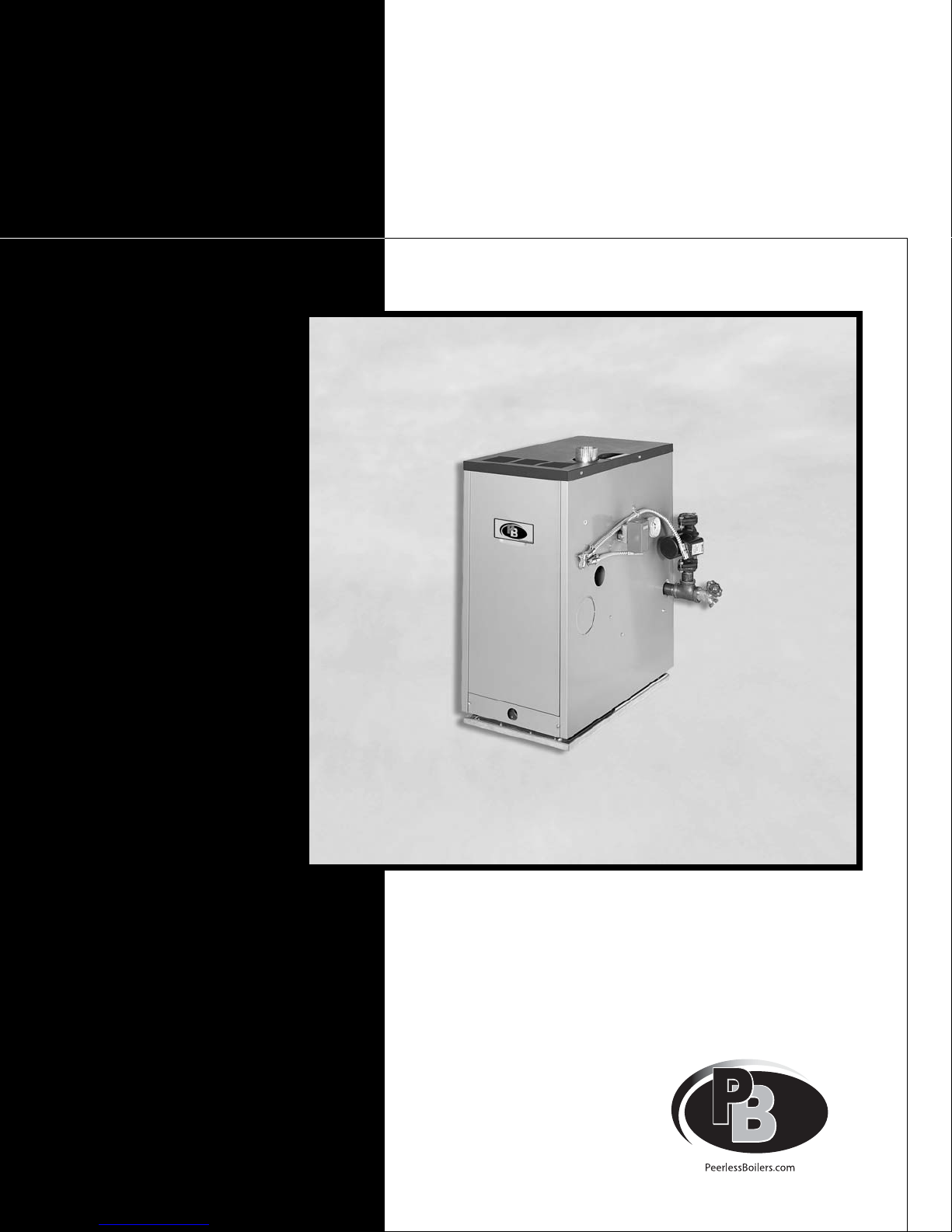

PB Heat PSC-06, PSC-05, PSC-04, PSC-03 Installation, Operation & Maintenance Manual

