Payne PY2PNB060090AA, PY2PNB060115AA, PY2PNB042060AA, PY2PNB048090AA, PY2PNB036060AA Installation Guide

...Page 1

Installation & Start-up

Instructions

PY1P, PY2P

Single Packaged Gas Heating/

Electric Cooling Units

NOTE: Read the entire instruction manual before starting the insta]lation.

TABLE OF CONTENTS

SAFETY CONSIDERATIONS ..................................................................................................................................................................................... 2

INTRODUCTION .......................................................................................................................................................................................................... 3

RECEIVING AND INSTALLATION .......................................................................................................................................................................... 3

CHECK EQUIPMENT ............................................................................................................................................................................................ 3

IDENTIFY UNIT ................................................................................................................................................................................................ 3

INSPECT SHIPMENT ........................................................................................................................................................................................ 3

INSTALLATION ................................................................................................................................................................................................ 3

PROVIDE UNIT SUPPORT ................................................................................................................................................................................... 3

ROOF CURB ...................................................................................................................................................................................................... 3

SLAB MOUNT ................................................................................................................................................................................................... 3

GROUND MOUNT ............................................................................................................................................................................................ 3

FIELD FABRICATE DUCTWORK ....................................................................................................................................................................... 3

PROVIDE CLEARANCES ...................................................................................................................................................................................... 6

RIG AND PLACE UNIT ......................................................................................................................................................................................... 8

CONNECT CONDENSATE DRAIN ...................................................................................................................................................................... 8

INSTALL FLUE HOOD .......................................................................................................................................................................................... 8

INSTALL GAS PIPING .......................................................................................................................................................................................... 9

INSTALL DUCT CONNECTIONS ...................................................................................................................................................................... 12

CONFIGURING UNITS FOR DOWNFLOW (VERTICAL) DISCHARGE ................................................................................................ 12

INSTALL ELECTRICAL CONNECTIONS ........................................................................................................................................................ 14

HIGH-VOLTAGE CONNECTIONS ............................................................................................................................................................... 14

SPECIAL PROCEDURES FOR 208-V OPERATION ................................................................................................................................... 15

CONTROL VOLTAGE CONNECTIONS ...................................................................................................................................................... 15

HEAT ANTICIPATOR SE'FflNG .................................................................................................................................................................. 15

TRANSFORMER PROTECTION ................................................................................................................................................................... 15

PRE-START-UP .......................................................................................................................................................................................................... 16

START-UP ................................................................................................................................................................................................................... 18

CHECK FOR REFRIGERANT LEAKS ............................................................................................................................................................... 18

START-UP HEATING AND MAKE ADJUSTMENTS ..................................................................................................................................... 18

CHECK HEATING CONTROL ...................................................................................................................................................................... 18

CHECK GAS INPUT ....................................................................................................................................................................................... 22

ADJUST GAS INPUT ...................................................................................................................................................................................... 22

CHECK BURNER FLAME ............................................................................................................................................................................. 23

AIRFLOW AND TEMPERATURE RISE ...................................................................................................................................................... 23

HEATING SEQUENCE OF OPERATION ..................................................................................................................................................... 23

LIMIT SWITCHES ........................................................................................................................................................................................... 23

AUXILIARY LIMFF SWITCH (ROLLOUT) ................................................................................................................................................. 24

START-UP COOLING AND MAKE ADJUSTMENTS ..................................................................................................................................... 24

CHECKING COOLING CONTROL OPERATION ....................................................................................................................................... 24

CHECKING AND ADJUSTING REFRIGERANT CHARGE ...................................................................................................................... 24

INDOOR AIRFLOW AND AIRFLOW ADJUSTMENTS ............................................................................................................................. 25

COOLING SEQUENCE OF OPERATION .................................................................................................................................................... 25

MAINTENANCE ........................................................................................................................................................................................................ 26

AIR FILTER ..................................................................................................................................................................................................... 28

EVAPORATOR BLOWER AND MOTOR .................................................................................................................................................... 28

FLUE GAS PASSAGEWAYS ......................................................................................................................................................................... 30

COMBUSTION-AIR BLOWER ...................................................................................................................................................................... 30

LIMIT SWITCH ............................................................................................................................................................................................... 31

BURNER IGNITION ........................................................................................................................................................................................ 31

Form: IM-PY1P-03 Cancels: IM-PY1P-02 Printed in U.S.A. 11-02 Catalog No. 53PY-1P15

Page 2

MAIN BURNERS ............................................................................................................................................................................................. 31

CONDENSER COIL, EVAPORATOR COIL, AND

CONDENSATE DRAIN PAN .......................................................................................................................................................................... 33

CONDENSER FAN .......................................................................................................................................................................................... 33

ELECTRICAL CONTROLS AND WIRING .................................................................................................................................................. 34

REFRIGERANT CIRCUIT ............................................................................................................................................................................... 35

GAS INPUT ...................................................................................................................................................................................................... 35

EVAPORATOR AIRFLOW ............................................................................................................................................................................. 35

METERING DEVICE ACUTROL DEVICE ............................................................................................................................................. 35

LIQUID LINE STRAINER .............................................................................................................................................................................. 35

TROUBLESHOOTING ............................................................................................................................................................................................... 35

START-UP CHECKLIST ............................................................................................................................................................................................ 35

NOTE TO INSTALLER Before the installation, READ THESE INSTRUCTIONS CAREFULLY AND COMPLETELY. Also, make sure the

User's Manual and Replacement Guide are left with the unit after installation. The furnace is NOT to be used for temporary heating of buildings

or structures under construction.

A99338

Fig. 1--Unit PYIP and PY2P

(Low NOx Model Available)

SAFETY CONSIDERATIONS

installation and servicing of air*conditioning equipment can be hazardous clue to system pressure and electrical components. Only trained and

qualified personnel should install, repair, or service air*conditioning equipment.

Untrained personnel can perform basic maintenance functions of cleaning coils and filters. All other operations should be performed by trained

service personnel. When working on air-conditioning equipment, observe precautions in the literature, tags, and labels attached to the unit, and

other safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work gloves. Use quenching cloth for unbrazing operations. Have fire extinguisher available for

all brazing operations.

WARNING: Improper installation, adjustment, alteration, service, maintenance, or use can cause carbon monoxide

poisoning, fire, or an explosion which can result in personal injury or unit damage. Consult a qualified installer, service

agency, or gas supplier for information or assistance. The qualified installer or agency must use only factory-authorized kits

or accessories when modifying this product.

A WARNING: Before performing service or maintenance operations on unit, turn off gas supply to unit. Then turn off unit

main power switch and install lockout tag, Electrical shock or explosion could cause serious injury or death.

Recognize safety information. This is the safety-alert symbolz_x. When you see this symbol in instructions or manuals, be alert to the potential

for personal injury.

Understand the signal words DANGER, WARNING, CAUTION, and NOTE. These words are used with the safety*alert symbol. DANGER

identifies the most serious hazards which will result in serious injury or death. WARNING signifies a hazard which could result in serious injury

or death. CAUTION is used to identify unsafe practices which would result in minor personal injury or product and property damage. NOTE is

used to highlight suggestions which will result in enhanced installation, reliability, or operation.

.... 2==.

Page 3

These instructions cover minimum requirements and conform to existing national standards and safety codes. In some instances, these instructions

exceed certain local codes and ordinances, especially those that may not have kept up with changing residential construction practices. We require

these instructions as a minimum for a safe installation.

INTRODUCTION

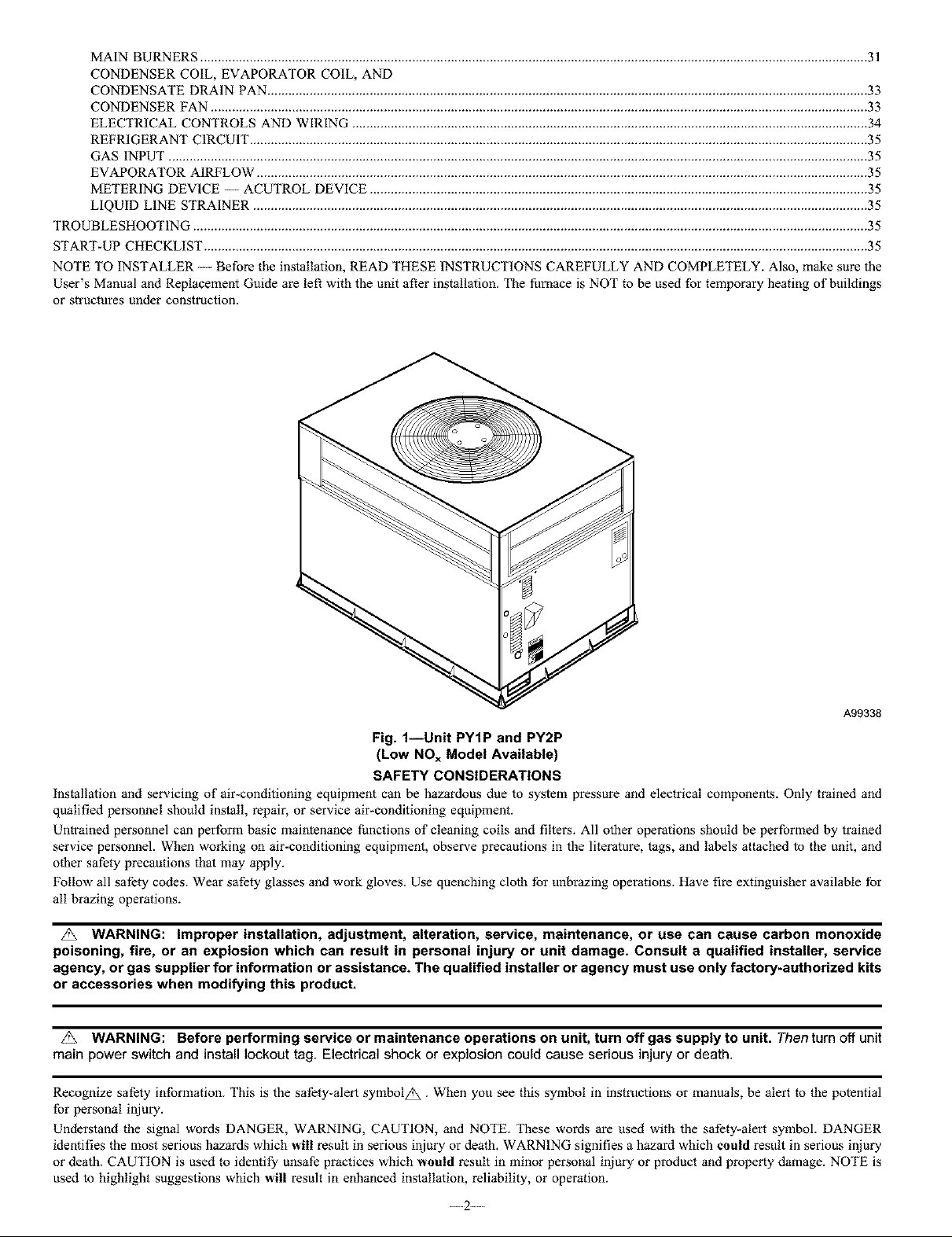

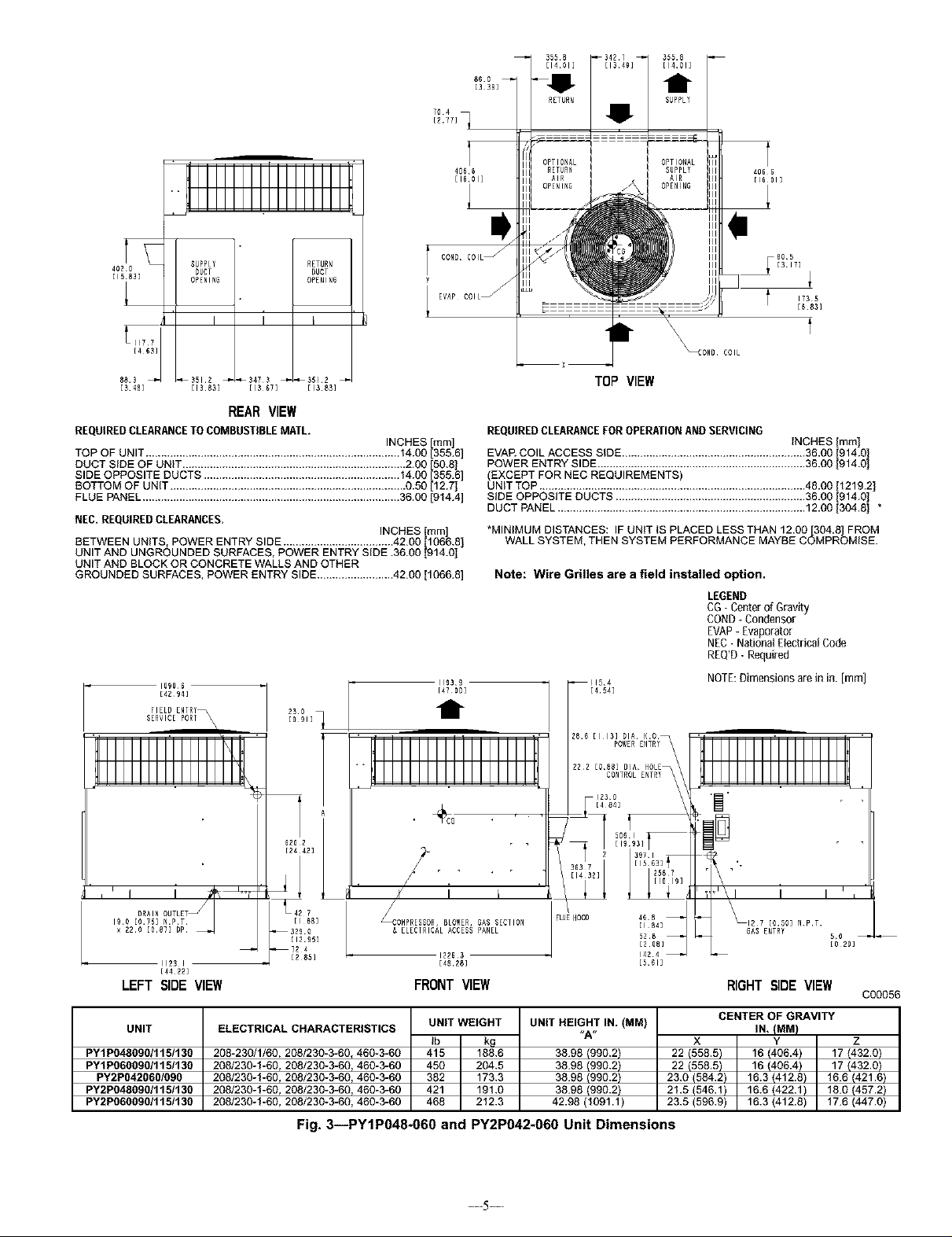

The PYIP and PY2P units (See Fig. I) are fully self-contained, combination Category 1gas heating/electric cooling units designed for outdoor

installation (See Fig. 2 and 3 for unit dimensions). All unit sizes have return and discharge openings for both horizontal and downflow

configurations, and are factory shipped with all downflow duct openings covered. Units may be installed either on a rooftop, a cement slab, or

directly on the grounst if local codes permit (See Fig. 4 for roof curb dimensions).

