Page 1

Boiler

Peerless

®

Gas

Installation,

Operation &

Maintenance

Manual

Combi 160

™

INSTALLER, THESE INSTRUCTIONS TO BE AFFIXED ADJACENT TO THE BOILER.

WARNING!!!

This manual must

be used by a

qualified heating

installer/service

technician. Read all

instructions,

including this

manual, before

installing. Perform

steps in the order

given. Failure to

comply could result

in severe personal

injury, death, or

substantial property

damage.

Save this manual for

future reference.

As an ENERGY STAR®Partner, PB Heat, LLC has determined that

this product meets the ENERGY STAR guidelines for energy efficiency.

Page 2

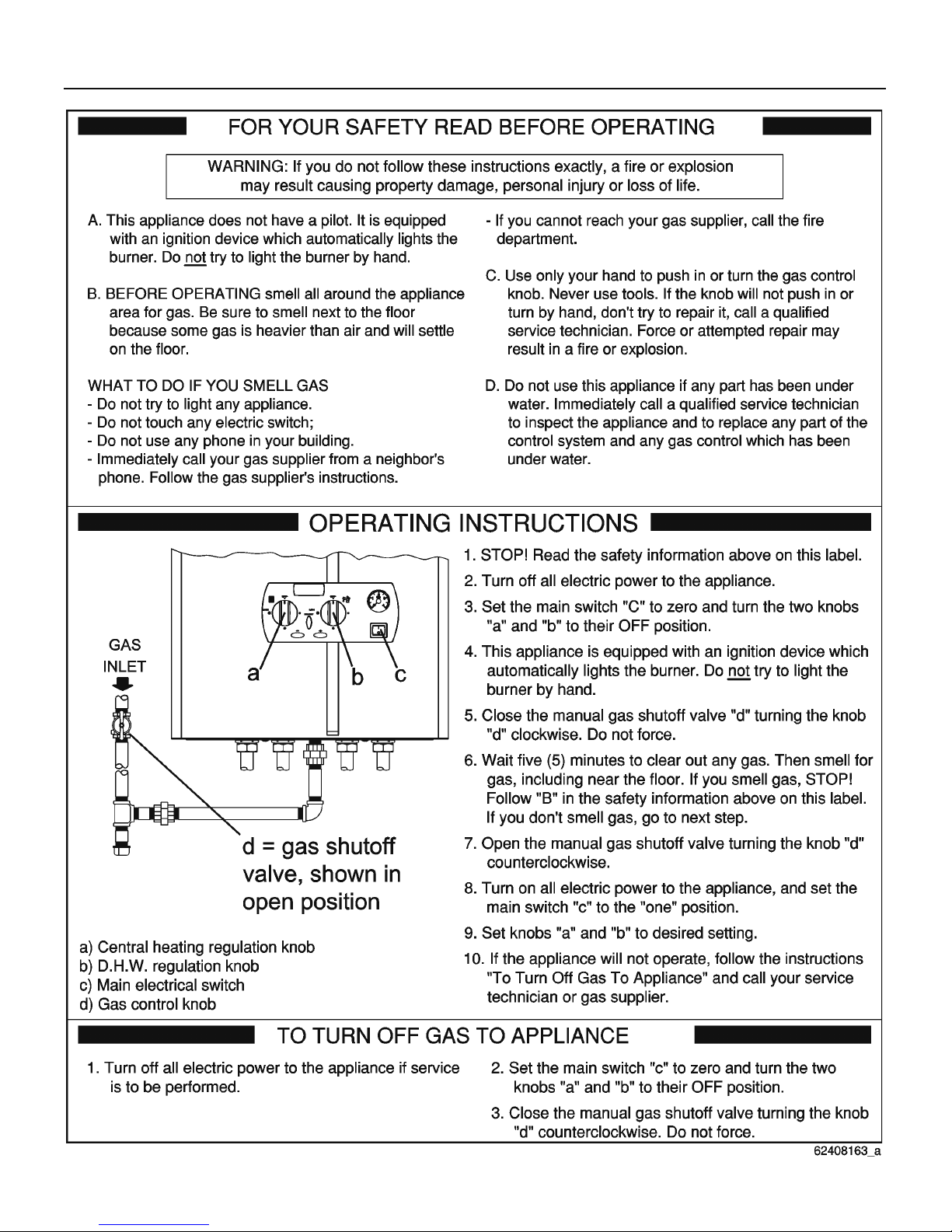

SAFETY INSTRUCTIONS

WARNING: If the information in these

instructions is not followed exactly, a fi re

or explosion may result causing property

damage, personal injury or death.

- Do not store or use gasoline or other

fl ammable vapors and liquids in the

vicinity of this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Immediately call your gas supplier from

a neighbor’s phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier,

call the fi re department.

- Installation and service must be performed

by a qualifi ed installer, service agency or

the gas supplier.

AVERTISSMENT: Assurez vous de bien

suivre les instructions données dans

cette notice pour réduire au minimum

le risque d’incendie ou d’explosion ou

pour éviter tout dommage matériel, toute

blessure ou la mort

- Ne pas entreposer ni utiliser d’essence

ou ni d’autres vapeurs ou liquides

infl ammables à proximité de cette appareil

ou de tout autre appareil.

- QUE FAIRE SI VOUS SENTEZ UNE ODEUR

DE GAZ:

• Ne pas tenter d’allumer l’appareil.

• Ne touchez à aucun interrupteur, ne

pas vous servir des téléphones se

trouvant dans le bâtiment

• Appelez immédiatement votre

fournisseur de gas de puis un voisin.

Suivez les instructions du fournisseur.

• Si vous ne pouvez rejoindre le

fournisseur, appelez le service des

incendies

- L’installation et l’entretien doivent être

assurés par un installateur ou un service

d’entretien qualifi é ou par le fournisseur

de gaz.

2

Page 3

SAFETY INSTRUCTIONS

3

Page 4

SAFETY INSTRUCTIONS

WARNING!!! These instructions must be read

prior to installation. If the information in these

instructions is not followed exactly, a fi re or

explosion may result, causing property damage,

personal injury, or death.

Liability

The manufacturer declines all liability, contractual or

otherwise, for damages resulting from the incorrect

installation of this boiler. This includes the failure

to comply with the instructions provided by the

manufacturer or from a failure to comply with the

applicable local and national regulations in force.

The manufacturer declines all liability, contractual

or otherwise, for any damage to people, animals or

property caused by the incorrect use of this boiler or

inadequate or incorrect service or maintenance.

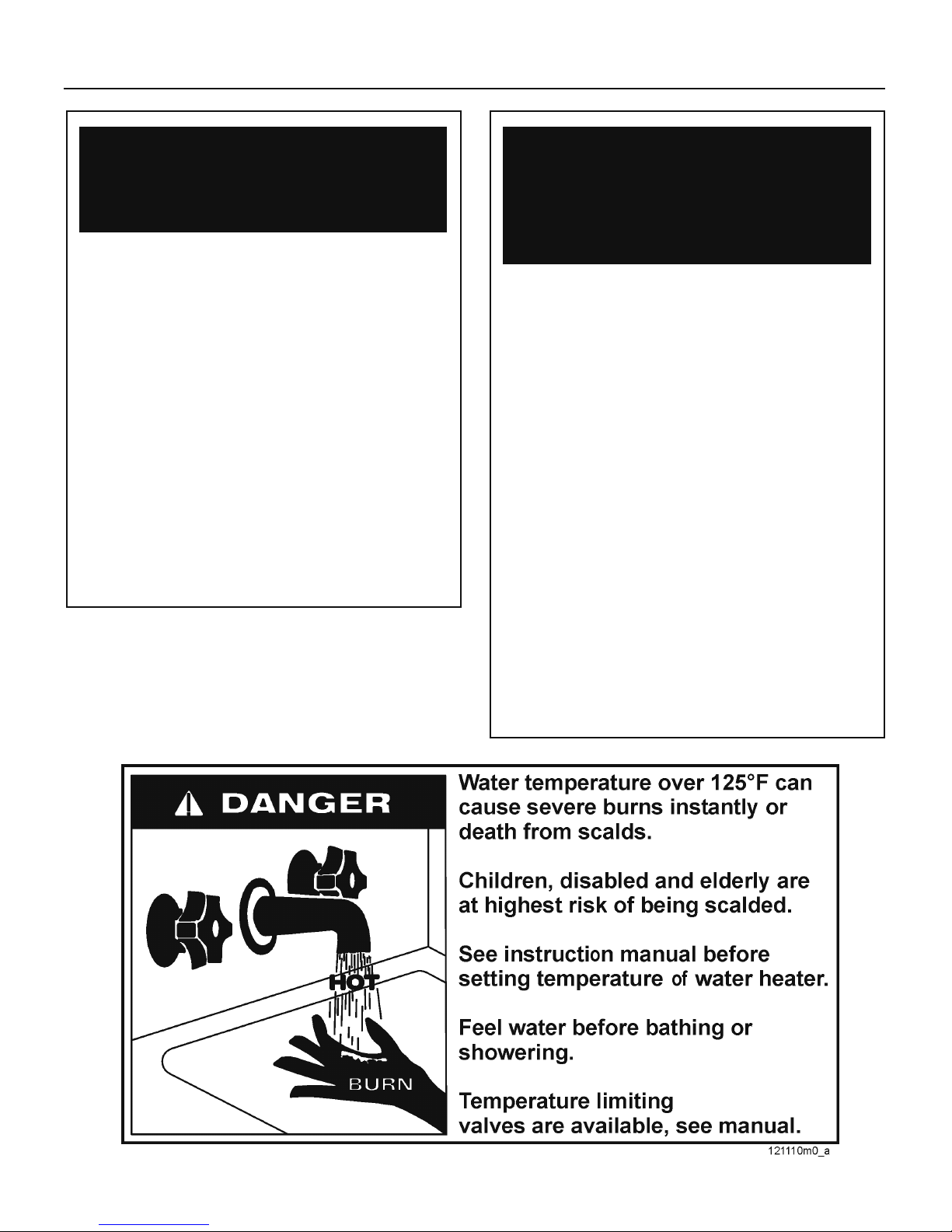

Hazards and Your Safety - Hot Water Can Scald!

Water temperature over 125°F (52°C) can cause

severe burns instantly, or death from scalds. Children,

the disabled, and the elderly are at highest risk of

being scalded; see instruction manual before setting

temperature at boiler! Feel water before bathing or

showering.

If there is a smell of combustion products, turn the

unit off, air out the room and call a licensed authorized

technician. Failure to take proper precautions can

result in excessive levels of carbon monoxide which

can cause severe personal injury or death!

Qualifi ed Technicians:

Qualifi ed technicians are individuals with specifi c,

technical training in space heating systems, domestic

hot water systems, fuel gas systems and electrical

systems. These individuals must have the legally

required qualifi cations.

Installation and Alterations:

Licensed, authorized personnel must carry out the

installation and calibration of the boiler. Never modify

the boiler or its fl ue gas carrying components in any

way. This boiler must be properly vented. Failure to

follow these instructions could result in personal injury

or death!

For safety and environmental reasons, the packing

materials must be properly disposed of. Any replaced

part or packaging should never be left within the reach

of children. Failure to follow these instructions could

result in severe personal injury

In the event of a breakdown and/or malfunction

of the boiler, turn off the unit and do not make any

attempt to repair it. The boiler must be serviced

exclusively by a qualifi ed technician using original

spare parts. Failure to comply with this requirement

may compromise the safety of the unit and void its

warranty.

Use the service switch to disconnect the boiler

from the electrical circuit before carrying out any

service or maintenance operations.

Electrical

CAUTION: Label all wires prior to disconnection when

servicing controls. Wiring errors can cause improper

and dangerous operation. Verify proper operation after

servicing.

ATTENTION: Au moment de l’entretien des

commandes, étiquetez tous les fi ls avant de les

débrancher. Des erreurs de câblage peuvent entraîner

un fonctionnement inadéquat et dangereux. S’assurer

que l’appareil fonctionne adéquatement une fois

l’entretirn terminé.

Correct Use:

This boiler must only be used for the purpose for which

it has been expressly designed: heating of water for

closed circuit systems for central heating and the

production of domestic hot water.

Should overheating occur or the gas supply fail

to shut off, do not turn off or disconnect the electrical

supply to the pump. Instead, shut off the gas supply at

a location external to the appliance.

En cas de surchauffe ou si l’alimentation de gaz

ne peut être coupée, ne pas couper ni débranch

l’alimentation électrique de la ponpe. Fermer plutôt le

robinet d’admission de gaz à l’extérieur de l’appareil

Do not use this appliance if any part has been

under water. Immediately call a qualifi ed service

technician to inspect the appliance and to replace any

part of the control system and any gas control, which

has been under water.

N’utilisez pas cet appareil s’il a été plongé dans

l’eau, même partiellement. Faites inspecter l’appareil

par un tecnicien qualifi é et remplacez toute partie du

système de contrôle et toute commande qui ont été

plongés dans l’eau.

