Payne PA13NR06000GAAAA, PA13NR042000AAAA, PA13NR04200GAAAA, PA13NR048000AAAA, PA13NR04800GAAAA Installation Guide

...Page 1

Installation Instructions

SAFETY CONSIDERATIONS

Improper installation, acljustment, alteration, service, maintenance,

or use can cause explosion, fire, electrical shock, or other

conditions which may cause death, personal iniury, or property

damage. Consult a qualified installer, service agency, or your

distributor or branch for information or assistance. The qualified

installer or agency must use factory-authorized kits or accessories

when modifying this product. Refer to the individual instructions

packaged with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses, protective clothing,

and work gloves. Use quenching cloth for brazing operations.

Have fire extinguisher available. Read these instructions

thoroughly and follow all warnings or cautions included in

literature and attached to the unit. Consult local building codes and

current editions of the National Electrical Code ( NEC ) NFPA 70.

In Canada, refer to current editions of the Canadian electrical code

CSA 22.1.

Recognize safety information. This is the safety-alert symbol _X

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury. Understand

these signal words; DANGER, WARNING, and CAUTION.

These words are used with the safety-alert symbol. DANGER

identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies hazards which could

result in personal injury or death. CAUTION is used to identify

unsafe practices which would result in minor personal injury or

product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation, reliability,

or operation.

ELECTRICALSHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF position.

There may be more than 1 disconnect switch. Lock out and

tag switch with a suitable warning label.

INSPECT NEW UNIT

After un-crating unit, inspect thoroughly for hidden damage. If

damage is found, notify the transportation company immediately

and file a concealed damage claim.

LOCATION

Check local codes for regulations concerning zoning, noise,

platforms, and other issues.

Locate unit away from fresh air intakes, vents, or bedroom

windows. Noise may carry into the openings and disturb people

inside.

Locate unit in a well drained area, or support unit high enough so

that water runoff will not enter the unit.

Locate unit away from areas where heat, lint, or exhaust fumes will

be discharged onto unit (as from dryer vents).

Locate unit away from recessed or confined areas where

recirculation of discharge air may occur (refer to CLEARANCE

REQUIREMENT section of this document).

Roof-top installation is acceptable providing the roof will support

the unit and provisions are made for water drainage and

noise/vibration dampening.

NOTE: Roof mounted units exposed to wind may require wind

baffles. Consult the manufacturer for additional information.

CLEARANCE REQUIREMENTS

When installing, allow sufficient space for airflow clearance, wiring,

refrigerant piping, and service.

Allow 24 in. (609.6 mm) clearance to service end of unit and 48 in.

(1219.2 mm) (above unit. For proper airflow, a 6-in. (152.4 mm)

clearance on 1 side of unit and 12-in. (304.8 mm) on all remaining

sides must be maintained. Maintain a distance of 24 in. (609.6 mm)

between units or 18 in. (45%2 mm) if no overhang within 12 ft. (3.66

m).

Position so water, snow, or ice from roof or eaves cannot fall directly

on unit.

NOTE: 18" (457.2 mm) clearance option described above is

approved for outdoor units with wire grille coil guard only. Units

with louver panels require 24" (609.6 mm) between units. On

rooftop applications, locate unit at least 6 in. (152.4 mm) above

roof surface.

EXPLOSION HAZARD

Failure to follow this warning could

result in death, serious personal iniury,

and/or property damage.

Never use air or gases containing

oxygen for leak testing or operating

refrigerant compressors. Pressurized

mixtures of air or gases containing

oxygen can lead to an explosion.

Page 2

UNIT SUPPORT

NOTE: Unit nmst be level _+ 2 degrees {3/8 inch rise or fall per

foot of run (10 mm rise or fall per 305 mm of run) } or compressor

may not function properly.

