PBI SAS SUPER IAQ Instruction Manual

ENGLISH

“SAS SUPER IAQ” - Code n. 90578

IINNSSTTRRUUCCTTIIOONNSS M

MAANNUUAALL

Carefully read this Manual before operating your instrument.

This document is the property of International PBI Spa Milan

It may not be duplicated or distributed without the owner’s authorisation

Patent Pending

Manufactured by International PBI Spa Milan, Italy

REFERENCES

FDA – 1987 Guideline on Sterile Drug Products produced by Aseptic Process

ACGIH – Guideline for the Assessment of Bioaerosol in the Indoor Environment

ASTM – Draft Protocol – Committee D22.05.06

USP 23-NF 18 8

th

Supplement 1116 (May 1998) – Microbiological Evaluation of Clean Rooms

and other Controlled Environments

EU Guide for GMP – Manufacture of Sterile Medicinal Products Control of Medicines and

Inspection

CEN/TC 243 Norms for Clean Room Technology

International PBI S.p.A.

Via Novara, 89 – 20153 Milano – Italy – Tel + 39 02 48779-1– Fax + 39 02 40090010

E-mail:

info@internationalpbi.it – www.internationalpbi.it

ENGLISH

INSTRUCTIONS MANUAL

READ CAREFULLY THIS HANDBOOK

SAFETY INSTRUCTIONS

• Use the device just for the indicated purposes.

• The Device must be correctly used according to manual instructions, before starting

any operation.

• Replace immediately any electrical cable when damaged ; never use a damaged or

worn electrical cable.

• Always disconnect the charger before:

A. Repairing or maintenance; these operations must be carried out by qualified staff;

B. Keep the unit clean;

• Use original spare parts and accessories for any replacement;

• Do not use this device in the presence of explosive gas.

GENERAL CAUTION

CAUTION

Be aware that the voltage and frequence of the electrical

system are compatible with the electrical requirements of the

battery charger.

CAUTION

Never use a non-OEM charger to charge the air sampler.

Use of improper charger may damaged the unit

ENGLISH

SUMMARY

SECTION ONE PAGE

Brief Operating Instructions 1

Visual Display Presentation 1

SECTION TWO

Operating Instructions 2

1. Principle 2

2. The basic idea 2

3. Installation 3

3.1 The Practical Use 3

3.2. List of MENU and SUB-MENU 4

3.3. Preliminary Inspection 5

3.4. 55 mm Contact Plate holder adjusting 6

3.5. 84 mm Maxi Contact Plate use (optional) 6

3.6. Tripod Installation (optional) 7

4. Operations 7

4.1. Start with the previous volume 8

4.2. User Mode 8

4.3. Program mode 9

4.4. Utility Mode Program 15

4.4.1. Set Time 15

4.4.2. Sampling Site 15

4.4.3. Operator Identification 16

4.4.4. Language 17

4.4.5. Clear Record 17

4.4.6. Display Record 18

4.4.8. Autoswitch OFF 19

4.5. Delay Mode 22

4.6. Low Battery Message 25

4.7. Remote Switch Use 26

4.8. Contact Plate Holder Adjustment 27

ENGLISH

SECTION TWO (continued) PAGE

4.9. Sanitation of Air Sampler 17

4.10. Contact Plate 17

4.11. Contact Plate Preparation 18

4.12. Total Bacterial Count and/or Micro-organisms Identification by

Dilution

19

5. Final Operation 19

6. Result Calculation and Recording 19

6.1. CFU/1000 Litres 19

SECTION THREE

7. Specifications 23

7.1. Messages Shown On Display 25

7.2. Sampling Time Requested For Different Air Volumes 26

7.3. Battery Charger Operation 26

7.4. Automatic Switch OFF 27

SECTION FOUR

8. Maintenance 28

8.1. Cleaning 28

8.2. Validation and Calibration 28

8.3. Performance Routine Monitoring 28

8.4. Trouble Shooting 29

8.5. Battery Replacement 29

8.6. Accessory and Spare Part List 30

SECTION FIVE

9. Brief Instructions 31

SECTION SIX

10. EN 17025 Documentation 32

“SAS Super IAQ” Rev. 1 Pg. 1

ENGLISH

SECTION ONE

• BRIEF OPERATING INSTRUCTIONS FOR SAS SUPER IAQ

The air flow is displayed after the automatic presentation each time the ins trument is switched

on.

