will be voice prompt (a prolonged blast) from

the buzzer 1 minute before shutdown, and then the

meter will shut down automatically.

2) After shutdown, press FUNC key and the meter

will resume operation.

3) If the "B.L/HOLD" key is pressed during startup,

the function of automatic shutdown will cancel

automatically.

4.14. Measurement preparation

1) Turn the change-over switch to power on the

meter. If the battery is in under-voltage state (the

voltage ≤ 7.2 V), the display will display the symbol

" ", and then the battery shall be replaced.

2) " " means that the input voltage or current shall

not be greater than the indicated value in order to

prevent

the internal circuit from damage.

3) Turn the change-over switch to the required

measurement function and range.

4) For wiring, connect the public testing line at first

and then connect the energized testing line. For

disconnecting,

remove the energized testing line at first.

4.15 AC current measurement

Warning

Electric shock.

Remove the probe from the meter before

measuring with the current clamp.

1) Turn the change-over switch to AC current gear.

At this time, the meter is in AC current measurement

state, and then the suitable range shall be selected.

Page 26

51 52

2) Hold the trigger, and open the clamp to clamp one

conductor of measured circuits.

3) Read the current value from LCD display.

Note:

1) If two or more circuits of the measured circuits are

clamped, the measurement result will be not correct.

2) In order to acquire the accurate reading,

the measured conductor shall be in the center

of clamp as far as possible.

3) " " means that the maximum AC input

current is 1,000 A.

4) When the reading is greater than 600.1 A

at 60 A/600 A, there will be the alarm sound

"beep" from the meter. When the reading is

greater than 620 A rms, the ACA will display

overload.

5) When the reading is greater than 1001 A at

1,000 A, there will be the alarm sound "beep"

from the meter. When the reading is greater

than 1,100 A rms, the ACA will display

overload.

Figure 1 Schematic Diagram for Current

Measurement at AC Gear

Page 27

53 54

4.16. Voltage measurement

Warning

Electric shock.

Pay special attention to high voltage

measurement to avoid electric shock.

Do not input the voltage with the

effective value greater than AC 750.

1) Plug the black probe into COM jack, plug the red

probe into INPUT jack, and select the suitable

range.

2) Turn the change-over switch to AC/DC voltage

gear. In this case, the meter is in the DC voltage

measurement state. If the AC voltage shall be

measured, press the FUNC key and the meter will

enter the AC voltage measurement state.

3) Connect the probe to both ends of voltage source

or load to conduct measurement.

4) Read the voltage value from LCD.

Note:

1) The auto range will be unavailable under the

relative measurement mode.

2) " " means that the maximum input voltage is

750 V AC or 1,000 V DC.

3) There will be the alarm sound "beep" from the

meter, when the measured reading of the meter is

greater than 600 V rms ACV.

When the reading is greater than 750 V rms ACV,

the meter will display overload.

4) There will be the alarm sound "beep" from the

meter, when the measured reading of the meter is

greater than 1,000 V rms DCV.

When the reading is greater than 1100V rms, the

DCV will display overload.

Page 28

55 56

Figure 2: Schematic Diagram for AC Voltage

Measurement at AC/DC Voltage Gear

4.17 Measuring frequency and duty ratio

1) Frequency measurement with clamp (at

current gear):

Warning

Electric shock.

Remove the probe from the meter before

measuring with the current clamp.

⑴Turn the change-over switch to AC current gear.

⑵Hold the trigger, and open the clamp to clamp one

conductor of measured circuits.

⑶ Press the "Hz/%INRUSH/▲"button shortly to

switch into the status of frequency measurement.

⑷Read the frequency value from LCD display.

⑸Press "Hz/%INRUSH/▲"again to enter the status

of duty ratio measurement.

Page 29

57 58

Note:

⑴If two or more circuits of the measured circuits are

clamped, the measurement result will be not correct.

⑵The measurement range of frequency is 10 Hz ~

1 kHz. If the measured frequency is less than 10 Hz,

the frequency greater than 10 kHz might be

measured, but the accuracy of measurement

cannot be guaranteed.

⑶The measurement range of duty ratio is 10 ~ 95%.

⑷The maximum input current of " " is 1000A AC

(effective value).

