Page 1

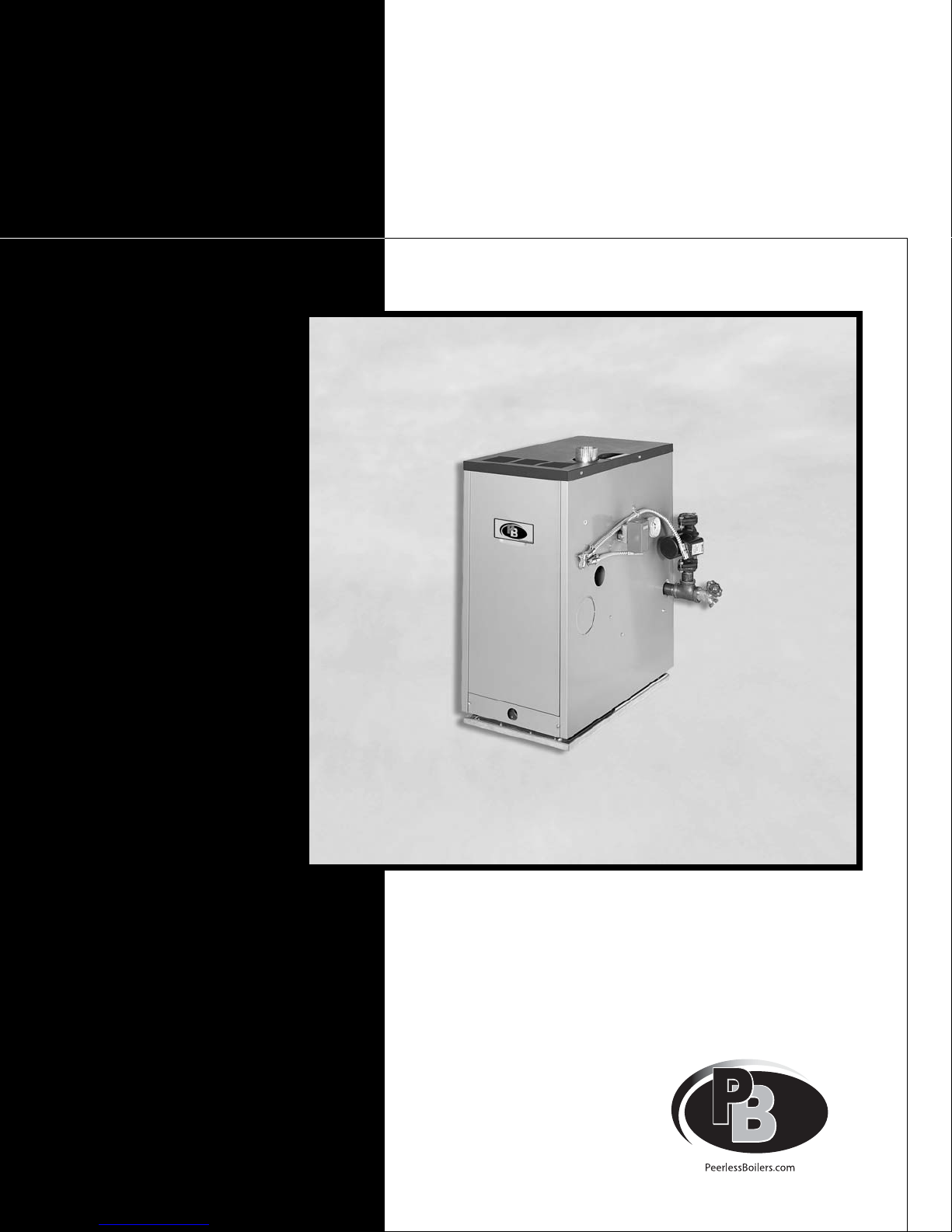

PSC

Boilers

Series

Gas

Installation,

Operation &

Maintenance

Manual

Page 2

i

USING THIS MANUAL 1

A. INSTALLATION SEQUENCE . . . . . . . . . . . . .1

B. SPECIAL ATTENTION BOXES . . . . . . . . . . . .1

1. PREINSTALLATION 2

A. ACCESSIBILITY CLEARANCES . . . . . . . . . . .2

B. CLEARANCE FROM COMBUSTIBLE

CONSTRUCTION . . . . . . . . . . . . . . . . . . . . . .2

C. INSTALLATION SURVEY . . . . . . . . . . . . . . . .2

D. PLANNING THE LAYOUT . . . . . . . . . . . . . . . .2

2. BOILER SET-UP 3

3. WATER PIPING AND CONTROLS 4

A. BOILER SUPPLY AND RETURN . . . . . . . . . . .4

B. SAFETY RELIEF VALVE . . . . . . . . . . . . . . . . .5

C. PIPING FOR ZONED SYSTEMS . . . . . . . . . . .6

D. EXPANSION TANK . . . . . . . . . . . . . . . . . . . . .7

E. INDIRECT-FIRED WATER HEATER . . . . . . . .7

F. FREEZE PROTECTION . . . . . . . . . . . . . . . . . .7

4. VENTING, VENTILATION AND

AIR INLET 8

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

B. PSC WALL THIMBLE . . . . . . . . . . . . . . . . . . .8

C. ROOF TERMINATIONS . . . . . . . . . . . . . . . .10

D. VENT PIPE INSTALLATION . . . . . . . . . . . . .11

E. AIR INLET PIPE INSTALLATION . . . . . . . . .11

F. AIR FOR VENTILATION . . . . . . . . . . . . . . . .12

G. BOILER REMOVAL FROM COMMON

VENTING SYSTEM . . . . . . . . . . . . . . . . . . .12

5. GAS PIPING 13

6. ELECTRICAL 15

A. WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

B. ZONED SYSTEM WIRING . . . . . . . . . . . . . .15

C. CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . .15

D. SEQUENCE OF OPERATION . . . . . . . . . . . .16

7. START-UP PROCEDURES 19

A. COMPLETING THE INSTALLATION . . . . . . .19

B. CONTROL DESCRIPTIONS . . . . . . . . . . . . .22

C. ADJUSTMENT OF GAS PRESSURE

REGULATOR . . . . . . . . . . . . . . . . . . . . . . . . .22

D. CHECKING BURNER INPUT . . . . . . . . . . . . .22

E. CHECK-OUT PROCEDURE . . . . . . . . . . . . . .22

8. TROUBLESHOOTING 24

A. SHUT-DOWN CAUSED BY PILOT OUTAGE,

PRESSURE SWITCH OR FLAME ROLL-OUT

SAFETY SHUT-OFF SWITCH . . . . . . . . . . . .24

B. TROUBLESHOOTING GUIDES . . . . . . . . . .24

C. MEASURING SUCTION PRESSURE . . . . . .24

9. MAINTENANCE 28

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . .29

B. DAILY (WITH BOILER IN USE) . . . . . . . . . . .29

C. WEEKLY (WITH BOILER IN USE) . . . . . . . . .29

D. MONTHLY (WITH BOILER IN USE) . . . . . . .29

E. ANNUALLY (BEFORE START OF HEATING

SEASON) . . . . . . . . . . . . . . . . . . . . . . . . . . .30

10. BOILER DIMENSIONS & RATINGS 32

11. REPAIR PARTS 33

TABLE OF CONTENTS

Page 3

1

USING THIS MANUAL

A. INSTALLATION SEQUENCE

Follow the installation instructions provided in this

manual in the order shown. The order of these

instructions has been set in order to provide the installer

with a logical sequence of steps that will minimize

potential interferences and maximize safety during

boiler installation.

B. SPECIAL ATTENTION BOXES

Throughout this manual you will see special attention

boxes intended to supplement the instructions and make

special notice of potential hazards. These categories

mean, in the judgment of PB Heat, LLC:

Indicates special attention is needed, but not directly

related to potential personal injury or property

damage.

NOTICE

Indicates a condition or hazard which will or can

cause minor personal injury or property damage.

CAUTION

DANGER

Indicates a condition or hazard which will cause

severe personal injury, death or major property

damage.

USING THIS MANUAL

Indicates a condition or hazard which may cause

severe personal injury, death or major property

damage.

WARNING

Page 4

2

PREINSTALLATION

A. ACCESSIBILITY CLEARANCES

Install boiler not less than 24″ (610 mm) between the left

side, top, and front of the boiler and adjacent wall or

other appliance, when access is required for servicing.

B. CLEARANCE FROM COMBUSTIBLE

CONSTRUCTION

The design of this boiler is certified for closet installation

with the following clearances:

1. 6″ (152 mm) between right side, front and

combustible construction.

2. 12″ (305 mm) between top of jacket and

combustible construction.

3. 1″ (25 mm) between left side, rear and combustible

construction.

4. 2″ (51 mm) between vent pipe and combustible

construction.

5. Zero clearance between wall thimble and

combustible construction.

6. This boiler is design certified for use on combustible

flooring.

C. INSTALLATION SURVEY

For new and existing installations, a Water Installation

Survey is available from PB Heat, LLC. The survey will

provide information on how a hot water boiler works

with your specific system and will provide an overview

of hot water system operation in general.

You can also use this survey to locate system problems

which will have to be corrected. To obtain copies of the

Water Installation Survey, contact your PB Heat

representative.

D. PLANNING THE LAYOUT

Prepare sketches and notes of the layout to minimize the

possibility of interferences with new or existing

equipment, piping, venting and wiring. Review

limitations on vent pipe, vent terminal, and air inlet pipe

locations and ventilation air requirements in Section 4.

1. PREINSTALLATION

Read carefully, study these instructions before beginning work.

This boiler must be installed by a qualified contractor.

The boiler warranty can be voided if the boiler is not installed, maintained and serviced correctly.

The equipment must be installed in accordance with those installation requirements of the authority having

jurisdiction or, in the absence of such requirements,to the current edition of the

National Fuel Gas Code,

ANSI

Z223.1/NFPA 54 and/or CAN/CSA B49.1,

Natural Gas and Propane Installation Code

.

Where required by the authority having jurisdiction, the installation must conform to

American Society of Mechanical

Engineers Safety Code for Controls and Safety Devices for Automatically Fired Boilers,

ANSI/ASME CSD-1.

NOTICE

Do not install this boiler on carpeting. Boiler

installation on carpeting is a fire hazard. Install this

boiler on non-combustible flooring or use a

combustible floor pan to install this boiler on other

non-carpeted flooring.

DANGER

Liquefied Petroleum (LP) is heavier than air and may

collect or “pool” in a low area in the event of a leak

from defective equipment.This gas may then ignite,

resulting in a fire or explosion.

WARNING

Page 5

3

BOILER SET-UP

1. Provide a sound, level foundation. Locate boiler as

near to the outside wall as possible and centralized

with respect to the heating system.

2. Locate boiler in front of installation position before

removing crate.

4. Separate the wood shipping pallet from the boiler

base by removing two (2) hold-down bolts at each

end of the boiler base.