Press ON/OFF switch.

Press START button to sample the same air volume of the last sampling cycle.

To change the air volume, use the arrow buttons and select “User Mode” from menu.

Refer to instruction manual to change settings.

Press ENTER to confirm selection.

Press arrows for menu selection to modify other pre-set parameters:

USER MODE

PROGRAM MODE

DELAY MODE

UTILITY MODE

Press ENTER to reach the sub-menu of the chosen parameter.

Refer to instruction manual to change settings.

Press ON/OFF switch at the end of sampling operations.

Press “CLEAR” each time you need to end an action. Then the unit will come back to the initial

configuration.

• VISUAL DISPLAY PRESENTATION

(Press ON/OFF black button switch).

Each time the ON/OFF switch is pressed, a ten seconds visual display presentation will appear

displaying the following information:

(1) INTERNATIONAL

PBI

(2) S/N XXXX

Rev. XXX.XX (Firmware revision)

(3) PRESS ARROWS

FOR NEW MENU SELECTION

(4) SAS SUPER IAQ

(5) ID XXXX

SITE XXXX

(6) START FOR XX

MM/DD/YY - HH/MM

This information are displayed automatically. Avoid pushing any button before the end of the

few seconds presentation; during this presentation all functions are disabled.

“SAS Super IAQ” Rev. 1 Pg. 2

ENGLISH

SECTION TWO

• OPERATING INSTRUCTIONS

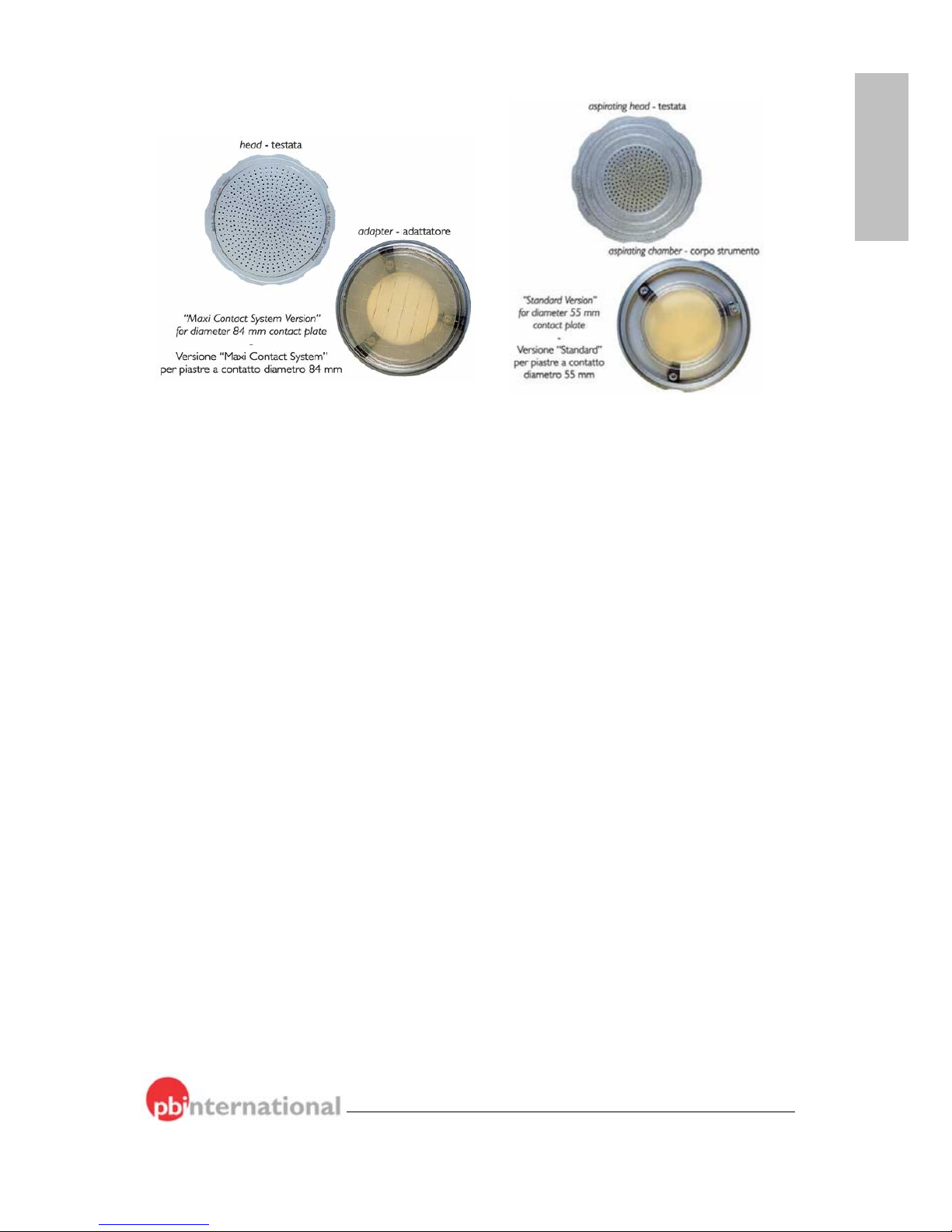

1. PRINCIPLE OF SURFACE AIR SYSTEM

The Surface Air System (SAS) encompasses several models which use the same principle.