Models with an N in the thirteenth position of the model number are dedicated Low NO×units designed for California installations.

These models meet the California maximum oxides of nitrogen (NOx) emissions requirements of 40 nanograms/joule or less as shipped from the

factory and must be installed in California Air Quality Management Districts where a Low NO× rule exists.

RECEIVING AND INSTALLATION

PROCEDURE I--CHECK EQUIPMENT

A. IDENTIFY UNIT

The unit model number and serial number are stamped on unit identification plate. Check this information against shipping papers and job data.

Verify unit voltage and amperage requirements listed on unit rating plate agree with power supply provided to unit.

B. INSPECT SHIPMENT

inspect for shipping damage while Emitis still on shipping pallet. If unit appears to be damaged or is torn loose from its anchorage, have it examined

by transportation inspectors before removal. Forward claim papers directly to transportation company. Manufacturer is not responsible for any

damage incurred in transit.

Check all items against shipping list. immediately notify the nearest distributor if any item is missing.

To prevent loss or damage, leave all parts in original packages until installation.

C. INSTALLATION

1. Remove unit from shipping carton. Leave top shipping skid on the unit as a spreader bar to prevent the rigging straps from damaging the

unit. if the wood skid is not available, use a spreader bar of sufficient length to protect unit from damage.

2. Position the lifting bracket assembly around the base of the unit. Be sure the strap does not twist.

3. Place each of the 4 metal lifting brackets into the rigging holds in the composite pan.

4. Thread lifting bracket strapping around bottom perimeter of unit as follows:

a. Open lever of tension buckle (ratchet type).

b. Feed strapping through tension buckle as shown in Fig. 7A.

c. Pull strapping through tension buckle unit taut.

d. Snap lever down to lock strap in tension buckle. To release strapping, squeeze safety latch, lift lever, and pull webbing outward.

5. Tighten the tension buckle until it is taut. Lifting brackets must be secure in the rigging holds.

6. Attach field-supplied clevis or hook of sufficient strength to hole in the lifting bracket (See Fig. 7B).

7. Attach the 2 safety straps directly to the clevis or hook at the 4 rigging brackets. DO NOT attach the safety straps to the

lifting brackets (See Fig. 7B).

8. Position lifting point directly over the unit's center of gravity.

9. Lift unit. When unit is directly over the roof curb, remove the 2 safety straps. Lower the equipment onto the roof curb.

PROCEDURE 2--PROVIDE UNIT SUPPORT

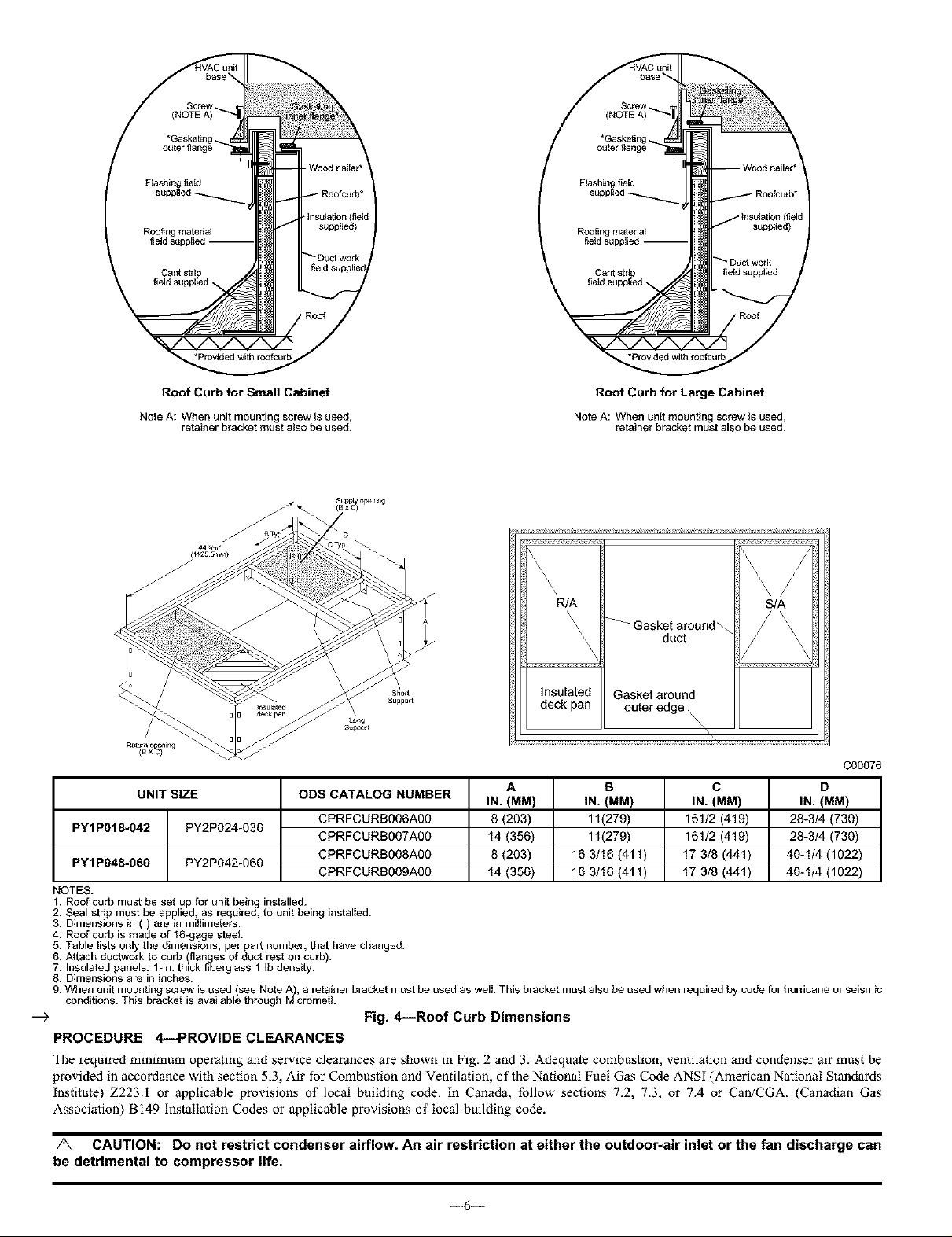

A. ROOFCURB

install accessory roof curb in accordance with instructions shipped with curb (See Fig. 4 for roof curb dimensions), install insulation, cant strips,

roofing, and flashing. Ductwork must be attached to curb.

IMPORTANT: The gasketing of the unit to the roof curb is critical for a watertight seal. Install gasketing material supplied with the roof curb.

improperly applied gasketing can also result in air leaks and poor unit performance.

Curb should be level to within 1/4 in. This is necessary for unit drain to function properly. Refer to accessory roof curb installation instructions

for additional information as required.

B. SLAB MOUNT

Place the unit on a solid, level concrete pad that is a minimum of 4 in. thick with 2 in. above grade. The slab should be flush on the compressor

end of the unit (to allow condensate drain installation) and should extend 2 in. on the three remaining sides of the unit (See Fig. 6). Do not secure

the unit to the slab except when required by local codes.

C. GROUND MOUNT

The unit may be installed either on a slab or placed directly on the ground if local codes permit. Place the unit on level ground prepared with gravel

for condensate discharge.

PROCEDURE 3--FIELD FABRICATE DUCTWORK

Secure all ducts to roof curb and building structure on vertical discharge units. Do not connect ductwork to unit. For horizontal applications, unit

is provided with flanges on the horizontal openings. Installation of flexible duct connector is recommensted to prevent transmission of vibration

and/or noise to structure. All ductwork should be secured to the flanges, insulate and weatherproof all external ductwork, joints, and roof openings

with counter flashing and mastic in accordance with applicable codes.

.... 3___

Page 4

BLOCKOFFPANELON0180NL/_

[15.83] 0PENIN6 OPENING

\

\

SUPPLT RETUR_

DUCT DUCT

I I

[3_48]

-- 249_6 --550.5 149_6

REAR VIEW

REQUIRED CLEAP_,NCE TO COMGUSTIBLE MATL,

TOP OF UNIT ................................................................................... 1400 3556]

DUCT S DE OF UNIT ......................................................................... 2.00 508

SIDE OPPOSITE DUCTS ................................................................ 1400 3558]

BOTTOM OF UN T ............................................................................. 0.50 127

ELECTRIC HEAT PANEL ................................................................. 3600 [9t4 4]

NEC. REQUIRED CLEARANCES.

BETWEEN UN TS, POWER ENTRY S DE .................................... 4200 10668

UNIT AND UNGROUNDED SURFACES, POWER ENTRY SIDE 3600 [91401

UNIT AND BLOCK OR CONCRETE WALLS AND OTHER

GROUNDED SURFACES, POWER ENTRY SIDE ......................... 4206 [1066 8]

iNCHES [mm]

_NCHES mm]

LEGEND

CG- Center of Gravity

COND- Coi_densor

EVAP_Evaporator

NEC -NationalElectricalCode

REQrD- Required

NOTE:Dimensions areinin [mm]

I193_

[4700]

t

EVAP_ C01L_

/

TOPVIEW

REQUIRED CLEARANCE F0N OPERATION AND SERVICING

EVAR CO_L ACCESS SIDE ............................................................ 36.00 9140

POWER ENTRY SIDE .................................................................... 36001914 0l

(EXCEPT FOR NEe REQUIREMENTS)

UNIT TOP ....................................................................................... 48.00 [1219.2

S DE OPPOS TE DUCTS .............................................................. 3600 [9 40

DUCT PANEL ................................................................................. 1200 [304 8] *

*MINIMUM DISTANCES: IF UNIT iS PLACED LESS THAN 1200 [304 8] PROM

WALL SYSTEM, THEN SYSTEM PERFORMANCE MAYBE COMPROMISE

iNCHES [mm]

Note: Wire Grilles are a field installed option.

--1163

[4.58]

I /J, , ,

L_COMPRES_OR, BLO_ER_ GAS SECTION

& ELECTRICAL ACCESS PANEL

122_3

[482B]

FRONT VIEW

Ib k9

"A"

50

[0.20]

RIGHT SIDE VIEW

CENTER OF GRAVITY

X Y

IN. {aM)

20.0 (508.0) 14.0 (355.6)

22.5 (571.5) 13.0 (330.2)

21.5 (548.1) 13.75 (349.3)

22.5 (571.5) 14.0 (355.6)

21.5 (548.1) 13.5 (342.9)

22.0 (558.8) 14.5 (368.3)

22.0 (558.8) 15.3 (387.4)

22.0 (558.8) 15.3 (387.4)

UNIT

PYtPO18040

PY1 P824040/860

PY1 P930040/860

PY1 P936060/890

PY1 P942060/890

PY2P824040/060

PY2P930040/860

PY2P936060/890

42 7

[h_B]

--326_5

_72 4

_31.0

[32.72]

[2_85]

LEFT SIDE VIEW

ELECTRICAL CHARACTERISTICS UNIT WEIGHT UNIT HEIGHT IN. (MM)

208/230-1-60 249.0 113.2 35.02 (889.5)

208/230-1-60 280.0 127.3 35.02 (889.5)

208/230-I-60, 208/230-3-60 280.0 127.3 35.02 (889.5)

208/230-1-60, 208/230-3-60, 460-3-60 320.0 145.1 37.02 (940.3)

208/230-1-60, 208/230-3-60, 460-3-60 355.0 161.4 35.02 (889.5)

208/230-1-60 290.0 131.5 37.02 (940.3)

208/230-I-60, 208/230-3-60 313.0 142.0 39.02 (991.1)

208/230-1-60, 208/230-3-60, 460-3-60 321.0 145.6 35.02 (889.5)

Fig. 2--PYIP018-042 and PY2P024_036 Unit Dimensions

Ducts passing through an unconditioned space must be insulated and covered with a vapor barrier.

if a plenum return is used on a vertical unit, the return should be ducted through the roof deck to comply with applicable fire codes.

A minimum clearance is not required around ductwork. Cabinet return-air static shall not exceed -.25 in. wg.

.... 4 ....