5. Move boiler into final position.

2. BOILER SET-UP

Page 6

4

WATER PIPING AND CONTROLS

A. BOILER SUPPLY AND RETURN

1. Size the supply and return to suit the system. A

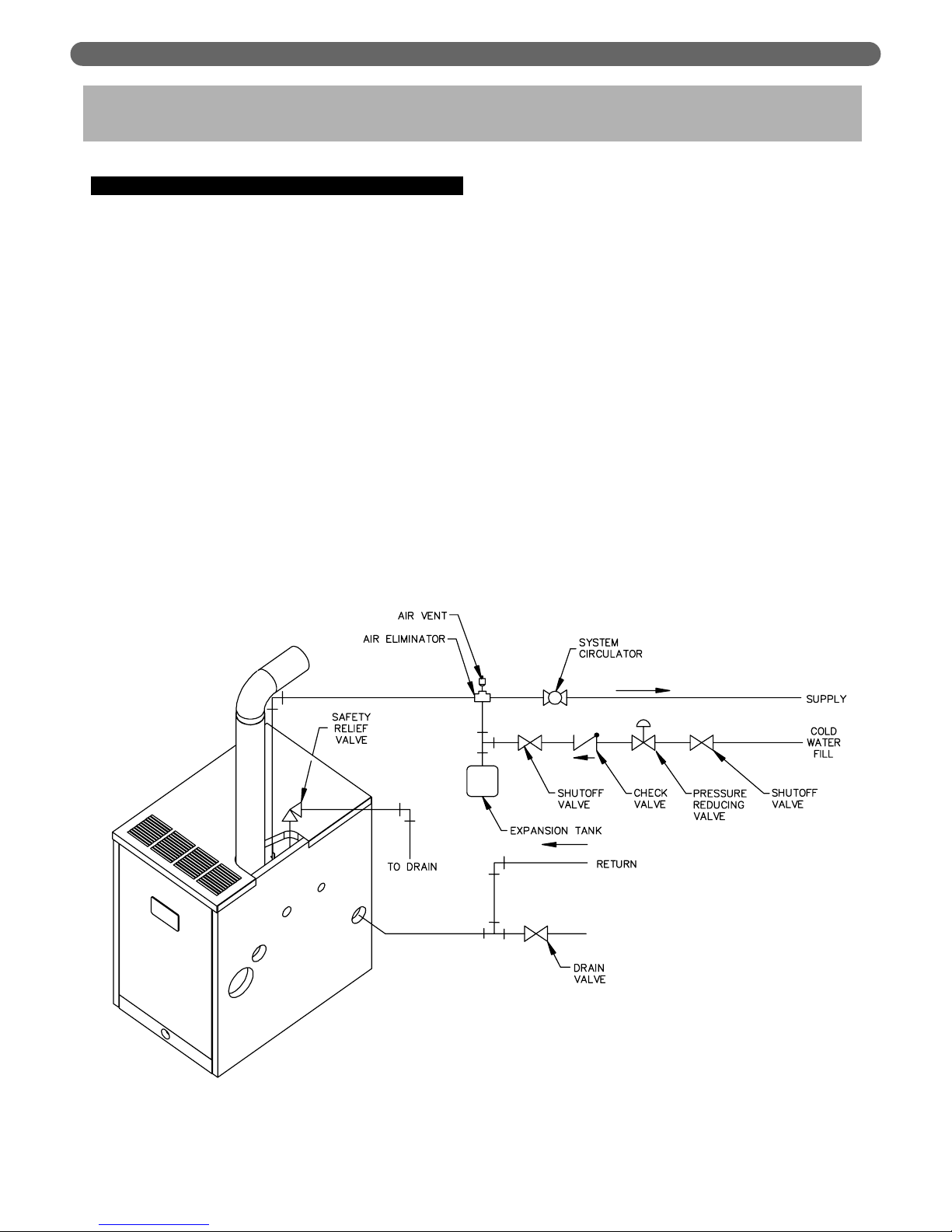

typical piping arrangement is shown in Figure 3.1.

Refer also to the Hydronics Institute Residential

Hydronic Heating Installation Design Guide and the

PB Heat Water Survey for additional guidance

during water piping installation.

2. Return Piping:

Pipe the outlet connection of the circulator to a tee,

provided with a drain valve, at the 1-1/4″ NPT return

tapping near the bottom of the right section. Pipe the

return to the inlet connection of the circulator.

3. Supply Piping:

a. Pipe the supply to the 1-1/2″ NPT supply tapping

at the top of the boiler.

b. Provide clearance to venting system

(see Section 4).

4. When system return water temperature will be below

130°F (54°C), pipe the boiler with a bypass

arrangement to blend the system return and hot

supply to obtain at least 130°F (54°C)entering the

boiler. For more information on bypass piping,

consult the PB Heat Water Survey.

5. If desired, install the circulator in the alternate

location shown in Figure 3.1. Consult the PB Heat

Water Survey for more information on circulator

location.

3. WATER PIPING AND CONTROLS

Figure 3.1: Supply and Return Piping

Page 7

5

WATER PIPING AND CONTROLS

6. Install this boiler so that the gas ignition system

components are protected from water (dripping,

spraying, etc.) during appliance operation and

service (circulator replacement, condensate trap,

control replacements, etc.).

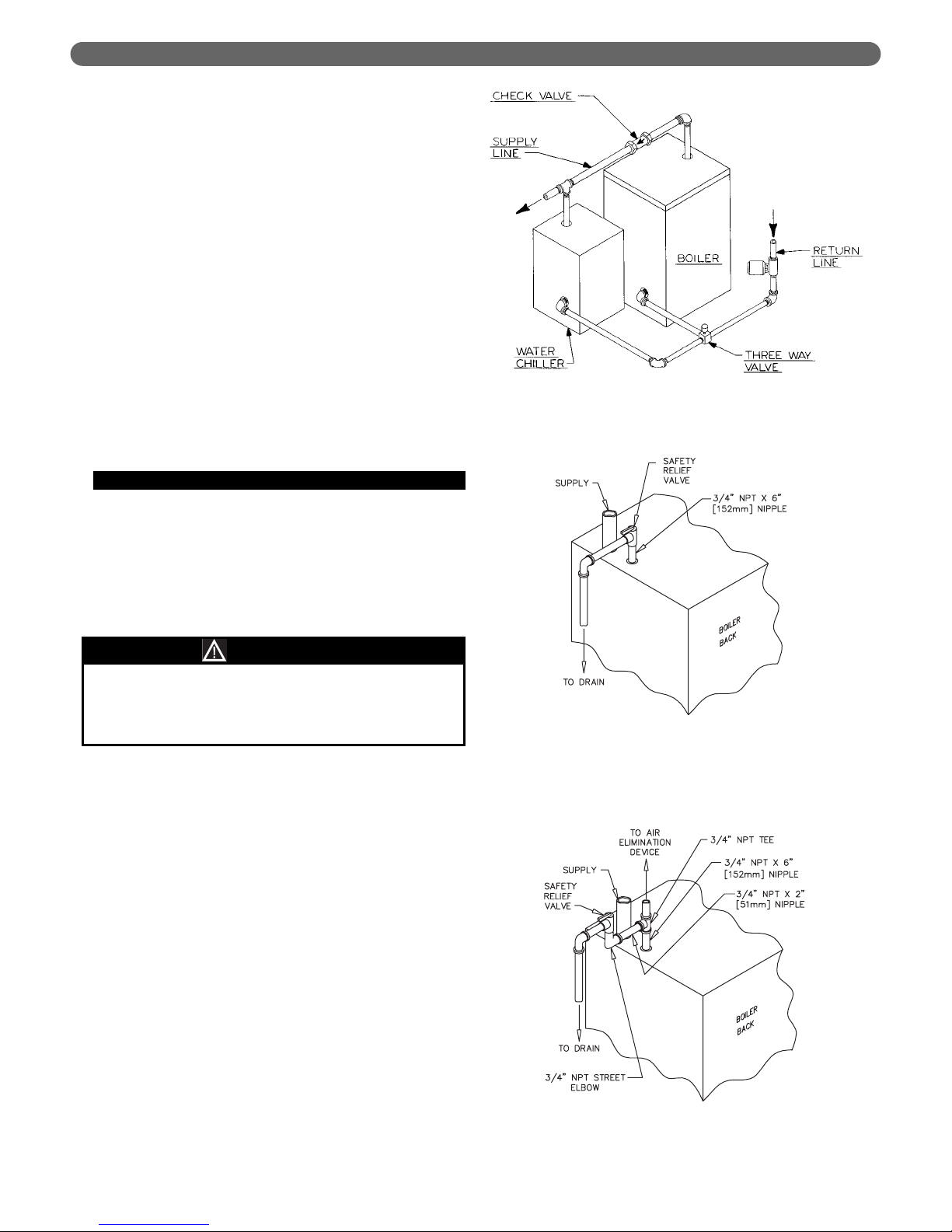

7. If this boiler and distribution system is used in

conjunction with a refrigeration system, pipe the

chilled medium in parallel with the boiler and install

the proper valve to prevent the chilled medium from

entering the boiler. A drawing illustrating this hookup is provided in Figure 3.2.

8. When the boiler is connected to heating coils located

in air handling units where they may be exposed to

refrigerated air circulation, install flow control valves

or other automatic means to prevent gravity

circulation of the boiler water during the cooling

cycle.

9. If this boiler is installed above radiation level,

provide a low water cutoff device, either as a part of

the boiler or at the time of boiler installation.

B. SAFETY RELIEF VALVE

1. Locate safety relief valve and fittings in bag

assembly.

2. If air elimination is not required at the safety relief

valve tapping, install valve and piping as shown in

Figure 3.3.

3. For air elimination at the safety relief valve tapping,

install valve and piping as shown in Figure 3.4.

Pipe the discharge of safety relief valve to prevent

injury in the event of pressure relief. Pipe the

discharge to a drain. Provide piping that is the same

size as the safety relief valve outlet.

CAUTION

Figure 3.4: Safety Relief Valve Hook-Up with

Air Elimination

Figure 3.3: Safety Relief Valve Hook-Up

Installation with Air Elimination in

System Piping

Figure 3.2: Parallel Hook-up with Water Chiller

Page 8

6

WATER PIPING AND CONTROLS

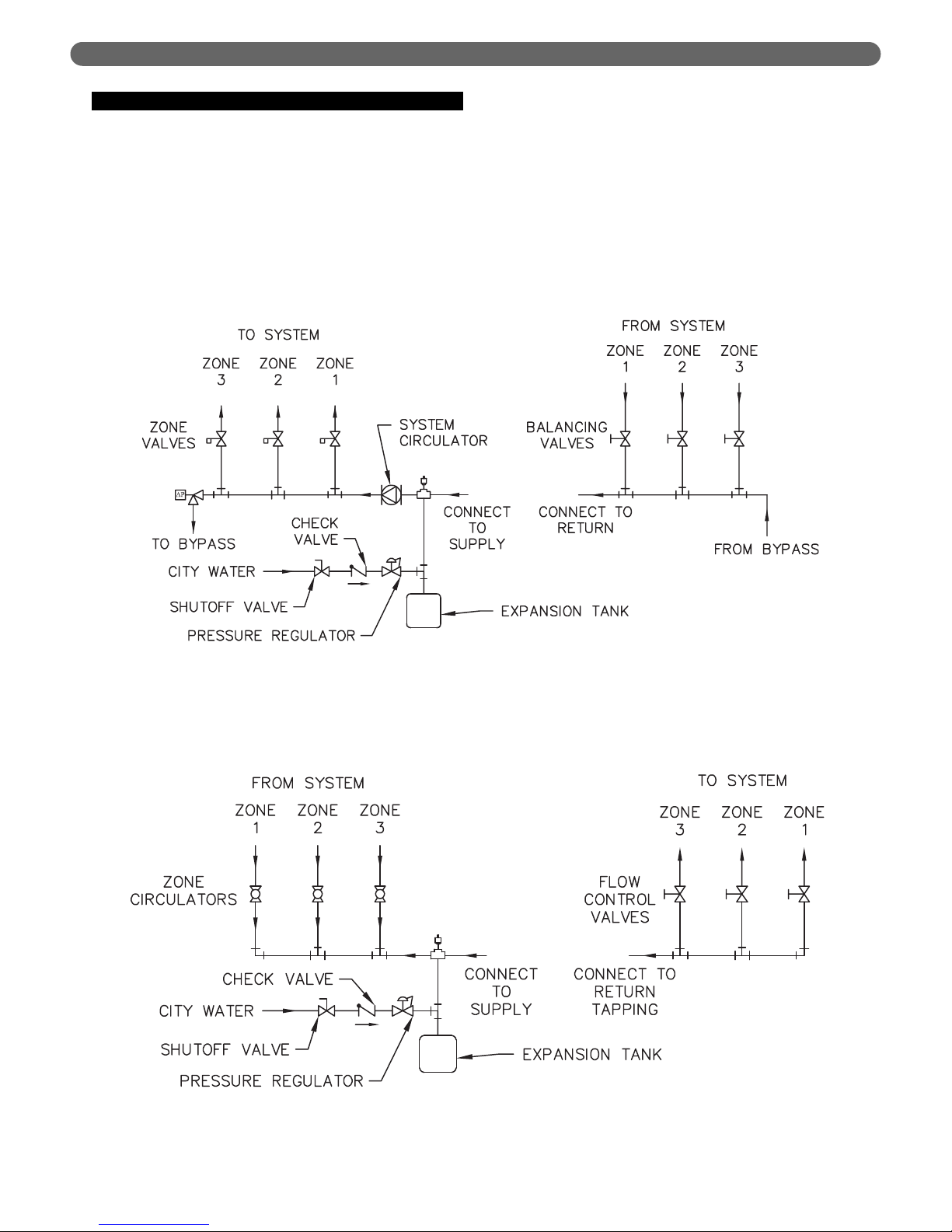

C. PIPING FOR ZONED SYSTEMS

1. See Figures 3.5 and 3.6 for basic zoned system

layouts.