Do not obstruct the air intake or vent pipe

terminals. Failure to take proper precautions can

result in excessive levels of carbon monoxide which

can cause severe personal injury or death!

Maintenance:

At least once a year the user must call in a licensed

authorized technician for routine maintenance.

Any optional extras or kit fi tted subsequently

must be original Cosmogas parts.

4

Page 5

SAFETY INSTRUCTIONS

Local approval: of the fl ue system and the

condensate connection to the public sewer system may

be required.

Local approval: The local building regulations

stipulating the installation rules at the time of installation

should be followed.

Defects: If you fi nd any defects you must inform the

owner of the system of the defect and associated hazard

in writing.

When servicing the boiler, to avoid severe burns,

allow the boiler to cool before performing maintenance.

When calling or writing about the boiler- Please

have the boiler model and serial number from the boiler

rating plate.

Any claims for damage or shortage in shipment

must be fi led immediately against the transportation

company by the consignee.

Factory warranty (shipped with unit) does

not apply to units improperly installed or improperly

operated.

5

Page 6

TABLE OF CONTENTS

SAFETY INSTRUCTIONS ................................................................................................................................................ 2

TABLE OF CONTENTS ....................................................................................................................................................6

1 - INSTALLATION - CODE REQUIREMENTS .............................................................................................................. 10

1.1 - National installation legislation ...........................................................................................................................10

1.2 - Commonwealth of Massachusetts Installation Requirements ............................................................................10

2 - GENERAL INFORMATION ........................................................................................................................................ 12

2.1 - Key to symbols used ..........................................................................................................................................12

2.2 - Description of the Peerless

3 - MAIN COMPONENTS ............................................................................................................................................... 13

4 - FUNCTION OVERVIEW ............................................................................................................................................ 15

4.1 - Intended use and functions of the boiler ...........................................................................................................16

4.2 - Setting of the boiler ............................................................................................................................................16

4.3 - Effi ciency up to 98% ...........................................................................................................................................17

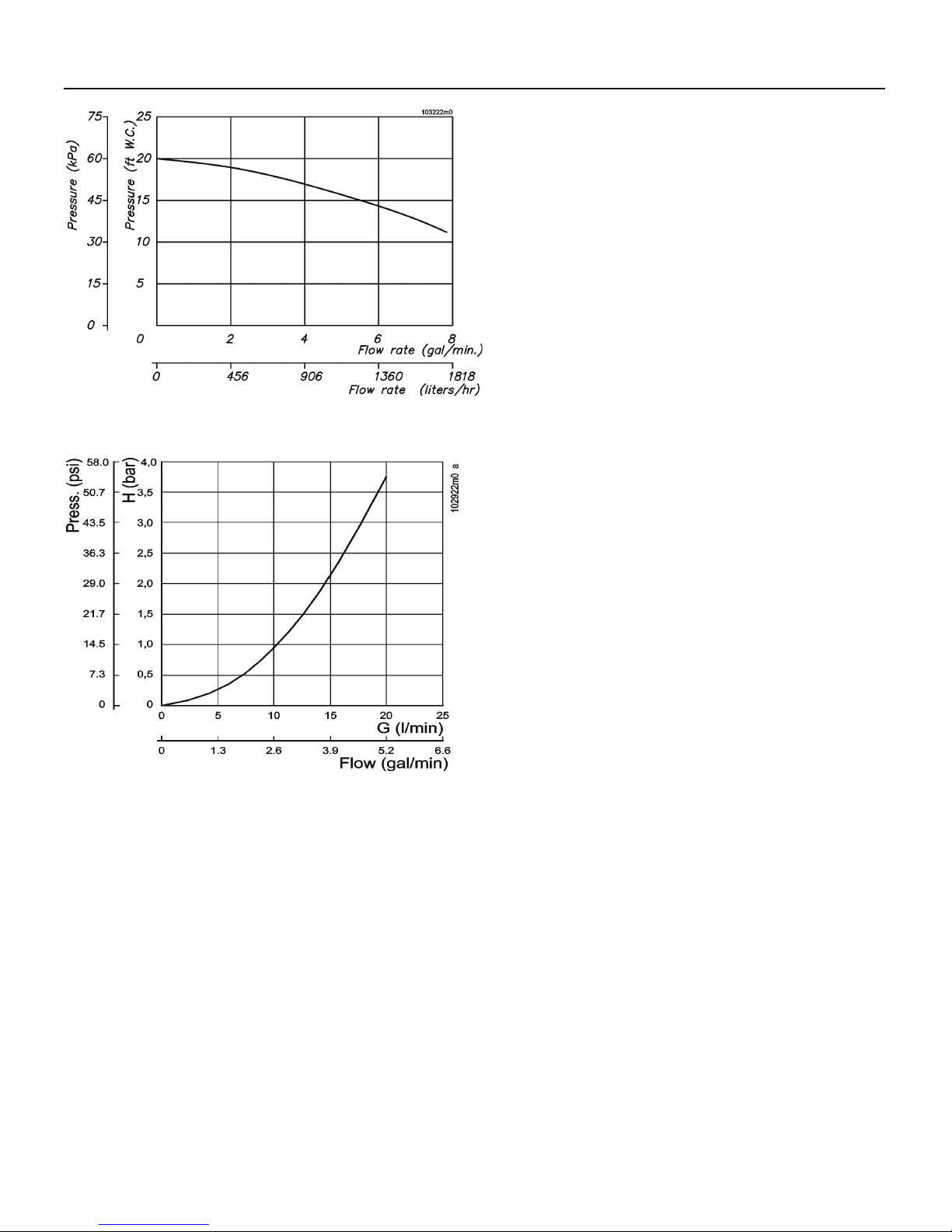

4.4 - Characteristic curves of heating system’s residual head ...................................................................................18

4.5 - Characteristic curve of the domestic side ..........................................................................................................18

5 - INSTALLATION - Mounting & gas and water connections ................................................................................... 19

5.1 - Clearances for installation and servicing ............................................................................................................19

5.2 - Clearances from combustible material ...............................................................................................................19

5.3 - Choosing the installation location .......................................................................................................................20

5.4 - Mounting the boiler .............................................................................................................................................21

5.5 - Gas and water connections ................................................................................................................................21

5.6 - Condensate disposal ..........................................................................................................................................22

5.7 - Near boiler heating piping components ..............................................................................................................22

5.8 - Relief valve .........................................................................................................................................................23

5.9 - Supply and return piping ....................................................................................................................................23

5.9.1 - Converting a combi boiler into a heating only boiler .............................................................................24

5.10 - Low temperature heating systems ...................................................................................................................24

5.11 - Use of glycol and other chemicals ....................................................................................................................24

5.12 - Domestic hot and cold water ............................................................................................................................24

5.13 - Gas supply piping .............................................................................................................................................24

5.14 - Propane gas .....................................................................................................................................................25

5.15 - Operating at high altitudes ...............................................................................................................................25

5.16 - Convert the boiler from Natural Gas to Propane Gas or vice versa .................................................................26

5.17 - Suggested piping and wiring connections ........................................................................................................28

6 - INSTALLATION - Electrical connections ................................................................................................................29

6.1 - Electrical connections: overview ........................................................................................................................29

6.2 - Connecting the power supply cable ...................................................................................................................30

6.3 - Choosing the room thermostat ...........................................................................................................................30

6.4 - Thermostat wiring ...............................................................................................................................................30

6.5 - Installing the outdoor temperature sensor (optional) ..........................................................................................31

6.6 - Alarm output .......................................................................................................................................................31

7 - INSTALLATION - Indirect storage tank connections .............................................................................................32

7.1 - Connecting the boiler to an indirect storage tank ..............................................................................................32

7.2 - Indirect water heater priority selection ..............................................................................................................33

8 - INSTALLATION - Vent & combustion air ................................................................................................................ 34

8.1 - Removing of a boiler from a common venting system .......................................................................................34

8.2 - Venting systems .................................................................................................................................................35

8.3 - Design of the venting system .............................................................................................................................37

8.4 - Prevent Combustion air contamination ..............................................................................................................37

8.5 - Install Vent and Combustion air piping ...............................................................................................................37

®

Combi 160™: .........................................................................................................12

6

Page 7

TABLE OF CONTENTS

8.6 - Air inlet pipe materials ........................................................................................................................................39

8.6.1 - Sealing of Type “B” double-wall or galvanized air inlet pipe material ....................................................39

8.6.2 - Sealing of PVC, CPVC or ABS air inlet pipe .........................................................................................39

8.7 - PVC/CPVC vent piping materials .......................................................................................................................40

8.7.1 - Installing PVC/CPVC vent and air piping ..............................................................................................40

8.7.2 - PVC/CPVC air intake/vent connections ................................................................................................40

8.8 - Flue terminal location in compliance with CAN/CSA B149 ................................................................................42

8.9 - Single pipe vent (not sealed combustion) ..........................................................................................................43

8.9.1 - Combustion Air and Ventilation openings .............................................................................................43

8.9.2 - Determine location ................................................................................................................................44

8.10 - Sidewall termination - Two pipes ......................................................................................................................45

8.10.1 - Vent/air termination .............................................................................................................................45

8.10.2 - Determine location ..............................................................................................................................45

8.10.3 - Prepare wall penetrations ...................................................................................................................47

8.10.4 - Termination and fi ttings .......................................................................................................................47

8.10.5 - Multiple vent/air terminations ..............................................................................................................47

8.11 - Sidewall termination - Concentric vent ............................................................................................................. 48

8.11.1 - Description and usage ........................................................................................................................48

8.11.2 - Sidewall termination installation .......................................................................................................... 48

8.11.3 - Multiventing sidewall terminations .......................................................................................................49

8.12 - Vertical termination - Two pipes ....................................................................................................................... 50

8.12.1 - Determine location ..............................................................................................................................50

8.12.2 - Prepare roof penetrations ...................................................................................................................50

8.12.3 - Termination and fi ttings .......................................................................................................................50

8.12.4 - Multiple vent/air terminations ..............................................................................................................51

8.13 - Vertical termination - Concentric vent ..............................................................................................................52

8.13.1 - Description and usage ........................................................................................................................52

8.13.2 - Determine location ..............................................................................................................................52

8.13.3 - Vertical termination installation ...........................................................................................................52

8.13.4 - Multiventing vertical terminations ........................................................................................................53

8.13.5 - Alternate vertical concentric venting ...................................................................................................54

8.14 - Existing vent as a chase ..................................................................................................................................55

9 - INSTALLATION - Split venting system ...................................................................................................................56

9.1 - Split system (polypropylene) or AL29-4C (UL 1738/UL C 636) system .............................................................56

9.2 - Split system components ...................................................................................................................................58

9.3 - Split system components ...................................................................................................................................59

9.4 - Split system: installation examples ....................................................................................................................60

10 - INSTALLATION - Coaxial venting system ............................................................................................................61

10.1 - Coaxial system .................................................................................................................................................61

10.2 - Coaxial system components ............................................................................................................................62

10.3 - Coaxial system components ............................................................................................................................63

10.4 - Coaxial system: installation examples .............................................................................................................64

11 - OPERATING ............................................................................................................................................................65

11.1 - Operating ..........................................................................................................................................................65

11.1.1 - User instructions .................................................................................................................................65

11.1.2 - Filling the condensate trap .................................................................................................................. 65

11.1.3 - Filling the heating system ....................................................................................................................65

11.1.4 - Filling the domestic hot water heat exchanger ....................................................................................66

11.1.5 - Auto-purging the heating system ......................................................................................

