Page 1

& Start-Up Instructions

PHI P, PH2P

Single-Packaged Heat Pump Units

NOTE: Read the entire instl_action manual before starting the installation

TABLE OF CONTENTS

SAFETY ( ONSIDERATIONS 2

INTRODUCTION .......................................................................................................................................................................................................... 2

RECEIVrNG AND INSTALLATION .......................................................................................................................................................................... 2

Check Equipment ..................................................................................................................................................................................................... 2

IDENTIFY UNIT ................................................................................................ 2

INSPECT SHIPMENT ............................................................................................ 3

Provide Lnit Support ................................................................................................. 3

ROOF CURB ...................................................................................................................................................................................................... 3

SLAB MOUNT ................................................................................................................................................................................................... 4

GROUND MOUNT ............................................................................................... 4

Provide Clearances ................................................................................................. 5

Rig and Place Unit ................................................................................................................................................................................................... 5

INSPE( TION ...................................................................................................................................................................................................... 5

INSTALLATION ................................................................................................................................................................................................ 5

Select and Install Ductwork ................................................................................................ 7

CONVERTING HORIZONTAL DIS(HARGE UNITS TO DOVv_FLOW (VERTICAL) DIS(HARGE UNITS .................... 8

Provide fbr (ondensate Disposal ................................................................................... 9

Install Electrical Connections ....................................................................................... 11

HIGH-VOLTAGE ( ONNECTIONS ....................................................................................

ROUTING POWER LEADS INTO UNIT .............................................................................. 11

CONNE(TING GROUND LEAD TO GROUND LUG ............................................................ 11

ROUTING (ONTR()L POWER WIRES (24-V) ......................................................................... 11

SPE(IAL PRO(EDURES FOR 208-V OPERATION .................................................................. 13

PRE-START-L P ...................................................................................................... 17

START-UP ............................................................................................................... 18

(beck for Refi'igerant Leaks ........................................................................................ 18

Start-Up Adjustments .............................................................................................. 19

CHECKING (00LING AND HEATING

CONTROL OPERATION ........................................................................................... I9

CHE(KING AND ADJUSTING REFRIGERANT (HARGE ........................................................ 19

REFRIGERANT CHARGE ........................................................................................... I9

NO CHARGE 19

LOW CHARGE COOLING 19

TO USE COOLING CHARGING (HARTS 19

INDOOR AIRFLOW AND AIRFLOW ADJUSTMENTS 20

MAINTENANCE 21

Air Filter 22

Indoor blower and motor 22

OUTDOOR COIL, INDOOR (OIL, AND

CONDENSATE DRAIN PAN 22

Outdoor fhn 23

Electrical controls and wiring 24

Refrigerant circuit 25

Indoor airflow ......................................................................................................................................................................................................... 25

Metering device ...................................................................................................................................................................................................... 25

Liquid line strainers ................................................................................................................................................................................................ 26

High Flow Valves .................................................................................................................................................................................................. 26

Time-delay relay 27

Loss of"charge switch 27

Check defiost them_ostat 27

Defi'ost Thermostat 27

Form: IM-PH1P-04 Cancels: tM-PHIP-03 Printed in U.S.A. 11-02 Catalog No. 53PH-1P7

Page 2

TROUBLESHOOTING 27

START-UP ( HECKLIST 27

NOTE TO INSTALLER READ THESE INSTRU(TIONS (AREFULLY AND COMPLETELY befbre installing this unit. Also, make sure

the Owner's Manual and Service Instl_/ctions are left with the unit after installation.

C99001

Fig. l--ModeJ PHIP/PH2P

SAFETY CONSIDERATIONS

Installation and servicing of air=conditioning equipment can be hazardous due to system pressure and electrical components Only trained and

qualified personnel should install, repair, or service air-conditioning equipment.

Untrained personnel can perform basic maintenance fkmctions of cleaning coils and filters. All other operations should be performed by tlained

service personnel. When working on air-conditioning equipment, observe precautions in the literature, tags, and labels attached to the unit, and

other safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work gloves. Use quenching cloth for unbrazing operations. Have fire extinguisher available for

all brazing operations.

Z_ WARNING: Improper installation, adjustment, aReration, service, maintenance, or use can cause explosion, fire,

electric shock, or other occurrences, which could cause serious injury or death or damage your property. ConsuR a qualified

installer or service agency for information or assistance. The qualified installer or agency must use only factory-authorized

kits or accessories when modifying this product.

Recognize safety information. This is the safBty=alert symbolz_ x . When you see this symbol on the product or in instructions or manuals, be alert

to the potential for personal iajury.

Understand the signal words DANGER, WARNING, CAUTION, and NOTE. Danger identifies the most serious hazards, which will result in

severe personal injury or death. Warning indicates a condition that could cause serious personal injury or death. Caution is used to identif)- unsafe

practices, which would result in minor personal injury or product and property damage. NOTE is used to highlight suggestions which will result

in enhanced installation, reliability, or operation.

1. The power supply (volts, phase, and hertz) must cot_'espond to that specified on unit rating plate.

2. The electrical supply provided by the utility must be sufEcient to handle toad imposed by this unit.

3. This installation must cont'orm with local building codes and with NEC (National Electrical Code). Refer to provincial and local plurnbing

or waste water codes and other applicable local codes.

Z_ WARNmNG: Before performing service or maintenance operations on system, turn off main power to unit. Turn off

accessory heater power switch if applicable. Electrical shock could cause severe injury or death.

INTRODUCTmON

The PH1P and PH2P heat pumps are fully self-contained and designed for outdoor installation (See Fig. 1). Standard units are shipped in a

horizontal=discharge configuration _br installation on a ground=level slab. Units can be converted to downflow (vertical) discharge configurations

fbr rooftop applications.

RECEBMmNG AND INSTALLATION

PROCEDURE I--CHECK EQUBPMENT

A. BDENTIFY UNIT

The unit model number and serial number are stamped on the unit identification plate Check this inJ:bm_ation against shipping papers

2

Page 3

CORNER4 L_

• EVAPORA/OR CO_L

TOP VIEW

IlJllJllJitllllI]lllt

i tlJtIIIIJltlIItlIIIItL

l .............

4020

_15831

J i

117¸7

[463]

883 _ _ ......

_s4B_ REAR VIEW

.... OPEN NG

-5505 .................

!983) [21 6T} [9 83]

_UCT

REQUIRED CLEARANCES TO COMBUS_BLE MATL.

10P O_ UNII .......................... 3556 [14 OOJ

DUCT SIDE OF UNiT ......................................... 508 1200]

SIDE OPPOSITE DUCTS ........................ 3556 [140O]

BOTTOM OF UNIT ..................................... IRT [050]

EIECTRIC HEAT PANEl...................................... 9144 [3NDD]

NEC. REQUIRE) CLEARANCES.

BETWEEN UNITS, POWER [NTRT SIDE ............... lORD8 [4200]

UNIT AND UNGROUNDED SURFACES. POWER ENTRY SIDE .......... 9140 [3600]

UNIT AND DLOC_ OR CONCREIE WALLS AND OTIER

GROUNDED SURFACES, POWER ENTRY S!DE .................... _ODD8 [4200]

91!

MULIMETERS /IN]

MIILIMETERS IIN]

[47 00]

t

i]4j iJJ-JJiiiJ IIJlJii

IIIII IIIIIIIIIH

I_QUIP_) CLEARANCE FOR OP_A_ON AND SERV_INC

EVAP COIL ACCESS S_DE .................. 9F4 O [3600]

POWER ENTRY SiDE ........................................ 9[40 [360D]

(EXCEPT FOR NEC REQUIREMENTS)

UNIT TOP ......................................... 9F4 O [3600]

SIDE OPPOSITE DUCTS ..................................... 9140 [BROO]

DUCI PANEL .................... 304 B IIROOD

,MINIMUM DISTANCES:IF UNIT IS PIACED LESS THAN 3048 !I?DO] FROM WAIL

SYSTEM,THEN SYSTEM PERFORMANCE MAYBE COMPROMISED

MILLIMETERS EJN1

DIMENSIONS IN [] ARE }N }NCHES

....iiii i11iil....

lilllilillillill

\.

Z

_2;6 3

{48 281

FRONT VIEW

UNIT WEIGHT UNiT HEIGHT

UNIT

[3272] _DRAIN 0UT[E]

LEFT SIDE VIEW _90 [0 ?S] N PT

220 [087] DP

ELECTRICAL CHARACTERBSTICS IN. (MM)

Ib kg "A"

PH1P018

PH1P024

PH1P030

PH1P036

PH1P042

PH2P024

PH2P030

PH2P03$

208/230-1-80, 208/230-3-60, 460-3-80

208/230-1-60, 208/230-3-60, 480-3-60

208/230-1-80, 208/230-3-80, 480-3-80

208/230-1-60

208/230-1-60

208/230-I-60, 208/230-3-60

208/230-1-60

208/230-1-60, 208/230-3-60

283 19.5 (495.3)

289 19.7 (500.4)

287 19.5 (495.3)

291 19.5 (495.3)

323 19.7 (500.4)

299 19.0 (482.6)

320 19.7 (500.4)

328 19.7 (500.4)

128.4 37.02 (940.3)

131.1 39.02 (991.1)

130.2 39.02 (991.1)

132.0 37.02 (940.3)

146.5 37.02 (940.3)

135.6 41.02 (1041.9)

145.2 37.02 (940.3)

148.8 37.02 (940.3)

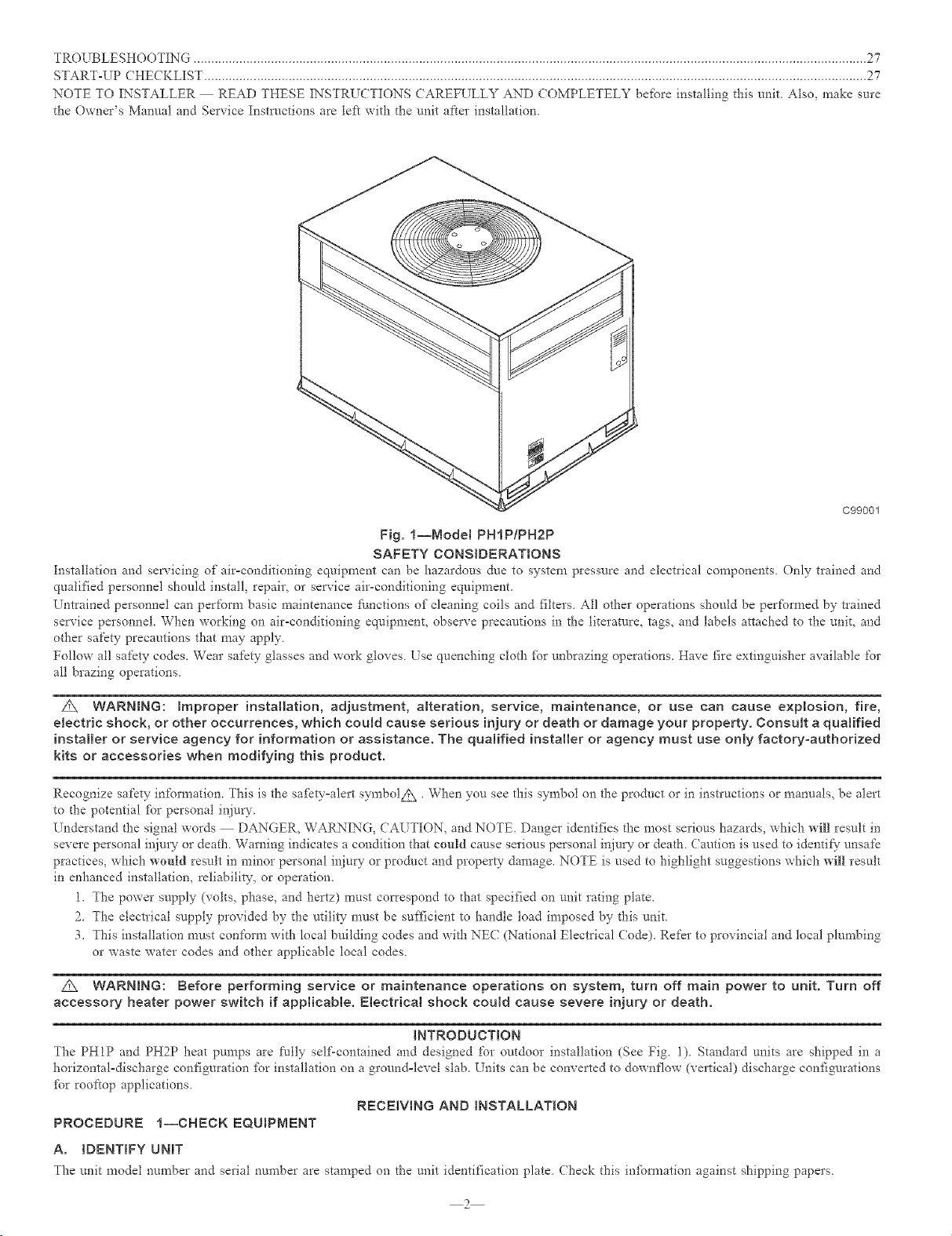

Units shown with Optional Field installed Wire Griles

Fig. 2--PHIP018-042/PN2P024-036 Unit Dimensions

B. INSPECT SHIPMENT

Inspect %r shipping damage while unit is still on shipping pallet. If unit appears to be damaged or is torn loose fi'om its anchorage, have it examined

by transportation inspectors before removal Fmavard claim papers directly to transportation company Manuf_mtmer is not responsible [br any

damage incun'ed in transit. Check all items against shipping list. Immediately notif) the nearest Payne Air Conditioning office if any item is

missing. To prevent loss or damage, leave all parts in original packages until installation.