A. GROUND LEVEL INSTALLATION

The unit must be level and supported above grade by beams,

platform, or a pad. Platform or pad can be of open or solid

construction but should be of permanent materials such as

concrete, bricks, blocks, steel, or pressure-treated timbers approved

for ground contact. Soil conditions must be considered so that the

platform or pad does not shift or settle and leave the unit partially

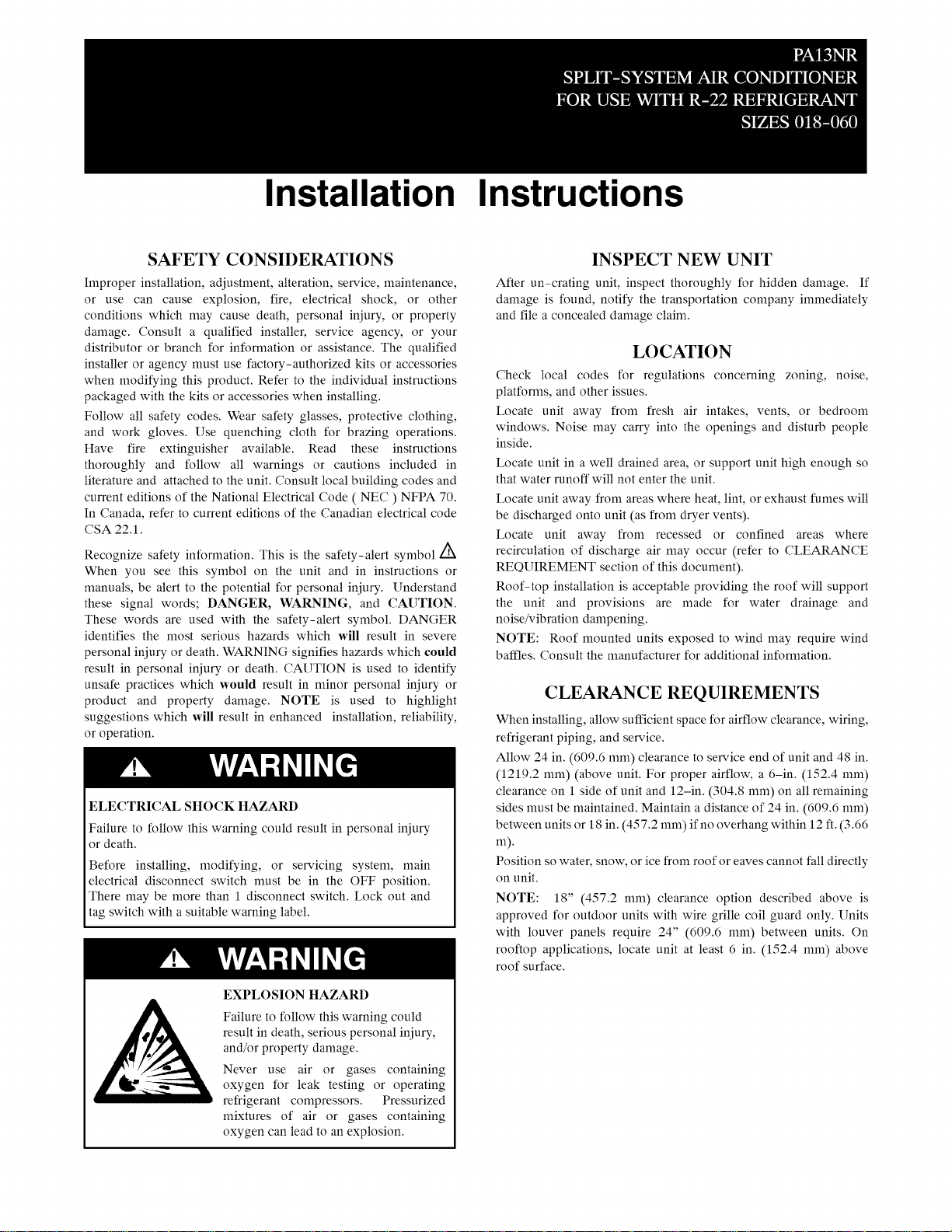

supported. Minimum pad dimensions are shown in Fig. 1.

If beams or an open platform are used for support, it is

recommended that the soil be treated or area be graveled to reduce

the growth of grasses and weeds.

To minimize vibration or noise transmission, it is recommended

that supports not be in contact with the building structure.

However, slabs on grade constructions with an extended pad are

normally acceptable.

B. ROOF TOP INSTALLATION

This type of installation is not recommended on wood frame

structures where low noise levels are required.

Supporting structure or platform for the unit must be level. If

installation is on a fiat roof, locate unit minimum 6 inches (152

ram) above roof level.

Place the unit over one or more load bearing walls. If there are

several units, mount them on platforms that are self-supporting

and span several load bearing walls. These suggestions are to

minimize noise and vibration transmission through the structure. If

the structure is a home or apartment, avoid locating the unit over

bedrooms or study.

NOTE: When unit is to be installed on a bonded guaranteed roof,

a release must be obtained from the building owner to free the

installer from all liabilities.

C. FASTENING UNIT DOWN

If conditions or local codes require the unit be attached in place,

remove the knockouts in the base pan and install tie down bolts

through the holes (see Fig. 1).

Contact local distributor for hurricane hold-down details and the

P.E. (Professional Engineer) certification, when required.

