Model 2508-01A/TCS-2A

Reaction Torque Sensor

Installation and Operating Manual

For assistance with the operation of this product,

contact PCB Piezotronics, Inc.

Toll-free: 800-828-8840

24-hour SensorLine: 716-684-0001

Fax: 716-684-0987

E-mail: info@pcb.com

Web: www.pcb.com

Service, Repair, and Return

Policies and Instructions

The information contained in this document supersedes all similar information that

may be found elsewhere in this manual.

Service – Due to the sophisticated

nature of the sensors and associated

instrumentation provided by PCB

Piezotronics, user servicing or repair is

not recommended and, if attempted,

may void the factory warranty. Routine

maintenance, such as the cleaning of

electrical connectors, housings, and

mounting surfaces with solutions and

techniques that will not harm the

physical material of construction, is

acceptable. Caution should be observed

to ensure that liquids are not permitted

to migrate into devices that are not

hermetically sealed. Such devices

should only be wiped with a dampened

cloth and never submerged or have

liquids poured upon them.

Repair – In the event that equipment

becomes damaged or ceases to

operate, arrangements should be made

to return the equipment to PCB

Piezotronics for repair. User servicing or

repair is not recommended and, if

attempted, may void the factory

warranty.

Calibration – Routine calibration of

sensors and associated instrumentation

is recommended as this helps build

confidence in measurement accuracy

and acquired data. Equipment

calibration cycles are typically

established by the users own quality

regimen. When in doubt about a

calibration cycle, a good “rule of thumb”

is to recalibrate on an annual basis. It is

also good practice to recalibrate after

exposure to any severe temperature

extreme, shock, load, or other

environmental influence, or prior to any

critical test.

PCB Piezotronics maintains an ISO9001 certified metrology laboratory and

offers calibration services, which are

accredited by A2LA to ISO/IEC 17025,

with full traceability to SI through

N.I.S.T. In addition to the normally

supplied calibration, special testing is

also available, such as: sensitivity at

elevated or cryogenic temperatures,

phase response, extended high or low

frequency response, extended range,

leak testing, hydrostatic pressure

testing, and others. For information on

standard recalibration services or

special testing, contact your local PCB

Piezotronics distributor, sales

representative, or factory customer

service representative.

Returning Equipment – Following

these procedures will ensure that your

returned materials are handled in the

most expedient manner. Before

returning any equipment to PCB

Piezotronics, contact your local

distributor, sales representative, or

factory customer service representative

to obtain a Return Warranty, Service,

Repair, and Return Policies and

Instructions Materials Authorization

(RMA) Number. This RMA number

should be clearly marked on the outside

of all package(s) and on the packing

list(s) accompanying the shipment. A

detailed account of the nature of the

problem(s) being experienced with the

equipment should also be included

inside the package(s) containing any

returned materials.

A Purchase Order, included with the

returned materials, will expedite the

turn-around of serviced equipment. It is

recommended to include authorization

on the Purchase Order for PCB to

proceed with any repairs, as long as

they do not exceed 50% of the

replacement cost of the returned

item(s). PCB will provide a price

quotation or replacement

recommendation for any item whose

repair costs would exceed 50% of

replacement cost, or any item that is not

economically feasible to repair. For

routine calibration services, the

Purchase Order should include

authorization to proceed and return at

current pricing, which can be obtained

from a factory customer service

representative.

Contact Information – International

customers should direct all inquiries to

their local distributor or sales office. A

complete list of distributors and offices

can be found at www.pcb.com.

Customers within the United States may

contact their local sales representative

or a factory customer service

representative. A complete list of sales

representatives can be found at

www.pcb.com. Toll-free telephone

numbers for a factory customer service

representative, in the division

responsible for this product, can be

found on the title page at the front of this

manual. Our ship to address and

general contact numbers are:

PCB Piezotronics, Inc.

