PB Heat TC Series, TC-04, TC-05, TC-06, TC-07 Installation, Operation & Maintenance Manual

...Page 1

TC

™

Gas/Oil Boilers

Series

Oil, Gas &

Installation,

Operation &

Maintenance

Manual

Page 2

USING THIS MANUAL 1

A. MANUAL ORGANIZATION . . . . . . . . . . . . . .1

B. SPECIAL ATTENTION BOXES . . . . . . . . . . . .1

1. PREINSTALLATION 2

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

B. CODES & REGULATIONS . . . . . . . . . . . . . . .2

C. BOILER LOCATION . . . . . . . . . . . . . . . . . . . . .2

D. COMBUSTION & VENTILATION AIR . . . . . . .3

E. CHIMNEY & BREECHING. . . . . . . . . . . . . . . .3

F. BOILER FOUNDATION . . . . . . . . . . . . . . . . . .4

G. INSTALLATION SURVEY . . . . . . . . . . . . . . . .5

H. PLANNING THE LAYOUT . . . . . . . . . . . . . . . .6

I. VERIFY COMPONENTS . . . . . . . . . . . . . . . . . .6

2. BOILER ASSEMBLY 9

A. PACKAGED BOILERS . . . . . . . . . . . . . . . . . . .9

B. ASSEMBLED BLOCKS . . . . . . . . . . . . . . . . . .9

C KNOCKDOWN BOILERS . . . . . . . . . . . . . . . .9

D. HYDROSTATIC TESTING . . . . . . . . . . . . . . .13

E. CLEAN-OUT COVER INSTALLATION . . . . .13

F. BURNER MOUNTING PLATE . . . . . . . . . . .14

G. REAR OBSERVATION PORT . . . . . . . . . . . .14

H. FLUE COLLECTOR INSTALLATION . . . . . . .15

I. BURNER MOUNTING . . . . . . . . . . . . . . . . . .15

3. INSTALLATION 16

A. PREPARATION . . . . . . . . . . . . . . . . . . . . . . .16

B. STEAM BOILER PIPING . . . . . . . . . . . . . . . .16

C. MULTIPLE STEAM BOILER PIPING . . . . . . .17

D. WATER BOILER PIPING . . . . . . . . . . . . . . . .17

E. MULTIPLE WATER BOILER PIPING . . . . . . .21

F. TANKLESS HEATER INSTALLATION . . . . . .21

G. JACKET PREPARATION . . . . . . . . . . . . . . . .22

H. JACKET ASSEMBLY . . . . . . . . . . . . . . . . . .22

I. FUEL PIPING . . . . . . . . . . . . . . . . . . . . . . . . .23

J. INSTALL CONTROLS AND TRIM . . . . . . . .24

4. OPERATION 28

A. STARTING THE BOILER . . . . . . . . . . . . . . . .28

B. CLEANING BOILER WATERWAYS . . . . . . .29

5. MAINTENANCE 30

6. REPAIR PARTS 32

7. BOILER RATING & DIMENSIONS 34

TABLE OF CONTENTS

TABLE OF CONTENTS

Page 3

1

A. MANUAL ORGANIZATION

The Series TC™ Installation, Operation & Maintenance

Manual is divided into five basic sections:

1. Preinstallation (Sections A through I)

2. Boiler Assembly (Sections A through I)

3. Installation (Sections A through J)

4. Operation (Section A through B)

5. Maintenance

B. SPECIAL ATTENTION BOXES

Throughout this manual you will see special attention

boxes intended to supplement the instructions and make

special notice of potential hazards. These categories

mean, in the judgment of the PB Heat, LLC:

Indicates special attention is needed, but not directly

related to potential personal injury or property

damage.

NOTICE

Indicates a condition or hazard which will or can

cause moderate personal injury or property damage.

CAUTION

DANGER

Indicates a condition or hazard which will cause

severe personal injury, death or major property

damage.

USING THIS MANUAL

USING THIS MANUAL

Indicates a condition or hazard which may potentially

cause severe personal injury, death or major property

damage.

WARNING

Page 4

2

A. GENERAL

Series TC™ boilers are supplied completely knocked

down for field assembly, completely assembled as

packaged boilers or as assembled blocks of cast iron

sections. All items should be inspected for damage upon

receipt and any damage reported to wholesaler and

trucking company. All components should be stored in a

clean, dry area.

Carefully read these instructions, burner instructions, and

control instructions before beginning work. This boiler

must be installed by a qualified contractor. The boiler

warranty may be voided if the boiler is not installed

correctly.

B. CODES & REGULATIONS

1. All work is to be peformed in strict accordance with

the requirements of state and local regulating

agencies and codes dealing with boiler installations.

2. In the absence of such local requirements, the

following codes should be followed:

ASME B & PV Code, Section IV – "Heating Boilers"

ASME B & PV Code, Section VI – "Care and

Operation of Heating Boilers"

ANSI/NFPA 31 – "Installation of Oil Burning

Equipment"

ANSI Z223.1 – "National Fuel Gas Code"

ANSI/NFPA 70 – "National Electric Code"

ASME CSD-1 – "Controls & Safety Devices for

Automatically Fired Boilers"

ANSI/NFPA 211 – "Chimneys, Fireplaces, Vents and

Solid Fuel Burning Appliances"

3. In Canada, the following codes should be used in

addition to those in Section 1.B.2.

CAN1.3.1-77 (R1996) – "Industrial and Commercial

Gas Fired Package Boilers”

CSA B140.0-M87 – "General Requirements for Oil

Burning Equipment"

CSA B140.7.2-1967 – "Oil-Fired Steam and Hot

Water Boilers for Commercial and Industrial Use"

CAN/CSA C22.2 No.0-M91 – "General

Requirements – Canadian Electrical Code Part II

CSA C22/2 No.3-M1988 – "Electrical Features of

Fuel Burning Equipment"

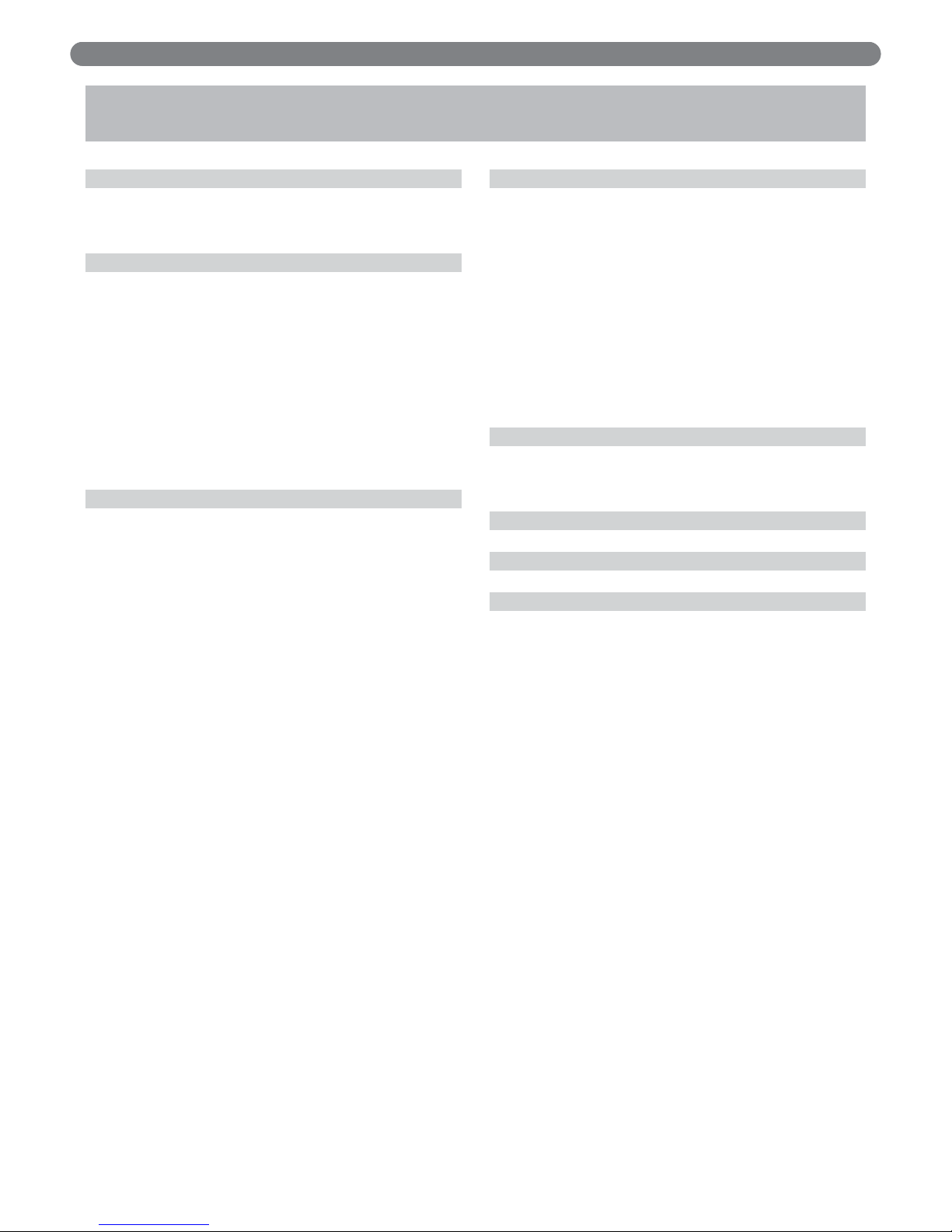

C. BOILER LOCATION

1. Locate the boiler close to the chimney to minimize

the breeching length, but allow adequate clearance

for piping, service, maintenance, and tankless coil

replacement. A clearance of 36" [914 mm] on all

sides of the boiler and 48" [1219 mm] in front of the

boiler is recommended for serviceability.

PREINSTALLATION

1. PREINSTALLATION

WARNING

Do not install this boiler on carpeting. A significant

fire hazard could result, with potential for property

damage, personal injury or death.

Figure 1.1: Clearance Requirments

Page 5

3

2. The minimum clearances to combustible materials,

based on ANSI/NFPA 31 are as follows. See

Figure 1.1.

Right Side: 6 inches [152 mm]

Left Side: 24 inches [610 mm]

Rear of Jacket: 6 inches [152 mm]

Front of Boiler: 24 inches [610 mm]

Top of Jacket: 6 inches [152 mm]

Vent/Chimney/Flue Collector: 9" [229 mm]

D. COMBUSTION & VENTILATION AIR

1. Provide adequate air for combustion and ventilation.

2. Unless the boiler room construction and natural air

infiltration supply all necessary combustion air,

provide an outside air opening or duct. The free

cross-sectional area of the opening or duct shall meet

or exceed 1 square inch [645 square millimeters] per

4000 Btu/hr [1.17 kW] input for all installed

appliances. At altitudes greater than 2000 feet [610

meters] above sea level, this requirement is to be

increased by 4% per each thousand feet [304

meters] above sea level.

Example: at 5000 feet above sea level.

Free Area = 1 + (0.04 x 5)

Free Area =

1.20 sq. in.

Free Area =

4000

Btu/hr

Example: at 1500 meters above sea level.

Free Area = 1 + (0.04 x

1500

)

Free Area = 1 + (0.04 x

304

Free Area = 1.2 x 645 =

772 sq. mm

Free Area = 1 + (0.04 x

1.17 kW

3. The boiler room must never be under negative

pressure. If exhaust fans or other equipment that can

potentially cause a negative pressure are used, the

air openings must be engineered to assure a neutral

or slightly positive pressure in the boiler room at all

times of operation.

a) If the equipment design and air openings cannot

assure this, the boiler must be located in a room

isolated from these appliances.

b) If the vent system terminates in any area where

wind-generated down drafts are likely, install a

suitable vent cap which can control wind effects.

