PCB Piezotronics 377B02, 426B03, HT378B02, 426B31, 377A12 Installation And Operating Manual

...

Model 377B02

Precision Condenser Microphone

Installation and Operating Manual

For assistance with the operation of this product,

contact PCB Piezotronics, Inc.

Toll-free: 800-828-8840

24-hour SensorLine: 716-684-0001

Fax: 716-684-0987

E-mail: info@pcb.com

Web: www.pcb.com

Warranty, Service, Repair, and

Return Policies and Instructions

The informati on contained in this document supersedes all similar i nformation th at

may be found elsewhere in this manual.

Total Customer Satisfaction – PCB

Piezotronics guarantees Total Customer

Satisfaction. If, at any time, for any

reason, you are not completely satisfied

with any PCB product, PCB will repair,

replace, or exchange it at no charge. You

may also choose to have your purchase

price refunded in lieu of the repair,

replacement, or exchange of the product.

Service – Due to the sophisticated nature

of the sensors and associated

instrumentation provided by PCB

Piezotronics, user servicing or repair is

not recommended and, if attempted, may

void the factory warranty. Routine

maintenance, such as the cleaning of

electrical connectors, housings, and

mounting surfaces with solutions and

techniques that will not harm the

physical material of construction, is

acceptable. Caution should be observed

to insure that liquids are not permitted to

migrate into devices that are not

hermetically sealed. Such devices should

only be wiped with a dampened cloth

and never submerged or have liquids

poured upon them.

Repair – In the event that equipment

becomes damaged or ceases to operate,

arrangements should be made to return

the equipment to PCB Piezotronics for

repair. User servicing or repair is not

recommended and, if attempted, may

void the factory warranty.

Calibration – Routine calibration of

sensors and associated instrumentation is

recommended as this helps build

confidence in measurement accuracy and

acquired data. Equipment calibration

cycles are typically established by the

users own quality regimen. When in

doubt about a calibration cycle, a good

“rule of thumb” is to recalibrate on an

annual basis. It is also good practice to

recalibrate after exposure to any severe

temperature extreme, shock, load, or

other environmental influence, or prior

to any critical test.

PCB Piezotronics maintains an ISO9001 certified metrology laboratory and

offers calibration services, which are

accredited by A2LA to ISO/IEC 17025,

with full traceablility to N.I.S.T. In

addition to the normally supplied

calibration, special testing is also

available, such as: sensitivity at elevated

or cryogenic temperatures, phase

response, extended high or low

frequency response, extended range, leak

testing, hydrostatic pressure testing, and

others. For information on standard

recalibration services or special testing,

contact your local PCB Piezotronics

distributor, sales representative, or

factory customer service representative.

Returning Equipment – Following

these procedures will insure that your

returned materials are handled in the

most expedient manner. Before returning

any equipment to PCB Piezotronics,

contact your local distributor, sales

representative, or factory customer

service representative to obtain a Return

Materials Authorization (RMA)

Number. This RMA number should be

clearly marked on the outside of all

package(s) and on the packing list(s)

accompanying the shipment. A detailed

account of the nature of the problem(s)

being experienced with the equipment

should also be included inside the

package(s) containing any returned

materials.

A Purchase Order, included with the

returned materials, will expedite the

turn-around of serviced equipment. It is

recommended to include authorization

on the Purchase Order for PCB to

proceed with any repairs, as long as they

do not exceed 50% of the replacement

cost of the returned item(s). PCB will

provide a price quotation or replacement

recommendation for any item whose

repair costs would exceed 50% of

replacement cost, or any item that i s not

economically feasible to repair. For

routine calibration services, the Purchase

Order should include authorization to

proceed and return at current pricing,

which can be obtained from a factory

customer service representative.

Warranty – All equipment and repair

services provided by PCB Piezotronics,

Inc. are covered by a limited warranty

against defective material and

workmanship for a period of one year

from date of original purchase. Contact

DOCUMENT NUMBER: 21354

DOCUMENT REVISION: B

ECN: 17900

PCB for a complete statement of our

warranty. Expendable items, such as

batteries and mounting hardware, are not

covered by warranty. Mechanical

damage to equipment due to improper

use is not covered by warranty.