3425 Walden Ave.

Depew, NY14043 USA

Toll-free: (800) 828-8840

24-hour SensorLineSM: (716) 684-0001

Website: www.pcb.com

E-mail: info@pcb.com

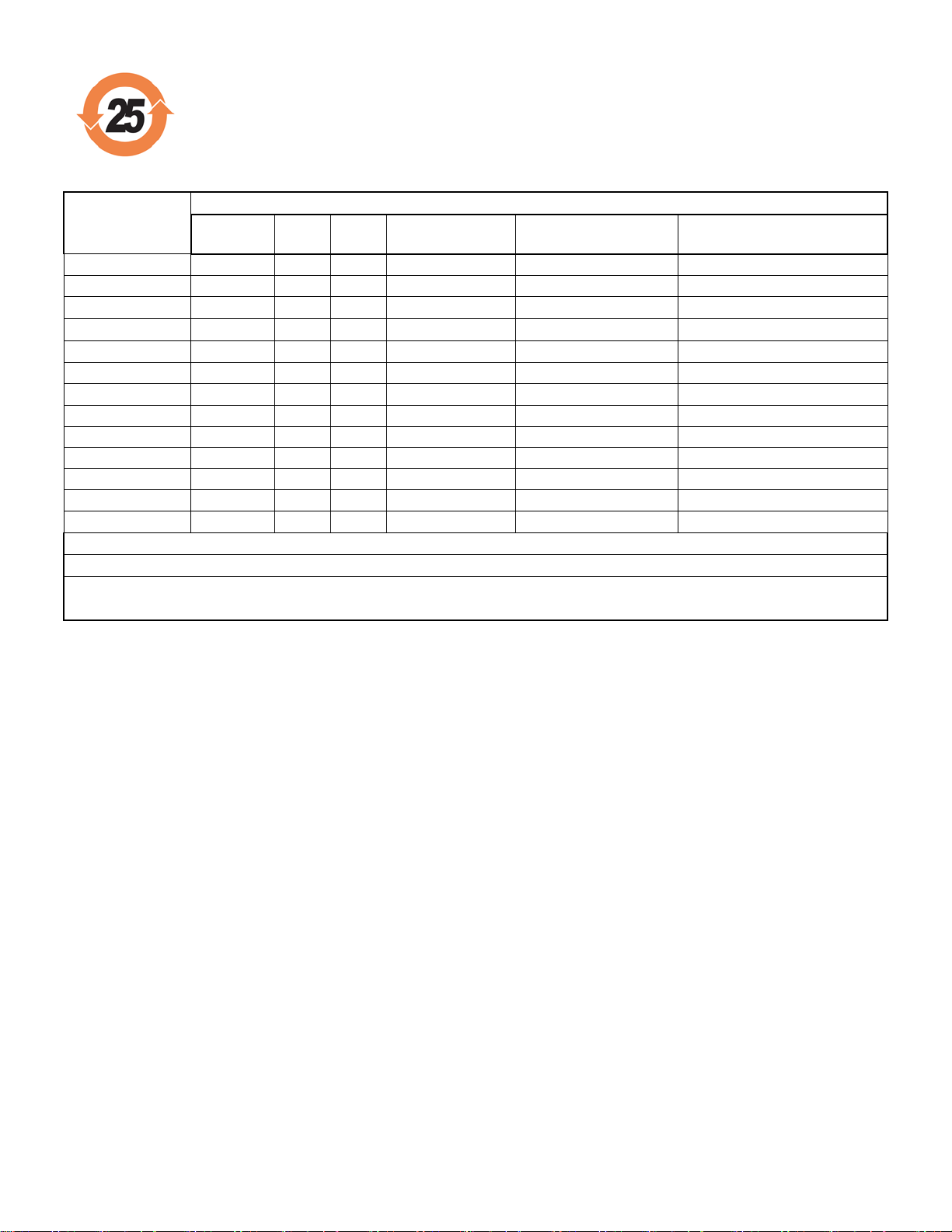

PCB工业监视和测量设备 - 中国RoHS2公布表

PCB Industrial Monitoring and Measuring Equipment - China RoHS 2 Disclosure Table

部件名称

有害物质

铅 (Pb)

汞

(Hg)

镉

(Cd)

六价铬 (Cr(VI))

多溴联苯 (PBB)

多溴二苯醚 (PBDE)

住房

O O O

O O O

PCB板

X O O

O O O

电气连接器

O O O

O O O

压电晶体

X O O

O O O

环氧

O O O

O O O

铁氟龙

O O O

O O O

电子

O O O

O O O

厚膜基板

O O X

O O O

电线

O O O

O O O

电缆

X O O

O O O

塑料

O O O

O O O

焊接

X O O

O O O

铜合金/黄铜

X O O

O O O

本表格依据 SJ/T 11364 的规定编制。

O: 表示该有害物质在该部件所有均质材料中的含量均在 GB/T 26572 规定的限量要求以下。

X: 表示该有害物质至少在该部件的某一均质材料中的含量超出 GB/T 26572 规定的限量要求。

铅是欧洲RoHS指令2011/65/ EU附件三和附件四目前由于允许的豁免。

CHINA RoHS COMPLIANCE

Component Name

Hazardous Substances

Lead

(Pb)

