PB Heat Gas-Oil Boilers User Manual

LC/LCE

Gas/Oil Boilers – Water

Series

Oil, Gas &

Installation,

Operation &

Maintenance

Manual

USING THIS MANUAL 1

A. INSTRUCTION MANUALS . . . . . . . . . . . . . . .1

B. SPECIAL ATTENTION BOXES . . . . . . . . . . . .1

1. PREINSTALLATION 2

A. ACCESSIBILITY CLEARANCES . . . . . . . . . . .2

B. CLEARANCE FROM COMBUSTIBLE

CONSTRUCTION . . . . . . . . . . . . . . . . . . . . . .3

C. COMBUSTION AND VENTILATION AIR . . . .3

D. CHIMNEY OR VENT . . . . . . . . . . . . . . . . . . . .3

E. BOILER SETTING . . . . . . . . . . . . . . . . . . . . . .4

F. INSTALLATION SURVEY . . . . . . . . . . . . . . . .5

G. PLANNING THE LAYOUT . . . . . . . . . . . . . . . .5

H. VERIFY COMPONENTS . . . . . . . . . . . . . . . . .5

2. PLACE THE BOILER 10

A. PACKAGED BOILER . . . . . . . . . . . . . . . . . . .10

B. ASSEMBLED BLOCK BOILER . . . . . . . . . . .10

C. KNOCKDOWN BOILER – PLACING

THE SECTIONS . . . . . . . . . . . . . . . . . . . . . .10

D. INSTALL COILS OR PLATES . . . . . . . . . . . .17

E. HYDROSTATIC TEST THE BOILER . . . . . . .17

F. APPLY CLEANOUT COVER PLATES . . . . . .18

G. INSTALL FLUE COLLAR . . . . . . . . . . . . . . . .18

H. INSTALL FLUE BAFFLES . . . . . . . . . . . . . . .19

I. INSTALL CHAMBER LINER . . . . . . . . . . . . .19

3. PIPE THE BOILER 20

A. PREPARATION . . . . . . . . . . . . . . . . . . . . . . .20

B. SUPPLY AND RETURN PIPING . . . . . . . . . .20

C. LOW SYSTEM TEMPERATURE . . . . . . . . . .20

D. CHILLED WATER SYSTEMS . . . . . . . . . . . .23

E. HIGH FLOW RATE PIPING . . . . . . . . . . . . . .23

F. MULTIPLE BOILER INSTALLATIONS . . . . . .23

4. ASSEMBLE THE JACKET 27

A. PREPARE THE PARTS . . . . . . . . . . . . . . . . .27

B. APPLY JACKET SIDES AND CORNERS . . .27

C. APPLY JACKET FRONT PANELS . . . . . . . . .27

D. APPLY JACKET REAR PANEL . . . . . . . . . . .27

E. APPLY JACKET TOP PANELS . . . . . . . . . . .27

F. APPLY PLATES AND LABELS . . . . . . . . . . .27

5. VENTING 29

6. INSTALL THE BURNER 29

A. BURNER APPLICATION . . . . . . . . . . . . . . . .29

B. INSTALL BURNER MOUNTING PLATE . . . .29

C. MOUNT THE BURNER . . . . . . . . . . . . . . . . .29

7. CONNECT FUEL PIPING 31

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . .31

B. INSTALL FUEL OIL PIPING . . . . . . . . . . . . .31

C. INSTALL GAS SUPPLY PIPING . . . . . . . . . .31

D. TEST GAS SUPPLY PIPING . . . . . . . . . . . . .31

8. INSTALL CONTROLS AND TRIM 33

A. INSTALL SAFETY RELIEF VALVE . . . . . . . .33

B. INSTALL DRAIN VALVE . . . . . . . . . . . . . . . .33

C. INSTALL LOW WATER COUTOUT(S) . . . . .33

D. INSTALL CONTROLS & TRIM . . . . . . . . . . .33

E. PIPE TANKLESS HEATERS IF USED . . . . . .34

F. CONNECT SUPPLY WIRING . . . . . . . . . . . .34

G. INSTALL CONTROL WIRING . . . . . . . . . . . .34

9. STARTING THE BOILER 37

A. CHECK THE PIPING . . . . . . . . . . . . . . . . . . .37

B. FILL THE BOILER . . . . . . . . . . . . . . . . . . . . .37

C. RUN BURNER CHECK-OUT . . . . . . . . . . . . .37

D. CHECK BOILER CONTROLS . . . . . . . . . . . .38

10. MAINTENANCE 39

A. PLACING BOILER IN OPERATION . . . . . . . .40

B. TO SHUT DOWN THE BOILER . . . . . . . . . .40

C. MAINTENANCE – ANNUAL . . . . . . . . . . . . .40

D. MONTHLY MAINTENANCE . . . . . . . . . . . . .41

E. DAILY MAINTENANCE . . . . . . . . . . . . . . . . .41

11. BOILER RATINGS & DIMENSIONS 42

12. REPAIR PARTS 45

A SERIES LC BOILER ASSEMBLY . . . . . . . . .45

B. SERIES LCE BOILER ASSEMBLY . . . . . . . .48

TABLE OF CONTENTS

TABLE OF CONTENTS

1

A. INSTRUCTION MANUALS

The Series LC/LCE Installation, Operation &

Maintenance Manual is divided into four basic sections:

1. Preinstallation (Section 1)

2. Installation (Sections 2 through 8)

3. Start-Up (Section 9)

4. Maintenance (Section 10)

B. SPECIAL ATTENTION BOXES

Throughout this manual you will see special attention

boxes intended to supplement the instructions and make

special notice of potential hazards. These categories

mean, in the judgment of PB Heat, LLC:

Indicates special attention is needed, but not directly

related to potential personal injury or property

damage.

NOTICE

Indicates a condition or hazard which will or can

cause minor personal injury or property damage.

CAUTION

DANGER

Indicates a condition or hazard which will cause

severe personal injury, death or major property

damage.

USING THIS MANUAL

USING THIS MANUAL

Indicates a condition or hazard which may cause

severe personal injury, death or major property

damage.

WARNING

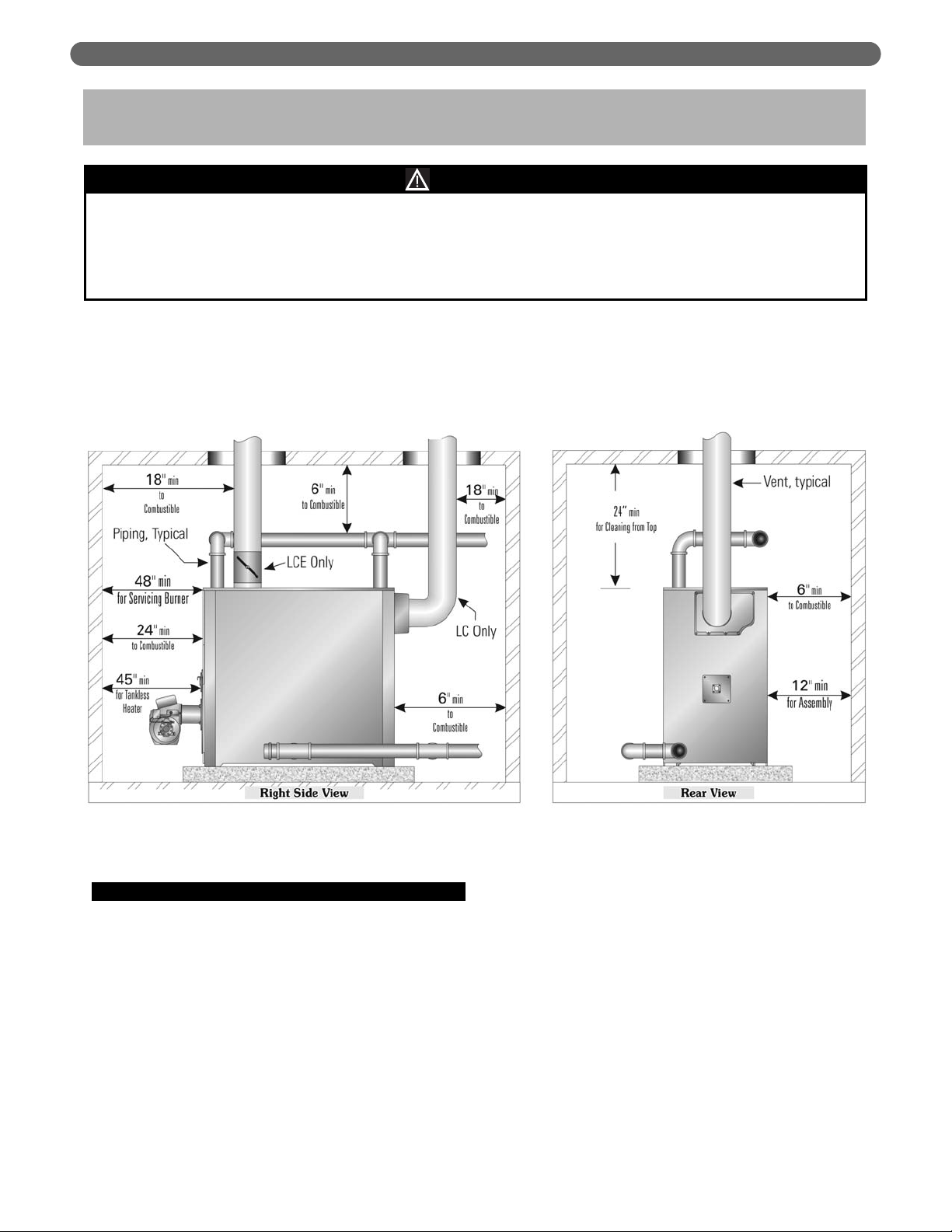

A. ACCESSIBILITY CLEARANCES

1. Clearances for service and from combustible surfaces

are the same for the LCE as for the LC. The

following recommendations allow for reasonable

access to the boiler. Follow local codes and

requirements when setting actual layout. See

Figure 1.1.

a) For installing, removing and servicing the burner:

provide 48" between the front of the boiler and

any adjacent wall or other appliance.

b) For access to the top of the boiler for cleaning

flueways: provide 24" above top of jacket.

c) For accessing and servicing of level controls and

inspection tappings (if used): provide 24"

minimum from the right side of the boiler to any

wall or obstruction.

d) For installation of jacket: provide at least 12"

from the left side of the boiler to any wall or

obstruction. More clearance may be needed for

longer boilers unless the jacket is pre-assembled

before placing the boiler.

e) For installation and removal of tankless heaters:

provide 45" between the end of the boiler and

any adjacent wall of obstruction. [This provides

for all available tankless coils. The spacing can

be closer for Heater Number X-1020 (allow 30")

or Heater Number X-1021 (allow 35")].