PROCEDURE 2--PROVIDE UNIT SUPPORT

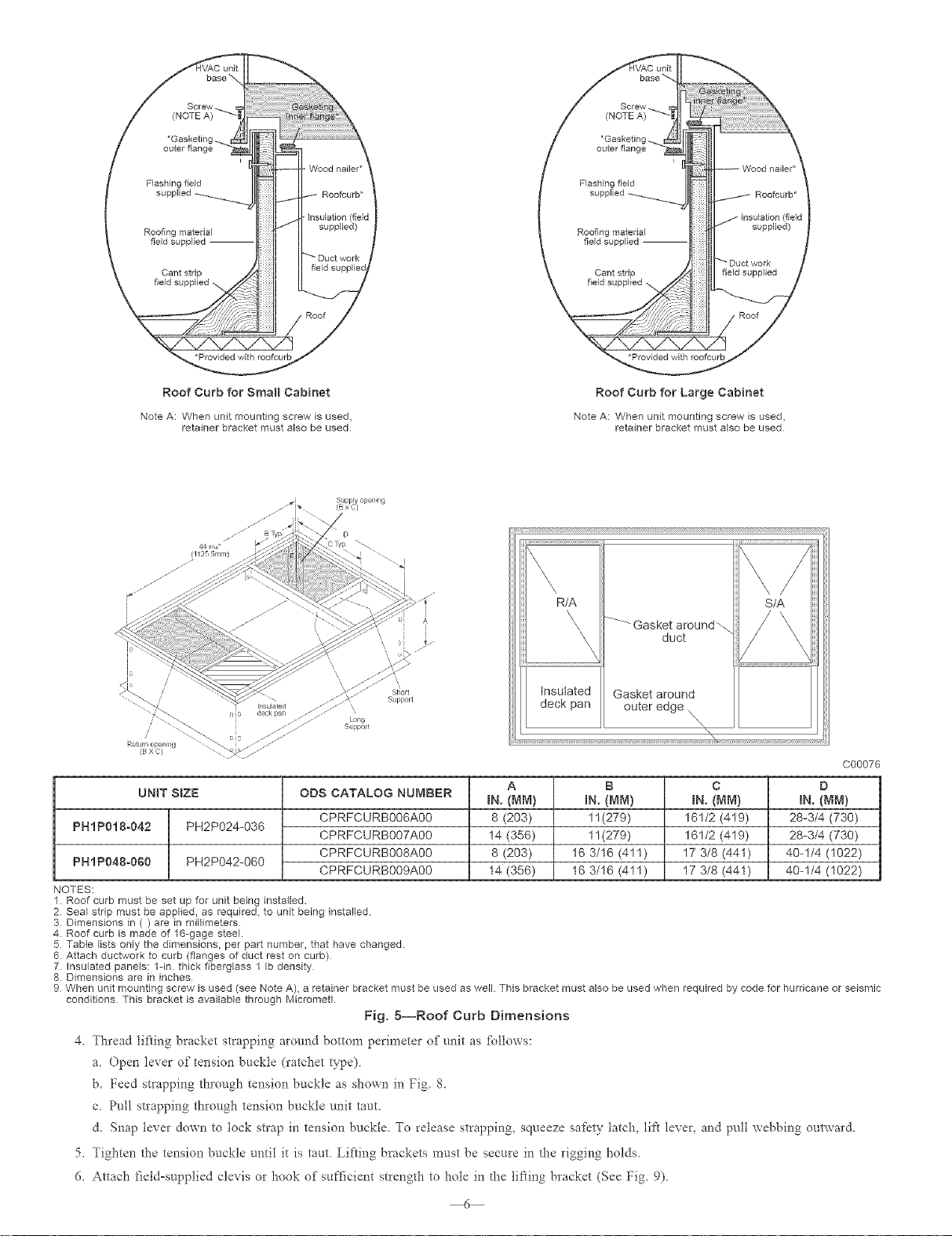

A. ROOF CURB

Install accesso W roof curb in accordance with instructions shipped with curb (See Fig 5) Install insulation, cant strips, roofing, and flashing_

Ductwork must be attached to curb

IMPORTANT: The gasketing of the unit to the roof curb is critical for a watertight seal, Install gasketing material supplied with the roof curb,

Improperly applied gasketing also can result in air leaks and poor unit performance.

3

{1087]

BT_

[3¸43}

122 2

_4 B!l

RIGHT SIDE VIEW

CENTER OF GRAVITY

IN. (MM)

X

13.7 (348.0)

13.9 (353.1)

13.7 (348.0)

13.7 (348.0)

14.0 (355.6)

13.7 (348.0)

14.0 (355.6)

14.0 (355.6)

{o 2o}

C00137

¥

Z

15.0 (381.0)

15.0 (381.0)

15.0 (381.0)

13.0 (330.2)

13.0 (330.2)

16.0 (406.4)

17.6 (447.0)

16.5 (419.1)

Page 4

.........lITIl 'ffTT

IIIIIlllIllllllIl

SUPPL? • RETURN

7

DQCT DUCT

4020

[15631

OPENING • OPENING

J

UNIT

PN1P048

PN1P060

PN2P042

PN2P048

PN2P0$0

t TOP VIEW

REtiRED CLEARAr_ES TO COMBJSTIBLE MATL

TOP OF UNIT ............................................. 355¸0 [1400]

DUCT SIDE OF UNIT .... S0 8 [200]

S!DE OPPOSITE OUCIS ..................................... 355¸0 [1400]

BOTTOM OF UNIT ........................... {27 (050]

ELECTRIC _EAT PANEL ...................................... 9[4¸4 [30001

NEC. REQUIRED CLEARANCE&

BETWEEN UNITS, POWER ENTRY SIDE ........... 10668 I4E00]

UNIT AND UNGROUNOED SURFACES, POWER ENTRY SlOE .......... 914¸0 [3600]

UNIT AND BLOCK OR CONCRETE WALLS AND OTNER

GROUNDED SURFACES, POWER ENTRY SIDE .................. 1066¸8 [4200]

1090 6

[42 94/

F£LD ENTRY_

SERVICE PORTS

h

]

MIllIMETERS [IN]

M_LLiMEEERS [IN]

{47 00]

.....T

I IItlllllIIIlIIIIll

z

__LL_____ ±

.......................................... 1{234 ............................................... _ 148 28]

[44 22] \_

LEFT SIDE VIEW ,,,o_o,.D, FRONT VIEW

\ORAIN OUTLET

_90 [075] NPT

_=LECTRBCAL CNARACTr=R_STICS

208/230-1-60, 208/230-3-60, 460-3-60

208/230-1-60, 208/230-3-60, 460-3-60

208/230-1-60, 208/230-3-60, 460-3-60

208/230-1-60, 208/230-3-60, 460-3-60

208/230-1-60, 206/230-3-60, 460-3-60

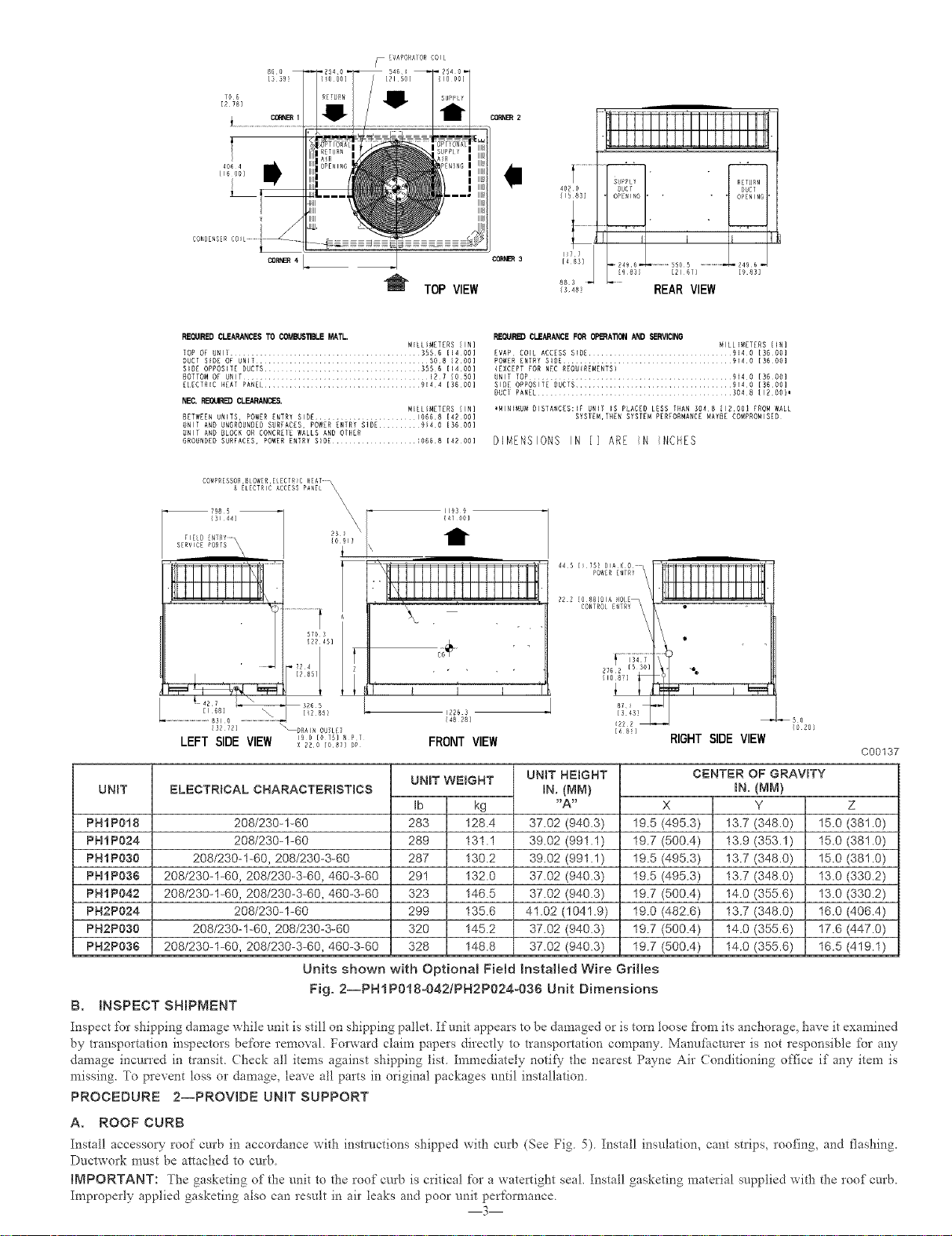

Units shown with Optional Field Installed Wire Grilles

Fig, 3--PNIP048-060/PHEP042-060 Unit Dimensions

12Z_ 3

UNIT WEIGNT

Ib kg

353 160.1

418 189.6

350 158.8

315 170.1

428 194.1

[4 631

88 5

{3 48}

[13 831 {13 6/] [13 8_]

REAR VIEW

REQUIRE_ CLEARANCE FOR OPERATION AND SERVICING

EVAP COIL ACCESS SIDE .................................. 9140 [36001

POWER ENTRY SIDE .............. 914 0 [36 001

{EXCEPT FOR NEC REOUIREMENIS}

UNIT TOP ............................. 9140 [36001

SIDE OPPOSITE DUCTS .................................... 9140 [3600]

OUCT PANEL .............................................. 3048 [1200],

,M]N!M_M D_STANBES;W UNI[ IS PLACED LESS IHAN 3048 [IRO0] FROM WALL

DIMENSIONS IN [1 ARE IN INCHES

STSTEM,TREN SYSTEM PERFORMANCE MAYBE COMPROMISED¸

445

POWER

222 [o 88] O{A ilOL[_

CONTROL EN#RY

•%

13 431

_222 _"

[48}]

...... 50

MILLIMETERS [IN1

{020}

RIGHT SIDE VIEW

UNIT HEIGHT

IN. {MM)

_A_

38.98 (990.2)

38.98 (990.2)

40.98 (1040.9)

40.98 (I040.9)

42.98 (1091.7)

19.9 (505.5)

19.9 (505.5)

19.9 (505.5)

19.9 (505.5)

19.9 (505.5)

CENTER OF GRAVITY

IN.(NM)

X

15.7 (398.8)

15.7 (398.8)

15.7 (398.8)

15.7 (398.8)

15.7 (398.8)

Y

C00136

Z

17.0 (431.8)

17.0 (431.8)

16.6 (421.6)

18.0 (457.2)

17.6 (447.0)