...................66

7

Page 8

TABLE OF CONTENTS

11.2 - General warnings concerning gas supply ........................................................................................................66

11.3 - Confi rming the boiler’s gas type .......................................................................................................................66

11.4 - Gas type conversion .........................................................................................................................................66

11.5 - Start-up .............................................................................................................................................................66

11.6 - Ignition control testing ......................................................................................................................................67

11.7 - Gas supply pressure checking and adjustment ................................................................................................67

11.8 - Check the combustion air pressure ..................................................................................................................68

11.9 - Checking and adjusting CO2 levels .................................................................................................................69

11.10 - Adjusting the heating capacity ........................................................................................................................70

11.11 - Domestic hot water fl ow rate adjustment ........................................................................................................70

11.12 - Cold start boiler ..............................................................................................................................................70

12 - USE ..........................................................................................................................................................................71

12.1 - Check heating system pressure .......................................................................................................................71

12.2 - Overview ..........................................................................................................................................................71

12.3 - Displays ............................................................................................................................................................71

12.4 - Start-up procedure ...........................................................................................................................................72

12.5 - Summer mode ..................................................................................................................................................72

12.6 - Winter mode .....................................................................................................................................................72

12.7 - Adjusting the domestic hot water temperature .................................................................................................73

12.8 - Heating system temperature adjustment .........................................................................................................73

12.9 - Heating system type selection .........................................................................................................................73

12.10 - Outdoor reset adjustment ...............................................................................................................................73

12.10.1 - Outdoor reset applications ................................................................................................................73

12.10.2 - Outdoor reset adjustment precautions ..............................................................................................74

12.10.3 - Outdoor reset: setting parameters ....................................................................................................74

12.10.4 - Outdoor reset: zone adjustments ......................................................................................................74

12.10.5 - Outdoor reset activation ....................................................................................................................74

12.10.6 - Outdoor reset with room compensation ............................................................................................74

12.11 - Boiler switch settings ......................................................................................................................................76

12.12 - Delays, alarms and protective actions ...........................................................................................................76

12.13 - Circulator pump and three way valve protection ............................................................................................76

12.14 - Freeze protection ...........................................................................................................................................76

12.15 - Display in energy saving mode .....................................................................................................................76

12.16 - “Users’ menu” .................................................................................................................................................77

12.17 - “Installer’s menu” ............................................................................................................................................78

12.18 - Diagnostics .....................................................................................................................................................80

12.18.1 - Diagnostics: “L” lock-outs ..................................................................................................................81

12.18.2 - Diagnostics: “E” blocking errors ........................................................................................................83

13 - MAINTENANCE .......................................................................................................................................................85

13.1 - General precaution ...........................................................................................................................................85

13.2 - Removing the casing ........................................................................................................................................86

13.3 - Cleaning the burner and primary heat exchanger, fl ue gas side ...................................................................... 87

13.4 - Correct positioning of the ignition and fl ame detection electrodes ..................................................................88

13.5 - Domestic hot water heat exchanger .................................................................................................................88

13.6 - Condensate trap cleaning ................................................................................................................................89

13.7 - Circulator pump motor replacement .................................................................................................................90

13.8 - Expansion tank pressure ..................................................................................................................................90

13.9 - 3-way valve removal ........................................................................................................................................91

13.10 - Draining the heating side of the boiler ............................................................................................................92

13.11 - Draining the domestic hot water side of the boiler .........................................................................................92

8

Page 9

TABLE OF CONTENTS

13.12 - Overrides ........................................................................................................................................................92

13.12.1 - Auto-purging ......................................................................................................................................92

13.12.2 - Fan ...................................................................................................................................................92

13.12.3 - Minimum and maximum output .........................................................................................................92

13.12.4 - Checking the fl ame current ...............................................................................................................92

13.13 - Water and fl ue temperature sensor ................................................................................................................93

13.14 - Outdoor temperature sensor (optional) ..........................................................................................................93

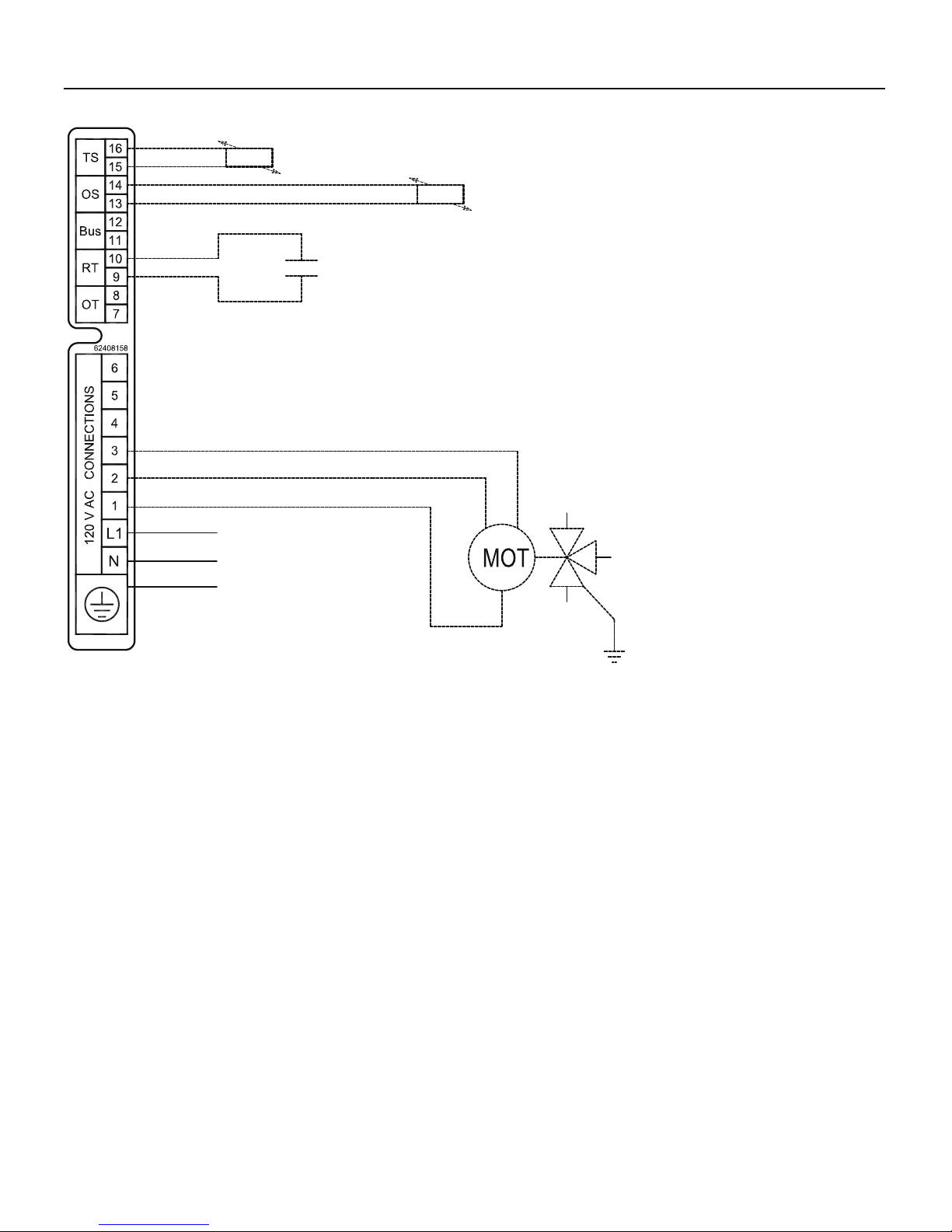

13.15 - Functional wiring diagram ..............................................................................................................................94

13.16 - Multiwire wiring diagram .................................................................................................................................96

14 - TECHNICAL DATA .................................................................................................................................................. 98

15 - SPARE PARTS ........................................................................................................................................................99

16 - READ OUT FLOW CHART ...................................................................................................................................102

9

Page 10

1 - INSTALLATION - CODE REQUIREMENTS

1.1 - National

installation

legislation

- The installation must conform to the

requirements of the authority having

jurisdiction or, in the absence of such

requirements, to the latest edition of

the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 and or CAN/CSA

B149.1, Natural Gas and Propane

Installation Code.

- Where required by the authority

having jurisdiction, the installation

must conform to the Standard for

Controls and Safety Devices for

Automatically Fired Boilers, ANSI/

ASME CSD-1.

NOTICE!

This boiler meets the safety and

other performance requirements as

specifi ed in ANSI Z21.13 standard

- Per DOE mandate, the operator

control incorporates an automatic

means (outdoor reset) of adjusting

the boiler hot water temperature for

hot water heating. The boiler must not

operate without the automatic means

enabled.

IMPORTANT!

In accordance with Section 325 (f)(3)

of the energy policy and conservation

Act, this boiler is equipped with a

feature that saves energy by reducing

the boiler water temperature as the

heating load decreases. This feature

is equipped with an override which is

provided primarily to permit the use

of an external management system

that serves the same function. THIS

OVERRIDE MUST NOT BE USED

UNLESS AT LEAST ONE OF THE

FOLLOWING CONDITIONS IS

TRUE:

An external energy management

system is installed that reduces

the boiler water temperature as the

heating load decreases.

This boiler is not used for any

space heating.

This boiler is part of a modular

multiple boiler system having a total

input of 300,000 BTU/hr or greater.

This boiler is equipped with a

tankless coil.

1.2- Commonwealth

of Massachusetts

Installation

Requirements

In the Commonwealth of

Massachusetts, the installation

must be performed by a licensed

plumber or gas fi tter. WARNING!!!

WARNING!!! Improper

venting can result in excessive

levels of carbon monoxide

which can cause severe

personal injury or death!

(a) For all side wall horizontally

vented gas fueled equipment

installed in every dwelling, building

or structure used in whole or in

part for residential purposes,

including those owned or operated

by the commonwealth and

where the side wall exhaust vent

termination is less than seven (7)

feet above fi nished grade, in the

area of the venting, including but

not limited to decks and porches,

the following requirements shall be

satisfi ed:

1. INSTALLATION OF CARBON

MONOXIDE DETECTORS. At

the time of installation of the side

wall horizontal vented gas fueled

equipment, the installing plumber

or gasfi tter shall observe that

a hard wired carbon monoxide

detector with an alarm and battery

back-up is installed on the fl oor

level where the gas equipment

is to be installed. In addition, the

installing plumber or gasfi tter shall

observe that a battery operated

or hard wired carbon monoxide

detector with an alarm is installed

on each additional level of the

dwelling, building or structure

served by the side wall horizontal

vented gas fueled equip-ment.

It shall be the responsibility of

the property owner to secure the

services of qualifi ed licensed

professionals for the installation

of hard wired carbon monoxide

detectors.

10

a. In the event that the side wall

horizontally vented gas fueled

equipment is installed in a crawl

space or an attic, the hard wired

carbon monoxide detector with

alarm and battery back-up may

be installed on the next adjacent

fl oor level.

b. In the event that the

requirements of this subdivision

can not be met at the time

of completion of installation,

the owner shall have a period

of thirty (30) days to comply

with the above requirements;

provided, however, that during

said thirty (30) day period,

a battery operated carbon

monoxide detector with an

alarm shall be installed.

2. APPROVED CARBON

MONOXIDE DETECTORS. Each

carbon monoxide detector as

required in accordance with the

above provisions shall comply with

NFPA 720 and be ANSI/UL 2034

listed and IAS certifi ed.

3. SIGNAGE. A metal or plastic

identifi cation plate shall be

permanently mounted to the

exterior of the building at a

minimum height of eight (8) feet

above grade directly in line with

the exhaust vent terminal for the

horizontally vented gas fueled

heating appliance or equipment.

The sign shall read, in print size

no less than one-half (1/2) inch

in size, “GAS VENT DIRECTLY

BELOW. KEEP CLEAR OF ALL

OBSTRUCTIONS”.

4. INSPECTION. The state or local

gas inspector of the side wall

horizontally vented gas fueled

equipment shall not approve

the installation unless, upon

inspection, the inspector observes

carbon monoxide detectors and

signage installed in accordance

with the provisions of 248 CMR

5.08(2)(a)1 through 4.

Page 11

1 - INSTALLATION - CODE REQUIREMENTS

(b) Exemptions

The following equipment is exempt

from 248 CMR 5.08(2)(a) 1 through

4:

1. The equipment listed in Chapter

10 entitled “Equipment Not

Required To Be Vented” in the

most current edition of NFPA 54

as adopted by the Board; and

2. Product Approved side wall

horizontally vented gas fueled

equipment installed in a room

or structure separate from the

dwelling, building or structure used

in whole or in part for residential

purposes.

(c) MANUFACTURER

REQUIREMENTS - GAS

EQUIPMENT - VENTING SYSTEM

PROVIDED.

When the manufacturer of Product

Approved side wall horizontally vented

gas equipment provides a venting

system design or venting system

components with the equipment,

the instructions provided by the

manufacturer for installation of the

equipment and the venting system

shall include:

1. Detailed instructions for the

installation of the venting system

design or the venting system

components; and

2. A complete parts list for the

venting system design or venting

system.

(e) A copy of all installation

instructions for all Product

Approved side wall horizontally

vented gas fueled equipment, all

venting instructions, all parts lists

for venting instructions, and/ or

all venting design instructions

shall remain with the appliance or

equipment at the completion of the

installation.

(d) MANUFACTURER

REQUIREMENTS – GAS

EQUIPMENT - VENTING SYSTEM

NOT PROVIDED.

When the manufacturer of a Product

Approved side wall horizontally

vented gas fueled equipment does not

provide the parts for venting the fl ue

gases, but identifi es “special venting

systems”, the following requirements

shall be satisfi ed by the manufacturer:

1. The referenced “special venting

system” instructions shall be

included with the appliance or

equipment installation instructions;

and

2. The “special venting systems”

shall be Product Approved by

the Board, and the instructions

for that system shall include a

parts list and detailed installation

instructions.

11

Page 12

2 - GENERAL INFORMATION

2.1 - Key to

symbols used

WARNING!!! Failure to follow

these indications can causing

an explosion, extensive property

damage, severe personal injury or

death!

CAUTION!!!

Electrical caution! Risk of electric

shock: failure to observe this warning

may compromise the smooth running

of the appliance or cause serious

damage to individuals, animals or

property.

CAUTION!!!