2) At voltage gear:

Warning

Electric shock.

Pay special attention to high voltage

measurement to avoid electric shock.

Do not input the voltage with effective value

greater than AC 750.

⑴Insert the black probe into COM jack, and insert

the red probe into INPUT jack.

⑵Turn the change-over switch to AC/DC voltage

gear, press FUNC to enter the status of AC voltage

measurement.

⑶Press the "Hz/%INRUSH/▲"button to switch into

the frequency measurement state.

⑷Connect the probe to both ends of signal source

or load to conduct measurement.

⑸Read on the LCD.

⑹Press "Hz/%INRUSH/▲"again to enter the status

of duty ratio measurement.

Note:

⑴The measurement range of frequency is 10 Hz ~

10kHz. If the measured frequency is less than 10 Hz,

the LCD will display "00.0", the frequency less than

10 kHz might be measured, but the accuracy of

measurement cannot be guaranteed.

⑵The measurement range of duty ratio is 10 ~ 95%.

Page 30

59 60

⑶The maximum input voltage of " " is 750 V AC

(effective value).

3) At HZ/DUTY gear:

Warning

Electric shock.

Pay special attention to high voltage

measurement to avoid electric shock.

Do not input the voltage with effective value

greater than AC 750 V.

⑴Insert the black probe into COM jack, and insert

the red probe into INPUT jack.

⑵Turn the change-over switch to HZ% gear.

⑶Connect the probe to both ends of signal source

or load to conduct measurement.

⑷Read on the LCD.

⑷Press "Hz/%INRUSH/▲"again to enter the status

of duty ratio measurement.

Note:

The measurement range of frequency is 10 Hz ~

9.999 MHz, if the measured frequency less than 10

Hz,

the LCD will display "00.0"; the frequency greater

than 9.999 MHz might be measured, but the

accuracy of measurement cannot be guaranteed.

Figure 3: Schematic Diagram for Frequency

Measurement at HZ% Gear

Page 31

61 62

4.18 Resistance measurement

Warning

Electric shock.

When measuring the impedance on the

circuit, the circuit power should be

disconnected, and the capacitor in the

circuit should be completely discharged.

1) Insert the black probe into COM jack, and insert

the red probe into INPUT jack.

2) Place the change-over switch on the gear,

and set the meter in the status of resistance

measurement.

3) Connect the probes to both ends of the

measured resistor or the circuit for measurement.

4) Read on the LCD.

Note:

1) When the input is open-circuited, the LCD will

display "0L" for over range.

2) If the resistance of measured resistor is greater

than 1 MΩ, the reading of the meter might be stable

after a few seconds, and it is common for the high

resistance readings.

Figure 4 Schematic Diagram for Resistance

Measurement at Gear

Page 32

63 64

4.19 Diode test

1) Insert the black probe into COM jack, and insert

the red probe into INPUT jack.

2) Turn the change-over switch to the gear.

3) Press "FUNC" to switch into the status of

measurement.

4) Connect the red probe to the positive pole of the

diode, and connect the black probe to the negative

pole for measurement.

5) Read on the LCD.

Note:

1) The approximate value of the forward voltage

drop of diode will be displayed on the meter.

2) If the probe is connected inversely or the probe is

open-circuited, the LCD will display "0L".

Figure 5 Schematic Diagram for Diode Testing at

Gear

Page 33

65 66

4.20 Circuit continuity test

Warning

Electric shock.

For the circuit continuity test, the circuit

power should be disconnected, and the

capacitor in the circuit should be

completely discharged.

1) Insert the black probe into COM jack, and insert

the red probe into INPUT jack.

2) Turn the change-over switch to the gear.

3) Press "FUNC" button to switch to the status of

circuit continuity testing.

4) Connect the probes to both ends of the circuit for

measurement.

5) If the resistance of measured circuit is less than

50, the buzzer inside the meter will make a sound.

6) Read the resistance value of the circuit from LCD.

Note:

If the probe is open-circuited or the resistance of the

measured circuit is greater than 600, the "0L" will

be displayed.

Figure 6 Schematic Diagram for Circuit Continuity

Test at Gear

Page 34

67 68

4.21 Capacitance measurement

Warning

Electric shock.