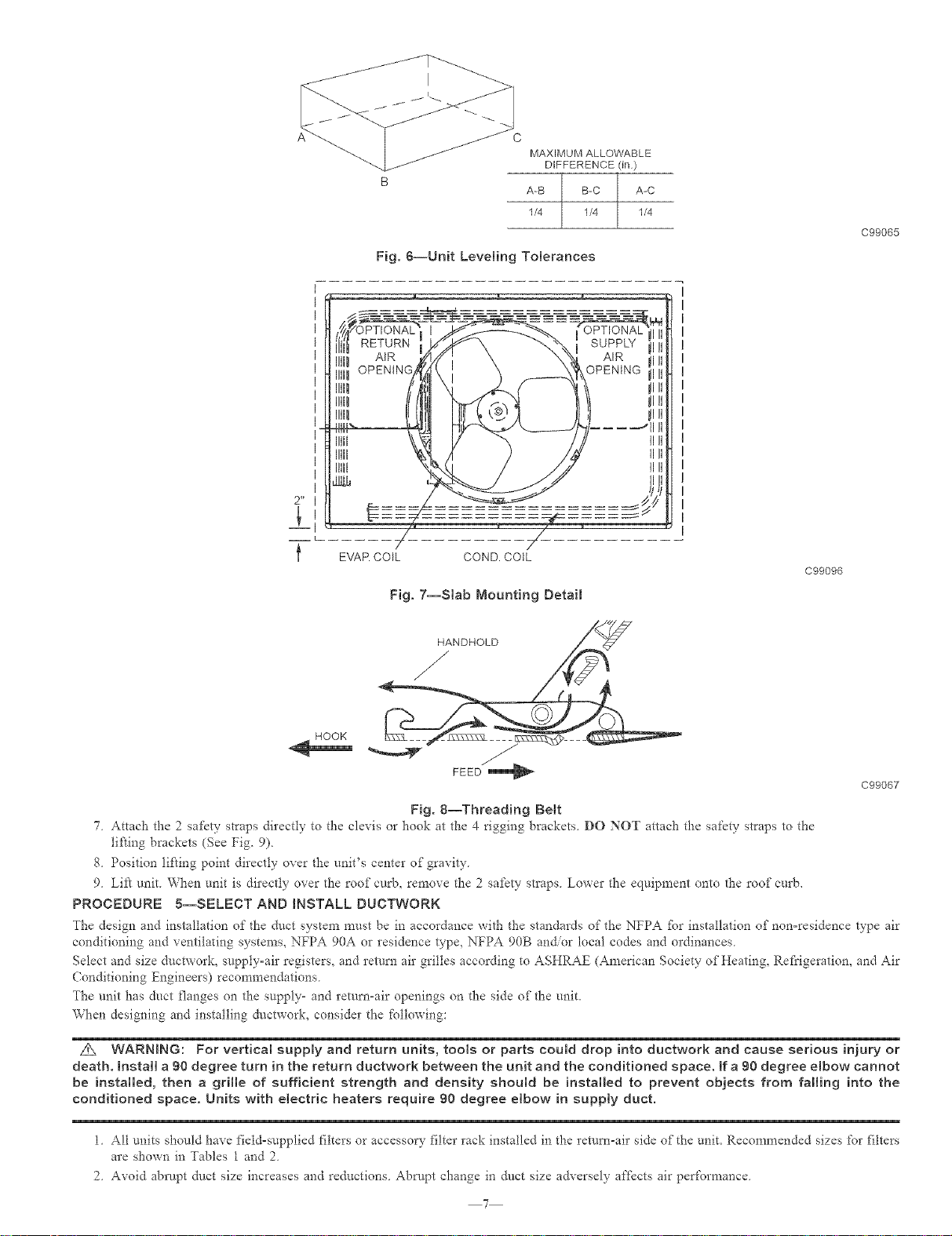

Curb should be level to within 1/4 in. (See Fig. 6). This isnecessary %r unit drain to _hnction properly. Refer to accessory- roof curb installation

instructions fbr additional infbrmation as required

B. SLAB MOUNT

Place the unit on a solid, level concrete pad that is a minimum of" 4 in tl-gick with 2 in. above grade (See Fig. 7) The slab should extend

approximately 2 in beyond the casing on all 4 sides of the unit Do not secure the unit to the slab except when required by local codes.

C. GROUND MOUNT

The unit may be installed either on a slab or placed directly on the ground if total codes permit Place the unit on tevel ground prepared with gravel

fbr condensate discharge, 4

Page 5

1 2

Y

4 x 3

C00071

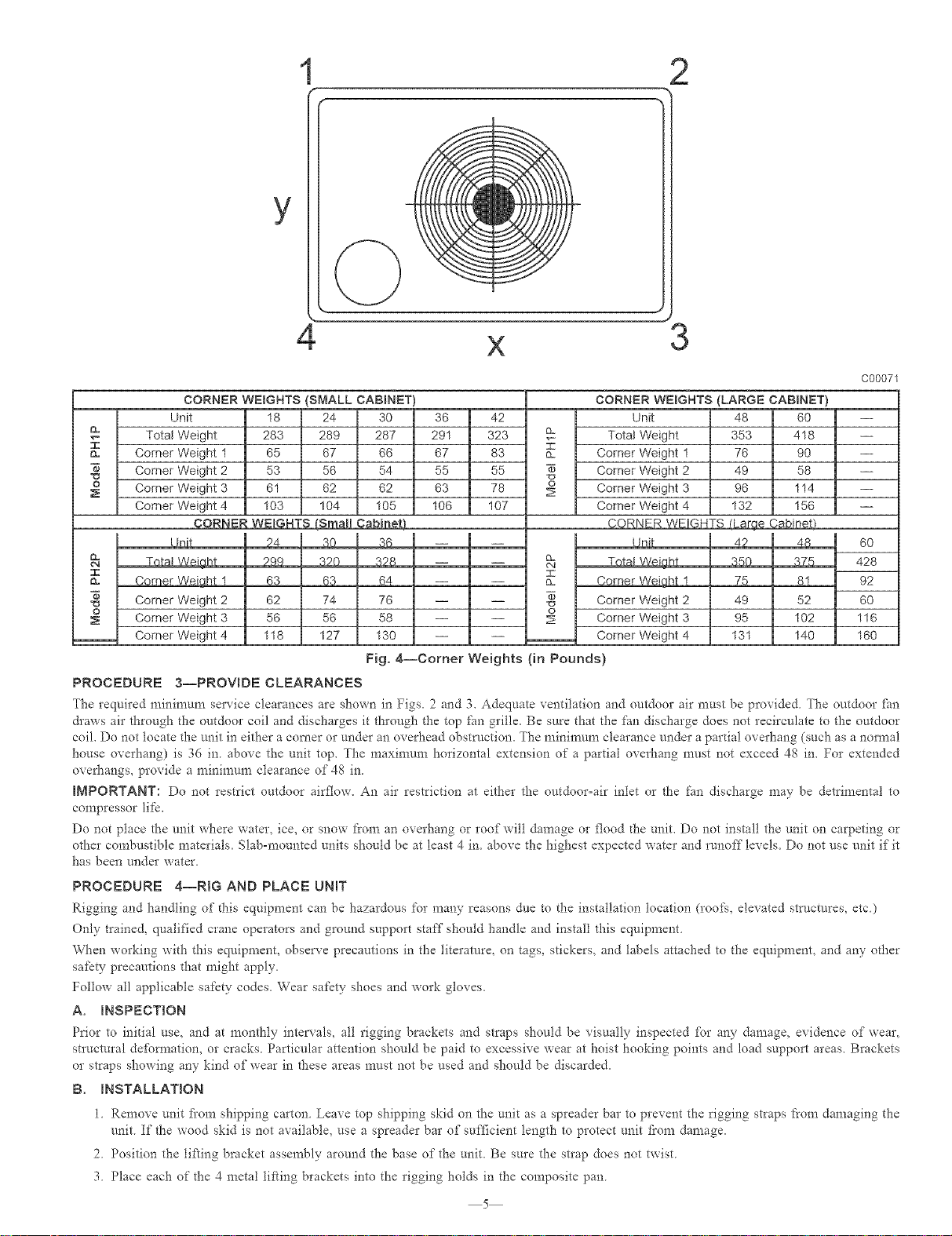

CORNER WEIGHTS (SMALL CABINET)

Unit 18 24 30 36 42

Total Weight 283 289 287 291 323

Corner Weight 1 65 67 66 67 83

Corner Weight 2 53 56 54 55 55

o

Corner Weight 3 61 62 62 63 78

Corner Weight 4 103 104 105 106 107

i

Corner Weiqht 1 63 63 64 -- --

Corner Weight 2 62 74 76 -- --

o

Corner Weight 3 56 56 58 -- --

Corner Weight 4 118 127 130 -- --

PROCEDURE 3--PROVIDE CLEARANCES

The required minimum service clearances are shown in Figs. 2 and 3. Adequate ventilation and outdoor air must be provided. The outdoor fire

&aws air through the outdoor coil and discharges it through the top fun grille. Be sure that the fan discharge does not recirculate to the outdoor

coil. Do not locate the unit in either a comer or under an overhead obstruction. The minimum clearance under a partial overhang (such as a no*real

house overhang) is 36 in. above the unit top. The maximum horizontal extension of a partial overhang must not exceed 48 in. For extended

overhangs, provide a minimum clearance of 48 in

mMPORTANT: Do not restrict outdoor airflow. An air restriction at either the outdoor-air inlet or the fan discharge may be detrimental to

compressor life.

Do not place the unit where water, ice, or snow from an overhang or roof will damage or flood the unit. Do not install the unit on carpeting or

other comhustible materials. Slab-mounted units should be at least 4 in. above the highest expected water and runoff levels. Do not use unit if it

has been under water.

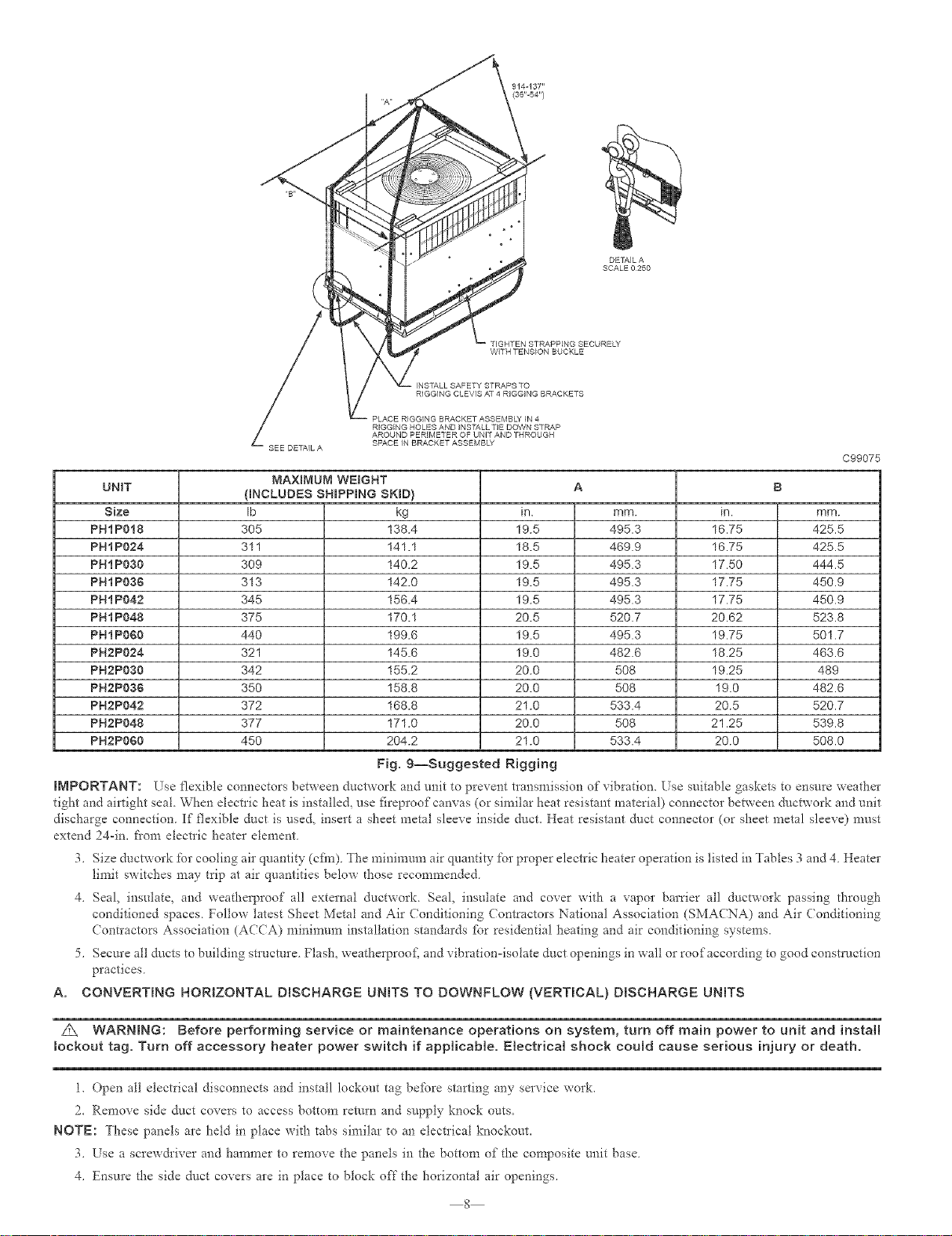

PROCEDURE 4--RIG AND PLACE UNmT

Rigging and handling of d_is equipment can be hazardous %r many reasons due to the installation location (roofs, elevated structures, etc.)

Only trained, qualified crane operators and ground support staff should handle and install this equipment

When working with this equipment, observe precautions in the literature, on tags, stickers, and labels attached to the equipment, and any other

safety precautions that might apply.

Follow all applicable safety codes. Wear safety shoes and work gloves.

A. mNSPECTION

Prior to initial use, and at monthly intervals, all rigging brackets and straps should be visually inspected for any damagQ evidence of wear,

structural defbm_atiom or cracks. Particular attention should be paid to excessive wear at hoist hooking points and load support areas. Brackets

or straps showing any kind of wear in these areas must not be used and should be discarded.

B. mNSTALLATION

1. Remove unit from shipping carton Leave top shipping skid on the malt as a spreader bar to prevent the rigging straps from damaging the

unit If the wood skid is not available, use a spreader bar of sufficient length to protect unit f?om damage.

