Paxton

ins-40213-US

Paxlock US

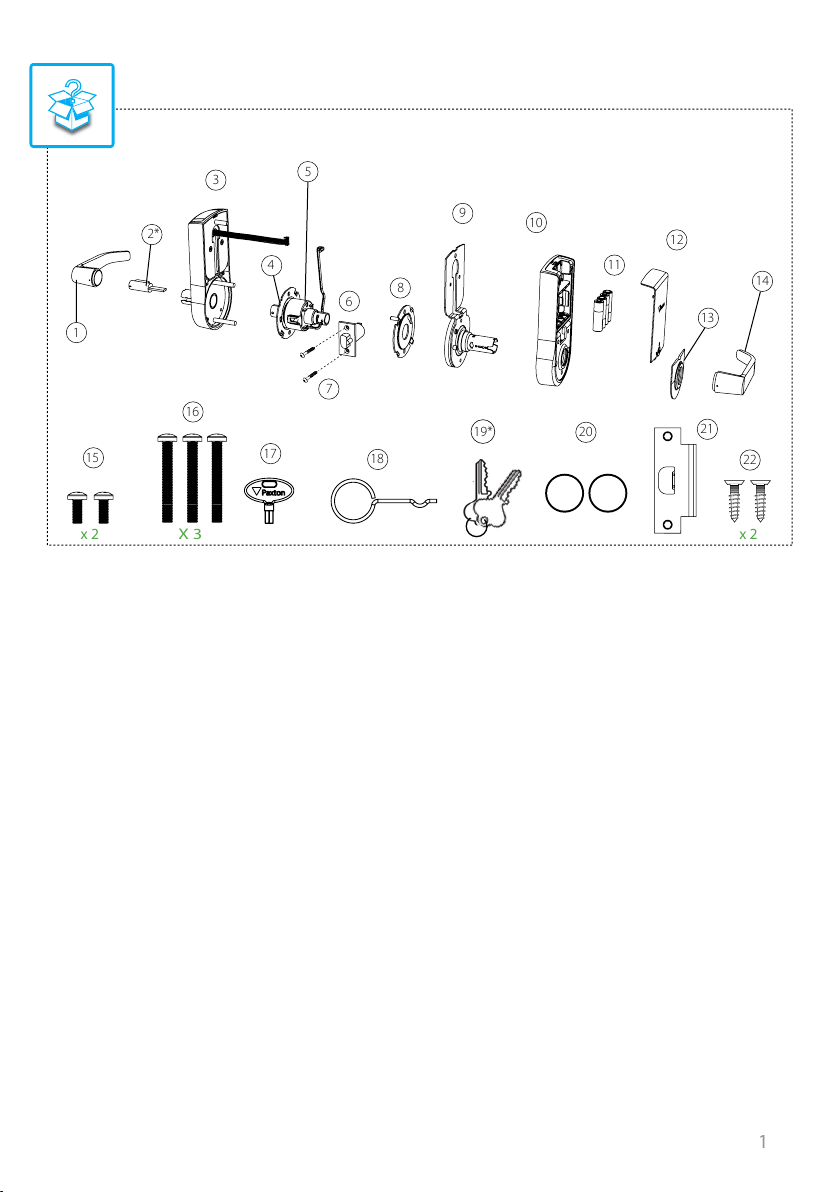

3

2*

1

16

15

5

9

4

8

6

7

17

18

19*

10

11

20

12

14

13

21

22

x 2 x 2

X 3

What’s in the box

1) Front handle

2) Lock Cylinder *

3) Paxlock front housing

4) Motor adjustment plate

5) Motor

6) 2-3/8” Latch

7) Latch screws x 2

8) Motor backplate

9) Backplate/Rose assembly

10) Paxlock rear housing

11) 4 x AA Alkaline batteries

* Not for SFIC

12) Rear battery cover

13) Rear handle cover

14) Rear Handle

15) Small mounting screws x 2

16) Long mounting screws x 3

17) Battery cover key

18) Handle removal pin

19) Keys x 2 *

20) Handle washers x 2

21) Strike plate

22) Strike plate screws x 2

Tools List

Power Drill

Drill bits (1”, 5/16”, 5/8”, 1/8”)

Crosshead screwdriver

Chisel 1”