3/8" (10mm) dia. Tie Down Knockouts

In Basepan (2 places)

I View From Top I

Base

Pan

Depth

oO

A

Base Pan Width

Inches (mm)

Base Pan

W x D

23 x 23

(584 x 584)

25-11/16 x

25-11/16

(652 x 652)

31-1/8 x

31-1/8

(791 x 791)

Tie Down

Knockouts

A

7- 6/4

(197)

9-1/16

(230)

B C

4-7/16 18

(113) (457)

4-7/16 21-1/4

(113) (540)

9-1/16 6-1/2 24-5/8

(230) (165) (625)

Minimum

Mounting Pad

Dimensions

23 x 23

(584 x 584)

26 x 26

(660 x 660)

31-1/2 x 61-1/2

(800x800)

Fig. 1 - Tie Down Knockouts

REFRIGERATION SYSTEM

EXPLOSION AND FIRE HAZARD

Failure to follow this caution could result in property

damage, personal iniury and/or death.

This unit utilizes R-22 refrigerant. Use only R-22

refrigerant when servicing this unit.

DO NOT, under any circumstances, use R-410A

refrigerant in this system.

PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in property

damage.

Inadequate unit support may cause excessive vibration,

noise, and/or stress on the refrigerant lines, leading to

refrigerant line failure.

A. COMPONENT MATCHES

Check to see that the proper system components are in place,

especially the indoor coil.

R-22 outdoor units can only be used with R-22 specific indoor

coils. If there is a refrigerant ntis-match, consult the indoor coil

manufacturer to deternfine if a refrigerant conversion kit is

available for the indoor coil.

This outdoor unit is designed for use only with indoor coils that

utilize a TXV refrigerant metering device. If any other type of

metering device is installed on the indoor coil, consult the indoor

coil manufacturer to deternfine if a TXV conversion kit is available

The compressors for these units are supplied with Polyol Ester

(POE) Oil. If the existing line set and indoor coil has residual

nfineral oil (MO) there is no concern with percentage of oil

nfixtures as both are nfiscible with the R-22. Mixtures of both oils

at any percentage will lubricate and return with the R-22.