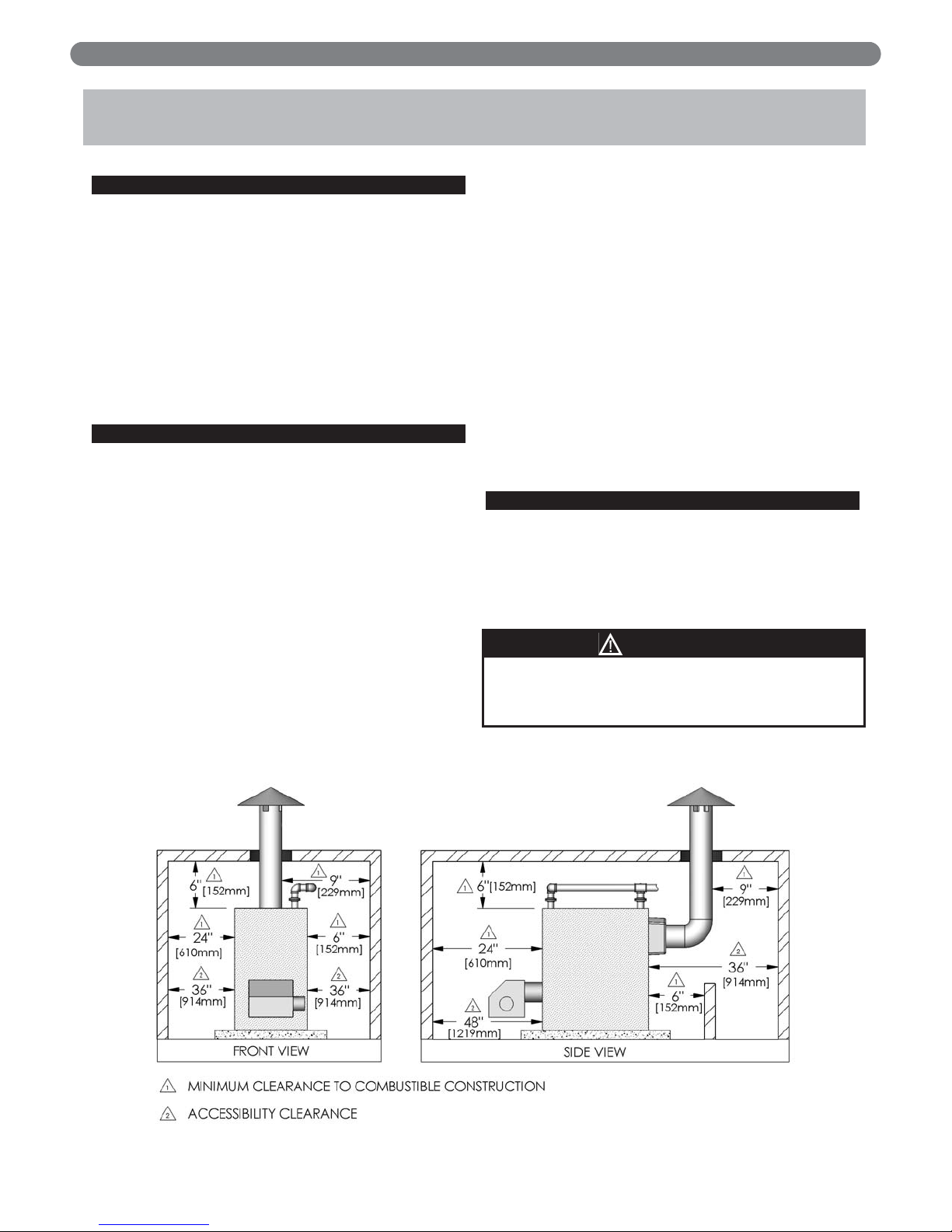

4. If motorized dampers are used on the combustion

and ventilation air openings they must include an

interlock device that prevents the boiler from

operating if they do not open. See Figure 1.2 for this

configuration.

E. CHIMNEY & BREECHING

1. Vent System Inspection:

a) Inspect the existing chimney or vent system.

Look for damage due to corrosion or other

causes. Make sure the vent system is in good

condition and all vent connectors and chimneys

are properly supported.

b) Inspect the chimney liner and repair or replace as

necessary.

2. Vent System Sizing:

a) The vent system must be sized and installed to

remove all combustion products. If the vent

system is not sized properly, the burner may not

operate correctly. This may cause poor

combustion or sooting.

b) The breeching connection between the boiler

and chimney should be as short as possible with

a minimum number of elbows.

c) Breeching Diameter:

The breeching must be the same diameter as the

boiler outlet for Model TC-04 through TC-16 and

18" [457 mm] diameter for Model TC-17 & TC18 Boilers.

The vent sizes for all Series TC™ Boilers are

listed in the "Ratings and Dimensions" section of

this manual.

d) If extreme length, excessive elbows, or a

reduction in diameter is necessary, consult your

PB Heat representative for recommendations.

PREINSTALLATION

Figure 1.2: Motorized Vent Damper Interlock

WARNING

If this boiler is to be installed on combustible

flooring, consult local building authorities for proper

installation, or in the absence of regulations consult

ANSI/NFPA 31 – "Installation of Oil Burning

Equipment." Failure to comply with this warning may

result in a fire, severe personal injury or death.

Page 6

4

3. Vent System Installation:

a) The vent system and installation must be in

accordance with the current edition of the

American National Standard ANSI/NFPA 211,

"Chimneys, Fireplaces, Vents, and Solid Fuel

Burning Appliances" or applicable provisions of

local building codes.

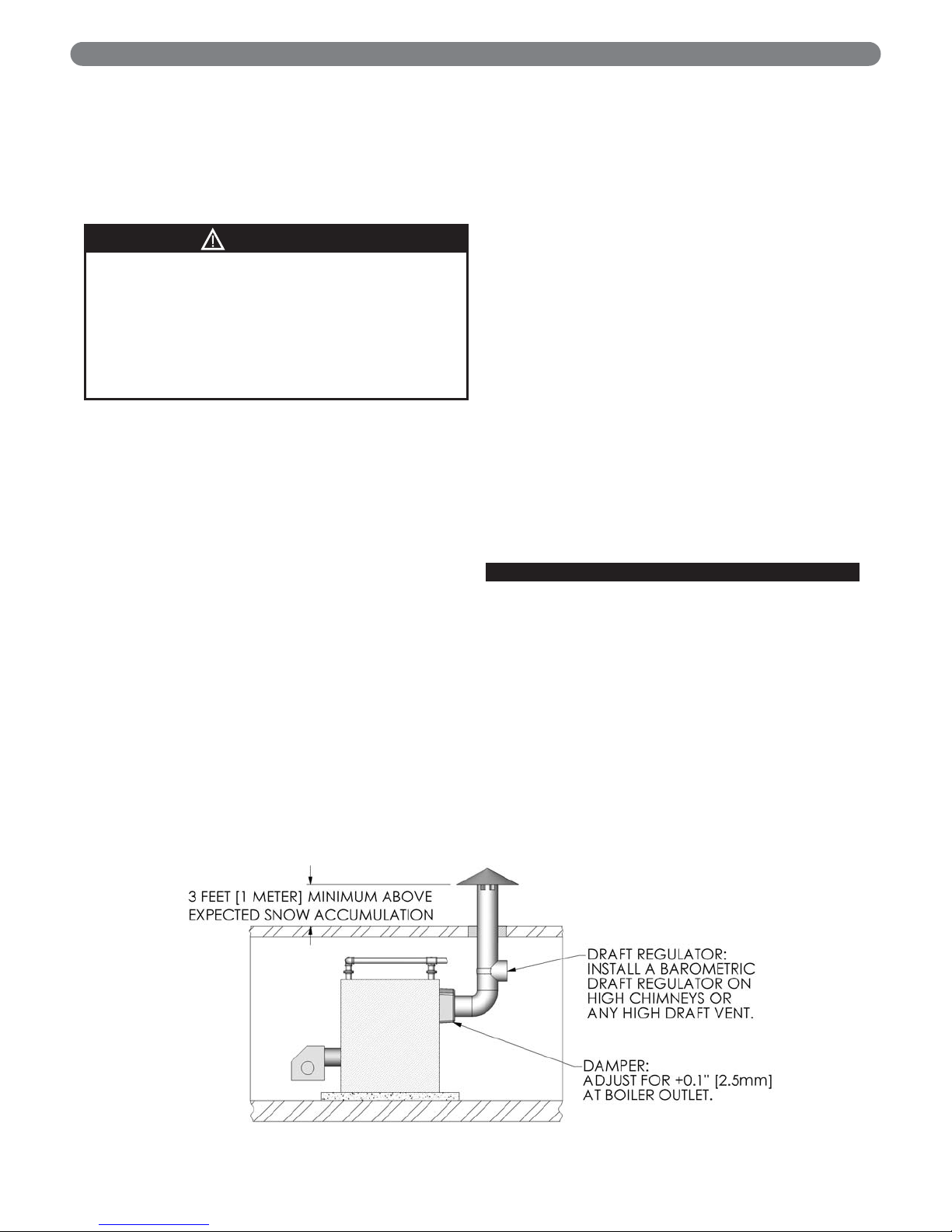

b) Vent Terminations:

1. Vent terminations must be extended to three

feet above expected snow accumulation. See

Figure 1.3.

2. If the vent system terminates in any area

where wind-generated down drafts are likely,

install a suitable vent cap to help control

wind effects.

c) Vent Connection Support

1. Support the vent system independently of the

boiler flue connection.

2. Provide support of the vent connector

(breeching) at maximum 12 foot [3.66 meter]

intervals to prevent sagging.

d) Horizontal runs of vent are to be sloped back

toward the boiler at approximately ¼" per foot [2

cm per meter].

e) Breeching used with forced draft boilers must be

sealed, of heavy gauge construction and must

comply with all applicable codes of construction.

f) Exterior Vents: Insulate vent pipes that pass

through unheated spaces sufficiently to prevent

excessive condensation and ensure adequate

draft.

g) Multiple Appliances: Do not vent multiple

appliances with venting that operates under

positive pressure into a common chimney or vent

connector. This may cause products of

combustion to circulate into the boiler room

when one of the appliances is not operating.

h) Draft Regulator: Install a barometric draft

regulator when using a high chimney or any high

draft vent.

1. This is necessary to prevent negative draft

conditions in the boiler.

2. Excessive draft will cause flame lifting, poor

combustion, or impingement.

4. Vent System Operation:

a) This boiler is designed to fire only with a

pressurized combustion chamber. The breeching

and vent may be sized for negative, neutral, or

positive pressure as desired.

b) Maintain maximum of +0.1 inches [2.5 mm] of

water at the boiler outlet.

c) Avoid excessive negative pressure in the

combustion chamber. This may cause the flame

to lift off of the burner causing unstable

combustion. In addition, this may cause

impingement of the burner flame onto the crown

sheet, which may lead to overheating.