C00055

Z

15.0 (381.0)

15.0 (381.0)

15.0 (381.0)

13.0 (330.2)

13.0 (330.2)

16.0 (406.4)

17.6 (447.0)

16.5 (419.1)

Page 5

li tttil

j lllLL

4066

[16 01]

1

402T0•

[15i_3]

SUPPLY FURN

DUCT JCT

OPENING " 1

NING

T COND

Y COIL _

EVAP

L

[3.48]

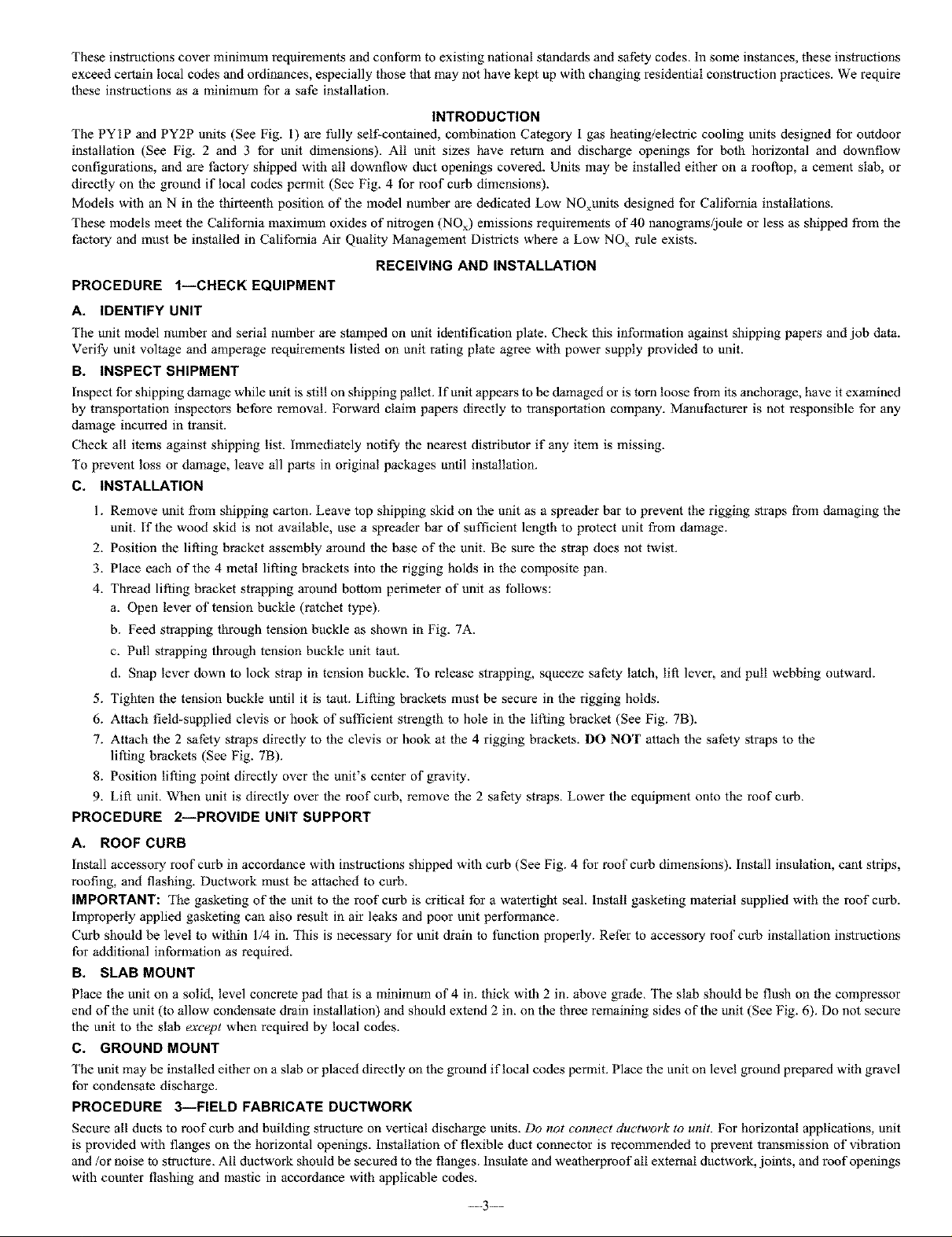

REQUIRED CLEARANCE TO COMBUSTIBLE MATL.

TOP OF UNIT ................................................................................... 14.00 [355.6]

DUCT SIDE OF UNIT ......................................................................... 2.00 [50.8]

SIDE OPPOSITE DUCTS ................................................................ 14.00 [355.6]

BOTTOM OF UNIT ............................................................................. 0.50 [12.7]

FLUE PANEL .................................................................................... 36.00 [914.4]

NED. REQUIRED CLEARANCES.

BETWEEN UNITS, POWER ENTRY SIDE .................................... 42.00 [1066.8]

UNIT AND UNGROUNDED SURFACES, POWER ENTRY SIDE .36.00 [914.0]

UNIT AND BLOCK OR CONCRETE WALLS AND OTHER

GROUNDED SURFACES, POWER ENTRY SIDE ......................... 42.00 [1066.8]

3512 3473

[13 83] [13 67] [ 13.83]

REARVIEW

1090B

[4294]

\

INCHES [mm]

INCHES [mm]

1193.9

[47 00]

t

TOP VIEW

REQUIRED CLEARANCE FOR OPERATION AND SERVICING

EVAP. COIL ACCESS SIDE ............................................................ 36.00 [914.0]

POWER ENTRY SIDE .................................................................... 36.00 {914.0]

(EXCEPT FOR NEC REQUIREMENTS)

UNIT TOP ....................................................................................... 48.00 [1219.2]

SIDE OPPOSITE DUCTS .............................................................. 36.00 [914.0[

DUCT PANEL ................................................................................. 12.00 [304.8] *

*MINIMUM DISTANCES: IF UNIT IS PLACED LESS THAN 12.00 [304.8] FROM

WALL SYSTEM, THEN SYSTEM PERFORMANCE MAYBE COMPROMISE.

Note: Wire Grilles are a field installed option.

LEGEND

CG- Centerof Gravity

COND-Condensor

EVAP-Evaporator

NEC-NationalElectricalCode

REQ'D-Required

--115.4

[454]

NOTE:Dimensionsarein in. [ram]

INCHES [mini

1123 I

[44 22]

LEFT SIDEVIEW

UNIT

PY1 P048090/115/130

PY1 P060090/115/130

PY2P042060/090

PY2P048090/115/139

PY2P060090/115/139

T ] 141111 llllll

/ !Jlttt ittttl

[I 6_]

_3290

[1295]

_;2 4

[285]

ELECTRICAL CHARACTERISTICS

208-230/1/60, 208/230-3-60, 460-3-60

208/230-1-60, 2081230-3-60, 460-3-60

208/230-1-60, 208/230-3-60, 460-3-60

208/230-1-60, 208/230-3-60, 460-3-60

208/230-1-60, 208/230-3-60, 460-3-60

Fig. 3--PYIP048-060 and PY2P042-060 Unit Dimensions

_OMPRES_OR, BLOWER, GAS SECTION

& ELECTRICAL ACCESS PANEL

122L3

[48.2_]

FLUEHOOD

FRONTVIEW

UNIT WEIGHT UNIT HEIGHT IN. (MM)

Ib k 9

415 188.6 38.98 (990.2)

450 204.5 38.98 (990.2)

382 173.3 38.98 (990.2)

421 191.0 38.98 (990.2)

468 212.3 42.98 (1091.1)

"A"

[5.61]

RIGHTSIDEVIEW

CENTER OF GRAVITY

X Y Z

22 (558.5) 16 (406.4) 17 (432.0)

22 (558.5) 16 (406.4) 17 (432.0)

23.0 (584.2) 16.3 (412.8) 16.6 (421.6)

21.5 (546.1) 16.6 (422.1) 18.0 (457.2)

23.5 (596.9) 16.3 (412.8) 17.6 (447.0)

IN. (MM}

C00056

Page 6

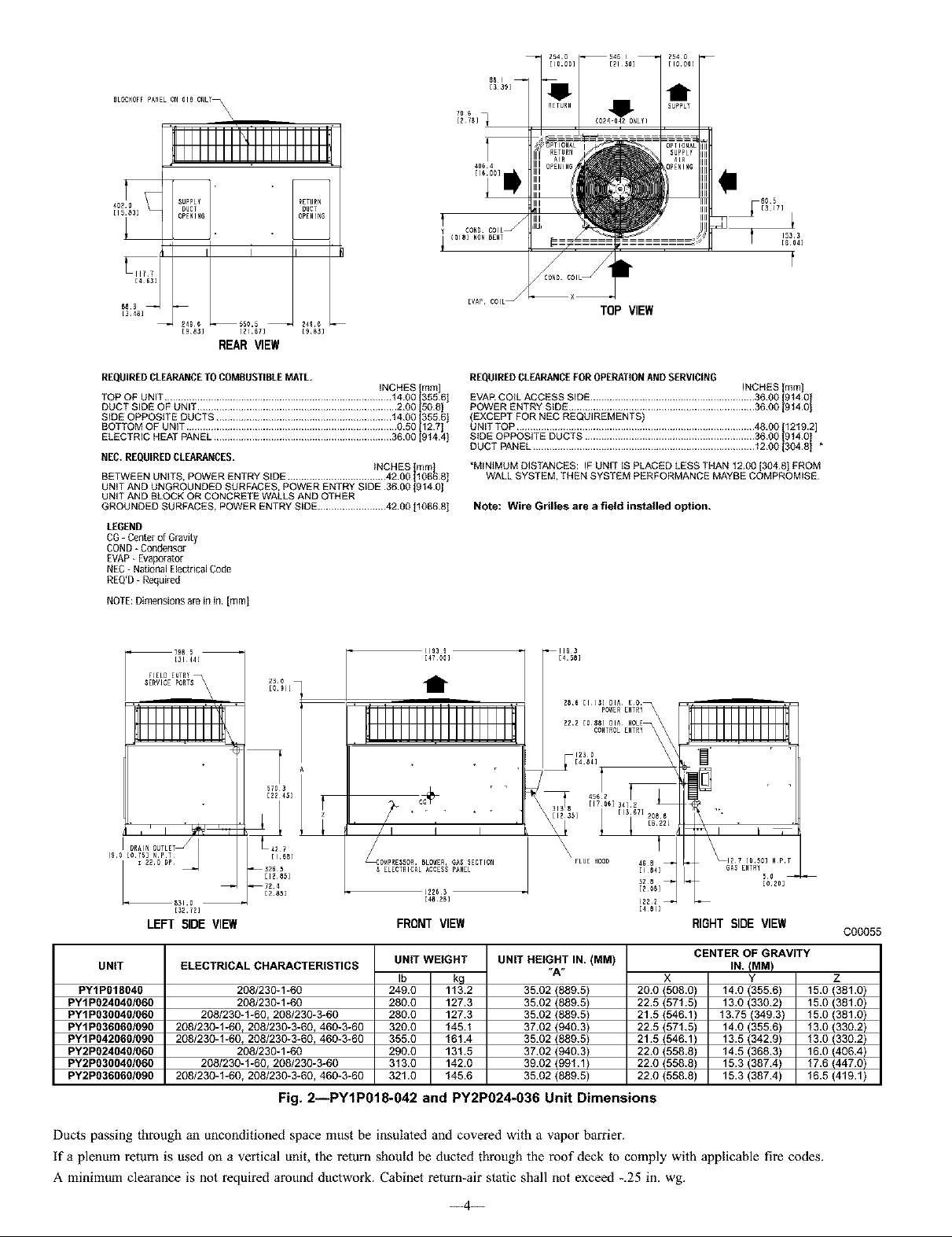

Roof Curb for Small Cabinet

Note A: When unit mounting screw is used,

retainer bracket must also be used.

UNIT SIZE

PYIP018-042 PY2P024-036

PYIP048-060 PY2P042-060

ODS CATALOG NUMBER

CPRFCURB006A00

CPRFCURB007A00

CPRFCURB008A00

CPRFCURB009A00

insulated Gasket around

deck pan outer edge \

A

IN. (MM)

8 (203)

14 (356)

8 (203)

14 (356)

Roof Curb for Large Cabinet

Note A: When unit mounting screw is used,

retainer bracket must also be used.

, /

\

\

\

R/A S/A

"_-_Gssket areund_ / _

\\\ duct

\x

B

IN. (MM)

11(279)

11(279)

16 3/16 (411)

16 3/16 (411)

C

IN. (MM)

161/2 (419)

161/2 (419)

17 3/8 (441)

17 3/8 (441)

\ /

COOO76

D

iN. (aM)

28-3/4 (730)

28-3/4 (730)

40-1/4 (1022)

40-1/4 (1022)

NOTES:

1. Ro_ curb mustbe setup Drunitbeinginstalled.

2. Seal strip must be applied, as required, to unit being installed.

3. Dimensions in ( ) are in millimeters.

4. Roof curb is made of f6-gage steel.

5. Table lists only the dimensions, per part number, that have changed.

6. Attach ductwork to curb (flanges of duct rest on curb).

7. Insulated panels: 1-in. thick fiberglass 1 Ib density.

8. Dimensions are in inches.

g. When unit mounting screw is used (see Note At, a retainer bracket must be used as well. This bracket must also be used when required by code for hurricane or seismic

conditions. This bracket is available through Micromefl.

Fig. 4--Roof Curb Dimensions

PROCEDURE 4---PROVIDE CLEARANCES

The required minimum operating and service clearances are shown in Fig. 2 and 3. Adequate combustion, ventilation and condenser air must be

provided in accordance with section 5.3, Air for Combustion and Ventilation, of the National Fuel Gas Code ANSI (American National Standards

institute) Z223.1 or spplicable provisions of local building code. In Canada, follow sections 7.2, 7.3, or 7.4 or CardCGA. (Canadian Gas

Association) B149 Installation Codes or applicable provisions of local building code.

CAUTION: Do not restrict condenser airflow. An air restriction at either the outdoor*air inlet or the fan discharge can

be detrimental to compressor life.

.... 6__.