The equipment must be installed in accordance with installation requirements of the authority having

jurisdiction or, in the absence of such requirements, to the current edition of the

National Fuel Gas Code

, ANSI

Z223.1/NFPA 54.

Where required by the authority having jurisdiction, the installation must conform to

American Society of

Mechanical Engineers Safety Code for Controls and Safety Devices for Automatically Fired Boilers,

ASME CSD-1.

NOTICE

PREINSTALLATION

1. PREINSTALLATION

Carefully read these instructions before beginning work. Understand all aspects of the installation. Contact your PB Heat’s sales

representative or customer service for help in answering questions.

This boiler must be installed by a qualified contractor. The boiler warranty can be voided if the boiler is not installed, maintained

and serviced correctly.

Figure 1.1: Clearance Requirements

2

B. CLEARANCE FROM COMBUSTIBLE

CONSTRUCTION

Provide the following minimum clearances to

combustible construction. See Figure 1.1.

1. Sides: 6"

2. Rear of Jacket: 6"

3. Front of Jacket: 24"

4. Top of Jacket: 24"

5. Hot Water Pipes: 6"

6. Vent or Chimney Connector: 18"

C. COMBUSTION AND VENTILATION AIR

1. The installation must provide adequate air for

combustion and ventilation.

2. Unless the boiler room construction and natural air

infiltration are sure to provide all the air needed,

provide an opening or duct to the outside with a free

cross sectional area of at least 1 square inch per

4000 Btuh input for all installed appliances. At high

altitude, increase this requirement 4% for each 1000

feet above sea level.

3. The boiler room must never be under negative

pressure. If exhaust fans or other equipment can

cause a negative pressure in the boiler room, the air

openings and equipment design must be engineered

to assure a neutral or slightly positive pressure in the

boiler room at all times of operation. If the

equipment design and air openings cannot assure

this, then the boiler must be located in an isolated

room.

4. Using combustion air dampers:

a) If motorized dampers are used on the

combustion and ventilation air openings, wire

them such that they must open when the boiler

tries to operate. They must include a switch

which prevents the boiler from operating if they

do not open. See Figure 1.2.

D. CHIMNEY OR VENT

1. Inspect the existing chimney or vent system. Make

sure it is in good condition. Inspect chimney liner

and repair or replace if necessary.

2. The vent system and installation must be in

accordance with the current edition of the American

National Standard ANSI/NFPA 211, “Chimneys,

Fireplaces, Vents, and Solid Fuel Burning

Appliances”, or applicable provisions of the local

building codes. The venting requirements for the

LCE are the same as for the LC. Figure 1.3 shows

the top flue outlet required on LCE boilers.

3. Chimney/Vent Operation: The vent system must be

sized and installed to remove all combustion

products. If the vent system is not sized properly, the

burner may not operate properly. This can cause

poor combustion or sooting to occur.

4. If the vent terminates in an area where windgenerated downdrafts are likely, install a suitable vent

cap which can control wind effects.

5. This boiler is designed to fire only with a pressurized

fire box. The breeching and vent may be sized for

negative, neutral or positive pressure (no more than

0.l inches water column at the boiler outlet) as

desired. But negative pressure overfire can cause

lifting of the flame and poor combustion or

overheating of the boiler crown sheet.

6. Forced draft breechings and vents must be sealed

and of heavy gauge steel construction and must

comply with all applicable codes of construction.

7. The vent diameter and minimum height for stub

vents are listed in the Ratings and Dimensions

Section of this manual. Always extend vent

terminations at least 3 feet above the roof line. See

Figure 1.3.

3

PREINSTALLATION

Figure 1.2: Motorized Vent Damper Interlock Figure 1.3: Vent Termination, Typical

Failure to provide adequate venting can result in

severe property damage, personal injury or death.

WARNING

4

8. Exterior Vents:

a) Insulate sufficiently to ensure adequate draft and

to prevent vent damage due to condensation.

9. Vent Connection to Boiler:

a) Support the weight of the vent system

independently of the boiler flue connection.

b) Provide support of the vent connector

(breeching) at maximum 12 foot intervals to

prevent sagging and to provide a minimum

upward slope of 1/4" per foot.

10. Do not vent natural draft appliances in a combined

vent which operates under positive pressure.

11. Draft Regulator: Install a barometric draft regulator

where using high chimney or any high draft vent.

This is needed to prevent causing negative draft in

the boiler. Excess draft will cause flame lifting and

possible impingement.

12. The Draft Damper for the LCE boiler is a separate

piece, shipped in the Top Flue Outlet Carton.

a) Install the Draft Damper as close as possible to

the boiler flue outlet. It can be installed vertically

or horizontally provided that the connecting vent

piping and fittings are designed and installed for

pressurized service.

b) Secure the damper to the vent with screws and

seal the joints with a bead of high temperature

silicone sealant (found in Section Assembly Kits).

c) The vent must be installed so it can be

disconnected and the Top Flue Outlet removed

for proper cleaning of the flueways.

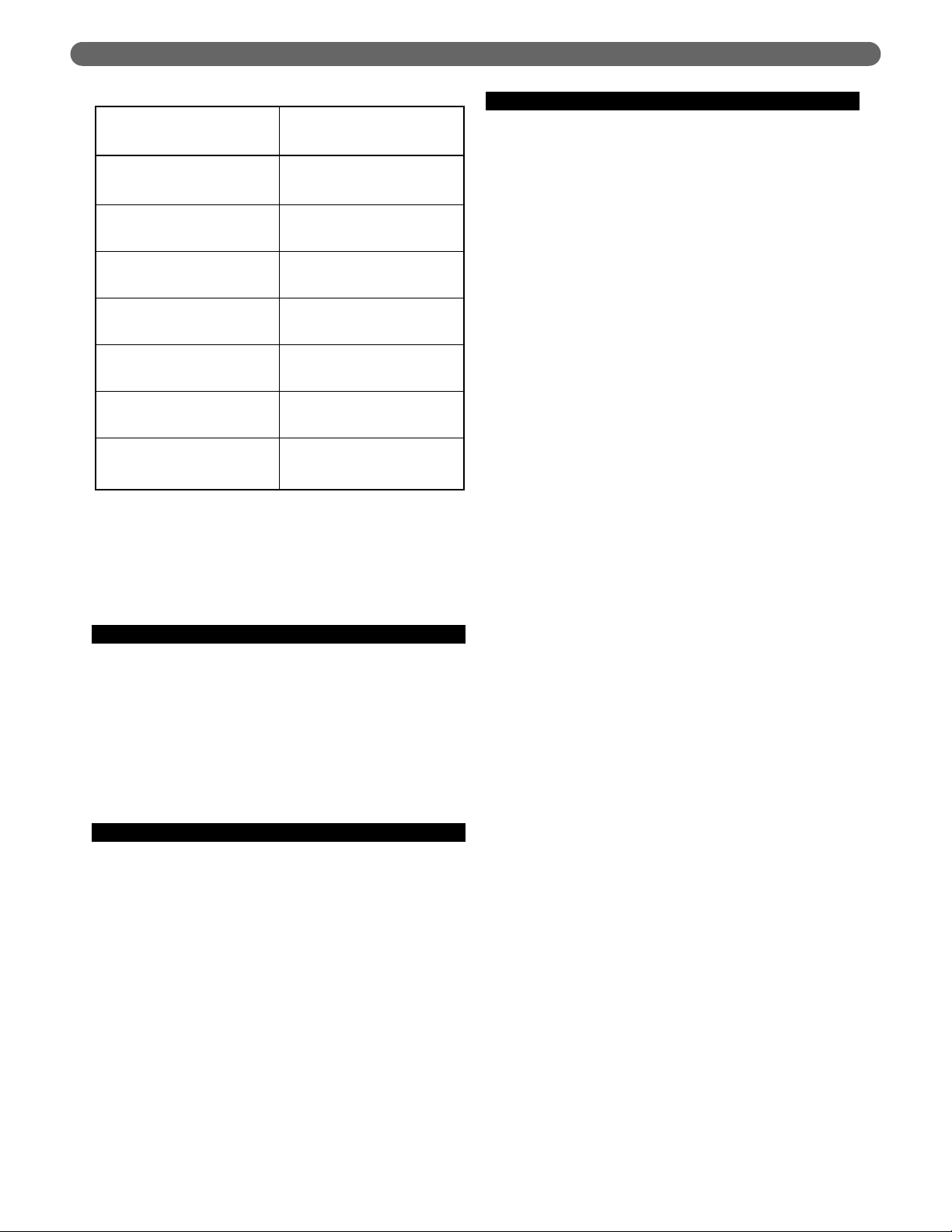

E. BOILER SETTING

1. If the boiler room floor is not level or if additional

structural support is needed, provide a good, level

foundation for the boiler with the minimum

dimensions given in Table 1.1. The flooring and

structural support system must be suitable for the

operating weight of the boiler and any connected

piping. Place the Steel Channels on the foundation

as shown in Figure 1.4.