Mercury

(Hg)

Cadmium

(Cd)

Chromium VI

Compounds

(Cr(VI))

Polybrominated

Biphenyls

(PBB)

Polybrominated

Diphenyl

Ethers (PBDE)

Housing O O O O O O

PCB Board

X O O O O

O

Electrical

Connectors

O O O O O

O

Piezoelectric

Crystals

X O O O O

O

Epoxy O O O O O O

Teflon O O O O O O

Electronics

O O O O O

O

Thick Film

Substrate

O O X O O

O

Wires O O O O O O

Cables X O O O O O

Plastic O O O O O O

Solder X O O O O O

Copper Alloy/Brass

X O O O O

O

This table is prepared in accordance with the provisions of SJ/T 11364.

O: Indicates that said hazardous substance contained in all of the homogeneous materials for this part is below the limit

requirement of GB/T 26572.

X: Indicates that said hazardous substance contained in at least one of the homogeneous materials for this part is above

the limit requirement of GB/T 26572.

Lead is present due to allowed exemption in Annex III or Annex IV of the European RoHS Directive 2011/65/EU.

DOCUMENT NUMBER: 21354

DOCUMENT REVISION: D

ECN: 46162

REACTION TORQUE SENSOR OPERATION MANUAL

TABLE OF CONTENTS

Section Page

1.0 Introduction 2

2.0 Safety Information 3

3.0 Mechanical Installation 3

4.0 Electrical Installation 4

5.0 Polarity 4

6.0 Shunt Calibration 4

7.0 Operation 5

8.0 Troubleshooting 6

9.0 Maintenance 6

LIST OF ILLUSTRATIONS

Figure Page

1. Flange Mount Reaction Torque Sensor 2

2. Wheatstone Bridge Circuit 2

3. Western Regional Strain Gage Committee Wiring Code 2

4. Axis and Sense Nomenclature 3

5. Reaction Torque Sensor Configurations 3

6. Shunt Resistor Locations 4

7. Reaction Torque Sensor System Configurations 5

1

MANUAL NUMBER: 18622

MANUAL REVISION: A

ECN NUMBER: 17765

VOLTAGE IN

VOLTAGE OUT

REACTION TORQUE SENSOR OPERATION MANUAL

2

1.0 INTRODUCTION

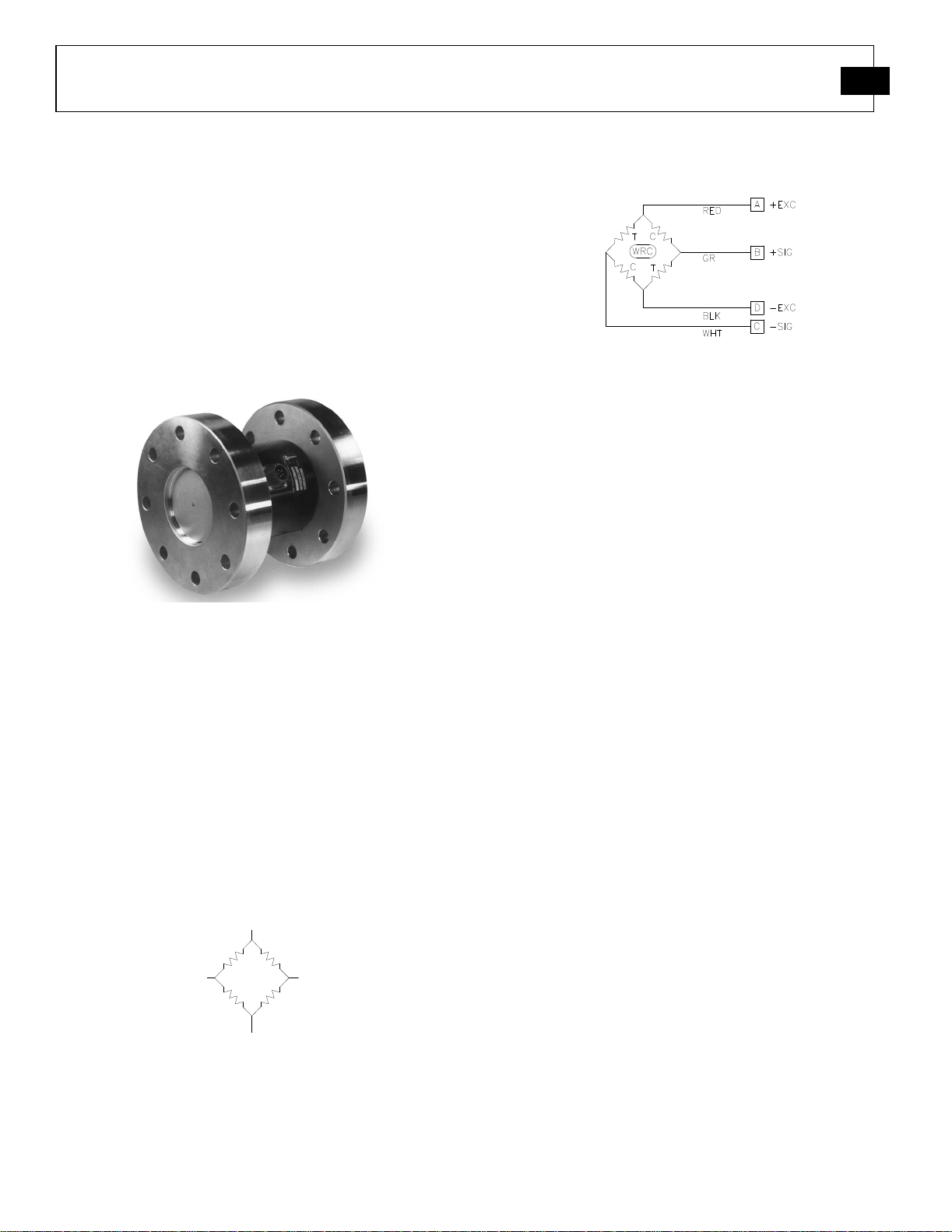

Reaction torque sensors manufactured by the ForceTorque Division of PCB are strain gage based

measuring instruments suitable for a wide range of

torque measurement applications. They are rigid

structures with no moving parts and are typically

mounted in a fixed position. Their output signal

varies proportionally to an applied torsional force.

Capacities range from 5 to 500k in-lb (0.56 to 56.5k

N-m).

Figure 1 – Flange Mount Reaction Torque Sensor