Knife

Adhesive tape

Pencil

Tape measure

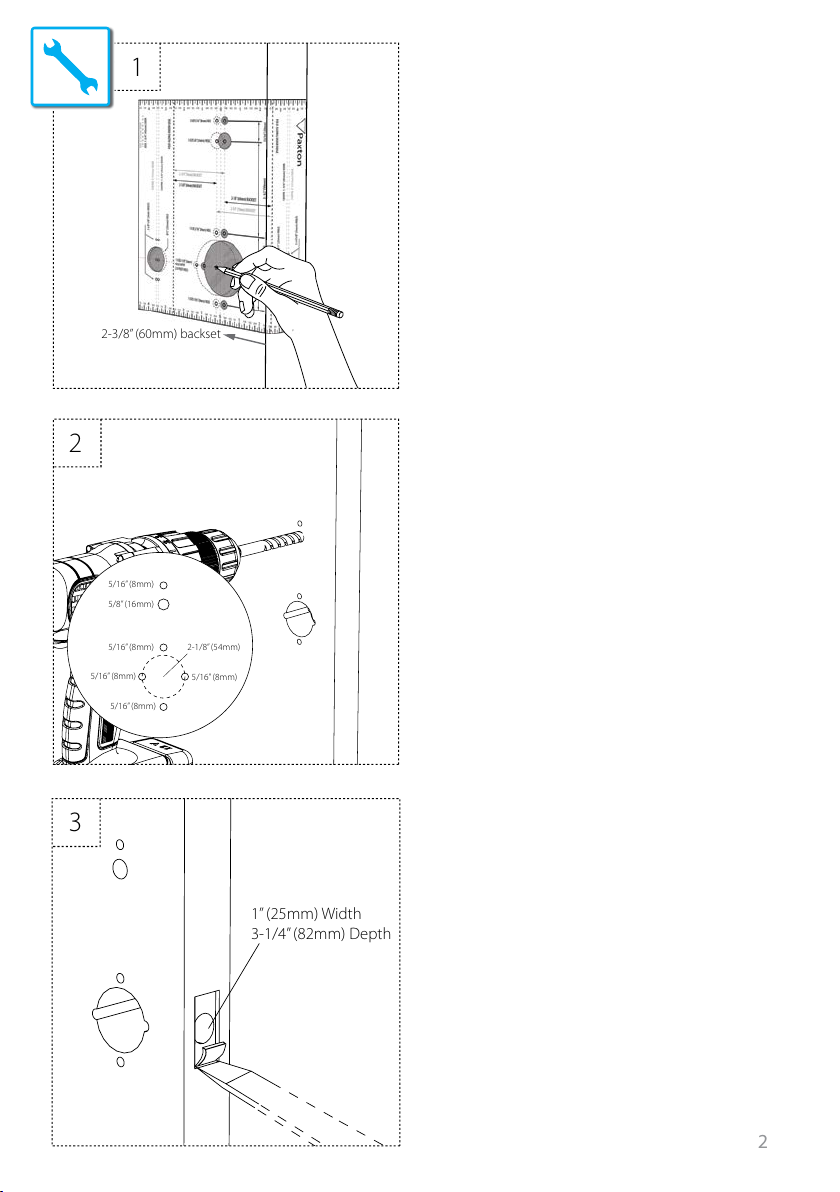

1

1

2-3/8” (60mm) backset

Step 1: Marking out

Tape template to door, mark holes then remove

template for drilling.

2

3

5/16” (8mm)

5/8” (16mm)

5/16” (8mm)

5/16” (8mm)

5/16” (8mm)

2-1/8” (54mm)

5/16” (8mm)

1” (25mm) Width

3-1/4” (82mm) Depth

Step 2: Drilling

To ensure accuracy you should drill holes from

both sides of the door towards the center. This

avoids the risk of damaging the door face when

the drill breaks through.

Make sure to include pilot holes either side of

the central hole to ensure ush tting of the

motor plates.

Step 3: Marking out and chiseling for latch

To install the latch; drill a 1” (25mm) hole, slide in

the latch, then draw around the faceplate.

Remove the latch and score the outline with

a knife to avoid splitting the wood when

chiselling.