PSC

Boilers

Series

Gas

Installation,

Operation &

Maintenance

Manual

i

USING THIS MANUAL 1

A. INSTALLATION SEQUENCE . . . . . . . . . . . . .1

B. SPECIAL ATTENTION BOXES . . . . . . . . . . . .1

1. PREINSTALLATION 2

A. ACCESSIBILITY CLEARANCES . . . . . . . . . . .2

B. CLEARANCE FROM COMBUSTIBLE

CONSTRUCTION . . . . . . . . . . . . . . . . . . . . . .2

C. INSTALLATION SURVEY . . . . . . . . . . . . . . . .2

D. PLANNING THE LAYOUT . . . . . . . . . . . . . . . .2

2. BOILER SET-UP 3

3. WATER PIPING AND CONTROLS 4

A. BOILER SUPPLY AND RETURN . . . . . . . . . . .4

B. SAFETY RELIEF VALVE . . . . . . . . . . . . . . . . .5

C. PIPING FOR ZONED SYSTEMS . . . . . . . . . . .6

D. EXPANSION TANK . . . . . . . . . . . . . . . . . . . . .7

E. INDIRECT-FIRED WATER HEATER . . . . . . . .7

F. FREEZE PROTECTION . . . . . . . . . . . . . . . . . .7

4. VENTING, VENTILATION AND

AIR INLET 8

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

B. PSC WALL THIMBLE . . . . . . . . . . . . . . . . . . .8

C. ROOF TERMINATIONS . . . . . . . . . . . . . . . .10

D. VENT PIPE INSTALLATION . . . . . . . . . . . . .11

E. AIR INLET PIPE INSTALLATION . . . . . . . . .11

F. AIR FOR VENTILATION . . . . . . . . . . . . . . . .12

G. BOILER REMOVAL FROM COMMON

VENTING SYSTEM . . . . . . . . . . . . . . . . . . .12

5. GAS PIPING 13

6. ELECTRICAL 15

A. WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

B. ZONED SYSTEM WIRING . . . . . . . . . . . . . .15

C. CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . .15

D. SEQUENCE OF OPERATION . . . . . . . . . . . .16

7. START-UP PROCEDURES 19

A. COMPLETING THE INSTALLATION . . . . . . .19

B. CONTROL DESCRIPTIONS . . . . . . . . . . . . .22

C. ADJUSTMENT OF GAS PRESSURE

REGULATOR . . . . . . . . . . . . . . . . . . . . . . . . .22

D. CHECKING BURNER INPUT . . . . . . . . . . . . .22

E. CHECK-OUT PROCEDURE . . . . . . . . . . . . . .22

8. TROUBLESHOOTING 24

A. SHUT-DOWN CAUSED BY PILOT OUTAGE,

PRESSURE SWITCH OR FLAME ROLL-OUT

SAFETY SHUT-OFF SWITCH . . . . . . . . . . . .24

B. TROUBLESHOOTING GUIDES . . . . . . . . . .24

C. MEASURING SUCTION PRESSURE . . . . . .24

9. MAINTENANCE 28

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . .29

B. DAILY (WITH BOILER IN USE) . . . . . . . . . . .29

C. WEEKLY (WITH BOILER IN USE) . . . . . . . . .29

D. MONTHLY (WITH BOILER IN USE) . . . . . . .29

E. ANNUALLY (BEFORE START OF HEATING

SEASON) . . . . . . . . . . . . . . . . . . . . . . . . . . .30

10. BOILER DIMENSIONS & RATINGS 32

11. REPAIR PARTS 33

TABLE OF CONTENTS

1

USING THIS MANUAL

A. INSTALLATION SEQUENCE

Follow the installation instructions provided in this

manual in the order shown. The order of these

instructions has been set in order to provide the installer

with a logical sequence of steps that will minimize

potential interferences and maximize safety during

boiler installation.

B. SPECIAL ATTENTION BOXES

Throughout this manual you will see special attention

boxes intended to supplement the instructions and make

special notice of potential hazards. These categories

mean, in the judgment of PB Heat, LLC:

Indicates special attention is needed, but not directly

related to potential personal injury or property

damage.

NOTICE

Indicates a condition or hazard which will or can

cause minor personal injury or property damage.

CAUTION

DANGER

Indicates a condition or hazard which will cause

severe personal injury, death or major property

damage.

USING THIS MANUAL

Indicates a condition or hazard which may cause

severe personal injury, death or major property

damage.

WARNING

2

PREINSTALLATION

A. ACCESSIBILITY CLEARANCES

Install boiler not less than 24″ (610 mm) between the left

side, top, and front of the boiler and adjacent wall or

other appliance, when access is required for servicing.

B. CLEARANCE FROM COMBUSTIBLE

CONSTRUCTION

The design of this boiler is certified for closet installation

with the following clearances:

1. 6″ (152 mm) between right side, front and

combustible construction.

2. 12″ (305 mm) between top of jacket and

combustible construction.

3. 1″ (25 mm) between left side, rear and combustible

construction.

4. 2″ (51 mm) between vent pipe and combustible

construction.

5. Zero clearance between wall thimble and

combustible construction.

6. This boiler is design certified for use on combustible

flooring.

C. INSTALLATION SURVEY

For new and existing installations, a Water Installation

Survey is available from PB Heat, LLC. The survey will

provide information on how a hot water boiler works

with your specific system and will provide an overview

of hot water system operation in general.

You can also use this survey to locate system problems

which will have to be corrected. To obtain copies of the

Water Installation Survey, contact your PB Heat

representative.

D. PLANNING THE LAYOUT

Prepare sketches and notes of the layout to minimize the

possibility of interferences with new or existing

equipment, piping, venting and wiring. Review

limitations on vent pipe, vent terminal, and air inlet pipe

locations and ventilation air requirements in Section 4.

1. PREINSTALLATION

Read carefully, study these instructions before beginning work.

This boiler must be installed by a qualified contractor.

The boiler warranty can be voided if the boiler is not installed, maintained and serviced correctly.

The equipment must be installed in accordance with those installation requirements of the authority having

jurisdiction or, in the absence of such requirements,to the current edition of the

National Fuel Gas Code,

ANSI

Z223.1/NFPA 54 and/or CAN/CSA B49.1,

Natural Gas and Propane Installation Code

.

Where required by the authority having jurisdiction, the installation must conform to

American Society of Mechanical

Engineers Safety Code for Controls and Safety Devices for Automatically Fired Boilers,

ANSI/ASME CSD-1.

NOTICE

Do not install this boiler on carpeting. Boiler

installation on carpeting is a fire hazard. Install this

boiler on non-combustible flooring or use a

combustible floor pan to install this boiler on other

non-carpeted flooring.

DANGER

Liquefied Petroleum (LP) is heavier than air and may

collect or “pool” in a low area in the event of a leak

from defective equipment.This gas may then ignite,

resulting in a fire or explosion.

WARNING

3

BOILER SET-UP

1. Provide a sound, level foundation. Locate boiler as

near to the outside wall as possible and centralized

with respect to the heating system.

2. Locate boiler in front of installation position before

removing crate.

4. Separate the wood shipping pallet from the boiler

base by removing two (2) hold-down bolts at each

end of the boiler base.