2. Do not operate the boiler until the foundation, if new

concrete, has thoroughly cured. The concrete might

be damaged if heated too quickly due to the

entrained moisture remaining.

3. If the boiler is installed in a penthouse or if wiring of

any sort is run underneath the boiler foundation,

construct the foundation with provision for air flow

underneath between the main floor and the top of

the boiler foundation.

a) An acceptable foundation would be concrete

blocks laid with the openings lined up.

Do not install this boiler on carpeting or any

combustible flooring. A significant fire hazard could

result, with potential for property damage, personal

injury or death.

WARNING

Figure 1.4: Foundation Layout

PREINSTALLATION

b) If the foundation must be a concrete slab, use an

air cell high temperature insulating board, at least

1/2 inch thick, with aluminum backing,

aluminum side up. 1/2 inch thick high

temperature millboard with aluminum backing is

acceptable as well. Place the insulating board on

the slab between the steel channels.

F. INSTALLATION SURVEY

For new and existing installations, a Water Installation

Survey is available from PB Heat, LLC. The survey will

provide information on how a hot water boiler works

with your specific system and will provide an overview

of hot water system operation in general.

You can also use this survey to locate system problems

which will have to be corrected. To obtain copies of the

Water Installation Survey, contact your PB Heat

representative or download it from PeerlessBoilers.com.

G. PLANNING THE LAYOUT

Prepare sketches and notes of the layout to minimize the

possibility of interferences with new or existing

equipment, piping, venting and wiring.

H. VERIFY COMPONENTS

1. Packaged: All components should be inside crate. In

some cases the burner may be shipped separately.

Optional equipment, such as barometric draft

dampers, may also be shipped separately.

2. Knockdown: All components shipped for field

assembly. See Table 1.2 for standard components.

See Tables 1.3 through 1.8 for optional components.

a) Channel Rails

b) Sections

c) Assembly Kit Carton(s): Includes flow port

gaskets, tie rods with hardware, high temperature

rope, and cleanout cover plates.

d) Flue Box Carton: Includes flue box, rear flue

cover plate (LCE only), rear observation

assembly and port cover plates.

e) Baffle Carton

i) LC: Includes baffles, combustion chamber

liner and rating label.

ii) LCE-21 through LCE-24: Baffles

f) Jacket Cartons: Include ASME plate

g) Draft Damper (LCE only)

h) Label Carton (LCE only)

i) Burner Mounting Plate

j) Trim Carton: Includes safety relief valve and

temperature-pressure gage

k) Control Carton: Limit controls

l) Tankless Heater(s)

m) Additional controls and fittings

3. Assembled Block: Same as knockdown except

channel rails, sections and assembly kit cartons are

assembled into a block as a single shipping level

component.