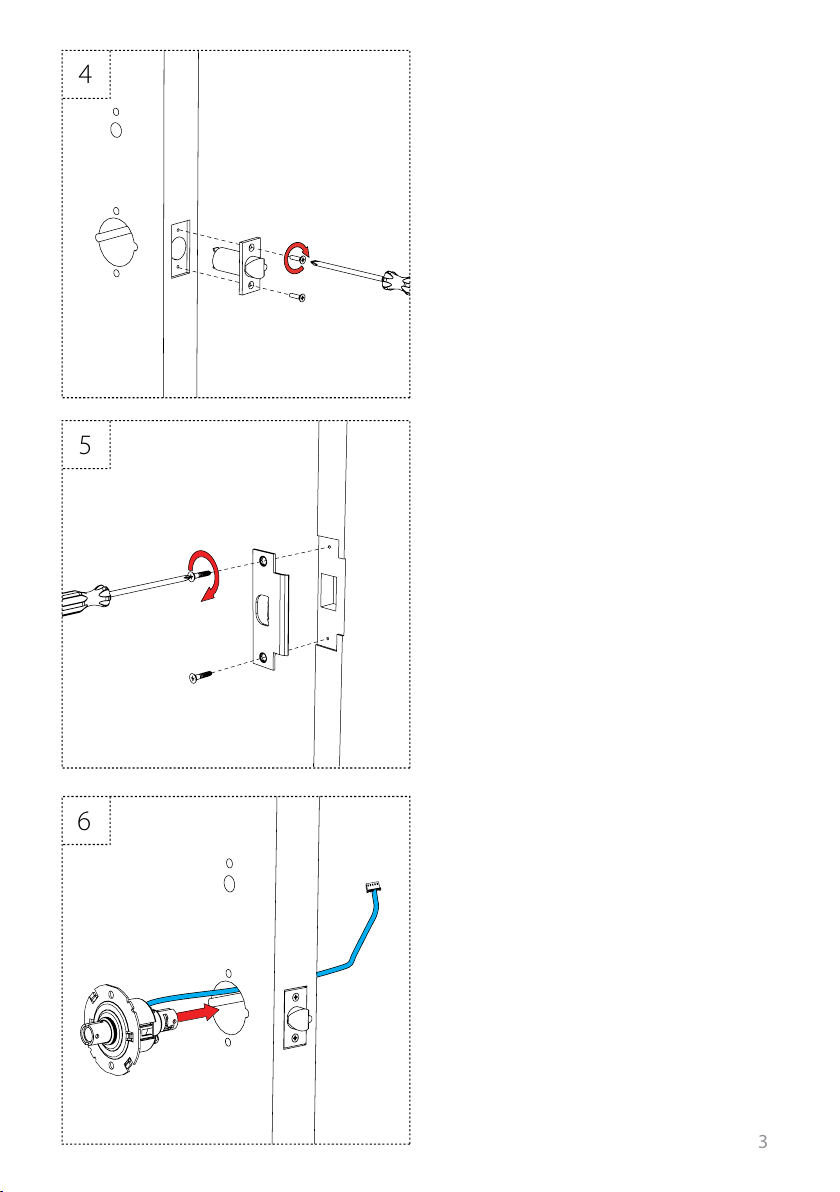

2

4

Step 4: Fitting the door latch

Attach the latch using the screws provided.

5

Step 5: Fitting the strike plate

Close the door to mark the horizontal line of the

strike plate.

Measure one half of door thickness from door

stop to mark vertical center line of the strike.

Drill 1” (25.4mm) hole, 1/2” (12.7mm) deep at

intersection of horizontal and vertical center

lines.

Cut out jamb 3/32” (2.4mm) deep or until the

strike is ush with jamb. Tighten the strike plate

screws securely.

Step 6: Inserting the motor

6

Pass the motor through the central hole within

the door, making sure to pass the motor lead

through the hole rst.