To avoid electric shock, the capacitor

should be completely discharged before

the capacitance measurement.

1) Insert the black probe into COM jack, and insert

the red probe into INPUT jack.

2) Turn the change-over switch to the gear.

3) Connect the probe to the both ends of the

measured capacitor for measurement after the

capacitor is completely discharged.

4) Read the capacitance value from LCD.

Note:

To improve the accuracy of the measured value less

than 10 nF,the distributed capacitance of the meter

and conductors should be subtracted.

Figure 7 Schematic Diagram for Capacitance

Measurement at Gear

Page 35

69 70

4.22 Measurement of inrush current

Warning

Electric shock.

Remove the probe from the meter before

measuring with the current clamp.

4.10.1 Turn the change-over switch to 60/600 A or

1000 A AC current gear.

4.10.2 Hold the trigger, and open the clamp to clamp

one conductor of measured circuits.

4.10.3 Long press the "HZ%/INRUSH/▲" button

more than 2 seconds to enter the mode of inrush

current measurement. Then the LCD will display

"INR", and the meter will display and hold the inrush

current value until the motor start-up is detected.

4.10.4 Read the inrush current value from LCD

display.

Note:

1) If two or more circuits of the measured circuits are

clamped, the measurement result will be not correct.

2) In order to acquire the accurate reading, the

measured conductor shall be in the center of clamp

as far as possible.

3) The LCD only displays "OL" in the manual range

mode indicating the over range, and the higher

range should be selected.

4) Under the manual range mode, if the measured

value is not known in advance, the highest level

should be set for the range.

5) " " means that the maximum input current is

1000A AC (effective value).

Page 36

71 72

Figure 8 Schematic Diagram for Inrush Current

Measurement at AC Current Gear

4.23 NCV measurement

1) Turn the change-over switch of the meter to the

NCV gear.

2) The top of the meter should be arranged near the

conductor. When the detected voltage is great than

110 Vac (RMS), the voltage sensing indicator may

be on, and the buzzer may make the alarm sound

"beep".

Note:

1: The voltage may still exist even without

instructions. Do not determine whether there is

voltage in the conductor only by using the noncontact voltage detectors. The detecting operation

might be affected by the socket design, insulation

thickness, type and other factors.

2: When there is input voltage to the input terminal

of the meter, the voltage sensing indicator may also

be on.

Page 37

73 74

3: Intrusive sources (such flashlight, motor, etc.) in

the external environment may cause a wrong trigger

of non-contact voltage detection.