General caution. Failure to observe

this warning may compromise the

smooth running of the appliance or

cause serious damage to individuals,

animals or property.

Operation symbol

Important indication symbol

2.2 - Description

of the Peerless®

™

Combi 160

Combi version (space heating and

instantaneous D.H.W. production).

Modulating gas-fi red, condensing hot

water boiler, with sealed combustion

chamber and pre-mix burner, with

maximum power input of 160,000 Btu/

hr (47 kW) and minimum of 30,000

Btu/hr (9 kW)

:

12

Page 13

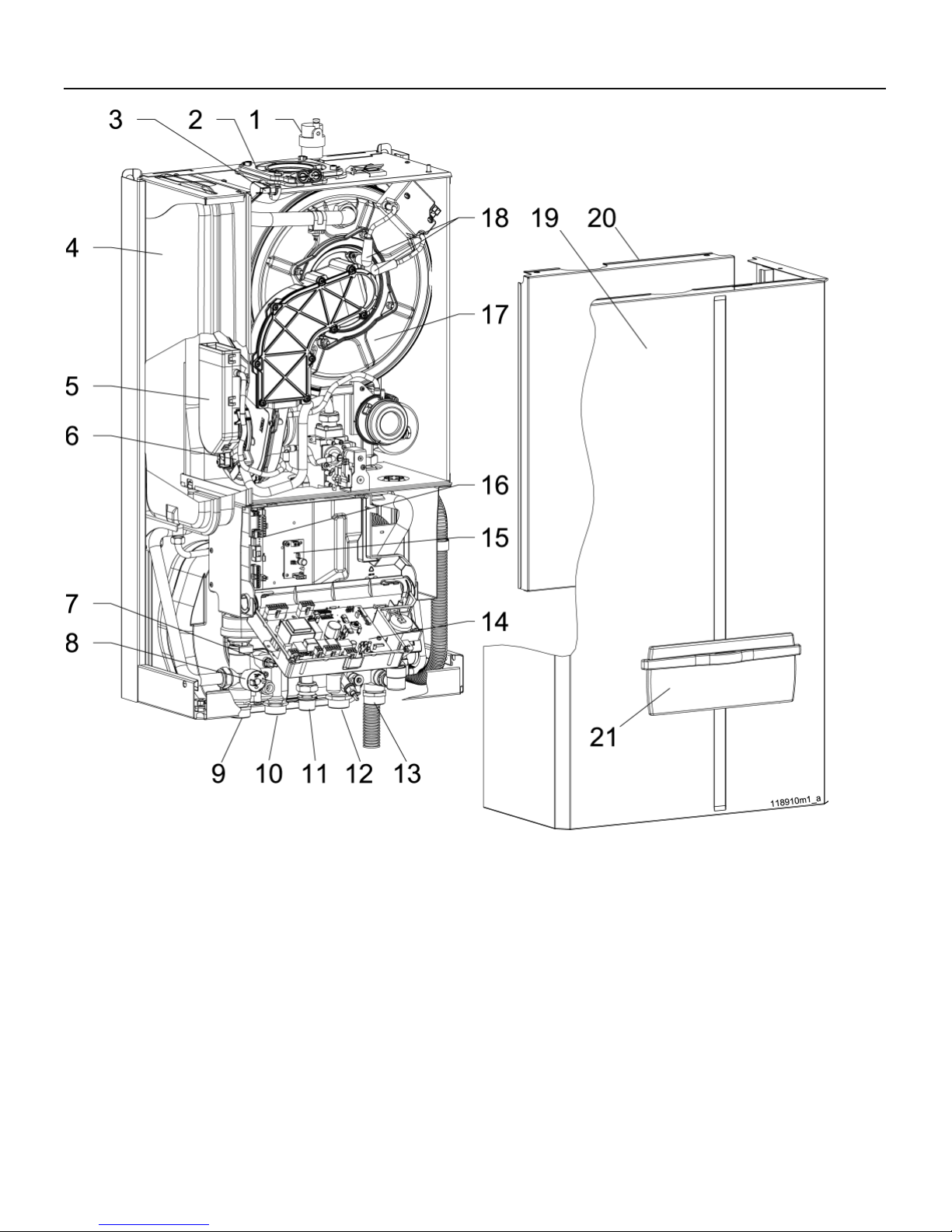

3 - MAIN COMPONENTS

1 - Automatic air vent

2 - Air intake and fl ue gas discharge fi tting (venting system)

3 - U7 fl ue gas temp. sensor and fl ue safety switch

4 - Expansion tank

5 - Inlet air plenum

6 - Air/gas mixer device

7 - U2 d.h.w. temp. sensor

8 - Heating pressure switch (low water cut-off)

9 - Heating supply connection

10 - DHW connection

11 - Gas inlet connection

12 - Cold water connection

Figure 1 - Main components

13 - Heating return connection

14 - Power Control Board

15 - Openterm interface board (optional)

16 - Connection board

17 - Primary heat exchanger

18 - Spark cable

19 - External jacket

20 - Combustion chamber door

21 - Instrument panel door

13

Page 14

3 - MAIN COMPONENTS

22 - Combustion analysis tap

23 - U1 supply temperature sensor

24 - Burner window

25 - Air/gas manifold

26 - U6 high temperature limit sensor

27 - Flue gas back fl ow preventer

28 - Fan

29 - Gas valve

30 - Heating pressure gauge

31 - Display

32 - Domestic hot water temperature control

33 - Heating temperature control

34 - On/off power switch

35 - Three way valve

36 - U3 domestic cold water temp. sensor

37 - Cable clamp

Figure 1 - Main components

38 - ASME Safety relief valve

39 - U8 return temperature sensor

40 - By-pass pipe

41 - Condensation discharge pipe

42 - Secondary heat exchanger for domestic hot water production

(For P/N see Section 15)

43 - Expansion tank connection pipe

44 - Circulator pump screw

45 - Circulator pump

46 - Condensation discharge trap

47 - Flame-proving electrode

48 - Burner

49 - Right ignition electrode

50 - Left ignition electrode

51 - Spark generator

52 - Flue pressure switch

14

Page 15

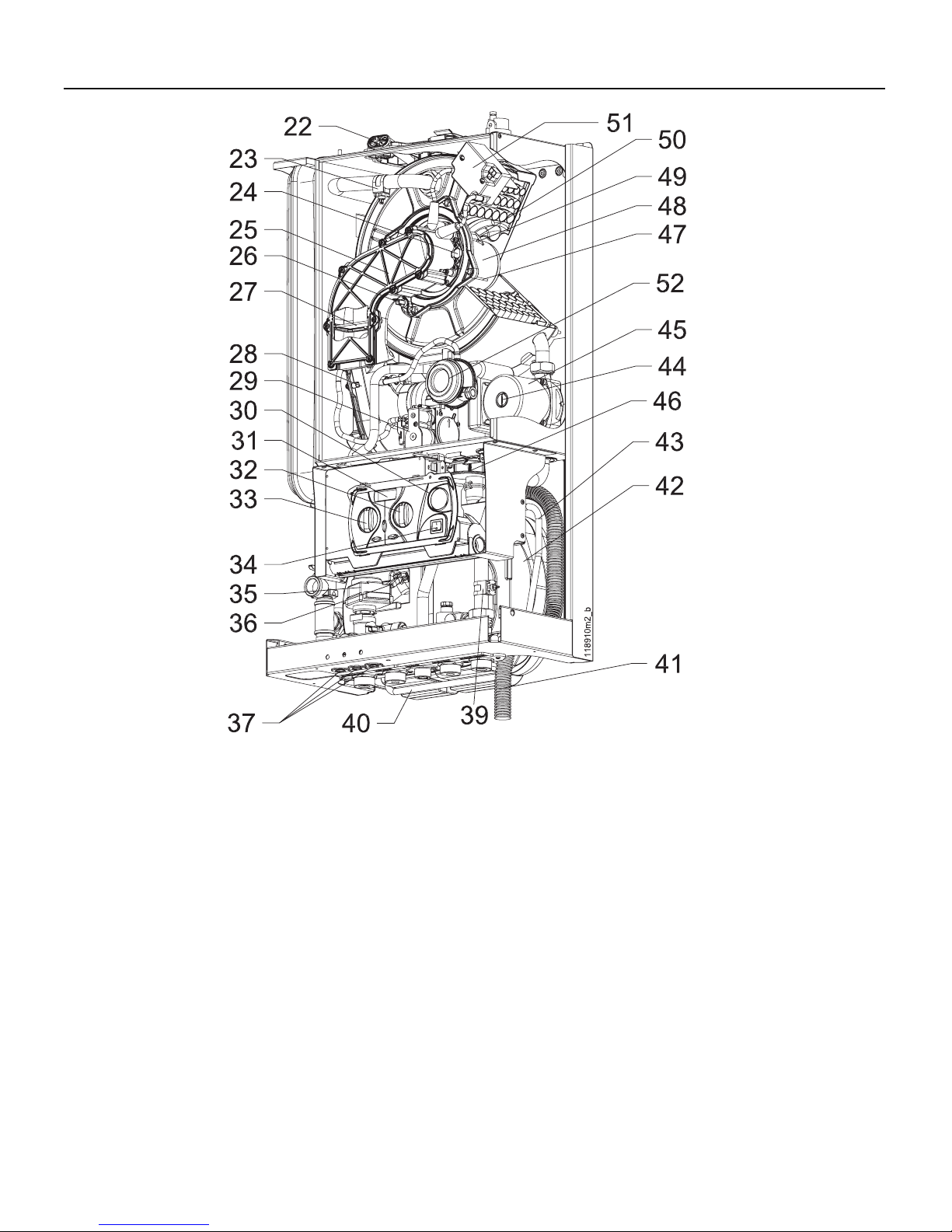

4 - FUNCTION OVERVIEW

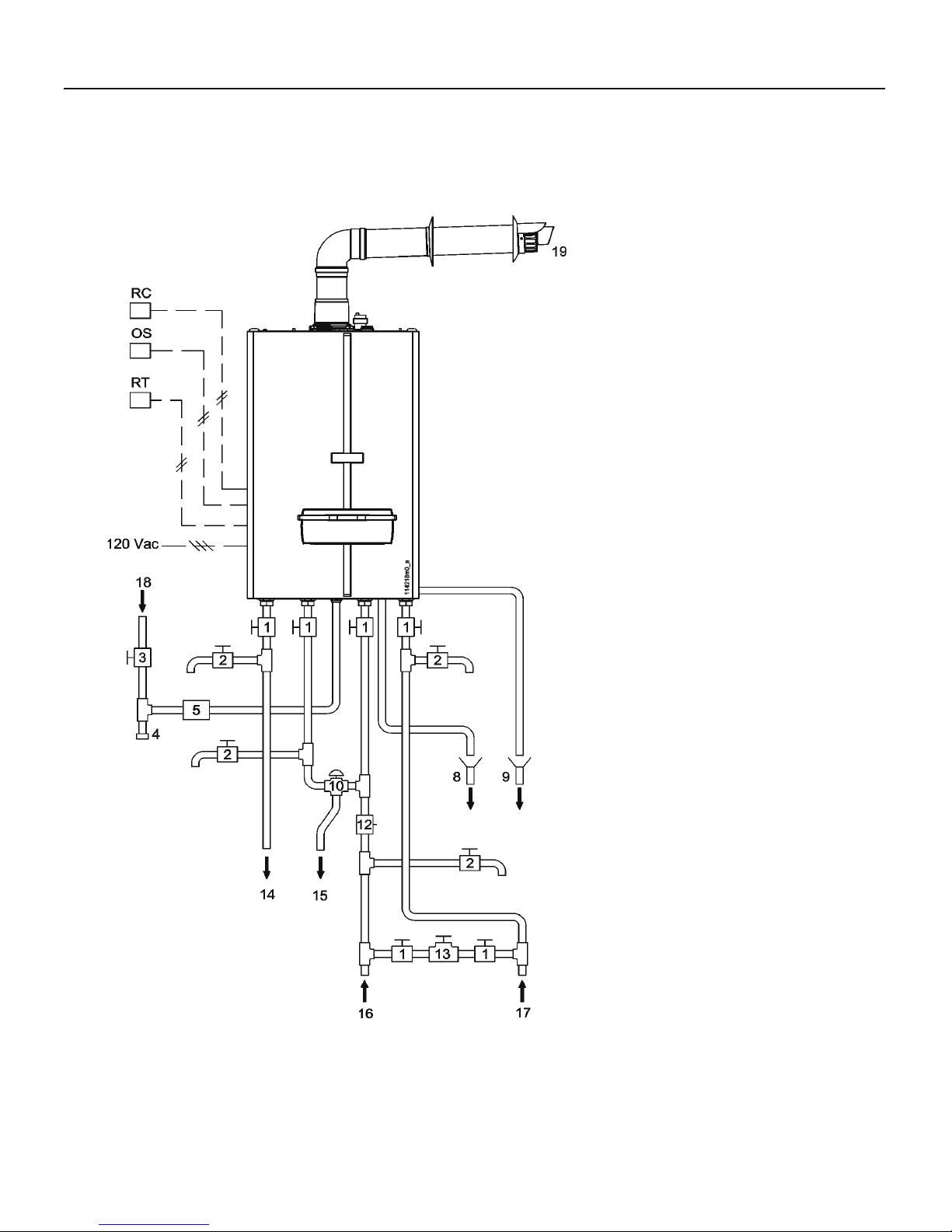

Key to fi gure 2:

1 = boiler

2 = automatic air vent

3 = air intake

4 = fl ue gases discharge

5 = sealed combustion chamber

6 = expansion tank

7 = burner

8 = fan

9 = gas valve

10 = condensate discharge trap

11 = circulator pump

12 = 3-way valve

13 = secondary heat exchanger for d.h.w.