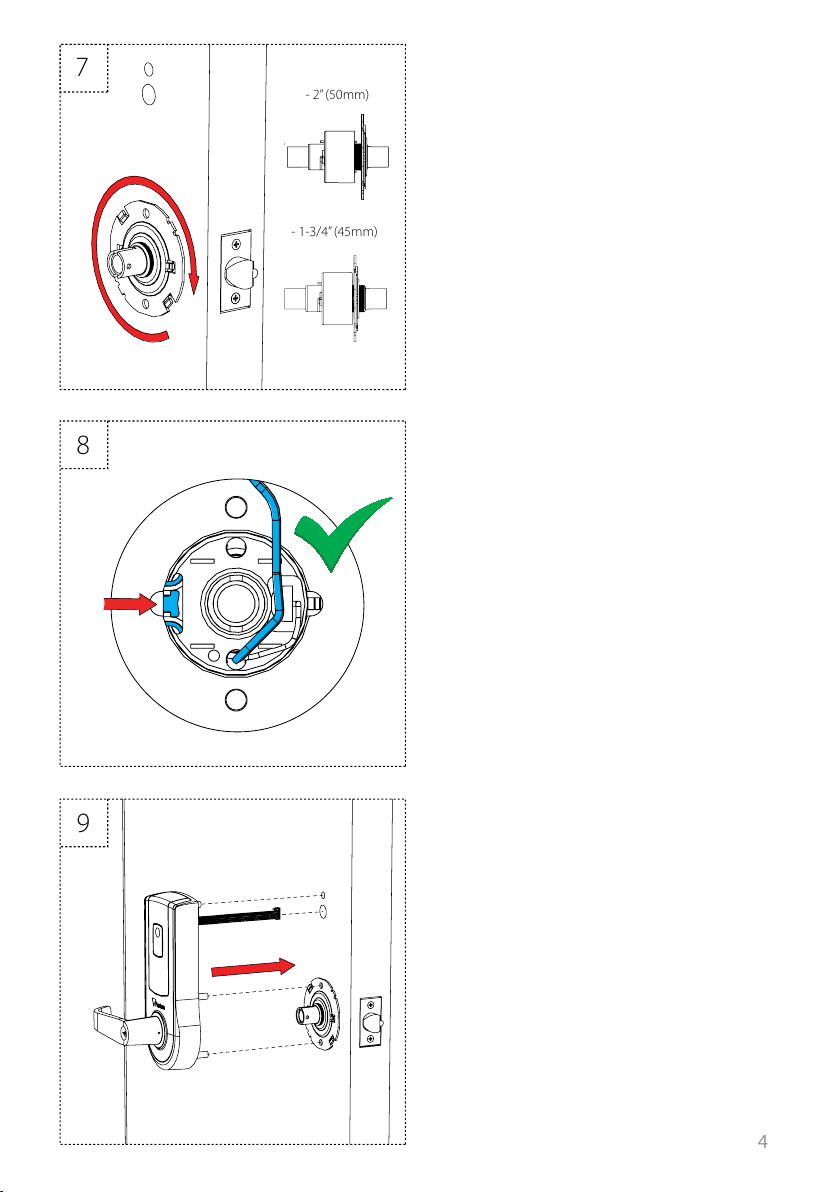

3

7

Step 7: Rotating the motor adjustment plate

- 2” (50mm)

- 1-3/4” (45mm)

To ensure that the motor adjustment plate is at

the correct distance, rotate until it sits ush with

the door and the motor has engaged properly.

Please refer to the diagram for the correct

position of the plate for each door thickness.

8

Step 8: Ensuring the latch engages

Make sure the tail of the latch is engaging with

the motor retractor correctly as illustrated.

Step 9: Fitting the front housing

9

Line up front housing and ensure the body is

ush to the door.

*PaxLock US is set up for RH doors by default –

please see page 8 for LH operation.

4

13

14

15

10

Step 10: Fitting the rear backplate

assembly

Feed the motor cable through the

hole in the motor back plate.

11

12

Step 11: Fitting the rear housing and motor

wiring

Feed both the cables through the rear housing

cutout and t the lower long mounting screws.

Step 12: Fitting the rear lock assembly and

wiring

Fit top, long mounting screws and 2 lower short

screws.

5

13

Step 10: Fitting the batteries

14

15

Step 11: Securing the rear cover

Step 12: Fitting the cover plate and handle

6

Optional step: Handle orientation for LH door

To congure for LH door operation, remove the front and rear handles using the handle removal

pin. Unscrew the 4 screws securing the rose to the front/rear housings, rotate 180 degrees and

screw back together.