5. Move boiler into final position.

2. BOILER SET-UP

4

WATER PIPING AND CONTROLS

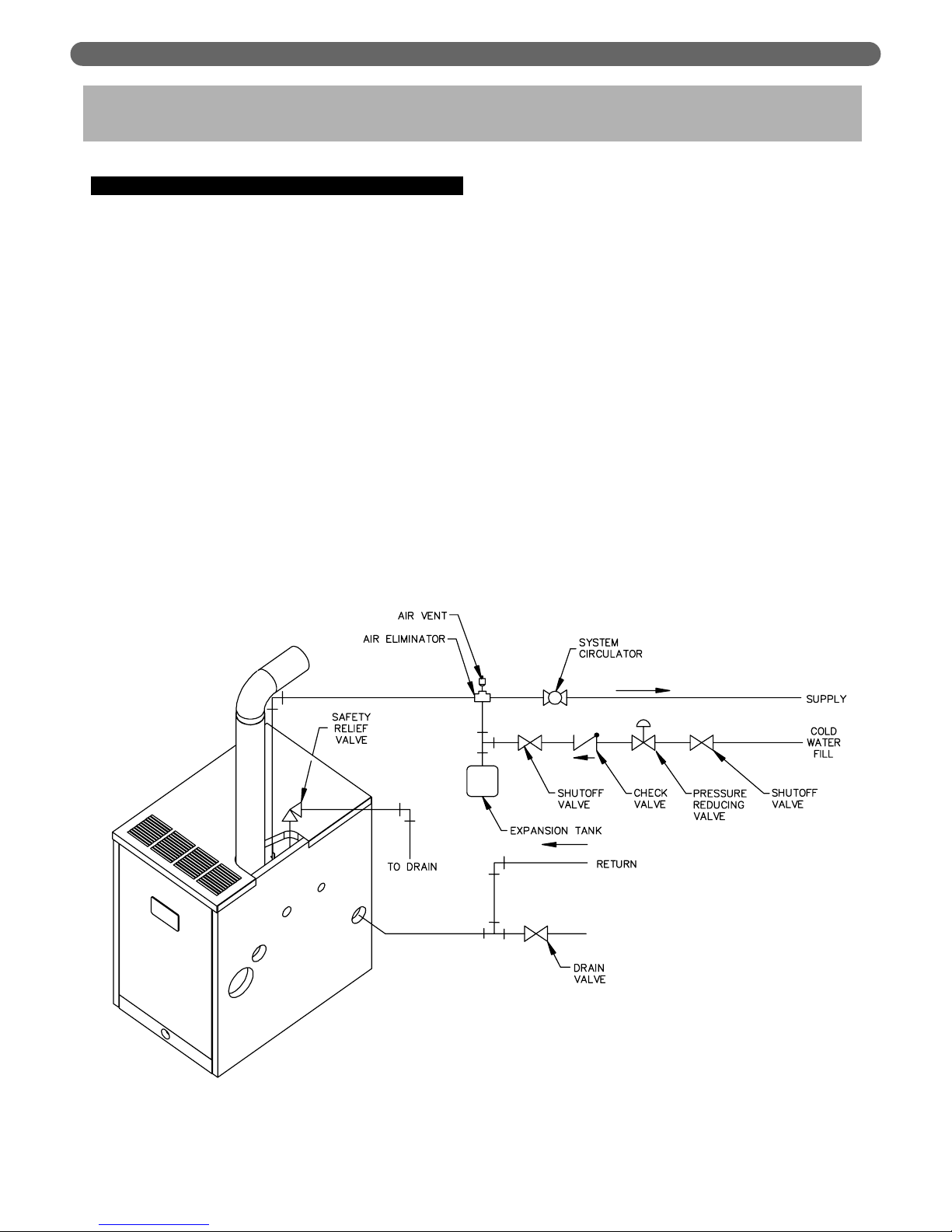

A. BOILER SUPPLY AND RETURN

1. Size the supply and return to suit the system. A

typical piping arrangement is shown in Figure 3.1.

Refer also to the Hydronics Institute Residential

Hydronic Heating Installation Design Guide and the

PB Heat Water Survey for additional guidance

during water piping installation.

2. Return Piping:

Pipe the outlet connection of the circulator to a tee,

provided with a drain valve, at the 1-1/4″ NPT return

tapping near the bottom of the right section. Pipe the

return to the inlet connection of the circulator.

3. Supply Piping:

a. Pipe the supply to the 1-1/2″ NPT supply tapping

at the top of the boiler.

b. Provide clearance to venting system

(see Section 4).

4. When system return water temperature will be below

130°F (54°C), pipe the boiler with a bypass

arrangement to blend the system return and hot

supply to obtain at least 130°F (54°C)entering the

boiler. For more information on bypass piping,

consult the PB Heat Water Survey.

5. If desired, install the circulator in the alternate

location shown in Figure 3.1. Consult the PB Heat

Water Survey for more information on circulator

location.

3. WATER PIPING AND CONTROLS

Figure 3.1: Supply and Return Piping

5

WATER PIPING AND CONTROLS

6. Install this boiler so that the gas ignition system

components are protected from water (dripping,

spraying, etc.) during appliance operation and

service (circulator replacement, condensate trap,

control replacements, etc.).