Due to the fact that these sensors do not utilize

bearings, slip rings, or any other rotating elements,

their installation and use can be very cost effective.

Reaction torque sensors are particularly useful in

applications where the introduction of a rotating

mass between the driver and driven is undesirable.

All models utilize strain gages configured into a

Wheatstone Bridge Circuit to produce the primary

sensing element. The four-arm Wheatstone Bridge

configuration is shown below in Figure 2.

SIGNAL OUT

SIGNAL IN

Figure 2 - Wheatstone Bridge Circuit

Most PCB reaction torque sensors follow a wiring

code established by the Western Regional Strain

Gage Committee as revised in May 1960. The

wiring code is as follows:

Figure 3 - Western Regional Strain Gage Committee

Wiring Code

Refer to the wiring drawing included with this

manual for specific wiring of the supplied torque

sensor.

The gages are bonded to the sensor’s structure.

Typically, a regulated DC or AC excitation is

applied between A and D of the bridge. When

torque is applied to the sensor, the Wheatstone

Bridge becomes unbalanced, causing an output

voltage between B and C which is proportional to

the applied torque. The magnitude of the output

voltage corresponds to the torsional deflection of

the sensor structure and therefore the applied torque.

This configuration allows for temperature and

pressure compensation, as well as cancellation of

signals caused by forces not directly applied to the

axis of the applied load. Output is typically

expressed in units of millivolt per volt of excitation.

Optional signal conditioners are available from

PCB. A signal conditioner may have analog voltage

output, current output, or digital output. Digital

display signal conditioners are also available.

Axis Definition

PCB force products comply with the Axis and

Sense Definitions of NAS-938 (National Aerospace

Standard-Machine Axis and Motion) nomenclature

and recommendations of the Western Regional

Strain Gage committee. These axes are defined in

terms of a "Right Handed" orthogonal coordinate

system as show below. A (+) sign indicates force in

a direction which produces a (+) signal voltage and

generally defines a clockwise torque.