Electronic circuitry failure caused by the

introduction of unregulated or improper

excitation power or electrostatic

discharge is not covered by warranty.

Contact Information – International

customers should direct all inquiries to

their local distributor or sales office. A

complete list of distributors and offices

can be found at www.pcb.com.

Customers within the United States may

contact their local sales representative or

a factory customer service

representative. A complete list of sales

representatives can be found at

www.pcb.com. Toll-free telephone

numbers for a factory customer service

representative, in the division

responsible for this product, can be

found on the title page at the front of this

manual. Our ship to address and general

contact numbers are:

PCB Piezotronics, I nc.

3425 Walden Ave.

Depew, NY 14043 USA

Toll-free: (800) 828-8840

24-hour SensorLine

SM

: (716) 684-0001

Website: www.pcb.com

E-mail: info@pcb.com

PRODUCT GUIDE

377 SERIES MICROPHONES

426 SERIES PREAMPLIFIERS

Contents:

1.0 Introduction ................................................................................ 1

2.0 Standards .................................................................................... 1

3.0 Setting up a Microphone Measurement System ........................ 1

4.0 Taking Measurements ................................................................ 2

5.0 Accessories ................................................................................. 3

6.0 Maintenance ............................................................................... 3

7.0 Calibration .................................................................................. 4

8.0 Warranty and Service ................................................................. 4

1.0 Introduction

Thank you for your purchase of a PCB high quality microphone. These microphones offer highly accurate

and reliable acoustic measurements and are typically used in research and design applications. They are

accurate enough for laboratory usage, yet rugged enough for field-testing.

Sound within the typical 20 to 20,000 Hz audible range of a healthy human ear can either be pleasing to

the ear, as in music, or unpleasant (or harmful), as in noise. As a result, many applications, from the development of consumer products to research in acoustics, measure sound, even sound outside the range of

human hearing. The instrument typically used to measure sound is the microphone, which is designed,

like the human ear, to transform pressure oscillations into a corresponding voltage oscillation.

2.0 Standards

Before selecting an acoustical instrument, it is important to identify which acoustical standards are appropriate for the application in which the instrument will be used. Whether for legal purposes or for quality

assurance programs, these standards will help determine the required quality, accuracy and consistency of

the instrument. Standards that correspond to the performance requirements, dimensions and characteristics of acoustical components are established for microphones, sound level meters, calibrators, or other

related components. The most common organizations producing these standards are the American National Standards Institute (ANSI) and the International Electrotechnical Commission (IEC). IEC 1094-4

establishes specifications for the mechanical dimensions and certain electroacoustic characteristics for

standard industrial microphones. The performance specification sheet supplied with each PCB microphone identifies the standards to which the microphone is compliant.

3.0 Setting up a Microphone Measurement System

After the proper microphone has been selected, the corresponding preamplifier, cabling, power supplies,

signal conditioning and data acquisition selections are ready to be installed. Not all of these components

are required for all test set-ups. The figures below show typical set-ups for externally polarized and prepolarized microphone systems.

A prepolarized microphone can be used with a standard Microphone Power Supply designed for externally polarized microphones, and its preamplifier, provided the supply voltage is set to zero.

1

dB

PS

V

SPL

ref

rms

Log20

dB

Pressure

Example

0

0.00002 Pa

Threshold of Hearing

60

0.02 Pa

Business Office

80

0.2 Pa

Shop Noise

94

1 Pa

Large Truck

100

2 Pa

Jackhammer

120

20 Pa

Airplane Take-Off

140

200 Pa

Threshold of Pain

Externally Polarized Microphone System

Prepolarized Microphone System

4.0 Taking Measurements

The following formula is used to calculate the pressure measured by the microphone from the output voltage signal. The sensitivity of a microphone is typically measured at 250 Hz.

Pressure (Pa) = Voltage (mV) / Sensitivity (mV/Pa).