2. Run each zone pipe down then up to zone to

prevent air accumulation in piping.

3. If required, provide means to isolate and drain each

zone separately.

Figure 3.5: Zone Piping with Zone Valves

Figure 3.6: Zone Piping with Circulators

Page 9

7

WATER PIPING AND CONTROLS

D. EXPANSION TANK

1. Consult the tank manufacturer’s instructions for

specific information relating to tank installation. Size

the expansion tank for the required system volume

and capacity. See Table 10.2 in Section 10 for boiler

water capacity.

2. Expansion tanks are available with built-in fill valves

and check valves for reducing supply water pressure

and maintaining minimum system pressure. Check

the design features of the tank and provide valves as

necessary.

Refer back to Figure 3.1 for typical expansion tank piping.

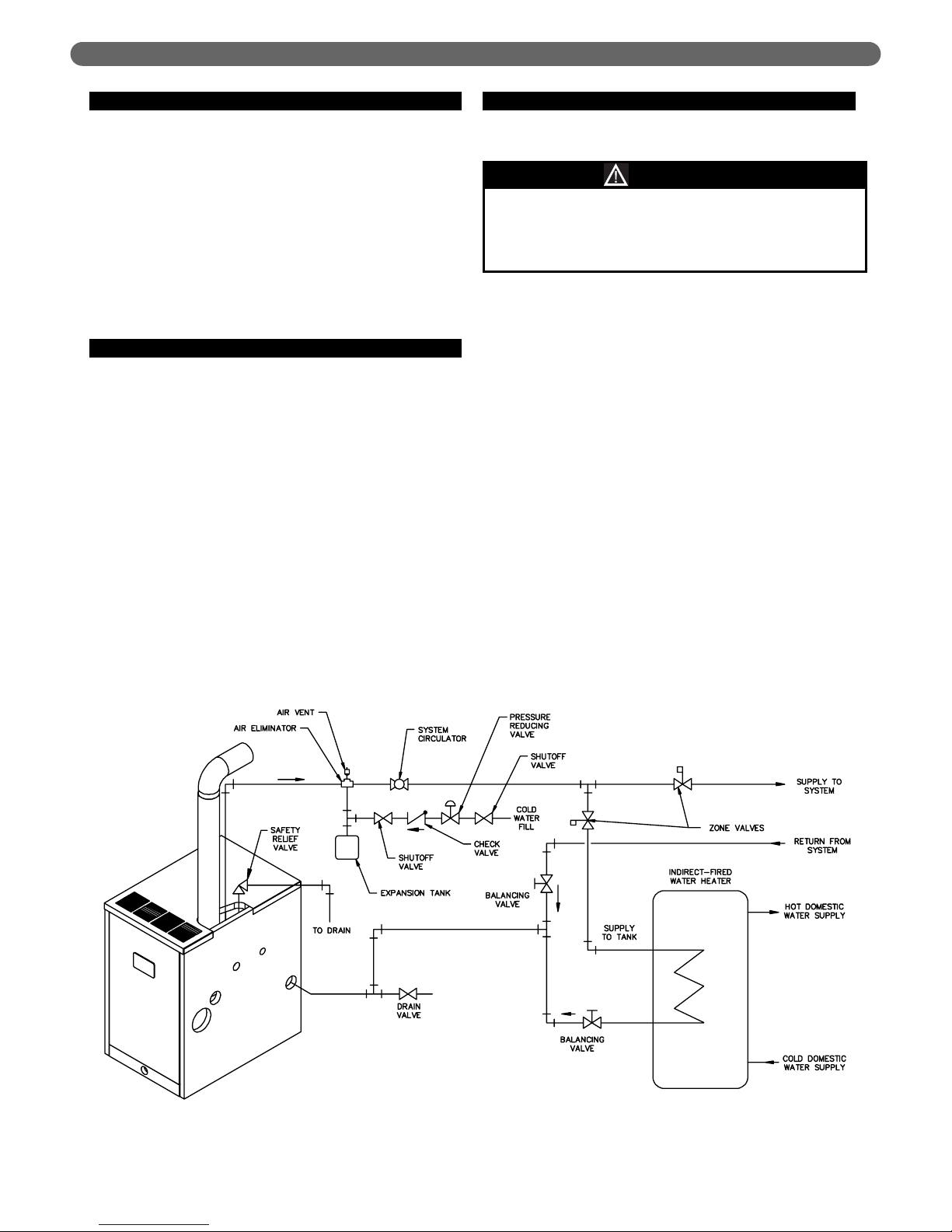

E. INDIRECT-FIRED WATER HEATER

If the boiler is to be used in conjunction with an indirectfired water heater, refer to Figure 3.7 for typical piping.

Follow the instructions provided by the water heater

manufacturer. Pipe the water heater as a separate zone.

F. FREEZE PROTECTION

For new or existing systems that must be freezeprotected:

1. Glycol in hydronic applications is specially

formulated for this purpose. It includes inhibitors

which prevent the glycol from attacking metallic

system components. Make certain that the system

fluid is checked for the correct glycol concentration

and inhibitor level.

2. The glycol solution should be tested at least once a

year and as recommended by the antifreeze

manufacturer.

3. Glycol solutions expand more than water. For

example, a 50% by volume solution expands 4.8%

in volume for a temperature increase from 32°F (0°C)

to 180°F (82°C) , while water expands 3% with the

same temperature rise. Allowance must be made for

this expansion in system design.

4. For more information, consult the PB Heat Water

Installation Survey and the antifreeze manufacturer.

Figure 3.7: Typical Piping with Indirect-Fired Water Heater

Use only inhibited propylene glycol solutions of up to

50% by volume with water. Ethylene glycol is toxic

and can attack gaskets and seals used in hydronic

systems.

WARNING

Page 10

VENTING, VENTILATION AND AIR INLET

A. GENERAL

Install vent system in accordance with Venting of

Equipment part of the National Fuel Gas Code, ANSI

z223.1/NFPA 54 or sections 7.2, 7.3 or 7.4 of CAN/CSA

B149.1, Natural Gas and Propane Installation Code.

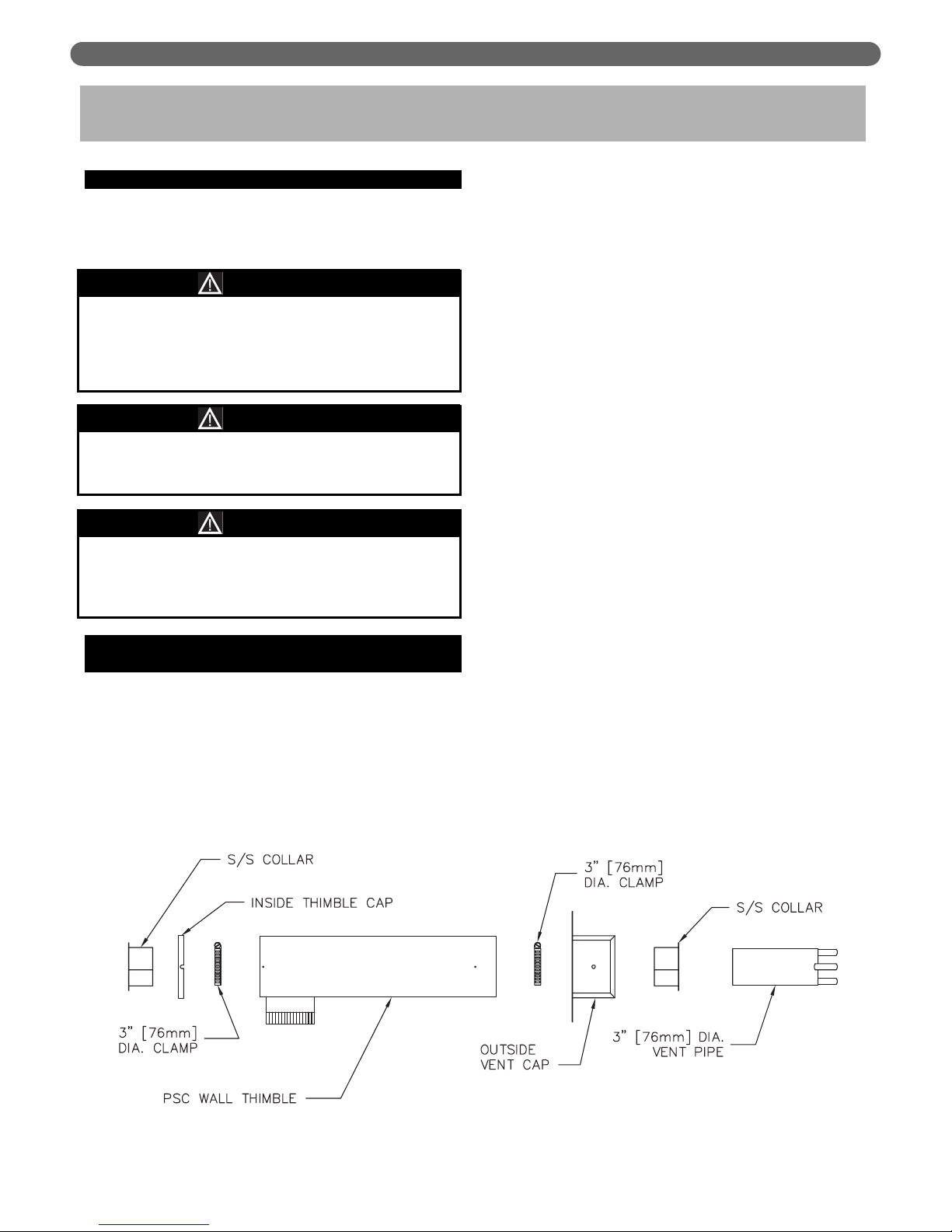

B. PSC WALL THIMBLE (SIDEWALL

VENTING ONLY)

1. Determine vent cap (terminal) location.

a. Must be within the maximum and minimum vent

and air intake lengths shown in Tables 4.1 and 4.2.

b. Maximum wall thickness for the 19-1/2″ (495 mm)

long PSC Wall Thimble (standard) is 11-1/2″ (292

mm). Maximum wall thickness for the optional

28″ (711 mm) long thimble is 20″

(508 mm).

c. Provide 2″ (51 mm) clearance between vent pipe

and combustible construction. No clearance is

required between Thimble and combustible

construction.

d. Provide 3 feet (1 meter) clearance above any

forced air inlet within 10 feet (3 meters).

e. Provide 1 foot (0.3 meters) clearance below, 1 foot

(0.3 meters) beside, or 1 foot (0.3 meters) above

any door, window, or gravity air inlet into any

building.

f. Provide 1 foot (0.3 meters) clearance between

bottom of vent terminal and ground level and

normal snow lines.

g. Provide 4 feet (1.2 meters) horizontal clearance

from from electric meters, gas meters, regulators

and relief equipment. In Canada, this dimension

must be 6 feet (2 meters).

h. Do not locate vent terminal over public walkways

where condensate could create a nuisance or

hazard.

i. When adjacent to a public walkway, locate vent

terminal at least 7 feet (2.1 meters) above grade.

j. Do not locate directly under roof overhangs to

prevent icicles from forming.