Figure 9 Schematic Diagram for Voltage Detection

at NCV Gear

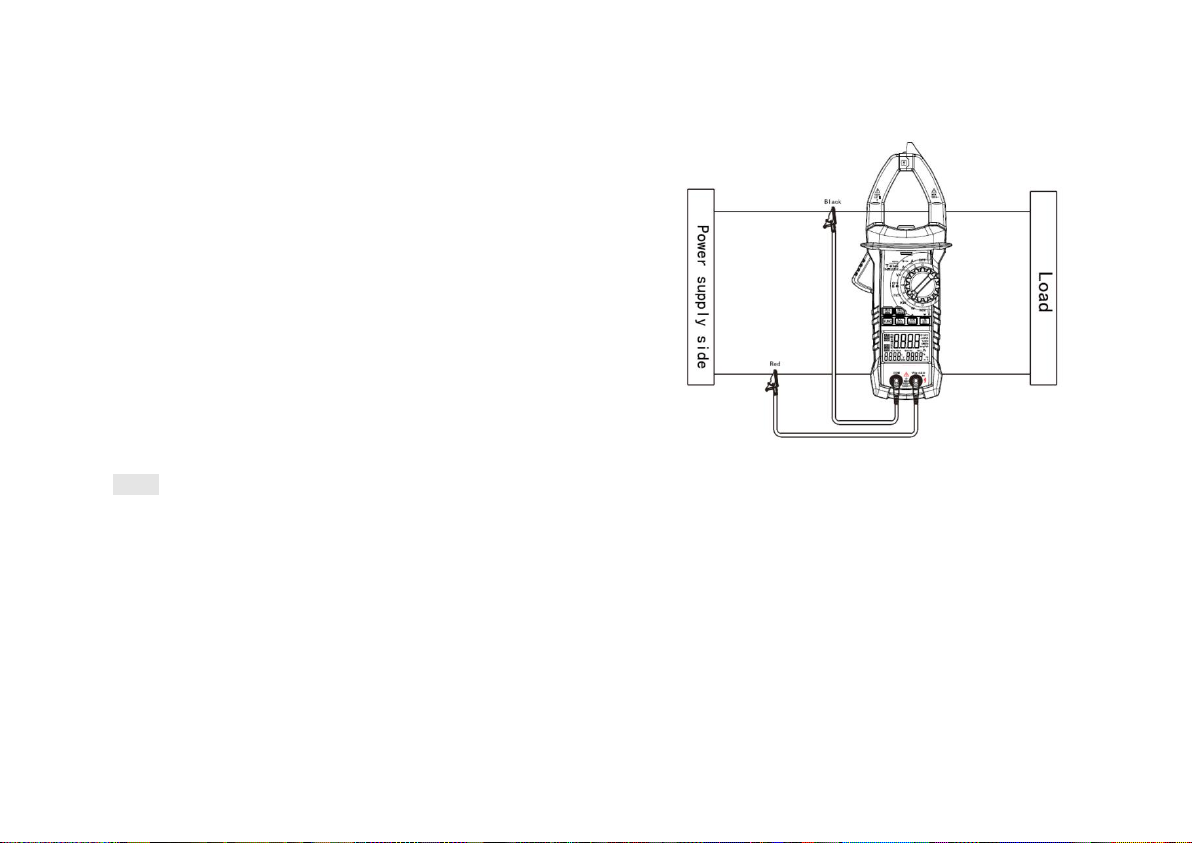

4.24 Active power measurement

Warning

Electric shock.

Pay special attention to high voltage and high

current measurement to avoid electric shock.

Do not input the voltage with the effective

value greater than AC 750 and the current with

the effective value greater than 1,000 A.

1) Turn the change-over switch to kW or W gear.

2) Clamp the measured conductor of the power

supply or load with the clamp. Input the measured

voltage from the V end and COM end. After the

measuring circuits are connected correctly, the

active power shall be read from the LCD and the

LCD displays the effective values of measured

voltage and current simultaneously.

Page 38

75 76

3) Determine whether the switch shall be turned to

the KW gear or W gear according to the measured

current. At the W gear, the measurement range of

current is 1 mA - 4,000 mA and at the KW gear, the

measurement range of current is 1 A - 1,000 A. The

measurement range of voltage at both the KW gear

and W gear is 1 V -750 V.

4) Press MAX/MIN key in the active power

measurement interface to enter the

maximum/minimum value measurement mode, and

the LCD will display the measured value of active

power and the maximum and minimum values of

active power within a certain period simultaneously.

Press the Hz/%INRUSH/▲ key or LINK/REL/▼ key

again in this interface, the LCD will display the

recording time and real-time measurement value of

active power.

Note:

1)The maximum measurement range of active

power is 750 kW, and the LCD will display OL for

over range.

2)The maximum measured current is 4,000 mA at

W gear. Please do not operate by mistake.

3)The minimum measured voltage is 1 V and the

minimum measured current is 1 mA.

4)The maximum measured voltage is 750 V and

the maximum measured current is 1,000 A.

Page 39

77 78

Figure10 Schematic Diagram for Active Power

Measurement at KW Gear

4.25 Apparent power measurement

Warning

Electric shock.

Pay special attention to high voltage and high

current measurement to avoid electric shock.

Do not input the voltage with the effective

value greater than AC 750 and the current with

the effective value greater than 1,000 A.

1) Turn the change-over switch to the kW or W gear,

press FUNC key to enter the apparent power

measurement interface.

2) Clamp the measured conductor of the power

supply or load with the clamp. Input the measured

voltage from the V end and COM end. After the

measuring circuits are connected correctly, read the

apparent power from the LCD and the LCD displays

the effective values of measured voltage and

current simultaneously.