The lowest amplitude a healthy human ear can detect is 20 millionths of a Pascal (20Pa). Another scale

more commonly used to describe sound pressure level is the decibel (dB). To convert the output voltage

signal (measured in Vrms) to sound pressure level (measured in decibels), use the following formula:

where S is the sensitivity of the microphone in mV/Pa, and P

is the reference pressure in air, which is

ref

20 x 10-6 Pa. The decibel scale is logarithmic and more closely matches the response reactions of the

human ear to the pressure fluctuations. Some examples of typical sound pressure levels are shown in the

table below.

At very high-pressure amplitudes, the microphone’s diaphragm will start to distort the measured sound

pressure. The maximum rated sound pressure level of a microphone is expressed as the amplitude at

which the Total Harmonic Distortion (THD) reaches a specified amount, typically 3% THD. It is important to note that the highest sound pressure level that can be measured with a microphone system may

be limited by other parts of the system, such as the preamplifier, signal conditioner, or instrumentation.

Conversely, the Cartridge Thermal Noise (CTN) specification provides the lowest measurable sound pressure level that can be detected above the electrical noise inherent within the microphone.

2

Temperature and pressure will affect the sensitivity of a microphone but these effects can be accounted

for by adjusting the recorded microphone values using the coefficients specified for each microphone

model. Simply calculate the difference in temperature and ambient pressure from those recorded during

calibration and multiply this value by the proper coefficient to determine the sensitivity offset. In most

cases, the offset will be very small and is therefore unnecessary.

5.0 Accessories

Transducer Electronics Data Sheet (TEDS)

Preamplifiers can incorporate TEDS devices, which have a built in read/write memory that contains relevant information about the sensor and its use. Information includes manufacturer name, model number,

serial number, sensitivity, etc. The operation of TEDS devices is defined by IEEE P1451.4. A TEDS microphone system includes a microphone mated with a preamplifier that contains the TEDS memory programmed with both the microphone and preamplifier information. This is particularly helpful when using

large channel count systems and array set-up.

A-Weight Inline Filter

The inline filter is used in conjunction with an ICP® preamplifier to provide A-weighting for acoustical

measurements. The filter’s frequency response is weighted according to the A-weighting filter portion of

both ANSI S1.4 and IEC 60651 Type 1 Sound Level Meter Standards. ICP® signal conditioners of 4 mA

or greater are recommended when using inline filters.

Windscreens and Nose cones

Wind induced noise can be reduced by using a windscreen. This can offer some protection against dust

particles and mechanical damage. In the presence of high-speed airflow from a well-defined direction,

such as wind tunnels, a nose cone is recommended. When using windscreens and noise cones, the frequency response of the microphone will be attenuated at higher frequencies.

Clamps and stands

When holding a microphone in place, it is important to minimize the influence of the stand on the sound

being measured. This can be accomplished by using low profile stands and clamps available from PCB.

Cables and Electronics

PCB carries LEMO cables as well as coaxial cables with BNC and 10-32 connectors. Traditional externally polarized microphone power supplies along with a variety of ICP® signal conditioners are available

that will fit almost any need.

6.0 Maintenance

Microphones are very stable over long periods of time, provided they are handled and stored properly.

The microphone contains fragile components that can be damaged by misuse, in particular the diaphragm,

which is made up of a very thin proprietary material and should be kept clean of dust, dirt, moisture and

free any type of imperfection (scratch, dent, etc.).

The microphone’s grid cap is designed to let the true sound pressure level through to the diaphragm while

preventing items from coming in contact with it. We do not recommend that you ever remove the grid cap

or clean the microphone. If you take the precautionary measures to keep the microphone clean and dry, it

should not be necessary. Use of accessories, like windscreens, and desiccants will help keep moisture off

the microphone and maintain the specified sensitivity level. Nose cones will help keep turbulence off the

microphone diaphragm and allow the sound pressure to be measured with greater accuracy.

Keep the microphone and preamplifier assembled while preparing for testing. Keep the rubber maintenance caps on the preamplifier’s electrical connector only. Do not place these rubber caps over the microphone. This will create a vacuum and undo pressure on the microphone diaphragm, which can stretch the

diaphragm and cause a change in sensitivity. Store the microphones and preamplifiers in their protective

3

cases when not in use. With proper maintenance, the microphone and preamplifier should provide stable

Manual Number: 27042

Manual Revision: C

ECO 42502

Printed in the U.S.A.

and accurate results for years to come.