5

Table 1.1: Foundation Lengths

LC-04

LC-05

LC-06

LC-07

LC-08

LC-09

LC-10

LC-11

LC-12

LCE-13

LCE-14

LCE-15

LCE-16

LCE-17

LCE-18

LCE-19

LCE-20

LCE-21

LCE-22

LCE-23

LCE-24

Model

Foundation Length, Inches

37¹⁵⁄₁₆

43

48¹⁄₁₆

53¹⁄₈

58⁵⁄₁₆

63³⁄₈

68⁷⁄₁₆

73¹⁄₂

78⁹⁄₁₆

83³⁄₄

88¹³⁄₁₆

93⁷⁄₈

98¹⁵⁄₁₆

104¹⁄₈

109³⁄₁₆

114¹⁄₄

119⁷⁄₁₆

124¹⁄₂

129⁹⁄₁₆

134⁵⁄₈

139¹¹⁄₁₆

PREINSTALLATION

6

PREINSTALLATION

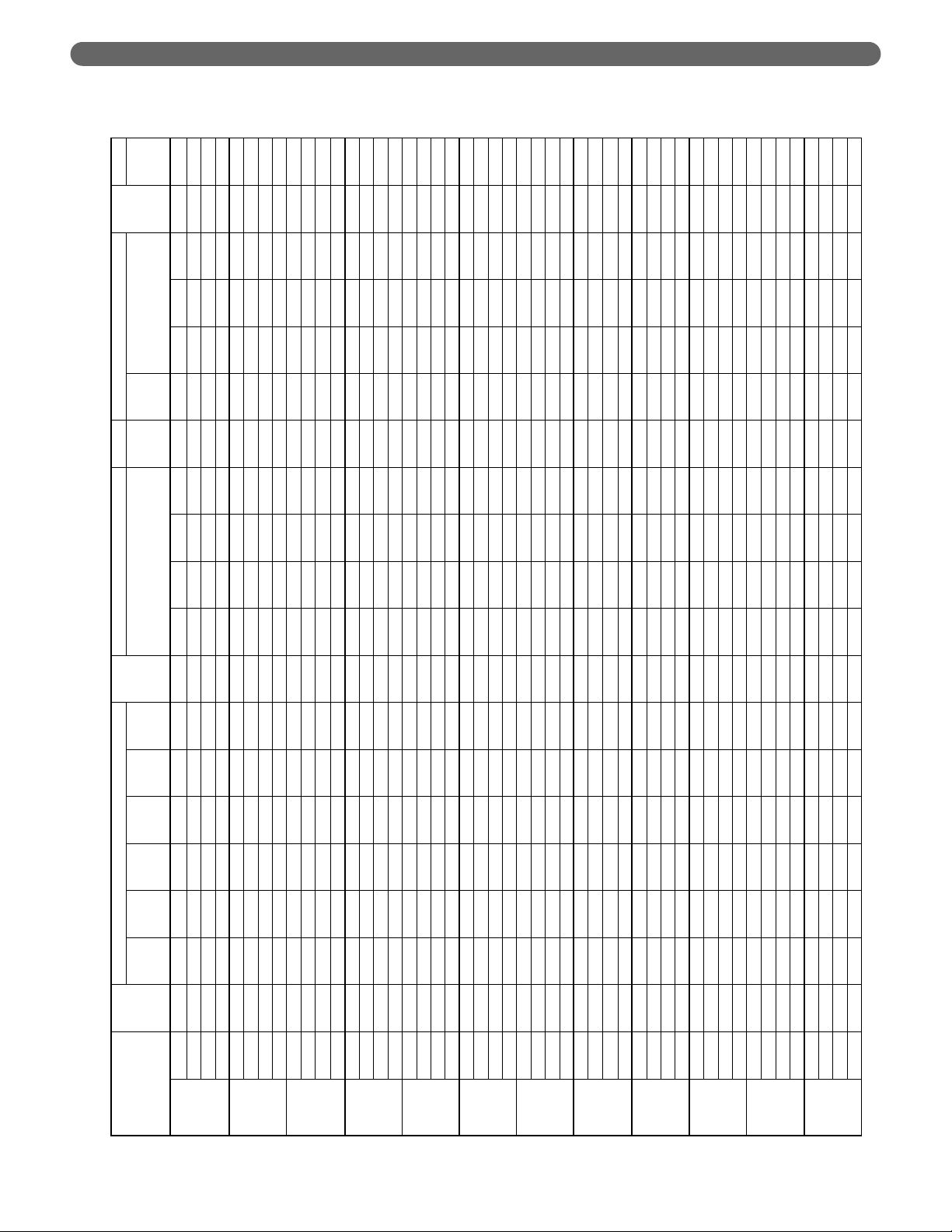

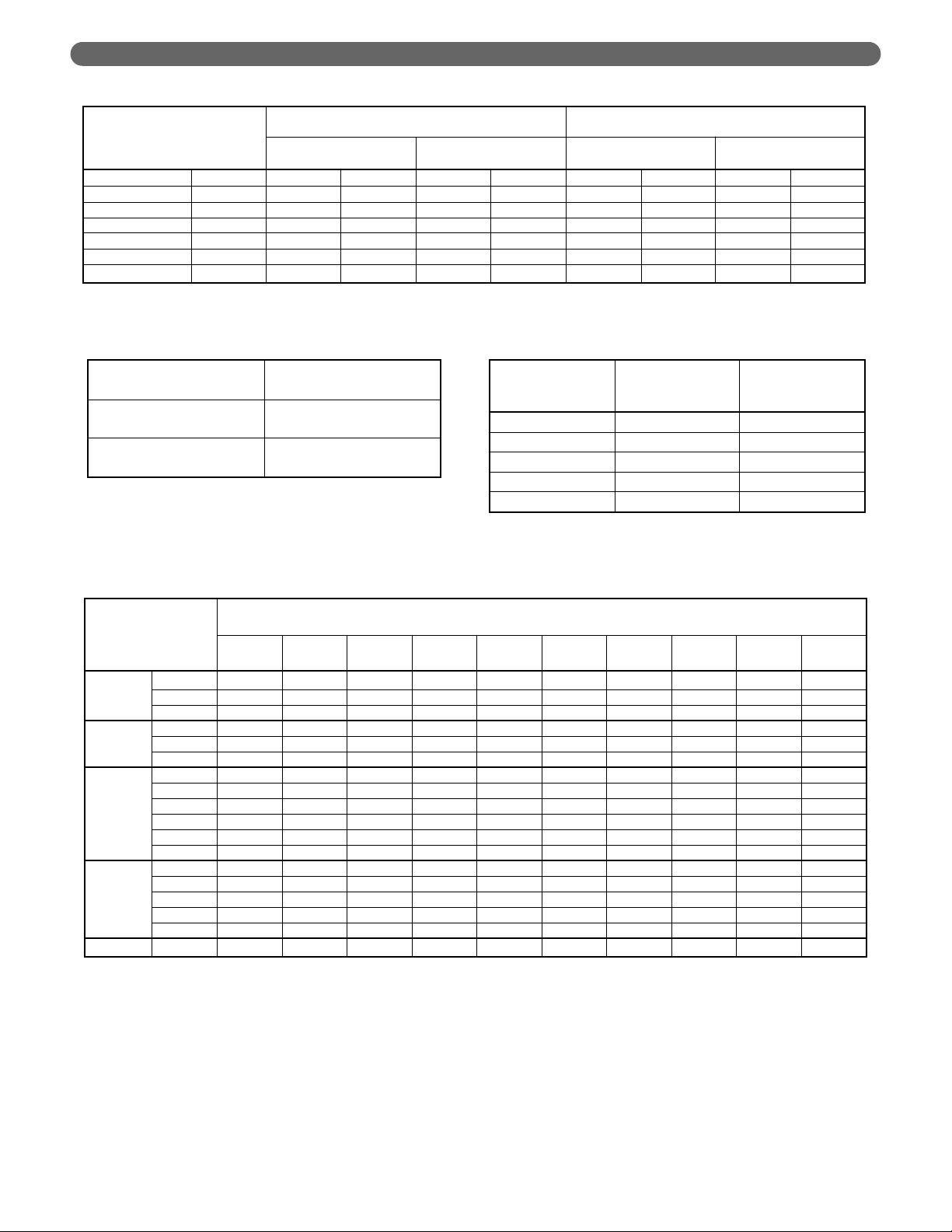

Table 1.2A: Series LC Shipping List

Panels

Top/Side

Hardware

(Tbl 1.4, 1.5 Options)Flue Ctn.

Panels

Front/Rear

Contents

See Below

Contents

See Below

Assembly Kit Ctns. Jacket Cartons

Baffle

3" Tap.

1"

LWCO

Chamber Liner

1

LC-6017

1

LC-6016

Hardware

1

Item 2

LC-5004

Item 1

1

LC-1022

1

LC-1023

Carton

Interm.

1

Interm.

LC-1000-1

A

A

A

LC-04

86031

86030

86040

86050

85004

86005

1

1

1

1

1

1

B

LC-6017-1

LC-6016

A

LC-5004

B

LC-1022-1

LC-05

LC-1023

LC-1000-1

86032

86030

86040

86051

85105

86005

1

1

1

1

1

1

B

LC-6017-1

LC-6016

A

LC-5004

B

LC-1022-1

LC-05

LC-1023-1

LC-1000-1

86032

86030

86040

86051

85005

86005

1

1

1

1

1

1

C

LC-6017-2

LC-6016

B

LC-5004-1

C

LC-1022-2

LC-06

LC-1023-2

LC-1000-1

86033

86030

86041

86052

85006

86005

1

1

1

1

1

1

D

LC-6017-3

LC-6016

B

LC-5004-1

D

LC-1022-3

LC-07

LC-1023-3

LC-1000-1

86034

86030

86041

86053

85007

86005

1

1

1

1

1

1

1

1

1

B

LC-6017-1

A

LC-6017

LC-6016

B

LC-5004-1

B

LC-1022-1

A

LC-1022

LC-08

LC-1023-4

LC-1003

LC-1000-1

86032

86031

86030

86041

86051

86050

85008

86008

86005

2

1

1

2

1

1

1

B

LC-6017-1

LC-6016

C

LC-5004-2

B

LC-1022-1

LC-09

LC-1023-5

LC-1003

LC-1000-1

86032

86030

86042

86051

85009

86008

86005

1

1

1

1

1

1

1

1

1

C

LC-6017-2

B

LC-6017-1

LC-6016

C

LC-5004-2

C

LC-1022-2

B

LC-1022-1

LC-10

LC-1023-6

LC-1003

LC-1000-1

86033

86032

86030

86042

86052

86051

85010

86008

86005

2

1

1

2

1

1

1

C

LC-6017-2

LC-6016

C

LC-5004-2

C

LC-1022-2

LC-11

LC-1023-7

LC-1003

LC-1000-1

86033

86030

86042

86052

85011

86008

86005

1

1

1

1

1

1

1

1

1

D

LC-6017-3

C

LC-6017-2

LC-6016

C

LC-5004-2

D

LC-1022-3

C

LC-1022-2

LC-12

LC-1023-8

LC-1003

LC-1000-1

86034

86033

86030

86042

86053

86052

85012

86008

86005

1

Plain

Interm.

1

Back

Standard Sections (See Table 1.3 for Options)

Channel

Boiler

Front

Rail

Bundle

Model

Number

1

1

Quantity

LC-04

LC-1000

LC-1007

LC-1001

Label

Par t N o.

86004

86022

86000

90160

Stock Code

2

LC-1000

1

LC-1007

1

LC-1001

1

Par t N o.

Quantity

LC-05R

Label

2

86004

1

86022

1

86000

1

90161

Quantity

Stock Code

LC-05

LC-1000

LC-1007

LC-1001

Label

Par t N o.

3

86004

1

86022

1

86000

1

90161

Quantity

Stock Code

LC-06

LC-1000

LC-1007

LC-1001

Label

Par t N o.

4

86004

1

86022

1

86000

1

90162

Quantity

Stock Code

LC-07

LC-1000

LC-1007

LC-1001

Label

Par t N o.

4

86004

1

86022

1

86000

1

90163

Quantity

Stock Code

LC-08

LC-1000

LC-1007

LC-1001

Label

Par t N o.

5

86004

1

86022

1

86000

1

90164

Quantity

Stock Code

LC-09

LC-1000

LC-1007

LC-1001

Label

Par t N o.

6

86004

1

86022

1

86000

1

90165

Quantity

Stock Code

LC-10

LC-1000

LC-1007

LC-1001

Label

Par t N o.

7

86004

1

86022

1

86000

1

90166

Quantity

Stock Code

LC-11

LC-1000

LC-1007

LC-1001

Label

Par t N o.

8

86004

1

86022

1

86000

1

90167

Quantity

Stock Code

LC-12

LC-1000

LC-1007

LC-1001

Label

Par t N o.

86004

86022

86000

90168

Stock Code

1 Assembly Kit Cartons Contents: Flow Port Gaskets, Silicone Sealant, Tie Rods, Washers, Tie Rod Nuts, Section Seal Rope, Spray Adhesive, Cleanout Plates, Mounting Hardware

2 Flue Box Carton Contents: Flue Box, Seal Rope, Observation Assembly, Coil Cover Plates, Cover Plate Gaskets, Mounting Hardware

7

PREINSTALLATION

Table 1.2B: Series LCE Shipping List

1

Label

Rating

1

Draft

Damper

1

1

Panels

Top/Side

Hardware

Chamber Liner

1

1

Panels

Hardware

Front/Rear

1

Item 1

Contents

See Below

1

Assembly Kit Cartons Jacket Cartons (See Table 1.4, 1.5 for Options)Flue Ctn. Lbl. Ctn.