2. Cut a 5-1/8″ (130 mm) square hole in sidewall to

allow Peerless Wall Thimble to go through.

3. Insert Thimble from inside wall with 4″ (102 mm)

diameter air inlet connection facing down. Extend

Thimble 3-1/2″ (89 mm) past outside wall surface.

The cut-out opening of thimble is pointed down.

4. Use a minimum 2-1/2 foot (762 mm) piece of 3″

(76 mm) diameter AL29-4C stainless steel vent pipe

for insertion through Wall Thimble. See Vent Pipe

section below for vent pipe requirements.

4. VENTING

Figure 4.1: PSC Wall Thimble

This vent system will operate with a positive

pressure in the vent pipe. Do not connect vent

connectors serving appliances vented by natural

draft into any portion of mechanical draft systems

operating under positive pressure.

Flue gases will condense as they exit the vent

termination.This condensate can freeze on exterior

building surfaces which may cause discoloration of

these surfaces.

NOTICE

WARNING

WARNING

All joints of positive pressure vent systems must be

sealed completely to prevent leakage of flue products

into the living space.

8

Page 11

VENTING, VENTILATION AND AIR INLET

5. Slide Stainless Steel Collar over vent pipe and slide

3″ (76 mm) diameter hose clamp and collar to vent

pipe.

6. Insert pipe with collar through Outside Vent Cap and

slide 3″ (76 mm) diameter hose clamp and collar to

vent pipe.

7. Leave at least 2″ (51 mm) of vent pipe protruding

beyond face of Vent Cap and secure hose clamp and

collar to vent pipe.

8. Place Outside Vent Cap over Wall Thimble with air

openings in Vent Cap facing down. Secure Cap to

Thimble with #10 sheet metal screws.

9. Place 3″ (76 mm) diameter hose clamp over pipe

protruding through inside of Wall Thimble.

10. Place Inside Thimble Cap and Collar onto Wall

Thimble. Access hose clamp through 4″ (102 mm)

diameter collar on bottom of Thimble and secure hose

clamp over collar and vent pipe as per step 7 above.

11. Secure Inside Thimble cap to Wall Thimble with #10

screws. Seal Thimble Cap perimeter with silicone.

12. Seal all openings between Wall and Thimble and

around the 3″ (76 mm) diameter stainless steel vent

pipe that protrudes through inside and outside of

Wall Thimble.

13. Add any bracing that may be needed to support Wall

Thimble on inside of wall structure.

14. Secure Outside Vent Cap to exterior wall with four

#10 sheet metal screws provided.

15. Attach Z-Flex #2SVSTPF03 terminal to protruding

vent pipe. Refer to Figure 4.2. To attach to HEATFAB pipe, insert into pipe end and fold over tabs to

secure. Otherwise, silicone terminal to vent pipe.

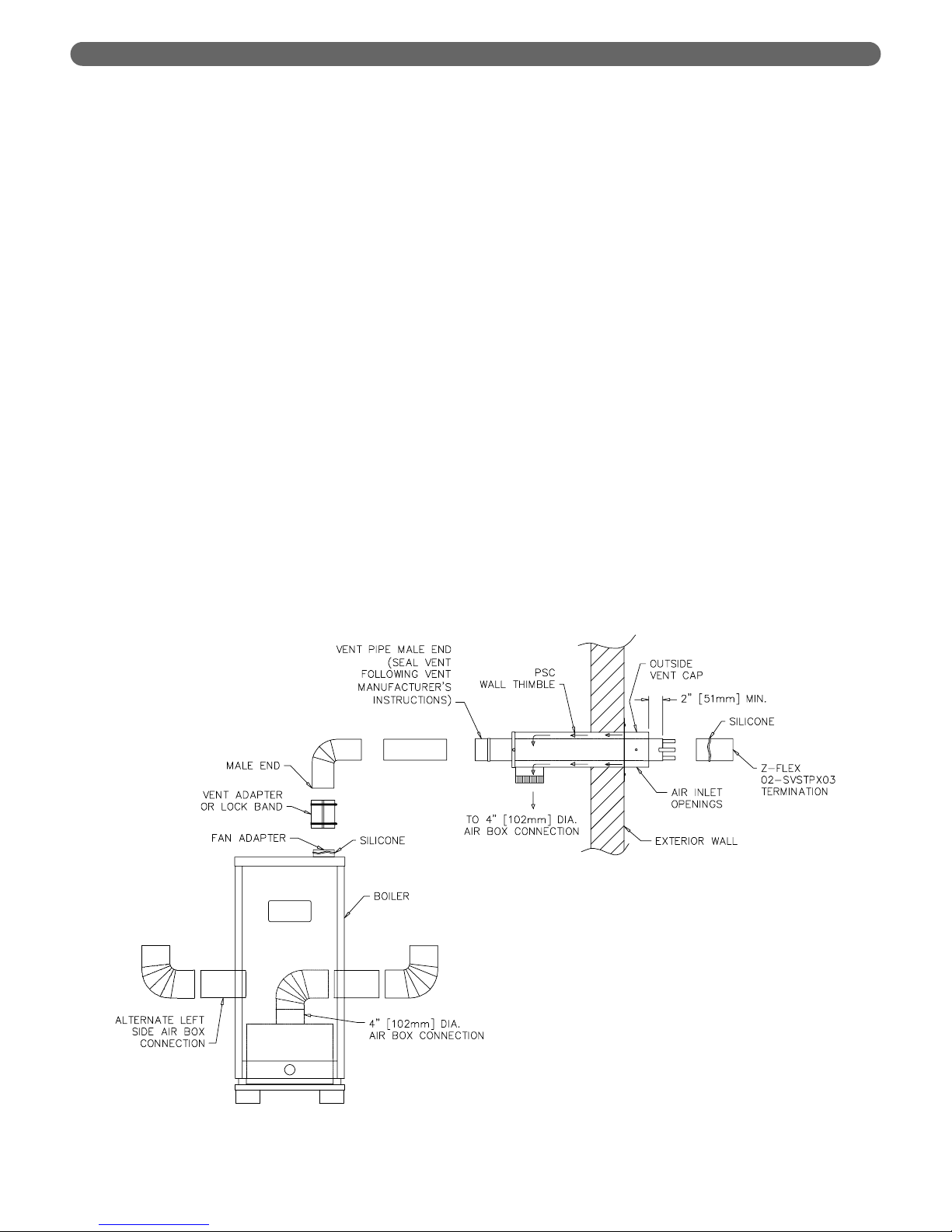

Figure 4.2: Side Wall Venting System

9

Page 12

10

VENTING, VENTILATION AND AIR INLET

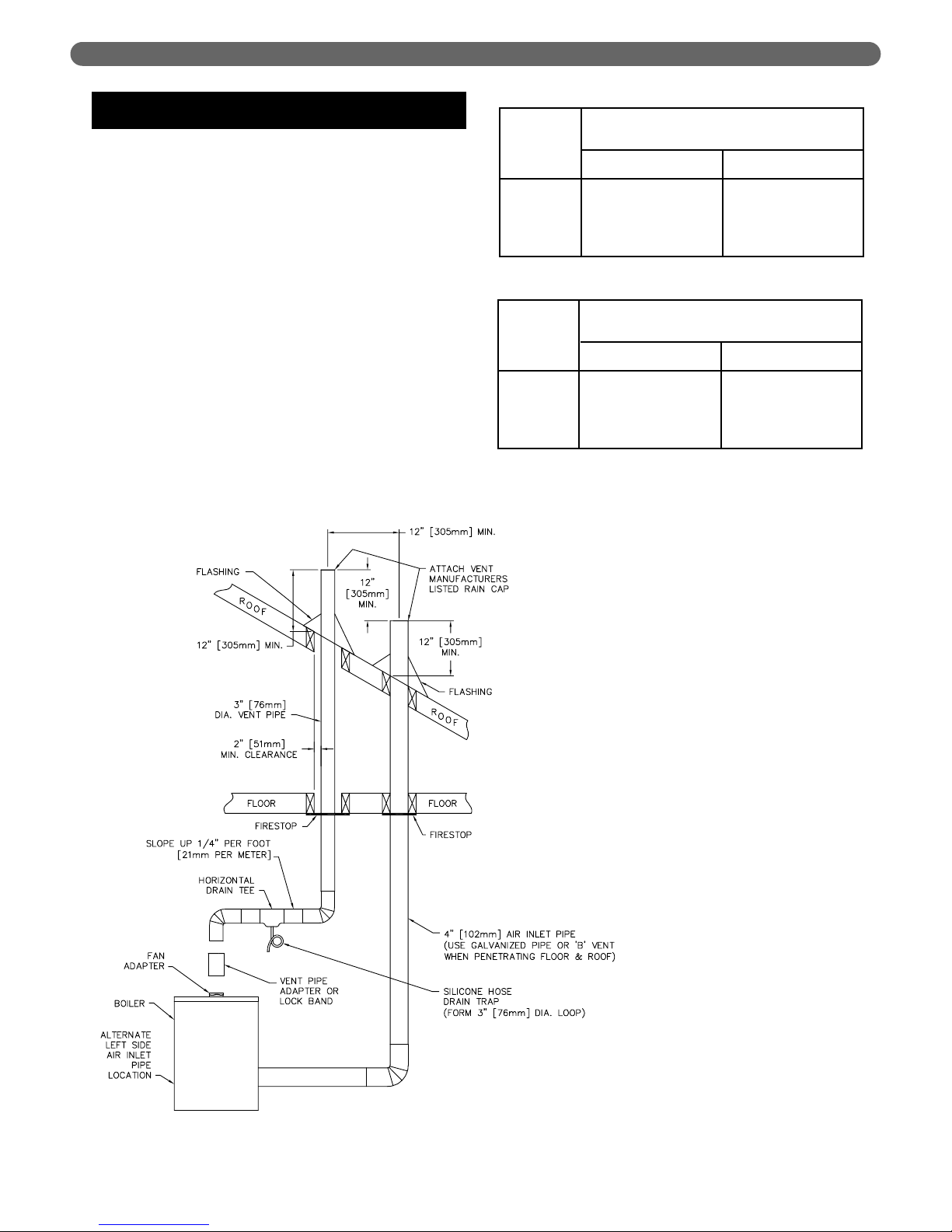

C. ROOF TERMINATIONS (VERTICAL

VENTING)

1. Vent pipe and air inlet terminations must be within

the maximum and minimum vent and air intake

lengths shown in Tables 4.1 and 4.2.

2. Vent pipe and air inlet pipe must terminate 12"

(305 mm) above expected snow lines. Vent pipe

must be a minimum 12" (305 mm) above and 12"

(305 mm) horizontally from air inlet pipe. See Figure

4.3.

3. Attach a vent manufacturer's listed rain cap to both

the vent pipe and air inlet pipe.

4. Provide 2" (51 mm) clearance between vent pipe

and combustible construction. No clearance is

required between air inlet pipe and combustible

construction.

5. See vertical venting section in vent manufacturer's

instructions for recommendations for penetration

through roof.

52 feet (15.5 m)

52 feet (15.5 m)

45 feet (13.5 m)

45 feet (13.5 m)

PSC-03

PSC-04

PSC-05

PSC-06

Boiler Model

8 feet (2.5 m)

8 feet (2.5 m)

8 feet (2.5 m)

8 feet (2.5 m)

Table 4.1:

*Equivalent Length of 3″ (76 mm) Diameter

Stainless Steel Vent Pipe

Minimum Vent Length

Maximum Vent Length

70 feet (21.0 m)

70 feet (21.0 m)

63 feet (19.0 m)

63 feet (19.0 m)

PSC-03

PSC-04

PSC-05

PSC-06

Boiler Model

12 feet (4.0 m)

12 feet (4.0 m)

12 feet (4.0 m)

12 feet (4.0 m)

Table 4.2:

*Equivalent Length of 4″ (102 mm) Diameter

Aluminum/Galvanized Air Inlet Pipe

Minimum Length

Maximum Length

*Each 90° elbow equals 5 feet (1.5 meters) of equivalent

length.