7. If this boiler and distribution system is used in

conjunction with a refrigeration system, pipe the

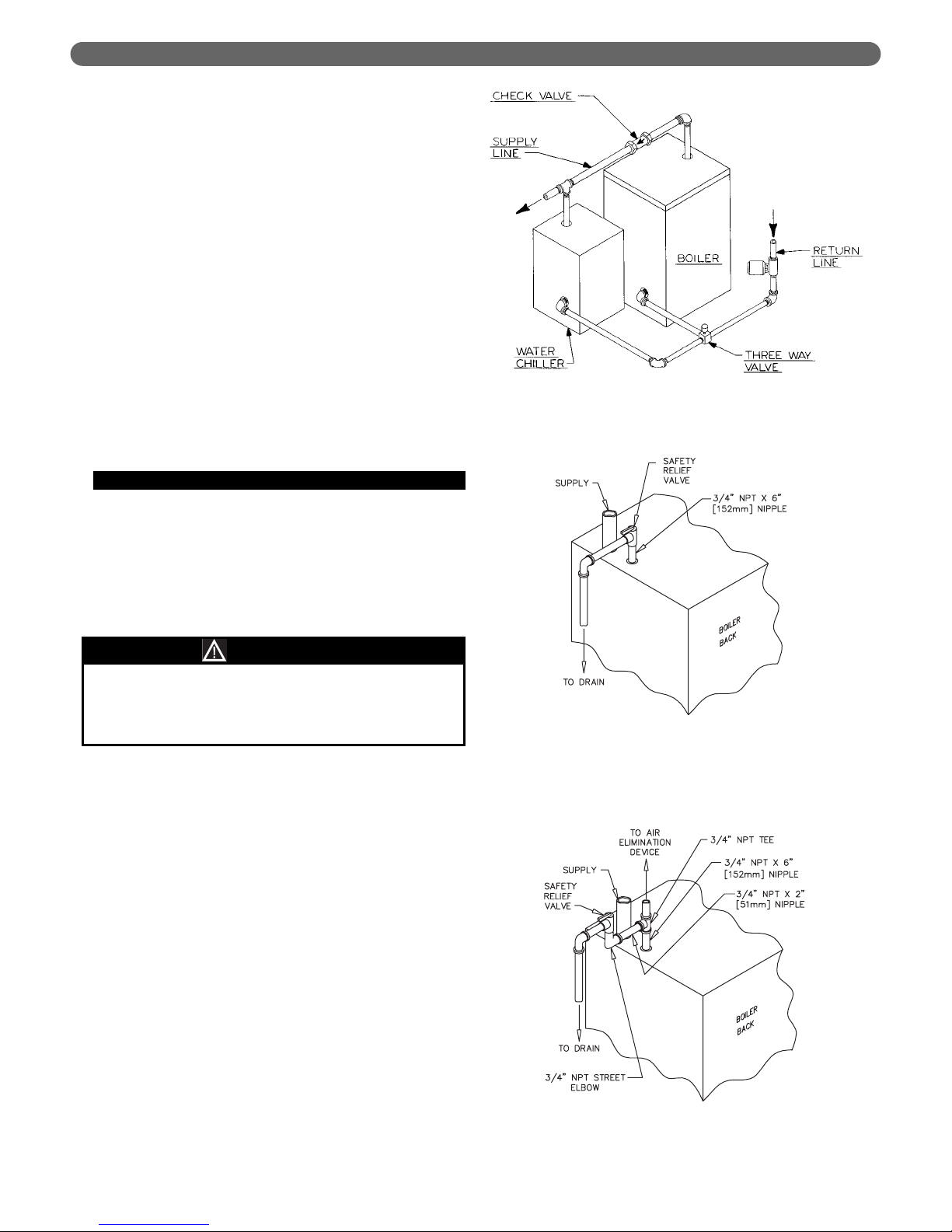

chilled medium in parallel with the boiler and install

the proper valve to prevent the chilled medium from

entering the boiler. A drawing illustrating this hookup is provided in Figure 3.2.

8. When the boiler is connected to heating coils located

in air handling units where they may be exposed to

refrigerated air circulation, install flow control valves

or other automatic means to prevent gravity

circulation of the boiler water during the cooling

cycle.

9. If this boiler is installed above radiation level,

provide a low water cutoff device, either as a part of

the boiler or at the time of boiler installation.

B. SAFETY RELIEF VALVE

1. Locate safety relief valve and fittings in bag

assembly.

2. If air elimination is not required at the safety relief

valve tapping, install valve and piping as shown in

Figure 3.3.

3. For air elimination at the safety relief valve tapping,

install valve and piping as shown in Figure 3.4.

Pipe the discharge of safety relief valve to prevent

injury in the event of pressure relief. Pipe the

discharge to a drain. Provide piping that is the same

size as the safety relief valve outlet.

CAUTION

Figure 3.4: Safety Relief Valve Hook-Up with

Air Elimination

Figure 3.3: Safety Relief Valve Hook-Up

Installation with Air Elimination in

System Piping

Figure 3.2: Parallel Hook-up with Water Chiller

6

WATER PIPING AND CONTROLS

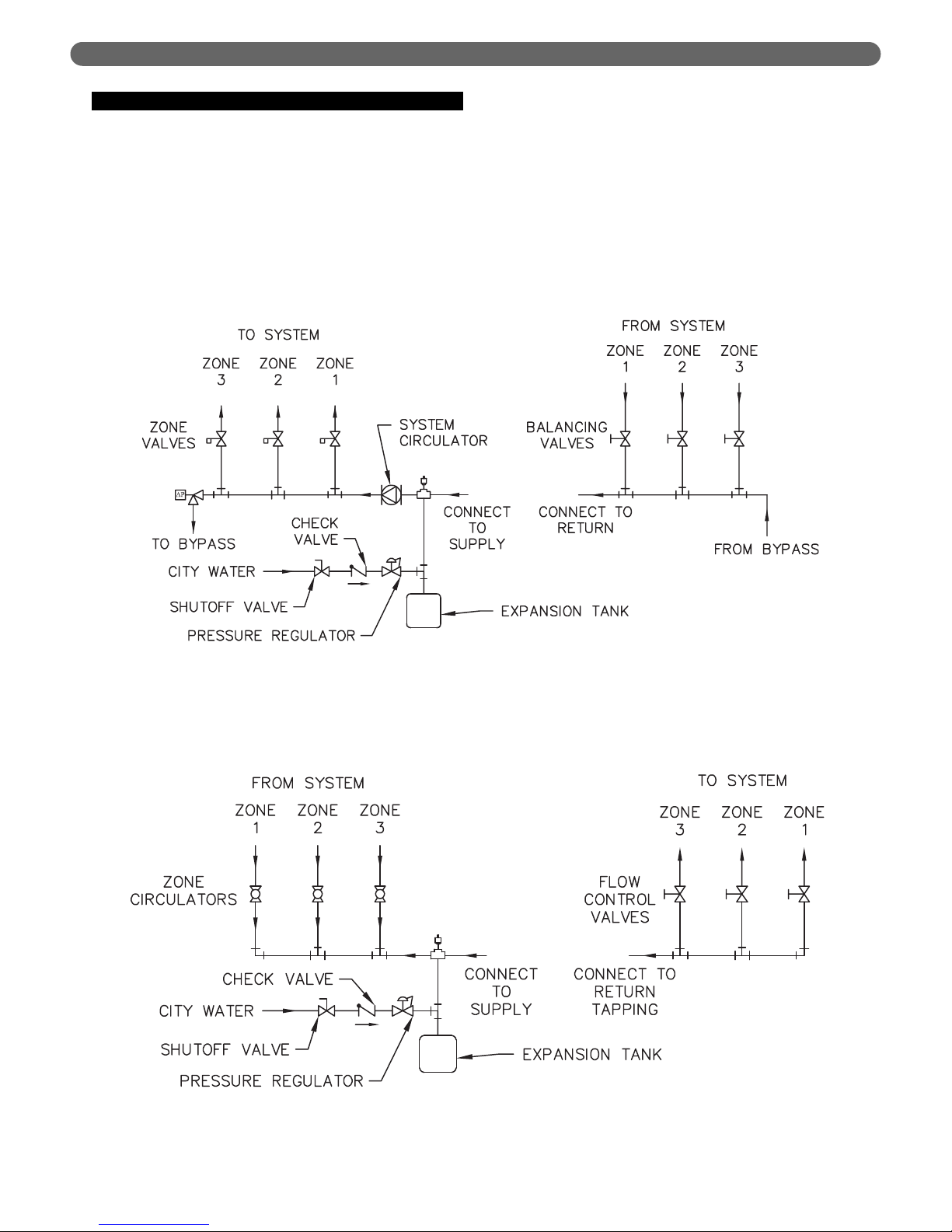

C. PIPING FOR ZONED SYSTEMS

1. See Figures 3.5 and 3.6 for basic zoned system

layouts.