Flow Port Gaskets, Silicone Sealant,

1

Tie Rods, Washers, Tie Rod Nuts, Section Seal Rope,

Spray Adhesive, Cleanout Plates, Mounting Hardware

85013

LCE-8028

A

90523

S-5007-3

E

86094

LCE-6023

B

86032

LCE-6017-1

A

86031

LCE-6017

86030

LCE-6016

D

86043

LCE-5011

E

86054

C

86052

1

LCE-8028-1

1

S-5007-3

1

LCE-6023

2

LCE-6017-1

1

LCE-6016

1

LCE-5011

1

1

1

85014

1

A

90523

1

E

86094

1

1

B

86032

1

86030

1

D

86043

1

1

E

86054

1

D

86053

85015

LCE-8028-2

A

90523

S-5007-3

E

86094

LCE-6023

C

86033

LCE-6017-2

B

86032

LCE-6017-1

86030

LCE-6016

D

86043

LCE-5011

E

86054

B

86051

A

86050

1

1

1

2

1

1

1

2

85016

LCE-8028-3

A

90523

S-5007-3

E

86094

LCE-6023

C

86033

LCE-6017-2

86030

LCE-6016

D

86043

LCE-5011

E

86054

B

86051

1

LCE-8028-4

1

S-5007-3

1

LCE-6023

2

LCE-6017-1

1

LCE-6017

1

LCE-6016

1

LCE-5011

1

1

1

1

85017

1

A

90523

1

E

86094

B

86032

3

A

86031

1

86030

1

D

86043

E

86054

1

C

86052

2

B

86051

85018

LCE-8028-5

B

90524

S-5007-4

E

86094

LCE-6023

B

86032

LCE-6017-1

86030

LCE-6016

E

86044

LCE-5012

E

86054

C

86052

1

1

1

1

2

1

1

1

1

1

85019

LCE-8028-6

B

90524

S-5007-4

E

86094

LCE-6023

C

86033

LCE-6017-2

B

86032

LCE-6017-1

86030

LCE-6016

E

86044

LCE-5012

E

86054

D

86053

C

86052

1

LCE-8028-7

1

S-5007-4

1

LCE-6023

2

LCE-6017-1

2

LCE-6017

1

LCE-6016

1

LCE-5012

1

2

1

85020

1

B

90524

1

E

86094

3

B

86032

1

A

86031

1

86030

1

E

86044

1

1

1

E

86054

1

D

86053

85021

LCE-8028-8

B

90524

S-5007-4

E

86094

LCE-6023

B

86032

LCE-6017-1

A

86031

LCE-6017

86030

LCE-6016

E

86044

LCE-5012

E

86054

D

86053

B

86051

A

86050

1

LCE-8028-9

1

S-5007-4

1

LCE-6023

4

LCE-6017-1

1

LCE-6016

1

LCE-5012

1

1

2

1

85022

1

B

90524

1

E

86094

1

3

B

86032

1

86030

1

E

86044

1

1

E

86054

1

D

86053

1

B

86051

85023

LCE-8028-10

B

90524

S-5007-4

E

86094

LCE-6023

C

86033

LCE-6017-2

B

86032

LCE-6017-1

86030

LCE-6016

E

86044

LCE-5012

E

86054

D

86053

C

86052

B

86051

1

LCE-8028-11

1

S-5007-4

1

LCE-6023

2

LCE-6017-2

2

LCE-6017-1

1

LCE-6016

1

LCE-5012

1

1

2

85024

B

90524

E

86094

C

86033

B

86032

86030

E

86044

E

86054

D

86053

C

86052

Baffle

Carton

1

6

Plain

Interm. Back

1

3" Tap.

Interm.

1

1"

LWCO

Interm.

3

Top

Flue

Interm.

Standard Sections (See Table 1.3 for Options)

1

Front

2

Rail

Bundle

Channel

Quantity

Boiler

Model

Number

LCE-13

LC-1007

LC-1000

LC-1003

LC-1000-1

LCE-1056

LC-1001

Label

Par t No.

1

86022

7

86004

1

86008

1

86005

3

86100

1

86000

2

90162

Quantity

Stock Code

LCE-14

LC-1007

LC-1000

LC-1003

LC-1000-1

LCE-1056

LC-1001

Par t No.

Label

1

86022

8

86004

1

86008

1

86005

3

86100

1

86000

2

90162

Quantity

Stock Code

LCE-15

LC-1007

LC-1000

LC-1003

LC-1000-1

LCE-1056

LC-1001

Label

Par t No.

1

86022

9

86004

1

86008

1

86005

3

86100

1

86000

2

90163

Quantity

Stock Code

LCE-16

LC-1007

LC-1000

LC-1003

LC-1000-1

LCE-1056

LC-1001

Label

Par t No.

1

86022

10

86004

1

86008

1

86005

3

86100

1

86000

2

90163

Quantity

Stock Code

LCE-17

LC-1007

LC-1000

LC-1003

LC-1000-1

LCE-1056

LC-1001

Label

Par t No.

1

86022

11

86004

1

86008

1

86005

3

86100

1

86000

2

90164

Quantity

Stock Code

LCE-18

LC-1007

LC-1000

LC-1003

LC-1000-1

LCE-1056

LC-1001

Label

Par t No.

1

86022

12

86004

1

86008

1

86005

3

86100

1

86000

2

90164

Quantity

Stock Code

LCE-19

LC-1007

LC-1000

LC-1003

LC-1000-1

LCE-1056

LC-1001

Label

Par t No.

1

86022

13

86004

1

86008

1

86005

3

86100

1

86000

2

90165

Quantity

Stock Code

LCE-20

LC-1007

LC-1000

LC-1003

LC-1000-1

LCE-1056

LC-1001

Label

Par t No.

1

1

86022

13

86004

2

86008

1

86005

3

86100

1

86000

2

90165

Quantity

Stock Code

LCE-21

LCE-1074

LC-1007

LC-1000

LC-1003

LC-1000-1

LCE-1056

LC-1001

Label

Par t No.

1

86113

1

86022

14

86004

2

86008

1

86005

3

86100

1

86000

2

90166

Quantity

Stock Code

LCE-22

LCE-1074

LC-1007

LC-1000

LC-1003

LC-1000-1

LCE-1056

LC-1001

Label

Par t No.

1

86113

1

86022

15

86004

2

86008

1

86005

3

86100

1

86000

2

90166

Quantity

Stock Code

LCE-23

LCE-1074

LC-1007

LC-1000

LC-1003

LC-1000-1

LCE-1056

LC-1001

Label

Par t No.

1

86113

1

86022

16

86004

2

86008

1

86005

3

86100

1

86000

2

90167

Quantity

Stock Code

LCE-24

LCE-1074

LC-1007

LC-1000

LC-1003

LC-1000-1

LCE-1056

LC-1001

Label

Par t No.

86113

86022

86004

86008

86005

86100

86000

90167

Stock Code

1 Flue Box Carton Contents: Top Flue Plate, Rear Flue Cover, Seal Rope, Observation Assembly, Coil Cover Plates, Cover Plate, Gaskets, Mounting Hardware

Part #/UPC

Part #/UPC

Part #/UPC

Part #/UPC

Part #/UPC

Part #/UPC

Part #/UPC

8

PREINSTALLATION

Note: 80 psig MAWP not available in Canada.

Note: Boilers with inspection tappings in front and back sections only use

standard cartons.

Table 1.5: Standard and Optional Jacket Cartons,

Top/Side Panels

Front

Plain Interm.

Top Flue Interm.

LWCO Interm.

3" Tap. Interm.

Closed Back

Coil Back

Sections

50 psig MAWP 80 psig MAWP

w/Inspection Tappings

Standard

No Inspection Tappings

No Inspection Tappings w/Inspection Tappings

LC-1001

LC-1000

LCE-1056

LC-1000-1

LC-1003

LC-1007

LC-1002

86000

86004

86100

86005

86008

86022

86036

LC-1013

LC-1014

LCE-1064

LC-1014-2

LC-1015

LC-1016

LC-1017

86010

86014

86110

86092

86016

86018

86026

LC-1001-2

LC-1000-2

LCE-1056-1

LC-1000-3

LC-1003-2

LC-1007-2

LC-1002-2

86002

86006

86111

86007

86009

86024

86038

LC-1013-2

LC-1014-1

LCE-1064-1

LC-1014-3

LC-1015-1

LC-1016-2

LC-1017-2

86012

86015

86112

86093

86017

86020

86028

Table 1.6A: Burner Mounting Plates

Model

CF-800

CF-1400

CF-2300

301CRD

702CRD

801CRD

S4.2

R6.2

R6.3

R8.1

R8.2

R8.3

C1

C2

J15A

J30A

J50A

JB1

Boiler Model

86070*

86070*

86070*

86071

86072

86071

LC-04

86070*

86070*

86070*

86071

86072

86071

LC-05R

86069*

86069*

86078

86071

86072

86071

LC-05

86069*

86069*

86078

86071

86072

86071

LC-06

86069*

86069*

86079

86071

86072

86071

LC-07

86074*

86069*

86079

86076

86077

86075

LC-08

86074*

86073

86079

86076

86077

86075

LC-09

86074*

86073

86079

86076

86077

86075

LC-10

86074*

86073

86079

86076

86077

86075

LC-11

86074*

86073

86079

86076

86075

LC-12

Beckett

Carlin

Gordon

Piatt

Power

Flame

Webster

* Standard Burner Mounting Plate

Standard 50

psig MAWP

86030

30 psig MAWP 86059

80 psig MAWP 86058

Table 1.4: Standard and Optional Jacket

Cartons, Front/Back Panels

Jacket Label

Standard

(No Inspection

Tappings)

With Inspection

Tappings

A 86031 86101

B 86032 86102

C 86033 86103

D 86034 86104

E 86094 86097

Table 1.3: Standard and Optional Sections for Knockdown Boilers

9

PREINSTALLATION

Table 1.8: Control Cartons

Table 1.7: Trim Cartons

LC-04

LC-05R

LC-05

LC-06

LC-07

LC-08

LC-09

LC-10

LC-11

LC-12

LCE-13

LCE-14

LCE-15

LCE-16

LCE-17

LCE-18

LCE-19

LCE-20

LCE-21

LCE-22

LCE-23

LCE-24

Model

87030

87030

87030

87030

87031

87031

87032

87032

87032

87032

87032

87033

87033

87033

87033

87033

87034

87034

87034

87034

87034

87034

Output

1

30 psig

87050

87050

87050

87050

87050

87050

87051

87051

87051

87051

87052

87052

87052

87052

87052

87052

87052

87053

87053

87053

87053

87053

50 psig

87080

87080

87080

87080

87080

87080

87080

87081

87081

87081

87081

87081

87082

87082

87082

87082

87082

87802

87082

87082

87082

87082

80 psig

1 Safety Relief Valve selection based on capacity determined by boiler

output (Gross I=B=R Output). Applies to most locations in United

States and Canada.