Page 7

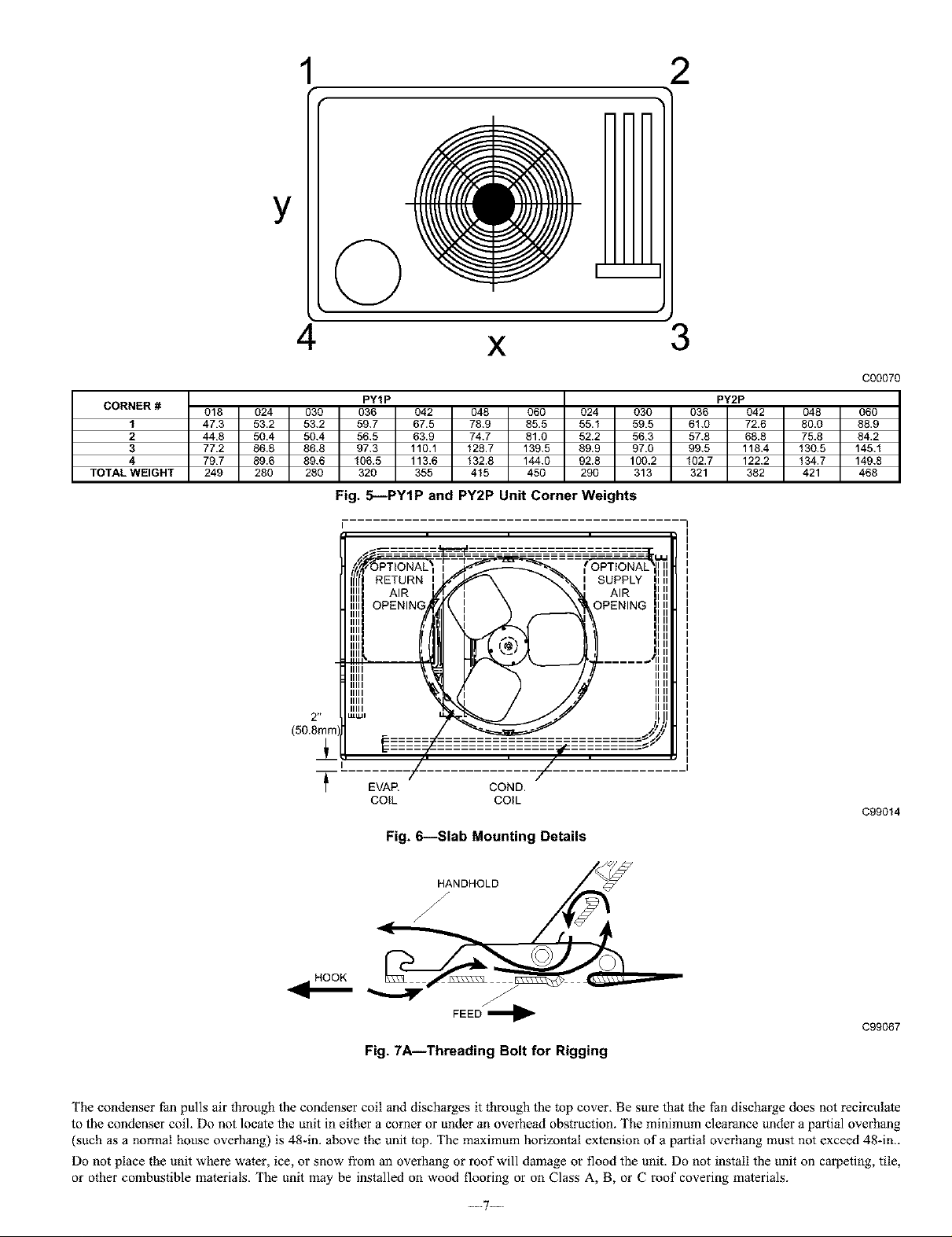

1 2

Y

©

!

Z

CORNER # 018 024 030 036 042 048 060 024 030 036 042 048 060

1 47.3 53.2 53.2 59.7 67.5 78.9 85.5 55.1 59.5 61.0 72.6 80.0 88.9

2 44.8 50.4 50.4 56.5 63.9 74.7 81.0 52.2 56.3 57.8 68.8 75.8 84.2

3 77.2 86.8 86.8 97.3 110.1 128.7 139.5 89.9 97.0 99.5 118.4 130.5 145.1

4 79.7 89.6 89.6 106.5 113.6 132.8 144.0 92.8 100.2 102.7 122.2 134.7 149.8

TOTAL WEIGHT 249 280 280 320 355 415 450 290 313 321 382 421 468

PYIP PY2P

Fig. 5--PYIP and PY2P Unit Corner Weights

I

EVAP. COND.

COIL COIL

Fig. 6--Slab Mounting Details

X

3

C00070

C99014

HOOK

FEED

Fig. 7A--Threading Bolt for Rigging

The condenser fan pulls air through the condenser coil and discharges it through the top cover. Be sure that the fan discharge does not recirculate

to the condenser coil. Do not locate the unit in either a corner or under an overhead obstruction. The minimum clearance under a partial overhang

(such as a normal house overhang) is 48-in. above the unit top. The maximum horizontal extension of a partial overhang must not exceed 48-in..

Do not place the unit where water, ice, or snow from an overhang or roof will damage or flood the unit. Do not install the unit on carpeting, tile,

or other combustible materials. The unit may be installed on wood flooring or on Class A, B, or C roof covering materials.

.... 7 ....

C99067

Page 8

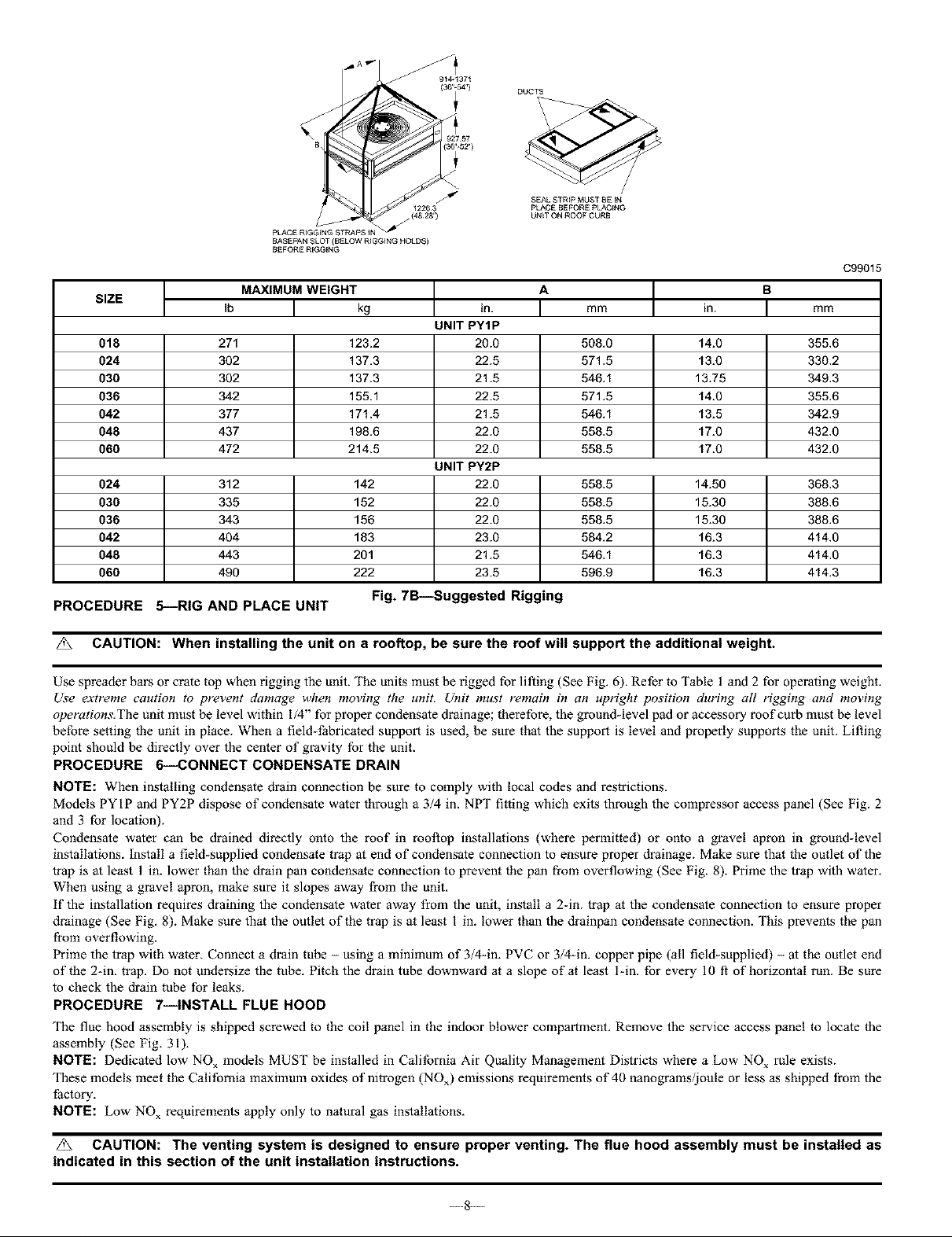

C99015

SIZE

MAXIMUM WEIGHT A B

I kg in. I mm I mm

JNIT PYIP

018 271 123.2 20.0 508.0 14.0 355.6

024 302 137.3 22.5 571.5 13.0 330.2

030 302 137.3 21.5 546.1 13.75 349.3

036 342 155.1 22.5 571.5 14.0 355.6

042 377 171.4 21.5 546.1 13.5 342.9

048 437 198.6 22.0 558.5 17.0 432.0

060 472 214.5 22.0 558.5 17.0 432.0

INIT PY2P

024 312 142 22.0 558.5 14.50 368.3

030 335 152 22.0 558.5 15.30 388.6

036 343 156 22.0 558.5 15.30 388.6

042 404 183 23.0 584.2 16.3 414.0

048 443 201 21.5 546.1 16.3 414.0

060 490 222 23.5 596.9 16.3 414.3

PROCEDURE 5--RIG AND PLACE UNIT Fig. 7B--Suggested Rigging

CAUTION: When installing the unit on a rooftop, be sure the roof will support the additional weight.

Use spreader bars or crate top when rigging the unit. The units must be rigged for lifting (See Fig. 6). Refer to Table 1 and 2 for operating weight.

Use extreme caution to prevent damage when moving the unit. Unit must remain in an upright position during all rigging and moving

operations.The unit must be level within I/4" for proper condensate drainage; therefore, the ground-level pad or accessory roof curb must be level

before setting the unit in place. When a field-fabricated support is used, be sure that the support is level and properly supports the unit. Lifting

point should be directly over the center of gravity for the unit.

PROCEDURE 6--CONNECT CONDENSATE DRAIN

NOTE: When installing condensate drain connection be sure to comply with local codes and restrictions,

Models PYIP and PY2P dispose of condensate water through a 3/4 in. NPT fitting which exits through the compressor access panel (See Fig. 2

and 3 for location).

Condensate water can be drained directly onto the roof in rooftop installations (where permitted) or onto a gravel apron in ground-level

installations. Install a field-supplied condensate trap at end of condensate connection to ensure proper drainage. Make sure that the outlet of the

trap is at least 1 in. lower than the drain pan condensate connection to prevent the pan from overflowing (See Fig. 8). Prime the trap with water.

When using a gravel apron, make sure it slopes away from the unit,

if the installation requires draining the condensate water away from the unit, install a 2-in. trap at the condensate connection to ensure proper

drainage (See Fig. 8). Make sure that the outlet of the trap is at least I in. lower than the drainpan condensate connection. This prevents the pan

fi'om overflowing.

Prime the trap with water, Connect a drain tube - using a minimum of 3/4-in. PVC or 3/4-in. copper pipe (all field-supplied) - at the outlet end

of the 2-in. trap. Do not undersize the tube. Pitch the drain tube downward at a slope of at least 1-in. for every 10 fl of horizontal run. Be sure

to check the drain tube for leaks.

PROCEDURE 7--INSTALL FLUE HOOD

The flue hood assembly is shipped screwed to the coil panel in the indoor blower compartment. Remove the service access panel to locate the

assembly (See Fig. 31).

NOTE: Dedicated low NO× models MUST be installed in California Air Quality Management Districts where a Low NO× rule exists.

These models meet the California maximum oxides of nitrogen (NO×) emissions requirements of 40 nanograms/joule or less as shipped from the

factory.

NOTE: Low NO× requirements apply only to natural gas installations.

A CAUTION: The venting system is designed to ensure proper venting. The flue hood assembly must be installed as

indicated in this section of the unit installation instructions.

Page 9

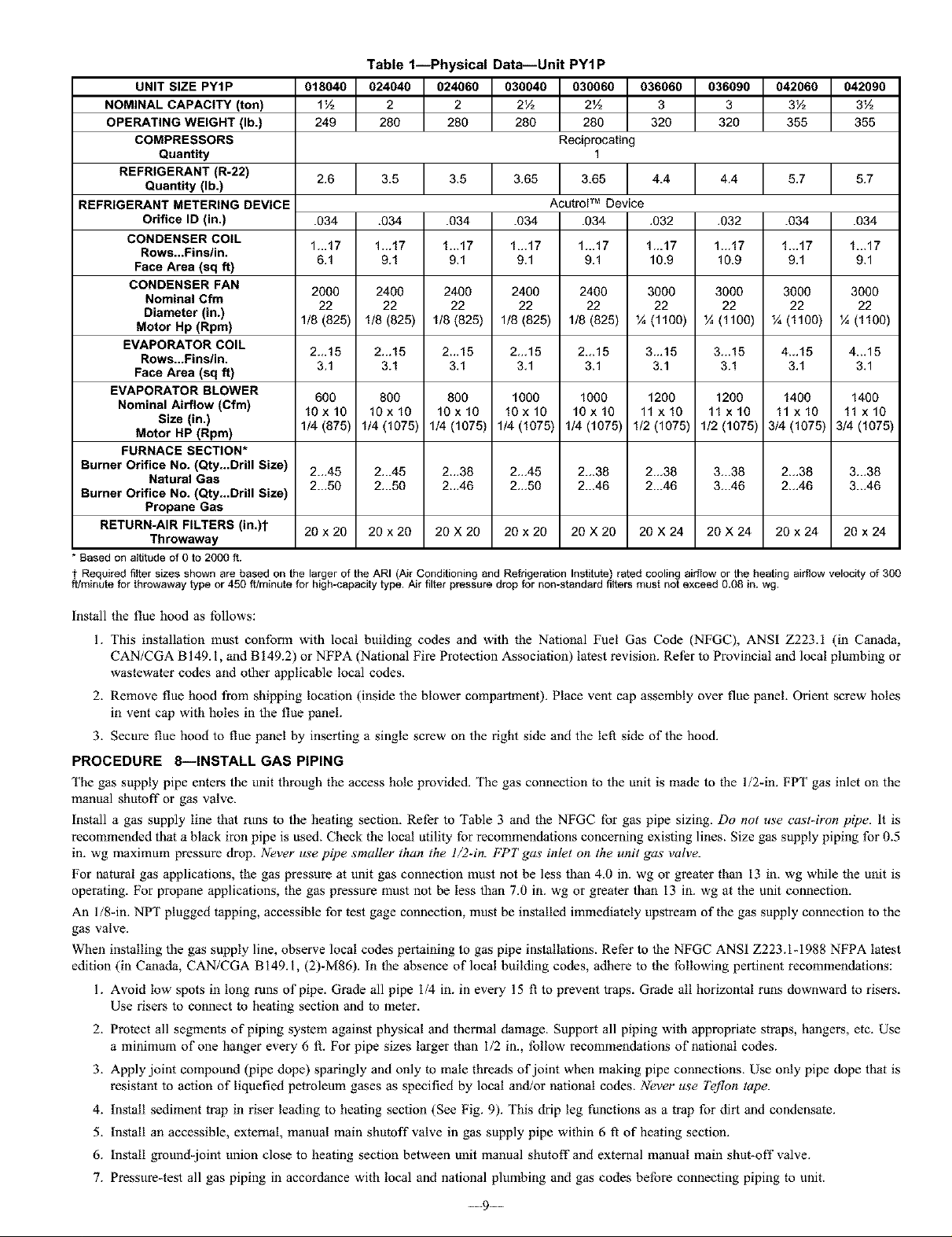

Table l--Physical Data--Unit PYIP

UNIT SIZE PYIP

NOMINAL CAPACITY (ton)

OPERATING WEIGHT (lb.)