14 = pressure gauge

15 = by-pass valve

17 = safety relief valve

21 = condensate discharge pipe

22 = heating supply pipe

23 = domestic hot water outlet

24 = gas inlet

25 = cold water inlet

26 = heating return pipe

45 = U7 = fl ue gas temperature sensor

46 = U1 = boiler temperature sensor

47 = U6 = high limit temperature sensor

48 = U3 = domestic cold water sensor/storage tank

sensor

49 = U2 = domestic hot water temperature sensor

50 = U8 = return temperature sensor

51 = fl ue pressure switch

Figure 2 - PC160™ Hydronic functional schematic

15

Page 16

4 - FUNCTION OVERVIEW

4.1 - Intended use

and functions of

the boiler

This gas-fi red condensing boiler,

is designed to be used for central

heating and producing domestic hot

water.

The maximum output heat is always

guaranteed for the production of

domestic hot water since it is given

priority over space heating demands.

Follow the specifi c procedure in

section 12.7 for the adjustment of the

domestic hot water temperature.

Using a PC160™ boiler you can

create a system for the production

of instantaneous domestic hot water

and a heating system with heating

elements functioning at temperatures

ranging between 68°F (20°C) and

189°F (87°C).

The boiler can also function directly

with a radiant fl oor panel, see section

5.10.

When connecting the boiler to the

heating system the installer must

consider the head loss of the heating

system to verify that the boiler pump

is adequate. Pump curve is shown in

fi gure 4. The same verifi cation must

be done for the domestic installation,

see fi gure 5.

The PC160

to an indirect storage tank for the

production of domestic hot water,

section 7.1.

The PC160

to a room thermostat, section 6.3 and

6.4.

An outdoor air temperature sensor

can also be connected to the boiler for

an outdoor reset supply temperature

control for maximum fuel effi ciency

and comfort (see section 6.5). In this

confi guration the room thermostat will

compensate by adjusting the room

temperature. The room temperature

compensation can be of an ON /

OFF type or two-stage. For further

information on the outdoor-air reset,

refer to section 12.10.

™

can be connected

™

boiler can be connected

The boiler must be connected to

a heating system and a domestic

hot water supply with compatible

specifi cations, performance and

power rating.

Before installation, thoroughly

fl ush the heating and plumbing

systems of any residue

or impurities which might

compromise the smooth running

of the boiler.

This boiler is designed for indoor

installation.

Refer to fi gure 6 for minimum

clearance distances for installation

and future maintenance.

Refer to section 5.2 for minimum

clearance distances from

combustible material.

4.2 - Setting of the

boiler

Section 16 details the setting changes

that should be made to best match the

boiler’s operation to the needs of each

application.

16

Page 17

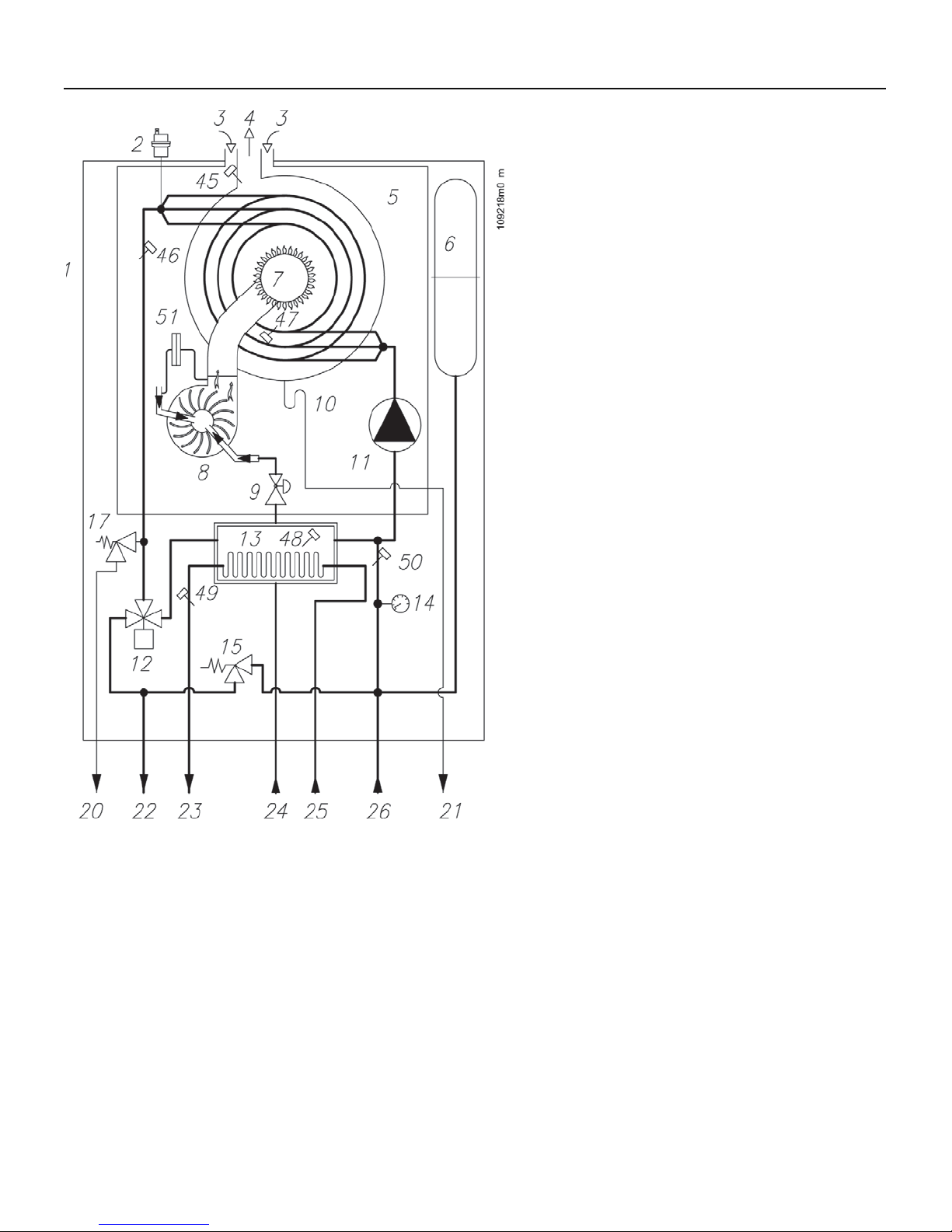

4 - FUNCTION OVERVIEW

4.3 - Effi ciency up

to 98%

When the outdoor reset is activated

(see section 12.10) and an outside

sensor is connected, this boiler

is designed to always work at

the maximum effi ciency. It will

automatically change the supply

temperature in relation with the

outdoor temperature (Outdoor reset).

The graph in fi gure 3 shows an

example on how it can work.

This graph is an example where is

represented an installation where

the supply and return temperatures

are 139°F and 115°F respectively ,

and the outside temperature is 23°F.

The outdoor reset drives the boiler,

to progressively reduce the supply

temperature and thereby optimize

the effi ciency. It changes from 87%

when outside is -10°F, to 94.8% when

outside is 23°F and up to 98% when

the outside temperature rises up to

67°F.

Figure 3 - Outdoor reset control to optimize the effi ciency

17

Page 18

4 - FUNCTION OVERVIEW

Figure 4 - Available Head for heating circuit

4.4 - Characteristic

curves of heating

system’s residual

head

The PC160™ boiler is fi tted with a

Grundfos circulator pump. The head

available to supply fl ow through

the heating system at the boiler

connections is shown in graph form in

fi gure 4.

4.5 - Characteristic

curve of the

Figure 5 - Domestic Water Coil Head Loss

domestic side

The PC160™ boiler, offers resistance

to the passage of domestic water (see

graph fl ow/pressure of fi gure 5). The

installer or the engineer must take

account of this in order to ensure the

correct domestic water fl ow to the

utilities.

18

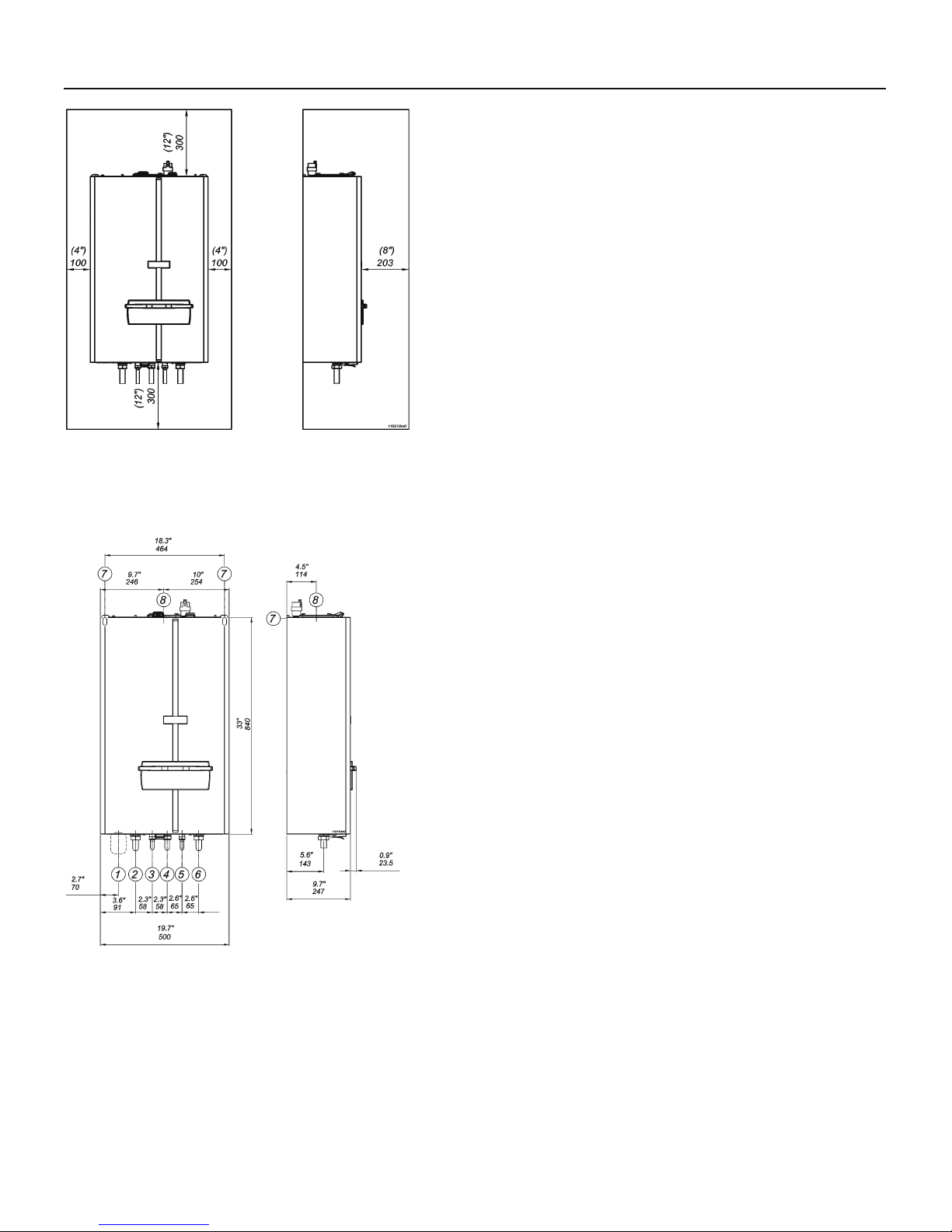

Page 19

5 - INSTALLATION - Mounting & gas and water connections

5.1 - Clearances for

installation and servicing

Figure 6 shows the clearances required for installation

and servicing.

NOTE: Service clearances are not mandatory, but

are recommended to ensure ease of service should

it be required.