Ret the handles, and push home until the axle engagement clicks.

Optional step: Contact switch Optional step: Inserting the handle washers

Handle feel can be tightened with the use of

the included washers.

7

Software installation

0 m

3m

15m

20m

30m

50ft

65ft

100ft

10ft

0 ft

≤ 200

Net2 Pro/Net2 Lite: http://paxton.info/1438

Wireless Signal Range

x1

x1

≤ 1000

8

1

2

4

5

6

3

Enrolling a PaxLock

1

4

2

3

21

43

9

PaxLock reset

1

3

Battery replacement

2

4

21

43

10

Specications

Features

Maximum number of users/tokens

Access Levels

Time zones

Door unlock time

Recommended number of Paxlock’s per Net2Air bridge

Net2Air bridge per system

Net2Air wireless range

Events stored

Environment

Battery type

Typical Battery life

Operating temperature

Moisture resistance

External Use

Vandal resistance

Dimensions

Total outside dimensions (includes handle clearance)

UL has only evaluated the Operating temperature specication

Min

1 sec 60 secs

50 ft

Min

4 x AA Alkaline

20,000 operations 30,000 operations

0 °C (-32 °F)

IPX4

No

No

Width Height

6” 8

1/2

” 3”

MaxTyp

10,000

250

64

10

200

3,584

Max

+55 °C (+131°F)

Depth

11

+44 (0)1273 811011

support@paxton.co.uk

paxton.support

+44 (0)1273 811011

support@paxton.co.uk

paxton.support

+1(800) 672-7298

supportUS@paxton-access.com

usapaxton.support

+1(800) 672-7298

supportUS@paxton-access.com

usapaxton.support

+49 (0) 251 2080 6900

support@paxton-gmbh.de

paxton.gmbh.support

+31 (0)76 3333 999

support@paxton-benelux.com

paxton.benelux.support

+31 (0)76 3333 999

support@paxton-benelux.com

paxton.benelux.support

+31 (0)76 3333 999

support@paxton-benelux.com

paxton.benelux.support

+33 (0)157 329356

support@paxtonaccess.fr

paxton.support

+27 (0) 272 14276691

support@paxtonaccess.co.za

paxton.support

+44 (0)1273 811011

support@paxton.co.uk

paxton.support

12

The declaration of conformity is available on request. Contact details are provided at:

http://paxton.info/596

These products are not suitable for retail sale. All warranties are invalid if these products are not installed

by a competent person.

North America:-

Product Compliance and limitations

Wiring methods shall be in accordance with the National Electrical Code (ANSI/NFPA70), local codes, and the authorities

having jurisdiction.

To comply as a UL listed installation, the following conditions must apply:-

• Server based functions (Antipassback, Time and Attendance, etc) have not been evaluated by UL and cannot be

used for UL 294 installations.

• Where an equivalent cable / wire is used it must be ‘ UL Listed ‘All interconnecting devices must be UL Listed.

• The use of Wiegand readers and the conguration software has not been evaluated by ‘UL’

• Door contact connections are limited to a maximum of 30m.

• IP rating not veried by UL.

• Indoor use only

UL listed to the following standards: ANSI/UL 10C compliant (20 min re doors), CAN/ULC S104 compliant (20 min re

doors), UL 294 compliant, CSA C22.2 NO. 205-12 compliant

FCC Compliance

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

Changes or modications not expressly approved by the party responsible for compliance could void the user's authority

to operate the equipment.

The Paxlock US has been designed and complies with the safety requirements for portable (<20cm) RF exposure in accordance with FCC rule part 2.1093 and KDB 447498 D01 as demonstrated in the RF exposure analysis. Installers must

ensure that this device must not be co-located or operated in conjunction with any other antenna or transmitter except

in accordance with FCC multi-transmitter product procedures.

IC Compliance

This device complies with Industry Canada licence-exempt RSS standard(s).

Operation is subject to the following two conditions:

(1) this device may not cause interference, and (2) this device must accept any interference, including interference that

may cause undesired operation of the device.

The Paxlock US has been designed and complies with the safety requirements for RF exposure in accordance with RSS102 as demonstrated in the RF exposure analysis.

13

14

Made in the UK

© Paxton Ltd 22/10/2014

1.0.0

Loading...

Loading...