Figure 4.3: Vertical Venting System

Page 13

Figure 4.4: Vent Connection to Boiler

D . VENT PIPE INSTALLATION

1. For minimum and maximum vent pipe lengths see

Table 4.1.

2. Use only 3″ (76 mm) diameter Heat-Fab Saf-T Vent,

Z-Flex Z-Vent, ProTech FasNSeal, or Flex-L Star-34

Type AL29-4C stainless steel vent pipe and fittings for

venting of flue gases from the boiler.

3. Connect vent pipe to boiler by spreading a 1/4″

(6 mm) bead of high-temp GE-106 silicone or

Silicones Unlimited S45005 Red around the fan

adapter. Attach proper vent adapter to fan adapter

(not applicable, Z-Flex). Z-Flex vent pipe/fitting

connects directly to fan adapter, secure to fan adapter

using Z-Flex lock band. See Figure 4.4.

4. Attach remaining pipe and fittings per each

manufacturer’s vent instructions. Use only the silicone

recommended by vent pipe manufacturers. Maintain

proper clearance to combustible construction – see

Section 1, Preinstallation.

5. a. Side Wall Venting Only – Horizontal lengths of

the vent pipe shall slope down

not less than 1/4″

per lineal foot (21 mm per meter) from the boiler

to the vent terminal. If vent pipe does slope back

toward boiler, a horizontal drain is required as

described in 5B and Figure 4.3.

b. Vertical Venting Only – A horizontal drain tee is

required. Slope horizontal lengths upward

not less

than 1/4" per lineal foot (21 mm per meter) from

the boiler to the vent terminal. Install drain tee as

shown in Figure 4.3. Use silicone hose and form a

3" (76 mm) diameter loop trap with a water seal.

Pipe to drain per local code.

6. Support horizontal lengths of the vent system to

prevent sagging by use of metal strapping or

equivalent means. Locate supports at not more than

four (4) foot intervals.

7. Vertical Venting Only – If there is no solid anchor

point in the system below the roof for supporting

vertical sections of the vent pipe (i.e. Firestop

Support, etc.), a special vent support system will be

required. See vent manufacturer's instructions for

additional information.

E. AIR INLET PIPE INSTALLATION

1. For maximum air inlet pipe lengths see Table 4.2.

2. Use only 4″ (102 mm) diameter galvanized pipe or 4″

(102 mm) diameter flexible aluminum vent for

supplying combustion air to boiler inlet air box.

3. Boiler connection can be from either right or left side

of boiler jacket. Determine which jacket side air inlet

piping is to be routed and remove the 4-1/2″ (114 mm)

jacket knock-out.

4. Attach a 4″ (102 mm) diameter 90 degree elbow to

top of air box and connect air inlet piping.

5. Support air inlet piping using the same methods and

requirements as shown in the previous section for vent

pipe support.

6. Seal all connections using silicone.

7. To prevent condensation from forming on exposed

portions of Wall Thimble and 4″ (102 mm) diameter

air inlet piping, wrap exposed areas with insulation.

11

VENTING, VENTILATION AND AIR INLET

Page 14

12

VENTING, VENTILATION AND AIR INLET

F. AIR FOR VENTILATION

1. Provide air openings for adequate ventilation to

prevent ambient boiler room temperature from

exceeding 120°F (49°C) during boiler operation. This

is to maintain all the boiler controls below maximum

service temperatures. Openings should be fixed in

the open position during operation.

G. BOILER REMOVAL FROM VENTING

SYSTEM

At the time of removal of an existing boiler, follow these

steps with each appliance remaining connected to the

common venting system placed in operation, while the

other appliances remaining connected to the common

venting system are not in operation:

a. Seal any unused openings in the common venting

system.

b. Visually inspect the venting system for proper size

and horizontal pitch and determine there is no

blockage or restriction, leakage, corrosion and other

deficiencies which could cause an unsafe condition.

c. Insofar as is practical, close all building doors and

windows and all doors between the space in which

the appliances remaining connected to the common

venting system are located and other spaces of the

building. Turn on any clothes dryers and any

appliance not connected to common venting system.

Turn on any exhaust fans, such as range hoods and

bathroom exhausts, so they will operate at maximum

speed. Do not operate a summer exhaust fan. Close

fireplace dampers.

d. Place in operation the appliance being inspected.

Follow the lighting instructions. Adjust thermostat so

appliance will operate continuously.

e. Test for spillage at the draft hood relief opening after

5 minutes of main burner operation. Use the flame

of a match or candle, or smoke from a cigarette,

cigar, or pipe.

f. After it has been determined that each appliance

remaining connected to the common venting system

properly vents when tested as outlined above, return

doors, windows, exhaust fans, fireplace dampers and

any other gas-burning appliance to their previous

conditions of use.

g. Any improper operation of the common venting

system should be corrected so that the installation

conforms with the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 and/or CAN/CSA B149.1, Natural

Gas and Propane Installation Code. When resizing

any portion of the common venting system, the

common venting system should be resized to

approach minimum size as determined using the

appropriate tables in the National Fuel Gas Code,

ANSI Z223.1/NFPA 54 and/or CAN/CSA B149.1,

Natural Gas and Propane Installation Code.

Page 15

1. Size and install the gas supply piping properly in

order to provide a supply of gas sufficient to meet

the maximum demand without undue loss of

pressure between the meter and the boiler.

2. Determine the volume of gas to be provided to the

boiler in cubic feet per hour. To obtain this value,

divide the Btu per hour rating (on the boiler rating

plate) by the heating value of the gas in Btu per

cubic feet. Obtain the heating value of the gas from

the gas supplier. As an alternative, use Table 5.1 on

the next page to obtain the volume of gas to be

provided to the boiler.

3. Use the value obtained above as the basis for piping

sizing. Size the gas piping in accordance with Table

5.2. Consult the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 and/or CAN/CSA B149.1, Natural

Gas and Propane Installation Code.

4. Locate the drop pipe adjacent to, but not in front of

the boiler.

5. Install a sediment trap. See Figure 5.1. Locate a tee

in the drop pipe at same elevation as the gas inlet

connection to the boiler. Extend the drop pipe to a

pipe cap.

6. Install a ground joint union ahead of the gas control

assembly to permit servicing of the control. Some

local codes require an additional service valve when

using the combination gas controls. If your code

requires such a valve, a suggested location is shown

in Figure 5.1.

7. Check piping for leaks prior to placing the boiler in

operation.

Use an approved gas detector, a non-corrosive leak

detection fluid or other leak detection method. If

leaks are found, turn off all gas flow and repair as

necessary.

8. Disconnect the boiler and its individual shut-off valve

from the gas supply piping system during any

pressure testing of that system at test pressure in

excess of 1/2 psig (3.5 kPa).

Isolate the boiler from the gas supply piping system

by closing its individual service valve during any

pressure testing of the gas supply piping system at

test pressure equal to or less than 1/2 psig (3.5 kPa).

9. Minimum permissible supply pressure for purposes of

input adjustment (Inches Water Column):

Natural Gas 5.0″ (1.2 kPa)

LP Gas 11.0″ (2.7 kPa)

Maximum permissible supply pressure to the boiler

(Inches Water Column):

Natural Gas 13.5″ (3.4 kPa)

LP Gas 13.5″ (3.4 kPa)

13

GAS PIPING

5. GAS PIPING

Figure 5.1: Gas Connection to Boiler

When checking for leaks, do not use matches,

candles, open flames or other methods that provide a

source of ignition.This can ignite a gas leak,

resulting in fire or explosion.

WARNING

Use a pipe joint sealing compound that is resistant to

the action of liquefied petroleum gas. A non-resistant

compound may lose sealing ability in the presence of

this gas, resulting in a gas leak and fire or explosion

potential.

WARNING

Do not subject the gas valve to more than 1/2 psi

(3.5 kPa) pressure. Doing so may damage the valve.

CAUTION

Page 16

14

GAS PIPING

Table 5.2: Pipe Capacity

Capacity of pipe of different diameters and lengths in cubic feet per hour (cubic meter per

hour) with pressure drop of 0.3 inches of water (75 Pa) and specific gravity of 0.60. No

allowance for an ordinary number of fittings is required.

Table 5.1: Natural Gas

Pipe

Length in

Feet (Meters)

³⁄₄

″″

Pipe

1

″″

Pipe

1¹⁄₄

″″

Pipe

1¹⁄₂

″″

Pipe

10 (3.0) 278 (7.9) 520 (14.7) 1050 (29.7) 1600 (45.3)

20 (6.1) 190 (5.4) 350 (9.9) 730 (20.7) 1100 (31.1)

30 (9.1) 152 (4.3) 285 (8.1) 590 (16.7) 890 (25.2)

40 (12.2) 130 (3.7) 245 (6.9) 500 (14.2) 760 (21.5)

50 (15.2) 115 (3.3) 215 (6.1) 440 (12.5) 670 (19.0)

60 (18.3) 105 (3.0) 195 (5.5) 400 (11.3) 610 (17.3)

Boiler

Model

Natural Gas Input LP Gas Input

Cu. Ft/hr Cu. Meter/hr Cu. Ft/hr Cu. Meter/hr

PSC-03 70 2.0 28 0.8

PSC-04 105 3.0 42 1.2

PSC-05 140 4.0 46 1.6

PSC-06 165 4.7 66 1.9

Specific Gravity 0.50 0.55 0.60 0.65 0.70 0.75

Correction Factor 1.10 1.04 1.00 0.96 0.93 0.90

Specific Gravity 0.80 0.85 0.90 1.00 1.10 1.20

Correction Factor 0.87 0.84 0.82 0.78 0.74 0.71

Specific Gravity 1.30 1.40 1.50 1.60 1.70 1.80

Correction Factor 0.68 0.66 0.63 0.61 0.59 0.58

Maximum Capacity Correction Factors for Specific Gravity

other than 0.60.

Page 17

A. WIRING

1. See Figure 6.1 for location of wiring and controls.

Use Figure 6.2 to connect the boiler to a power

supply and to connect components to the boiler.

2. Connect the boiler by a separate, permanently live

electrical supply line with a fused switch.

3. Adjust the thermostat heat anticipator to 0.2 Amp.

B. ZONED SYSTEM WIRING

See Figure 6.4 for typical wiring with zone valves. See

Figure 6.5 for typical wiring with zone circulators. When

wiring a zoned heating system, follow all applicable

codes, ordinances and regulations.

C. CONTROLS

1. For proper location of controls and accessories refer

to Figure 6.1.

2. See the attached control sheets for specific details

regarding the installation of the various controls.

3. This boiler is supplied with safety devices in addition

to the limit. For a description of these devices and

how they work to ensure the safe operation of the

boiler, see Section 7.

4. If the circulator is mounted in the supply piping,

provide longer wiring harness as required.

6. ELECTRICAL

This unit when installed must be electrically grounded in accordance with the requirements of the authority

having jurisdiction or, in the absence of such requirements, with the current edition of the

National Electrical

Code,

ANSI/NFPA 70 and/or the

Canadian Electrical Code

, Part 1, CSA C221.

NOTICE

Figure 6.1: Wiring, Controls and Safety Devices

Install all electrical wiring in accordance with the National Electrical Code and local requirements.

Do not power zone valves directly from the boiler

transformer. Doing so will greatly reduce the life of

the transformer. Use a separate transformer sized to

handle the total of all zone valve electrical loads.

NOTICE

15

ELECTRICAL

Page 18

16

ELECTRICAL

D. SEQUENCE OF OPERATION

1. Thermostat calls for heat, energizes R8285 Control

Relay (CR).

2. R8285 Control Relay (CR) energizes circulator.

3. Limit senses boiler water temperature. Prevents

boiler operation until water temperature falls

approximately 15

°

F (8°C) below the cut-out

temperature.