Air is aspirated at a fixed speed for variable time through a head which has been machined

with a series of small holes of a special design. The resulting laminar air flow is directed onto

the agar surface of a “RODAC Plate” (or a Petri dish) containing medium consistent with the

microbiological examination to be made. When the preset sampling cycle is completed, the

plate is removed and incubated. The organisms are then visible to the naked eye and can be

counted for an assessment of the level of contamination.

2. THE BASIC IDEA

The major points of the Surface Air System (SAS) are:

A. To use a simple and inexpensive “Contact Plate” (“SURFAIR PLATE”, “RODAC”) for

surface, hands or air control. These plates are very well known and easily available. They

can be purchased ready poured with different media.

B. To sample a known volume of air for a variable time to provide a range of sampling

volumes.

C. To aspirate air in a laminar flow pattern with sufficient velocity to impact organisms onto

an agar surface.

D. To accumulate data on the level of hygiene in each environment so that fluctuation can be

monitored.

E. To take advantage of advanced electronics for more reliable results in different operating

conditions.

F. To have the flexibility to choose between 55 mm Contact Plates, 84 mm Maxi Contact

Plates or 90 mm Standard Petri Dishes.

G. To apply cGLP and cGMP to air

sampling operations.

H. To organize sequential sampling

to obtain a more representative

sample under actual operating

conditions.