REACTION TORQUE SENSOR OPERATION MANUAL

3

Figure 4 - Axis and Sense Nomenclature for PCB Reaction

Torque Sensors

The principal axis of a transducer is normally the

MZ axis. The MZ axis will also be the axis of radial

symmetry or axis of rotation. In the event there is no

clearly defined axis, the following preference

system will be used z,x,y.

2.0 SAFETY INFORMATION

Failure of the sensor structure or fasteners used in

its installation may cause personal injury and

equipment damage. To prevent structure failure,

review the extraneous load limits listed on the

specification sheet supplied with this manual.

Extraneous load limits are extraneous side force,

thrust and bending moment that may be applied

without electrical or mechanical damage to the

torque sensor. Do not exceed moment (W x S) or

shear (W) whichever attained first. Measurement

inaccuracy and structure damage may result. Install

the sensor in a manner that minimizes these loads.

In addition, review data from manufacturers of

fixtures and fasteners used in the sensors

installation to determine if failure might occur due

to these loads.

3.0 MECHANICAL INSTALLATION

Refer to the outline drawing supplied with this

manual for specific outline dimensions and

installation details for your particular model. The

specification is also included to provide details of

the sensor’s characteristic properties.

Shown below are some of the standard reaction

torque sensor configurations offered by the

Force/Torque Division.

Figure 5 – Reaction Torque Sensor Configurations

REACTION TORQUE SENSOR OPERATION MANUAL

4

4.0 ELECTRICAL INSTALLATION

For proper electrical connections, refer to the

installation drawing for the torque sensor, and the

wiring drawing for the signal conditioner used.

Construct the interconnect cable from high-quality

shielded instrumentation cable. Various cable

assemblies are available through PCB.

Connect one end of the cable to the sensor

connector and the other end to the signal

conditioner. Make sure to tighten the cable

connector to the sensor. For installation in dirty,

humid, or rugged environments, it is suggested that

the connection be shielded against dust or moisture

with shrink tubing or other protective material.

Strain relieving the cable/sensor connection can also

prolong cable life. Mounting cables to a test

structure with tape, clamps, or adhesives minimizes

cable whip.

5.0 POLARITY

Clockwise torque upon standard PCB reaction

torque sensors produces a positive-going voltage

output. Counter-clockwise torque produces a

negative-going voltage output.

6.0 SHUNT CALIBRATION

Shunt calibration is the known, electrical,

unbalancing of a strain gage bridge by means of a

fixed resistor that is placed, or “shunted”, across

one leg of the bridge. The “Wheatstone Bridge”

utilized by PCB reaction torque sensors are typically

calibrated using the shunt calibration technique.

Shunt calibration is a method of periodically

checking the gain or span of a signal conditioner,

which is used in conjunction with a strain gage

based transducer, without exposing the transducer to

known, traceable, physical input values. If required,

adjustments can then be made to the signal

conditioner to insure accurate measurement results.

The strain gage bridge is “in balance” when the host

mechanical structure is unloaded and unstressed.

As the host structure (diaphragm, bending beam,

shear beam, column, etc.) is loaded or stressed, the

Wheatstone Bridge becomes unbalanced, resulting

in an output signal that is proportional to the applied

load.

Shunt calibration simulates the mechanical input to

a transducer by unbalancing the bridge with a fixed

resistor placed across, or in parallel with, one leg of

the bridge. For tension shunt calibration, or +CAL,

the shunt resistor (Rst) is shunted across the

+Excitation (A) and +Signal (B) leg of the bridge.

For compression shunt calibration, or –CAL, the

shunt resistor (Rsc) is shunted across the -Excitation

(D) and +Signal (B) leg of the bridge. Refer to

Figure 6 for shunt resistor locations in the

Wheatstone Bridge circuit.

Figure 6 - Shunt Resistor Locations

Shunt Calibration Procedure

1. Connect the transducer to an appropriate strain

gage signal conditioner and allow adequate time

for the system to stabilize.

2. Apply a full-scale, N.I.S.T. traceable,

mechanical input (or torque) to the transducer.

3. Adjust the signal conditioner’s gain or span

controls, as required, to obtain a full-scale

electrical output signal, and/or numeric display

that represents the applied, mechanical input

quantity.

4. Remove the mechanical input (or torque).

5. Place the shunt calibration resistor across an

appropriate leg of the Wheatstone Bridge as

discussed above.

REACTION TORQUE SENSOR OPERATION MANUAL

5

6. Record the value of the signal conditioner’s

output signal and/or numeric display. This

value is the shunt calibration value, or

equivalent torque.