5.2 - Clearances from

combustible material

This boiler may be installed directly onto a wall of combustible

material with the following clearance:

Ceiling: 2 inches (51 mm)

Front: 2 inches (51 mm)

Rear: 0 inches (0 mm)

Sides: 2 inches (51 mm)

Floor: 2 inches (51 mm)

Figure 6 - Recommended minimum clearance

distances for proper installation and servicing

Concentric vent: 0 inches (0 mm)

Split vent (fi rst 12” from the boiler): 1 inch (25 mm)

Split vent (after 12” from the boiler): 0 inches (0 mm)

1 = Area for power supply cable

2 = Heating supply connection (3/4”)

3 = Domestic hot water connection (3/4”)

4 = Gas connection (3/4”)

5 = Domestic cold water connection (3/4”)

6 = heating return connection (3/4”)

7 = positions for boiler support

8 = Flue discharge/air intake connection

Figure 7 - Dimensions for the PC160

™

19

Page 20

5 - INSTALLATION - Mounting & gas and water connections

5.3 - Choosing the

installation location

WARNING!!! Do not store any fl ammable

materials or liquids in the immediate vicinity of the

boiler. A fi re or explosion can result, causing severe

personal injury , death or substantial property damage.

WARNING!!! LIQUEFIED PETROLEUM (L.P.)

PROP ANE GAS-FIRED BOILER LOCATION REQUIRES

SPECIAL ATTENTION: 1994 UNIFORM MECHANICAL

CODE section 304.6: “LGP Appliances. Liquefi ed

petroleum gas-burning appliances shall not be

installed in a pit, basement or similar location where

heavier than air gas might collect. Appliances so

fueled shall not be installed in above-grade under-fl oor

space or basement unless such location is provided

with an approved means for removal of unburned

gas.” Failure to comply with this provision could

result in severe personal injury or substantial property

damage.

CAUTION!!! The boiler must be installed on a

vertical wall constructed to bear its weight or the boiler

and building may be damaged.

NOTE: The boiler must never be installed on carpeting.

CAUTION!!! This boiler is not designed for direct

outdoor installation. If installed outside of the structure

that it supplies hot water too, it must be sheltered so it is

protected from rain, wind, sun and frost. NEVER place this

boiler in a location that would subject it to temperatures at

or near freezing. Failure to properly locate this boiler can

result in premature failure voiding the warranty .

When locating the boiler the following factors must be

considered:

• the location of vent/air intake terminals;

• connection to the gas supply;

• connection to the water supply;

• connection to the heating system;

• connection to the domestic hot water system;

• connection to the electrical supply;

• disposal of the condensation produced by the boiler;

• connection to the room thermostat;

• piping of the safety relief valve discharge;

• possible connection of the outdoor temperature sensor;

• possible connection of an indirect storage tank, see

section 7.1.

20

Page 21

5 - INSTALLATION - Mounting & gas and water connections

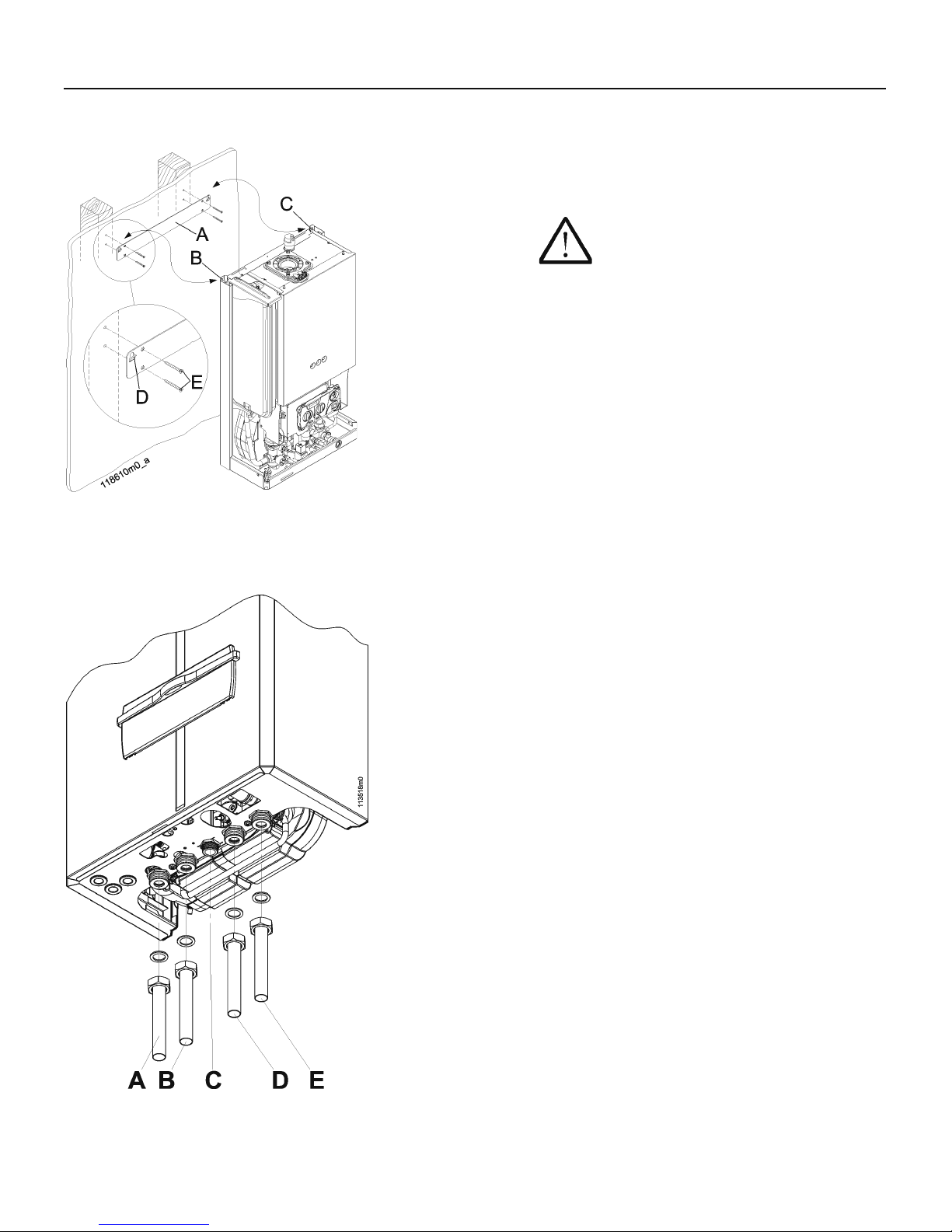

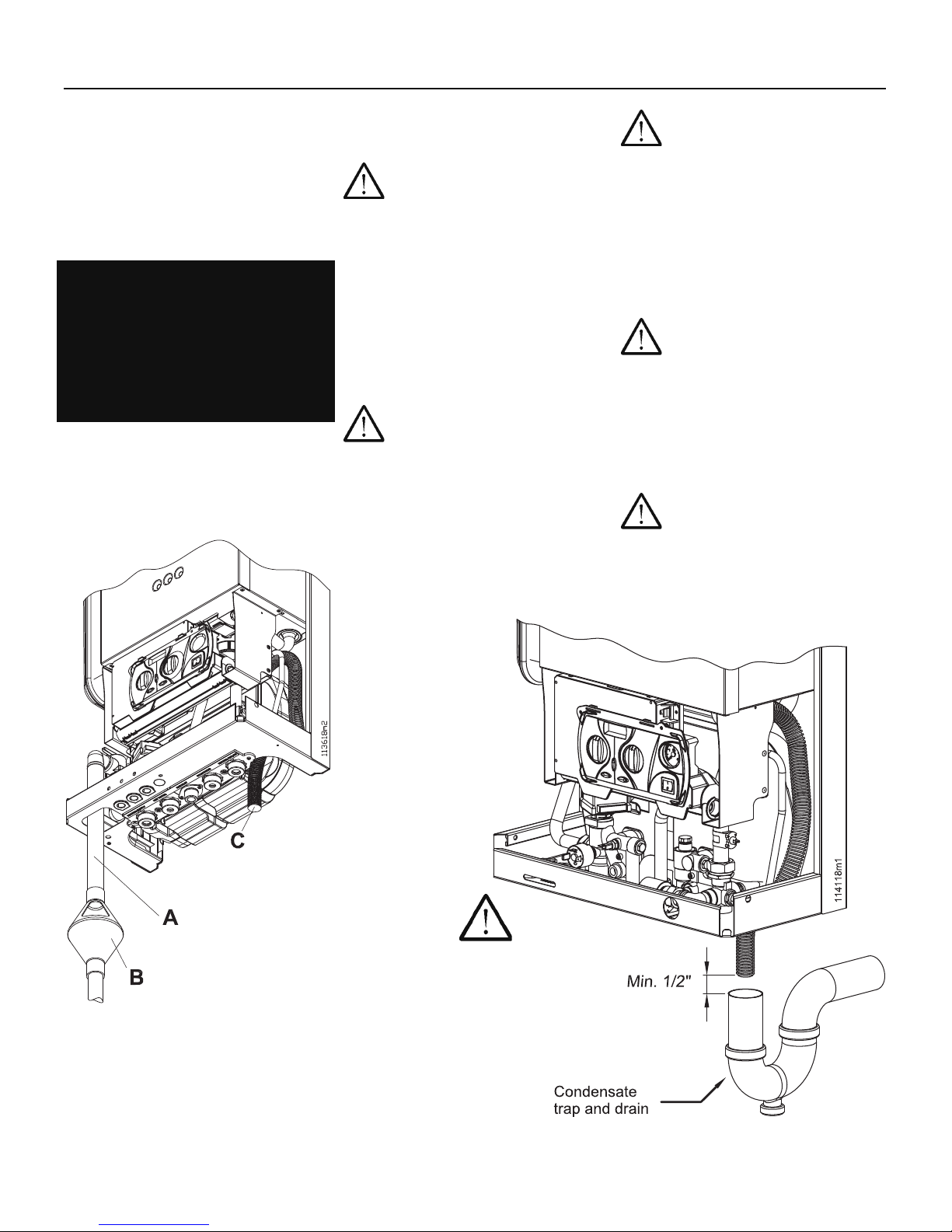

5.4 - Mounting the boiler

Refer to fi gure 8:

1. place the cardboard template, provided with the

boiler, against the wall;

2. ensure that the template is plumb and the

screw holes line up with the wall studs;

CAUTION!!! The wall bracket screws

must be screwed into the buildings framing

or other material capable of supporting the

weight of the boiler or the boiler and building

may be damaged.

3. mark the screw holes for the wall bracket, “A”;

4. remove the cardboard template;

5. install the wall bracket “A”, using the screws

“E”, provided;

6. hang the boiler on the wall bracket, “A”, by

hanging connections “B” and “C” on tabs “D”.

Figure 8 - Wall bracket installation

5.5 - Gas and water

connections

The boiler comes with the fi ttings shown in fi gure 9.

A = heating system supply (3/4”)

B = domestic hot water supply (3/4”)

C = Inlet gas connection (3/4”)

D = domestic cold water (3/4”)

E = heating system return (3/4”)

Figure 9 - Fittings supplied with the boiler

21

Page 22

5 - INSTALLATION - Mounting & gas and water connections

5.6 - Condensate

disposal

WARNING! The condensate trap

must be connected to the boiler

per the following instructions or

combustion gases will enter the

room. This can result in excessive

levels of carbon monoxide which

can cause severe personal injury

or death!

This boiler produces water as a

byproduct of combustion. The boiler

is equipped with a condensate trap,

fi gure 1, item 46, for the evacuation

of condensate and to prevent the

leakage of combustion products.

The condensate trap drains through

pipe “C” shown in Figure 10. The

condensation disposal system must:

be connected to the domestic

waste disposal system by means

of an appropriate trap capable of

preventing the pressurization of the

condensate system and the return

of sewer gases (see fi gure 11);

comply with national and/or local

codes for condensate neutralizer

between pipe “C” of fi gure 10 and

the waste disposal system;

be carried out with a pipe with

an internal diameter equal to or

greater than 1/2 in, 13 mm;

be installed in such a way so as to

avoid the freezing of the liquid;

never discharge into gutters or rain

collectors;

be properly pitched towards the

point of discharge avoiding high

points, which could place the

condensate system under pressure;

CAUTION!!! The condensate

drainage system is designed to

empty all the condensate produced

by one boiler only. Each boiler

must be equipped with its own

condensate drainage system or the

drainage system may malfunction.

5.7 - Near boiler

heating piping

components

1. Boiler system piping: boiler

system piping must be properly

sized. Reducing the pipe size can

restrict the fl ow rate through the

boiler, causing inadvertent high

limit shutdowns and poor system

performance.

2. Boiler system pump: Factory

Installed. Circulators must be

sized to meet the specifi ed fl ow

requirements of 5 GPM.

3. Indirect water heater circulating

pump: Field supplied. The

pump must be sized to meet

the specifi ed minimum fl ow

requirements of 5 GPM. Consult

the indirect water heater operating

guide to determine the fl ow

characteristics of the selected

product used.

4. Boiler isolation valves: Field

supplied. Full port ball valves

are required. Failure to use full

port ball valves could result in

restricted fl ow rate through the

boiler.

5. Domestic indirect hot water

isolation valves: Field supplied.