“SAS Super IAQ” Rev. 1 Pg. 3

ENGLISH

3. INSTALLATION

3.1 The practical use of contact plates

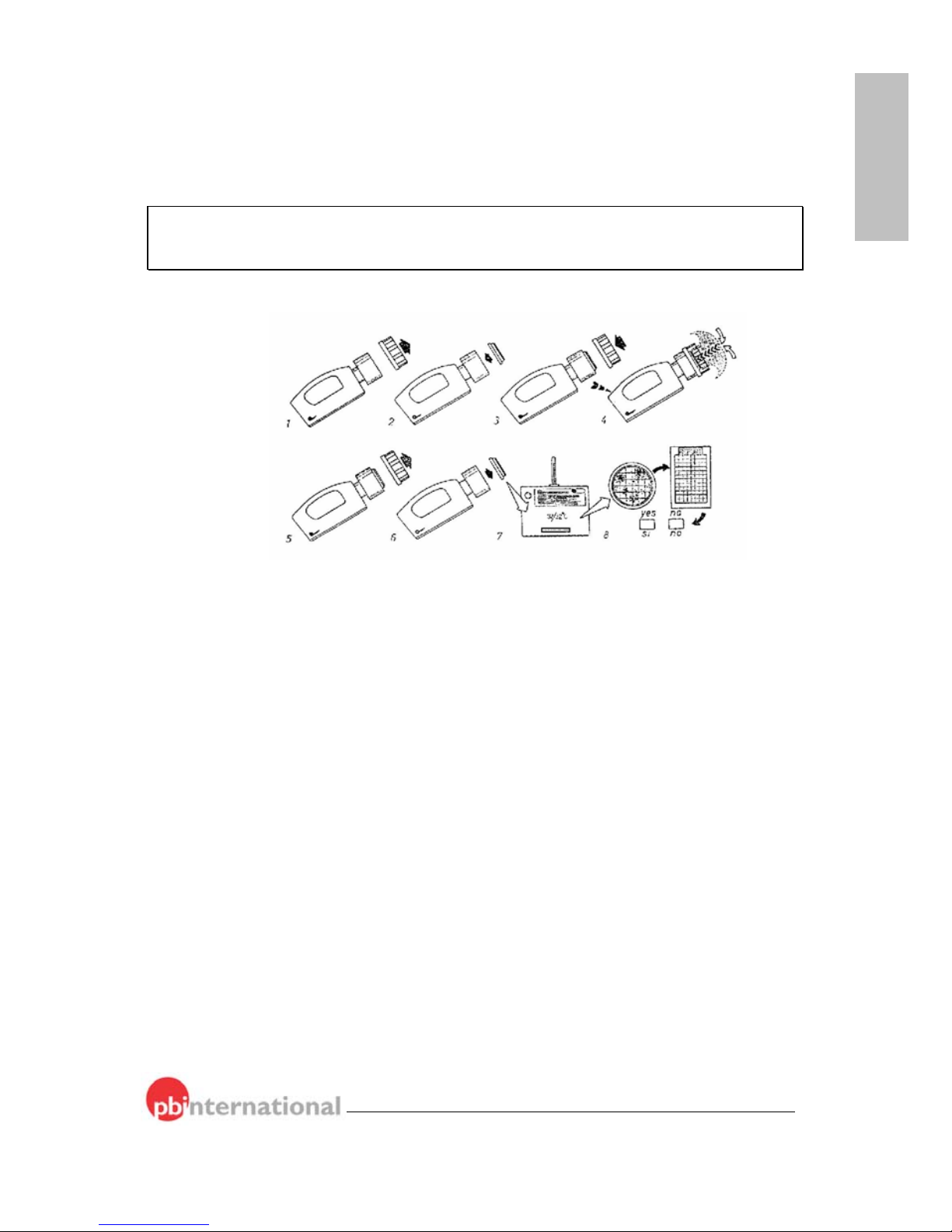

THE PRACTICAL USE OF “CONTACT PLATES” FOR AIR CONTROL

SAS SUPER IAQ

SAS SUPER IAQ FLOW SCHEME

1. Remove the aspirating head.

2. Insert an identified, closed and prepared Contact Plate and remove plate lid.

3. Replace the aspirating head.

4. Select the required air volume and start the unit. The air flow is directed onto the agar

surface of the Contact Plate.

5. At the end of the cycle, remove the aspirating head.

6. Close and remove the Contact Plate.

7. Incubate the Contact Plate

8. Count the colonies, record the results on the microbiological air sampling report and

analyze the results.