Dust, rain, oil, moisture or exposure to extreme temperatures may adversely affect the microphone and

preamplifier’s performance. If the microphone or the inside of the connection area of the preamplifier becomes contaminated, use a light pressure rubber bulb to gently blow clean, dry air onto the unit in order to

remove the dust. In the event that you absolutely must take off the grid cap and clean the microphone diaphragm, we recommend using a blow bulb or a light pressure, clean and dry air hose to gently blow contamination off the diaphragm. The direction of the air should be parallel with the diaphragm, not directly

(0 degree incidence) pointed at the diaphragm. Do not touch the microphone’s diaphragm with your fingers or let it come in contact with any sharp or pointed object. Please note that any contact to the microphone’s diaphragm can negatively impact the sensitivity and long term stability of the microphone.

If the microphone is ever dropped or comes into contact with any contamination, or is exposed to extreme

temperatures, we recommend immediate recalibration of the microphone. Please note that heat from your

hands can affect the calibration results. It is always good practice to wait a minimum of 30 seconds after

placing the microphone on a test system before taking a calibration reading in order to minimize the effect

that heat from your hands has on the calibration.

7.0 Calibration

PCB offers recalibration services for our precision microphones, as well as units produced by other A2LA

manufacturers. Our internal metrology laboratory is certified to ISO 9001, accredited by A2LA to ANSI/IEC 17025 and ANSI/NCSL Z540-1, complies with ISO 10012-1 (and former MIL-STD-45662A), and

uses equipment directly traceable to one or more of the following National Labs (NIST, PTB or DFM).

Our investment in equipment, traceability and conformance to industry standards ensures accurate calibration against relevant specifications. We also carry a line of acoustic calibrators that can be used to calibrate microphone sensitivity on site as needed.

8.0 Warranty and Service

All equipment and repair services provided by PCB Piezotronics, Inc. are covered by a warranty against

defective material and workmanship under a Total Customer Satisfaction policy. If, at any time, for any

reason, you are not completely satisfied with any PCB product, PCB will repair, replace, or exchange it at

no charge. You may also choose to have your purchase price refunded. See the supplemental sheet, contained with this manual, for information on our service, repair and return policies, procedures and instructions. When unexpected problems arise, call our 24-Hour SensorLineSM (716-684-0001) to speak with an

Application Engineer. Visit www.pcb.com for a complete statement of our warranty.

3425 Walden Avenue, Depew, NY 14043-2495 24-hour SensorLineSM: 716-684-0001

E-Mail: info@pcb.com U.S.A. Fax: 716-684-0987

Website: www.pcb.com Toll-free (in the U.S.A.): 800-828-8840

A PCB GROUP COMPANY ISO 9001 CERTIFIED A2LA ACCREDITED to ISO 17025

2014 PCB Group, Inc. In the interest of constant product improvement, specifications are subject to change without notice.

PCB and ICP are registered trademarks of PCB Group, Inc. Sensor Line is a service mark of PCB Group, Inc. All other trademarks are properties of the respective owners.