Full port ball valves are required.

Failure to use full port ball valves

could result in a restricted fl ow

rate through the boiler.

6. Anti scald mixing valves: Field

supplied. An anti scald mixing

valve is recommended (see Figure

16). It is recommended also when

an indirect water heater is present.

7. Unions: Field supplied.

Recommended for unit

serviceability.

8. Pressure relief valve: Factory

supplied. The pressure relief valve

is sized to ASME specifi cations.

9. Indirect Water heaters: Field

supplied. This boiler may be piped

to an indirect water heater to heat

domestic hot water with the space

to heat transfer medium. There

are two options when utilizing an

indirect water heater.

a. The space heating piping will

branch off to fl ow the space

heat transfer medium through a

single wall heat exchanger coil

inside the indirect water heater.

b. The indirect water heater is

connected to the system supply

piping. A pump controlled by

the boilers control will regulate

the fl ow of water through

the indirect water heater.

The indirect water heater’s

temperature will be regulated by

the boiler’s control. The boiler

is pre-confi gured to control the

operation of the DHW pump

with Domestic Hot Water

Prioritization programming.

CAUTION!- It is up to the installer

to ensure the minimum system fl ow

is not less then 5 GPM at any time.

WARNING!!! The National

Standard Plumbing Code, the

National Plumbing Code of Canada

and the Uniform Plumbing Code limit

the pressure of the heat transfer fl uid

to less then the minimum working

pressure of the potable water system

up to 30 psi maximum. Also, the

heat transfer fl uid must be water or

other non-toxic fl uid having a toxicity

of Class 1, as listed in the Clinical

T oxicology of Commercial Products,

5th Edition.

10. Filter: Field supplied. A Filter or

equivalent multipurpose strainer is

recommended at the return pipe

of the boiler to remove system

particles from older hydronic

systems and protect newer

systems.

22

Page 23

5 - INSTALLATION - Mounting & gas and water connections

5.8 - Relief valve

Each boiler is equipped with a safety

relief valve set at 30 psi (2 bar) which

must be piped in accordance with

the ANSI/ASME Boiler and Pressure

Vessel Code, Section IV, to prevent

scalding in the event of a discharge,

see Figures 1, item “38” and fi gure 10.

WARNING!!! Failure to properly

pipe the relief valve discharge can

result in scalding of individuals and

animals. Never install any type of

valve between the boiler and the

relief valve or an explosion causing

extensive property damage, severe

personal injury or death may occur!

5.9 - Supply and

return piping

CAUTION!!! All heating

system piping must be installed in

accordance with the ANSI/ASME

Boiler and Pressure Vessel Code,

Section IV. All applicable local

codes and ordinances must also

be followed. If the boiler is installed

above any radiation elements it

must be fi tted with a low water

cutoff device installed above the

normal boiler water level! Failure

to do this can result in damage the

unit and void the warranty!

CAUTION!!! This boiler

must have adequate water fl owing

through it whenever the burner is

on. Failure to do this will damage

the unit and void the warranty!

CAUTION!!! Before

connecting the boiler to the heating

system the heating system must

be thoroughly fl ushed to remove

sediment, fl ux, fi lings and other

foreign matter. An approved

inhibitor should be added to the

heating system water to prevent

limestone and magnetite deposits

from forming and to protect the

boiler from galvanic corrosion.

CAUTION!!! This boiler is

equipped with an ASME safety

relief valve set at 30 psi (2 bar). The

heating system must be designed

so that no piping or radiation

elements are higher than 65 ft (20

m) or else the hydraulic head of the

system will cause the relief valve to

open.

CAUTION!!! The

manufacturer cannot be held

responsible for any damage caused

by incorrect use of additives in the

heating system.

A = 3/4” pipe extension (not provided)

B = Discharge device open to the atmosphere

(not provided)

C = Condensate discharge pipe

Figure 10 - Relief valve connection

CAUTION!!!

Minimum air gap

of ½” between

discharge pipe and

drain. Failure to do

this will damage

the unit and void

warranty .

Figure 11 - Condensate trap and drain

23

Page 24

5 - INSTALLATION - Mounting & gas and water connections

5.12 - Domestic hot

CAUTION!!! This boiler

can supply heating water at a

temperature up to 190°F (88°C).

If the heating system is built with

materials not able to resist to this

temperature, you must to install a

device that shut-off the boiler before

the material’s limit temperature.

Figure 9 illustrates the position of

the supply and return pipes.

Install a metallic mesh fi lter on the

return pipe to prevent any residue

from the system returning to the

boiler.

Do not use the appliance for

adding any type of additive to the

system.

5.9.1 - Converting a

combi boiler into a

heating only boiler

If you are in possession of a PC160™

boiler you can use it as a heating

system only without using the

domestic hot water circuit. To do so,

simply plug the two fi ttings, items

“3” and “5” of fi gure 7, and move

switch No. 5 (see fi gure 21) from OFF

position to ON position. Now knob

“32” of fi gure 1 is disabled.

5.10 - Low

temperature

heating systems

CAUTION!!! When the boiler

is installed in a low temperature

system, the switch No. 6 in fi gure

21 must be placed in the ON

position to prevent the supply

water temperature from exceeding

113°F (45°C) or damage to the low

temperature system components

could occur (see section 5.9).

With switch No. 6 in fi gure 21, in the

ON position, the boiler will maintain

the supply water temperature between

68°F (20°C) and 113°F (45°C). No

setting changes made from the control

panel will cause the supply water

temperature to exceed 113°F (45°C).

CAUTION!!! To protect the

fl oor panel against over heating

you must to install a safety device

that shut-off the boiler before

it reach the fl oor panel’s limit

temperature.

CAUTION!!! If the boiler

is installed in a radiant panel

heating system using plastic

piping, precautions must be taken

against corrosion caused by water

oxygenation. If the piping does

not incorporate an oxygen barrier,

the radiant panel circuit must be

isolated from the boiler using a

titanium plate heat exchanger.

5.11 - Use of

glycol and other

chemicals

WARNING!!! Never use nonapproved additives or toxic boiler

treatment chemicals in the heating

system as they can cause serious

health problems or possibly death.

Any additives introduced into the

heating system must be recognized

as safe by the United States Food

and Drug Administration.

If glycol is used, it must be used in

accordance with the instructions

supplied with the product.

CAUTION!!! Any additives

added to the heating system must

not be added directly inside the

boiler but through the heating

system piping to prevent damage

to the boiler.

and cold water

CAUTION!!! If the water

hardness is greater than 9 gr/gal

(150 mg/l) we recommend installing

a water softener with fi lter.

Figure 9 illustrates the positioning

of the domestic hot and cold water

pipes.

For servicing purposes, install an

isolation valve upstream from the

cold water inlet.

To correctly set the domestic water

fl ow, install an adjustable fl ow

restrictor upstream the cold water

inlet (see fi gure 16 item “12”)

The PC160

used as heating only boilers.

No connection is needed to the

domestic pipes “B” and “D” of

fi gure 9.

™

boiler can also be

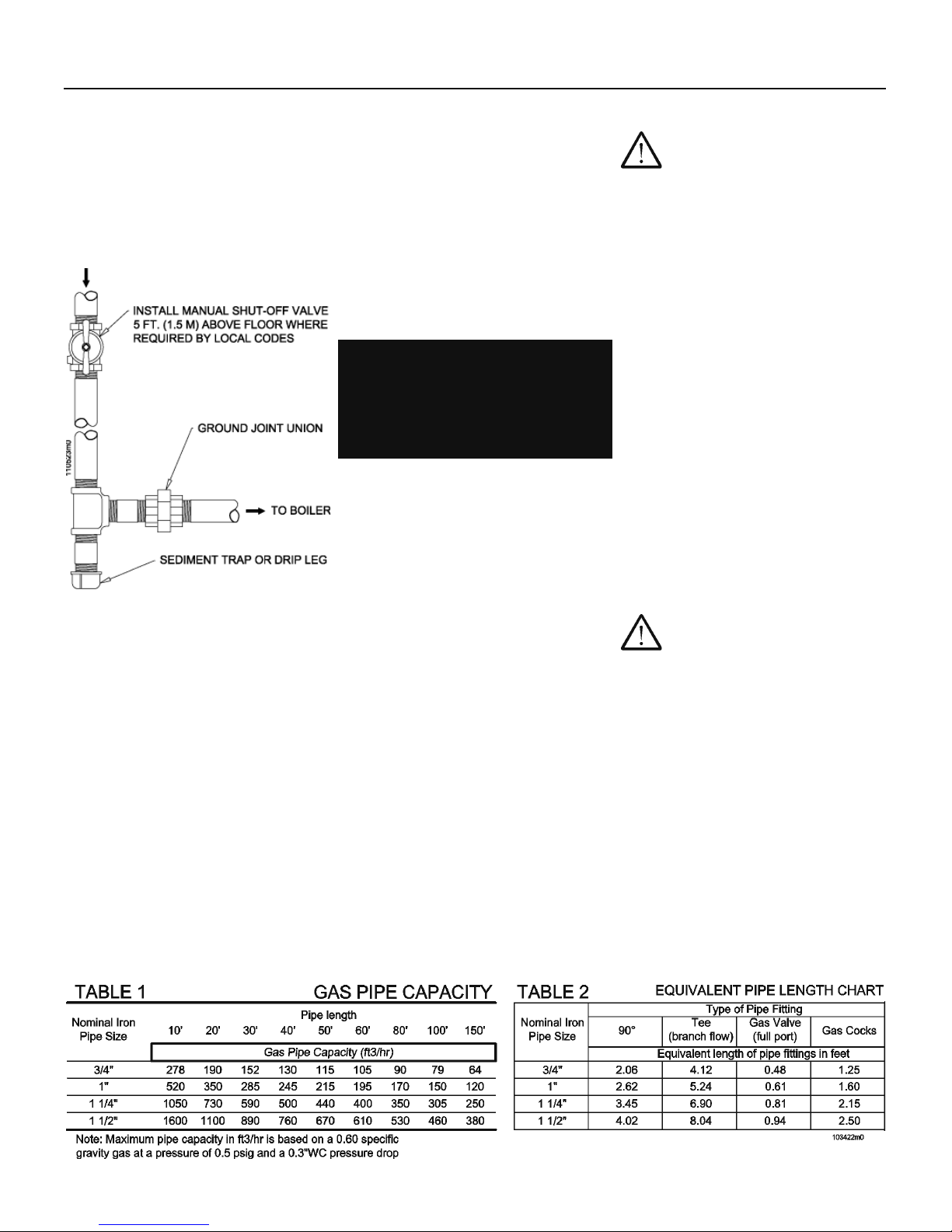

5.13 - Gas supply

piping

WARNING!!! Check that the type

and the pressure of the gas

supplied correspond with those

required for the boiler as stated

on the rating plate. Never use a

gas different than that stated on

the boiler rating plate. Failure

to comply with this warning can

result in a fi re or explosion causing

extensive property damage, severe

personal injury or death!

If the gas type and/or the supply

pressure do not match those stated

on the boiler rating plate the boiler

must be converted to the type

of gas and/or supply pressure

available. A conversion kit is

supplied together with the boiler.

24

Page 25

5 - INSTALLATION - Mounting & gas and water connections

The boiler comes from the factory

ready to be piped to the gas supply.

The National Fuel Gas Code, ANSI

Z223.1/NFPA 54 and local codes

for gas piping requirements and

sizing must be followed.

Install a manual gas shutoff valve

and drip leg as shown in Figure 12.

Figure 12 - Gas supply

piping

The gas supply piping to the boiler

must be properly sized to guarantee

that the gas supply meets the

maximum requirements. If more

than one appliance is supplied by

the same gas supply pipe, the gas

supply piping must be sized based

on the maximum possible demand.

Do not neglect the pressure drop due

to pipe fi ttings. Table 1 below, should

be used in conjunction with Table 2

below, to ensure that the gas supply

piping is sized properly. See section

14 for values of “maximum gas supply

pressure” and “minimum gas supply

pressure” and also section 11.7.

Before installation a thorough

internal cleaning of the gas supply

line should be performed. Figure

9 shows the positioning of the gas

connection on the heater.

The boiler and its gas connection

must be leak tested before placing

the boiler in operation.

To avoid damaging the gas control,

perform a leak test at a pressure

of no greater than 20 in W.C. (50

mbar).

WARNING!!! Never use an open

fl ame to test for gas leaks. Always

use an approved leak detection

method. Failure to comply with

this WARNING could result in an

explosion!

The boiler and its individual shutoff

valve must be disconnected from

the gas supply piping during any

pressure testing at test pressures in

excess of 1/2 psi (3.5 kPa).

The boiler must be isolated from

the gas supply piping by closing

its individual manual shutoff valve

during any pressure testing at test

pressures equal to or less than 1/2

psi (3.5 kPa).

Install 100% lockup gas pressure

regulator in supply line if inlet

pressure can exceed 13”W.C. at

any time. Adjust lockup regulator

for 13”W.C. maximum.