2 Position the lifting bracket assembly around the base of the unit. Be sure the strap does not twist

3 Place each of the 4 metal lifting brackets into the rigging holds in the composite pan

CORNER WEIGHTS {Small Cabinet_

Yota_ Weidht 999 320 32_ -- --

Fig. 4--Corner Weights

5

c_ Corner Weight 1 76 90

"O

:_ Corner Weight 3 96 114

o_ Yet_t W_ir_ht 350 375 428

oJ

!

m. Corner Weiaht 1 75 81 92

_ Corner Weight 2 49 52 60

:_ Corner Weight 3 95 102 116

in Pounds)

CORNER WEIGHTS (LARGE CABINET)

Unit 48 60

Total Weig ht 353 418

O

Corner Weight 2 49 58

Corner Weight 4 132 156

CORNER WEIGHTS (Lame Cabinet_

_tnit 47 4,_ 60

O

Corner Weight 4 131 140 160

Page 6

Roof Curb for Small Cabinet

Note A: When unit mounting screw is used,

retainer bracket must also be used

Roof Curb for Large Cabinet

Note A: When unit mounting screw is used,

retainer bracket must also be used

(/125 5mrr)

\ /

\

\\ /

R/A

\ _ Gasket around_,

\

Insulated Gasket around

deck pan outer edge \

UNIT SIZE

PH1P018-042 PH2P024-036

PH1P048-060 PH2P042-060

NOTES:

1 Roof curb must be set up for unit being installed.

2 Seal strip must be applied, as required, to unit being installed.

3 Dimensions in ( ) are in millimeters

4 Roof curb is made of 16-gage steel.

5 Table lists only the dimensions, per part number, that have changed.

6 Attach ductwork to curb (flanges of duct rest on curb)

7 Insulated panels: i-in thick fiberglass 1 Ib density

8 Dimensions are in inches

9 When unit mounting screw is used (see Note A), a retainer bracket must be used as well This bracket must also be used when required by code for hurricane or seismic

conditions This bracket is available through Micrometl.

4. Thread lifting bracket strapping around bottom perimeter of unit as %ltows:

a Open lever of tension buckle (ratchet type)

b. Feed strapping through tension buckle as shown in Fig 8

c Pull strapping through tension buckle unit taut.

d. Snap lever down to lock strap in tension buckle To release strapping, squeeze safety latch, lift lever, and pull webbing outward.

5. Tighten the tension buckle until it is taut Lifting brackets must be secure in the rigging holds.

d. Attach fieldosupplied clevis or hook of sufficient strength to hole in the lifting bracket (See Fig. 9).

ODS CATALOG NUMBER

CPRFCURB006A00

CPRFCURB007A00

CPRFCURB098A00

CPRFCURB009A00

Fig. 5--Roof Curb Dimensions

A

IN. (MN)

8 (203)

14 (356)

8 (203)

14 (356)

d

B

IN. {MM)

11(279)

11(279)

16 3/16 (411)

16 3/16 (411)

duct

\\\

C

IN. (MM)

161/2 (419)

161/2 (419)

17 3/8 (441)

17 3/8 (441)

S/A

/2

C00076

D

IN. (NM)

28-3/4 (730)

28-3/4 (730)

40-1/4 (1022)

40-1/4 (1022)

Page 7

2" I

±I

I- IIIII

I lllll

I lllll

I

L

Fig. 6--Unit Leveling Tolerances

EVAP.COIL

COND. COIL

Fig. 7--Slab Mounting Detail

C

MAXIMUM ALLOWABLE

DIFFERENCE (in)

A-B B-C A-C

1/4 1/4 1/4

C99065

C99096

HANDHOLD

/

/

/

HOOK _ ....

FEED m_I_

C99067

Fig. 8--Threading Belt

7 Attach the 2 safety straps directly to the clevis or hook at the 4 rigging brackets DO NOT attach the safety straps to the

lifting brackets (See Fig. 9)

g Position lifting point directly over the unit's center of gravity

9. Lift unit. When unit is directly over the roof curb, remove the 2 safety straps. Lower the equipment onto the roof curb.

PROCEDURE 5--SELECT AND BNSTALL DUCTWORK

The design and installation of the &/ct system must be in accordance with the standards of [l_e NFPA [br installation of non-residence type air

conditioning and ventilating systems, NFPA 90A or residence type, NFPA 90B and/or local codes and ordinances.

Select and size ductwork, supply=air registers, and remm air grilles according to ASHRAE (American Society of Heating, Refrigeration, and Air

Conditioning Engineers) recommendations.

The unit has duct flanges on the supply- and return-air openings on the side of the unit.

When designing and installing ¢lt/ctwork_ consider the following:

z_ WARNING: For vertical supply and return units, tools or parts could drop into ductwork and cause serious injury or

death. Install a 90 degree turn in the return ductwork between the unit and the conditioned space. If a 90 degree elbow cannot

be installed, then a grille of sufficient strength and density should be installed to prevent objects from falling into the

conditioned space. Units with electric heaters require 90 degree elbow in supply duct.

1. All units shonld have field=supplied filters or accessory filter rack installed in the return-air side of the unit. Recommended sizes %r filters

are sho_xn in Tables 1 and 2

2. A_oid abla/pt duct size increases and reductions. Abrupt change in duct size adversdy affects air performance.

7

Page 8

DETAIL A

SCALE 0250

TIGHTEN STRAPPING SECURBL:Y

WITH TENSION SUCKLE

INSTALL SAFETY STRAPS TO

RIGGING CLEVIS AT 4 RIGGING BRACKETS

/

SEE DETAIL A

UNiT A B

MAXIMUM WEIGHT

{INCLUDES SHIPPING SKID)

PLACE RIGGING BRACKET ASSEMBLY IN 4

RIGGING HOLES AND INSTALL TIE DOWN STRAP

AROUND PERIMETER OF UNIT AND THROUGH

SPACE IN BRACKET ASSEMBLY

C99075

Size Ib kg in. mm. in. mm.

PH1P018 305 138.4 19.5 495.3 16.75 425.5

PH1P024 311 141.1 18.5 469.9 16.75 425.5

PH1P030 309 140.2 19.5 495.3 17.50 444.5

PH1P036 313 142.0 19.5 495.3 17.75 459.9

PH1P042 345 156.4 19.5 495.3 17.75 450.9

PH1 P048 375 170.1 20.5 520.7 20.62 523.8

PH1P0$0 440 199.6 19.5 495.3 19.75 501.7

PH2P024 321 145.6 19.0 482.6 18.25 463.6

PH2P030 342 155.2 20.0 508 19.25 489

PH2P036 350 158.8 20.0 508 19.0 482.6

PH2P042 372 168.8 21.0 533.4 20.5 520.7

PN2P048 377 171.0 20.0 508 21.25 539.8

PN2P0g0 450 204.2 21.0 533.4 20.0 508.0

Fig. 9--Suggested Rigging

mNPORTANT: /se flexible connectors between ductwork and m_it to prevent tlansmission of vibration./se s_/itable gaskets to ensure weather

tight and airtight seal When electric heat is installe& use fireproof canvas (or similar heat resistant material) connector between ductwork and unit

discharge connection. If flexible duct is used, insert a sheet metal sleeve inside duct. Heat resistant duct connector (or sheet metal sleeve) must

extend 24-in. from electric heater element.

3. Size ductwork for cooling air quantity (cfm). The minimum air quantity' %r proper electric heater operation is listed in Tables 3 and 4. Heater

limit switches may trip at air quantities below those recommended.

4. Seal, insulate, and weatherproof all external ductworlc Seal, insulate and cover with a vapor barrier all ductwork passing through

conditioned spaces. Follow latest Sheet Metal and Air Conditioning Contractors National Association (SMACNA) and Air ( onditioning

Contractors Association (AC(A) minimum installation standards for residential heating and air conditioning systems.

5. Secure all ducts to building stlucmre. Flash, weatherproo£ and vibration-isolate duct openings in wall or roof according to good construction

practices.

A, CONVERTING HORIZONTAL DISCHARGE UNITS TO DOWNFLOW (VERTICAL) DISCHARGE UNITS

Z_ WARNING: Before performing service or maintenance operations on system, turn off main power to unit and install

lockout tag. Turn off accessory heater power switch if applicable. Electrical shock could cause serious injury or death.

1. Open all electrical disconnects and install lockout tag be%re starting any service work.

2. Remove side duct covers to access bottom return and supply knock outs.

NOTE: These panels are held in place with tabs similar to an electrical knockont.

3. Use a screw&iver and hammer to remove the panels in the bottom of the composite unit base

4. Ensure the side duct covers are in place to block off the horizontal air openings.

8

Page 9

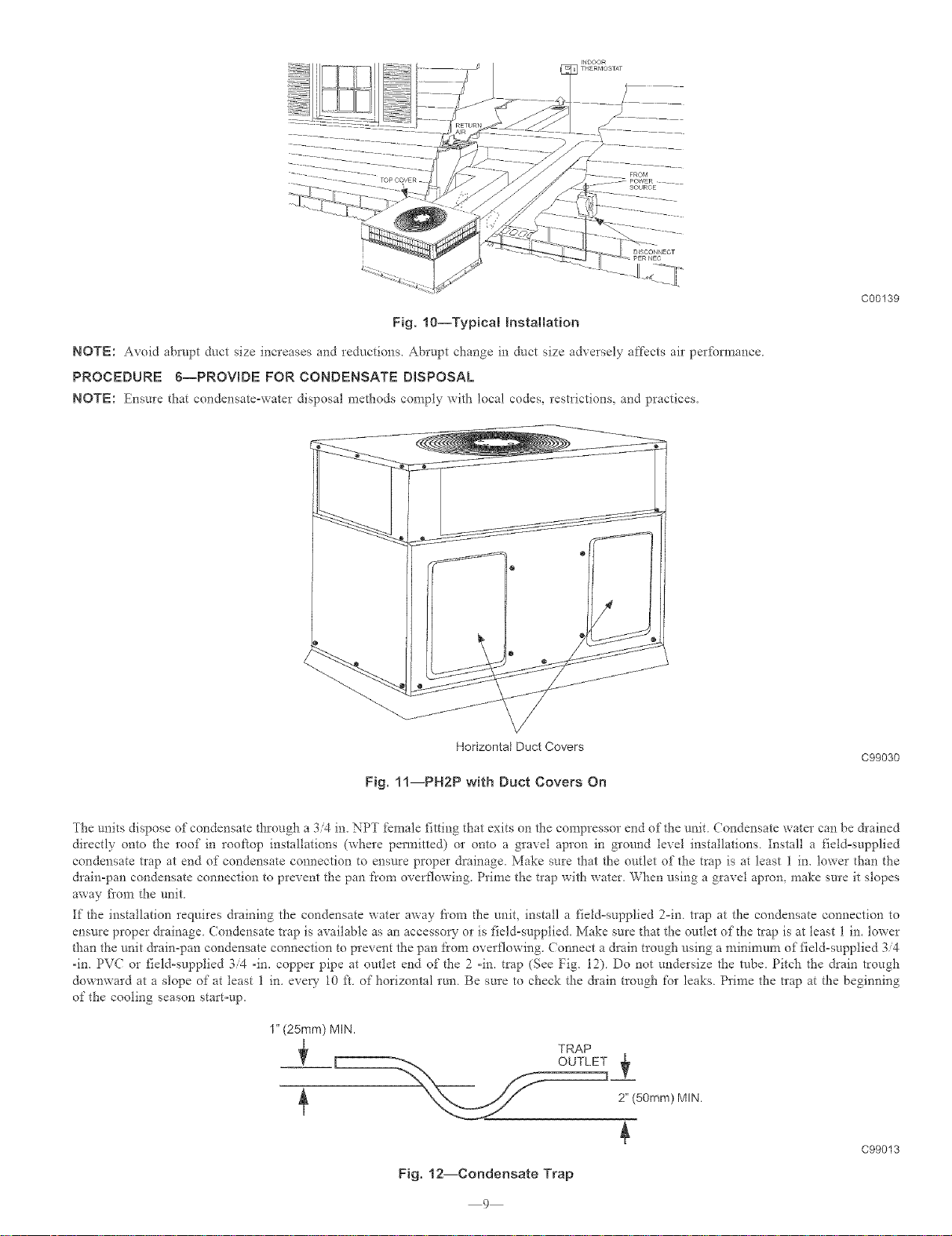

Fig.10--TypicalInstallation

NOTE:Avoidab_/ptductsizeincreasesandreductions,Abruptchangeinductsizeadveiselya_:_ctsairper%m_ance

PROCEDURE6--PROVBDEFORCONDENSATEDISPOSAL

NOTE:Ensurethatcondensate-waterdisposallllethodscomplywithlocalcodes,restrictions,andpractices.

C00139

Horizontal Duct Covers

C99030

Fig, 11--PH2P with Duct Covers On

The units dispose of condensate through a 3/4 in. NPT female fitting that exits on the compressor end of the unit Condensate water can be &ained

directly onto the roof in toot'top installations (where permitted) or onto a gravel apron in ground level installations. Install a field=supplied

condensate trap at end of condensate connection to ensure proper drainage. Make sure that the outlet of the trap is at least 1 in. lower than the

&ain-pan condensate connection to prevent the pan l:i'om overflowing. Prime the a'ap with water. When using a gravel apron, make sure it slopes

away fi'om the unit.

If the installation requires draining the condensate water away fi'om the unit. install a field=supplied 2=in. tIap at the condensate connection to

ensure proper drainage. (ondensate trap is available as an accessoE¢ or is field-supplied. Make sure that the outlet of the trap is at least 1 in. lower

than the unit &ain-pan condensate connection to prevent the pan t'rom overflowing. Connect a drain trough using a mininmna of field=supplied 3/4

-in. PVC or field-supplied 3/4 -in. copper pipe at outlet end of the 2 =in. trap (See Fig. 12). Do not undersize the robe. Pitch the drain trough

downward at a slope of at least 1 in. ever}' 10 it. of horizontal run. Be sure to check the &ain trough for leaks. Prime the tIap at the beginning

of the cooling season start-up.