COMPRESSORS

Quantity

REFRIGERANT (R-22)

Quantity (lb.)

REFRIGERANT METERING DEVICE

Orifice ID (in.)

CONDENSER COIL

Rows...Fins/in.

Face Area (sq ft)

CONDENSER FAN

Nominal Cfm

Diameter (in.)

Motor Hp (Rpm)

EVAPORATOR COIL

Rows...Fins/in.

Face Area (sq ft)

EVAPORATOR BLOWER

Nominal Airflow (Cfm)

Size (in.)

Motor HP (Rpm)

FURNACE SECTION*

Burner Orifice No. (Qty_.Drill Size)

Burner Orifice No. (Qty_.Drill Size)

RETURN-AIR FILTERS (in.)t

* Based on aRitudeof 0 to 2000 ft.

t Required filter sizes shown are based on the larger of the ARI (Air Conditioning and Refrigeration Institute) rated cooling airflow or the heating ai_ow velocity of 300

if/minute for throwaway type or 450 ft/minute for high-capacity type. Air filter pressure drop for non-standard filters must not exceed 0.08 in. wg.

Natural Gas

Propane Gas

Throwaway

018040 024040

1½ 2

249 280

2.6 3.5 3.5 3.65 4.4 5.7 5.7

.034 .034

1-.17 1...17

6.1 9.1

2000 2400

22 22

1/8 (825) 1/8 (825)

2-.15 2.-15

3.1 3.1

600 800

10x10 10x10

1/4 (875) 114(1075)

2.-45 2...45

2.-50 2...50

024060

2

280

.034

1.-17

9.1

2400

22

1/8 (825)

2.-15

3.1

800

10 x 10

114(1075)

2.-38

2.-46

20 X 20

030040

2½

280

.034

1.-17

9.1

2400

22

1/8 (825)

2,-15

3.1

1000

10x10

1/4 (1o75)

2,-45

2,-50

20 x 20

030060 036060

2½ 3

280 320

Reciprocating

1

3.65 4.4

Acutrol TM Device

.034 .032

1_.17 1..,17

9.1 10.9

2400 3000

22 22

1/8 (825) ¼ (1100)

2.,.15 3..,15

3.1 3.1

1000 1200

10x10 11x10

1/4 (1075) 1/2 (1075)

2.,.38 2..,38

2._46 2...46

20 X 20 20 X 24

036090

3

320

.032

1...17

10.9

3000

22

¼ (1100)

3...15

3.1

1200

11 x 10

112 (1075)

3...38

3-.46

20X24

042060

3½

355

.034

1.-17

9.1

3000

22

¼ (1100)

4...15

3.1

1400

11 x 10

3_ (1075)

2.-38

2.-46

20x2420 x 20 20 x 20

042090

3½

355

.034

1.-17

9.1

3000

22

¼ (1100)

4.-15

3.1

1400

11 x 10

3_ (1075)

3,..38

3.-46

20 x 24

install the flue hood as follows:

i. This installation must conform with local building codes and with the National Fuel Gas Code (NFGC), ANSI Z223.1 (in Canada,

CAN/CGA B i49. I, and B 149.2) or NFPA (National Fire Protection Association) latest revision. Refer to Provincial and local plumbing or

wastewater codes and other applicable local codes.

2. Remove flue hood #am shipping location (inside the blower compartment). Place vent cap assembly over flue panel. Orient screw holes

in vent cap with holes in the flue panel.

3. Secure flue hood to flue panel by inserting a single screw on the right side and the left side of the hood.

PROCEDURE 8--INSTALL GAS PIPING

The gas supply pipe enters the unit through the access hole provided. The gas connection to the unit is made to the i/2-in. FPT gas inlet on the

manual shutoff or gas valve.

install a gas supply line that runs to the heating section, Refer to Table 3 and the NFGC for gas pipe sizing. Do not use cast-iron pipe, It is

recommended that a black iron pipe is used. Check the local utility for recommendations concerning existing lines. Size gas supply piping for 0.5

in. wg maximum pressure drop. Never use pipe smaller than the 1/2-in. FPT gas inlet on the unit gas valve.

For natural gas applications, the gas pressure at unit gas connection must not be less than 4.0 in. wg or greater than 13 in. wg while the unit is

operating. For propane applications, the gas pressure must not be less than 7.0 in. wg or greater than 13 in. wg at the unit connection.

An i/8-in. NPT plugged tapping, accessible for test gage connection, must be installed immediately upstream of the gas supply connection to the

gas valve.

When installing the gas supply line, observe local codes pertaining to gas pipe installations. Refer to the NFGC ANSI Z223.1-1988 NFPA latest

edition (in Canada, CAN/CGA B149. I, (2)-M86). in the absence of local building codes, adhere to the following pertinent recommendations:

i. Avoid low spots in long runs of pipe. Grade all pipe I/4 in. in every 15 ft to prevent traps. Grade all horizontal runs downward to risers.

Use risers to connect to heating section and to meter.

2. Protect all segments of piping system against physical and thermal damage_ Support all piping with appropriate straps, hangers, etc. Use

a minimum of one hanger every 6 ft. For pipe sizes larger than I/2 in., follow recommendations of national codes.

3. Apply joint compound (pipe dope) sparingly and only to male threads of joint when making pipe connections. Use only pipe dope that is

resistant to action of liquefied petroleum gases as specified by local and/or national codes. Never use Teflon tupe.

4. Install sediment trap in riser leading to heating section (See Fig. 9). This drip leg functions as a trap for dirt and condensate.

5. Install an accessible, external, manual main shutoff valve in gas supply pipe within 6 ft of heating section.

6. Install ground-joint union close to heating section between unit manual shutoff and external manual main shut-off valve.

7. Pressure-test all gas piping in accordance with local and national plumbing and gas codes before connecting piping to unit.

.... 9 ....

Page 10

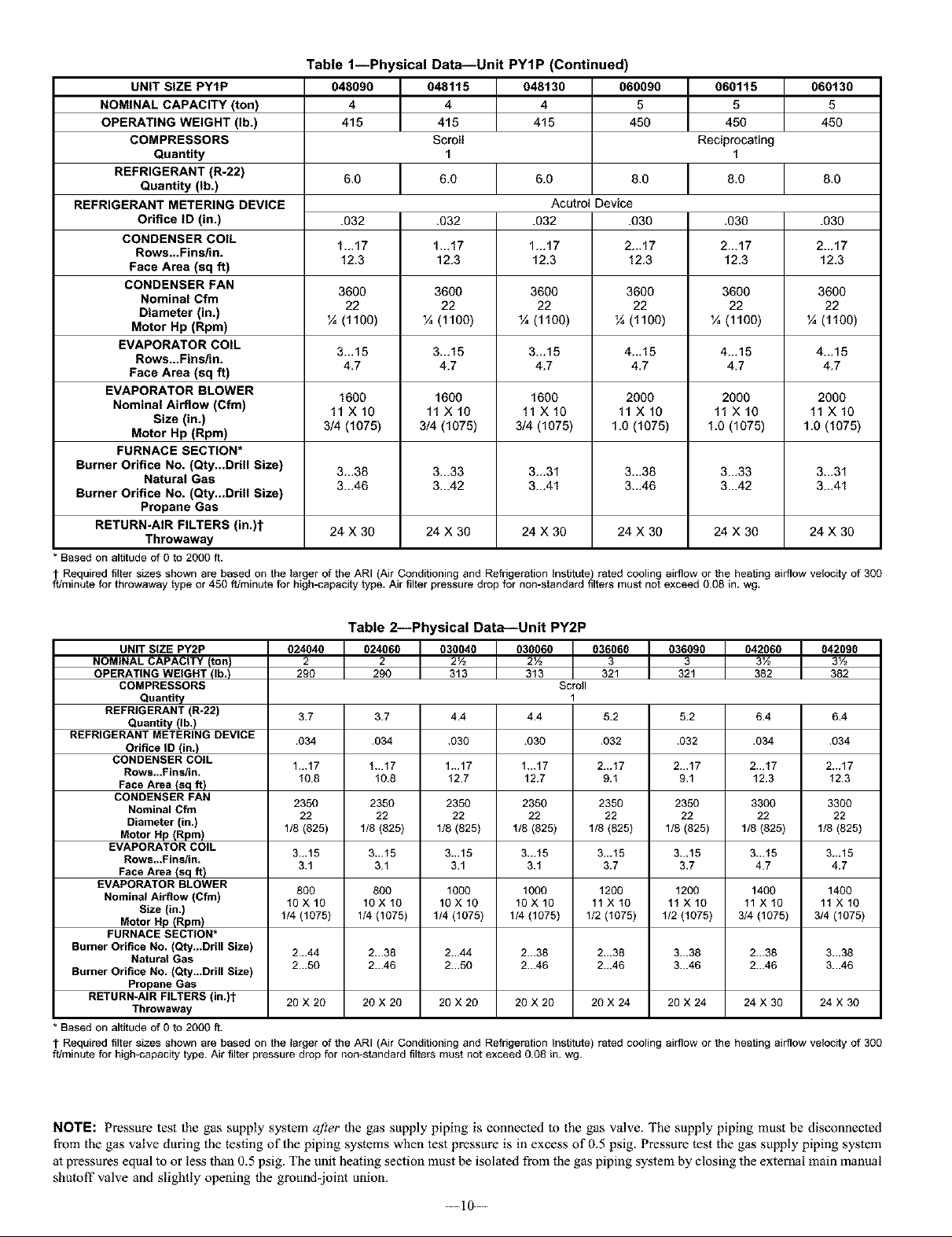

Table 1--Physical Data--Unit PYIP (Continued)

UNIT SIZE PYIP

NOMINAL CAPACITY (ton)

OPERATING WEIGHT (lb.)

COMPRESSORS

Quantity

REFRIGERANT (R-22)

Quantity (lb.)

REFRIGERANT METERING DEVICE

Orifice ID (in.)

CONDENSER COIL

Rows.-Fins/in.

Face Area (sq ft)

CONDENSER FAN

Nominal Cfm

Diameter (in.)

Motor Hp (Rpm)

EVAPORATOR COIL

Rows._Fins/in.

Face Area (sq ft)

EVAPORATOR BLOWER

Nominal Airflow (Cfm)

Size (in=)

Motor Hp (Rpm)

FURNACE SECTION*

Burner Orifice No. (Qty._Drill Size)

Natural Gas

Burner Orifice No. (Qty._Drill Size)

Propane Gas

RETURN-AIR FILTERS (in.)1"

Throwaway

* Based on altitude of 0 to 2000 ft.

Required filter sizes shown are based on the larger of the ARI (Air Conditioning and Refrigeration Instffute) rated cooling airflow or the heating airflow velocity of 300

ft/minute for throwaway type or 450 ftlminute for high-capacity type. Air filter pressure drop for non-standard filters must not exceed 0.08 in. wg.

048090 048115 060115 060139

4 4 5 5

415 415 450 450

048130 060090

4 5

415 450

Scroll Reciprocating

1 1

6.0 6.0 8.0 8.0

6.0 8.0

Acut rol Device

.032

1._17

12.3

3600

22

V, (1100)

3._15

4.7

1600

11 X 10

3/4 (1075)

3...38

3._46

24 X 30

.032

1...17

12.3

3600

22

¼ (1100)

3._15

4.7

1600

11X 10

3/4 (1075)

3...33

3-.42

24 X 30

.032 .030

1...17 2._17

12.3 12.3

3600 3606

22 22

I/, (1100) ¼ (1100)

3.-15 4-.15

4.7 4.7

1600 2000

11X10 11X10

3/4 (1075) 1.0 (1075)

3...31 3.-38

3.-41 3-.46

24 X 30 24 X 30

.030

2...17

12.3

3600

22

¼ (1100)

4_,15

4.7

2000

11 X 10

1.0 (1075)

3_.33

3...42

24X30

2...17

3600

V, (1100)

4...15

2000

11 X 10

1.0 (1075)

3...31

3...41

24 X 30

.030

12.3

22

4.7

Table 2iphysical DataiUnit PY2P

UNIT SIZE PY2P

NOMINAL CAPACITY (ton)

OPERATING WEIGHT (lb.)

COMPRESSORS

Quantity

REFRIGERANT (R-221

REFRIGERANT METERING DEVICE

Burner Orifice NO. (Qty...Drgl Size)

Burner Orifice NO. (Qty...Drgl Size)

* Based on altitude of 0 1o 2000 ft.