Use pipe sealing compound

compatible with propane gas. Apply

sparingly only to male threads of

the pipe joints so that pipe dope

does not block gas fl ow.

5.14- Propane gas

WARNING!!! These boilers

are typically shipped ready to fi re on

natural gas. Check boiler rating plate

to determine which fuel the boiler is

set for. If set to natural gas, it may

be converted to LP by following the

instructions in Section 5.17. Failure

to comply could result in severe

personal injury , death, or substantial

property damage.

Pipe sizing for propane gas

Contact gas supplier to size pipes,

tanks and 100% lockup gas pressure

regulator.

Propane supply pressure

requirements:

1. Adjust propane supply regulator

provided by the gas supplier for

13”W.C. maximum pressure.

2. Pressure required at gas valve

inlet port:

a. Maximum 13”W.C. with no fl ow

(lockup) or with boiler on.

b. Minimum 3”W.C. with gas

fl owing (verify at high fi re).

WARNING!!! Ensure that the

high pressure gas regulator is at least

6-10ft upstream of the appliance.

5.15 - Operating at

high altitudes

For installations in the United States,

the boiler is rated for operation at

altitudes up to 2,000 ft (609 m). For

installations at higher altitudes in

the United States, follow local codes

or, in the absence of local codes,

follow ANSI Z223.1/NFPA No. 54,

The National Fuel Gas Code. For

installations in Canada, the boiler is

rated for installations up to 2,000 ft

(609 m). For installations above this

altitude, follow local/provincial codes.

25

Page 26

5 - INSTALLATION - Mounting & gas and water connections

5.16- Convert the

boiler from Natural

Gas to Propane

Gas or vice versa

WARNING!!! The gas

conversion shall be performed

by a qualifi ed service agency in

accordance with this instructions and

all applicable codes and requirements

of the authority having jurisdiction.

The information in these instructions

must be followed to minimize the

risk of fi re or explosion or to prevent

property damage, personal injury or

death. The qualifi ed service agency is

responsible for the proper conversion

of the boiler. The installation is

not proper and complete until the

operation of the converted appliance

is checked as specifi ed in this

instructions.

WARNING!!! The conversion

shall be carried out in accordance

with the requirements of the

provincial authorities having

jurisdition and in accordance with the

requirements of the CAN-B149.1 and

CAN1-B149.2 installation code.

Contents:

The conversion kit (supplied with the

boiler) is composed of the following

elements, which are necessary for the

gas change:

- a label rating the new gas setting;

- an instruction sheet;

- an orifi ce;

Installing:

in order to make the gas change

please follow the instructions below:

1 - turn off power to the boiler;

2 - open the boiler’s casing (Follow

Section 14.2);

3 - open the instrument panel

(Follow Section 9.2);

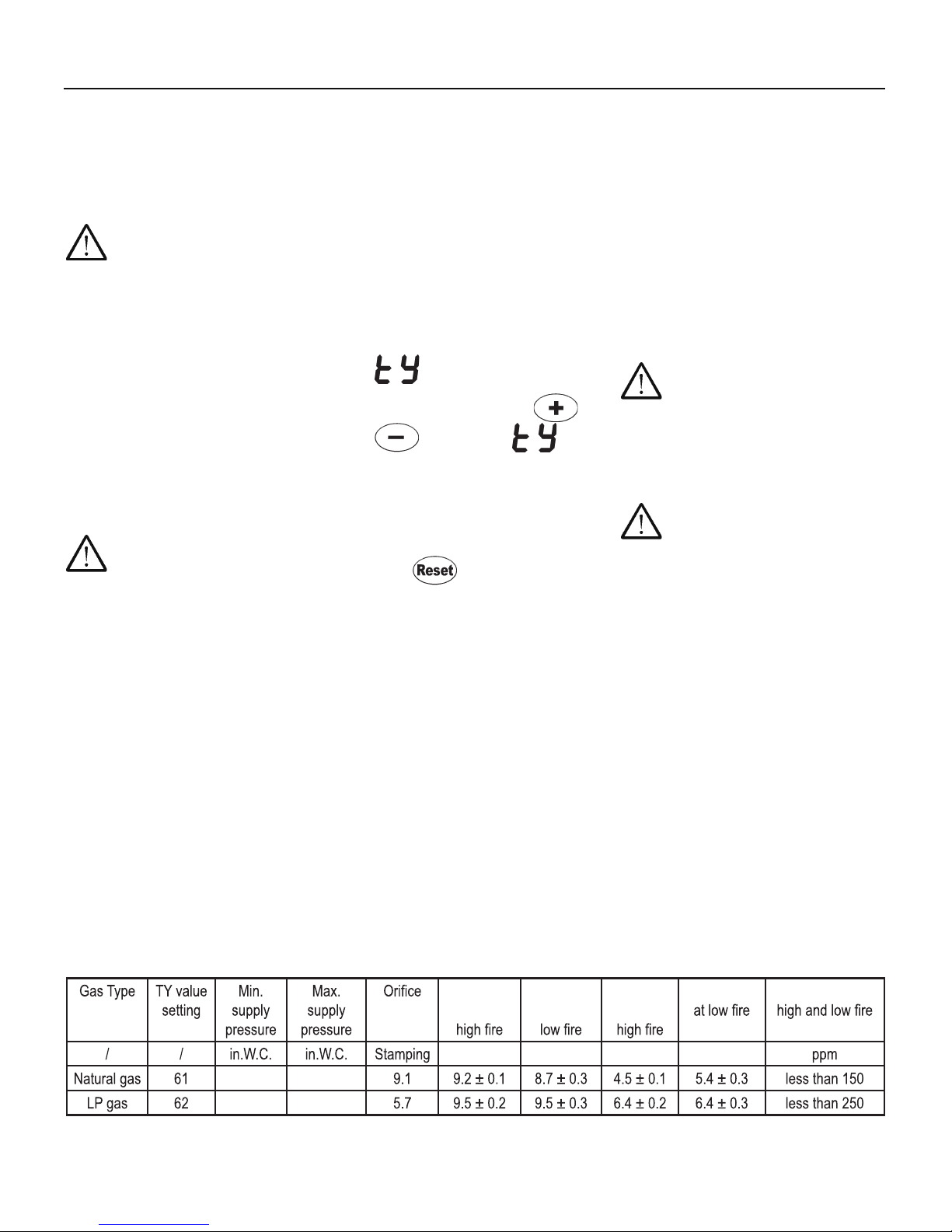

4 - Move switch #7 (see Figure 9-2)

from OFF position to ON position;

5 - turn on power to the boiler;

6 - on the boiler’s display you’ll see

followed by a number;

7 - using the push buttons and

set the input to:

- 61 to convert the boiler from LP

GAS to NATURAL GAS

or

- 62 to convert the boiler from

NATURAL GAS to LP GAS,

8 - push button to save the

new value;

9 - turn off power to the boiler;

10 - Move switch #7 (see Figure 9-2)

from ON position to OFF position;

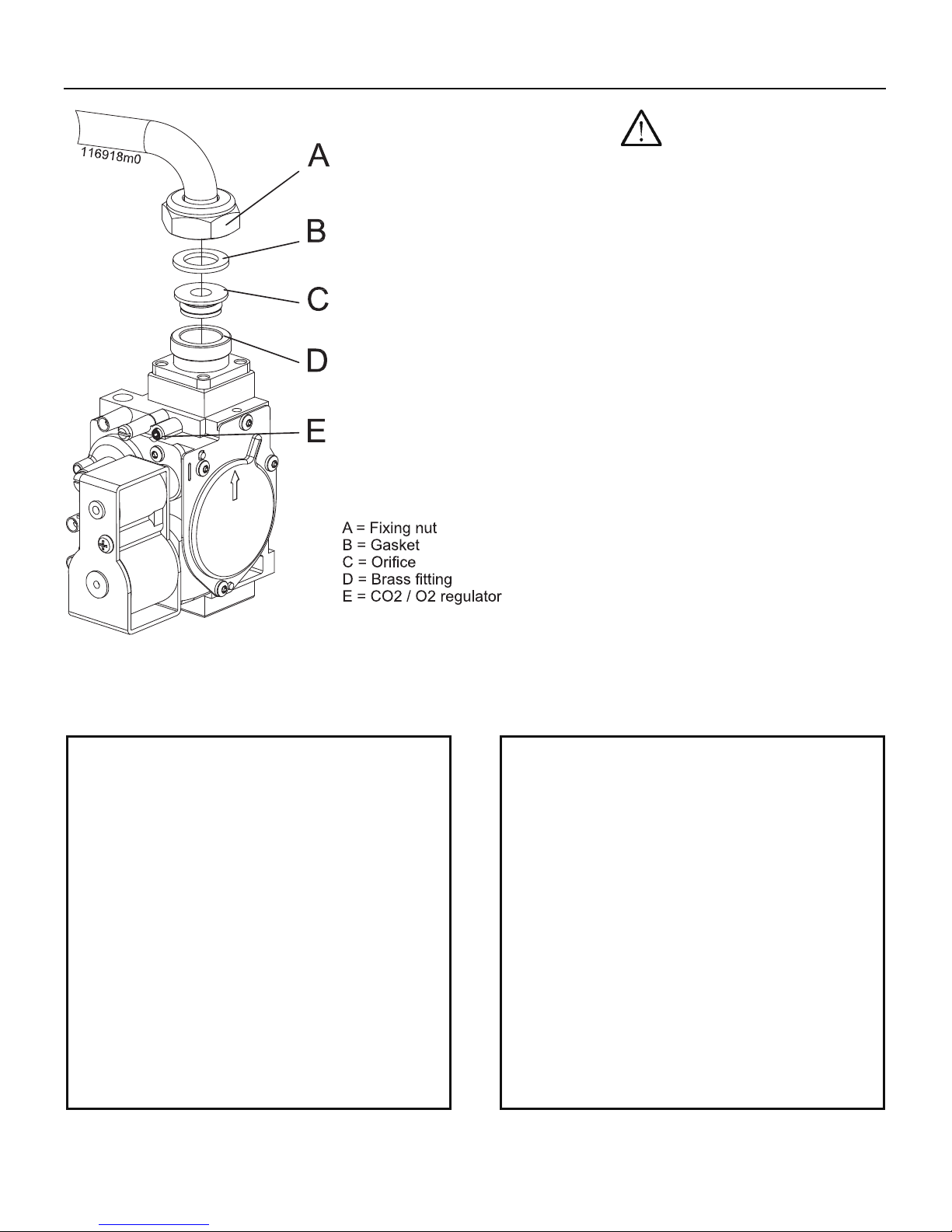

11 - Replace the orifi ce item “C” of

Figure 13 for the correct one

for the type of gas used. Verify

that the stamping on the orifi ce

matches the gas type (See Table

3).

11 - turn on power to the boiler;

12 - Turn completely counter

clockwise the screw E of Figure

13;

13 - Checking gas supply pressure

following Section 12.7. The Gas

supply pressure must be between

the maximum and minimum value

as stated in Table 3.

14 - Verifying the CO2 rate and its

eventual adjustment following

Section 12-9: The boiler during

its normal operation, within a

maximum altitude of 2000 ft, has

a CO2 exhaust rate as shown

in Table 3. If not within range of

value shown, malfunctions will

occur.

WARNING!!! The CO (carbon

monoxide) level should not exceed

values given in T able 3, when

combustion is correct. Failure to

comply with this requirement could

result in severe personal injury , death

or substantial property damage.

WARNING!!! All combustion

measurements must be performed

with calibrated equipment to ensure

proper reading and accuracy . Failure

to comply with this requirement could

result in severe personal injury , death

or substantial property damage.

TABLE 3 SETTINGS OF THE BOILER FOR NATURAL GAS AND LP GAS

313

313

CO2

content at

%%%%

CO2

content at

O2

content at

O2 content CO content at

26

Page 27

5 - INSTALLATION - Mounting & gas and water connections

WARNING!!! If the combustion

levels are not within the range given

in T able 3 for the fi ring rate, shut

the boiler down and contact your

distributor or the boiler manufacturer

(see reference in the last cover

page). Failure to comply with this

requirement could result in severe

personal injury , death or substantial

property damage.

15 - Attach to the front of the boiler

the appropriate conversion label,

found in the conversion kit (see

Figure 14 or Figure 15), stating the

new type of gas adjustment of the

boiler.

a - Apply the label in Figure 15 if the

boiler has been converted to LP

GAS;

b - Apply the label in Figure 14 if

the boiler has been converted to

NATURAL GAS.

Figure 13 - Gas valve

ATTENTION!!!

This heater has been converted for use with

NATURAL GAS

- Maximum inlet gas pressure: 13 In.W.C.

- Minimum inlet gas pressure: 3 In.W.C.

- Manifold pressure: (see rating plate)

- Input rating: (see rating plate)

This water heater was converted on (day-month-year)

___________________to ___________________ gas

with kit nº

by

_________________________________________

___________________________________