Page 3

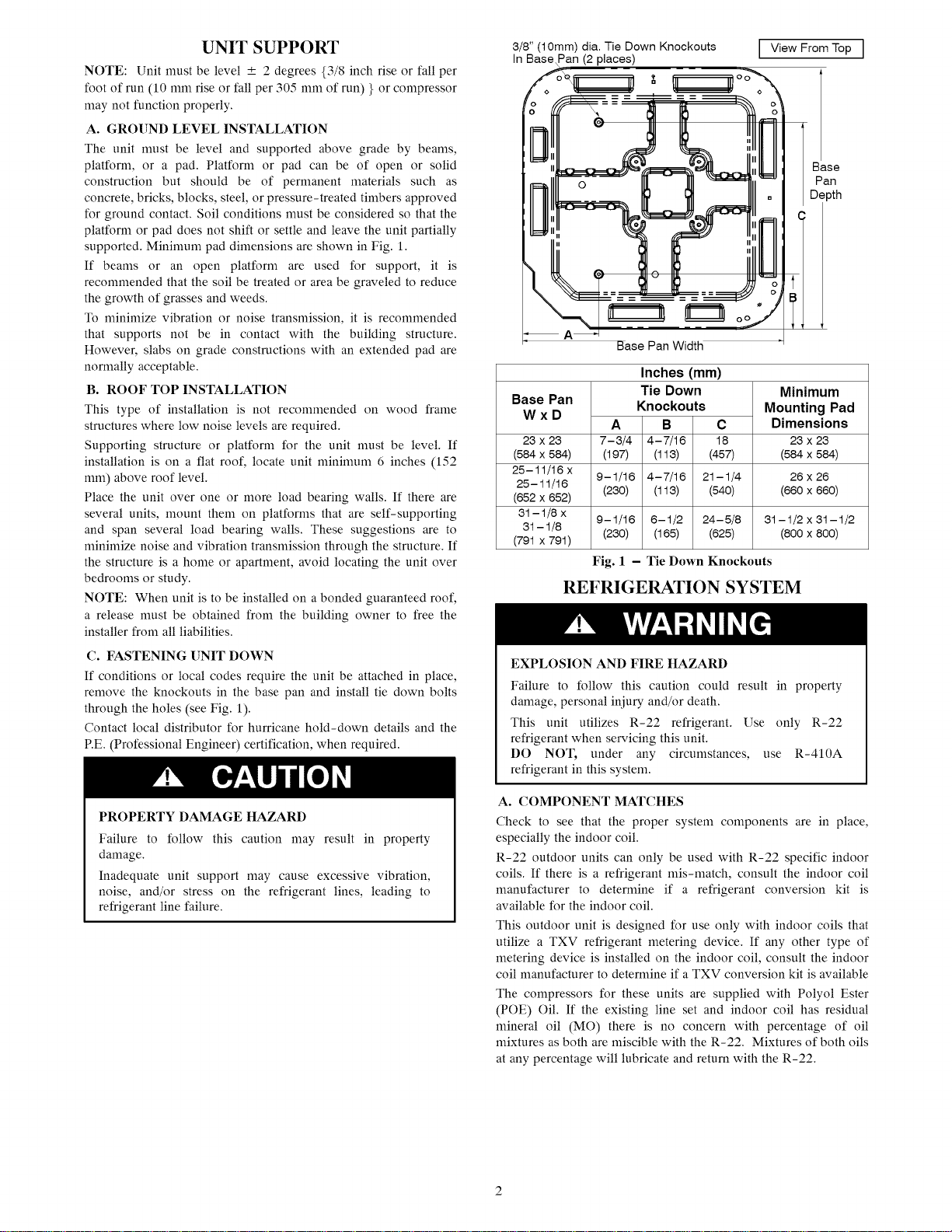

WheninstallingaTXVonanindoorcoil,followtheinstructions

providedwiththenewTXV.

AtypicalTXVinstallationisshowninFig.2.

EQUALIZER

TUBE

SENSING SUCTION

BULB TUBE

LIQUID

TUBE

TXV

SENSING BULB

(EITHER SIDE)

STRAP

\

8 O'CLOCK 4 O'CLOCK

Fig. 2 - Typical TXV Installation

B. REFRIGERANT LINE SETS

The refrigerant line set must be properly sized to assure maximum

efficiency and proper oil circulation.

Refer to Long Line Guideline for line set sizing.

NOTE: Total line set length must not exceed 200 feet (61 m).

A crankcase heater must be used when the refrigerant line length

exceeds 80 feet (24.4 m).

If vertical separation between indoor and outdoor units is greater

than 30 ft (9.14 m), refer to the Long Line Guideline.

If it is necessary to add refrigerant line in the field, use dehydrated

or dry, sealed, deoxidized, copper refrigeration tubing. Do not use

copper water pipe.

Do not remove rubber plugs or caps from copper tubing until

connections are ready to be made.

Be extra careful when bending refrigeration tubing. Tubing can

"kink" easily, and if this occurs, the entire length of tubing must be

replaced.

UNIT OPERATION HAZARD

Failure to follow this caution may result in improper unit

operation.

Do not leave system open to atmosphere any longer than

absolutely required for installation. Internal system

components - especially refrigerant oils - are extremely

susceptible to moisture contamination. Keep ends of tubing

sealed during installation until the last possible moment.