1" (25ram) MIN.

TRAP

2" (50ram) MIN.

C99013

Fig. 12--Condensate Trap

9

Page 10

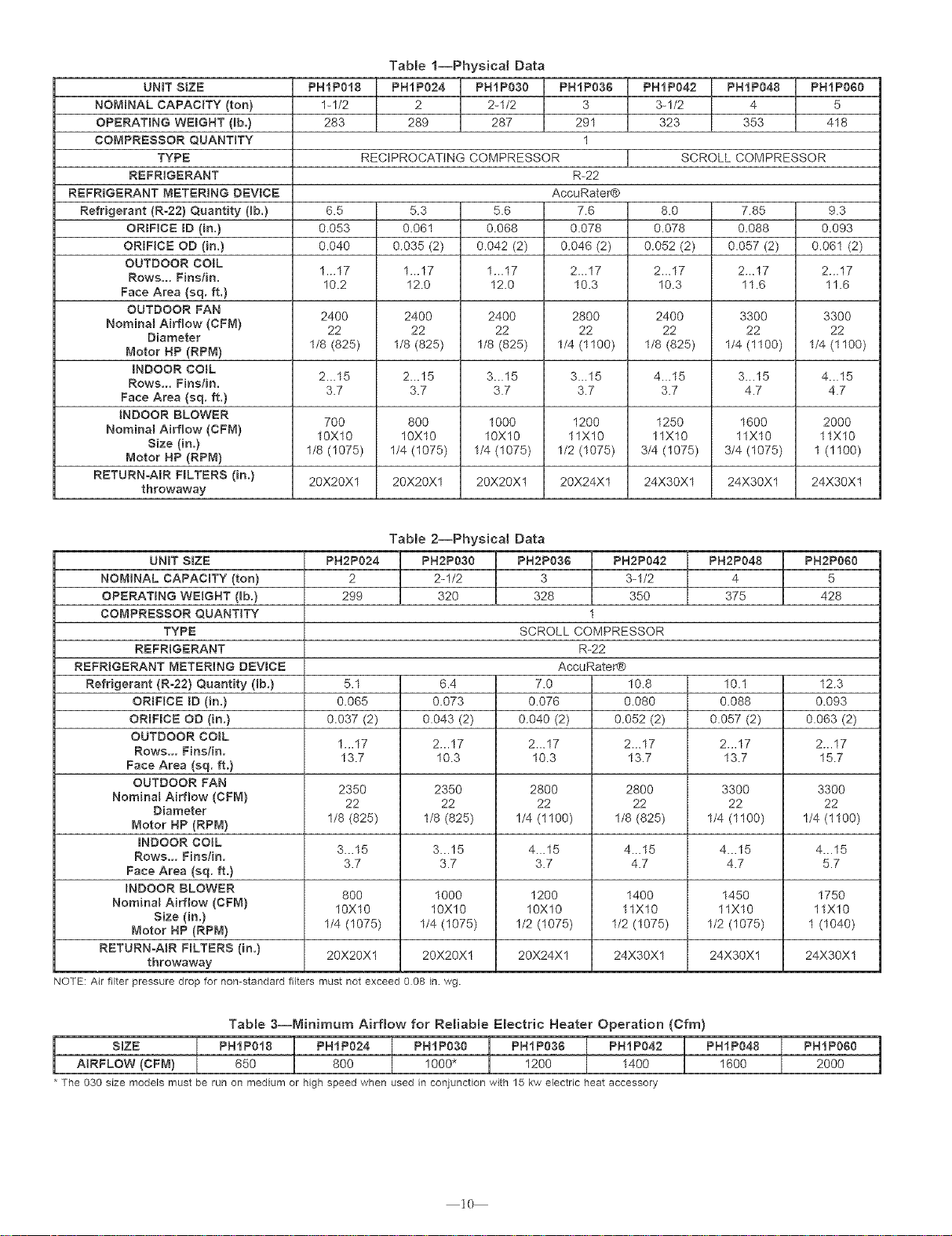

Table l--Physical Data

UNIT SIZE PH1PO18 PH1PO24 PH1PO3O PH1P036 PH1PO42 PN1PO48 PH1POG0

NOMINAL CAPACITY (ton) 1-1/2 2 2-1/2 3 3-1/2 4 5

OPERATBNG WEBGBT (_b.) 283 289 287 291 323 353 418

COMPRESSOR QUANTITY 1

TYPE RECIPROCATING COMPRESSOR SCROLL COMPRESSOR

REFRIGERANT R-22

REFRIGERANT METERING DEVICE AccuRater@

Refrigerant {R-22) Quantity (_b.) 6.5 5.3 5.6 7.6 8.0 7.85 9.3

ORIFICE ID (in.) 0.053 0.061 0.068 0.078 0.078 0.088 0.093

ORBFIOE OD (in.) 0.040 0.035 (2) 0.042 (2) 0.046 (2) 0.052 (2) 0.057 (2) 0.061 (2)

OUTDOOR COBL

Rows... Fins/in.

Face Area (sq. ft.)

OUTDOOR FAN

Nomina_ Airflow (CFM) 22 22 22 22 22 22 22

Diameter

Motor HP (RPM)

INDOOR COiL

Rows... Fins/in.

Face Area (sq. ft.)

iNDOOR BLOWER

Nomina_ Airflow (CFM) 10X10 10X10 10X10 11X10 11X10 11X1O 11X10

Size (in.) 1/8 (1075) 1/4 (1075) 1/4 (1075) 1/2 (1075) 3/4 (t075) 3/4 (I075) 1 (1100)

Motor NP (RPM)

RETURN-AIR FBLTERS (in.) 20X20Xl 20X20X1 20X20X1 20X24X1 24X30X1 24X30Xt 24X30X1

throwaway

1...17 1...17 1...17 2._17 2._17 2._17 2._17

10.2 12.0 12.0 10.3 10.3 11.6 11.6

2400 2400 2400 2800 2400 3300 3300

1/8 (825) 1/8 (825) 1/8 (825) 1/4 (1100) 1/8 (825) 1/4 (I100) 1/4 (1100)

2._15 2._15 3...15 3._15 4...15 3...15 4...15

3.7 3.7 3.7 3.7 3.7 4.7 4.7

700 800 1000 1200 1250 1600 2000

Tabme 2--Physical Data

UNiT SIZE PN2P024 PN2P030 PH2P036 PH2P042 PN2P648 PN2P660

NOMINAL CAPACBTY (ton) 2 2-1/2 3 3-1/2 4 5

OPERATING WEIGHT (_b.) 299 320 328 350 375 428

COMPRESSOR QUANTITY

TYPE SCROLL COMPRESSOR

REFRIGERANT R-22

REFRIGERANT METERING DEVBCE AccuRater®

Refrigerant {R-22} Quantity (lb.) 5.1 6.4 7.0 10.8 10.1 12.3

ORBFICE ID (in,) 0.065 0.073 0.076 0.080 0.088 0.093

ORBFICE OD (in.) 0.037 (2) 0.043 (2) 0.040 (2) 0.052 (2) 0.057 (2) 0.063 (2)

OUTDOOR COIL

Rows... Fins/in.

Face Area (sq. ft.)

OUTDOOR FAN

Nominal Airflow (CFM) 22 22 22 22 22 22

Diameter

Motor BP (RPM}

INDOOR CO_L

Rows... Finstin.

Face Area (sq. ft.)

iNDOOR BLOWER

Nominal Airflow (CFM) 1OX1O 1OX1O 10XI0 11X10 11X1O 11X1O

Size (in.)

Motor HP (RPM) 1/4 (1075) 1/4 (1075) 1/2 (1075) 1/2 (1075) 1/2 (1075) 1 (1040)

RETURN-AIR FILTERS (in.) 20X2OX1 20X2OX1 20X24X1 24X30X1 24X30X1 24X30X1

throwaway

NOTE: Air filter pressure drop for non-standard filters must not exceed 008 in wg.

1._17 2...17 2._17 2._17 2._17 2...17

13.7 10.3 10.3 13.7 13.7 15.7

2350 2350 2800 2800 3300 3300

1/8 (825) 1/8 (825) 1/4 (1100) 1/8 (825) 1/4 (1100) 1/4 (1100)

3...15 3...15 4...15 4._15 4...15 4...15

3.7 3.7 3.7 4.7 4.7 5.7

800 1600 1200 1400 1450 1750

Table 3--Minimum Airflow for Reliable Electric Heater Operation (Cfm)

AIRFLOW(CFM)I 660 600 1000" 1206 I 1400 I 1600 I 20OO

The 030 size models must be run on medium or high speed when used in conjunctionwith 15 kw electric heat accessory

]0

Page 11

Table 4--Minimum Airflow for Reliable Electric Heater Operation (Cfm)

sBzE l P.2Po24 P.2PoaoI P.2Poa6n PH2P042n P.2PO48U P.2PO6O

[ AI*FLOW(CFM) n S00 1000" I 1200 U 1400 1600 [ 200O

* The 030 size models must be run on medium or high speed when used in conjunction with 15 kw electric heat accessory

PROCEDURE 7--BNSTALL ELECTRICAL CONNECTIONS

Z_ WARMNG: The unit cabinet must have an uninterrupted, unbroken electrical ground to minimize the possibility of

personal injury if an electrical faumtshould occur. This ground may consist of an electrical wire connected to the unit ground

lug in the controJ compartment, or conduit approved for electrical ground when instalmed in accordance with NEC, ANS[/NFPA

American National Standards Institute/National Fire Protection Association {latest edition) (in Canada, Canadian Electrical

Code CSA C22.1) and local electrical codes. Failure to adhere to this warning could result in serious injury or death.

Z_ CAUTION: Failure to follow these precautions could resuR in damage to the unit being installed:

1. Make aH electrical connections in accordance with NEC ANSI/NFPA (latest edition) and local electricam codes governing

such wiring. In Canada, aH electricam connections must be in accordance with CSA standard C22.1 Canadian Electrical

Code Part 1 and applicable Bocal codes. Refer to unit wiring diagram.

2. Use only copper conductor for connections between field-supplied electrica! disconnect switch and unit. DO NOT USE ALUMINUM

WIRE.

3, Be sure that high-voltage power to unit is within operating voltage range indicated on unit rating plate. On 3°phase units, ensure

phases are balanced within 2 percent. Consult local power company for correction of improper voltage and/or phase imbalance.

4, Insulate low-voltage wires for highest voltage contained within conduit when low-voltage control wires are in same conduit as

high-voltage wires.

5, Do not damage internal components when drilling through any panel to mount electrical hardware, conduit, etc,

A. HGH-VOLTAGE CONNECTIONS

The unit must have a separate electrical service with a _ield-supplied., waterproof disconnect switch mounted at, oi"within sight flora the uniL Refer

to the unit rating plate, NEC and local codes for maximum f_/seicircuit breaker size and minimum circuit amps (ampacity) for wire sizing (See

Tables 5 and 6 for electrical data).

The field-supplied disconnect may be mounted on the unit over the high-voltage inlet hole (See Fig 2 and 3).

If the unit has an electric heater, a second disconnect may be required. Consult the Installation, Start=Up, and Service Instructions provided with

the accessory fbr electrical service connections.

Operation of unit on improper line voltage constitutes abuse and may cause unit damage that could aft'oct wa_Tanty.

B. ROUTING POWER LEADS BNTO UNBT

Use only copper wire between disconnect and unit. The high=voltage leads should be in a conduit until they enter the duct panel; conduit

termination at the duct panel must be watertight. Run the high-voltage leads through the power entry knockout on the power entry side panel See

Fig. 2 and 3 t'or location and size. When the toads are inside the unit, run leads up the high-voltage raceway to d_e tine wiring splice box (See Fig

13 19) For single-phase units, connect leads to the black and yellow wires; for 3=phase units, connect the leads to the black, yellow, and blue wires

(See Fig 18)

©

©

©

L_

Li

L_

©___

1__

THERMOSTAT

AND SUBBASE

Fig. 17--Control Connections

C. CONNECTING GROUND LEAD TO GROUND LUG

Connect the ground lead to the chassis using the ground tug in the wiring splice box (See Fig. 18)

D. ROUTING CONTROL POWER W_RES {24-V)

Form a dripqoop with the thermostat leads before routing them into the unit Route [he thermostat leads through grommeted, tow-voltage hole

provided in unit into unit control power splice box (See Fig. 2 and 3) ( onnect thermostat leads to unit control power tends as shown in Fig 17