4. Limit energizes Fan and R4222 Isolation Relay (IR).

5. Negative pressure induced by fan switches Pressure

Switch, continuing power through closed R4222

contacts (IR-1) and flame roll-out switch.

6. Gas valve energizes.

a. Igniter on.

b. Pilot gas on, igniting pilot.

7. Pilot flame detected.

a. Igniter off.

b. Main gas on, igniting main burners.

Note: If pilot flame is not detected within 30 seconds,

the igniter is turned off for 30 seconds, and then turned

back on for another 30 seconds. If the pilot remains

undetected in this second ignition period, the igniter and

pilot are turned off for 5 minutes. The sequence then

resumes at Step 6a.

8. Call for heat ends.

a. Pilot and main gas off, extinguishing pilot and

main burners.

b. Fan and circulator off.

Figure 6.2: Wiring and Connection Diagram

Page 19

17

ELECTRICAL

Figure 6.3: Ignition System Operating Sequence

Page 20

18

ELECTRICAL

Figure 6.4: Zone Wiring with Zone Valves

Figure 6.5: Zone Wiring with Circulators

Page 21

A. COMPLETING THE INSTALLATION

1. Confirm that all water, gas and electricity are

turned off.

2. Inspect the boiler combustion chamber for foreign

objects and remove if present.

3. Check physical condition of burners and pilot. Make

certain that there are no unusual bends or

perforations in the burners or pilot. Replace

components if necessary.

4. Verify that water piping, venting, gas piping and

electrical wiring and components are installed

properly. Refer back to previous sections of these

instructions as well as equipment manufacturer’s

instructions as necessary.

5. Fill the boiler and system with water, making certain

to vent all air from all points in the system. To check

water level in the system, open and close each vent

in the system. Water should exit from each vent

when it is opened.

6. The pressure reducing valve on the fill line will

typically allow the system to be filled and pressurized

to 12 psi (83 kPa). Consult the valve and expansion

tank manufacturer for more specific information.

7. Check joints and fittings throughout the system for

leaks. If leaks are found, drain the system and repair

as required.

8. Connect a manometer to the 1/8″ NPT inlet pressure

tap on the gas valve. See Figure 7.2.

9. Confirm that the gas supply pressure to the boiler is

above the minimum and below the maximum values

for the gas being used. See the end of Section 5 for

these values. If a supply pressure check is required,

isolate the boiler and gas valve before performing

the pressure check. If the supply pressure is too high

or too low, contact the gas supplier.

10. Turn on electricity and gas to boiler.

11. Light the boiler by following the Lighting/Operating

Instructions label mounted to the jacket panel. The

initial ignition may require several tries as the piping

is purged of air.

12. Use the sequence description and Figure 6.3 in

Section 6 (Electrical) to follow light-off and shutdown

sequences and to assist in diagnosing problems. If

the boiler does not function properly, consult Section

8, Troubleshooting.

7. START-UP PROCEDURES

19

START-UP PROCEDURES

Page 22

20

START-UP PROCEDURES

Figure 7.1: Gas Valve, Manifold and Burner Assembly – Intermittent Ignition

Figure 7.2: Valve Tapping and Adjustment Screw Locations

Page 23

21

START-UP PROCEDURES

Figure 7.3: Operating Instructions

Page 24

22

START-UP PROCEDURES

B. CONTROL DESCRIPTIONS

See Figure 6.1 in Section 6 (Electrical) for locations of

these devices.

1. FLAME ROLL-OUT SAFETY SHUT-OFF SWITCH

(FLAME ROLL-OUT SWITCH) – A thermally

activated switch located between the first burner

from the left and the manifold bracket. The flame

roll-out safety shut-off switch will sense excessive

temperature caused by continued flame roll-out and

shut down main burner gas. This is a non-recycling

switch that must be replaced once it has been

activated and the cause of the roll-out eliminated.

2. DIFFERENTIAL PRESSURE SWITCH – This device

senses a negative or suction pressure in the blower

housing and air box when the blower is energized. If

there is not excessive blockage in the venting system

or air inlet vent the switch will close, allowing power

to energize the ignition system.

3. LIMIT – A thermally activated, manually adjustable

switch located on the right side of the boiler. The

temperature sensing element is placed in the supply

and will shut down main burner gas if the supply

water exceeds the preset temperature limit. This is a

recycling switch that will automatically reset when

the supply water falls below the preset temperature.

4. LOW WATER CUT-OFF (FOR GRAVITY SYSTEMS

OR HOT WATER BOILERS INSTALLED ABOVE

RADIATION LEVEL) – A level-sensing device (float

or probe) located in supply piping near the boiler. If

water level in the system drops below the control’s

position, it will shut down main burner gas. The

control will automatically reset once the water level

rises above its position.

C. ADJUSTMENT OF GAS PRESSURE

REGULATOR

1. Move the manometer to either the outlet pressure

tap on the gas valve or to the burner manifold test

tap. Set manifold pressure as follows for various

gases.

a. Natural Gas . . .3.5″ Water Column (0.9 kPa)

b. LP Gas . . . . . .10.0″ Water Column (2.5 kPa)

2. To adjust gas pressure, turn adjusting screw of gas

pressure regulator counterclockwise to decrease

pressure, clockwise to increase pressure. Refer to

Figure 7.2 for location of gas pressure regulator.

Replace the cap screw when adjustment is complete.

3. In no case should the final manifold pressure vary

more than ±0.3 inches water column (0.07 kPa)

from the above specified pressures. Any necessary

major changes in the flow should be made by

changing the size of the burner orifice spuds.

4. When adjustment is complete, turn off boiler, gas

flow and electricity to boiler. Remove manometer

and plug tapping with plug provided. Turn utilities

back on and resume checkout.

D. CHECKING BURNER INPUT

1. Refer to rating label mounted on the jacket top panel

to obtain the rated BTU per hour input. In no case

shall the input to the boiler exceed the value shown

on the rating label.

2. Check input by use of the following formula

(PB Heat suggests reading meter for 2 Cu.Ft.

[0.0566 cubic meter]):

U.S. Customary Units:

Input (BTU/Hr.)= 3600 x F x H

T

Where:

3600 – Seconds per hour

F – Cubic Feet of Gas Registered on Meter

H – Heat Value of Gas in BTU/Cubic Feet

T – Time in Seconds the Meter is Read

SI Metric Units

Input (kW)= 3600 x F x H

T x 3.6

Where:

3600 – Seconds per hour

3.6 – Megajoule (MJ) per kilowatt hour (kWhr)

F – Cubic Meters of Gas Registered on Meter

H – Heating Value of Gas in MJ/Cubic Meter

T – Time in Seconds the Meter is Read

3. As an alternative, use Table 7.1a and 7.1b. Use the

heating value provided by gas supplier. Use a

stopwatch to record the time it takes for 2 cubic feet

(0.0566 cubic meter) of gas to pass through the

meter. Read across and down to determine rate.

E. CHECK-OUT PROCEDURE

1. After starting the boiler, be certain all controls are

working properly. Check to be sure that the limit will

shut off the boiler in the event of excessive water

temperature. This can be done by lowering the limit

setting until the main burners shut down. When

proper limit function is confirmed, return the dial to

its previous setting.

2. To check operation of the ignition system safety

shut-off features:

a. Turn gas supply off.

b. Set thermostat or controller above room

temperature to call for heat. Watch for igniter

glow at pilot burner.

c. Igniter will continue to glow for 30 seconds, de-

energize for 30 seconds, then re-energize and

glow for another 30 seconds. It will then deenergize for 5 minutes before restarting the

sequence.

d. Turn gas supply on.

e. Reset the boiler and control by following

Operating Instructions.

f. Observe boiler operation through one complete

cycle.

Page 25

3. Low Water Cut-Off (if used) – Consult the

manufacturer’s instructions for the low water cut-off

operational check procedure.

4. Check the system to make sure there are no leaks or

overfilling problems which might cause excessive

make-up water to be added. Make-up water causes

liming in the boiler and brings in oxygen. Oxygen

can cause severe damage to the boiler though

oxygen corrosion pitting.

5. Check the expansion tank and automatic fill valve (if

used) to confirm that they are operating correctly. If

either of these components causes high pressure in

the system, the boiler relief valve will weep or open,

allowing fresh water to enter the system.

6. Do not allow the system controls to subject the boiler

to excessively low water temperatures, which would

cause condensation of flue gases and corrosion of

the boiler. Operate the boiler at a temperature above

130°F (54°C). Adjust the boiler limit as required to

maintain boiler temperature above this level.

7. Check the general condition of the system including

piping support, joints, etc. Check cleanliness of the

radiators, baseboard units and/or convectors. Clean

them to the extent possible. If radiators do not heat

evenly, vent any remaining air from them.

8. Review operation and User’s Information Manual

with end-user.

9. Complete the Warranty Card and submit it to PB

Heat, LLC.

10. Hang the Installation, Operation and Maintenance

Manual, User’s Information Manual, and Vent

Manufacturer’s Information Manual in an accessible

position near the boiler

23

START-UP PROCEDURES

Table 7.1a: Meter Conversion Natural Gas

(U.S. Customary Units)

Table 7.1b: Meter Conversion Natural Gas

(SI Metric System)

Burner inputs in kW for various meter timings and

heating values. (Tables based on 0.0566 cubic meters

of gas through the meter).

Burner inputs in Btu/hr for various meter timings and

heating values. (Tables based on 2 cubic feet of gas

through the meter).

Time that

meter is

read (sec)

Heat Value of Gas

(MJ/cubic meter)

37.26 38.19 39.12

25

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100

105

110

115

120

125

84.36

70.30

60.25

52.72

46.86

42.18

38.34

35.15

32.44

30.13

28.12

26.36

24.81

23.43

22.20

21.09

20.08

19.17

18.34

17.57

16.87

86.46

72.05

61.76

54.04

48.03

43.23

39.30

36.03

33.25

30.88

28.82

27.02

25.43

24.02

22.75

21.62

20.59

19.65

18.80

18.01

17.29

88.57

73.81

63.26

55.35

49.20

44.28

40.26

36.90

34.06

31.63

29.52

27.68

26.05

24.60

23.31

22.14

21.09

20.13

19.25

18.45

17.71

Time that

meter is

read (sec)

Heat Value of Gas

(Btu/cubic foot)

1000 1025 1050

25

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100

105

110

115

120

125

288000

240000

205714

180000

160000

144000

130909

120000

110769

102857

96000

90000

84706

80000

75789

72000

68571

65455

62609

60000

57600

295200

246000

210857

184500

164000

147600

134182

123000

113538

105429

98400

92250

86824

82000

77684

73800

70286

67091

64174

61500

59040

302400

252000

216000

189000

168000

151200

137455

126000

116308

108000

100800

94500

88941

84000

79579

75600

72000

68727

65739

63000

60480

Page 26

24

TROUBLESHOOTING

A. SHUT-DOWN CAUSED BY PILOT

OUTAGE, PRESSURE SWITCH OR

FLAME ROLL-OUT SAFETY

SHUT-OFF SWITCH

In the event of a shut-down caused by a pilot outage,

action of the pressure switch or flame roll-out safety

shut-off switch effecting a shut-down of the main

burners:

a. Refer to the Lighting/Operating Instructions in Figure

7.3 to properly turn off the gas to the boiler.

b. Turn off all electric power to the boiler.

c. Call a qualified heating service organization or local

gas company and have the cause of the shut-down

investigated and corrected.

d. Refer to Operating Instructions to re-start boiler.

B. TROUBLESHOOTING GUIDES

Use Table 8.1 and Figure 8.2 to assist in determining

causes and providing corrective actions to boiler

problems. These guides must be used only by qualified

service technicians. These individuals must follow all

applicable codes and regulations in repair of any boiler

problems.