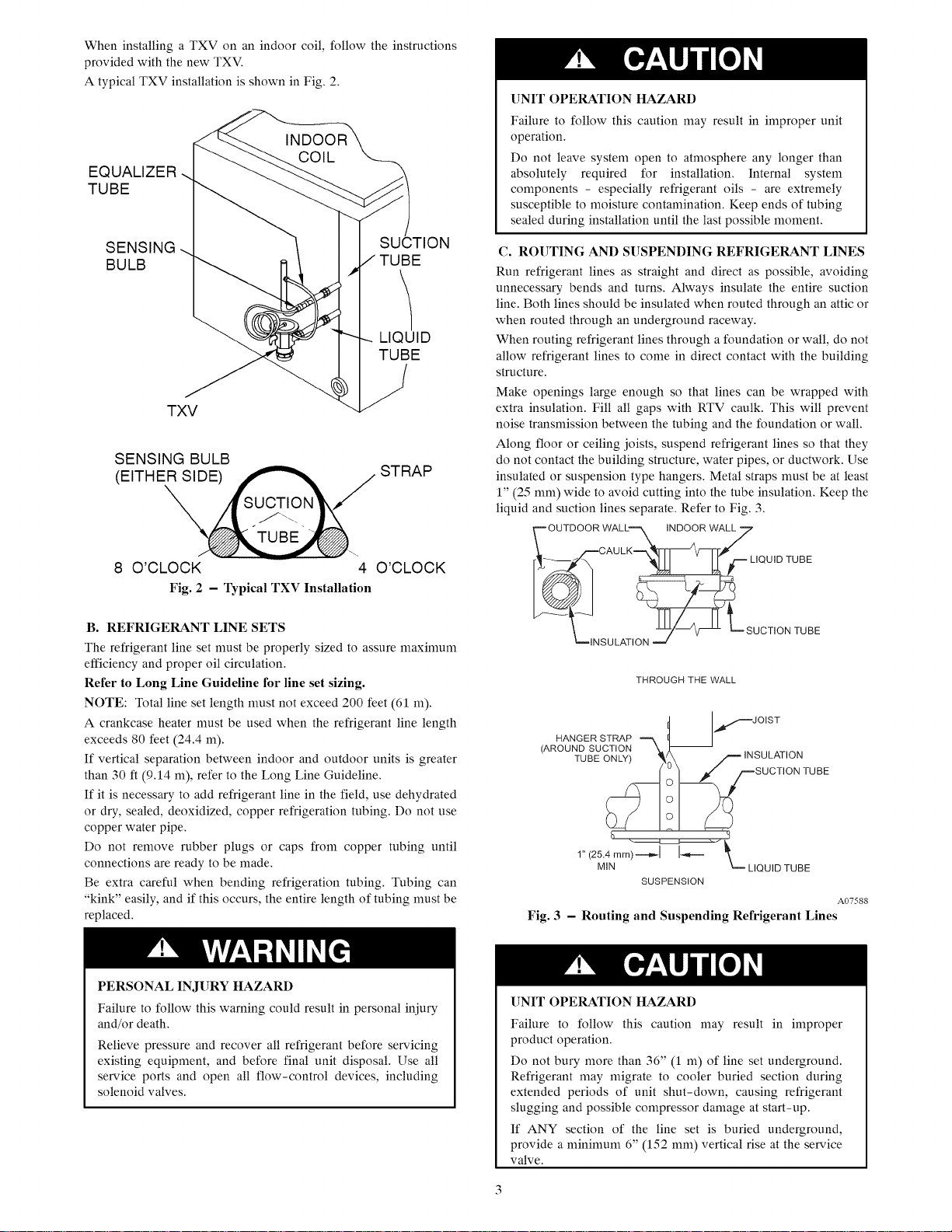

C. ROUTING AND SUSPENDING REFRIGERANT LINES

Run refrigerant lines as straight and direct as possible, avoiding

unnecessary bends and turns. Always insulate the entire suction

line. Both lines should be insulated when routed through an attic or

when routed through an underground raceway.

When routing refrigerant lines through a foundation or wall, do not

allow refrigerant lines to come in direct contact with the building

structure.

Make openings large enough so that lines can be wrapped with

extra insulation. Fill all gaps with RTV caulk. This will prevent

noise transmission between the tubing and the foundation or wall.

Along floor or ceiling joists, suspend refrigerant lines so that they

do not contact the building structure, water pipes, or ductwork. Use

insulated or suspension type hangers. Metal straps must be at least

1" (25 mm) wide to avoid cutting into the tube insulation. Keep the

liquid and suction lines separate. Refer to Fig. 3.

OUTDOORWALL--X '"DOORWALy

CAU LK_ _J

_/_'_ ' _[ r LLIQUIDTUBE

---el ---4 m/_[ _---SUCTIONTUBE

_-'-INSU LATION

THROUGH THE WALL

HANGER STRAP

(AROUND SUCTION _ --

TUBE_N

1" (25.4 mm_ _

MIN _-- LIQUID TUBE

SUSPENSION

Fig. 3 - Routing and Suspending Refrigerant Lines

_/---JOIST

/ _ INSULATION

/SUCTION TUBE

A07588

PERSONAL INJURY HAZARD

Failure to follow this warning could result in personal iniury

and/or death.

Relieve pressure and recover all refrigerant before servicing

existing equipment, and before final unit disposal. Use all

service ports and open all flow-control devices, including

solenoid valves.

UNIT OPERATION HAZARD

Failure to follow this caution may result in improper

product operation.

Do not bury more than 36" (1 m) of line set underground.

Refrigerant may migrate to cooler buried section during

extended periods of unit shut-down, causing refrigerant

slugging and possible compressor damage at start-up.

If ANY section of the line set is buried underground,

provide a minimum 6" (152 mm) vertical rise at the service

valve.

Page 4

D.OUTDOORUNITHIGHERTHANINDOORUNIT

Properoilreturntothecompressorshouldbemaintainedwith

suctiongasvelocity.Ifvelocitiesdropbelow1500fpm(feetper

minute),oilreturnwillbedecreased.Tomaintainsuctiongas

velocity, do not upsize vertical suction risers.

E. LIQUID LINE FILTER-DRIER

NOTE: It is required that an approved filter drier (XH-6 with

25% activated alumina / 75% molecular sieve desiccants) be

installed in the liquid line due to the POE oil.

Leave the plugs in the tube ends until the filter-drier is installed.

The optimal location for the filter-drier is close to the indoor coil.

Install the filter-drier with the arrow pointing towards the indoor

coil. Refer to Fig. 4.

FIRE HAZARD

Failure to follow this warning could result in personal injury,

death, and/or property damage.

Refrigerant and oil mixture could ignite and burn as it

escapes and contacts brazing torch. Make sure the refrigerant

charge is properly removed from both the high and low sides

of the system before brazing any component or lines.

Clean line set tube ends with emery cloth or steel brush. Remove

any grit or debris.

Insert line set tube ends into service valve tube stubs.

Apply heat absorbing paste or heat sink product between service

valve and joint. Wrap service valves with a heat sinking material

such as a wet cloth.

Braze joints using a Sil-Fos or Phos-copper alloy.