Table 1.6B: Burner Mounting Plates

Model

CF2300AKG

CF2300AKB

CF2500

CF3500AKM

CF3500AKL

801CRD

1050FFD

1150FFD

R10.9

R10

R10.1

R10.2

C2

C3

JB2

Boiler Model

86074*

86073

86088

86076

86081

LCE-13

86083*

86073

86088

86076

86081

LCE-14

86083*

86086

86088

86076

86081

LCE-15

86074*

86086

86088

86080

86081

LCE-16

86074*

86087

86088

86080

86081

LCE-17

86083*

86087

86088

86080

86081

LCE-18

86083*

86087

86088

86080

86081

LCE-19

86083*

86087

86088

86080

86081

LCE-20

86080*

86087

86088

86080

86081

LCE-21

86080*

86087

86088

86080

86081

LCE-22

86087

86088

86080

86081

LCE-23

N/A

86088

86080

86081

LCE-24

Beckett

Carlin

Gordon

Piatt

Power

Flame

Webster

* Standard Burner Mounting Plate

Not

Available

LC-04

Through

LCE-24

Model

Water

88510

A. PACKAGED BOILER

1. Remove crate top and sides. Remove any loose

cartons. Remove burner support pedestal and

nipple, if supplied

2. Lift boiler off crate pallet. Move to location

determined in Chapter 1: Preinstallation.

3. Remove lifting frame and hardware.

4. Re-install burner support pedestal and nipple if

necessary.

5. Proceed to Chapter 3: Piping the Boiler.

B. ASSEMBLED BLOCK BOILER

1. Move block to location determined in Chapter 1:

Preinstallation.

2. Remove lifting frame and hardware.

3. Proceed to Section D: Install Coils or Plates

C. KNOCKDOWN BOILER

1. Place channel rails as shown in Figure 1.4.

2. Open the Section Assembly Kit cartons. These

cartons contain the parts needed for assembly of the

sections.

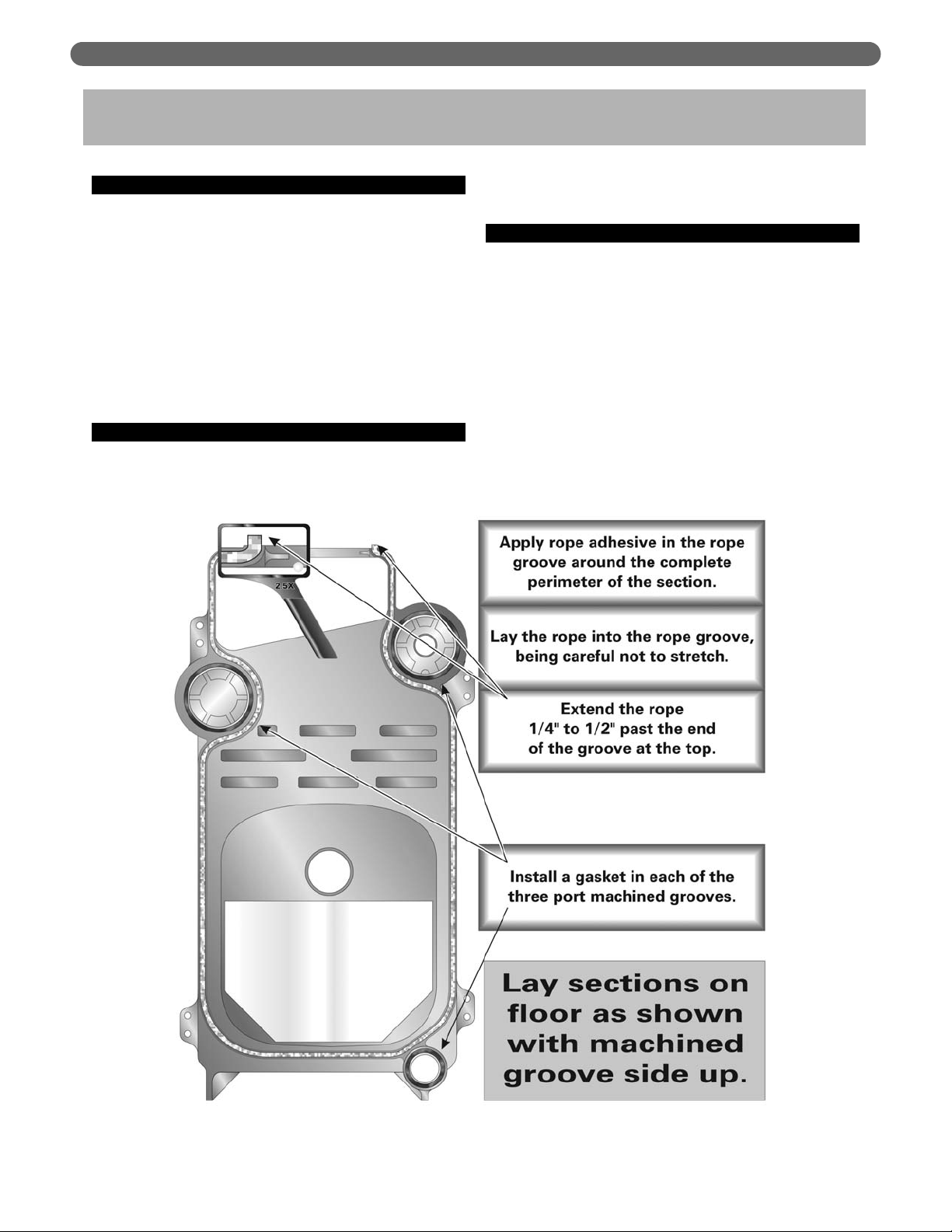

3. Place the Back Section on the floor as shown in

Figure 2.1.

4. The Back Section combustion chamber area is lined

with a ceramic fiber blanket liner. Make sure the liner

is in good condition. Minor tears are not a problem,

but there should be no holes in the insulation.

10

PLACE THE BOILER

2. PLACE THE BOILER

Figure 2.1: Lay Sections on Floor and Apply Rope Seal and Gaskets

5. Clean the area around the flow ports and in the seal

recess. Use solvent and a clean cloth to thoroughly

clean all of the sealing surfaces. Remove all foreign

matter to assure a water tight seal when the sections

are drawn together.

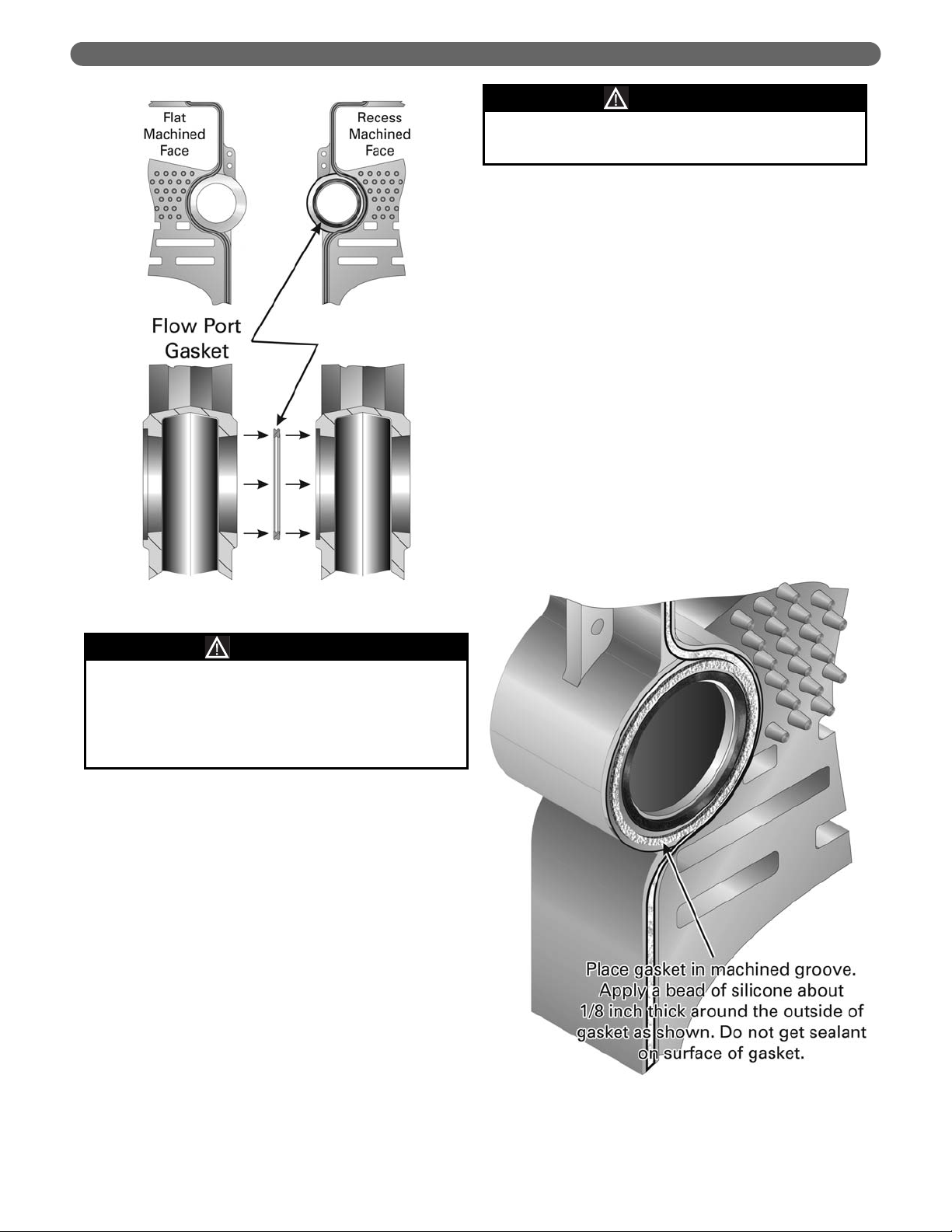

6. Place a Flow Port Gasket in each of the three flow

port recesses as shown in Figures 2.1 and 2.2.

7. Apply spray adhesive in the rope groove around the

perimeter of the section.