C. MEASURING SUCTION PRESSURE

Pressure switch requires minimum -0.45″ W.C. (-112 Pa)

fan suction pressure to energize control circuit. Measure

when boiler has been operating at least 15 minutes. See

Figure 8.1.

8. TROUBLESHOOTING

Should overheating occur or the gas supply fail to

shut off, do not turn off or disconnect the electrical

supply to the pump.This may aggravate the problem

and increase the likelihood of boiler damage. Instead,

shut off the gas supply at a location external to the

appliance.

CAUTION

Do not use this appliance if any part has been under

water. Improper or dangerous operation may result.

Immediately call a qualified service technician to

inspect the boiler and to replace any part of the

control system and any gas control which has been

under water.

WARNING

Label all wires prior to disconnection when servicing

controls.Wiring errors can cause improper and

dangerous operation.Verify proper operation after

servicing.

CAUTION

When servicing or replacing items that communicate

with the boiler water, be certain that:

●●

There is no pressure on the boiler.

●●

The boiler is not hot.

●●

The power is off.

When servicing the gas valve or pilot, be certain that:

●●

The gas is off.

●●

The electricity is off.

DANGER

Page 27

25

Figure 8.1: Measuring Fan Suction Pressure

TROUBLESHOOTING

*

Page 28

26

TROUBLESHOOTING

Table 8.1: Boiler Troubleshooting Guide (Burners Functioning)

PROBLEM POSSIBLE CAUSES CORRECTIVE ACTIONS

1. See Figure 8.2

Burners not functioning.

1. See Figure 8.2

1. Defective gas valve.

2. Short circuit.

Burners will not shut

down.

1. Use Figure 8.2 to troubleshoot intermittent

ignition gas valve. Replace if necessary.

2. Check and correct wiring.

1. Manifold gas pressure too low.

2. Improperly sized/drilled orifice spuds.

3. Leaking gas valve.

4. Burrs on orifice.

5. Low supply gas pressure.

Flashback or burning

at orifice spuds.

1. Adjust to proper pressure.

2. Install correct spuds.

3. Replace valve.

4. Remove burrs.

5. Contact gas supplier if natural gas. Adjust

regulator if LP gas.

1. Insufficient pilot flame.

2. Pilot burner/orifice clogged.

3. Overfiring.

4. Misaligned burners or pilot.

Delayed ignition.

1. Increase pilot gas flow.

2. Clean pilot burner and orifice.

3. Reduce rate to input on rating label.

4. Realign burners or pilot.

1. Vent pipe not sloped towards vent terminal.

Condensation at boiler

vent connector/fan.

1. Install condensate trap per vent manufacturer’s

. instructions.

2. Slope vent pipe towards vent terminal.

1. Underfiring.

2. Limit set too low.

3. Air in system.

4. Circulator malfunctioning.

5. Circulation system clogged.

6. Incorrect thermostat heat anticipator setting.

Boiler not heating

properly.

1. Increase rate to input on rating label.

2. Reset limit to higher setting.

3. Vent air from all points in system.

4. Check circulator, replace if necessary.

5. Shut down and cool boiler, drain and flush

system.

6. Adjust heat anticipator.

1. Leaks in gas piping or fittings.

2. Leaks in gas service line or meter.

3. Leaks in venting system.

4. Overfiring.

Fumes or gas odors

1. Locate and repair or replace.

2. Shut down boiler and notify gas provider.

3. Locate and repair or replace.

4. Reduce rate to input on rating label.

Page 29

27

TROUBLESHOOTING

Figure 8.2: Boiler Troubleshooting Guide (Burners Not Functioning)

ENDVIEW OF

INSET A

CONTROL

HARNESS

24VOLT

HOT

CONNECTOR

24

VOLTS

INSET B

HSI

TERMINAL

24VOLT

THERMOSTAT

24

VOLTS

24VOLT

ASSURE GASVALVE SWITCH IS

IN "ON" POSITION

DISCONNECT SYSTEM CONTROL

TURN OFF GAS SUPPLY

●●●

●

CHECK FOR DAMAGED OR MISSING

TERMINALS IN CONNECTOR

COMMON

HARNESS

SETTHERMOSTATTO CALL

FOR HEAT

●

●

●

LINEVOLTAGE POWER

LOWVOLTAGETRANSFORMER

LIMIT CONTROLLER

WIRING

THERMOSTAT

CHECK:

●●●●●

NO

YES

CHECK FOR PROPERVOLTAGE

AT CONTROL HARNESS (SEE INSET

A).VOLTAGE SHOULD BE 24V

BETWEENTHERMOSTAT AND

24V COMMON, AND 24V BETWEEN

24V COMMON AND 24V HOT.

NO

UNPLUG PILOT BURNER CABLE.

NO

PLUG HARNESS INTO GASVALVE

CONTROL.WAIT FOR INTERNAL

CHECK DELAY

REPLACE GASVALVE

RECONNECT PILOT BURNER

CABLE

YES

MEASUREVOLTAGE AT GAS VALVE

HSI ELEMENT OUTPUT (SEE INSET B)

24V NOMINAL

REPLACEIGNITER/FLAMERODASSEMBLY

RECONNECT PILOT BURNER CABLE

YES

IGNITERWARMS UP AND

GLOWS RED

NOTE:IGNITERWILL CYCLE OFF

AND BACK ON ONCE DURINGTHE

90 SECOND IGNITIONTRIAL

REPLACE GASVALVE

CHECKTHAT PILOT GAS IS FLOWING.

WAITTO ASSURE PILOT GAS TUBING

IS PURGED.

●●●

NO NO

PILOT BURNER LIGHTS

TURN ON GAS SUPPLY

●

●

CHECKTRANSFORMER AND

LINEVOLT SUPPLY

NO

YES

MEASUREVOLTAGE BETWEEN 24V

HOT AND 24V COMMON LEADSTO GAS

VALVE. MUST MEASURE AT LEAST

19.5VAC WITH IGNITER POWERED.

●●●●●●●

YES

SEE INSET ATO IDENTIFY PROPER

LEAD.THIS CHECK MUST BE DONE

WITHTHE GASVALVE CONNECTED

AND IGNITER POWERED.

REPLACEIGNITER/FLAMERODASSEMBLY

●

YES

CYCLETHERMOSTAT OFF AND BACK ON

CHECKTHAT PILOT FLAME MAKES

●

IF MAIN BURNERS DO NOT LIGHT,

REPLACE GASVALVE

CHECK FOR GOOD ELECTRICAL

IF BOTH OFTHE ABOVE ARE GOOD,

GOOD CONTACT WITH PILOT BURNER

FLAME ROD.

CONNECTIONTHROUGHTHE PILOT

TUBING

REPLACE IGNITER/FLAME ROD

●●●●●●●

NO

YES

MAINVALVE OPENS AND

MAIN BURNER LIGHTS

ASSEMBLY.

●

SYSTEM IS OKAY

SEETABLE 8.1

YES

DO BURNERS

FUNCTION?

YES

NO

DOES IGNITERWARM

UP AND GLOW RED?

(INTERMITTENTLY)

YES

NO

SWITCH "NO"TERMINALTO GROUND.

IF NOVOLTAGE,CHECK FOR:

- BLOCKED OR CRACKED SUCTION

x

1) CHECK FOR 24VAC AT PRESSURE

1)x

1)x

1)x

IS FAN RUNNING?

TUBING.

- FAN NOT GENERATING ADEQUATE

1)x-

1)x

SUCTION PRESSURE.

1)x-

CHECK FOR BROKEN/LOOSEWIRE.

CHECK FOR 120VAC BETWEEN R4222

RELAY BLACK AND WHITE WIRES. IF

2)x-

- IF NOVOLTAGE AT ONLY ONE BLWIRE,

2)x

2)x-

2)x-

SO,REPLACE RELAY.

3) CHECK FOR 24VAC AT FLAME ROLL-OUT

2)x-x3)x

SWITCH. IF SWITCH IS BLOWN,CORRECT

- DEFECTIVE PRESSURE SWITCH.

BLUEWIRESTO GROUND:

- IF NOVOLTAGE AT EITHER BL WIRES,

2) CHECK FOR 24VAC AT R4222 RELAY

1)xx2)x

2)x

CAUSE OF ROLL-OUT BEFORE

REPLACING SWITCH.

3)x

3)x

NO

NO

CHECKFOR 120VACHIGHLIMIT CONTROL.IF

POWERATONETERMINAL BUTNOTBOTH,

REPLACELIMITCONTROL.

NO

JUMPERTHERMOSTAT

AT CONNECTIONS

"G" AND "Y" ON R8285.

DOES BOILER RUN?

CHECK FOR 24VAC AT PRESSURE SWITCH

TERMINALS "C" AND "NC"TO GROUND:

IFVOLTAGE AT "NC" BUT NOT "C",

PRESSURE SWITCH IS STUCK IN

RUNNING POSITION. CHECK FOR BLOCKED

●●●●●

AIRTUBE.IF OKAY, REPLACE PRESSURE

●

●

YES

CORRECT

THERMOSTAT

PROBLEM

SWITCH.

IF NOVOLTAGE AT EITHER PRESSURE

SWITCHTERMINAL "C" OR "NC"TO

GROUND,CHECK FOR 120VAC INCOMING

POWER INSIDE JUNCTION BOX.IF PROPER

INCOMING POWER,REPLACE R8285.

●●●

●

Page 30

28

MAINTENANCE

9. MAINTENANCE

WARNING

Product Safety Information

Refractory Ceramic Fiber Product

This appliance contains materials made from refractory ceramic fibers (RCF). Airborne RCF,

when inhaled, have been classified by the International Agency for Research on Cancer

(IARC), as a possible carcinogen to humans. After the RCF materials have been exposed to

temperatures above 1800°F (980°C), they can change into crystalline silica, which has been

classified by the IARC as carcinogenic to humans. If particles become airborne during service or repair, inhalation of these particles may be hazardous to your health.

Avoid Breathing Fiber Particulates and Dust

Suppliers of RCF recommend the following precautions be taken when handling these

materials:

Precautionar

y Measures:

Provide adequate ventilation.

Wear a NIOSH/MSHA approved respirator.

Wear long sleeved, loose fitting clothing and gloves to prevent skin contact.

Wear eye goggles.

Minimize airborne dust prior to handling and removal by water misting the material and

avoiding unnecessary disturbance of materials.

Wash work clothes separately from others. Rinse washer thoroughly after use.

Discard RCF materials by sealing in an airtight plastic bag.

Fir

st Aid Procedures:

Inhalation: If breathing difficulty or irritation occurs, move to a location with fresh clean air.

Seek immediate medical attention if symptoms persist.

Skin Contact:Wash affected area gently with a mild soap and warm water. Seek immediate

medical attention if irritation persists.

Eye Contact: Flush eyes with water for 15 minutes while holding eyelids apart. Do not rub

eyes. Seek immediate medical attention if irritation persists.

Ingestion: Drink 1 to 2 glasses of water. Do not induce vomiting. Seek immediate medical

attention.

Page 31

29

A. GENERAL

1. Disconnect this boiler from the gas supply piping

during any pressure testing of the gas system.

2. Check pipes adjacent to cold walls or in unheated

spaces. Insulate and tape them if necessary to be

sure they can’t freeze up. Keeping the water moving

at all times will reduce the likelihood of freezing. See

Section 3 for antifreeze instructions.

3. If there is considerable foreign matter in the boiler

water, the boiler should be shut down and allowed to

cool, then drained and thoroughly flushed out. Use

the drain valve at the bottom of the return

connection to drain the boiler. Pipe the drain cock to

a suitable drain or containment device if antifreeze is

used. Flush the system to remove remaining matter.

If there is evidence that hard scale has formed on the

internal surfaces, the boiler should be cleaned by

chemical means as prescribed by a qualified water

treatment specialist.

B. DAILY (WITH BOILER IN USE)

Daily boiler observation can be performed by the owner.

If any potential problems are found, a qualified installer

or service technician/agency must be notified.