3) Determine whether the switch shall be turned to

the KW gear or W gear according to the measured

current. At the W gear, the measurement range of

current is 1 mA - 4,000 mA and at the KW gear, the

measurement range of current is 1 A - 1,000 A. The

measurement range of voltage at both the KW gear

and W gear is 1 V -750 V.

4) Press MAX/MIN key in the apparent power

measurement interface to enter the

maximum/minimum value measurement mode, and

Page 40

79 80

the LCD will display the measured value of apparent

power and the maximum and minimum values of

apparent power within a certain period

simultaneously. Press the Hz/%INRUSH/▲ key or

LINK/REL/▼ key once again in this interface. The

LCD will display the recording time and real-time

measurement value of apparent power.

Note:

1) The maximum measurement range of apparent

power is 750 kW, and the LCD will display OL for

over range.

2) The maximum measured current is 4,000 mA at

W gear. Please do not operate by mistake.

3) The minimum measured voltage is 1 V and the

minimum measured current is 1 mA.

4) The maximum measured voltage is 750 V and the

maximum measured current is 1,000 A.

Figure11 Schematic Diagram for Apparent Power

Measurement at KW Gear

Page 41

81 82

4.26 Power factor measurement

1)Turn the change-over switch to the kW or W gear,

press FUNC key to enter the power factor

measurement interface.

2)Clamp the measured conductor of the power

supply or load with the clamp. Input the measured

voltage from the V end and COM end. After the

measuring circuits are connected correctly, the

power factor from the LCD shall be read and the

LCD displays the value of reactive power

simultaneously.

3)Determine whether the switch shall be turned to

the KW gear or W gear according to the measured

current. At the W gear, the measurement range of

current is 1 mA - 4,000 mA and at the KW gear, the

measurement range of current is 1 A - 1,000 A. The

measurement range of voltage at both the KW gear

and W gear is 1 V -750 V.

4)There is a phase difference between the voltage

value and current value of the inductive load and

capacitive load. Generally. the power factor is

indicated by the cosine COSǾ of phase angle Ǿ.

When the power factor is negative, it means that the

measured load is capacitive load.

5) The reactive power is an indirectly measured

value. The computational formula of kVAr is:

222

k kWkVAVAr −=

, and the value is calculated out

with the measured voltage, current

and active power value.

Warning

Electric shock.

Pay special attention to high voltage and high

current measurement to avoid electric shock.

Do not input the voltage with the effective value

greater than AC 750 and the current with the

effective value greater than 1,000 A.

Page 42

83 84

Note:

1) The maximum measured current is 4,000 mA at

W gear. Please do not operate by mistake.

2) The minimum measured voltage is 1 V and the

minimum measured current is 1 mA.

3) The maximum measured voltage is 750 V and the

maximum measured current is 1,000 A.

Figure12 Schematic Diagram for Power Factor

Measurement at KW Gear

4.27 Phase angle measurement

1) Turn the change-over switch to the kW or W gear,

press FUNC key to enter the phase angle

measurement interface.

2) Clamp the measured conductor of the power

supply or load with the clamp. Input the measured

voltage from the V end and COM end. After the

measuring circuits are connected correctly, the

phase angle shall be read from the LCD and the

LCD displays the effective values of measured

voltage and current simultaneously.

Warning

Electric shock!

Pay special attention to high voltage and

high current measurement to avoid

electric shock.

Page 43

85 86

3) Determine whether the switch shall be turned to

the KW gear or W gear according to the measured

current. At the W gear, the measurement range of

current is 1 mA - 4,000 mA and at the KW gear, the

measurement range of current is 1 A - 1,000 A. The

measurement range of voltage at both the KW gear

and W gear is 1 V -750 V.

4) There is a phase difference between the voltage

vale and current value of the inductive load and

capacitive load. Generally, the phase difference is

indicated by the phase angle Ǿ.

Note:

1) The maximum measured current is 4,000 mA at

W gear. Please do not operate by mistake.

2) The minimum measured voltage is 1 V and the

minimum measured current is 1 mA.

3) The maximum measured voltage is 750 V and the

maximum measured current is 1,000 A.