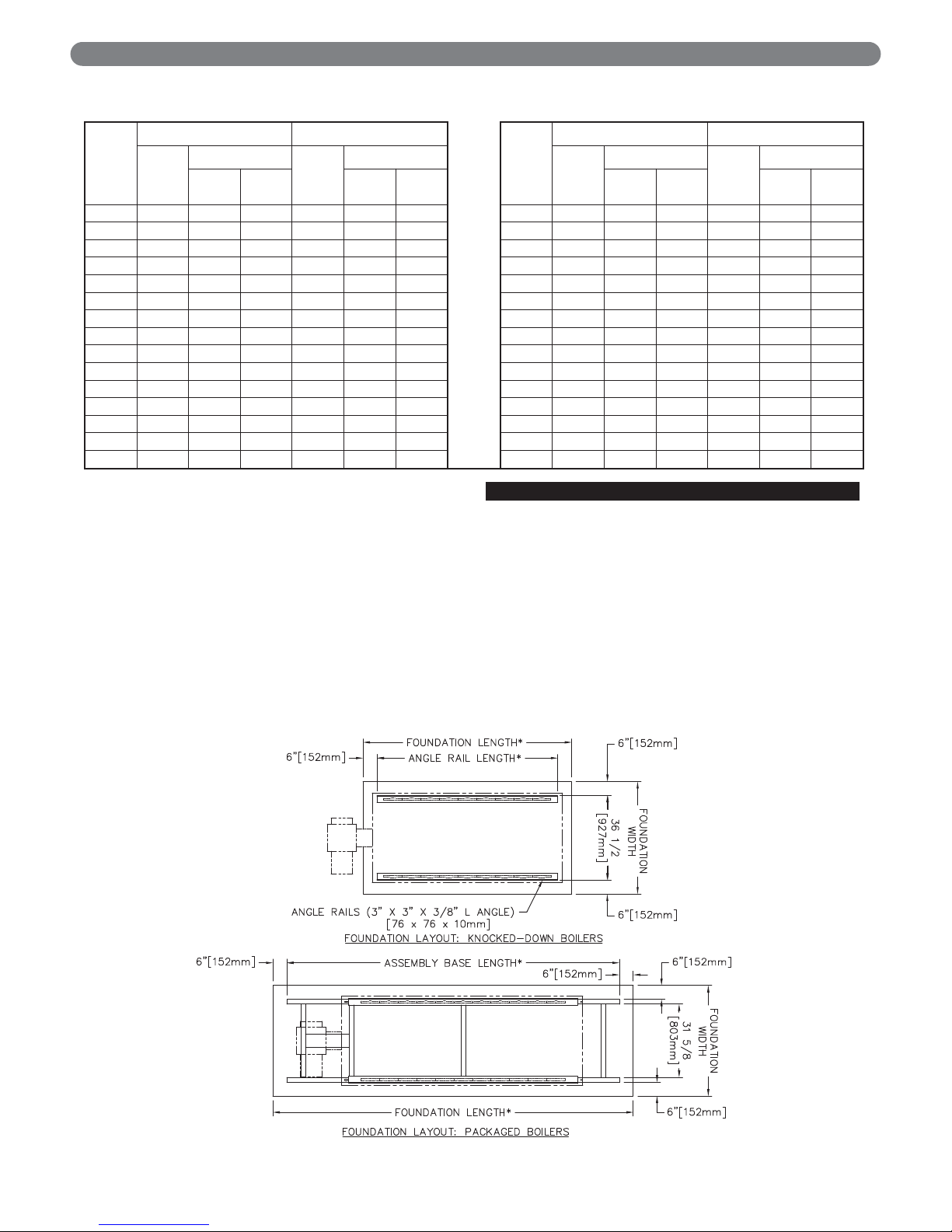

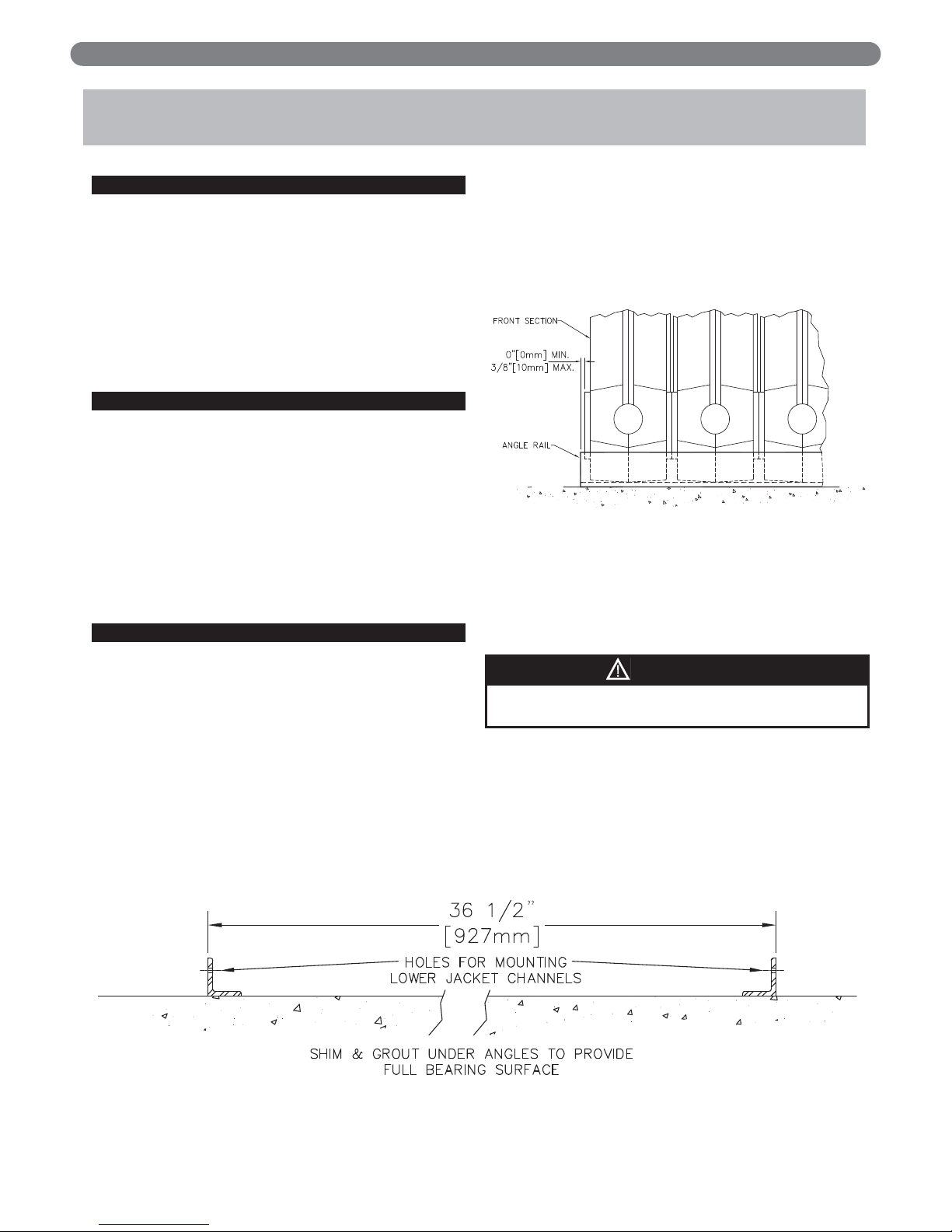

F. BOILER FOUNDATION

1. If the boiler room floor is not level or if additional

structural support is required, provide a level

concrete foundation pad for the boiler. The flooring

and structural support system must be suitable for

the operating weight of the boiler and any connected

piping.

a) Figure 1.4 shows the Foundation Layout for

Knocked-Down Boilers and Packaged Boilers.

b) Dimensions for the foundation are given in Table

1.1a and 1.1b.

2. Do not operate the boiler until the foundation, if

newly poured concrete, has thoroughly cured. Rapid

heating may damage the concrete due to expanding

moisture.

Figure 1.3: Typical Vent Termination

PREINSTALLATION

WARNING

Configuration of the breeching and chimneys on

some installations may result in a positive breeching

pressure. In these cases, the breeching must be

constructed of pressure tight materials. Consult

local building authorities for proper installation.

Failure to comply with this warning may result in

carbon monoxide poisoning or fire, resulting in

severe personal injury or death.

Page 7

5

3. If the boiler is installed in a penthouse or if wiring of

any sort is run underneath the boiler foundation,

construct the foundation with a provision for air flow

between the main floor and the top of the boiler

foundation.

a) An acceptable foundation would be concrete

blocks laid on their sides with the openings lined

up.

b) If the foundation must be a concrete slab, use an

air cell high temperature insulating board, at least

½" [13 mm] thick, with aluminum backing. ½"

[13 mm] thick, high temperature millboard with

aluminum backing is also acceptable. Place the

insulating board on the slab, with the aluminum

side up, between the angle rails.

G. INSTALLATION SURVEY

For new and existing installations, a Steam or Water

Installation Survey is available from PB Heat, LLC. The

survey will provide information on how a steam or water

boiler works with your specific system and will provide

an overview of steam or water system operation.

You can also use this survey to locate system problems

that will have to be corrected. To obtain copies of the

Steam or Water Installation Survey, contact your PB

Heat, LLC Representative or download it from

PeerlessBoilers.com.

PREINSTALLATION

Figure 1.4: Foundation Layout

Boiler

Model

Knocked-Down Boilers Packaged Boilers

Boiler

Model

Knocked-Down Boilers Packaged Boilers

Rail

Length

(inches)

Foundation

Base

Length

(inches)

Foundation

Rail

Length

(mm)

Foundation

Base

Length

(mm)

Foundation

Width

(inches)

Length

(inches)

Width

(inches)

Length

(inches)

Width

(mm)

Length

(mm)

Width

(mm)

Length

(mm)

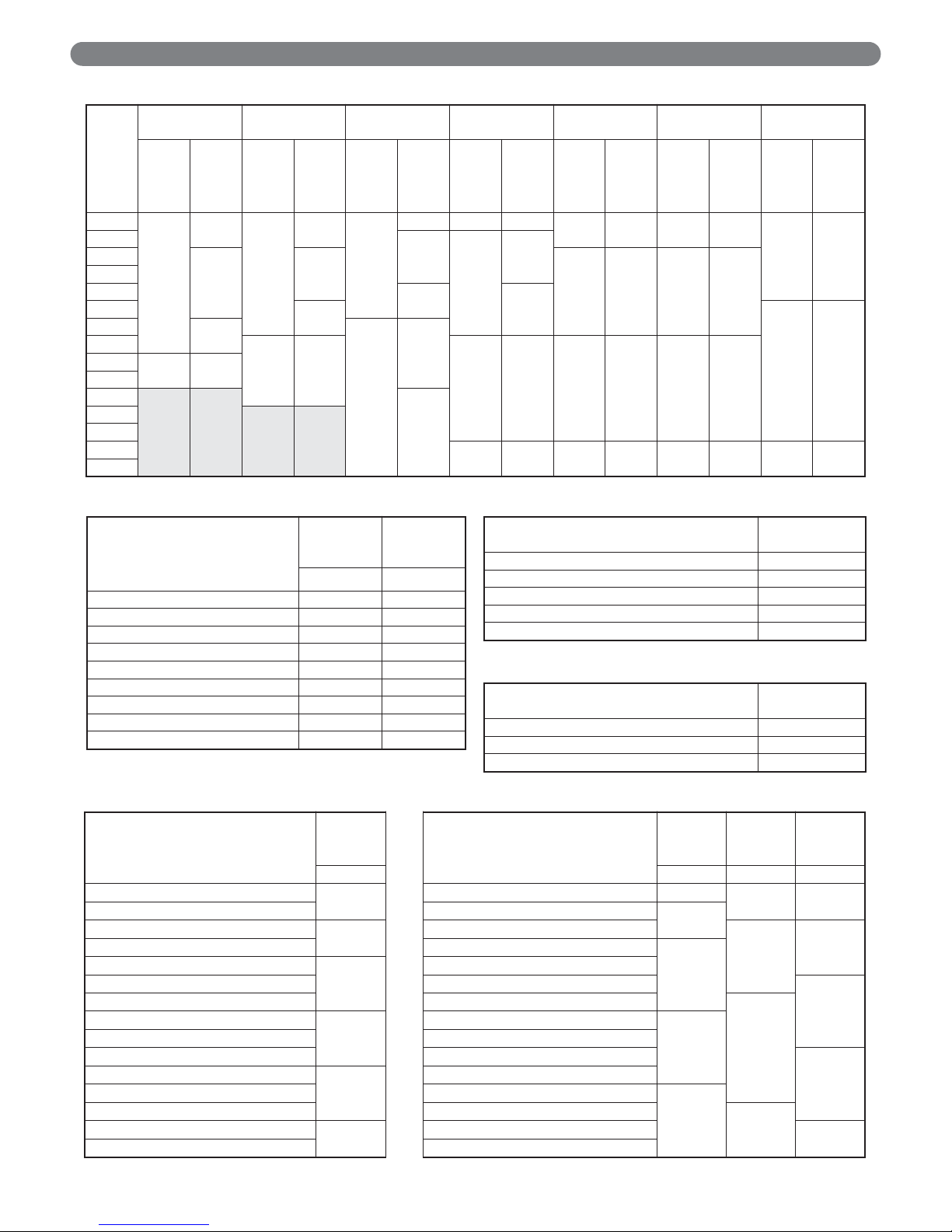

TC- 04 34.19 48.5 46.25 66.19 48.5 78.25 TC- 04 868 1232 1175 1681 1232 1988

TC- 05 42.25 48.5 54.25 74.25 48.5 86.25 TC- 05 1073 1232 1378 1886 1232 2191

TC- 06 50.31 48.5 62.50 82.31 48.5 94.50 TC- 06 1278 1232 1588 2091 1232 2400

TC- 07 58.38 48.5 70.50 90.38 48.5 102.50 TC- 07 1483 1232 1791 2296 1232 2604

TC- 08 66.44 48.5 78.50 98.44 48.5 110.50 TC- 08 1688 1232 1994 2500 1232 2807

TC- 09 74.50 48.5 86.50 106.50 48.5 118.50 TC- 09 1892 1232 2197 2705 1232 3010

TC- 10 82.56 48.5 95.00 114.56 48.5 127.00 TC- 10 2097 1232 2413 2910 1232 3226

TC- 11 90.63 48.5 103.00 122.63 48.5 135.00 TC-11 2302 1232 2616 3115 1232 3429

TC- 12 98.69 48.5 111.00 130.69 48.5 143.00 TC-12 2507 1232 2819 3320 1232 3632

TC- 13 106.75 48.5 119.00 138.75 48.5 151.00 TC-13 2711 1232 3023 3524 1232 3835

TC- 14 114.81 48.5 127.00 146.81 48.5 159.00 TC-14 2916 1232 3226 3729 1232 4039

TC- 15 122.88 48.5 135.00 154.88 48.5 167.00 TC-15 3121 1232 3429 3934 1232 4242

TC- 16 130.94 48.5 143.00 162.94 48.5 175.00 TC-16 3326 1232 3632 4139 1232 4445

TC- 17 139.00 48.5 151.00 171.00 48.5 183.00 TC-17 3531 1232 3835 4343 1232 4648

TC- 18 147.06 48.5 159.00 179.06 48.5 191.00 TC-18 3735 1232 4039 4548 1232 4851

Table 1.1a: Foundation Dimensions

(U.S. Customary Units)

Table 1.1b: Foundation Dimensions

(SI Metric Units)

Page 8

6

H. PLANNING THE LAYOUT

Prepare sketches and notes of the layout to minimize the

possibility of interference with new or existing

equipment, piping, venting, and wiring.