4

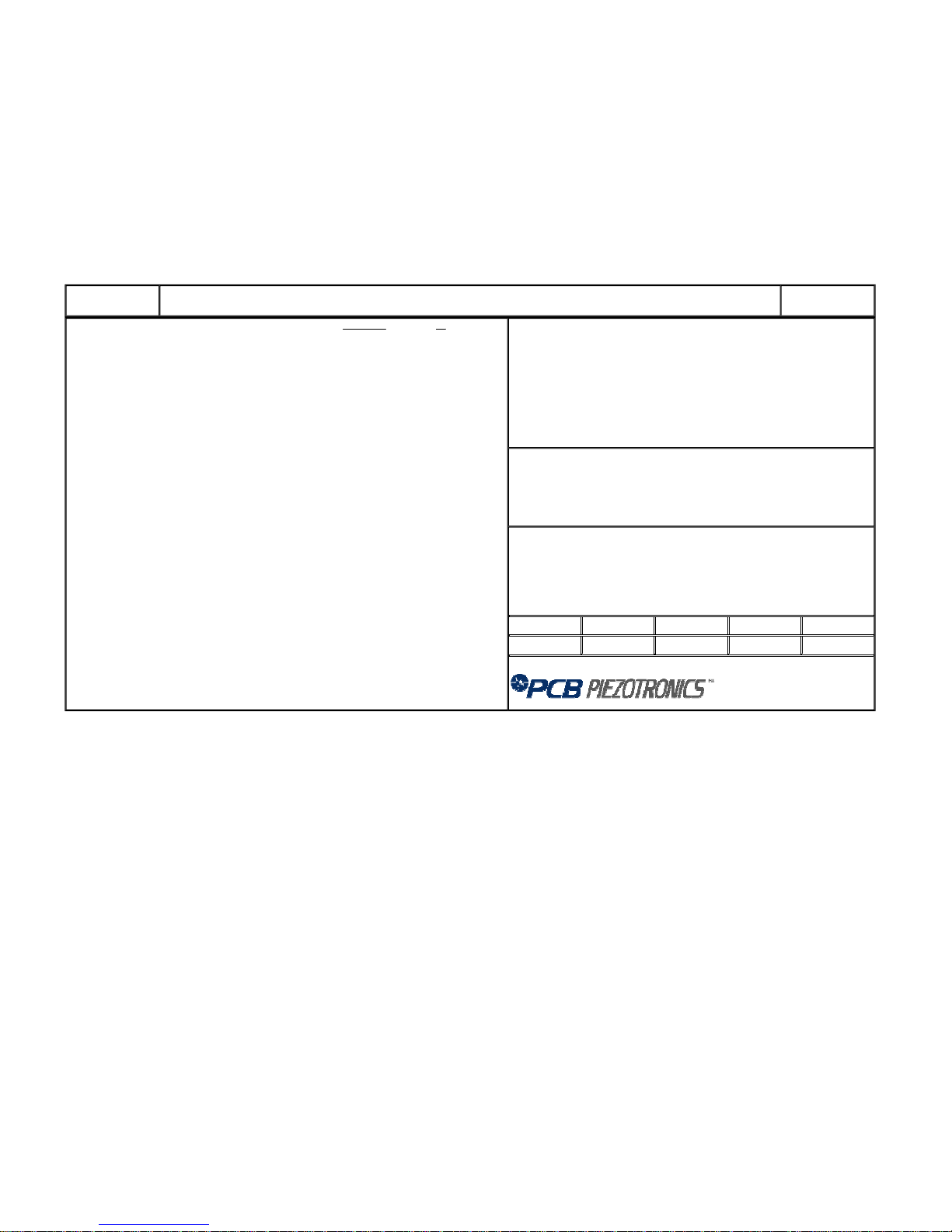

Model Number

377B02

PRECISION CONDENSER MICROPHONE

Revision: H

ECN #: 42896

Performance

ENGLISH

SI

Nominal Microphone Diameter

1/2"

1/2"

Frequency Response Characteristic(at 0° incidence)

Free-Field

Free-Field

Open Circuit Sensitivity

50 mV/Pa

50 mV/Pa

[3]

Open Circuit Sensitivity(± 1.5 dB)

-26 dB re 1 V/Pa -26 dB re 1 V/Pa

[3]

Frequency Range(± 1 dB)

5 to 10,000 Hz 5 to 10,000 Hz

Frequency Range(± 2 dB)

3.15 to 20,000 Hz 3.15 to 20,000 Hz

Lower Limiting Frequency(-3 dB)

1.0 to 2.4 Hz 1.0 to 2.4 Hz

Resonant Frequency(90° Phase Shift)

10,400 Hz

10,400 Hz

[1]

Inherent Noise

<15 dB(A) re 20

µPa

<15 dB(A) re 20

µPa

Dynamic Range(3% Distortion Limit)

>146 dB re 20 µPa >146 dB re 20 µPa

Standards Designation(IEC 61094-4)