Figure 13 Schematic Diagram for Phase Angle

Measurement at KW Gear

Page 44

87 88

4.28 Harmonics measurement (voltage signal)

1)Turn the change-over switch to the kW or W gear,

first long-press the FUNC key to enter the voltage

measurement interface, and then short-press the

FUNC key to enter the harmonics measurement

interface, and switch from 1st - 20th harmonic through

pressing the Hz/%INRUSH/▲ key or LINK/REL/▼

key.

2)Input the measured voltage signal from the V end

and COM end.

3)After the measuring circuits are connected

correctly, the effective value of the nth harmonic

component shall be read.

4)Short-press the FUNC key in the harmonic

measurement interface once again to enter into THDR (relative to the actual effective value) or THD-F

(relative to the fundamental wave) measurement

mode. The main interface displays the effective value

of the nth harmonic component and the minor

interface displays the total harmonic distortion.

5)Press MAX/MIN key in the voltage measurement

interface to enter the maximum/minimum value

measurement mode. In this case, the main interface

displays the measured effective value of voltage and

the minor interface displays the maximum and

minimum values within a certain period. Press the

Hz/%INRUSH/▲ key or LINK/REL/▼ key again in this

interface to enter into the time recording interface. In

this case, the main interface displays the limited

voltage measurements, and the minor interface

displays the time of maximum and minimum values.

Warning

Electric shock.

Pay special attention to high voltage

measurement to avoid electric shock.

Do not input the voltage with the effective

value greater than AC 750.

Page 45

89 90

Note:

1)The minimum measured voltage is 1 V and the

maximum measured voltage is 750 V. This interface

will display OL for over 750 V.

Figure 14 Schematic Diagram for Harmonics

Measurement of Voltage Signal at KW Gear

Page 46

91 92

4.29 Harmonics measurement (current signal)

1) Turn the change-over switch to the kW or W gear,

first long-press the FUNC key to enter the current

measurement interface, and then short-press the

FUNC key to enter into the harmonics measurement

interface, and switch from 1st - 20th harmonic

through pressing the Hz/%INRUSH/▲ key or

LINK/REL/▼ key.

2) Clamp the measured conductor of the power

supply or load with the clamp.

3) After the measuring circuits are connected

correctly, the effective value of the nth harmonic

component shall be read.

4) Short-press the FUNC key in the harmonic

measurement interface once again to enter into

THD-R (relative to the actual effective value) or

THD-F (relative to the fundamental wave)

measurement mode. The main interface displays

the effective value of the nth harmonic component

and the minor interface displays the total harmonic

distortion.

5) Press MAX/MIN key in the current measurement

interface to enter the maximum/minimum value

measurement mode. In this case, the main interface

displays the measured effective value of current and

the minor interface displays the maximum and

minimum values within a certain period. Press the

Hz/%INRUSH/▲ key or LINK/REL/▼ key again in

this interface to enter into the time recording

interface. In this case, the main interface displays

the limited voltage measurements, and the minor

interface displays the time of max. and min. values.

Warning

Electric shock.

Pay special attention to high current

measurement to avoid electric shock.

Do not input the current with the effective

value greater than AC 1,000 A.

Page 47

93 94

Note:

1)The minimum measured current is 1 mA and the

maximum measured current is 1,000 A. This

interface will display OL for over 1,000 A.

Figure 15 Schematic Diagram for Harmonics

Measurement of Current Signal at KW Gear

5 Maintenance

5.1 Battery replacement

Warning

Before opening the battery cover of meter,

take the probe away from the measuring

circuits to avoid electric shock.

1) If the meter displays the symbol " ", the battery

shall be replaced.

2) Unscrew the fastening screw of the meter battery

cover and remove it.

3) Replace the old battery.

4) Install the battery cover in the original position.

Note:

Do not install the battery in the incorrect direction.

Page 48

95 96

5.2 Probe replacement

Do not use the probe with damage or wear trace

(exposing the white layer). Otherwise, replace it

timely.

Warning

The replaced probe shall meet the EN61010031 Standard, rated CATI III 1,000 V, and the

range of current measurement shall be 10 A

or above.

The probe with damaged insulating layer and

exposed metal wire of conductor must be replaced.

6 Delivery scope

1 x Clamp meter PCE-PCM 3

1 x Transport bag

1 x Test lead set

1 x 9V block battery

1 x User manual

Loading...

Loading...