7. It is important to note that the shunt calibration

used. This value, and the particular resistor, are

now matched to the transducer and form a basis

of the transferable shunt calibration.

value is specific for the particular shunt resistor

Recalculating Shunt Calibration Value

The shunt calibration resistor value and the resulting transducer output can be recalculated using the following

formula:

Supplied Transducer Output

= New Resistor Value

New Transducer Output Supplied Resistor Value

Shunt calibration is accepted throughout the industry as a means of periodic calibration of a signal conditioner

and transducer between calibrations of known, applied, traceable, mechanical, input values. Consequently, most

all strain gage transducer manufacturers collect and supply shunt calibration data, along with a shunt calibration

resistor, as a standard feature.

7.0 OPERATION

Figure 7 – Reaction Torque Sensor System Configurations

Typical Reaction Torque Sensor System Configurations

Operation requires the connection of the sensor to a signal conditioner, then to a readout device (if signal

conditioner does not have a display). Strain gage signal conditioners and cable assemblies are available from

PCB.

Operation with a Signal Conditioner

The signal conditioner span and zero must be set before the torque sensor system can be used. The span can be

set using dead weights or the shunt calibration value. Refer to the shunt calibration information in this manual,

and the signal conditioner instruction manual, for proper set-up information.

REACTION TORQUE SENSOR OPERATION MANUAL

8.0 TROUBLESHOOTING

No output

No power

Loose or dirty connections

Circuit opens or shorts

Faulty or improper wiring

No load applied

Erratic or Improper Readings

Excitation voltage drift

Electrical noise

Loose fixturing

Circuit opens or shorts

Improper torque applied

Cable too long

Blinking Display

Overload condition

Open circuit

Zero Balance

Torque applied to sensor

Overloaded or side-loaded sensor

Open circuit

Improper electrical connections

Zero Shift

Fixture preload

Faulty or improper wiring

Improper tare

Zero Drift

Unconditioned power supply

Circuit opens or shorts

Loose wiring

RFI/EMI interface

Temperature change

Damaged or Deformed Equipment

Improper use

Often overlooked by the customer, is the error due

to the presence of non-measured forces and bending

moments. Even Though the Single Axis of

6

Measurement sensors are designed and built to

withstand these non-measured forces and bending

moments (extraneous loads), the errors due to them

are present. PCB engineers can design the set-up to

eliminate or minimize these extraneous loads.

However, if these extraneous loads are present, the

errors due to them should be considered. Due to

cost restraints, the Force/Torque Division, as with

its competition, does not typically measure or

compensate for errors due to extraneous loads. If

the presences of these extraneous loads are known,

the user should request the transducer manufacturer

to run a special test, at extra cost, to define and

quantify the extraneous load errors. These errors are

defined as cross-talk errors.

Error Analysis

The Force/Torque Division typically supplies

accuracy information on its products in the form of

individual errors (see specification sheet). They are:

Non-Linearity, Hysteresis, Non-Repeatability,

Effect of Temperature on Zero, and Effect of

Temperature on Output.

The customer can combine these individual errors to

establish the maximum possible error for the

measurement or just examine the applicable

individual error. If the temperature remains stable

during the test, temperature related errors may be

ignored. If the sensor is used for increasing load

measurement only, ignore the Hysteresis error. If

the load measurement is near the full capacity, the

linearity error can be ignored. If the capability exists

to correct the data through linearization-fit or a

look-up-table, the error in the measurement can be

minimized. A sophisticated user can get rid of all

the errors except for the non-repeatability error in

the measurement.

9.0 MAINTENANCE

Routine maintenance, such as cleaning of electrical

connectors, housings, and mounting surfaces with

solutions and techniques that will not harm the

physical material of construction is acceptable.

REACTION TORQUE SENSOR OPERATION MANUAL

7

Caution should be observed to insure that liquids

are not permitted to migrate into devices that are not

hermetically sealed. Such devices should only be

wiped with a damp cloth and never submerged or

have liquids poured on them.