UNIT CONTROL POWER

SPLICE BOX

C99056

11

Page 12

UNIT PH1P

SIZE

018

O24

O3O

036

O42

048

060

Table 5--Electrical Data--PHIP

VOLTAGE

V-PN-HZ

RANGE

MIN MAX

208/230-1-60

208/230-1-60

208/230-1-60

208/230-3-60 187 253 99 78 0.9 2.0

208/230-1-60

208/230-3-60

460-3-60

208/230-1-60

2081230-3-60

460-3-60

208/230-1-60

2081230-3-60

460-3-60

208/230-1-60

208/230-3-60

460-3-60

187 253

187 253

187 253

187 253

187 253

414 506

187 253

187 253

414 506

187 253

187 253

414 506

187 253

187 253

414 506

COMPRESSOR ELECTRIC NEAT

RLA LRA

90 48

128 61

147 82

168 82

99 85

55 40

206 115

124 90

67 45

244 140

141 105

71 53

288 165

194 125

80 63

OFM IFM

FLA FLA Nominal

0.9 1.8

0.9 2.0

0.9 2.0 5.4/72

1.5 4.1 5.4/72

1.5 4.1

0.8 19

0.9 38

0.9 3.8 75/10.0

0.8 18 10

1.5 35

1.5 35 75/10.0

0.8 18 10

1.5 62

1.5 62 75/10.0

0.8 3.2 10

Kw*

3.8/50

5.4/72

75/10.0

4-

3.8/50

5.4/72

75/10.0

4-

3.8/50

75/10.0

11.3/15.0

4-

3.8/50

75/10.0

11.3/15.0

4-

3.8/50

75/10.0

11.3/15.0

4-

3.8/50

75/10.0

11.3/15.0

5

10

15

3.8/50

5.4/72

75/10.0

11.3/15.0

15.0/20.0

4-

3.8/50

11.3/15.0

15.0/19.9

5

15

20.0

4-

3.8/50

5.4/72

75/10.0

11.3/15.0

15.0/19.9

4-

3.8/50

11.3/15.0

15.0/20.0

5

15

2O

3.8/50

5.4/72

75/10.0

11.3/15.0

15.0/20.0

4-

3.8/50

11.3/15.0

15.0/19.9

5

15

2O

FLA

-/-

181/208

260/300

361/417

4-

181/208

260/300

361/417

4-

181/208

260/300

361/417

542/625

4-

104/12 0

208/241

313/361

4-

181/208

260/300

361/417

542/625

-p

104/120

31 3/361

361/417

-p

6.0

120

180

4-

181/208

260/300

361/417

542/625

722/833

-p

104/120

208/241

31 3/361

41 6/480

-p

6.0

120

180

241

4-

181/208

260/300

361/417

542/625

722/833

-p

104/120

208/241

313/361

41 6/480

6.0

120

180

241

4-

181/208

260/300

361/417

542/625

722/833

4-

104/120

208/241

31 3/361

41 6/480

6.0

120

180

241

SINGLE POINT POWER SUPPLY

MCA

FUSE OR

CKT BKR

14.0/140 20/20

36.5/400 40/45

46.4/51 5 50/60

59.1/660

18.9/189 25/25

41.5/449 45/45

51.4/564 60/-

64.0/71 0

21.3/21 3 25/25

43.8/473 45/50

53.8/588

66.4/734

89.0/994

15.3/153 20/20

28.3/303 30/35

41.3/453 45/50

54.4/604 60/-

26.6/266

49.2/526

59.1/641

35/35

50/60

71.7/787

94.3/1047

18.0/180 25/25

31.0/330 35/35

44.0/480 45/50

57.1/631 60/-

9.6 15

17.1 20

24.6 26

32.1 35

30.5/305 40/40

53.0/565 60/60

62.9/680

75.6/825

98.1/1086

120.7/134.6

20.2/202 26/25

33.2/352 40/40

46.3/503 50/60

59.3/653 60/-

72.2/802

11.0 15

18.5 20

26.0 30

33.5 35

41.0 45

35.5/355 45/45

58.1/615

68.0/730

80.6/876

103.2/113.6

125.8/139.7

22.6/226 30/30

35.7/377 40/40

48.7/527 50/60

61.7/677

74.6/826

11.5 15

19.0 20

26.5 30

34.0 35

41.5 45

43.7/437 60/60

66.3/697

76.2/81 2

88.8/958

111.4/121.8

134.0/147.9

32.0/320 40/40

45.0/470 50/50

58.0/62 1

71.1/771

83.9/91 9

14.0 20

21.5 25

29.0 30

36.6 40

44.1 45

MOCP

60/70

-/70

70/80

70/70

70/80

90/100

-/70

70/80

80/80

100/110

-/70

80/90

80/90

100/110

125/150

-/70

80/90

70/70

90/90

90/100

110/125

150/150

70/70

80/90

70/80

100/110

100/110

125/125

150/150

60/70

80/80

90/100

The unit trans%rmer supplies 24-v pox_er %r complete system including accesso_ electrical heater An mltomaticoreset circuit breaker (See Fig

19) is provided in the 24-x circuit; see the caution label on the transformer or Fig. 20. Transformer is factory wired for _30o_ operation, If supply

0}

xoltage is 208=v, rewire trausfi_rmer primaw as described in Special Procedures for 208-v Operatiou section,

12

Page 13

UNIT PH2P

S_ZE

024

03O

036

042

048

06O

WPH=HZ

208/230-1-60

208/230-1-60

208/230-3-60

208/230-1-60

208/230-3-60

460-3-60

208/230-1-60

208/230-3-60

460-3-60

208/230-1-60

208/230-3-60

460-3-60

208/230-1-60

208/230-3-60

460-3-60

VOLTAGE

RANGE

MIN MAX

187 253

187 253

187 253

187 253

187 253

414 506

187 253

187 253

414 506

187 253

187 253

414 506

187 253

187 253

414 506

TaMe 6--Electrical Data--PH2P

COMPRESSOR ELECTRIC HEAT

RLA LRA

10.8 56

14.0 73 0.9

10.4 63 0.9

16.7 97 1.6

11.2 75 1.6

54 375 0.9

18.4 104 0.9

12.4 88 0.9

58 44 0.9

23.4 126 1.6

13.0 93 1.6

64 465 0.9

28.8 169 1.4

17.3 123 1.4

90 62 0.9

OFM

FLA

090

_FM

FLA

Nominal Kw _ FLA

4- 4-

20

3.8/50 181/208

5.4/72 260/300

7.5/10.0 361/417

4- 4-

21 5.4/72 260/300

3.8/50 181/208

7.5/10.0 361/417

11.3/15.0 542/625

4- 4-

21

3.8/50 104/120

7.5/10.0 208/241

11.3/15.0 313/361

4- 4-

3.8/50 181/208

36 5.4/72 260/300

7.5/10.0 361/417

11.3/15.0 542/625

4- 4-

36

19

3.8/50 104/120

7.5/10.0 361/417

11.3/15.0 313/361

-E 4-

5 6

10 12

15 18

4- 4-

3.8/50 181/208

41

5.4/72 260/300

7.5/10.0 361/417

11.3/15.0 542/625

15.0/20.0 722/833

4- 4-

3.8/50 104/120

41 7.5/10.0 208/241

11.3/15.0 313/361

15.0/20.0 416/480

-/- 4-

5 6

20 10 12

15 18

20 241

4- -/-

3.8/50 181/208

41

5.4/72 260/300

7.5/10.0 361/417

11.3/15.0 542/625

15.0/20.0 722/830

4- 4-

3.8/50 104/120

41 7.5/10.0 208/241

11.3/15.0 313/361

15.0/20.0 416/480

-/- 4-

5 6

20 10 12

15 18

20 241

4- 4-

3.8/50 181/208

62

5.4/72 260/300

7.5/10.0 361/417

11.3/15.0 542/625

15.0/20.0 722/833

4- 4-

3.8/50 104/120

62 7.5/10.0 208/241

11.3/15.0 313/361

15.0/19.9 416/480

-E 4-

5 6

32 10 12

15 18

20 241

SINGLE POINT POWER SUPPLY

MCA

164/164

390/424

489/539

61 5/685

205/205

431/465

530/580

656/726

882/986

160/160

290/31 0

421/461

551/61 1

261/261

486/521

586/636

71 2/782

938/104.2

192/192

322/342

452/493

583/643

96

171

246

321

280/280

506/540

605/655

731/801

957/106.1

1183/132.2

205/205

335/355

466/506

596/656

725/805

102

177

252

327

402

349/349

574/609

673/724

800/869

1025/113.0

1251/139.0

21 9/21 9

349/369

479/51 9

609/670

738/81 8

108

183

258

333

408

436/436

662/696

761/181.1

887/957

111 3/121.7

1339/147.8

292/292

423/443

552/594

683/743

81 2/892

154

229

304

379

454

FUSE OR

CKT BKR

20/20

40/45

60/60

25/25

45/50

20/20

35/35

45/50

35/35

50/60

35/35

50/50

15

2O

25

35

35/35

60/60

25/25

40/40

50/60

15

20

30

35

45

45/45

30/30

40/40

50/60

15

20

3O

35

45

60/60

35/35

50/50

60/60

20

25

35

40

50

MOCP

70/70

70/70

70/80

90/100

60/70

70/80

80/80

100/110

60/70

80/80

80/90

100/110

125/150

60/70

80/90

70/70

90/90

90/90

110/125

150/150

70/70

80/90

70/80

100/110

100/100

125/125

150/150

70/80

90/90

E. SPECIAL PROCEDURES FOR 208-V OPERATION

1 Disconnect the yellow primary lead from the transformer. See unit wiring label (See Fig 13 and 14).

2 Connect the yellow prima W lead to the trans_brmer terminal labeled 200°v,

Indoor blower-motor speeds may need to be changed for 208-v operation, Re_r to indoor airflow and airflow adjustments section,

13

Page 14

MAXIMUM WIRE I _ WlBLK

SIZE 2 AWG _ SUPPLY

USED WITH POWER

ACCESSORY EQUIP GND

NAXWIRE i YEL_

(30 AMP FOR S KW)_

USED WITH _BLKJ

ACCESSORY

ELECTHEAT I _W

OPTION ONLY I I GO AMP SB HTR:

USED WITH I _ELECT_ YLL

HEATER OPTIONS 60 AMP SB

5NW {048060) F

IOHW (DIS 060> I __BIK

210 MAXWIRE SO AMP SB

210 MANIWlRE

i II_I L WR YEL

I I BO AMP SB MIR

(FUI & FU4)_----

FIELD

BLK_

,

_MTPl

GO AMP SB

30 AMP SIB. HTR

_TO ,

30 AMP SB Hi_.

60 AMP SB HTRI

50 AMP S IB I

_TO I

_YEL TRANI

HEAT!%{ WOORN_

ZBT SEE NOTE

LW D RED

O"G L

FAN

AUTO sw

?N

"_N THI 0

/-

I

SUPPL SUPL HEAT E

SUPPL HEAT

FIELD THERMOSTAT

SEE NOTEA2

I f

24V SPLICE BOX

UNIT COMPONENT ARRANGEMENT

SECTION

OUTDOOR FAN

COMPRESSOR INDOOR FAN

SECTION SECTION

:ONNECTION

:OR i []

£LECT HEAT i

r_ _....U

SEE HEATER

FORWIRING

R

50JS048 & 060

SCHEMATIC _

_ _-_ECTI

_%SPL,C_

F7 SCHEMATIC

_ .C,--/ _ IDR _BLK _ 208/230-1-60

_ __,__w_ OLN_OLN _X

[_ __W4 YEL _¢Ap21cAp2 YBERLN_ )OFM

: i

i CCH {50JS036 ONLY) LwY YEL COMP

t BLK _ _W9 BLU_

/___TD_ RED o _&_To_LV)NED SPEED FOR

1"' ,ELo :E:T SmF

_W70 °LK

3.2 AMP

WIlD YEL_

MANUAL RE

DEFROST BOARD <DB)

W6 PNN

W72 WHT

W69 VIO

Wl2O GRA

W21BRN

WIIG BRN

DEFROS'_

BOARD

z_,P.

/

--24V POWER ENTRY

Fig, 13--Wiring Schematics (208/230o%60)

PL I

LEGEND

FIELD SPLICE AHA ADJU$TABLEHEAT ANTICIPATOR

O TERMINAL [MARKED3 C CONTACTOR

o TERMINAL (UNMARKEDI CAP CAPACITOR

• SPLICE CB CIRCUIT BREAKER

OISPLICE {MARKED3 CCH CRANKCASEHEATER

FACTORYWIRING ¢TD COMPRESSORTIME DELAY

FIELD CONTROLWIRING DB DEFROSTBOARD

i. FIELDPO_ER WIRING OFT DEFROSTTHERMOSTAT

=ii ACCESSORYOR OPTIONAL DR DEFROSTRELAY

WIRING EOUlP EOUlPMENT

I TO INDICATECOMMON GND GROUND

POTENTIALONLY: HR HEATERRELAY

NOT TO REPRESENTWIRING HTR HEATER

NOTE_

I_ IF ANY OF THEORIGINALWIRESFURNISHEDARE REPLACED,

IT _U_T BE REPLACED_ITH TYPE_0 DE_REEC _IRE OR

IT'SEQUlVALENT_

_ SEE PRICEPAGESFORTHERMOSTATAND SUBBASES_

USE7S DEGREECOPPERCONDUCTORSFORFIEL_ INST_LLATION

4_ FOR HIGH _PEEDIF_,DlSCONNECTRED

*IREFRO_ T_R _ ANDCONNECT_LK_IREFBOM IF_

FOR _EDIUMSPEED,DISCONNECTRE__IRE

FRO_TDR _ ANDCONNECTBLU_IRE FRO_IFM_

S_ _EFROSTTIMERTO BESET AT _0MINUTESEXCEPT

FOR 50JSO4aA_ MODELSSETAT _0 MINUTES_

COMP COMPRESSORMOTOR

FU FUSE

IFM INDOORFAN MOTOR

LPS LOWPRESSURESWITCH

OFM OUTDOOR FAN MOTOR

QT QUADRUPLETERMINAL

RV_ REVERSINGVALVE SOLENOID

$B, SLOWBLOW FU_E

TC THERMOSTATCOOLING

TDR TIMEDELAY RELAY

TH THERMOSTATHEATING

TRAM TRANSFORMER

cAPSoR;2

GRN YEL_

GRN YEL

PNK_ PNK_

LPS

BLU_ BLU_jI023 BRNBRN

°LK_W23 BRN

ACCESSSORY ELECTRIC HEAT_

[5 NW) Wl23 °RN

HR, EY hrY

HRI & 2 (10 KW)__22 BRN

I

HRI,2 & 3 (15 KW}_ I 121 °RN

HRI,2,3 & 4 (20 KW)

_Wl23 BRN

TDR(I 3) FAN SEQUENCE

i _T',O

ENERGIZED DE ENERGIZED

CTD (TI,T2) COMPRESSOR DELAY

I , i i MIIN.

o 5 SECT T+5

CI CI

CLOSES OPENS

TSAT

CYCLE T:90

15oJ85OOOO516.c

Wll BRN

W12 BRN

W12 BRN

116 BRN

I

C

00133

14

Page 15

MAXIMUMWIRE m _Wl BLK

S'ZE2AW°__ W2YEL

SCHEMATIC

208/230-3-60

OFM

ACCESSORY

ELECT HEAT m _ _ '

OPTION ONLY L BLK R

USED WITH I_ _TO HT

5 & IOKW (0_ I

060)

MAXWlRE

2 AWG I

(50 AMP FOR K I

HEATER OPTIC I

USED WITH I

ACCESSORY

ELECTHEAT

OPTION ONLY

USED WITH I

HEATER OPTIC

16 K W (024 060)

19.9 NW {042 060)

2/0 MAXWIRE i

I%EOUIP GND Wl2111BLUUSED WITH .....