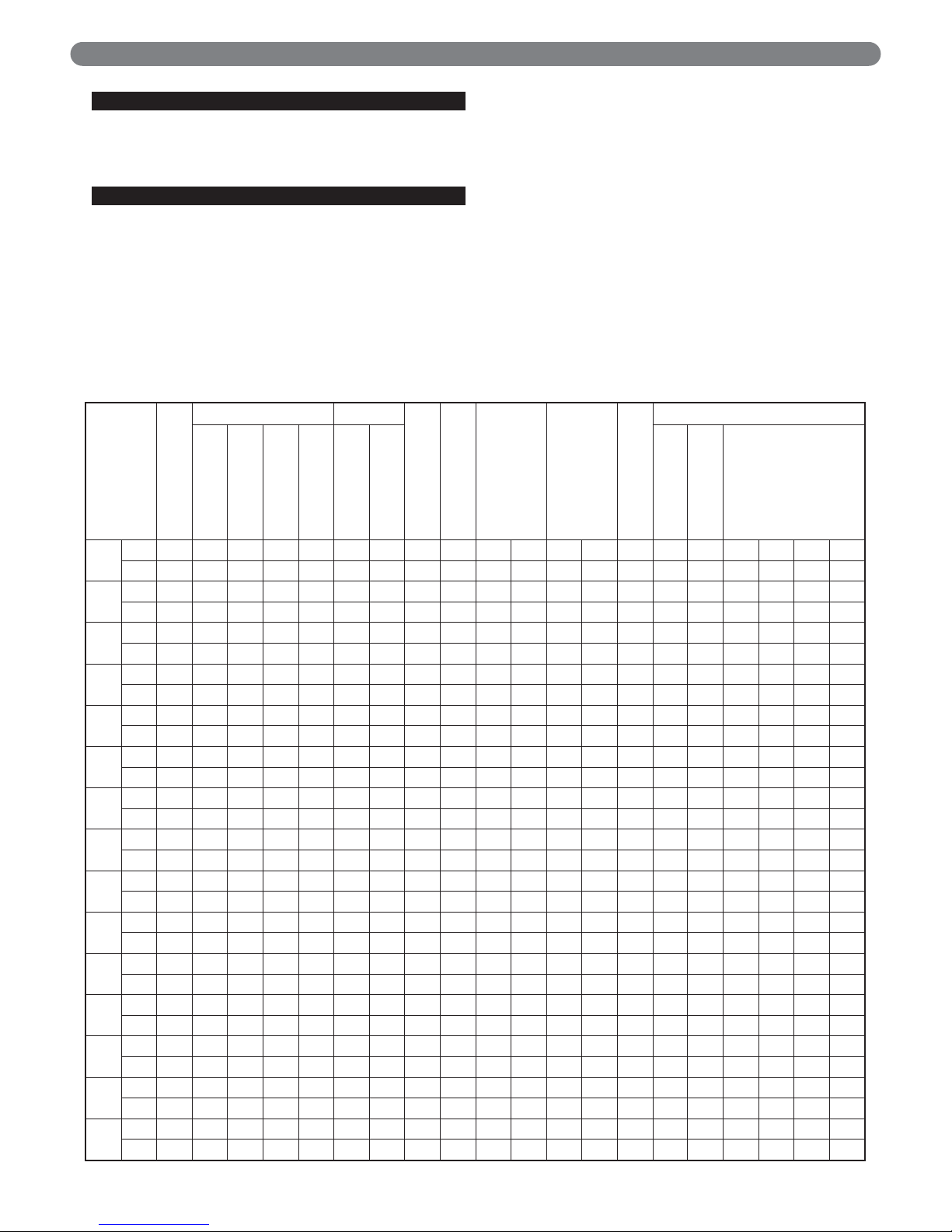

I. VERIFY COMPONENTS

1. Packaged Boilers: All standard components are

located in the boiler package with the following

exceptions:

a) Relief Valves are assembled with piping and

included in a separate carton to prevent damage

in shipment.

b) The Return Yoke is not mounted or assembled

for shipment. This assembly is included in a

separate carton.

c) In some cases, the Burner and/or Gas Train may

be shipped separately.

d) The Optional Barometric Draft Damper is

shipped in a separate carton.

2. Knocked-down Boilers: All components are shipped

for field assembly. See Tables 1.2a and 1.2b for

standard components. See Tables 1.3 through 1.8

for optional components.

3. Assembled Block Boilers: These are similar to

knocked-down boilers except the angle rails, sections

and section assembly kit cartons are pre-assembled

into a single shipping level component.

PREINSTALLATION

Table 1.2a: Series TC™ Shipping List (Steam Boilers)

Boiler Model Number

Angle Rail

Standard Sections Flue Outlet

Controls Carton

Trim Carton

Section Assembly

Cartons

Graphite Port

Connector Carton

Miscellaneous Parts

Carton

Jacket Panels

Front

Rear

Plain Intermediate

Supply Intermediate

Flue Collector

Outlet Adapter

Jacket Channel

Carton

Jacket Front/Back

Carton

Jacket Top/Side

Carton

TC- 04

Qty. 2 1 1 1 1 1 1 1 1 1 1 1 1 1

SCN 74004 76000 76001 76002 76003 76060 88512 77000 76050 76053 76070 75004 76030 76031

TC- 05

Qty. 2 1 1 2 1 1 1 1 1 1 1 1 1 1

SCN 74005 76000 76001 76002 76003 76060 88512 77000 76051 76054 76070 75005 76030 76032

TC- 06

Qty. 2 1 1 2 2 1 1 1 1 1 1 1 1 1 1

SCN 74006 76000 76001 76002 76003 76060 88512 77001 76052 76055 76070 75006 76030 76033 76035

TC- 07

Qty. 2 1 1 3 2 1 1 1 2 2 1 1 1 1 1

SCN 74007 76000 76001 76002 76003 76061 88512 77001 76050 76053 76070 75007 76030 76031 76036

TC- 08

Qty. 2 1 1 4 2 1 1 1 1 1 1 1 1 1 1 1 1

SCN 74008 76000 76001 76002 76003 76061 88512 77002 76050 76051 76053 76054 76070 75008 76030 76031 76037

TC- 09

Qty. 2 1 1 5 2 1 1 1 2 2 1 1 1 1 1

SCN 74009 76000 76001 76002 76003 76062 88512 77002 76051 76054 76071 75009 76030 76031 76038

TC- 10

Qty. 2 1 1 6 2 1 1 1 1 1 1 1 1 1 1 1 1

SCN 74010 76000 76001 76002 76003 76062 88512 77002 76051 76052 76054 76055 76071 75010 76030 76032 76038

TC- 11

Qty. 2 1 1 6 3 1 1 1 2 2 1 1 1 1 2

SCN 74011 76000 76001 76002 76003 76062 88512 77003 76052 76055 76071 75011 76030 76032 76036

TC- 12

Qty. 2 1 1 7 3 1 1 1 1 2 1 2 1 1 1 1 1 1

SCN 74012 76000 76001 76002 76003 76062 88512 77003 76050 76051 76053 76054 76071 75012 76030 76032 76036 76037

TC- 13

Qty. 2 1 1 8 3 1 1 1 3 3 1 1 1 1 2

SCN 74013 76000 76001 76002 76003 76062 88512 77003 76051 76054 76071 75013 76030 76032 76037

TC- 14

Qty. 2 1 1 9 3 1 1 1 1 2 1 2 1 1 1 1 1 1

SCN 74014 76000 76001 76002 76003 76063 88512 77004 76050 76052 76053 76055 76071 75014 76030 76032 76037 76038

TC- 15

Qty. 2 1 1 10 3 1 1 1 1 2 1 2 1 1 1 1 2

SCN 74015 76000 76001 76002 76003 76063 88512 77004 76051 76052 76054 76055 76071 75015 76030 76032 76038

TC- 16

Qty. 2 1 1 11 3 1 1 1 3 3 1 1 1 1 1 1 1

SCN 74016 76000 76001 76002 76003 76063 88512 77004 76052 76055 76071 75016 76030 76032 76035 76039 76038

TC- 17

Qty. 2 1 1 12 3 1 1 1 1 4 4 1 1 1 1 2 2

SCN 74017 76000 76001 76002 76003 76063 76064 88512 77005 76051 76054 76071 75017 76030 76034 76040 76037

TC- 18

Qty. 2 1 1 13 3 1 1 1 1 3 1 3 1 1 1 1 1 2 1 1

SCN 74018 76000 76001 76002 76003 76063 76064 88512 77005 76051 76052 76054 76055 76071 75018 76030 76034 76040 76037 76038

Page 9

7

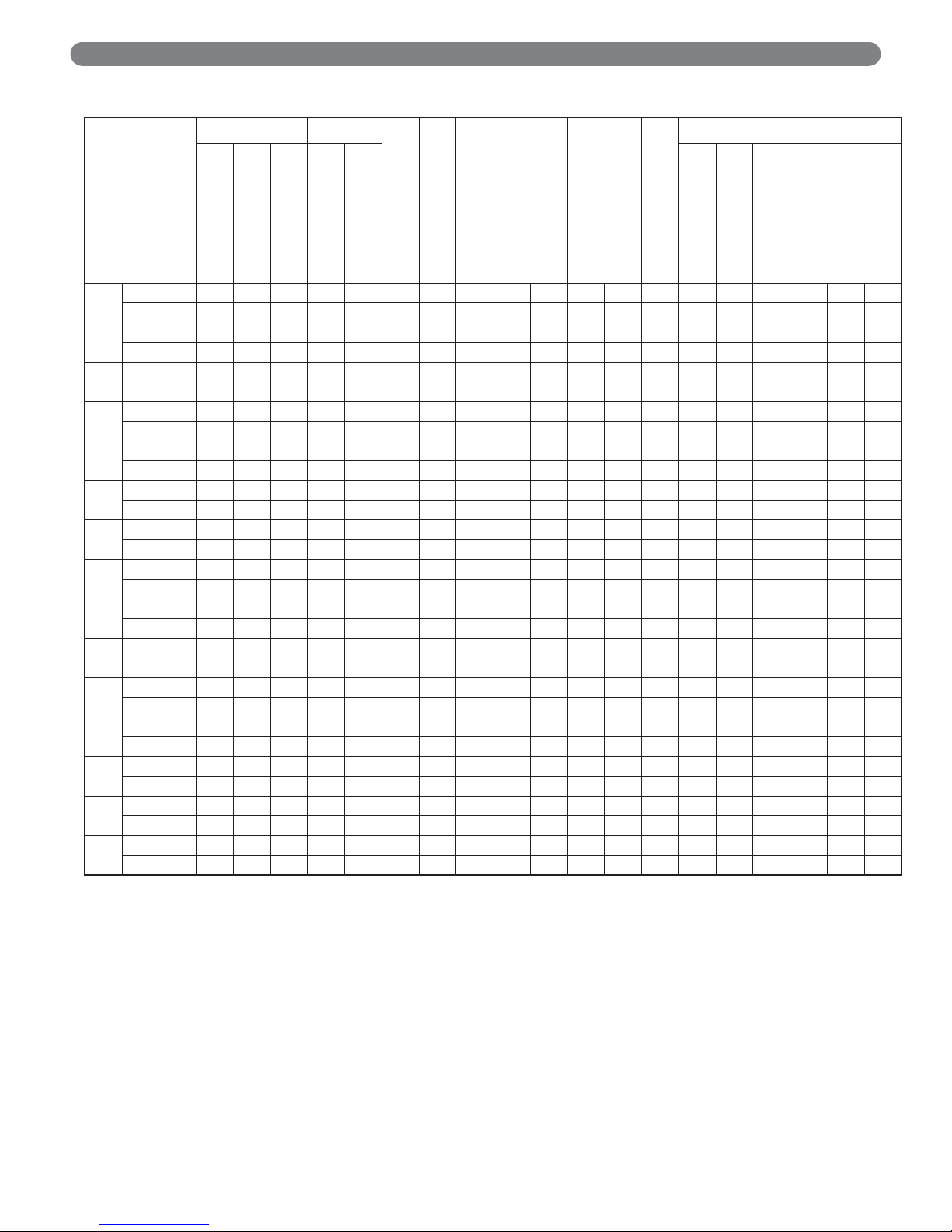

PREINSTALLATION

Boiler Model Number

Angle Rail

Standard Sections Flue Outlet

Controls Carton

Trim Carton

Yoke

Section Assembly Cartons

Graphite Port Connector

Carton

Miscellaneous Parts Carton

Jacket Panels

Front

Rear

Plain Intermediate

Flue Collector

Outlet Adapter

Jacket Channel Carton

Jacket Front/Back

Carton

Jacket Top/Side Carton

TC- 04

Qty. 2 1 1 2 1 1 1 1 1 1 1 1 1 1

SCN 74004 76000 76001 76002 76060 78510 77030 76072 76050 76053 76070 75004 76030 76031

TC- 05

Qty. 2 1 1 3 1 1 1 1 1 1 1 1 1 1

SCN 74005 76000 76001 76002 76060 78510 77031 76072 76051 76054 76070 75005 76030 76032

TC- 06

Qty. 2 1 1 4 1 1 1 1 1 1 1 1 1 1 1

SCN 74006 76000 76001 76002 76060 78510 77031 76072 76052 76055 76070 75006 76030 76033 76035

TC- 07

Qty. 2 1 1 5 1 1 1 1 2 2 1 1 1 1 1

SCN 74007 76000 76001 76002 76061 78510 77032 76072 76050 76053 76070 75007 76030 76031 76036

TC- 08

Qty. 2 1 1 6 1 1 1 1 1 1 1 1 1 1 1 1 1

SCN 74008 76000 76001 76002 76061 78510 77032 76072 76050 76051 76053 76054 76070 75008 76030 76031 76037

TC- 09

Qty. 2 1 1 7 1 1 1 1 2 2 1 1 1 1 1

SCN 74009 76000 76001 76002 76062 78510 77032 76072 76051 76054 76071 75009 76030 76031 76038

TC- 10

Qty. 2 1 1 8 1 1 1 1 1 1 1 1 1 1 1 1 1

SCN 74010 76000 76001 76002 76062 78510 77032 76072 76051 76052 76054 76055 76071 75010 76030 76032 76038

TC- 11

Qty. 2 1 1 9 1 1 1 1 2 2 1 1 1 1 2

SCN 74011 76000 76001 76002 76062 78510 77033 76072 76052 76055 76071 75011 76030 76032 76036

TC- 12

Qty. 2 1 1 10 1 1 1 1 1 2 1 2 1 1 1 1 1 1

SCN 74012 76000 76001 76002 76062 78510 77033 76072 76050 76051 76053 76054 76071 75012 76030 76032 76036 76037

TC- 13

Qty. 2 1 1 11 1 1 1 1 3 3 1 1 1 1 2

SCN 74013 76000 76001 76002 76062 78510 77033 76072 76051 76054 76071 75013 76030 76032 76037

TC- 14

Qty. 2 1 1 12 1 1 1 1 1 2 1 2 1 1 1 1 1 1

SCN 74014 76000 76001 76002 76063 78510 77033 76072 76050 76052 76053 76055 76071 75014 76030 76032 76037 76038

TC- 15

Qty. 2 1 1 13 1 1 1 1 1 2 1 2 1 1 1 1 2

SCN 74015 76000 76001 76002 76063 78510 77034 76072 76051 76052 76054 76055 76071 75015 76030 76032 76038

TC- 16

Qty. 2 1 1 14 1 1 1 1 3 3 1 1 1 1 1 1 1

SCN 74016 76000 76001 76002 76063 78510 77034 76072 76052 76055 76071 75016 76030 76032 76035 76039 76038

TC- 17

Qty. 2 1 1 15 1 1 1 1 1 4 4 1 1 1 1 2 2

SCN 74017 76000 76001 76002 76063 76064 78510 77034 76072 76051 76054 76071 75017 76030 76034 76040 76037

TC- 18

Qty. 2 1 1 16 1 1 1 1 1 3 1 3 1 1 1 1 1 2 1 1

SCN 74018 76000 76001 76002 76063 76064 78510 77034 76072 76051 76052 76054 76055 76071 75018 76030 76034 76040 76037 76038