“SAS Super IAQ” Rev. 1 Pg. 4

ENGLISH

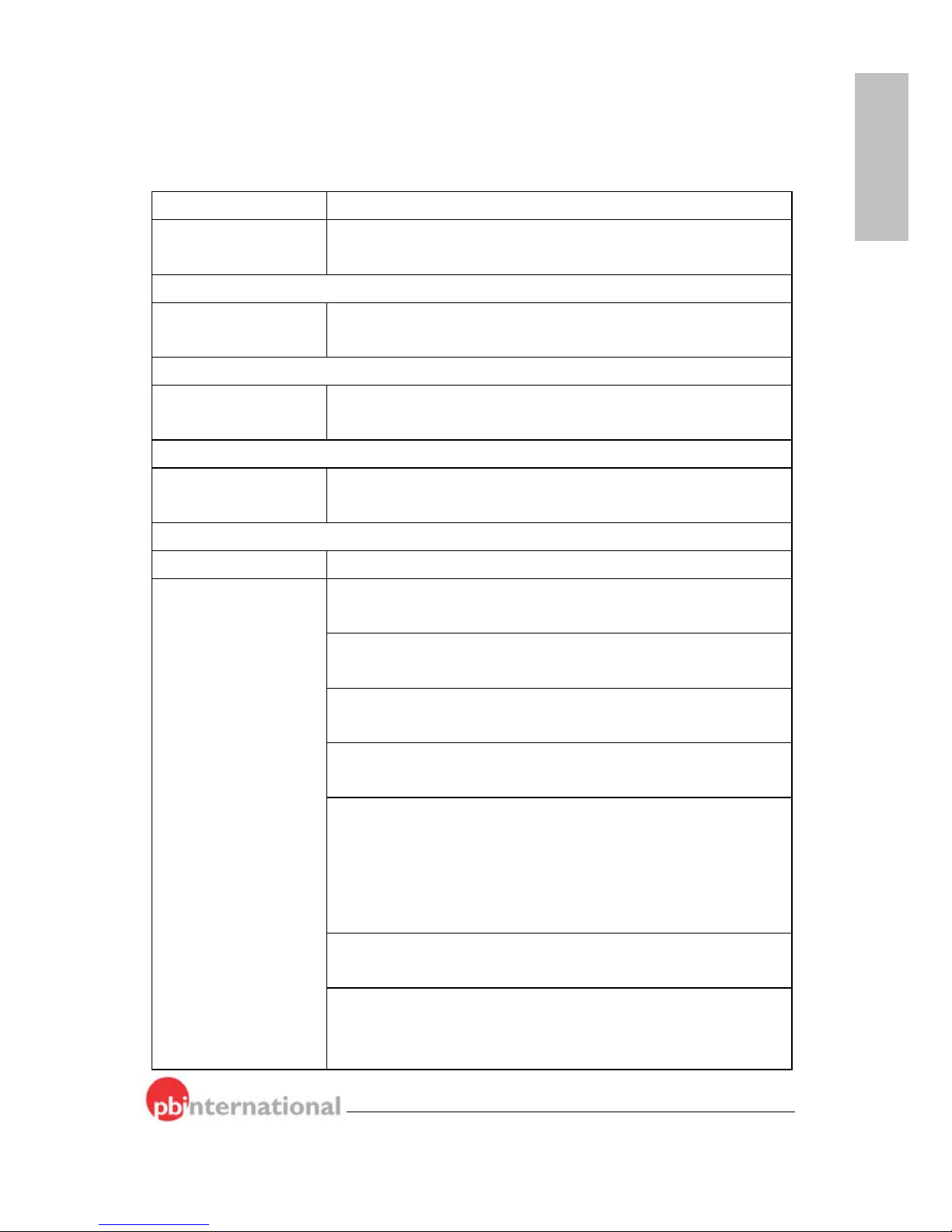

3.2. LIST OF MENU AND UTILITY SUB-MENU

MENU DESCRIPTION

START FOR XXX This message indicates the air sampler is ready to sample the

volume shown

USER MODE With this function the air sampler can be set to select one of eight

programmable sampling volumes

PROGRAM MODE With this function you can to modify the eight programmable

sampling volumes

DELAY MODE With this function the air sampler can be set to start after a

programmable delay

UTILITY MODE This function led to the following Sub-Menu:

SET TIME

To adjust date and time

SAMPLING SITE

To identify the sampling point

IDENTIFY

To identify the operator’s name

LANGUAGE

To display text in different languages

CLEAR RECORD

To clear the recorded sampling data

DISPLAY RECORD

To show the recorded sampling data

AUTO SWITCH OFF

To disconnect the automatic switch off when the “Infrared

Remote” is used

“SAS Super IAQ” Rev. 1 Pg. 5

ENGLISH

3.3 PRELIMINARY INSPECTION

The apparatus is subject to specific working tests before shipping and it is carefully packed to

avoid possible damage during transit. However, a visible check should be carried out as soon

as possible to determine any transit damage. This must be reported immediately. The following

procedures should be followed to check that the unit is working properly.

The battery pack of the instrument must be charged for at least 4 hours before the test (14 hours

if slow battery charger is used).

SAS SUPER IAQ

After the ON/OFF button is pressed an automatic visual presentation will be displayed.

In the following displays, the entry of “XX” indicates numerical figures.

ACTION DISPLAY

I N T E R N A T I O N A L Switch on the ON/OFF

switch (black button)

P B I

S N X X X X

P R E S S A R R O

W

S F O

R

NEW ME N U S ELECT.

S A S S U P E R I A Q

“SAS Super IAQ” Rev. 1 Pg. 6

ENGLISH

I D X X X X

SI TE XXXX

S T A R T F O R X X

M/ D / Y - H: M

Push START button

to start air sampling

with last cycle

( X X ) X X

M/ D / Y - H : M

The motor will run until the figures in brackets reach the same figure as displayed to the right

and then it will stop. During the sampling the two red leds are flashing (see position 16 and 28

in the figures at page 24).