Required filter sizes shown are based on the larger of the ARI (Air Conditioning and Refrigeration institute) rated cooling airflow or the heating airflow velocity of 300

ft/minute for high-capacity type. Air filter pressure drop for non-standard filters must not exceed 0.08 in. wg.

Quantity (lb.)

Orifice ID fin.)

CONDENSER COIL

Rows...Fins/in.

Face Area (sq ft)

CONDENSER FAN

Nominal Cfm

Diameter (in.)

Motor Hp {Rpm)

EVAPORATOR COIL

Rows...Fins/in.

Face Area (sq ft)

EVAPORATOR BLOWER

Nominal Airflow (Cfm)

Size (in.)

Motor Hp {Rpm)

FURNACE SECTION*

Natural Gas

Propane Gas

RETURN*AIR FILTERS (in.)_

Throwaway

624040 024060 630046 030060 036060 636096 042060 042090

2 2 2½ 2½ 3 3 3½ 3½

290 290 313 313 321 321 382 382

3.7 3.7 4.4 4.4 5.2 5.2 6.4 6.4

.034 .034 .030 .030 .032 .032 .034 .034

1...17 1...17 1...17 1...17 2._17 2...17 2...17 2...17

10.8 10.8 12.7 12.7 g.f 9.1 12.3 12.3

2350 2350 2350 2350 2350 2350 3300 3300

22 22 22 22 22 22 22 22

1/8 (825) i/8 (825) 1/8 (825) 118 (825) 1_ (825) 1/8 (825) im (825) 1/8 (825)

3...15 3...15 3...15 3...15 3...15 3...15 3...15 3...15

3.1 3.1 3.1 3.1 3.7 3.7 4.7 4.7

800 800 1000 1000 1200 1200 1400 1400

10X10 10X10 10Xf0 i0X10 11X10 11X10 11X10 11Xf0

iN (1075) 1/4(1075) 114 (1075) 1_ (1075) 1/2(1075) i/2 (1075) 3/4 (1075) 314 (1075)

2...44 2...38 2...44 2...38 2._38 3...36 2...38 3...38

2...50 2...46 2...50 2...46 2...46 3...46 2...46 3...46

20X20 20X20 20X20 20X20 20X24 20X24 24X30 24X30

Scroll

1

NOTE: Pressure test the gas supply system after the gas supply piping is connected to the gas valve. The supply piping must be disconnected

from the gas valve during the testing of the piping systems when test pressure is in excess of 0,5 psig. Pressure test the gas supply piping system

at pressures equal to or less than 0.5 psig. The unit heating section must be isolated from the gas piping system by closing the external main manual

shutoff valve and slightly opening the ground-joint union.

.... I0 ....

Page 11

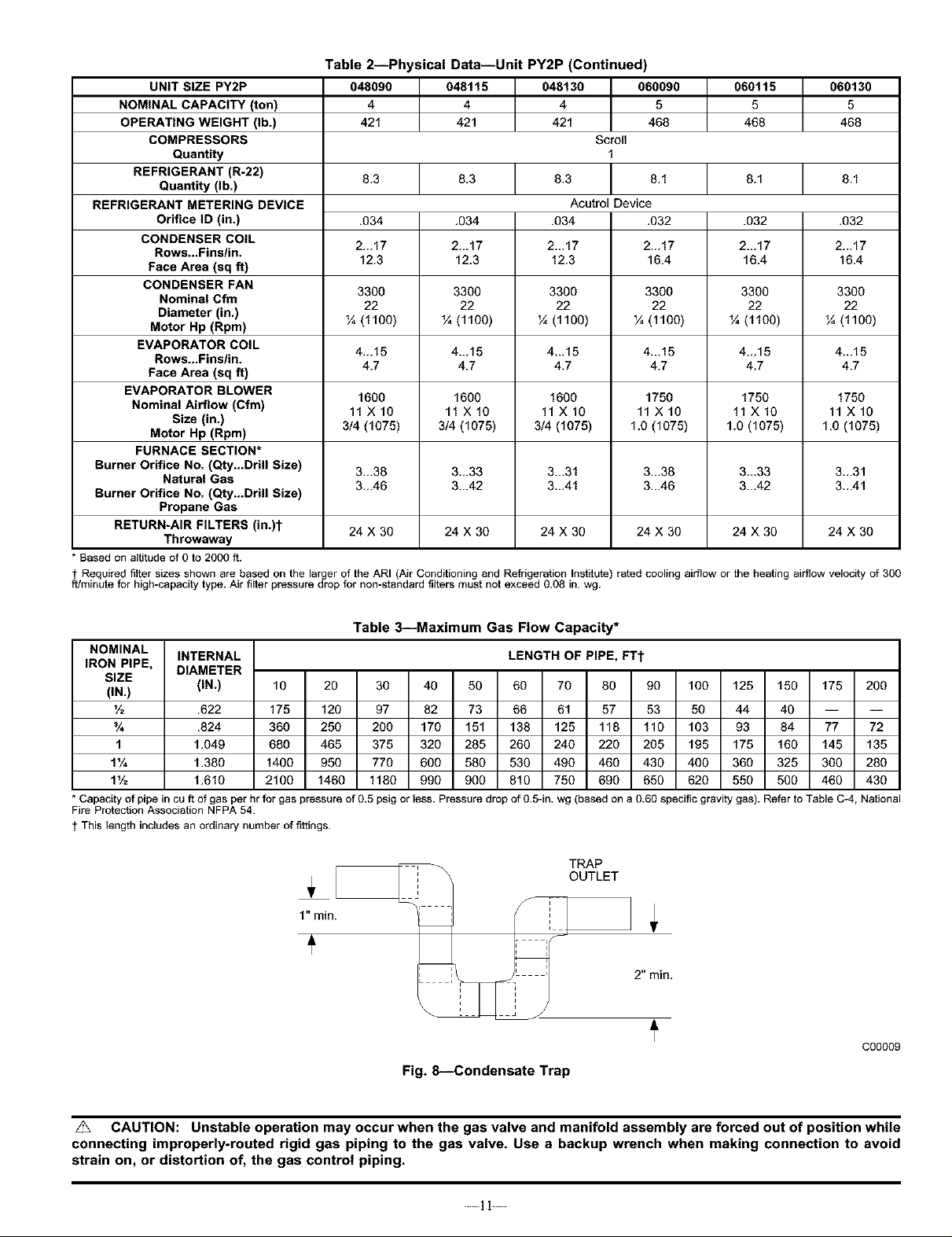

Table 2iphysical DataiUnit PY2P (Continued)

UNIT SIZE PY2P 048090 048115 048130 060090 060115 060130

NOMINAL CAPACITY (ton) 4 4 4 5 5 5

OPERATING WEIGHT (lb.) 421 421 421 468 468 468

COMPRESSORS Scroll

Quantity 1

REFRIGERANT (R-22) 8.3 8,3 8,3 8.1 8.1 8.1

Quantity (lb.)

REFRIGERANT METERING DEVICE Acutrol Device

Orifice ID (in.) .034 ,034 .034 ,032 .032 .032

CONDENSER COIL 2_.17 2_,17 2._17 2...17 2,,.17 2._17

Rows...Fins/in.

Face Area (sq ft) 12.3 12.3 12.3 16.4 16,4 16.4

CONDENSER FAN 3300 3300 3300 3300 3300 3300

Nominal Cfm 22 22 22 22 22 22

Diameter (in.)

Motor Hp (Rpm) ¼ (1100) 1/, (1100) ¼ (1100) ¼ (1100) 1/, (1100) ¼ (1100)

EVAPORATOR COIL 4,,.15 4..,15 4._15 4...15 4.,.15 4_.15

Rows...Fins/in. 4.7 4.7 4.7 4.7 4.7 4.7

Face Area (sq ft)

EVAPORATOR BLOWER 1600 1600 1600 1750 1750 1750

Nominal Airflow (Cfm) 11 X 10 11 X 10 11 X 10 11 X 10 11 X 10 11 X 10

Size (in.)

Motor Hp (Rpm) 3/4 (1075) 3/4 (1075) 3/4 (1075) 1.0 (1075) 1.0 (1075) 1.0 (1075)

FURNACE SECTION*

Burner Orifice No. (Qty._Drill Size) 3-.38 3.,,33 3._31 3_,38 3,-33 3_.31

Burner Orifice No. (Qty._Drill Size)

RETURN-AIR FILTERS (in.)1" 24 X 30 24 X 30 24 X 30 24 X 30 24 X 30 24 X 30

* Based on a_titudeof 0 to 2000 ft.

t Required filter sizes shown are based on the larger of the ARI (Air Conditioning and Refrigeration Institute) rated cooling airflow or the heating airflow velocityof 300

if/minute for high-capacitytype. Air filter pressuredrop for non-standard filters mustnot exceed 0.06 in. wg.

Natural Gas 3_.46 3._42 3._41 3_.46 3...42 3_.41

Propane Gas

Throwaway

Table 3--Maximum Gas Flow Capacity*

NOMINAL INTERNAL LENGTH OF PIPE, FT t

IRON PIPE, DIAMETER

SIZE

(IN.) (IN.) 10 20 30 40 50 60 70 80 90 100 125 150 175 200

'/2 .622 175 120 97 82 73 66 61 57 53 50 44 40 -- --

_/, .824 360 250 200 170 151 138 125 118 110 103 93 84 77 72

1 1,049 680 465 375 320 285 260 240 220 205 195 175 160 145 135

1'/, 1,380 1400 950 770 600 580 530 490 460 430 400 360 325 300 280

1'/2 1,610 2100 1460 1180 990 900 810 750 690 650 620 550 500 460 430

* Capacity of pipe in cuft of gas per br for gas pressure of 0.5 psig or less. Pressure drop of 0.5-in. wg (based on a 0.60 specific gravity gas). Refer to Table C-4, National

Fire Protection Association NFPA 54.

t This length includes an ordinary number of fittings.

TRAP

OUTLET

1" rain.

2" rain,

COOOOg

Fig. 8iCondensate Trap

CAUTION: Unstable operation may occur when the gas valve and manifold assembly are forced out of position while

connecting improperly*routed rigid gas piping to the gas valve. Use a backup wrench when making connection to avoid

strain on, or distortion of, the gas control piping.

.....]i .........

Page 12

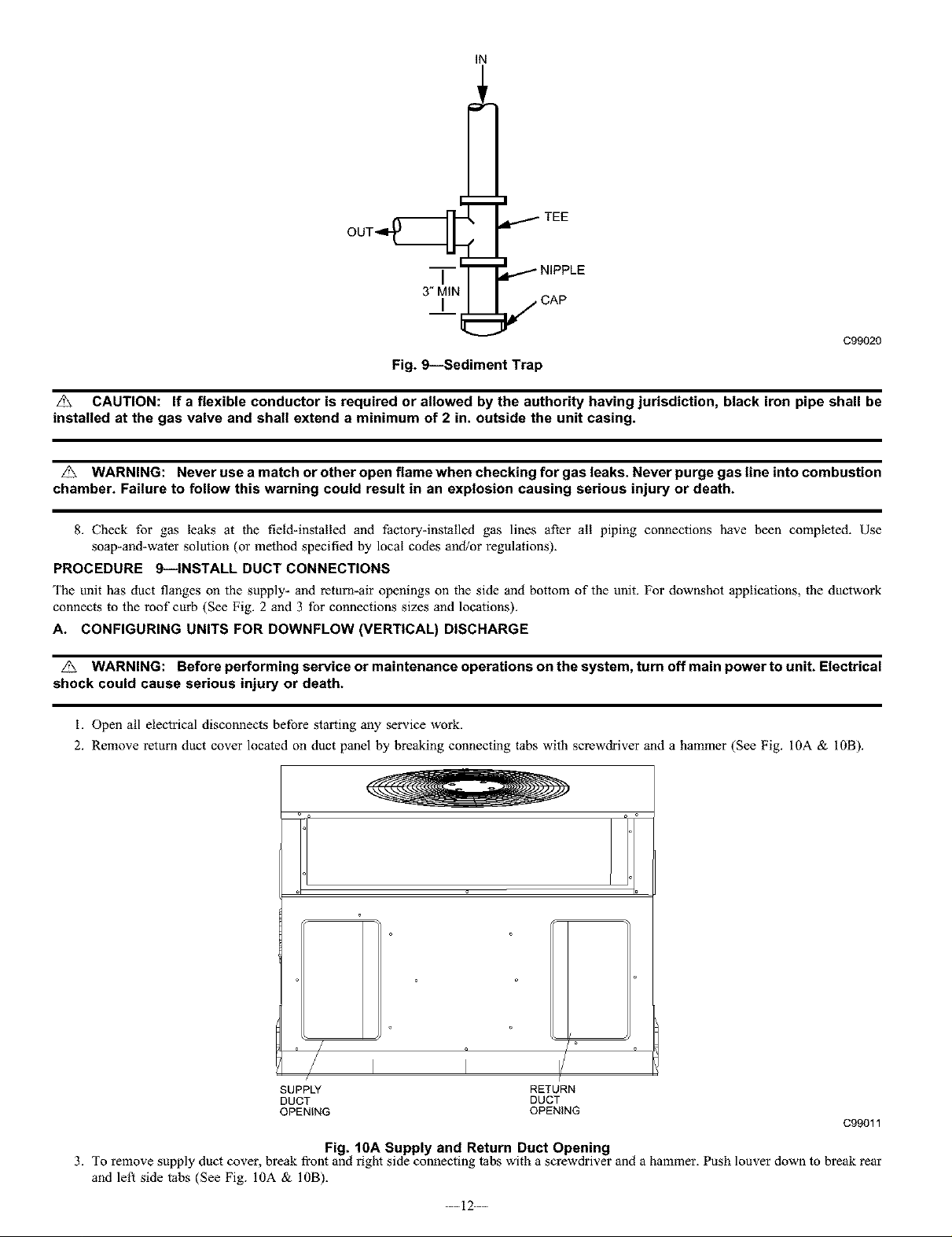

IN

TEE

I

3-MIN

I

Fig. 9--Sediment Trap

CAUTION: If a flexible conductor is required or allowed by the authority having jurisdiction, black iron pipe shall be

installed at the gas valve and shall extend a minimum of 2 in. outside the unit casing.