UNIT DAMAGE HAZARD

Failure to follow this caution may result in unit component

damage.

Service valves must be wrapped while brazing in a heat

sink material, such as a wet cloth.

A05178

Fig. 4 - Liquid Line Filter Drier Installed at Indoor Unit

F. SERVICE VALVES

Service valves are closed and tube stubs are plugged from the

factory. Outdoor units are shipped with a dry nitrogen holding

charge sealed in the unit. Leave the service valves closed until all

other refrigerant system work is complete or the charge will be

lost. Leave the plugs in place until line set tubing is ready to be

inserted.

Service valve bodies are brass and tube stubs are copper.

G. BRAZING CONNECTIONS

NOTE: Remove valve core from schrader port on both Service

Valves BEFORE brazing. This helps prevent overheating and

damage to valve seals (refer to Fig. 5). Replace valve core when

brazing is completed.

VALVE SERVICE

CORE

Fig. 5 - Service Valve

H. OPENING SERVICE VALVES

Outdoor units are shipped with a dry nitrogen holding charge

sealed in the unit. Opening the service valves releases this charge

into the system.

NOTE: Open the Suction service valve first. If the Liquid service

valve is opened first, oil from the compressor may be drawn into

the indoor coil TXV, restricting refrigerant flow and affecting

operation of the system.

Remove Suction service valve cap and insert a hex wrench into the

valve stem. Hold the valve body steady with an end-wrench and

back out the stem by turning the hex wrench counterclockwise.

Turn the stem until it just contacts the rolled lip of the valve body.

After the nitrogen charge has bled into the system, open the Liquid

service valve.

NOTE: These are not back-seating valves. It is not necessary to

force the stem tightly against the rolled lip.

The service valve cap is a primary seal for the valve and must be

properly tightened to prevent leaks. Make sure cap is clean and

apply refrigerant oil to threads and sealing surface on inside of cap.

Tighten cap finger tight and then tighten additional 1/6 of a turn (1

wrench flat) to properly seat the sealing surfaces.

nitrogen pressure from the system before attaching vacuum

I NOTE: Using the service ports (or gauge set), release the I

pump.

Page 5

I. EVACUATINGCONDENSER,LINE SET, AND

INDOORCOIL

PRODUCT DAMAGE HAZARD

Failure to follow this caution may result in product damage.

Never use the outdoor unit compressor as a vacuum pump.

Doing so may damage the compressor.

Condenser, line set, and indoor coil should be evacuated using the

recommended deep vacuum method of 500 microns. If deep

vacuum equipment is not available, the alternate triple evacuation

method may be used by following the specified procedure.

If vacuum must be interrupted during the evacuation procedure,

always break vacuum with dry nitrogen.

UNIT OPERATION HAZARD

Failure to follow this caution may result in improper unit

operation..

This unit is filled with a Nitrogen charge. Prior to starting

this unit, evacuate to 500 microns and charge with

refrigerant listed on rating label. Purge nitrogen before

connection to vacuum pump.

Deep Vacuum Method

The deep vacuum method requires a vacuum pump capable of

pulling a vacuum to 500 microns and a vacuum gauge capable of

accurately measuring this vacuum level. The deep vacuum method

is the most positive way of assuring a system is free of air and

water.

Watch the vacuum gauge as the system is pulling down. The

response of the gauge is an indicator of the condition of the system

(refer to Fig. 6).

With no leaks in the system, allow the vacuum pump to run for 30

minutes minimum at the deep vacuum level.

5000

4500

4000

ff18500

g aooo

_2500

m

2000

1500- VACUUM TIGHT

1000

500 TIGHT

0 1 2 3 4 5 6 7

MINUTES

Fig. 6 - Deep Vacuum Gauge Response

and System Conditions

TOO WET

DRY SYSTEM

A95424

Triple Evacuation Method

The triple evacuation method should only be used when system

does not contain any water in liquid form and vacuum pump is

only capable of pulling down to 28 inches of mercury (711 mm

Hg). Refer to Fig. 8 and proceed is as follows:

1. Pull system down to 28 inches of mercury (711 mm Hg)

and allow pump to continue operating for an additional 15

minutes.

2. Close manifold valves or valve at vacuum pump and shut

off vacuum pump.

3. Connect a nitrogen cylinder and regulator to system and fill

with nitrogen until system pressure is 2 psig.

4. Close nitrogen valve and allow system to stand for 1 hour.

During this time, dry nitrogen will diffuse throughout the

system absorbing moisture.

5. Repeat this procedure as indicated in Fig. 7.

6. After the final evacuate sequence, confirm there are no leaks

in the system. If a leak is found, repeat the entire process

after repair is made.