2. Run each zone pipe down then up to zone to

prevent air accumulation in piping.

3. If required, provide means to isolate and drain each

zone separately.

Figure 3.5: Zone Piping with Zone Valves

Figure 3.6: Zone Piping with Circulators

7

WATER PIPING AND CONTROLS

D. EXPANSION TANK

1. Consult the tank manufacturer’s instructions for

specific information relating to tank installation. Size

the expansion tank for the required system volume

and capacity. See Table 10.2 in Section 10 for boiler

water capacity.

2. Expansion tanks are available with built-in fill valves

and check valves for reducing supply water pressure

and maintaining minimum system pressure. Check

the design features of the tank and provide valves as

necessary.

Refer back to Figure 3.1 for typical expansion tank piping.

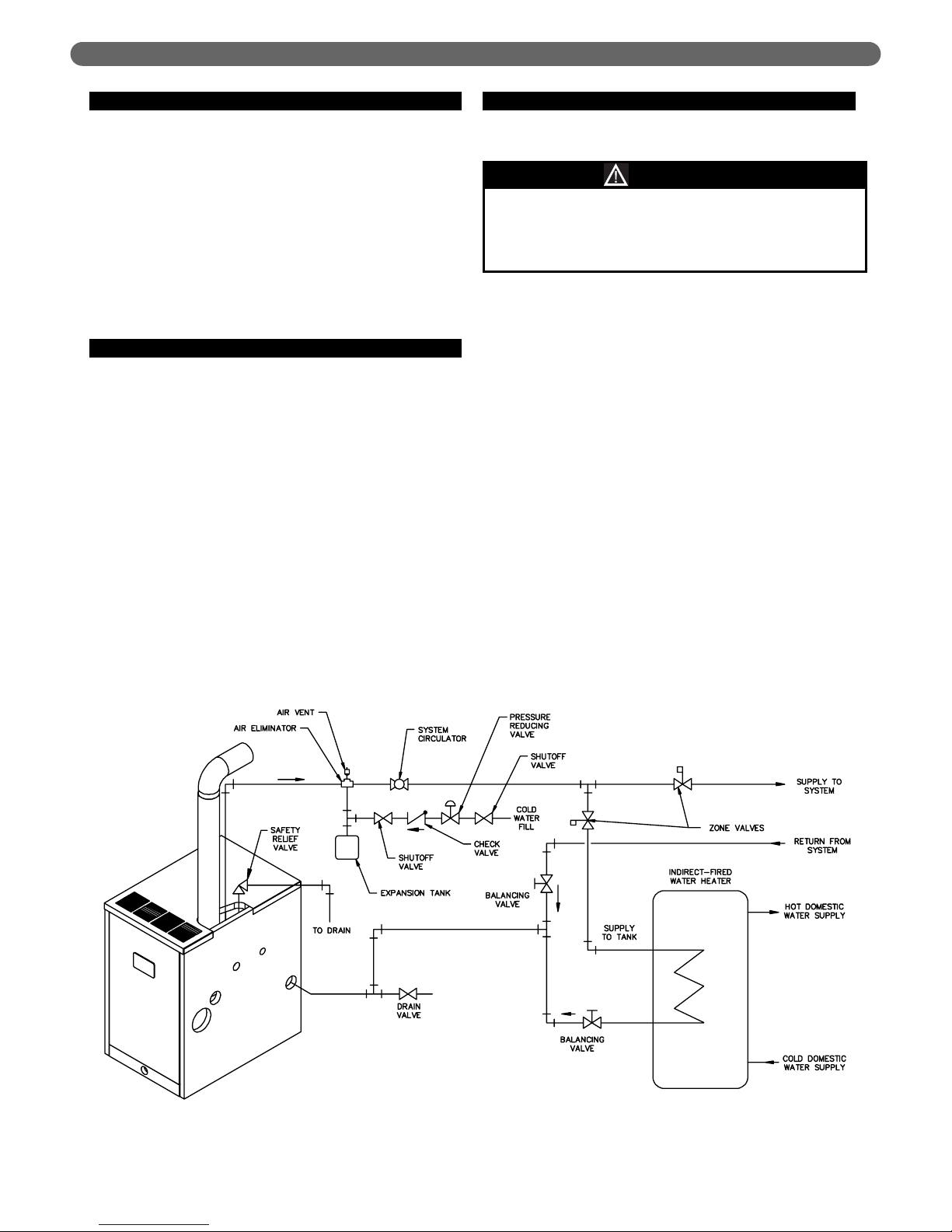

E. INDIRECT-FIRED WATER HEATER

If the boiler is to be used in conjunction with an indirectfired water heater, refer to Figure 3.7 for typical piping.

Follow the instructions provided by the water heater

manufacturer. Pipe the water heater as a separate zone.

F. FREEZE PROTECTION

For new or existing systems that must be freezeprotected:

1. Glycol in hydronic applications is specially

formulated for this purpose. It includes inhibitors

which prevent the glycol from attacking metallic

system components. Make certain that the system

fluid is checked for the correct glycol concentration

and inhibitor level.

2. The glycol solution should be tested at least once a

year and as recommended by the antifreeze

manufacturer.