WARNING: Never use a match or other open flame when checking for gas leaks. Never purge gas line into combustion

chamber. Failure to follow this warning could result in an explosion causing serious injury or death.

C99020

8. Check for gas leaks at the field-installed and factoryqnstalled gas lines after all piping connections have been completed. Use

soap-and-water solution (or method specified by local codes and/or regulations).

PROCEDURE 9--INSTALL DUCT CONNECTIONS

The unit has duct flanges on the supply- and return-air openings on the side and bottom of the unit. For downshot applications, the ductwork

connects to the roof curb (See Fig. 2 and 3 for connections sizes and locations).

A. CONFIGURING UNITS FOR DOWNFLOW (VERTICAL) DISCHARGE

WARNING: Before performing service or maintenance operations on the system, turn off main power to unit. Electrical

shock could cause serious injury or death.

I. Open all electrical disconnects before starting any service work.

2. Remove return duct cover located on duct panel by breaking connecting tabs with screwdriver and a hammer (See Fig. 10A & 10B).

o

• o

/

;UPPLY RETURN

DUCT DUCT

OPENING OPENING

3. To remove supply duct cover, break fi'ont and right side connecting tabs with a screwdriver and a hammer. Push louver down to break rear

and left side tabs (See Fig. 10A & 10B).

Fig. 10A Supply and Return Duct Opening

.... 12....

C99011

Page 13

DUCT COVERS REMOVED

C99012

Fig. lOB---Vertical Duct Cover Removed

4. If unit ductwork is to be attached to vertical opening flanges on the unit composite base 0ackstand applications only), do so at this time.

z_ CAUTION: Collect ALL screws that were removed. Do not leave screws on rooftop as permanent damage to the roof may

occur,

5. It is recommensted that the unit base insulation around the perimeter of the vertical return-air opening be secured to the unit base with

aluminum tape. Applicable local codes may require aluminum tape to prevent exposed fiberglass.

6. Cover both horizontal duct openings with the duct covers fi'om the accessory duct cover kit. Ensure opening is air- and watertight.

7. After completing unit conversion, perform all safety checks and power up unit.

NOTE: The design and installation of the duct system must be in accordance with the standards of the NFPA for installation of nonresidenceqype

air conditioning and ventilating systems, NFPA 90A or residence*type, NFPA 90B; and/or local codes and ordinances.

Adhere to the following criteria when selecting, sizing, and installing the duct system:

1. Units are shipped for horizontal duct installation (by removing duct covers).

2. Select and size ductwork, supply*air registers, and return*air grilles according to American Society of Heating, Refrigeration and Air

Constitioning Engineers (ASHRAE) recommendations.

3. Use flexible transition between rigid ductwork and unit to prevent transmission of vibration. The transition may be screwed or bolted to

duct flanges. Use suitable gaskets to ensure weathertight and airtight seal.

4. All units must have field*supplied filters or accessory filter rack installed in the return*air side of the unit. Recommended sizes for filters

are shown in Tables 1 and 2.

5. Size all ductwork for maximum required airflow (either heating or cooling) for unit being installed. Avoid abrupt duct size increases or

decreases or performance may be affected.

6. Adequately insulate and weatherproof all ductwork located outdoors, insulate ducts passing through unconditioned space, and use vapor

barrier in accordance with latest issue of Sheet Metal and Air Conditioning Conlractors National Association (SMACNA) and Air

Conditioning Contractors of America (ACCA) minimum installation standards for heating and air conditioning systems. Secure all ducts

to building structure.

7. Flash, weatherproof, and vibration-isolate all openings in building structure in accordance with local codes and good building practices.

....13....

Page 14

PROCEDURE 10--INSTALL ELECTRICAL CONNECTIONS

WARNING: The unit cabinet must have an uninterrupted, unbroken electrical ground to minimize the possibility of

serious injury if an electrical fault should occur. This ground may consist of an electrical wire connected to the unit ground

lug in the control compartment, or conduit approved for electrical ground when installed in accordance with NEC (National

Electrical Code) ANSI/NFPA (latest edition) and local electrical codes. In Canada, follow Canadian Electrical Code CSA

(Canadian Standards Association) C22.1 and local electrical codes. Failure to adhere to this warning could result in serious

injury or death.

A CAUTION: Failure to follow these precautions could result in damage to the unit being installed:

1. Make all electrical connections in accordance with NEC ANSI/NFPA (latest edition) and local electrical codes governing

such wiring, in Canada, all electrical connections must be in accordance with CSA standard C22.1 Canadian Electrical

Code Part 1 and applicable local codes. Refer to unit wiring diagram.

2. Use only copper conductor for connections between field-supplied electrical disconnect switch and unit. DO NOT USE ALUMINUM

WIRE.

3. Be sure that high-voltage power to unit is within operating voltage range indicated on unit rating plate.

4. Do not damage internal components when drilling through any panel to mount electrical hardware, conduit, etc. On 3-phase units,

ensure phases are balanced within 2 percent. Consult local power company for correction of improper voltage and/or phase

imbalance.

A. HIGH-VOLTAGE CONNECTIONS

The unit must have a separate electrical service with a field-supplied, waterproof, disconnect switch mounted at, or within sight from, the unit.

Refer to the unit rating plate for maximum fuse/circuit breaker size and minimum circuit amps (ampacity) for wire sizing (See Tables 4 and 5 for

electrical data).

The field*supplied disconnect switch box may be mounted on the unit over the high-voltage inlet hole when the standard power and low-voltage

entry points are used (See Fig. 2 and 3 for acceptable locution).

See unit wiring label and Fig. 11 for reference when making high voltage connections. Proceed as follows to complete the high-voltage connections

to the unit.

m

HIGHVOLTAGE r- - - -

POWER LEADS 4¢c-

(SEE UNIT WIRING

LABEL) _-

--_--

FIELD-SUPPLIED

GND

CONTROL BOX

LOW-VOLTAGE _ O-

POWER LEADS-

(SEE UNIT O-

WIRING LABEL) _O-

SPLICE BOX

FUSED DISCONNECT

O-

_G_RN_(G_)_ (TTHy_IRcMAOL_TAT

Fig. 11--High- and Control-Voltage Connections

Single phaseunits:

I. Run the high*voltage (LI, L2) and ground leads into the control box.

2. Connect ground lead to chassis ground connection.

3. Connect LI to pressure lug connection I 1 of the compressor contactor.

4. Connect L2 to pressure lug connection 23 of the compressor contactor.

Three-phase units:

I. Run the high-voltage (LI, L2, L3) and ground leads into the control box.

2. Connect ground lead to chassis ground connection.

3. Locate the black and yellow wires connected to the lines side of the contactor.

4. Connect field LI to black wire on connection 11 of the compressor contactor.

5. Connect field wire L2 to yellow wire on connection 13 of the compressor contactor.

....14....

C99018

Page 15

Table4--Electrical Data--Unit PYIP

UNIT

SIZE

PYIP

018 208/230-1-60 187 253 9.0

024 208/230-1-60 187 253 12.8

030

036 208/230-3-60 187 253 9.0

042 208/230-3-60 187 253 10.7

848 208/230-3-60 187 253 13.5

060 208/230-3-60 187 253 18.6

V-PH-HZ

208/230-1-60 187 253 14.4

208/230-3-60 187 253 12.6

208/230-1-60 187 253 13.0

460-3-60 414 506 4.5

208/230-1-60 187 253 18.6

460-3-60 414 506 5.3

208/230-1-60 197 253 25.3

460-3-60 414 506 6.7

208/230-1-60 187 253 28.9

460-3-60 414 506 8.5

VOLTAGE

RANGE

Min Max

COMPRESSOR MOTOR

RLA LRA FLA

45.0

61.0

73.0

68.0

81.0

78.0

40.0

105.0

85.0

42.0

131.0

108.0

47.5

147.0

125.0

66.5

OUTDOOR FAN

0.8

0.8

0.8

0.8

1.6

1.6

0.9

1.6

1.6

0.9

1.6

1.6

0.9

1.6

1.6

0.9

INDOOR FAN

MOTOR POWER SUPPLY

FLA MCA Max Fuse or

1.8 13.9 20

2,0 18.8 30

2,0 20.8 30

2,0 13.2 20

3.6 24.0 35

3.6 16.5 25

1.9 8.4 15

3.8 27.5 45

3.8 18.8 25

2,0 9.5 15

3.8 37.0 60

3.8 22.3 35

2,0 11.3 15

6.2 43.9 60

6.2 31.1 45

3.2 14.7 20

C_ Bkr

6. Connect field wire L3 to Blue wire from compressor.

B. SPECIAL PROCEDURES FOR 208-V OPERATION

z_x WARNING: Before making any wiring changes, make sure the gas supply is switched off first. Then switch off the power

supply to the unit and install lockout tag, Electrical shock can cause serious injury or death,

C. CONTROL VOLTAGE CONNECTIONS

Do not use any type of power-stealing thermostat. Unit control problems may result.

Use no, 18 American Wire Gage (AWG) color-coded, insulated (35 C minimum) wires to make the control voltage connections between the

thermostat and the unit, if the thermostat is located more than 100 fi from the unit (as measured along the control voltage wires), use no. 16 AWG

color-coded, insulated (35 C minimum) wires.

STANDARD CONNECTION

Remove knockout hole located in the flue panel adjacent to the control access panel (See Fig. 2 and 3). Remove the rubber grommet from the

installer's packet (included with unit) and install grommet in the knockout opening. Provide a drip loop before running wire through panel.

Run the low-voltage leads from the thermostat, through the inlet hole, and into unit low-voltage splice box.

Locate five 18-gage wires leaving control box. These low-voltage connection leads can be identified by the colors red, green, yellow, brown, and

white (See Fig. 11). Ensure the leads are long enough to be muted into the low-voltage splice box (located below right side of control box). Route

leads through hole in bottom of control box and make low-voltage connections (See Fig. 11). Secure all cut wires, so that they do not interfere

with operation of unit.

D. HEAT ANTICIPATOR SETTING

The room themmstat heat anticipator must be properly adjusted to ensure proper heating performance. Set the heat anticipator, using an ammeter

between the W and R terminals to determine the exact required setting.

NOTE: For thermostat selection purposes, use 0.18 amp for the approximate required setting. Failure to make a proper heat anticipator adjustment

will result in improper operation, discomfort to the occupants of the conditioned space, and inefficient energy utilization; however, the required

setting may be changed slightly to provide a greater degree of comfort for a particular installation.

E. TRANSFORMER PROTECTION

The trans[brmer is of the energy-limiting type. It is set to withstand a 30-sec. overload or shorted secondary condition.

.... 15....

Page 16

EXAMPLE: Supply voltage is 460-3-60.

FLA -- Full Load Amps l_ AC = 455 v

LRA -- Locked RotorAmps Average Voltage = 452 + 464 + 455

MCA -- Minimum Circuit Amps 3

MOCP -- Maximum Overcurrent Protection

RLA -- Rated Load Amps = 137"1

CKT BKR -- Circuit Breaker 3

NOTES:

1. In compliance with NEC (National Electrical Code) requirements

for multimotor and combination load equipment (refer to NEC

Articles 430 and 440), the overcurrent protective device for the

unit shall be Power Supply fuse. Canadian units may be

fuse or circuit breaker.

2. Minimum wire size is based on 60 C copper wire. If other than

60 C wire is used, or if length exceeds wire length in table,

determine size from NEC.

3. Unbalanced 3-Phase Supply Voltage

Never operate a motor where a phase imbalance in supply volt-

age is greater than 2%. Use the following formula to determine

the percentage of voltage imbalance.

% Voltage imbalance

= 100 x max voltage deviation from average voltage

LEGEND LIP_I_US A B C AB=452V

(_ BC = 464 v

Determine maximum deviation from average voltage.

(AB) 457 452=5v

(BC) 464 457=7v

(AC) 457 455=2v

Maximum deviation is 7 v.

Determine percent of voltage imbalance.

% Voltage Imbalance = 100 x --

= 1.53%

This amount of phase imbalance is satisfactory as it is below the

maximum allowable 2%.

average voltage

iMPORTANT: If the supply voltage phase imbalance is

more than 2%, contact your local electric utility company

immediately.

= 457

7

457

Table 4iLegend

Table 5iElectrical DataiUnit PY2P

UNIT RANGE

SIZE V-PH-HZ

PY2P Min Max

024 208/23(_1-60 187 253

030

036 208/230-3-60 187 253

042 208/23(_3-60 187 253

048 208/230-3-60 187 253

060 208/230-3-60 187 253

208/230-1-60 187 253

208/230-3-60 187 253

208/230-1-60 187 253

460-3-60 414 506

208/230-1-60 187 253

460-3-60 414 506

208/230-1-60 187 253

460-3-60 414 506

208/230-1-60 187 253

460-3-60 414 506

VOLTAGE

COMPRESSOR

RLA LIRA

10.9 54.0

13.5 73.0

9.0 63.0

16.7 97.0

11.2 75.0

5.4 37.5

17.9 104.0

12.4 88.0

6.1 44.0

23.4 126.0

13.0 93.0

6.4 46.5

28.8 169.0

17.3 123.0

9.0 62.0

OUTDOOR FAN

MOTOR

FLA

0.9

0.8

0.8

0.8

0.8

0.9

1.6

1.6

0.9

1.5

1.5

0.9

1.6

1.6

0.9

INDOOR FAN POWER SUPPLY

MOTOR

FLA MCA Ckt Bkr

2.0 15.7 25

2.1 19.8 30

2.1 14.2 20

3.6 25.3 40

3.6 18.4 25

1.9 9.6 15

4.1 28.1 45

4.1 21.2 30

2.0 10.5 15

4.1 34.9 45

4.1 21.9 30

1.9 10.8 15

6.2 43.8 60

6.2 29.4 45

3.2 15.4 20

Max Fuse or

C99024

PRE-START*UP

WARNING: Failure to observe the following warnings could result in serious injury:

1. Follow recognized safety practices and wear protective goggles when checking or servicing refrigerant system.

2. Do not operate compressor or provide any electric power to unit unless compressor terminal cover is in place and secured.