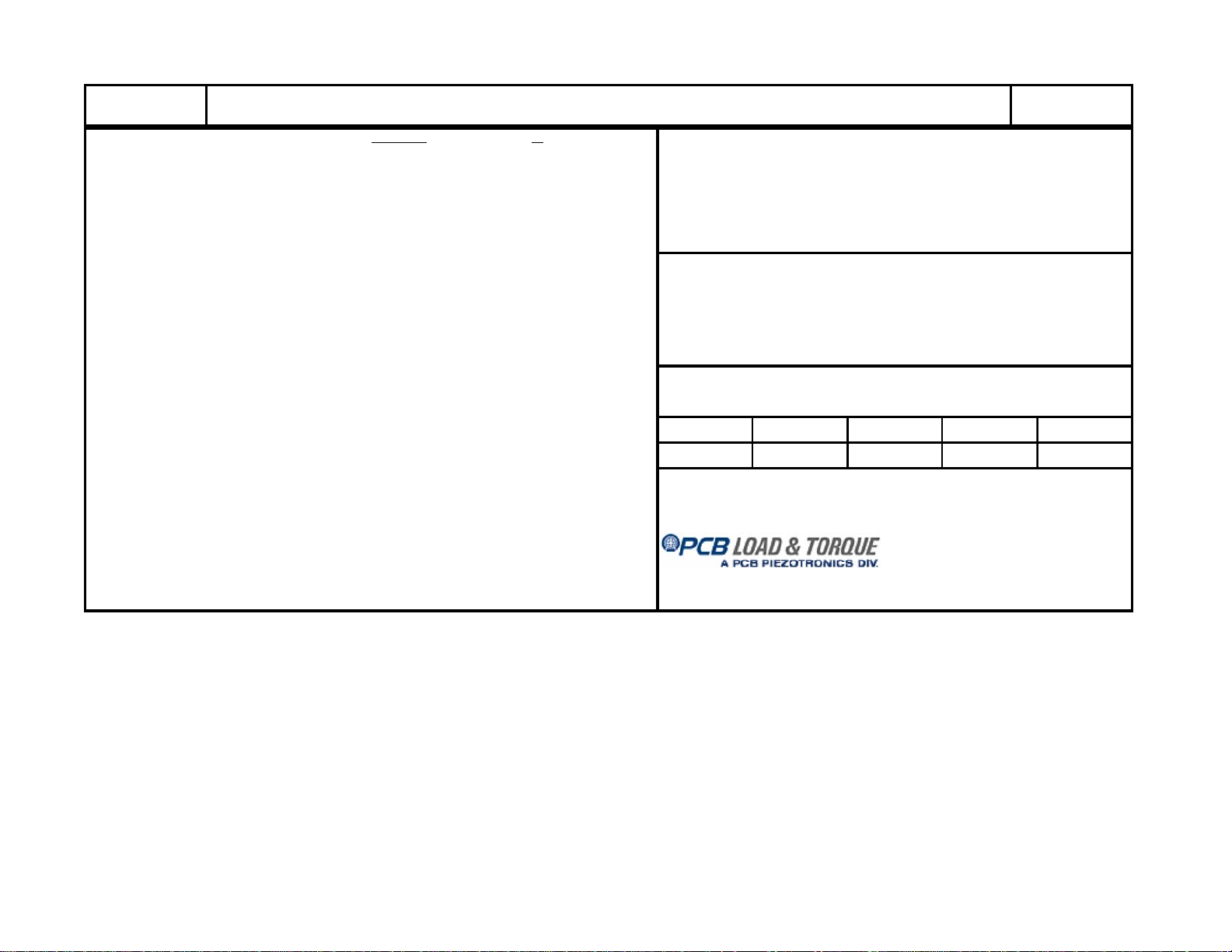

Model Number

e

I

l

l

.

[4]

.