3. Glycol solutions expand more than water. For

example, a 50% by volume solution expands 4.8%

in volume for a temperature increase from 32°F (0°C)

to 180°F (82°C) , while water expands 3% with the

same temperature rise. Allowance must be made for

this expansion in system design.

4. For more information, consult the PB Heat Water

Installation Survey and the antifreeze manufacturer.

Figure 3.7: Typical Piping with Indirect-Fired Water Heater

Use only inhibited propylene glycol solutions of up to

50% by volume with water. Ethylene glycol is toxic

and can attack gaskets and seals used in hydronic

systems.

WARNING

VENTING, VENTILATION AND AIR INLET

A. GENERAL

Install vent system in accordance with Venting of

Equipment part of the National Fuel Gas Code, ANSI

z223.1/NFPA 54 or sections 7.2, 7.3 or 7.4 of CAN/CSA

B149.1, Natural Gas and Propane Installation Code.

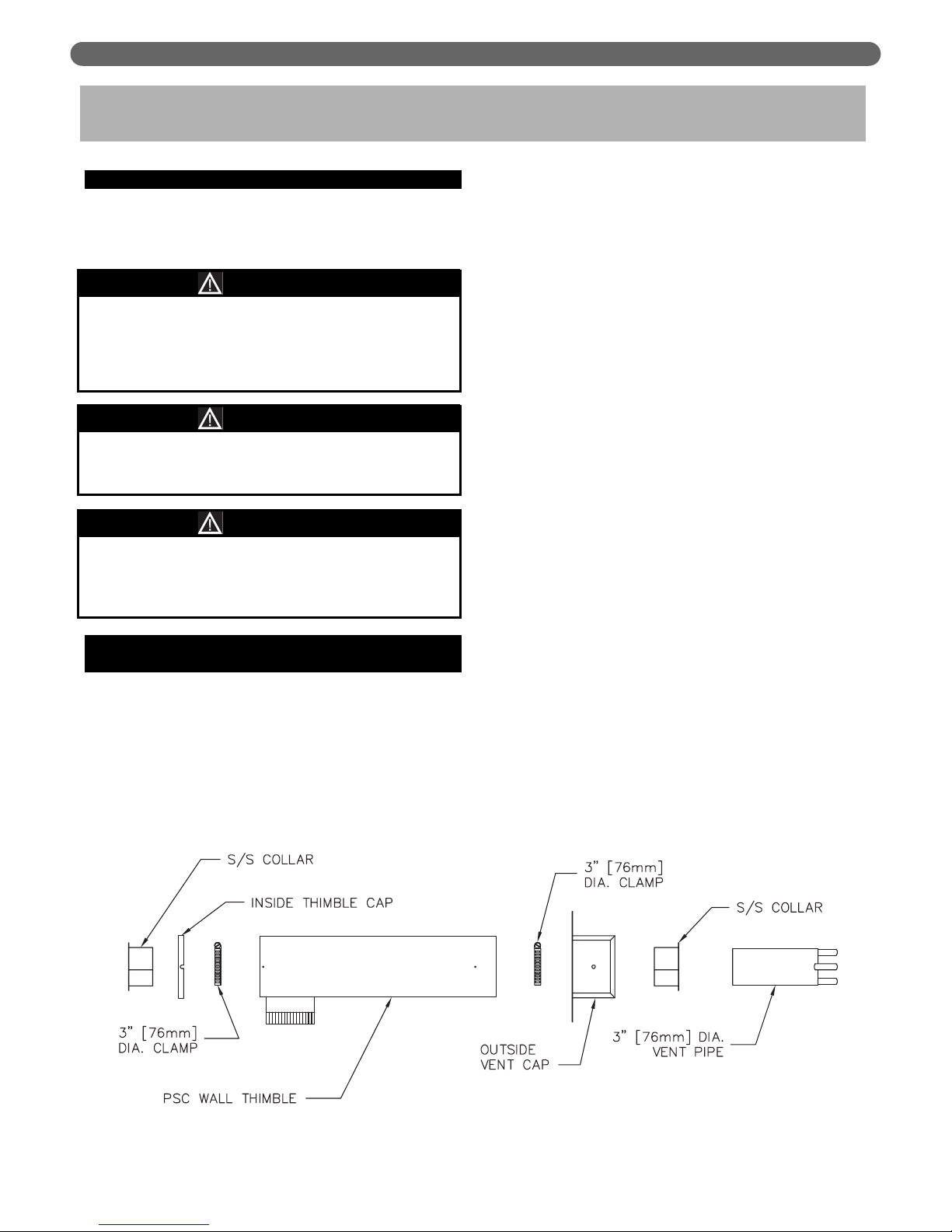

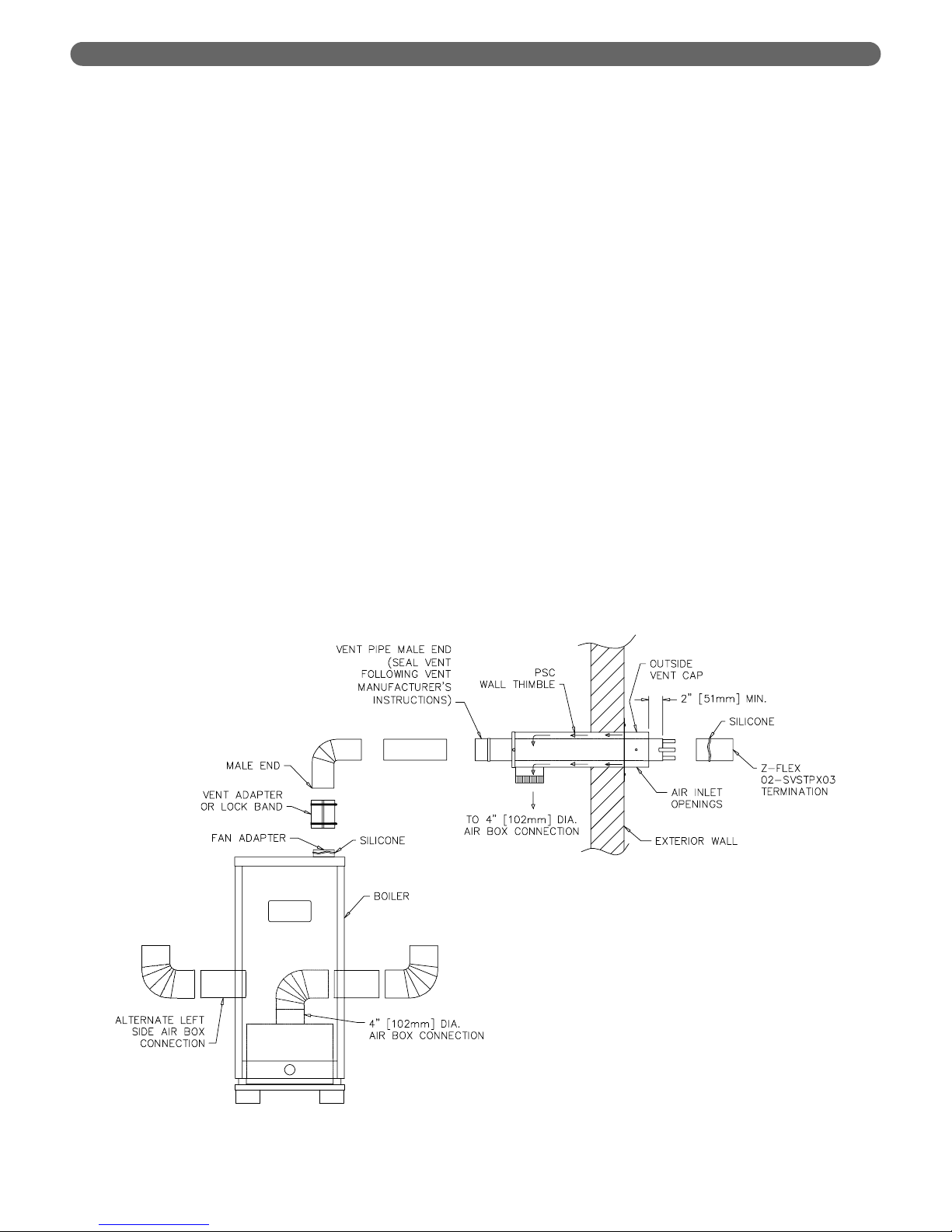

B. PSC WALL THIMBLE (SIDEWALL

VENTING ONLY)

1. Determine vent cap (terminal) location.

a. Must be within the maximum and minimum vent

and air intake lengths shown in Tables 4.1 and 4.2.

b. Maximum wall thickness for the 19-1/2″ (495 mm)

long PSC Wall Thimble (standard) is 11-1/2″ (292

mm). Maximum wall thickness for the optional

28″ (711 mm) long thimble is 20″

(508 mm).

c. Provide 2″ (51 mm) clearance between vent pipe

and combustible construction. No clearance is

required between Thimble and combustible

construction.

d. Provide 3 feet (1 meter) clearance above any

forced air inlet within 10 feet (3 meters).

e. Provide 1 foot (0.3 meters) clearance below, 1 foot

(0.3 meters) beside, or 1 foot (0.3 meters) above

any door, window, or gravity air inlet into any

building.

f. Provide 1 foot (0.3 meters) clearance between

bottom of vent terminal and ground level and

normal snow lines.

g. Provide 4 feet (1.2 meters) horizontal clearance

from from electric meters, gas meters, regulators

and relief equipment. In Canada, this dimension

must be 6 feet (2 meters).

h. Do not locate vent terminal over public walkways

where condensate could create a nuisance or

hazard.

i. When adjacent to a public walkway, locate vent

terminal at least 7 feet (2.1 meters) above grade.

j. Do not locate directly under roof overhangs to