Table 1.2b: Series TC™ Shipping List (Water Boilers)

Page 10

8

PREINSTALLATION

Boiler

Model

Beckett Carlin Gordon-Piatt

Power Flame

(Gas) Power Flame (Oil)

Power Flame

(Gas/Oil) Webster

Mounting

Plate Stock

Code

Burner

Model

Mounting

Plate Stock

Code

Burner

Model

Mounting

Plate Stock

Code

Burner

Model

Mounting

Plate Stock

Code

Burner

Model

Mounting

Plate Stock

Code

Burner

Model

Mounting

Plate Stock

Code

Burner

Model

Mounting

Plate Stock

Code

Burner

Model

TC- 04

76027

CF1400

76027

702CRD

76023

R8 76028 J30A

76028 C1 76028 C1

76028 JB1

TC- 05

R8.2

76027

J50ATC- 06

CF2300

801CRD

76027 C2 76027 C2

TC- 07

TC- 08

R8.4

C2TC- 09

1050FF

D

76025 JB2

TC- 10

CF2500

76026

R10.1

TC- 11

76024

1150FF

D

76024 C3 76024 C3 76024 C3

TC- 12

76024 CF3500

TC- 13

TC- 14

R10.2

TC- 15

TC- 16

TC- 17

76022 C4 76022 C4 76022 C4 76022 JB3

TC- 18

Table 1.3: Burner Mounting Plates

Section

Standard

With

Inspection

Tappings

Stock Code Stock Code

Front 76000 76010

Intermediate 76002 ---Intermediate with Boss 76005 76007

Intermediate with LWCO Tappings 76011 ---Intermediate Supply with Boss 76003 76008

Intermediate Supply w/ LWCO Taps 76012 ---Intermediate Heater 76004 76009

Intermediate Heater w/ LWCO Taps 76013 ---Back 76001 76006

Description Stock Code

Heater Cover Plate Assembly 76075

Heater Cover Plate Gasket 74019

Tankless Coil -8 GPM 76073

Tankless Coil -12 GPM 76074

Return Yoke - Water Boiler 76072

Description Stock Code

Steam Controls Carton - L404A 88511

Steam Controls Carton - PA404A 88512

Water Controls Carton - L4006A 78510

Table 1.4: Standard & Optional Sections

Table 1.5: Tankless Coil & Cover Plate Options

Table 1.6: Controls Cartons

Description

15 PSI

[103 kPa]

Steam

Description

30 PSI

[207 kPa]

50 PSI

[345 kPa]

80 PSI

[552 kPa]

Stock Code Stock Code Stock Code Stock Code

Steam Trim Carton TC-04

77000

Water Trim Carton TC-04 77030

77050 77080

Steam Trim Carton TC-05 Water Trim Carton TC-05

77031

Steam Trim Carton TC-06

77001

Water Trim Carton TC-06

77051

77081Steam Trim Carton TC-07 Water Trim Carton TC-07

77032

Steam Trim Carton TC-08

77002

Water Trim Carton TC-08

Steam Trim Carton TC-09 Water Trim Carton TC-09

77082

Steam Trim Carton TC-10 Water Trim Carton TC-10

77052

Steam Trim Carton TC-11

77003

Water Trim Carton TC-11

77033

Steam Trim Carton TC-12 Water Trim Carton TC-12

Steam Trim Carton TC-13 Water Trim Carton TC-13

77083

Steam Trim Carton TC-14

77004

Water Trim Carton TC-14

Steam Trim Carton TC-15 Water Trim Carton TC-15

77034

Steam Trim Carton TC-16 Water Trim Carton TC-16

77053Steam Trim Carton TC-17

77005

Water Trim Carton TC-17

77084

Steam Trim Carton TC-18 Water Trim Carton TC-18

Table 1.7: Steam Trim Cartons Table 1.8: Water Trim Cartons

Page 11

9

A. PACKAGED BOILERS

1. All assemblies should be carefully inspected for

shipping damage on arrival. Any damage should be

reported immediately to the shipping company and

PB Heat.

2. Remove shrink-wrap and inspect the jacket, cast iron

sections, and burner (if supplied) for damage.

Remove the left side panels and inspect the clean out

covers for damaged or missing silicone seals.

3. Continue to Section 3, Installation.

B. ASSEMBLED BLOCKS

1. All assemblies should be carefully inspected for

shipping damage on arrival. Any damage should be

reported immediately to the shipping company and

PB Heat.

2. Check the component list in Tables 1.2a and 1.2b

and packing slip to assure that all shipping level

items are received. Inspect all packages for shipping

damage.

3. Continue to Section 2.F, Burner Mounting Plate

Installation.

C KNOCKDOWN BOILERS

1. Check the component list in Tables 1.2a and 1.2b

and packing slip to assure that all shipping level

items are received. Inspect all packages for shipping

damage.

2. Report any damage to the shipping company and

PB Heat immediately.

3. Lay the angle rails provided at the point of final

installation. Set the angles in parallel position

measuring 36-1/2" [927 mm] outside-to-outside of

angles as shown in Figure 2.1. Shim the angles to

level them and grout under angles after the sections

are assembled.

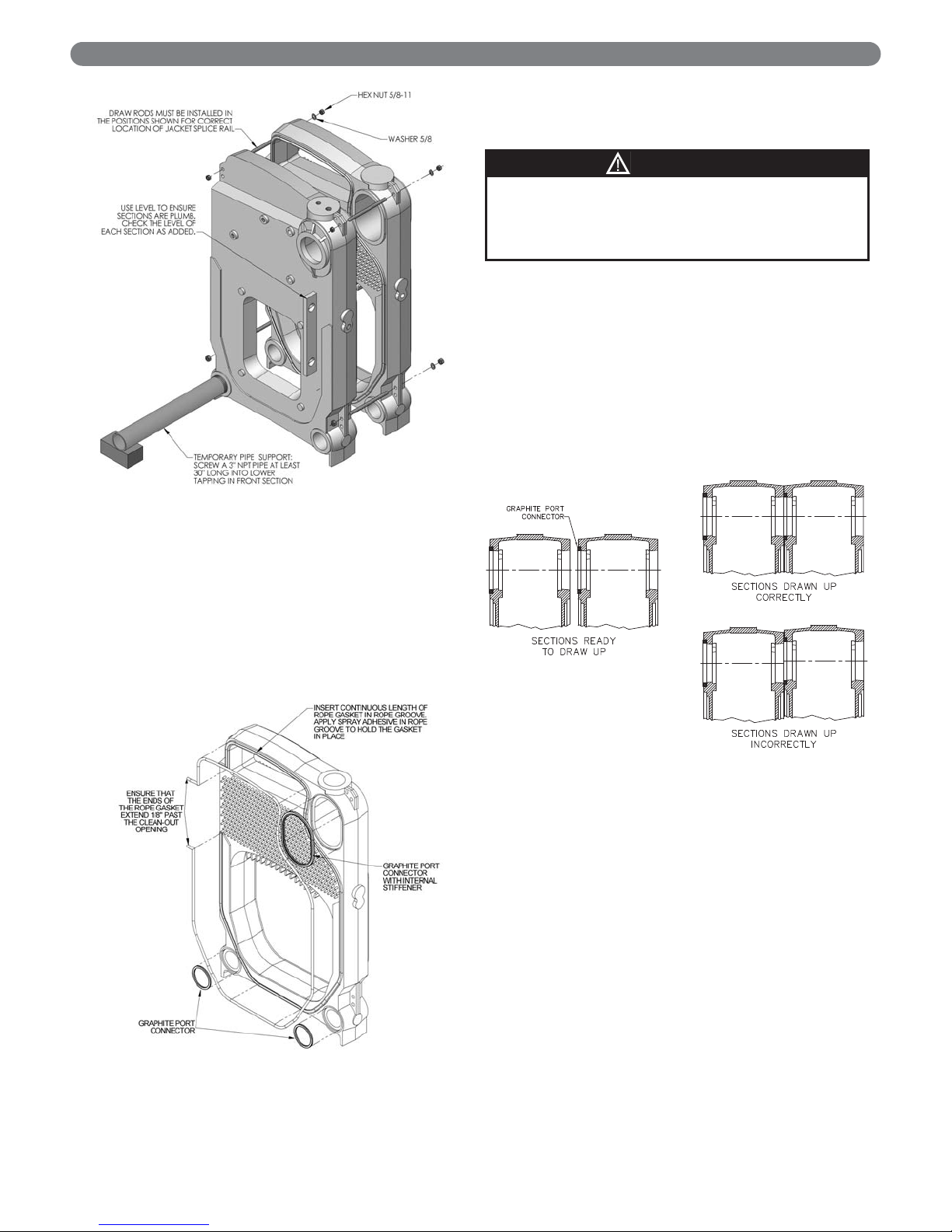

4. Place the Front Section in position on the angles as

shown in Figure 2.2. The end of the floor angle must

either be flush with the boss for the wash out

connection or extend beyond it by as much as

3/8" [10 mm].

5. The Front Section should be supported vertically as

shown in Figure 2.3. Install a 3" NPT x 30" [762

mm] long pipe in the wash out connection at the

rear of the section and block with wood.

6. Inspect the port connector recesses and rope groove

on the cast iron rear section for dirt and obstructions.

7. Clean the port connector recesses with a stiff wire

brush.

ASSEMBLY

2. ASSEMBLY

Figure 2.1: Angle Rail Placement

Figure 2.2: Front Section Placement

The cast iron sections are top heavy. Handle with care

to avoid tipping or falling.

WARNING

Page 12

10

8. Apply the spray-on adhesive supplied with the boiler

to the rope groove. This will hold the rope gasket in

place during assembly.

9. Apply a length of rope gasket (supplied in the

section assembly cartons), avoiding bends and

twists in the rope. Ensure that the ends of the rope

gasket extend past the clean-out cover opening as

shown in Figure 2.4.

10. Install the large graphite port connector with steel

inner ring into the upper port making sure that the

inner ring stays inside the port connector.

11. Install the two small, circular, graphite port

connectors with steel inner rings in the lower recess

ports. Make sure that the inner rings stay inside the

port connectors. Spray adhesive used for attaching

rope may be used to keep the port connectors in

place during assembly.

12. Select the correct intermediate section (refer to Table

2.2), and slide it into place against the front section.

Ensure that the sections are plumb and the port

connectors are properly seated in the port recesses as

indicated in Figure 2.5.

13. Install the draw rods as shown in Figure 2.3 and

tighten them lightly. Note: Draw rods must be

installed as shown to ensure correct installation of

the Jacket Channel Splice Rail.

14. Inspect the rope gasket to ensure that it remains in

the rope groove.

15. Check the section alignment and port connector

position by looking through the ports. If necessary,

reposition the port connector by loosening the draw

rods and then retightening them.

16. Check the floor angles and sections for alignment.

ASSEMBLY

Figure 2.3: Front Section Support

Figure 2.4: Rope Gasket and Port Connector

Instalation

Handle the graphite port connectors with care. Do

not bend, twist, stretch or drop the port connectors. If

the graphite port conector is damaged it must be

replaced.

NOTICE

Figure 2.5: Drawing Up Sections

Page 13

11

17. Gently tighten the draw rods to the torque

specification and sequence as described in Table 2.1.

Make sure the port connectors stay inside the boiler

ports. Do not completely tighten any draw rod out of

sequence. Gradually work each side until the correct

torque is reached.

18. If any ports develop leaks during the hydrostatic test,

the torque may be increased up to 200 ft. lbs. [270

Nm] on the upper right and 150 ft. lbs. [203 Nm] on

both of the lower ports.

19. Prepare the rope groove and gasket recess on the

intermediate section as described for the front

section in paragraph 2.C.6 through 2.C.11.

20. Select the next appropriate section in accordance

with Table 2.2.

21. For TC-08 through TC-18 refer to Figure 2.6, 2.7

and Table 2.3 for correct placement of nuts and

washers for jacket channel splice piece.

ASSEMBLY

Table 2.1: Torque Specifications for Series TC™

Boiler with Graphite Port Connectors

Seq.

No.

Draw Rod

Position

Torque

(ft. lbs.)