3.4 “55 mm CONTACT PLATES” HOLDER ADJUSMENT

The Contact Plate holders can be adjusted (using a screw driver) in case the available plates

slightly different in diameter from the standard 55 mm Contact Plate (see the figure in the

Chapter 4.10).

3.5 “84 mm MAXI-CONTACT PLATES”

If high fungal contamination is expected in the sampled air, Maxi-Contact Plates are suggested.

This is because moulds tend to spread and consequently make counting difficult after

incubation.

The “84 mm Maxi-Contact Plates” are inserted into the SAS SUPER IAQ using a special

adaptor (Cat.n. 19123). For more details see Application Note N. 89.

“SAS Super IAQ” Rev. 1 Pg. 7

ENGLISH

3.6. TRIPOD INSTALLATION (OPTIONAL)

The SAS SUPER IAQ can be fixed to a table tripod or a floor tripod. The threaded connection

is located under the unit, between the two front feet. When not in use, the screw is protected by

an threaded plug.

4. OPERATIONS

Push the Main switch (black button) once to switch on the unit.

The Main switch (black button) must be pushed twice to switch on the unit if the automatic

switch off timer operated when last used.

Press “CLEAR” at any time to return to the initial “START FOR” configuration.

The air sampler is provided with eight programmable air volumes (“User Mode”) selectable by

the operator.

The selection of the volume is made by pressing the “UP” or “DOWN” arrows when the

program is in the relevant sub-menu.

The following volumes of air are suggested:

- Contaminated areas (communities, processing rooms, etc.) 10-200 litres of air

- Normal areas (laboratory benches, houses, etc.) 200-500 litres of air

- Sterile or high risk areas (operating theatres, etc.) 500-1000 litres of air.

“SAS Super IAQ” Rev. 1 Pg. 8

ENGLISH

4.1. TO START WITH THE SAME AIR VOLUME AS THE PREVIOUS SAMPLE

ACTION DISPLAY

Switch on the ON/OFF

switch (black button)- wait

6 seconds

S T A R T F O R X X

(Last aspirated volume of

air)

M / D / Y - H / M

Push “START” (after the

visual

( X X ) X X

display presentation) M / D / Y - H / M

4.2 TO START WITH ONE OF THE EIGHT OPERATOR PROGRAMMABLE

SAMPLING VOLUMES MEMORISED IN THE “USER MODE” PROGRAM

Up to eight volumes, can be programmed into the unit.

ACTION DISPLAY

Switch on the ON/OFF switch

STAR T FOR XX

(black button)

M/ D/ Y - H/ M

Press “¿” to select

USE R MODE

the USER MODE

M/ D/ Y - H/ M

Press “ENTER” to select the

S . PR OG XXXX

pre-memorized volumes

M/ D/ Y - H/ M

Press “¿” to select the chosen

S . PR OG XXXX

pre-memorized volumes

M/ D/ Y - H/ M

Press ENTER

START FOR XXXX

to confirm

M/ D/ Y - H/ M

Press START to run the sampling cycle.

The total number of available “USER MODE” programs is eight.

The maximum volume of air for each sampling cycle is 1999 litres.

“SAS Super IAQ” Rev. 1 Pg. 9

ENGLISH

4.3 “PROGRAM MODE”: MODIFICATION OF AN EXISTING “USER MODE”

PROGRAM

Using this procedure, it is possible to memorise up to eight differen t volumes (from 1 to 1999

litres of air). (See chapter 4.2.)

ACTION DISPLAY

Switch on the ON/OFF

S T A R T F O R X

X

switch (black button)

M / D / Y - H / M

Press “¿” to select

P R O G R A M M O D

E

PROGRAM MODE

M / D / Y - H / M

Press ENTER and then “¿”

S. PR OG XXXX

to select the volume

of air to be modified

M / D / Y - H / M

Press ENTER

X X X X - 0 0 0 0

M/ D / Y - H/ M

Press “¿” to select

X X X X - X 0 0 0

the thousands of litres

M / D / Y - H / M

Press ENTER and then “¿”

X X X X - X X 0 0

to select the hundreds of litres

M / D / Y - H / M

Press ENTER and then “¿”

X X X X - X X X 0

to select the tens of litres

M / D / Y - H / M

Press ENTER and then “¿”

X X X X - X X X X

to select the units of litres

M / D / Y - H / M

Loading...

Loading...