8. Place the sealing rope completely around the rope

groove, being careful not to stretch the rope. Extend

the rope from 1/4" to 1/2" past the end of the groove

on both sides of the cleanout opening on top of the

section. This will assure a gas tight seal when the

cleanout cover plate is applied.

9. Apply a bead of silicone sealant around each flow

port as shown in Figure 2.3. Do not get sealant on

the flow port gaskets.

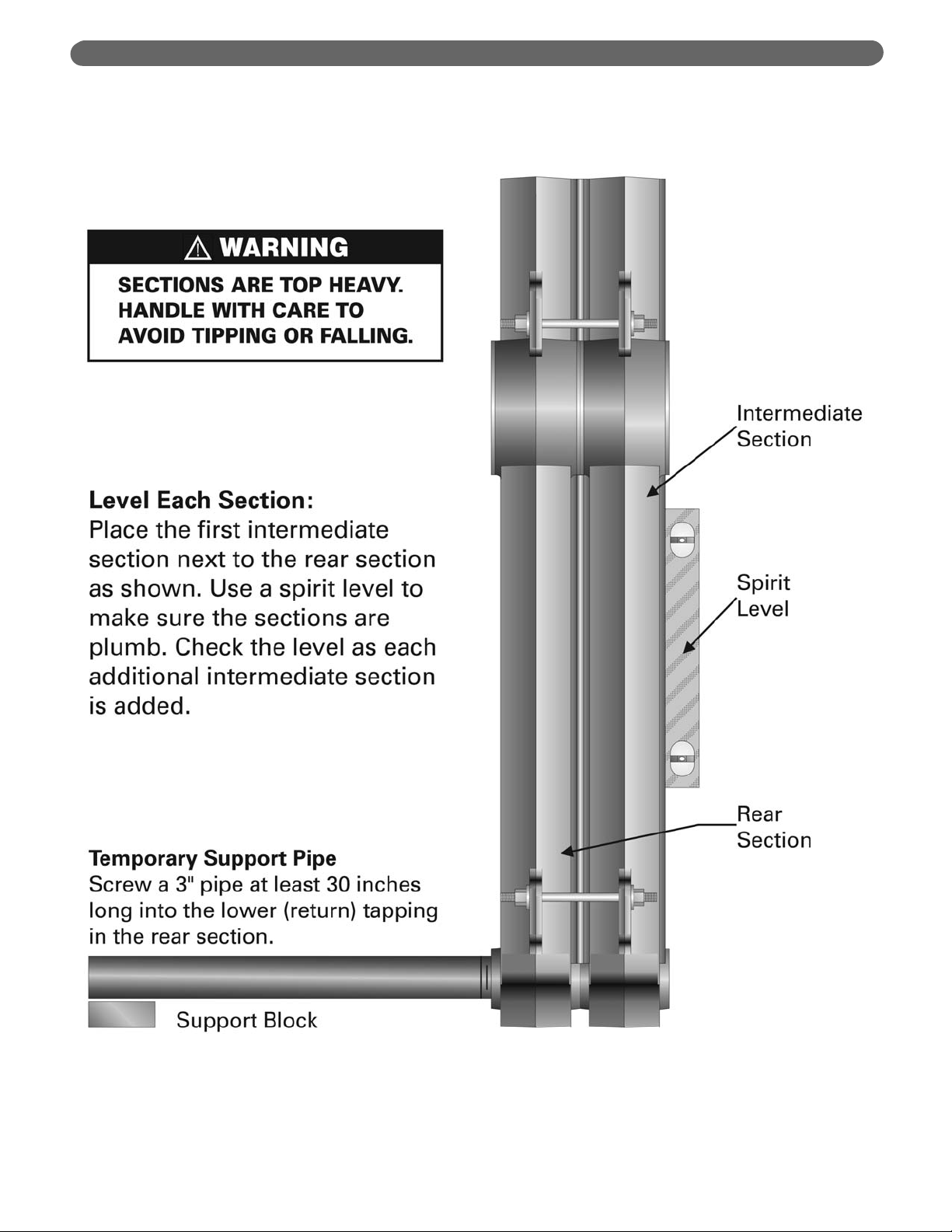

10. Lift up the Rear Section and move into position on

the steel channels on the boiler foundation.

11. Screw a 3" pipe at least 30 inches long into the

lower 3" tapping on the back of the Rear Section as

shown in Figure 2.4. Place a block under the pipe as

shown in the figure and use as a brace during

assembly.

12. Place a Plain Intermediate Section on the floor and

prepare as above.

13. Carefully place the Intermediate Section against the

Rear Section and visually line up the flow ports as

close as possible.

14. Insert a tie rod with one nut and washer applied

into each of the four tie rod lugs. See Figures 2.5

and 2.6.

15. Place the nut and washer on the other end of the tie

rod and draw finger tight.

11

PLACE THE BOILER

Figure 2.3: Apply Silcone Sealant

Gaskets will be damaged by petroleum or its

derivatives. Completely remove all solvent residue

before placing gaskets.

Do not use petroleum based compounds in the

boiler.

CAUTION

Figure 2.2: Flow Port Machining & Gasket

The sections are heavy and must be supported

securely.

WARNING

12

PLACE THE BOILER

Figure 2.4: Install Additional Sections. Use level on each section as tie rod bolts are drawn up.