Torque

(Nm)

1 Upper Right 25 34

2 Lower Left 25 34

3 Lower Right 25 34

4 Upper Left 10 14

5 Upper Right 50 68

6 Lower Left 50 68

7 Lower Right 50 68

8 Upper Right 75 102

9 Lower Left 75 102

10 Lower Right 75 102

11 Upper Left 30 41

12 Upper Right 125 169

13 Lower Left 125 169

14 Lower Right 125 169

15 Upper Right 125 169

16 Upper Left 40 54

Table 2.2a: Steam Section Arrangement

F Front Section

T Intermediate Section w/5" Steam Tapping (Steam Only)

TLIntermediate Section w/5" Steam & LWCO Tappings (Steam Only)

H Optional Intermediate Section w/Heater Connections

HLOptional Intermediate Section w/Heater Connections & LWCO Tapping

P Plain Intermediate Section

PLPlain Intermediate Section & LWCO Tappings

B Back Section

F T HLB

F H TLH B

F T HLT H B

F T HLP T H B

F T HLP H T H B

F T HLP H P T H B

F H TLH P H P T H B

F H TLH P T H P T H B

F H TLH P T H P H T H B

F H TLH P H T H P H T H B

F H TLH P H T H P H P T H B

F H TLH P H P T H P H P T H B

F H TLH P H P H T H P P H T H B

F H TLH P H P H T H P

H

P H T H B

F H TLH P H P H

P

T H P

H

P H T H B

TC-04

TC-05

TC-06

TC-07

TC-08

TC-09

TC-10

TC-11

TC-12

TC-13

TC-14

TC-15

TC-16

TC-17

TC-18

Notes:

1) Tapped Intermediate Sections with LWCO Tappings (T

L

) are optional and if not used are replaced with a Tapped Intermediate Section (T).

2) Intermediate Sections with Heater Connections (H) & (H

L

) are optional. The locations shown indicate the possible placement of these sections if they

are ordered. Unless Intermediate Heater Sections are specified, the sections provided will be Plain Intermediate Sections (P) or (P

L

).

3) Sections with Low Water Cut-Off (LWCO) Tappings are optional. However, if used, they must be placed at the third position from the front in order to

assure proper jacket fit.

Page 14

12

ASSEMBLY

F P HLP H P P H B

F H PLH P H P P H B

F H PLH P P H P P H B

F H PLH P P H P H P H B

F H PLH P H P H P H P H B

F H PLH P H P H P H P P H B

F H PLH P H P P H P H P P H B

F H PLH P H P H P H P P H P H B

F H PLH P H P H P H P

H

P H P H B

F H PLH P H P H

P

P H P

H

P H P H B

TC-04

TC-05

TC-06

TC-07

TC-08

TC-09

TC-10

TC-11

TC-12

TC-13

TC-14

TC-15

TC-16

TC-17

TC-18

Notes:

1) Intermediate Sections with Heater Connections (H) & (H

L

) are optional. The locations shown indicate the possible placement of these sections if they

are ordered. Unless Intermediate Heater Sections are specified, the sections provided will be Plain Intermediate Sections (P) or (P

L

).

2) Sections with Low Water Cut-Off (LWCO) Tappings are optional. However, if used, they must be placed at the third position from the front in order to

assure proper jacket fit.

F P HLB

F H PLH B

F P HLP H B

F P HLP P H B

F P HLP H P H B

Table 2.2b: Water Section Arrangement

Figure 2.6: Numbered Section Illustration

Page 15

13

D. HYDROSTATIC TESTING

1. Plug all openings in the boiler waterways and fill the

boiler with cold water. While filling the boiler, recheck the torque on all ports and tighten the draw

rods if necessary.

2. Hydrostatically test the boiler for leaks in accordance

with ASME Code, Section IV.

a) Steam Boilers: The assembled boiler shall be

subjected to a hydrostatic test pressure of not less

than 45 psig [310 kPa].

b) Water Boilers: The assembled boiler shall be

subjected to a hydrostatic test pressure of not less

than 1-1/2 times the maximum allowable

working pressure.

c) The test pressure shall not exceed the minimum

requirements shown above by more than 10 psi

[69 kPa].

3. If any port connector leaks, tighten the draw rods

until either the joint achieves full metal-to-metal

contact or until or the maximum torque is reached

(Upper Right - 200 ft. lbs. [270 Nm]; Lower Ports 150 ft. lbs.[203 Nm]). Check the torque on the other

draw rods that may have been affected by the draw

rod that was tightened.

E. CLEAN-OUT COVER INSTALLATION

1. Attach the clean-out cover plates and insulation to

the clean-out openings on the left side of the boiler.

Use the T-bolt assemblies and hex nuts provided in

the Section Assembly Cartons. See Figure 2.8.

2. Press each clean-out cover plate with insulation over

the protruding T-bolts until the bolts punch through

the insulation. Install a 5/16" flat washer and 5/16"

brass nut on each bolt and tighten until the

insulation forms a good seal around the clean-out

opening.

3. Seal tops and bottoms of insulation with silicone

sealant.

ASSEMBLY

Table 2.3: Splice Piece Nut & Washer Locations

Boiler Model Splice Piece & Washer Locations

TC- 04 N/A

TC- 05 N/A

TC- 06 N/A

TC- 07 N/A

TC- 08 Between Sections 3-4 & Sections 5-6

TC- 09 3-4 & 5-6

TC- 10 5-6 & 7-8

TC- 11 5-6 & 7-8

TC- 12 5-6 & 7-8

TC- 13 5-6 & 7-8

TC- 14 7-8 & 9-10

TC- 15 5-6 & 7-8 9-10 & 11-12

TC- 16 5-6 & 7-8 9-10 & 11-12

TC- 17 5-6 & 7-8 9-10 & 11-12

TC- 18 5-6 & 7-8 11-12 & 13-14

Figure 2.7

Note: Splice Piece nuts and washers are to be installed as shown in Figure 2.7 on

the draw rods that connect the sections indicated. The sections are numbered

from front to back as indicated in Figure 2.6. The Splice Pieces are shown in

Section 3 in Figure 3.12.

Do not exceed the maximum torque specifications

(upper Right – 200 ft. lbs. [270 Nm]; Lower Ports –

150 ft. lbs. [203 Nm]). Tighten the rods in the

sequence shown in Table 2.2.

Do not continue to tighten the sections after metalto-metal contact is made. Over-tightening the draw

rods will not improve the seal and may cause

damage to the castings.

NOTICE

When the boiler is put into operation for the first

time, the temperature should be brought up slowly

(low fire on burners with this capability).

NOTICE

Page 16

14

. BURNER MOUNTING PLATE

F. BURNER MOUNTING PLATE

INSTALLATION

1. Inspect the rope groove on the Burner Mounting

Plate for dirt and obstructions. Use a wire brush if

necessary to clean the groove.

2. Spray the rope groove with the spray adhesive

provided in the Misc. Parts Carton and apply the

3/8" diameter rope gasket.

3. Install the 7/16" x 2-1/2" Studs provided into the four

threaded holes around the perimeter of the burner

opening in the Boiler Front Section as shown in

Figure 2.9.

4. Insert the Burner Insulation Block into the burner

opening with the notch for the Observation Port on

the top left side.

5. Place the Burner Mounting Plate over the block and

force the block inward until the Studs extend far

enough through the holes to accept 7/16" Hex Nuts

and Washers. Tighten the nuts.

6. Use a long drill, awl, or other such tool to create holes

in the Insulation Block for four 1/4" machine screws.

7. Install the 1/4" x 5" machine screws through the

holes in the Burner Mounting Plate, supporting the

Insulation Block on the inside to prevent tearing.

8. Install the stainless steel washers and 1/4" hex nuts

on the inside of the Insulation Block and tighten

lightly. Be careful not to crush the insulation.

9. Install the four 3/8-16 x 1-1/4" studs provided into

the screw seats provided on the Burner Mounting

Plate.

10. When the burner is installed, the hole in the

Insulation Block for the Burner may need to be

enlarged and shaped. This can be cut with a

hacksaw blade.

G. REAR OBSERVATION PORT

INSTALLATION.

1. Assemble Rear Observation Port as shown in Figure

2.10:

a) Lift up the flapper door on the inside of the

Observation Port and insert the Hex Head Cap

Screw provided in the Misc. Parts Carton.

b) Slide the Spring over the hex head screw and

thread the Hex Nut onto the screw.

c) Thread the Knob onto the Hex Head Screw

behind the nut and lock into position using the

jam nut.

ASSEMBLY

Figure 2.8: Clean-Out Cover Installation

Figure 2.9: Burner Mounting Plate Installation

Figure 2.10: Rear Observation Port Assembly

Page 17

15

2. Thread the 5/16" x 1-1/2" studs into the screw seats

around the rear observation port opening in the

Boiler Back Section.

3. Apply a thin layer of furnace cement over the

mounting flap.

4. Install the Rear Observation Port Assembly on the

Boiler Back Section using three 5/16" hex nuts and

washers.

H. FLUE COLLECTOR INSTALLATION

1. Screw the eight 5/16-18 x 1-1/2" studs provided into

the screw seats around the flue collector outlet on the

Boiler Back Section.

2. Place the 1/8" [3 mm] thick x 3/4" [19 mm] wide

Bolt Tape provided in the Misc. Parts Carton over

the studs.

3. Place the flue collector in position and install the

5/16" washers and nuts. Tighten the nuts uniformly.

4. Open the Slide Damper to the full open position to

prepare for adjustment during Burner

commissioning.

5. Install 1/2" brass plug from Misc. Parts Carton.

I. BURNER MOUNTING

1. Read the Burner Instruction Manual before starting.

2. Remove the Burner from its crate. Verify that all

components are included with the burner.

3. Place the high temperature gasket specified by the

Burner Manufacturer on the Burner Mounting Plate

and secure the Burner using 3/8" flat washers and

hex nuts provided.

4. If the Burner is supplied with a pedestal support,

install it per the Burner Manufacturer’s Instructions.

The pedestal supports the burner and prevents

undue stress on the Boiler Castings.

ASSEMBLY

Figure 2.11: Rear Flue Collector Installation

Page 18

16

A. PREPARATION

1. The boiler must be hydrostatically pressure tested as

indicated in Section 2, paragraph D.

2. The jacket panels are designed so that they may be

installed after the boiler is piped. Use nipples long

enough to extend through the jacket.

B. STEAM BOILER PIPING

1. Refer to the PB Heat Steam Installation Survey for

guidance with steam boiler piping and components.

2. Piping for steam boilers is shown in Figure 3.1, 3.2,

and 3.3. Table 3.1 contains a pipe size schedule for

steam boilers.

3. Series TC™ Boilers are intended to be piped with

one, two or three risers to the header depending on

the boiler size.

a) Table 3.1 shows a pipe schedule for steam boiler

headers.

b) See Figure 3.1 for a typical piping arrangement

for boilers with one riser. (TC-04 & TC-05)

c) See Figure 3.2 for a typical piping arrangement

for boilers with two risers. (TC-06 through TC-10)

d) See Figure 3.3 for a typical piping arrangement

for boilers with three risers.

(TC-11 through TC-18)

4. A Hartford loop, as shown in Figures 3.1, 3.2 and

3.3 is recommended in all steam boiler installations.

The loop prevents the boiler from being drained

completely due to a leak in a return line.

5. Pumped Return Systems:

a) For pumped return systems, install a spring-

loaded check valve on the pump discharge. This

will prevent boiler water from backing up into the

condensate receiver.

b) If the pump discharge is looped above the

normal water level, install a spring-loaded check

valve at the connection to the boiler return. This

will ensure water under pressure in the vertical

pipe preventing water hammer due to hot

condensate flashing to steam.

INSTALLATION

3. INSTALLATION

Table 3.1: Piping Schedule

Do not reduce the size or number of risers shown in

Table 3.1. If the risers are undersized or incorrectly

placed, a sloped water line may occur in the boiler.

This may lead to the overheating of boiler sections.

CAUTION

Figure 3.1: Typical piping arrangement for boilers

with one riser.

Figure 3.2: Typical piping arrangement for boilers

with two risers.

Steam Boiler Piping

Boiler Model

Number of

5" NPT

Risers

Header Size

(NPT)

Equalizer Size

(NPT

TC-04 & TC-05 1 5" 2-1/2"

TC-06 & TC-07 2 5" 2-1/2"

TC-08 to TC-10 2 6" 4"

TC-11 to TC-18 3 8" 4"

Page 19

17

c) Install a flow regulating valve on the pump

discharge to allow throttling of the pump flow.

Excess return flow may cause water hammer and

water level fluctuations.

d) Use a Hartford Loop connection. Oversize the

equalizer slightly to make sure water doesn’t

spray into the header and cause hammering.

6. Always locate the steam supply take-off between the

equalizer and the last boiler riser. Failure to do this

will cause water carryover into the system because

the condensate will collect at the entrance to the

steam main.

7. Pitch the steam header to allow condensate to flow

toward the equalizer.

8. Feedwater requirements for steam boilers at full input

are shown in Tables 3.2a and 3.2b. Addition of

water to the boiler should be controlled by sensing

the boiler water level.

9. 1" NPT water column tappings are provided on the

front section for mounting low water cutoffs and level

controllers.

10. The front section has 3" NPT tappings at the base for

installation of 3" NPT close nipples and 3" NPT pipe

caps. Removal of caps allows flushing of sediment

from the boiler.

C. MULTIPLE STEAM BOILER PIPING

1. Figure 3.4 shows typical piping for multiple steam

boiler gravity return systems.

2. Figure 3.5 shows typical piping for multiple steam

boiler pumped return systems.

3. Provide separate feed lines for multiple steam boiler

pumped return systems. Use either separate feed

pumps or electrically actuated valves to isolate the

boiler feed. This is necessary to provide reliable level

control and avoid nuisance performance problems.