{FL 3 &

(20 KW SHOWN)

32 AMP CB

MANUAL RESET_[_.._,._,.._W60RN_

1

R oN ( I

ON ON (

"_N THI

FAF

/

LW 3 RED

GRM

TRANI

YEL_

RED

YEL

ORN YEL_W26 GRN YEL_

W26

/

COMP

GRN YEL GRN YEL

=

Wll BRN

SUPPL@_ _$UPL.HEAT _ _

SUPPL HEAT

FIELD THERMOSTAT

SEE NOTE#2

UNIT COMPONENT ARRANGEMENT

SECTION

OUTDOOR FAN {OFM_

COMPRESSOR INDOOR FAN

SECTION SECTION

Fq

rl T2 50JSO4B & 060

r3 /

[SOJSO36,50JX060 ONLY]

I

50JXC42 060

W120 BRN

24V SPLICE BOX

CONNECT ION

FORELECT HEAT

D

DEFROST

BOARD

"_'_F ____.____

PLI I

ACCESSORY ELECTRIC HEAT_

HRI,2 & 3 (15 KW)

BRN

HRI 2 3 & 4 (20 KW)_

LEGEND

_FIELD SPLICE _HA ADJUSTABLE HEAT ANTICIPATOR

C3TERMINAL (MARKED) CONTACTOR

o TERMINAL CUNMARKED3 CAP CAPACITOR

• SPLICE CCH CRANKCASE HEATER

@SPLICE [MARKED) COMP COMPRESSOR MOTOR

FACTORY WIRING CTP COMPRESSOR TIME DELAY

FIELD CONTROL WIRING DB DEFROST BOARD

ii FIELD POWER WIRING DFT DEFROST THERMOSTAT

111 ACCESSORY OR OPTIONAL DR DEFROST RELAY

WIRING EQUIP EQUIPMENT

I TO INDICATE COMMON GN_ GROUND

POTENTIAL ONLY: HR HEATER RELAY

NOT TO REPRESENT WIRING HTR HEATER

"EQUIP

GND

/

1

DISCONNECT I IF ANY OF THE ORIGINAL WIRES FURNISHED ARE REPLACED,

PER NEC7 IT MUST BE REPLACED WITH TYPE _0 DEGREE C _IRE OR

-- _ IT'S EOUIVALENT

--24V POWER ENTRY 3 U_E 75 DEGREE COPPER CONDUCTOR_ FOR FIELD INSTALLATION.

NOTES:

2 SEE PRICE PAGES FOR THERMOSTAT AND SUBBASES

4 FOR HIGH _PEED IFM,#I_CONNEGT RED

WIRE FBOM TDR 3 AND CONNECT BLK WIRE FROM IF_

FOR _EDIUM SPEED,_ISCONNECT RED _IRE

FROMTDR 3 AND CONNECT BLU _IRE FRO_ IFM

DEFROSTTI_ER TO BE _ET AT _O _INUTE_ EXCEPT

FOR 50J_04_,060 _ODELS SET AT 5D MINUTES

Fig. i4--WiMng Schematics (208/230o3o_0)

CB CIRCUIT BREAKER

FU FUSE

IFM INDOOR FAN MOTOR

LP3 LOW PRESSURE SWITCH

OFM OUTDOOR FAN MOTOR

QT QUADRUPLE TERMINAL

RW REVERSING VALVE _OLENOID

SLOW BLOW FUSE

_dB"

THERMOSTAT COOLING

TBR TIME DELAY RELAY

TH THERMOSTAT HEATING

TRAN THANSPORMER

_ W12 BRN

HH,

HRI & 2 {10 K__ N

,,

I

TDR (I13) FAN SEQUENCE

ENERGIZED DE ENERGIZED

CTD (TI,TZ) COMPRESSOR DELAY

LAST DFROST TzSO MAXIMUM

iT'00

l'_SEC_ T4M',N

CI CI

CLOSES OPENS

TSAT

ERGIZEm I

Rv_J _ T:30 _+I0 MIN

CYCLE T:90

I

C00134

15

Page 16

_Wl RLK

_M_MA%G!E -- iIIF_POWERw2 YE'L

___i w2 0LUl

EQUIP GND

OT .... ! !

ACCESSORY I I_BLK-- J

ELECT HEAT TO HTH

OPTION ONLY I IIHI_

USED WITH I --_YEL

HEATER OPTIONS L TO HTR

5, lO,I5 & 20 KW !_ p

MAXIWlREAwG I _LL BLU L< TO HTR

RED

YEL

OFR

SCHEMATIC

R ON

L V

SUPPLIHEAT

FIELD THERMOSTAT

SEE NOTE@2

UNIT COMPONENT ARRANGEMENT

SECTION

OUTDOOR FAN

COMPRESSOR INDOORFAN

SECTION SECTION

r_

COMP

T3_.2..__ F

TI T2 S 50JXD42 06O

_50JSO36,50JX060 ONLY)

50J5048 & 06O

W124 BRN

24V SPLICE BOX

ZLECTNEAT

_EQUIP TC THEBMOSTATCOOLIN6

SEE HEATER

SCHEMATIC I

FORWIRING

...... PER NEC___ IT MUSTBEREPLACED_ITH TYPE9DDEGREEC WIREOR

24V SPLICE --24V POWERENTRY USE_SDEGREECOPPERCONDUCTORSFORFIELD INSTALLATION¸

DISCONNECT NOTES:I IF ANYOFTHEORIGINALWIRESFURNISHEDAREREPLACED,

-- • SEEPRICEPAGESFORTHERMOSTATANDSUBBASES

Fig. i5--Wiring Schematics (460o3o60)

--W25 ORN YEL_W26 GRN YEL_

ORN YEL GRN YEL

ACCESSORY ELECTRIC

HRI & 2 {10 KW) BRN

NR2SSNW w LNR N

HRI,2,3 & 4 (20 KW)_

LEGEND

FIELD SPLICE

C>TERMINAL CMARKED3

o TERMINAL (UNMARKED3

• SPLICE

(31SPLICE (MARKED)

FACTORY WIRING

FIELD CONTROL WIRING

1- FIELD POWER WIRING

1.. ACCESSORy OR OPTIONAL

WIRING

I TO INDICATE COMMON

POTENTIAL ONLY:

NOT TO REPRESENT WIRING

GND TDR TIME DELAYRELAY

4 FORNIGHSPEEDIFM,DlSCONNECTRED

WIREFROMTDR3 ANDCONNECTBLKWIREFROMIFM

FORMEBlUMSPEED,DISCONNECTREDWIRE

FROMTDR3 ANDCONNECTBLUWIREFROMIFM.

5 DEFROSTTIMERTOBE SETAT 90 MINUTESEXCEPT

FOR50JSO4B,O_OMODELSSET AT 50MINUTES.

AHA ADJUSTABLE HEAT ANTICIPATOR

C CONTACTOR

CAP CAPACITOR

CB CIRCUIT BREAKER

CCH CRANKCASE HEATER

CONP COMPRESSOR MOTOR

CTD COMPRESSOR TIME DELAY

DB @EFROST BOARD

DFT DEFROST THERMOSTAT

DR DEFROST RELAY

EQUIP EQUIPMENT

HR HEATER RELAY

6ND GROUND

HTR HEATER

IFM INDOOR FAN MOTOR

OFM OUTDOOR FAN MOTOR

LpS LOW PRESSURE SWITCH

OFR OUTDOOR FAN RELAY

RVS REVERSING VALVE SOLENOID

OT QUADRUPLE TERMINAL

TH THERMOSTATHEATING

TRAN TRANSFORMER

Wll BRN

W12 BRN

WlO BRN

II BRN

Will BLU_wI09 BRN

HEAT_ W12 BRN

HRI {S KW) I_I17Z4 B_ N

[

TDR (13) FAN SEQUENCE

G

ENERGIZED DE ENERGIZED

CTD [TIT2) COMPRESSOR DELAY

I ; SEC T T+_ MIIN.

Cl CI

CLOSES OPENS

T_AT

CYCLE T:90

I

i 4o0

C00135

16

Page 17

LEGEND

FLA -- FultLoadAmps

LRA -- LockedRotorAmps 1,_

MCA-- MinimumCircuitAmps

MOCP-- MaximumOvercurrentProtection

RLA -- RatedLoadAmps

CKTBKR-- CircuitBreaker

NOTES:

1.IncompliancewithNEC(NationalElectricalCode)requirements

formultimotorandcombinationtoadequipment(refertoNEC

Articles430and440),theovercurrentprotectivedeviceforthe

unitshallbePowerSupplyfuse.Canadianunitsmaybe

fuseorcircuitbreaker.

2.Minimumwiresizeisbasedon60Ccopperwire.Ifotherthan

60Cwireisused,oriftengthexceedswirelengthintable,

determinesizefromNEC.

3.Unbalanced3-PhaseSupplyVoltage

Never operate a motor where a phase imbalance in supply volt-

age is greater than 2%. Use the following formula to determine

the percentage of voltage imbalance.

% Voltage imbalance

= 100 x max vottage deviation from average voltage

average vottage

Fig. 16--Emectrical Data Legend

EXAMPLE: Supply voltage is 460-3-60.

A B C AB = 452 v

AC = 455 v

Average Voltage =

BC = 464 v

Determine maximum deviation from average voltage.

(AB) 457 452=5v

(BC) 464 457=7v

(AC) 457 455=2v

Maximum deviation is 7 v.

Determine percent of 'voltage imbalance.

% Voltage Imbalance = 100 x --

= 1.53%

This amount of phase imbalance is satisfactory as it is below the

maximum allowable 2%.

IMPORTANT: If the supply voltage phase imbalance is

more than 2%, contact your local etectric utility company

immediately.

GROUND LUG

(IN SLPICE BOX

457

452 + 464 + 455

3

1371

3

= 457

7

c99024

GROUND __,_

LEAD

SINGLE-PHASE L1

CONNECTIONS

TO DISCONNECT

PER NEC L2

3-PHASE

CONNECTIONS

LEGEND

NEC - National Electrica! Code

Field Wiring

Spike Connections

L3 ......

NOTE: Use copper wire only.

C99057

Fig. 18--Line Power Connections

PRE-START-UP

z_ WARNING: Failure to observe the following warnings coumd result in serious personal injury or death:

1. Follow recognized safety practices and wear protective goggles when checking or servicing refrigerant system.

2. Do not operate compressor or provide any electric power to unit unless compressor terminal cover is in place and secured.

3. Do not remove compressor terminal cover until aH electrical sources are disconnected and tagged.

4. Relieve and recover all refrigerant from system before touching or disturbing anything inside terminal box if refrigerant

leak is suspected around compressor terminals.

5. Never attempt to repair soldered connection while refrigerant system is under pressure.

6. Do not use torch to remove any component. System contains oH and refrigerant under pressure.

To remove a component, wear protective goggles and proceed as follows:

a. Shut off electrical power to unit and install mockout tag.

b. Relieve and reclaim aH refrigerant from system using both high- and low-pressure ports.

c. Cut component connecting tubing with tubing cutter and remove component from unit.

d. Carefully unsweat remaining tubing stubs when necessary. OH can ignite when exposed to torch flame.

/se the Start-Up (hecklist supplied at the end of this book and proceed as %llows to inspect and prepare the unit %r initial start-up:

1 Remove access panel,

2 Read and follow instructions on all DANGER, WARNING, (AUTION, and INFORMATION labels attached to, or shipped with, unit,

3 Make the following inspections:

a, Inspect _br shipping and handling damages such as broken lines, loose parts, discom_ected wires, etc,

17

Page 18

24 V Circuit Breaker -_

24 Volt Compartment

C99070

Fig. 19--Control Wiring Plate

TRANSFORMER CONTAINS A MANUAL

RESET OVERCURRENT PROTECTOR

IT WILL NOT AUTOMATICALLY RESET

DISCONNECT POWER AND INSTALL

LOCKOUT TAG PRIOR TO SERVICING

THIS COMPARTMENT MUST BE CLOSED

EXCEPT WHEN SERVICING

C99058

Fig. 20--Transformer Label

b. Inspect foI oil at all refrigerant tubing connections and on unit base Detecting oil generally indicates a refrigerant leak. Leak-test all

refiigerant robing connections using electronic leak detector, or liquid=soap solution. Ifa ref'rigerant leak is detected_ see following Check

fbr Refiigerant Leaks section.

c. Inspect all field and fhctory=wiring connections. Be sure that connections are completed and tight.

d. Ensure wires do not touch refrigerant robing or sharp sheetmetal edges.

e. Inspect coil fins. If damaged dr/ring shipping and handling, carefhlly straighten fins with a fin comb.