IEVAOUATE I

IBREAKVACUUMWITH DRY NITROGEN I

r- Tq

IEVACUATEI

IBREAKVACUUMWITHDRYNITROGEN I

IEVACUATEI

ICHECKFORTIGHT'DRYSYSTEMI(IF IT HOLDS DEEP VACUUM)

I CHARGESYSTEMI

A95425

Fig. 7 - Triple Evacuation Sequence

J. GAUGE PORTS

Check for leaks at the schrader ports and tighten valve cores if

necessary. Install plastic caps finger tight.

Page 6

ELECTRICAL WIRING

ELECTRICALSHOCK HAZARD

Failure to follow this warning could result in personal iniury

or death.

Before installing, modifying, or servicing system, main

electrical disconnect switch nmst be in the OFF position.

There may be more than 1 disconnect switch. Lock out and

tag switch with a suitable warning label.

The supply voltage must be 208/230 volts (197 volt minimum to

253 volts naaxinmm) 60 Hz single phase.

Outdoor units are approved for use with copper conductors only.

Do not use alunfinum wire.

Refer to unit rating plate for minimum circuit ampacity and circuit

protection requirements.

Grounding

Permanently ground unit in accordance with the National Electrical

Code and local codes or ordinances. Use a copper conductor of the

correct size from the grounding lug in control box to a grounded

connection in the service panel or a properly driven and electrically

grounded ground rod.

ELECTRICALSHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Unit cabinet must have an uninterrupted or unbroken ground

to nfininfize personal iniury if an electrical fault should occur.

The ground may consist of electrical wire or metal conduit

when installed in accordance with existing electrical codes.

Wiring Connections

Make all outdoor electrical supply (Line Voltage) connections with

rain-tight conduit and fittings. Most codes require a disconnect

switch outdoors within sight of the unit. Consult local codes for

special requirements.

Route electrical supply (Line Voltage) wiring through knockout

hole in bottom of Control Box. Connect wires to Contactor and

Ground Lug according to Wiring Diagram on unit. Also refer to

Fig. 8.

Route thermostat wiring through rubber grommet in bottom of

Control Box. Low voltage lead wires are provided in the control

box for connection to thermostat wires (use wire nuts). Refer to

Wiring Diagram on unit and Fig. 9 for low voltage wiring

examples.

All wiring must be NEC Class 2 and must be separated from

inconfing power leads.

NOTE: Use No. 18 AWG (American Wire Gage) color-coded,

insulated (35 °C nfininmm) wire. If thermostat is located more than

100 feet (31 m) from unit as measured along the control voltage

wires, use No. 16 AWG color-coded wires to avoid excessive

voltage drop.

DISCONNECT

PER NEC AND/OR

LOCAL CODES

1

FIELD POWER

WIRING

FIELD GROUND

WIRING ] GROUND

Fig. 8 - Electrical Supply (Line Voltage) Connections

L.1 @

_- ®

CONTACTOR

[ 23 or 13

-g)

LUG

A10476

A/C Typical

THERMOSTAT FURNACE

24VACHOTE}"------Q

24VACCOM[D'------E]--

HEATSTAGE1....-El

COOLSTAGE1...."42]"'

,NDOORFANEl--------El

AIR

CONDITIONER

LEGEND

24-V FACTORY WIRING

24-V FIELD WIRING

C_ FIELD SPLICE CONNECTION

CONTACTOR

Fig. 9 - Typical Thermostat Connections

(See Thermostat Installation Instruction

for specific unit combinations)

A/C Typical AIR

THERMOSTAT FAN COIL CONDITIONER

24 MAC HOT [_,

24 MAC COM D"

HEAT STAGE 1 [_

COOL STAGE 1 [_

INDOOR FAN [_'

A97368

_,a4B

A02326

Page 7

START-UP PROCEDURE

1. Set indoor thermostat selector switch to OFF.

2. Turn ON all electrical disconnect devices.

3. If unit has a crankcase heater, energize the heater and wait

24 hours before proceeding.

4. Set indoor thermostat at desired temperature. Be sure set-

point is below indoor ambient temperature or thermostat

will not call for cooling.

5. Set indoor thermostat selector switch to COOL. Operate

unit for minimum 15 nfinutes, then check system refrigerant

charge.

REFRIGERANT CHARGE

Table 1 shows the suggested refrigerant charge quantities for a 15

foot (4.6 m) lineset. If shorter or longer refrigerant lines or a

different indoor coil are used, the charge will have to be adjusted.

For different line lengths, add or remove charge based on 0.6

ounces (17 g) charge per foot (305 ram) of difference. For

example, a 25 foot (7.6 m) line set is 10 feet (3 m) longer than the

specified 15 feet (4.6 m). Add 0.6 ounces (17 g) charge for each of

the extra 10 feet (3 m):

10 x 0.6 = 6.0 ounces additional charge

(3 m x 17 g = 51 g additional charge)

The initial charge should be weighed into the system per Table 1

and the additional amount for the length of line set. Then check

subcooling.