2508-01A

Performanc

Measurement Range(Full Scale Capacity) 50 lbf-in 5.65 Nm

Sensitivity(output at rated capacity) 2 mV/V 2 mV/V

Non-Linearity ≤ 0.10 % FS ≤ 0.10 % FS

Hysteresis ≤ 0.10 % FS ≤ 0.10 % FS

Non-Repeatability ≤ 0.02 % FS ≤ 0.02 % FS

Resonant Frequency 380 Hz 380 Hz

Maximum Torque 75 lbf-in 8.47 Nm

ENGLISH S

REACTION TORQUE SENSOR

Environmenta

Overload Limit(Axial Thrust) 200 lbf 890 N

Overload Limit(Overhung Moment) 50 lbf-in 5.65 Nm

Overload Limit(Shear) 13 lbf 57.8 N

Temperature Range(Operating) -65 to +200 °F -54 to +93 °C

Temperature Range(Compensated) +70 to +170 °F +21 to +77 °C

Temperature Effect on Output(Maximum) ± 0.002 %Reading/°F ± 0.0036 %Reading/°C

Temperature Effect on Zero Balance(Maximum) ± 0.002 %FS/°F ± 0.0036 %FS/°C

Electrical

Bridge Resistance 700 Ohm 700 Ohm

Excitation Voltage(Recommended) 10 VDC 10 VDC

Insulation Resistance 5 GOhm 5 GOhm

Zero Balance ≤ 1.0 %RO ≤ 1.0 %RO

Output Polarity cw+ cw+

Physica

Size (Diameter x Length) 2.0 in x 3.0 in 50.8 mm x 76.2 mm

Weight 2.0 lb 908 g

Mounting Flange (#10-24 Bolts) Flange (No Metric Equivalent)

Torsional Stiffness 2350 lbf-in/radian 265.5 N-m/radian

Sensing Element Strain Gage Strain Gage

Housing Material(Sensor) Anodized Aluminum Anodized Aluminum

Electrical Connector PT02E-10-6P PT02E-10-6P

All specifications are at room temperature unless otherwise specified.

In the interest of constant product improvement, we reserve the right to change specifications without notice.

Revision: G

ECN #: 47636

OPTIONAL VERSIONS

Optional versions have identical specifications and accessories as listed for the standard model

[5][4]

[4]

[4]

[4]

NOTES:

[2]

[1] Calibrated at 10 VDC, usable 5 to 20 VDC or VAC RMS

[2]

[2] Singularly applied, i.e. no other extraneous loads.

[2]

[3] Over compensated operating temperature range.

FS - Full Scale

[5] Nominal.

[3]

[6] See Drawing 32786 for Complete Dimensions

[4][3]

except where noted below. More than one option may be used.

SUPPLIED ACCESSORIES:

Model 181-012A PT06A-10-6S(SR) (1)

[1]

Entered: LK Engineer: PE Sales: KH Approved: JSD Spec Number:

Date: 2/22/2018 Date: 2/22/2018 Date: 2/22/2018Date: 2/22/2018

[6]

PCB Load & Torque

A Division of PCB Piezotronics

24350 Indoplex Circle

Farmington Hills, MI 48335

UNITED STATES

Phone: 866-684-7107

E-Mail: LTSales@pcb.com

Web site: www.pcb.com/LoadAndTorque

18531

PCB Load & Torque Inc. claims proprietary rights in

the information disclosed hereon. Neither it nor any

reproduction thereof will be disclosed to others without

the written consent of PCB Load and Torque Inc.

6

4

3

2

REVISIONS

REV DESCRIPTION ECO

D

UPDATED GD&T SPECS - 05.02.16, PTE

1

45413

8

7

2

3

1.00 [25.4]

B B

o

PT02E-10-6P RECEPTACLE

PIN A +EXC.

PIN B +SIG.

PIN C -SIG.

PIN D -EXC.

PIN E N/C

PIN F N/C

.253

6.43

.251

.001 A

.001 B

[ ]

6.38

2X

i

b

1.44 [36.6]

1.91 [48.4]

A

1.627

Ø

1.625

41.33

[ ]

41.28

1.627

1.625

41.33

[ ]

41.28

2.00 [50.8]Ø

45°

n

1.250 [31.75]2X B.C.

.14 [3.6]2X

r

.001 A

.31 [7.9] 2.38 [60.5]

10-24 UNC - 2B x .384X

EQUALLY SPACED

BOTH ENDS

n

.005 A

j

A A

b

B

.001 A

3.00 [76.2]

f

.001 B

UNLESS OTHERWISE SPECIFIED TOLERANCES ARE:

DIMENSIONS IN INCHES

DECIMALS XX ±.01

ANGLES

4

3

XXX ±.005

`

.5 DEGREES

FILLETS AND RADII

.015 MAX

DIMENSIONS IN MILLIMETERS

[ IN BRACKETS ]

DECIMALS X ± 0.3

ANGLES

XX ± 0.13

`

.5 DEGREES

FILLETS AND RADII

0.38 MAX

2

DRAWN CHECKED ENGINEER

01.20.12

MDF

TITLE

ECB

01.26.12

OUTLINE DRAWING

2508 SERIES

TORQUE SENSOR

PTE

1/20/12

24350 Indoplex Circ le, Farmington Hills,MI 48335

(716) 684-0001 E-M AIL: ltinfo@pcbloadtorque.com

DWG. NO.

32786

SCALE: SHEET

1

1 OF 1FULL

Loading...

Loading...