4. Condensate return units are not recommended for

multiple boiler installations. Use a boiler feed system

which is actuated by a boiler control that responds to

the needs of the boiler.

5. Install a float & thermostatic (F&T) trap at the boiler

normal water level on each of the boilers in a multiple

boiler system with pumped returns. This will prevent

flooding of idle boilers due to condensation of steam.

D. WATER BOILER PIPING

1. Refer to the Peerless®Water Installation Survey for

guidance with water boiler piping and components.

2. Typical piping for a Series TC™ water boiler is shown

in Figure 3.6.

INSTALLATION

Table 3.2a: Feedwater Requirements -

US Customary Units

Figure 3.3: Typical piping arrangement for boilers

with three risers.

Boiler

Model

I=B=R

Gross

Output

MBH

Evap. Rate

1

GPM

Minimum

Feedwater

Pump Flow

2

GPM

Condensate

Receiver

Capacity

3

Gallon

TC- 04 900 1.86 3.7 37

TC- 05 1166 2.41 4.8 48

TC- 06 1433 2.96 5.9 59

TC- 07 1699 3.50 7.0 70

TC- 08 1965 4.05 8.1 81

TC- 09 2232 4.60 9.2 92

TC- 10 2498 5.15 10.3 103

TC- 11 2764 5.70 11.4 114

TC- 12 3031 6.25 12.5 125

TC- 13 3297 6.80 13.6 136

TC- 14 3563 7.35 14.7 147

TC- 15 3830 7.90 15.8 158

TC- 16 4096 8.45 16.9 169

TC- 17 4362 9.00 18.0 180

TC- 18 4629 9.55 19.1 191

Boiler

Model

I=B=R

Gross

Output

KW

Evap. Rate

1

ltr/min

Minimum

Feedwater

Pump Flow

2

tr/min

Condensate

Receiver

Capacity

3

Liter

TC- 04 264 7.0 14.1 141

TC- 05 342 9.1 18.2 182

TC- 06 420 11.2 22.4 224

TC- 07 498 13.2 26.5 265

TC- 08 576 15.3 30.7 307

TC- 09 654 17.4 34.8 348

TC- 10 732 19.5 39.0 390

TC- 11 810 21.6 43.2 432

TC- 12 888 23.7 47.3 473

TC- 13 966 25.7 51.5 515

TC- 14 1044 27.8 55.6 556

TC- 15 1122 29.9 59.8 598

TC- 16 1200 32.0 64.0 640

TC- 17 1278 34.1 68.1 681

TC- 18 1357 36.2 72.3 723

Table 3.2b: Feedwater Requirements -

SI Metric Units

1. Evaporation rate is based on heat of vaporization at 212°F, 970 BTU/lbm.

2. Minimum feedwater pump flow is based on 2 times evaporation rate.

3. Condensate receiver capacities are based on 20 minute steam

1. Evaporation rate is based on heat of vaporization at 100°C, 2257 kJ/kb.

2. Minimum feedwater pump flow is based on 2 times evaporation rate.

3. Condensate receiver capacities are based on 20 minute steam cycle. Chart

3. shows actual capacity, not gross receiver volume

Page 20

18

3. A return yoke as shown in Figure 3.7 is provided as

standard equipment for each water boiler. Assemble

each joint as follows:

a) Cover edges and outer surface of the gasket with

a thin layer of petroleum-free silicone lubricant

(supplied).

b) Install each gasket by placing it over the ends of

the two pipes to be connected.

c) Center the gasket between the grooves.

d) Place the coupling housings over the gasket so

that the keys fully engage into grooves.

e) Insert the bolts into the coupling and tighten the

nuts until finger tight.

f) Alternately tighten the nuts evenly so they do not

bind the gasket. The gasket should not be visible

after fully tight.

4. The recommended supply and return pipe sizing in

Tables 3.3a and 3.3b is based on a flow rate through

the boiler that produces a 20°F [11°C] temperature

rise (1 gpm [3.79 ltr/min] of flow for each 10,000

Btu/hr [2.93 kW] of boiler output).

5. Using higher flow rates is not recommended because

it may cause poor distribution through the boiler.

INSTALLATION

Figure 3.4: Multiple Steam Boiler Piping – Gravity Return

Figure 3.5: Multiple Steam Boiler Piping – Pumped Return

Page 21

19

Figure 3.6: Water Boiler Piping

Figure 3.7: Return Yoke

INSTALLATION

Page 22

20

INSTALLATION

6. Lower flow rates are acceptable providing that the

return temperature to the boiler is a minimum of

130°F [54°C] on gas boilers and 150°F [66°C] on oil

boilers to prevent condensation of flue gases.

7. The size of supply and return connections given in

Tables 3.3a and 3.3b are the minimum size for a

20°F [36°C] temperature differential. Do not reduce

these sizes unless the flow is low enough to keep the

velocity from developing noise and erosion

problems.

8. When the boiler is connected to heating coils located

in air handling units, the boiler piping must be

equipped with flow control devices to prevent gravity

circulation of the boiler water during the cooling cycle.

9. Low Temperature Return Systems:

a) When the system return temperature will be

below 130°F [54°C] on gas or 150°F [66°C] on

oil for extended periods (heat pump systems,

radiant panels, snow melt, outdoor reset, etc.)

provide piping and controls to protect the boiler

from condensation. Excessive condensation will

lead to corrosion in the boiler and breeching,

which will shorten the life of the boiler.

b) Low return water temperatures are likely to occur

whenever the boiler is allowed to cool below

design temperatures (cold start). This is

acceptable as long as the frequency of these

shut-downs is very low.

Boiler

Model

I=B=R

Gross Output

(MBH)

Flow Rate

@20 F Rise

(GPM)

Recommended

Supply Size

(NPT)

Return Size

(NPT)

TC- 04 900 90 3 3

TC- 05 1166 117 3 3

TC- 06 1433 143 4 4

TC- 07 1699 170 4 4

TC- 08 1965 196 4 4

TC- 09 2232 223 4 4

TC- 10 2498 250 5 5

TC- 11 2764 276 5 5

TC- 12 3031 303 5 5

TC- 13 3297 329 5 5

TC- 14 3563 356 5 5

TC- 15 3830 383 5 5

TC- 16 4096 409 5 5

TC- 17 4362 436 5 5

TC- 18 4629 463 5 5

Boiler

Model

I=B=R

Gross Output

(kW)

Flow Rate

@36 C Rise

(ltr/min)

Recommended

Supply Size

(NPT)

Return Size

(NPT)

TC- 04 264 341 3 3

TC- 05 342 443 3 3

TC- 06 420 541 4 4

TC- 07 498 644 4 4

TC- 08 576 742 4 4

TC- 09 654 844 4 4

TC- 10 732 946 5 5

TC- 11 810 1045 5 5

TC- 12 888 1147 5 5

TC- 13 966 1245 5 5

TC- 14 1044 1348 5 5

TC- 15 1122 1450 5 5

TC- 16 1200 1548 5 5

TC- 17 1278 1650 5 5

TC- 18 1357 1753 5 5

Table 3.3a: Supply & Return Pipe Sizing –

US Customary Units

Table 3.3b: Supply & Return Pipe Sizing –

SI Metric Units

Figure 3.8: Chilled Water Systems

Page 23

21

INSTALLATION

c) For systems with variable low temperature

returns or constant low temperature returns

please refer to the Peerless

®

Water Survey for

system information.

10. Chilled Water Systems:

a) If the boiler will be used in conjuction with a

chilled medium system, the chiller must be piped

in parallel with the boiler to prevent the chilled

medium from entering the boiler and causing

damage. See Figure 3.8.

I

E. MULTIPLE WATER BOILER PIPING

1. Figure 3.9 shows a typical piping arrangement for

multiple water boilers. The optional bypass valve is

used when the system return water temperature is

consistently below 130°F [54°C] for gas boilers or

150°F [66°C] for oil boilers.

2. For systems with variable low temperature return

temperature, a three-way valve may be used (see

Peerless

®

Water Installation Survey for details).

F. TANKLESS HEATER INSTALLATION

1 Heater sections must be installed as shown in Table

2.2 in the Assembly section of this manual.

2. Inspect heater section for dirt or rust on the mating

surface. Clean with a wire brush if necessary.

3. Install 7/16" x 1-1/2" studs in the screw seats around

the heater opening as shown in Figure 3.10.

4. Place the heater gasket over the studs. Be sure the

gasket is not twisted.

5. Carefully install the heater coil. Install the nuts and

tighten them evenly to ensure uniform compression

of the gasket.

6. Install the operating control in the center tapping

on the heater mounting plate. Figure 3.11 shows

an acceptable piping arrangement for multiple

heater coils.

Figure 3.9: Multiple Water Boiler Piping

Figure 3.10: Tankless Heater Coil Installation

Figure 3.11: Typical Piping for Multiple Tankless

Heater Coils

WARNING

Provide anti-scald devices in the system where

needed. Failure to control water temperature to

showers or other usage areas where scald risk

exists may result in severe personal injury.

Page 24

22

G. JACKET PREPARATION

1. Collect all jacket cartons as listed in Table 1.2 in the

Pre-installation section of this manual. One Jacket

Channel Carton, one Jacket Front/Back Carton, and

one to five Jacket Top/Side Cartons are included.

2. The cartons contain pre-insulated panels and screws

for attaching them to the unit.

3. Remove all required knock-outs (Heater Coils, Steam

Supply, LWCO, etc.) from jacket panels before

assembly.

4. The boiler block must be completely assembled on

the Angle Rails supplied by PB Heat before installing

the jacket. The Angle Rails are drilled and tapped to

accept the Lower Jacket Channels.

5. Any limit controls, steam gauge glass, low water

cutoffs or gauges to be mounted on the front of the

boiler must be installed after the Front Jacket Panel,

F2, as shown in Figure 3.12.

6. All other piping, burner, and control connections

may be made before jacket installation.

H. JACKET ASSEMBLY

1. Figure 3.12 shows a typical jacket assembly.

a) Lower Channels: Locate Lower Channels on the

Angle Rails. TC-04 through TC-07 boilers require

only one Lower Channel per side. TC-08

through TC-14 boilers require two Lower

Channels per side and the TC-15 through TC-18

boilers require three Lower Channels per side.

On TC-08 through TC-18 be sure that the 5/16"

diameter holes in the outer flange of the Lower

Channels are at the front and rear of the boiler.

b) Front Panel: Locate Front Panel, F2, over the

front of the boiler with the bottom corners

supported by the Lower Channels. Align holes in

the Front Panel with those in the Lower

Channels and fasten with #10 washer head

sheet metal screws. Install panels F1 and F2A

with #10 washer head sheet metal screws.

c) Back Panel: Assemble Right Rear Post to Back

Panel (B1) with #10 washer head sheet metal

screw. Install Panel/Post assembly on rear of

boiler. Assemble Left Rear Post to Back Panel.

Align lower holes of right and left posts with

Lower Channel holes and attach with #10

washer head sheet metal screws. Install panel B2

with sheet metal screws.

INSTALLATION

Figure 3.12: Jacket Assembly

Page 25

23

d) Upper Channels:

1. TC-04 through TC-07 Boilers have one piece

Upper Channels. These are to be attached to

the top of the Front and Back Panels with

1/4"-20 round head machine screws, washers

and nuts.

2 TC-08 through TC-18 Boilers have two or three

piece Upper Channels. Install splice pieces with

the splice piece mounting hardware as shown

in Section 2, Assembly, Figures 2.6 & 2.7.

Attach the Upper Channels to the Splice Pieces

and to the Front and Back Panels with 1/4"-20

round head machine screws, washers, and nuts.

e) Side and Top Panels

1 Left Side Panels: Attach knobs to Left Side

Panels and install by inserting the top into the

Upper Channel and then dropping the Panel

into the space between the Lower Channel

and the Angle Rail.

2 Top Panels: Lay out the Top Panels so that

the knock-outs and openings correspond to

the piping and components on the assembled

boiler. After checking the layout, remove the

necessary knock-outs and install Top Panels.

f) Right Side Panels: Lay out the Right Side Panels

so that the knock-outs and openings correspond

to the piping and components on the assembled

boiler. After checking the layout, remove the

necessary knock-outs and install the Right Side

Panels by inserting them into the Upper

Channels then dropping them into the space

between the Lower Channels and Angle Rails.

I. FUEL PIPING

1. General:

a) Read the Burner Instruction Manual, supplied

with the boiler, or if the burner was purchased

separately, with the burner.

b) Review applicable code requirements for the

burner and fuel piping installations.

c) Install piping to allow for removal of burner and

access to combustion chamber for cleaning or

service.

2. Install Fuel Oil Piping:

a) Place the fuel oil tank and install the piping

in accordance with local codes or in the

absence of such codes with the codes listed

in paragraph 1.B.

b) Follow guidelines in the Burner Instruction

Manual for sizing oil lines. Never use smaller

than 1/2" [12.7 mm] OD copper tubing.

c) Install manual shut-off valves on the suction line

at the burner and at the oil line entrance to the

building.

d) If installing a shut-off valve on the return line,

you must provide an oil pressure relief valve

piped ahead of the shut-off valve and discharged

to the tank to prevent over-pressure conditions.

e) Install a two pipe oil distribution system when

possible. It will improve the reliability of the oil

delivery to the burner.

f) Use flare fittings when using copper tubing.

g) If the burner is above the top of the fuel oil tank,

install a check valve on the oil suction line at the

burner to prevent oil from evacuating the line.

h) If the burner is below the top of the tank, install

an anti-siphon device to prevent oil flow in the

event of an oil line break.