This outdoor unit is designed for use only with indoor coils that

utilize a TXV refrigerant metering device. With an indoor TXV,

use the subcooling method to make final charge adjustments:

NOTE: Only use subcooling charging method when the following

is true:

• outdoor ambient temperature is between 70°F and 100°F

(21°C and 38°C)

• indoor temperature is between 70 ° and 80°F

(21 °C and 27°C)

• line set is less than 80 feet (24.4 m).

1. Operate unit a minimum of 15 nfinutes before checking

charge.

NOTE: If outdoor unit has a 2-speed fan motor, motor will

operate in low speed when outdoor ambient temperature is

below 82°F (28°C). Pull one of the yellow low voltage

wires off the fan control and the unit will default to high

speed fan for servicing. Reconnect wire after servicing.

2. Measure liquid service valve pressure by attaching an

accurate gauge to service port.

3. Measure liquid line temperature by attaching an accurate

thernfistor type sensor or electronic thermometer to liquid

line near outdoor coil.

4. Refer to unit rating plate for required subcooling temperat-

ure.

5. Refer to Table 2. Find the required liquid line temperature

where the rating plate subcooling temperature intersects

measured liquid service valve pressure.

6. If the measured liquid line temperature is higher than the

chart number, add refrigerant to lower the measured temper-

ature.

NOTE: When adding refrigerant, charge in liquid form,

using a flow restricting device, into the suction port.

If the measured liquid line temperature is lower than the

chart number, reclaim refrigerant to raise the measured

temperature.

Tolerance is _+3 °F (_+ 1.7 °C).

Table 1--Suggested Refrigerant Charge Quantity

for 15 foot (4.6 m) Lineset

Model Number Ibs. (kg)

PA13NR018 3.56 (1.62)

PA13NR024 4.08 (1.85)

PA13NR030 4.11 (1.87)

PA13NR036 5.35 (2.43)

PA13NR042 7.01 (3.19)

PA13NR048 8.88 (4.04)

PA13NR080 10.52 (4.79)

Measured Liquid

Pressure (psig)

183

171

179

187

198

205

214

223

233

243

253

284

274

285

297

309

oF

83

86

89

92

95

98

101

104

107

110

113

116

119

122

125

128

Table 2--Required Liquid Line Temperature

Rating Plate (required) Subcooling Temperature ° F (° C)

oF oF

5

10 15

oF

20

R-22 Required Liquid Line Temperature ° F (° C)

78

81

84

87

90

93

96

99

102

105

108

111

114

117

120

123

73

76

79

82

85

88

91

94

97

1O0

103

106

109

112

115

118

68

71

74

77

80

83

86

89

92

95

98

101

104

107

110

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii_i_!_i!_i!_i!_i!_i!_i!_i!_i!_i!_i!_i!_i!_i!_i!_i!_i!_i!_i!_i!_i!_i!_i!_i!_!_i_i_

113

Page 8

SEQUENCE OF OPERATION

With power supplied to indoor and outdoor units, transformer is

energized.

On a call for cooling, the thermostat makes circuits R-Y and R-G.

Circuit R-Y energizes contactor, starting outdoor fan motor and

compressor. Circuit R-G energizes indoor unit blower relay,

starting indoor blower motor.

When thermostat is satisfied, its contacts open, de-energizing

contactor and blower relay. Compressor and motors stop.

NOTE: If indoor unit is equipped with a time-delay relay circuit,

the blower runs an additional length of time to increase system

efficiency.

MAINTENANCE

Condensate Drain

During the cooling season, check monthly for free flow of drainage

and clean if necessary.

Cleanliness

These tips will help keep the air conditioner looking better and

working more efficiently:

1. Free flow of air is essential. Keep fences, shrubs, trash cans,

and other obstructions at least 18 inches (0.5 m) from all

coil inlets.

2. Keep the coil free of grass clippings, leaves, weeds, and

other debris.

NOTE: Coil may occasionally require cleaning with a

liquid solution. The coil nmst be cold when cleaning. Use

an alkaline based cleaner only. Cleaning a hot coil or using

an acid based cleaner will remove the paint from the fins

and may clog the coil.

3. Never use a weather cover over the outdoor unit unless it is

a ventilated type or made of breathable fabric that will allow

moisture to evaporate rapidly. A cover that holds moisture

in the unit will cause more rust build-up and damage than

normal exposure to weather.

Copyright 2014 CAC/BDR • 7310 W. Morris St. • Indianapolis, IN 46231 edition date: 07/14

Manufacturer reserves the right to change, at any time, specification8 and design8 without notice and without obligations,

Catalog No: IM-PA13NR-06

Replaces: IM- PAl 3NR- 05

Loading...

Loading...