WS2F

WS2F

Environmental

Temperature Range(Operating)

-40 to +302 °F -40 to +150 °C

Temperature Coefficient of Sensitivity(+14 to +122°F (-10 to +50°C)) 0.005 dB/°F

0.009 dB/°C

[1][3]

Static Pressure Coefficient

-0.013 dB/kPa -0.013 dB/kPa

[1][3]

Humidity Coefficient of Sensitivity(0 to 100%, non-condensing)

± 0.001 dB/%RH ± 0.001 dB/%RH

[3]

Influence of Axial Vibration(0.1g (1 m/s²))

63 dB re 20 µPa 63 dB re 20 µPa

[1]

Long Term Stability(150°C (302°F))

>2 hrs/dB

>2 hrs/dB

Electrical

Capacitance(Polarized)

12 pF

12 pF

[1]

Polarization Voltage

0 V

0 V

[2]

Physical

Housing Material

Stainless Alloy Stainless Alloy

Venting

Rear

Rear

Mounting Thread(Preamplifier)

0.4606 - 60 UNS 11.7 mm - 60 UNS

Mounting Thread(Grid)

0.5 - 60 UNS 12.7 mm - 60 UNS

Size (Diameter x Height)(with grid)

0.52 in x 0.64 in

13.2 mm x 16.2

mm

Size (Diameter x Height)(without grid)

0.5 in x 0.6 in

12.7 mm x 15.3

mm

Weight

0.28 oz

7.8 gm

[1]

All specifications are at room temperature unless otherwise specified.

In the interest of constant product improvement, we reserve the right to change specifications without notice.

ICP® is a registered trademark of PCB Group, Inc.

OPTIONAL VERSIONS

Optional versions have identical specifications and accessories as listed for the standard model

except where noted below. More than one option may be used.

NOTES:

[1]

Typical.

[2] Prepolarized

[3]

re 250 Hz

SUPPLIED ACCESSORIES:

Model ACS-20 Calibration of Precision Condensor Microphones (1)

Entered: AP Engineer: MJN Sales: MV

Approved: MT

Spec Number:

Date: 5/7/2014 Date: 5/7/2014 Date: 5/7/2014 Date: 5/7/2014

29289

3425 Walden Avenue, Depew, NY 14043

Phone: 716-684-0001

Fax: 716-684-0987

E-Mail: info@pcb.com

PCB Piezotronics Inc. claims proprietary rights in

the information disclosed hereon. Neither it nor any

reproduction thereof will be disclosed to others

without the written consent of PCB Piezotronics Inc.

8

2

REVISIONS

REV DESCRIPTION DIN

NR RELEASED TO DRAFTING

1

8

2

9

2

DIAPHRAGM

B B

.52 [13.2]

.48 [12.1]

.47 [12.0]

.04[1.0]

BLACK O-RING

.5000-60 UNS

.64 [16.4]

[12.7mm-60 UNS]

THREADS

.60 [15.3]

.36 [9.2]

A A

.50 [12.7]

.4606-60 UNS

[11.7 mm-60 UNS]

THREADS

WITH GRID CAP

WITHOUT GRID CAP

UNLESS OTHERWISE SPECIFIED TOLERANCES ARE:

DIMENSIONS IN INCHES

DECIMALS XX ±.03

ANGLES 2 DEGREES

XXX ±.010

FILLETS AND RADII

.003 - .005

DIMENSIONS IN MILLIMETERS

[ IN BRACKETS ]

DECIMALS X ± 0.8

ANGLES 2 DEGREES

XX ± 0.25

FILLETS AND RADII

0.07 - 0.13

2

DRAWN CHECKED ENGINEER

TITLE

JDM

9/14/05

ECB

9/14/05

OUTLINE DRAWING

1/2" PRE-POLARIZED

MICROPHONES

CCL

9/14/05

3425 WALDEN AVE. DEPEW, NY 14043

(716) 684-0001 E-MAIL: sales@pcb.com

IDENT. NO.

52681

SCALE: SHEET

29288

4X

DWG. NO.

CODE

1

1 OF1

Loading...

Loading...