3. Install Gas Supply Piping

a) Size gas piping as required by Local codes or in

the absence of such authority, the codes listed in

paragraph 1.B.

b) Use Table 3.6 & 3.7 for sizing of piping for

natural gas with a system pressure drop of 0.3

inches of water [0.075 kPa].

INSTALLATION

Pipe

Length

(Feet)

1-1/4"

Pipe

1-1/2"

Pipe2"Pipe

2-1/2"

Pipe3"Pipe4"Pipe6"Pipe

10 1,050 1,600 3,050 4,800 8,500 17,500 44,000

20 730 1,100 2,100 3,300 5,900 12,000 31,000

30 590 890 1,650 2,700 4,700 9,700 25,000

40 500 760 1,450 2,300 4,100 8,300 22,000

50 440 670 1,270 2,000 3,600 7,400 20,000

60 400 610 1,150 1,850 3,250 6,800 18,000

70 350 560 1,050 1,700 3,000 6,200 17,000

90 320 490 930 1,500 2,600 5,400 15,000

100 305 460 870 1,400 2,500 5,100 14,000

150 250 380 710 1,130 2,000 4,100 11,500

Table 3.6: Capacity of Gas Supply Pipe in Cubic

Feet Per Hour of Natural Gas for a

Pressure Drop of 0.30 inches of water

Table 3.7: Capacity of Gas Supply Pipe in Cubic

Meters Per Hour of Natural Gas for a

Pressure Drop of 0.075 kPa

Pipe

Length

(meter)

1-1/4"

Pipe

1-1/2"

Pipe2"Pipe

2-1/2"

Pipe3"Pipe4"Pipe6"Pipe

3.05 30 45 86 136 241 496 1,246

6.10 21 31 59 93 167 340 878

9.14 17 25 47 76 133 275 708

12.19 14 22 41 65 116 235 623

15.24 12 19 36 57 102 210 566

18.29 11 17 33 52 92 193 510

21.34 10 16 30 48 85 176 481

27.43 9 14 26 42 74 153 425

30.48 9 13 25 40 71 144 396

45.72 7 11 20 32 57 116 326

Specific Gravity 0.50 0.55 0.60 0.65 0.70 0.75

Multiplier 1.10 1.04 1.00 0.96 0.93 0.90

Specific Gravity 0.80 0.85 0.90 1.00 1.10 1.20

Multiplier 0.87 0.84 0.82 0.78 0.74 0.71

Specific Gravity 1.30 1.40 1.50 1.60 1.70 1.80

Multiplier 0.68 0.66 0.63 0.61 0.59 0.58

Above ratings are based on natural gas with a specific gravity of 0.60 allowing

pressure drop of 0.3 inces of water (0.075 kPa). No allowance is needed for pipe

fittings. Apply the following factors to the above capacities for specific gravity

other than 0.60.

Page 26

24

c) Check the maximum inlet gas pressure in the

Burner Instruction Manual and make sure that

the system regulator will not allow the gas

pressure to exceed this value.

d) The minimum gas supply pressure is listed on the

Burner Rating Plate. Make sure the system

regulator and piping are sized and adjusted

properly to provide this pressure under all

conditions.

e) Install a Service Valve, Sediment Trap and

Ground Joint Union at the supply connection to

the Gas Control Train as shown in Figure 3.13.

These components are to be supplied by the

installing contractor and are not part of the boiler

or burner. Install them in accordance with local

codes or in the absence of such authority with

the codes listed in paragraph 1.B.

f) Use only pipe joint compounds rated for use with

Liquefied Petroleum Gases.

4. Test Gas Supply Piping

a) Isolate the Boiler Gas Control Train from the

system during testing.

b) For test pressures 1/2 psig [3.4 kPa] or less, close

the Manual Shut-Off Valve on the Boiler Gas

Control Train.

c) For test pressures above 1/2 psig [3.4 kPa],

disconnect the gas supply piping upstream of the

Boiler Manual Shut-Off Valve.

J. INSTALL CONTROLS AND TRIM

1. Install Safety Relief Valve:

a) Install a Safety Relief Valve on the 3" NPT

tapping at the top of the rear section for both

steam and water boilers as shown in Figure 3.14.

b) Water and Steam Trim Cartons contain safety

relief valves and fittings.

c) Be sure that the relief valve sizing meets local

code requirements.

INSTALLATION

Figure 3.14: Safety Relief Valve Installation

Do not expose the Gas Control Train to excessive

pressure. The gas valves can be damaged. This may

result in explosion hazard and severe personal injury

or death.

Do not test gas supply piping with an open flame.

Use a soap suds mixture brushed onto the pipe

joints to test for leaks.

WARNING

Pipe the discharge of the Safety Relief Valve away

from any traffic area, preferably to a floor drain. This

is necessary to prevent injury should the valve

discharge. Pipe the discharge in the same size pipe

or larger than the valve discharge size. Do not put

any valves or restrictions in the Safety Relief Valve

discharge piping.

CAUTION

Figure 3.13: Gas Supply Connection to Boiler

Page 27

25

2. Install Drain/Blowdown Valves

a) Water Boilers: Install a drain valve either in the

return piping or in one of the 3" NPT lower

tappings in the Front Section of the boiler. See

Figure 3.15.

b) Steam Boilers: Install a 1-1/4" NPT Full Port

Blowdown Valve either in the return piping or in

one of the 3" NPT connections in the Front

Section of the boiler. See Figure 3.15.

c) Pipe the valve discharge to a floor drain if

available or install a nipple and a pipe cap to

close off the discharge when not in use.

3. Install Low Water Cut-off

a) Mount an optional Float-type Low Water Cutoff

(LWCO) in the tappings provided in the top and

side of the Front Section or the Intermediate

LWCO Section (this optional section is located at

the third section from the front when supplied).

See Figure 3.16 for the location of control

connection tappings.

b) Figure 3.17 shows a typical control configuration

for a steam boiler and Figure 3.18 shows a

typical control configuration for a water boiler.

c) Provide piping for the Float-type LWCO such

that the vertical position of the device is as

recommended by the manufacturer.

1. LWCOs that are piped too high will result in

water carryover into the steam distribution

system and will cause erratic operation of the

boiler.

2. LWCOs that are piped too low will expose

the boiler crown sheet and cause damage to

the boiler.

d) For correct positions of common Float-type

LWCO devices see Figures 3.19 through 3.22.

e) Provide a blowdown valve for each Float-type

LWCO. Pipe the valve discharge away from high

traffic areas to a floor drain if possible. The

blowdown valve is required for proper

maintenance of the control.

f) Maintain a height of 50 1/2” [1283 mm] from

the bottom of the Angle Rails to the Normal

Water Level.

g) When using multiple Float-type Low Water

Cutoffs, always pipe them as shown in Figure

3.17. Do not mount these devices on opposite

ends of the boiler. This will cause erratic

operation and nuisance shut downs of the boiler.

INSTALLATION

Figure 3.16: Control Connection Locations

Tap.

No.

Tapping

Size

Connection Description

Steam Boiler Water Boiler

1 3/4" NPT Optional Probe LWCO –

2 1" NPT

Optional Water

Column - (top)

Air Removal, Water

Column (top)

3 1" NPT

Manual Reset High

Limit, Operating Control

& Steam Pressure Gauge

Optional Auxiliary

Firing Rate, Limit

Controls

4 3/4" NPT – Operating Control

5 3/4" NPT Water Gauge Glass

Manual Reset High Limit

(top) Temp/Press Gauge

(bottom)

6 1/4" NPT

Overfire Pressure

Tapping

Overfire Pressure

Tapping

7 1" NPT

Water Column (bottom)

Water Column (bottom)

8

7¹⁄₈" x 5¹⁄₄"

Tankless Heater Tankless Heater

9

1¹⁄₂" NPT

Optional Inspection

Tappings

Optional Inspection

Tappings

Table 3.4: Control Connections Sizes

(See Figure 3.16)

Figure 3.15: Boiler Drain/Blowdown Valve

Installation

Page 28

26

4. Install Limit Controls:

a) Steam Boilers: See Figure 3.17 for typical control

locations for steam boilers. Additional limit and

firing rate controls can be added to the 3/4" NPT

piped header.

b) Water Boilers: See Figure 3.18 for typical control

locations for water boilers. Additional limit and

firing rate controls can be added to the boiler

supply piping.

5. Connect Control Wiring:

a) Install all wiring in accordance with local codes,

the National Electrical Code and other

controlling agencies or governing bodies.

b) Use #14 gauge or heavier wire for supply wiring.

Protect the circuit with a fused disconnect switch

(supplied by others) and a grounded neutral.

c) Mount an electrical junction box on the boiler

Front Panel for connection of boiler controls to

the burner control panel.

d) Follow the instructions in the Burner Manual and

the wiring diagram supplied with the burner.

e) Install all line voltage (120 VAC) wiring in

conduit.

f) Do not install single pole switches including

safety controls in the neutral leg of a motor

control circuit.

INSTALLATION

Figure 3.19: Optional Model 67PE2 Low Water

Cutoff

Figure 3.18: Water Boiler Control Locations

Figure 3.17: Steam Boiler Control Locations

The boiler/burner must be electrically grounded in

accordance with the requirements of the local

authority having jurisdiction, or in the absence of

such requirements, with the current edition of the

National Electric Code, ANSI/NFPA 70.

NOTICE

Page 29

27

INSTALLATION

Figure 3.20: Optional Model 47-2 Low Water

Cutoff/Feeder

Figure 3.21: Optional Model 157 Low Water

Cutoff/Pump Control

Figure 3.22: Optional Model 51-2 Low Water

Cutoff/Feeder

Page 30

28

A. STARTING THE BOILER

1. Check the piping.

a) Water/Steam Piping

1. The Boiler must have been hydrostatically

tested.

2. Check the attached piping for joint tightness.

3. Continue monitoring as you proceed through

start up.

b) Gas Piping

1. Make sure the gas system piping and the

connections to the boiler Gas Control Train(s)

have been leak tested.

2. After the boiler is in operation, check the

tightness of all joints in the boiler gas piping

with a soap suds solution.

3. Purge the gas piping of all air up to the boiler

Gas Control Train.

c) Oil Piping

1. Check the oil piping visually. Make sure all

joints are tight.

2. When the burner is firing, check the suction

line and return line pressures.

3. If the pressure exceeds the allowable pressure

in the Burner Manual or if the suction line

vacuum is higher than allowable, correct the

piping as needed to bring the suction line and

return line pressures within acceptable range.

4. Excess pressure can cause pump seal failures.

Excess vacuum will cause fuel flow problems

with the burner oil pump.

2. Fill the boiler.

a) Steam: Fill the boiler to the normal water line.

1. Gravity Systems and Pumped Return with

Condensate Units – Fill to the normal water

level mark on front jacket panel.

2. Pumped Return with Boiler Feed Unit – Fill

the boiler using the boiler feed unit. Fill level

will depend on the control being used, but

should be at the normal water level mark on

front jacket panel.

3. Fill the boiler.

a) Water: Fill the boiler and system.

1. Fill the system with fresh water only. If the

water hardness is high, use water treatment

to reduce the deposition of minerals in the

boiler.

2. If the system requires antifreeze, use only

antifreeze designed for hydronic systems.

These contain inhibitors to prevent corrosion

of the boiler and system components. Do not

use ethylene glycol or automotive antifreezes.

• Make sure the antifreeze supplier can

provide periodic inhibitor check service.

• If automatic fill is used, the system will

have to be checked periodically to make

sure the antifreeze concentration has not

been diluted below design level.

• Local codes may require the use of a

backflow preventer or manual fill only

with separation from the city supply.

• Consider the minimum temperature of

potential exposure for the system when

deciding on the antifreeze concentration. A

concentration of 50% generally provides

protection from freezing down to -30°F.

3. Purge the air from the system.

4. Run burner check-out.

a) Before firing the burner, slide the Slide Gate

Damper on the rear flue box all the way down

(full open).

b) Follow the instructions in the Burner Manual for

starting the burner, adjusting air openings and

fuel rates. Perform ignition system and flame

supervisory control test and checkout as

described in the manual.

c) After burner is set at rate, close the damper until

the pressure reading at the test opening in the rear

flue box is between 0.0" wc and 0.1" wc positive.

d) When a barometric draft regulator is installed in

the venting system, adjust the boiler damper for

0.0” wc pressure reading at the damper. Adjust

the draft regulator for -0.05" wc draft between

the boiler damper and the draft regulator.

e) Adjust the burner as needed for a CO

2

reading of:

1. Oil burners: 12% to 12.5% or 1% less than

the level at which the smoke reading goes

above a trace on the Bacharach scale.

2. Natural gas burners: 9% to 10% with CO less

than 50 ppm.

5. Check boiler controls.

a) Limit and Operating Controls

1. Lower the setting of each control until the

burner shuts down.

b) Low Water Cutoffs

On installations with high draft, do not leave the boiler

with a negative draft reading at the rear flue box or

draft damper. High negative draft can pull the flame up

into the boiler crown sheet and overheat the iron. This

can result in cracked sections or shortened boiler life.

CAUTION

Check the system for leaks and make sure the

automatic fill valve (if used) and the expansion tank