1. Remove any combustible materials, gasoline and

other flammable liquids and substances that generate

flammable vapors from the area where the boiler is

contained. Make certain that the boiler area has

ample air for ventilation and that there are no

obstructions to the free flow of air to and from the

boiler.

2. Observe general boiler conditions (unusual noises,

vibrations, etc.)

3. Observe operating temperature and pressure on the

combination gauge located on the right side of the

boiler. Boiler pressure should never be higher than

5 psi (35 kPa) below the rating shown on the safety

relief valve (25 psig [172 kPa] maximum for a 30

psig [207 kPa] rating, 45 psig [310 kPa] maximum

for a 50 psig [345 kPa] rating). The valve rating can

be found on the top of the safety relief valve (see

Figure 3.4 for location of the safety relief valve).

Boiler temperature should never be higher than

250°F (121°C).

4. Check for water leaks in boiler and system piping.

5. Smell around the appliance area for gas. If you smell

gas, follow the procedure listed in the Operating

Instructions to shut down appliance in Figure 7.3.

C. WEEKLY (WITH BOILER IN USE)

1. Flush float-type low-water cut-off (if used) to remove

sediment from the float bowl as stated in the

manufacturer’s instructions.

D. MONTHLY (WITH BOILER IN USE)

1. Check boiler room floor drains for proper

functioning.

2. Check function of the safety relief valve (monthly

unless specified otherwise by manufacturer) by

performing the following test:

a. Check valve piping to determine that it is

properly installed and supported.

b. Check boiler operating temperature and pressure.

c. Lift the try lever on the safety relief valve to the

full open position and hold it for at least five

seconds or until clean water is discharged.

d. Release the try lever and allow the valve to close.

If the valve leaks, operate the lever two or three

times to clear the valve seat of foreign matter. It

may take some time to determine if the valve has

shut completely.

e. If the valve continues to leak, it must be replaced

before the boiler is returned to operation.

f. Check that operating pressure and temperature

have returned to normal.

g. Check again to confirm that valve has closed

completely and is not leaking.

3. Test low-water cut-off (if used) as described by the

manufacturer.

4. Test limit as described in Section 7, “Check-Out

Procedure.”

MAINTENANCE

Page 32

30

MAINTENANCE

5. Test function of gas safety shut-off features as

described by gas valve and ignition control

manufacturer.

E. ANNUALLY (BEFORE START OF HEATING

SEASON)

1. Inspect flueways, burners and vent system. See

Figure 9.2.

a. Refer to the Operating Instructions in Figure 7.3

to properly turn off the gas to the boiler. Turn off

all electrical power to the boiler.

b. Remove jacket removable door, air inlet pipe, air

box cover, and air box diffuser screen.

d. Remove burner hitch pin clips. Disconnect pilot

tubing at compression elbow.

e. Disconnect pilot harness at gas valve. Gently pull

pilot harness further inside air box to be able to

remove burner with attached pilot.

f. Remove burners and pilot.

g. Brush gas outlet ports lightly using a soft bristle

brush. If extensive corrosion in outlet ports,

replace.

h. Examine pilot hood and igniter for corrosion,

scale, ceramic cracking. Replace if necessary.

i. Remove 3″ (76 mm) diameter vent pipe from fan

adapter.

j. Remove top jacket panel, flue collector/fan

assembly, and flue baffles.

k. Examine flueways and flue collector/fan for scale,

soot, and loose rust.

l. If necessary, brush flueways with wire brush and

remove scale and loose rust from flue baffles. If

corroded, replace baffles.

m. Reinstall flue baffles.

n. Examine flue collector blanket seal.

Reposition/replace as necessary to assure air tight

seal between flue collector and heat exchanger.

o. Reinstall flue collector/fan assembly.

p. Reinstall jacket top panel.

q. Reinstall pilot, burners, hitch pin clips. Reconnect

pilot harness to gas valve, gently pulling harness

to length required to reach gas valve.

r. Reinstall air box diffuser.

s. Examine air box cover seal. Reposition/replace as

necessary to assure air tight seal.

t. Reinstall air box cover.

u. Examine entire vent system for corrosion,

support and joint integrity. Repair as necessary.

Remove any debris inside vent.

v. Reconnect vent pipe to fan adapter. Reseal using

high-temp silicones as shown in Section 4,

Venting, Ventilation and Air Inlet.

w. Refer to Operating Instructions in Figure 7.3 to

properly return the boiler to operation.

2. Check the pilot and main burner flame. See Figure

9.1. The pilot should provide a steady flame

enveloping 3/8″ to 1/2″ (1 cm to 1.2 cm) of the flame

sensor. If required, adjust the pilot as stated in the

gas valve manufacturer’s instructions. The main

burner flame inner cone should be approximately

1-1/2″ (4 cm) high and should have a very sharp,

blue color characteristic.

Figure 9.1: Intermittent Pilot and Main

Burner Flame

When servicing or replacing components, be

absolutely certain that the following conditions are

met:

●●

Water, gas and electricity are off.

●●

The boiler is at room temperature.

●●

There is no pressure in the boiler.

DANGER

Leaks in the vent system will cause products of

combustion to enter structure (vent system operates

under positive pressure).

WARNING

Soot accumulation indicates boiler malfunction.

Cause of malfunction must be determined and

corrected before returning boiler to service.

WARNING

Page 33

31

MAINTENANCE

Figure 9.2: Inspection of Flueways, Burners, and Vent System.

Page 34

32

BOILER DIMENSIONS & RATINGS

10. BOILER DIMENSIONS & RATINGS

Figure 10.1: Boiler Views

Table 10.1: Series PSC Boiler Dimensions

Table 10.2: Series PSC Boiler Ratings

1 Net I=B=R water ratings based on an allowance of 1.15.

2 Consult factory before selecting a boiler for installations having unusual piping and pickup

requirements, such as intermittent system operation, extensive piping systems, etc.

3 Heating Capacity and Annual Fuel Utilization Efficiency (AFUE) ratings are based on U.S.

Government test.

SERIES PSC BOILER DIMENSIONS

Boiler

Model

Number

Jacket Width “A”

PSC-03

12¹⁄₂″

318 mm

PSC-04

15⁷⁄₈″

403 mm

PSC-05

19¹⁄₄″

489 mm

PSC-06

22⁵⁄₈″

575 mm

SERIES PSC BOILER RATINGS

Boiler

Model

Number

Input

DOE Heating

Capacity

3

Net I=B=R

Ratings Water

1,2

Seasonal

Efficiency

3

(AFUE)%

Water Content

MBH kW MBH kW MBH kW Gallon Liter

PSC-03 70 21 58 17 50 15 83.0 4.72 17.87

PSC-04 105 31 88 26 77 23 83.0 6.00 22.71

PSC-05 140 41 117 34 102 30 83.0 7.28 27.56

PSC-06 175 51 146 43 127 37 83.0 8.56 32.40

Page 35

33

REPAIR PARTS

REPAIR PARTS

SERIES PSC GAS BOILER

Repair parts are available from your installer or by contacting PB Heat, LLC, New

Berlinville, PA. Use the figures and tables on pages 32-36 to assist in ordering parts.

Note: Remember to include boiler model number and serial number when ordering parts.

11. REPAIR PARTS

Figure 11.1

Page 36

34

REPAIR PARTS

Table 11.1

Base Assembly

Floor Pan

Base Rear Panel Assembly

Base Observation Port Cover

Base/Air box Spacer

Air Box Right Side

Air Box Left Side

Air Box Top/Front Cover

Air Box Diffuser Screen

Rope Gasket Seal, Air Box

Flame Rollout Switch, Thermodisc G4AM00167C

Flame Rollout Switch Bracket

Burner Less Pilot Bracket

Burner with Pilot Bracket

Orifice, #48, normal altitude Natural Gas only

Orifice, #56, normal altitude LP Gas only

Gas Manifold

Item

No.

Description

7800

50100

PSC2000

51771

(2) 50152

PSC2023

PSC2024

50143

PSC2025

(56″) 50718

51587

50136

(3) 51537

51539

(4) 50894

(4) 50899

50121

7803

50103

PSC2000-3

51771

(2) 50152

PSC2023

PSC2024

50146

PSC2025-3

(76″) 50718

51587

50136

(9) 51537

51539

(10) 50894

(10) 50899

50124

7802

50102

PSC2000-2

51771

(2) 50152

PSC2023

PSC2024

50145

PSC2025-2

(69″) 50718

51587

50136

(7) 51537

51539

(8) 50894

(8) 50899

50123

7801

50101

PSC2000-1

51771

(2) 50152

PSC2023

PSC2024

50144

PSC2025-1

(63″) 50718

51587

50136

(5) 51537

51539

(6) 50894

(6) 50899

50122

(Quantity/Length) Stock Code

PSC-0 3 PSC-0 4 PSC-05 PSC-06

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Page 37

35

REPAIR PARTS

Figure 11.2

Page 38

REPAIR PARTS

36

Table 11.2

16

17

18

19

20

21

22

23

24

25

Insulation Blanket, 1/2″ x 1.50″, block to base

Block

Flue Baffle

Insulation Blanket, 1/2″ x .75″, flue collector to block

Flue Collector

Gasket, Orifice Plate

Orifice Plate, normal altitude Natural Gas models only

Orifice Plate, normal altitude LP Gas models only

Fan

Fan Adapter

Jacket Set

Gas Valve, SV9501M2700, Natural Gas models only

Gas Valve, SV9501M2064, LP Gas models only

Pilot Assembly, Q3480B1058, w/Natural Gas Orifice

Pilot, Q3480B1058, LP Gas models only

Limit Control, L4080B1253 (less well)

Pressure Switch, Standard altitude, FS6124A2481

Transformer Relay Center, R8285D1026

Relay (mounted on jacket), R4222D1005

Safety Relief Valve, 30psi, Conbraco 10-408-05

Safety Relief Valve, 50psi, Watts #350

Temperature-Pressure Gauge

Circulator, Taco 007

Flange Set, Taco 110-Z53BP, 1 1/4″

Heat-Fab Vent Adapter 7301 AMTK

Z-Flex Locking Band SVSLBX03

ProTech Vent Adapter FSA-PSC/DE-3

Flex-L Star-34 Vent Adapter SRAPPA3

Wall Thimble Assembly, up to 11 1/2″ walls

Wall Thimble Assembly, up to 20″ walls

Heat-Fab vent pipe, elbows

Z-Flex, ProTech, Flex-L vent pipe, elbows

Item

No.

Description

(47″) 50867

90419

(2) 51584

(34″)50866

50131

(2) 50135

PSC5002

PSC5003

50775

50200

90366

51682

51691

7794

50205

50210

50080

50786

50790

50501

99950

51774

50782

51048

50199 (Also Available From Heat-Fab Distributor)

Available from Z-Flex Distributor

Available from ProTech Distributor

Available from Flex-L Distributor

90249

90350

Specify item including pipe length. Also available from Heat-Fab Distr.

Available from Vent Manufacturer Distributors

(61″) 50867

90421

(4) 51584

(47″)50866

50133

(2) 50135

PSC5002-2

PSC5003-2

50775

50200

90368

(54″) 50867

90420

(3) 51584

(41″)50866

50132

(2) 50135

PSC5002-1

PSC5003-1

50775

50200

90367

(Quantity/Length) Stock Code

PSC-0 3 PSC-0 4 PSC-05 PSC-06

(67″) 50867

90422

(5) 51584

(54″)50866

50134

(2) 50135

PSC5002-3

PSC5003-3

50775

50200

90369

Page 39

PSC

Boilers

Series

Gas

Installation,

Operation &

Maintenance

Manual

TO THE INSTALLER:

This manual is the property of the owner and must

be affixed near the boiler for future reference.

TO THE OWNER:

This boiler should be inspected annually by a

Qualified Service Agency.

HI Division

of gama

ASME

PB HEAT, LLC

PO BOX 447 • NEW BERLINVILLE, PA 19545-0447

©2005 WEB-1

PSC8030 R6 (9/05-2M)

Printed in U.S.A.

Loading...

Loading...