3. Do not remove compressor terminal cover until all electrical sources are disconnected.

4. Relieve and recover all refrigerant from system before touching or disturbing anything inside terminal box if refrigerant

leak is suspected around compressor terminals.

5. Never attempt to repair soldered connection while refrigerant system is under pressure.

6. Do not use torch to remove any component. System contains oil and refrigerant under pressure. To remove a component,

wear protective goggles and proceed as follows:

a. Shut off gas supply and then electrical power to unit,

b. Relieve and recover all refrigerant from system using both high- and low-pressure ports,

c, Cut component connecting tubing with tubing cutter and remove component from unit.

d. Carefully unsweat remaining tubing stubs when necessary, Oil can ignite when exposed to torch flame,

Proceed as follows to inspect and prepare the unit for initial startup:

I. Remove access panel.

2. Read and follow instructions on all WARNING, CAUTION, and INFORMATION labels attached to, or shipped with, unit.

.... 16....

Page 17

EXAMPLE: Supply voltage is 460-3_60,

A a C AB = 452 v

FLA -- Full LoadAmps

LRA -- Locked Rotor Amps b

MCA -- Minimum Circuit Amps

MOCP -- Maximum Overcurrent Protection

RLA -- Rated Load Amps

CKT BKR -- Circuit Breaker

NOTES:

1. In compliance with NEC (National Electrical Code) requirements

for multimotor and combination load equipment (refer to NEC

Articles 430 and 440), the overcurrent protective device for the

unit shall be Power Supply fuse. Canadian units may be

fuse or circuit breaker.

2. Minimum wire size is based on 60 C copper wire. If other than

60 C wire is used, or if length exceeds wire length in table,

determine size from NEC.

3. Unbalanced 3-Phase Supply Voltage

Never operate a motor where a phase imbalance in supply volt-

age is greater than 2%. Use the following formula to determine

the percentage of voltage imbalance.

% Voltage imbalance

= 100 x max voltage deviation from average voltage

3. Make the following inspections:

a. Inspect for shipping and handling damages such as broken lines, loose parts, disconnected wires, etc.

b. inspect for oil at all refrigerant tubing connections and on unit base. Detecting oil generally indicates a refrigerant leak.

c. Leak test all refrigerant tubing connections using electronic leak detector, halide torch, or liquid-soap solution. If a refrigerant leak is

detected, see the Checkjbr Re[Hgerant Leaks section.

d. inspect all field- and factory-wiring connections. Be sure that connections are completed and tight.

e. Ensure wires do not contact refrigerant tubing or sharp sheet metal edges.

fi Inspect coil fins. If damaged during shipping and handling, carefully straighten fins with a fin comb.

4. Verify the following conditions:

LEGEND " @ 118

average voltage

Table 5--Legend

(_ BC = 464 v

Determine maximum deviation from average voltage.

(AB) 457 452=5v

(B0) 464 457=7v

(AC) 457 455=2v

Maximum deviation is 7 v,

Determine percent of voltage imbalance.

% Voltage Imbalance = fog x !

This amount of phase imbalance is satisfactory as it is below the

maximum allowable 2%.

IMPORTANT: If the supply voltage phase imbalance isJ

more than 2%, contact your local electric utility company J

immediately.

AC = 455 v

Average Voltage = 452 + 464 + 455

= 1371

= 457

457

= 1.53%

3

3

3

J

C99024

CAUTION: Do not purge gas supply into the combustion chamber. Do not use a match or other open flame to check

for gas leaks. Failure to follow this warning could result in an explosion causing serious injury or death.

a. Make sure gas line is free of air. Before lighting the unit for the first time, perform the following with the gas valve in the "OFF'"

position: if the gas supply pipe was net purged before connecting the unit, it will be full of air. It is recommended that the ground joint

union be loosened, and the supply line be allowed to purge until the odor of gas is detected. Never purge gas lines into a combustion

chamber, immediately upon detection of gas odor, retighten the union. Allow 5 minutes to elapse, then light unit.

b. Make sure that condenser-fan blade is correctly positioned in fan orifice. Leading edge of condenser-fan blade should be 1/2 in.

maximum from fan orifice venturi.

c. Ensure fan hub is I/8 in. maximum from motor housing (See Fig. 12).

1

MOTOR AND FAN HUB MOTOR SHAFT

Fig. 12--Fan Blade Clearance

d. Make sure that air filter(s) is in place.

e. Make sure that condensate drain trap is filled with water to ensure proper drainage.

fi Make sure that all tools and miscellaneous loose parts have been removed.

.........17.........

C99009

Page 18

©

\

\,

MANIFOLD

Fig. 13--Burner Assembly

f _F)ANIFOLD

Fig. 14---Monoport Burner

START*UP

PROCEDURE 1--CHECK FOR REFRIGERANT LEAKS

Proceed as follows to locate and repair a refi'igerant leak and to charge the unit:

I. Locate leak and make sure that refrigerant system pressure has been relieved and reclaimed from both high- and low-pressure ports.

2. Repair leak following Refrigerant Service procedures.

NOTE: Install a filter drier whenever the system has been opened for repair.

3. Add a small charge of R-22 refi'igemnt vapor to system and leak-test unit.

4. Recover refrigerant from refrigerant system and evacuate to 500 microns if additional leaks are not found.

5. Charge unit with R-22 refrigerant, using a volumetric-charging cylinder or accurate scale. Rq[er to unit ratingplure[br required charge.

Be sure to add extra refi-igerant to compensate for internal volume of filter drier.

PROCEDURE 2--START*UP HEATING AND MAKE ADJUSTMENTS

PIPE PLUG

BURNER FLAME

BURNER

C99019

C99021

z_ CAUTION: Complete the required procedures given in the Pre-Start-Up section before starting the unit.

Do not jumper any safety devices when operating the unit.

Make sure that burner orifices are properly aligned. Unstable operation may occur when the burner orifices in the manifold are misaligned.

Follow the lighting instructions on the heating section operation label (located inside the burner or blower access door) to start the heating section.

NOTE: Make sure that gas supply has been purged, and that all gas piping has been checked for leaks.

A. CHECK HEATING CONTROL

Start and check the unit for proper heating control operation as follows (see furnace lighting instructions located inside burner or blower access

panel):

I. Place room thermostat SYSTEM switch in the HEAT position and the fan switch is placed in AUTO. position.

.... 18---

Page 19

FIELD

SUPPLY

EQUIP GND

POWER

SCHEMATIC

208/230q +60

COOUNGFANLOG_C

G G

ENERGIZED DE.ENERGIZED

HEATING FAN LOGIC

ENERGIZED DE.ENERGiZED

i

I 24VSPLICE BOX

W13 ELK

WlgWHT

_W2O GRN

Wt5YEL

SECONDARY

24V

CR

BR

W39 RED J2

IGC _

W43 ELK

OFM

COMP

IFM

_ IDM

W46 BRN

d

"(N?

C_5

°AUTO I

_COO TCI YI I

_To I I

_AN I I

FIELD-THERMOSTAT I

COMMON

UNIT COMPONENT ARRANGEMENT

OUTDOORFAN

SECTION

SECTION _ECTION

CQM£RESSORINDOORFAN _

COMP

C 8

R

LARGECHASSISLOC

I I

I I

I

I

I

W21 RED

I

_} vl0

@ v_o

YEL GVR

@ HF

_,_,

EQUEP

Lh

©

AHA - AdjuStabM Heat NEC - Nationa_ Electrical

Anticipator Code

BR - B_ower Relay OFM - Outdoor-Fan Motor

C -^ Contactor QT - OuadrupleTerminal

CAP -- Capacitor RS - Rollout Switch

COMP- Compressor Motor SEN - Sensor

CR - Combustion Relay SW - Switch

CS - Centrifugal Switch TRAN - Transformer

EQUIP- Equipment / k

FS - FMme Sensor _ Field Spllce

FU - Fuse

GND - Ground _ Terminal (Marked)

GV - Gas VMve

GVR - Gas Valve Relay O Terminal (Unmarked)

HS - Hail Effect Sensor

HV - High VoYage • Spli_

TRAN - Transformer

t - Ignitor _ Sptice (Marked)

tDM - tnd_tced-D_af[ Motor Factory Wiring

tFC - indoor-Fan Contacto_ Field Control Wiring

tFM - indoor-Fan Motor

tGC - integrated Gas Unit -- -- - Field Power Widng

Controller Accessory OF

LI - Line Optional Wiring

LS - Limlt Switch -- TO _ndlcate Common

LS1 - Limlt Switch Potengal Only, Not

MGV - Main Gas Valve to Represent Wiring

NOTES:

1 If any of the original wires fomJshed am replaced, they must be

replaced with type 90 degree C wire Or its equivalent¸

See pdce pages for thermostat and subbases

Use 75 degree C cop er conductors for field installation

41 For high speed IFM, _sconnect RED _re from IGC terminal BM

and connect BLK w_refrom IEM For medium speed, disconnect

RED wire from IGC terminal SM and connect BLU wire from IFM

BLU RS

_#SEE NOTE #5

BLU

MSV

W35 SRA _

_IAMESEN

YEL K? i _

DISCONNECT

PERN£C

LEGEND

W3OBRN

Fig. 15---208/230-1-60 Wiring Diagram, Units PYIP and PY2P

....19....

C00057

Page 20

COOLING FJ_t,JLOGIC

_, + T%

G G

ENR_IZF_ DEENERGrzED

HEATIN_ FAN LOGIC

I , I

W BFt W BR

ENERG[ZE_ DE ENERGIZED

_J_

O

_ °_TO

FAN G

F_ELD-THENM_-AT

ON

i

I I

I I r

J I I

W14 B K

TN,_NI

W_3 ELK

I 24V SPLICE BOX

I

WIgWIIT

_2_ GRN

W21 RED

W64YEL

W15YEL _RIMA_ v

2z-V

OR

BR

_g RED _L_ I Q

IGC

r _

i

(SEE NOTE _t4)_

WE£YEL

L

/

<N?

W43 BLK BLK_,..

W6YEL _RN

W8 BLK L_ (06!) ON_Y)

W58 BcJ _

vi0

v10

_F

e._P_ YEL OFM

L__ COMP

B_J4¢WI_T IFM

_ OAPI[)ORYE

YEL IDM

CA_3

_BR

QT _ _RNyE_L_

BLU

_GV

W35GRA_

FL_E SEN

W46 BRN

U NIT COMPONENT ARRANGEMENT

OU_OORFAN

S_¢TION

OOMFRE$$OR

$E¢_ON SECTION

¢

R

LEGEND

AHA - Adjustable Heat NEG - Nat:onz Ele¢_cal

A,_iJ¢ootor Code

BR - Bo_er R_lzy OFIV - Outdco,---a,_IVo#r

C - Cenf_oto, QT - QuzdrupeTer,t_i_al

CAP - t.tapacitor R_ - Rolout_'wi_¢h

CO'_P - _mp_'esscr Motor SEN - L*ierscr

CR - f._oml_stio_ Reay SW - _'v_itch

CS - t.tenfyit_g_Swi#h TRAN - Tr_nslonrer

E_P- Equipraert

FS - Flame Se_so" Field _plies

FU - FLSe

GND - G'curd 0 Ter,t_iral_Marked_

GV - GasValve

GVR - GasValveRelay 0 Ter,t_iral_Unmarked}

HS - Hall EPeot_e_scr

HV - H;ghVo;ta=ge • Splice

TP_N T_r_rra_"

I - _itO" _ Spliee(IVarked)

13M - _duced-Dt_ff. _o#r F_c_ry Wirin£

I--C - r'd¢o'-F_l _nf_ot_" Field_*3ertrolWidng

I--M - r'd¢o'-F_l IVo_r

IGC - _ ,ate4clGas Unit -- -- - Field Pc_rWidng

f.ten_lL'-" _SSO ry or

LI - Lhe O*_Jo_alWirir_

LS - Lb_it_'v_itch -- TOndi_.4_ Cen'_or

LS_ - Li,ait_.'_it_h PO_Otal Only, Not

MGV - WainGas V_ve to Repr'=,.sentWidng

NO=ES:

t. f any ofthe=orgi'_alwires fJrn sheda_ rep aced, _ey "nJstbe

_placed w;th _,pe 90 deg_e C w_ ori_ equivaler t

2. 8e_=pri_ p_J_ for them_o_L_ and _udba_e_.

;or high _ed IF'C, _'!sr_re_ RE_ w!_ _'n IGC _='mi_al BM

8_d _r_ BLK'_ir_ {1_1_iFM. For i_d!Ul_ •,_,_d_ d!sr_r_i

_ED _'_ _n_ IGC termiral BV and r,_lln_'_ _LU wi_ fl_m I;V.

[]

3A_8E_TION

E_UIF

D[SGCf_NECT

FERNE0

Fig. 1_208!230-3-60 Wiring Diagram, Units PYIP and PY2P

W_J BRN

CO005B

_0_

Page 21

ENEPGIZED DE=ENERG[ZF_

_OFF I

HEAT _

_HEAT I

°AUTO

"o

] 24VSPLICE BOX

I r

I I

W13 3LK

WIgWIIT

W2CGRN

_IRED

W3_ RED _ I_

F

/

, _

_D Vl0

@ vl_)

MGV

_CC'OTCIAtj_YI I

_ON •

FIELB-_ EF{r,4OSTAT I

I

COMMON

IJNIT OOMFON ENT ARRANGEMENT

OUTL30,OPF&_ []

_E0_ON

r_OMS0MP1 _

30MP

¢

,3

R

GAS_E_f_ON

[]

E(_JIP

GNI_I

_I$_3NNECT

PERNEC

VV35GRA_

FL_JE _EN

LEGEND

AHA - AdjLsf_ble "-eat

Ardicip_r

BR - Blowe, Relay

C - _3ortabor