4. Verify the following conditions:

a. Make sure that outdoor-fan blade is correctly positioned in fire orifice (See Fig. 21).

b. Make sure that condensate drain pan and trap are filled with water to ensure proper &ainage.

c. Make sure that all tools and miscellaneous loose parts have been removed.

5. (ompressors are internally spring mounted. Do not loosen or remove compressor holddown bolts.

6. Each unit system has 2 Schrader=type ports, one tow-side Schrader fitting located on the suction tine, and one high-side Schrader fitting

located on the compressor discharge line. Be sure that caps on the ports are tight.

7. High flow valves are located on the compressor hot gas and suction robes. These valves can not be accessed fbr service in the field. Ensure

the plastic caps are in place and tight or the possibility or refi'igerant leakage could occur.

START-UP

l_sing the Start-Up (hecklist supplied at the end of this book, proceed as %llows:

PROCEDURE I--CHECK FOR REFR{GERANT LEAKS

Locate and repair refi'igerant leaks and charge the unit as fbltows:

1. Use both high- and tow-pressure ports to relieve system pressure and reclaim remaining refi'igerant.

2. Repair leak fbltowing accepted practices.

NOTE: Install a bi=flow filter drier whenever the system has been opened for repair.

3. Check system for leaks using an approved method.

18

Page 19

MOTORANDFANHUB

MOTOR SHAFT

C99009

Fig. 21--Fan Blade Clearance

4 Reclaim refi'igerant and evacuate refl'igerant system to 500 microns if no additional leaks are found

5 Charge unit with R°22 refi'igerant, using a volumetric-charging cylinder or accurate scale. Refer to unit rating plate for required charge. Be

sure to add extra refiigerant to compensate for internal volume of filter drier.

PROCEDURE 2--START-UP ADJUSTNENTS

(omplete the required procedures given in the Pre-Starl=Erp section before starting the unit. Do not jumper any safety devices when operating the

unit. Do not operate the unit in (ooling mode when the outdoor temperature is below 40 _>F (unless accessory tow°ambient kit is installed). Do

not rapid-cycle the compressor. Allow 5 minute between "on" cycles to prevent compressor damage.

A, CHECKING COOLING AND HEATING

CONTROL OPERATION

Start and check the unit _br proper control operation as follows:

1. Place room thet_nostat SYSTEM switch in OFF position. Observe that blower motor starts when FAN" switch is placed in ON position and

shuts down within (50 sec. when FAN switch is placed in AUTO position.

2. Place SYSTEM switch in COOL position and FAN switch in AUTO position. Set control below room temperature. Observe that cooling

cycle shuts down when control setdng is satisfied.

3. Place system switch in HEAT position. Set control above room temperature. Observe that compressor, outdoor tim, and indoor blower

motors start. Observe that heating cycle shuts down when control setting is satisfied.

4. When using an atttomatic changeover room thermostat, place both SYSTEM and FAN" switches in AUTO positions. Observe that unit

operates in Cooling mode when temperatme control is set to "call for Cooling" (below room temperature), and unit operates in Heating

mode when temperature control is set to "call for Heating" (above room telaperamre).

IMPORTANT: ThreeophasQ scroll compressors are direction oriented. Unit must be checked to ensure proper compressor 3-phase power lead

orientation. If not corrected within 5 minute, the internal protector will shut off the compressor. The 3-phase power leads to the unit must be

reversed to cot_vct rotation. When turning backwards, scroll compressors emit elevated noise levels, and the difference between compressor suction

and discharge pressures may be dramatically lower than normal.

B. CHECKING AND ADJUSTING REFRIGERANT CHARGE

The refrigerant system is fldly charged with R-22 re['rigerant and is tested and fhctory sealed. Allow system to operate a minimum of 15 minutes

bel:bre checking or adjusting charge.

NOTE: Adjustment of the refl'igerant charge is not required unless the unit is suspected of not having the proper R-22 charge. The charging label

and the tables shown re_hr to system temperatures and pressures in cooling mode only. A refiigerant charging label is attached to the outside of

the service access door. If charge level is suspect in Heating mode, reclaim all re['rigerant and charge to nameplate amount. (This inJ:brmation may

be obtained from the physical data table also.)

IMPORTANT: When evaluating the refi'igerant charge, an indicated adjustment to the specified _i_ctoV charge must always be ve_- minimal. If

a substantial adjustment is indicated, an abnom_al condition exists somewhere in the cooling system, such as insu_l]cient airflow across either coil

or both coils.

C. REFRIGERANT CHARGE

The amount of refligerant charge is listed on the unit nameplate and/or the physical data table. Refer to the Refi'igeration Service Techniques

Manual Refi'igerants Section.

D, NO CHARGE

Check for leak. Use standard evacuating techniques, After evacuating system to 500 microns_ weigh in the specified amount of refrigerant (refer

to system data plate)

E. LOW CHARGE COOLmNG

Lse (ooling (harging Charts (Fig. 26-38) Va_- refi'igerant until the conditions of the chart are met Note that charging charts are different fiom

type normally used. (harts are based on charging the units to cot_'ect superheat for the various operating conditions Accurate pressure gage and

temperature sensing devices are required. ( onnect the pressure gage to the service port or* the suction line. Mount the temperature sensing device

on the suction tine and insulate it so that the outdoor ambient does not affect the reading, Indoor air CFM must be within the normal operating

range of the unit

g. TO USE COOLmNG CHARGING CHARTS

qake the outdoor ambient temperature and read d_e suction pressure gage. Refer to the chart to determine what the suction temperature shouk! be.

NOTE: [f the problem causing the inaccurate readings is a refi'igerant leak, refer to Check _br Refrigerant Leaks section.

19

Page 20

LEGEND

HPS - High Pressure Switch

LCS - Loss of Charge Switch

Accurate€' Metering Device

Arrow indicates direction of flow

Fig. 22--Typical Heat Pump Operation, Heating Mode

OUTDOOR COIL

Metering

Position

Bypass

Position

INDOOR COIL

C00095

OUTDOOR COIL

Meterh/g

Position

INDOOR COIL

1T

Bypass

LEGEND

HPS - High Pressure Switch

LCS - Loss of Charge Switch

Accurate€" Metering Device

[_ Arrow indicates direction of flow

Fig. 23--TypicN Heat Pump Operation, Cooling Mode

G. INDOOR AIRFLOW AND A_RFLOW ADJUSTMENTS

z:_ CAUTBON: For heating and cooling operation, the recommended airflow is 350 to 450 cfm for each 12,000 Btuh of rated

cooling capacity. For units with optional electric heat, the airflow must not be reduced bemow the levels stated in TaMes 3 and

4. Failure to maintain these airflows coumd resumt in damage to the unit.

Position

C00096

Tables 7 and g shows both heating and cooling airflows at various external static pressures Refer to these tables to detem_ine the airflow %r the

system being installed.

NOTE: Be sure that all supply-and return-air grilles are open, tiee fi'om obstructions, and adjusted properly

Airflow can be changed by changing the lead connection of the blower motor.

Unit PHIP and PH2P three-speed motors (except sizes PH1P 018 and PH2P 030) are factory wired for tow speed operation Unit PH2P 030 is

_actory wired for medium speed. Unit PHIP 018 has a two-speed motor wired for tow speed

For 208/230-v Motors: The motor leads are color-coded as follows:

3-SPEED

Black high speed

Blue medium speed

Red low speed

To change the speed of the indoor fhn motor (IFM), remove the _hn motor speed leg lead fi'om d-_eTime Delay Relay (TDR) This wire is attached

to TDR-3 fbr single-phase and 3-phase malts. To change the speed, remove and replace with lead for desired blower motor speed, i_s_date the

removed lead to avoid contact with chassis parts.

2O

Page 21

7O

Based on Indoor Entering Air of 70 F and Rated CFM

6O

BaBance Point Worksheet

£

m_50

O

I©

D °

g_

oU 40

ce_

80

_ C

®_ 30

I®

.N_

mg

"E 20

c

10

-10 0 10 17 20 30 40 47 50 60

Outdoor Air Temp (Deg F)

/

-4_=030

-4k_ 036

==x-=042

--_-- 048

-,,,a,_060

C00093

Fig, 24--PH2P Balance Point Worksheet

For 460-v OE Motors The motor leads are color coded as %llows:

3-SPEED

Black high

Violet jumper

O*ange medimn

Red tow

To change the speed of the indoor fan motor (IFM), remove £m motor speed lead flora the Time Delay Relay (TDR) and replace with the lead

for the desired blower motor speed The motor speed tend is attached to temainal TDR-3 For low and naedium speeds, black must be connected

to the jumper wire. Insulate removed tend end to avoid contact with chassis parts. To select high speed on 460=v GE motors, separate the black

fcnmle quick connect (QC) t'rom the .jumper lead nmle quick connect (QC) and connect the black lead to the BR Insulate the jumper to avoid

contact with any chassis parts

MAINTENANCE

To ensure continuing high per%mmnce, and to minimize the possibility of premature equipment failure, periodic nmintenance must be per%treed

on this equipl*nent This heat pump unit should be inspected at 1east once each year by a qualified service person. To troubleshoot unit, refer to

Table 1l.

NOTE TO EQI_ IPMENT OWNER: Consuh your tocal dealer about the availability of a maintenance contract

Z_x WARNBNG: The ability to properly perform maintenance on this equipment requires certain expertise, mechanical

ski[is, tools and equipment, if you do not possess these, do not attempt to perform any maintenance on this equipment, other

than those procedures recommended in the User's Manual FAILURE TO HEED THS WARNING COULD RESULT BNSERIOUS

raNJURY OR DEATH AND POSSIBLE DAMAGE TO THS EQUIPMENT.

Z_ WARNING: Failure to follow these warnings conrad resuR in serious injury or death:

1, Turn off electrical power to the unit and install lockout tag before performing any maintenance or service on this unit,

2. Use extreme caution when removing panels and parts. As with any mechanical equipment, personal injury can resuR from

sharp edges.

3. Never place anything combustible either on, or in contact with, the unit.

Z_ CAUTmON: Errors made when reconnecting wires may cause improper and dangerous operation. Labem aH wires prior

to disconnecting when servicing.

21

Page 22

7O

6O

£

F-

ro 50

zo°

oO_ 4o

c

0O 0_

:n® 30

c_

mg

"E 20

c

Balance Point Worksheet

Based on Indoor Entering Air of 70 F and Rated CFM

10

40 47 50 60

Outdoor Air Temp (Deg F)

C00094

Fig. 25--PHIP Balance Point Worksheet

The minimum maintenance requirements %r this equipment are as follows:

1. Inspect air filter(s) each month. Clean or replace when necessa_-.

2. Inspect indoor coil, &ain pan, and condensate &ain each cooling season for cleanliness. (?lean when necessary.

3. Inspect blower motor and wheel for cleanliness each cooling season. (lean when necessary.

4. (heck electrical connections fbr tightness and controls for proper operation each cooling season. Service when necessary.

5. Ensure wires are not contacting refl'igerant tubing or sharp sheet rnetal edges.

PROCEDURE 1--AIR FmLTER

mMPORTANT: Never operate the unit withou[ a suitable air filter in [be return-air duct system Always replace the filter with the same

dimensional size and gpe as originally installed (See Tables 1 and 2 fbr recommended filter sizes,)

Inspect air filter(s) at 1east once each month and replace (throwaway=type) or clean (cleanableqype) at 1east twice &ring each cooling season or

whenever the t'ilter becomes clogged with dust and tint

PROCEDURE 2--INDOOR BLOWER AND MOTOR

NOTE: All motors aIe prelubricated. Do not at[erupt to lubricate these motors

For longer lit), operating economy, and continuing efficiency, clean accumulated dirt and grease from the blower wheel and rnotor annually.

z_ WARNING: Disconnect and tag emectricam power to the unit before cleaning and lubricating the blower motor and

wheel Failure to adhere to this warning could cause serious injury or death.

PROCEDURE 3--OUTDOOR COIL, mNDOOR COraL, AND

CONDENSATE DRAIN PAN

Inspect the condenser coil, evaporator coil, and condensate drain pan at least once each heating and cooling season or sooner if conditions require.

The coils are easily cleaned when &y; therefbre, inspect and clean the coils either befbre or after each cooling season. Remove all obstructions,

including weeds and shrnbs, that interfere with the airflow through the condenser coil.

Straighten bent fins with a fin comb. If coated with dirt or lint, clean the coils with a vacuum cleaner, using the soft brt/sb attachment. Be careful

not to bend the fins. If coated with oil or grease, clean the coils with a mild detergent=and-water solution. Rinse coils with clear water, using a

garden hose. Be careful not to splash water on motors, insulation, wiring, or air filter(s). For best results, spray condenser coil fins fi'om inside

to outside the unit. On units with an outer and inner condenser coil, be sure to clean between the coils. Be sure to flush all dirt and debris fiom

the unit base.

22

Page 23

Tabme 7--Wet Colt Air Delivery

Unit PHIP 018-060 (Deduct 10 percent for 208oV)*

UNiT

018 Med

MOTOR EXTERNAL STATIC PRESSURE {IN. WG}

SPEED 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

Low

Watts 214 191 170

Cfm 821 696 575

Watts

Cfm

Watts 283 274 267

High Cfm 848 707 555

Low

024 Med

Watts 237 214 191

Cfm 971 821 696

Watts 368 366 365 360

Cfm 957 872 785 688

Watts 425 414

High Cfm 891 735

Low

30 Med

Watts 295 292 289

Cfm 928 882 802

Watts 388 383 377 372 366 361