prevent icicles from forming.

2. Cut a 5-1/8″ (130 mm) square hole in sidewall to

allow Peerless Wall Thimble to go through.

3. Insert Thimble from inside wall with 4″ (102 mm)

diameter air inlet connection facing down. Extend

Thimble 3-1/2″ (89 mm) past outside wall surface.

The cut-out opening of thimble is pointed down.

4. Use a minimum 2-1/2 foot (762 mm) piece of 3″

(76 mm) diameter AL29-4C stainless steel vent pipe

for insertion through Wall Thimble. See Vent Pipe

section below for vent pipe requirements.

4. VENTING

Figure 4.1: PSC Wall Thimble

This vent system will operate with a positive

pressure in the vent pipe. Do not connect vent

connectors serving appliances vented by natural

draft into any portion of mechanical draft systems

operating under positive pressure.

Flue gases will condense as they exit the vent

termination.This condensate can freeze on exterior

building surfaces which may cause discoloration of

these surfaces.

NOTICE

WARNING

WARNING

All joints of positive pressure vent systems must be

sealed completely to prevent leakage of flue products

into the living space.

8

VENTING, VENTILATION AND AIR INLET

5. Slide Stainless Steel Collar over vent pipe and slide

3″ (76 mm) diameter hose clamp and collar to vent

pipe.

6. Insert pipe with collar through Outside Vent Cap and

slide 3″ (76 mm) diameter hose clamp and collar to

vent pipe.

7. Leave at least 2″ (51 mm) of vent pipe protruding

beyond face of Vent Cap and secure hose clamp and

collar to vent pipe.

8. Place Outside Vent Cap over Wall Thimble with air

openings in Vent Cap facing down. Secure Cap to

Thimble with #10 sheet metal screws.

9. Place 3″ (76 mm) diameter hose clamp over pipe

protruding through inside of Wall Thimble.

10. Place Inside Thimble Cap and Collar onto Wall

Thimble. Access hose clamp through 4″ (102 mm)

diameter collar on bottom of Thimble and secure hose

clamp over collar and vent pipe as per step 7 above.

11. Secure Inside Thimble cap to Wall Thimble with #10

screws. Seal Thimble Cap perimeter with silicone.

12. Seal all openings between Wall and Thimble and

around the 3″ (76 mm) diameter stainless steel vent

pipe that protrudes through inside and outside of

Wall Thimble.

13. Add any bracing that may be needed to support Wall

Thimble on inside of wall structure.