13

PLACE THE BOILER

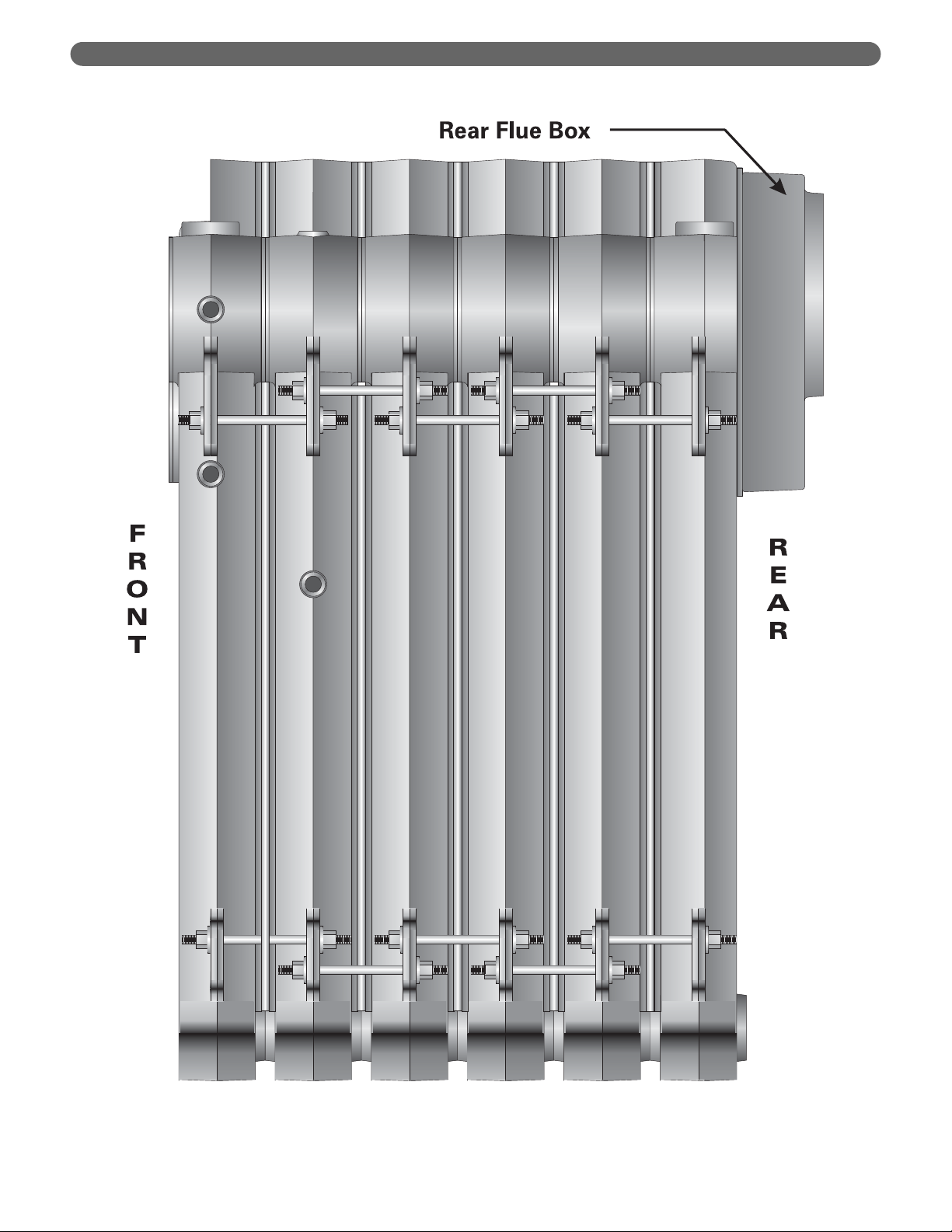

Figure 2.5: Series LC Boiler Assembly – Right Side View

14

PLACE THE BOILER

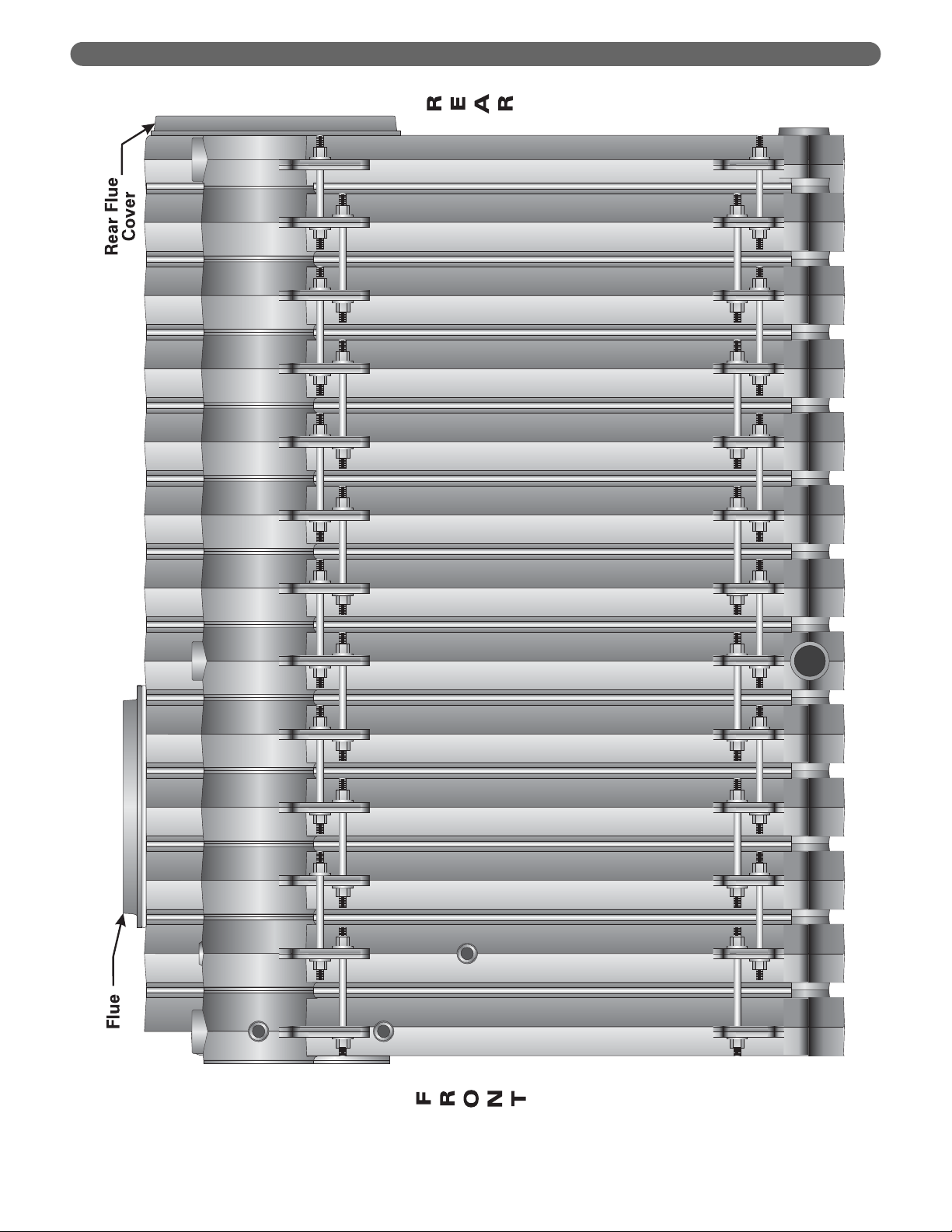

Figure 2.6: Series LCE Boiler Assembly – Right Side View

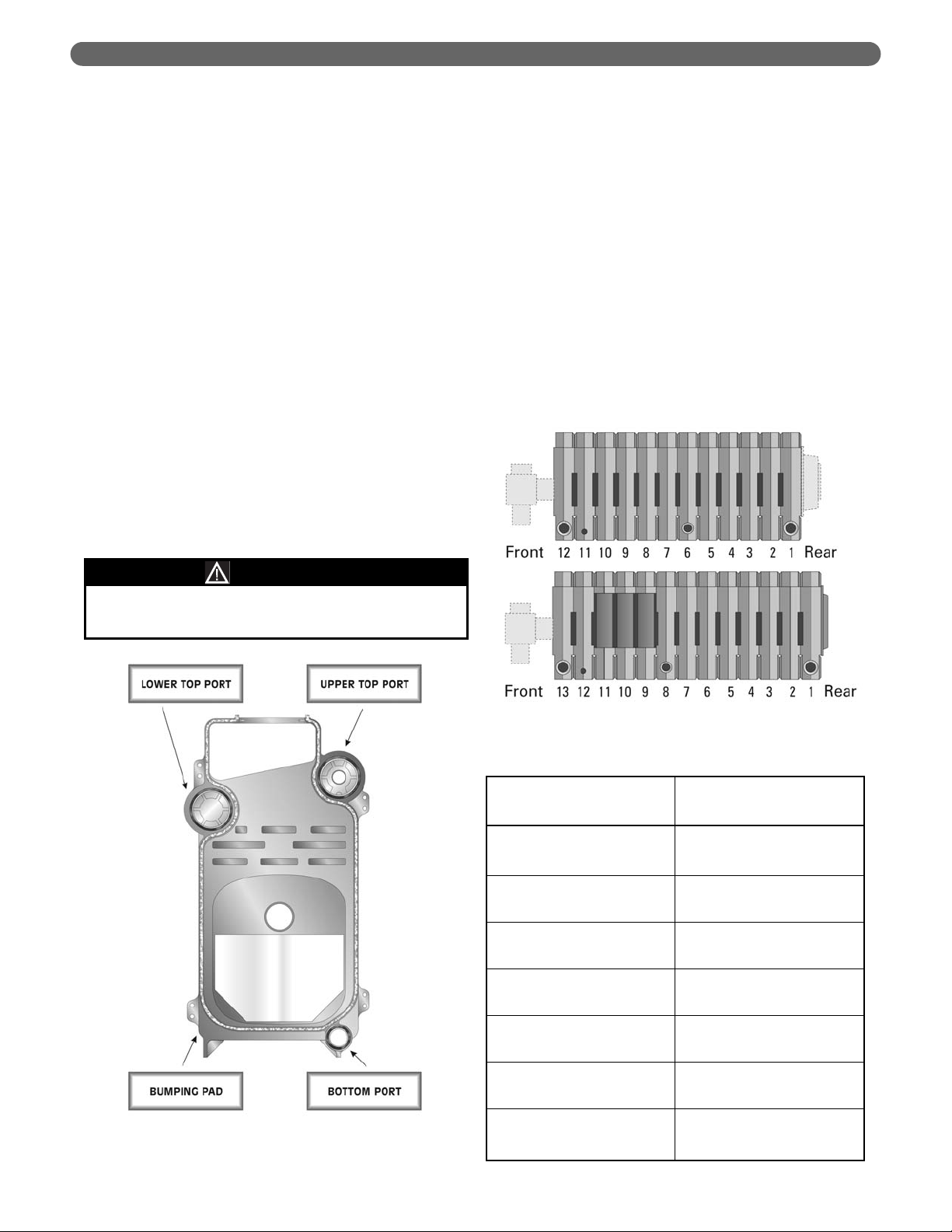

16. To properly assemble LC/LCE sections in the field,

the following steps must be followed to ensure that

no damage occurs to the tie rod lugs. A 0-100 ft-lbs

torque wrench is required.

a. Use a spirit level as shown in Figure 2.4 to check

the alignment of the sections as the nuts are

drawn up. Keep the sections plumb.

b. Draw the sections together evenly, in three

rotations. Torque each port to 20 ft-lbs for the

first rotation, then to 40 ft-lbs for the second

rotation, then to 60 ft-lbs for the third rotation.

Use the following sequence until all three ports

touch metal-to-metal at 60 ft-lbs. See Figure 2.7

for port reference.

i) First: Lower Top Port

ii) Second: Bottom Port

iii) Third: Upper Top Port

c. Tighten these (3) three locations only to a torque

value of 60 ft-lbs. DO NOT EXCEED.

d. After the three ports have been tightened to 60

ft-lbs, tighten the draw rod at the bumping pads

until metal-to-metal contact is reached. This will

assure a proper gas tight seal and prevent the

products of combustion from migrating into the

boiler room.

17. Repeat with the remaining sections.

a. Save the LWCO Intermediate with two 1"

tappings (for level control) for use as the section

closest to the front section.

b. Place the Intermediate Section with 3" top

tapping (Tapped Intermediate) in the position

given in Figure 2.9.

c. LCE ONLY. Save the (3) Top Flue Outlet

Intermediates (with wide opening in top of the

flue collector) for use as the sections closest to

the LWCO Intermediate Section. See Figure 2.9.

i) The sequence from Front to Rear is:

• Front Section

• 1" Low Water Cut-off Intermediate

• Three (3) Top Flue Outlet Intermediates

ii) The remaining intermediate sections are 3"

Tapped Intermediates or Plain Intermediates

as shown in Figure 2.8 and Figure 2.9.

15

Do not exceed the manufacturer’s torque

recommendations.

WARNING

PLACE THE BOILER

Figure 2.7: Torque Specification/Procedure

Figure 2.8: Section Positioning Numbering

Table 2.1: Section Numbering Sequence

LC-04

LC-05

LC-06

LC-07

LC-08

LC-09

LC-10

LC-11

LC-12

LCE-13

LCE-14

LCE-15

LCE-16

LCE-17

LCE-18

LCE-19

LCE-20

LCE-21

LCE-22

LCE-23

LCE-24

Model

Place a Tapped Intermediate

Section at Position

(Numbered Rear to Front)

NA

NA

NA

NA

4

5

5

6

6

8

9

10

11

9

9

9

9

9, 16

9, 17

10, 18

10, 19

Loading...

Loading...