14. Secure Outside Vent Cap to exterior wall with four

#10 sheet metal screws provided.

15. Attach Z-Flex #2SVSTPF03 terminal to protruding

vent pipe. Refer to Figure 4.2. To attach to HEATFAB pipe, insert into pipe end and fold over tabs to

secure. Otherwise, silicone terminal to vent pipe.

Figure 4.2: Side Wall Venting System

9

10

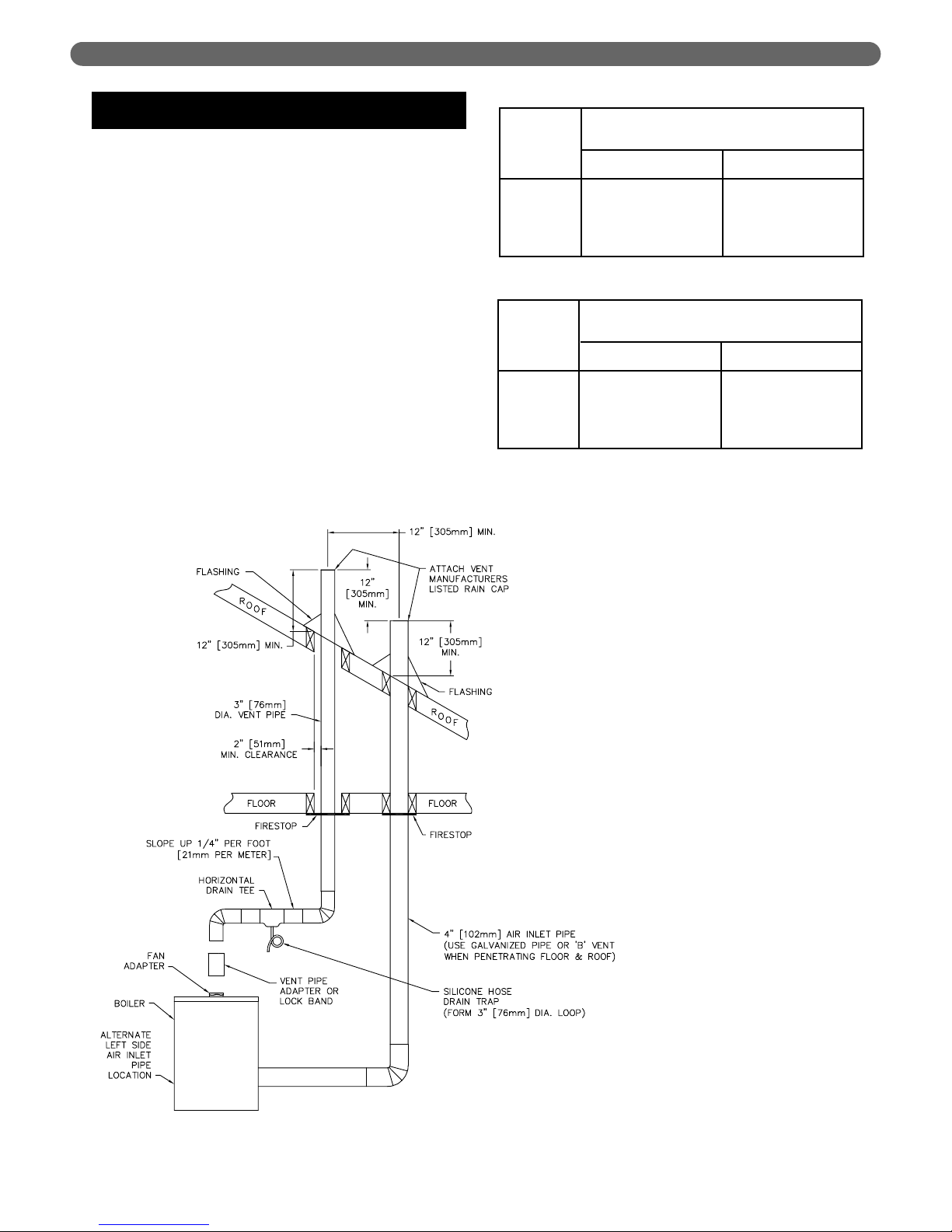

VENTING, VENTILATION AND AIR INLET

C. ROOF TERMINATIONS (VERTICAL

VENTING)

1. Vent pipe and air inlet terminations must be within

the maximum and minimum vent and air intake

lengths shown in Tables 4.1 and 4.2.

2. Vent pipe and air inlet pipe must terminate 12"

(305 mm) above expected snow lines. Vent pipe

must be a minimum 12" (305 mm) above and 12"

(305 mm) horizontally from air inlet pipe. See Figure

4.3.

3. Attach a vent manufacturer's listed rain cap to both

the vent pipe and air inlet pipe.

4. Provide 2" (51 mm) clearance between vent pipe

and combustible construction. No clearance is

required between air inlet pipe and combustible

construction.

5. See vertical venting section in vent manufacturer's

instructions for recommendations for penetration

through roof.

52 feet (15.5 m)

52 feet (15.5 m)

45 feet (13.5 m)

45 feet (13.5 m)

PSC-03

PSC-04

PSC-05

PSC-06

Boiler Model

8 feet (2.5 m)

8 feet (2.5 m)

8 feet (2.5 m)

8 feet (2.5 m)

Table 4.1:

*Equivalent Length of 3″ (76 mm) Diameter

Stainless Steel Vent Pipe

Minimum Vent Length

Maximum Vent Length

70 feet (21.0 m)

70 feet (21.0 m)

63 feet (19.0 m)

63 feet (19.0 m)

PSC-03

PSC-04

PSC-05

PSC-06

Boiler Model

12 feet (4.0 m)

12 feet (4.0 m)

12 feet (4.0 m)

12 feet (4.0 m)

Table 4.2:

*Equivalent Length of 4″ (102 mm) Diameter

Aluminum/Galvanized Air Inlet Pipe

Minimum Length

Maximum Length

*Each 90° elbow equals 5 feet (1.5 meters) of equivalent

length.

Figure 4.3: Vertical Venting System

Loading...

Loading...