Page 1

redaeR

:n oitu

a

C yl

nos

redaerC D V21roF

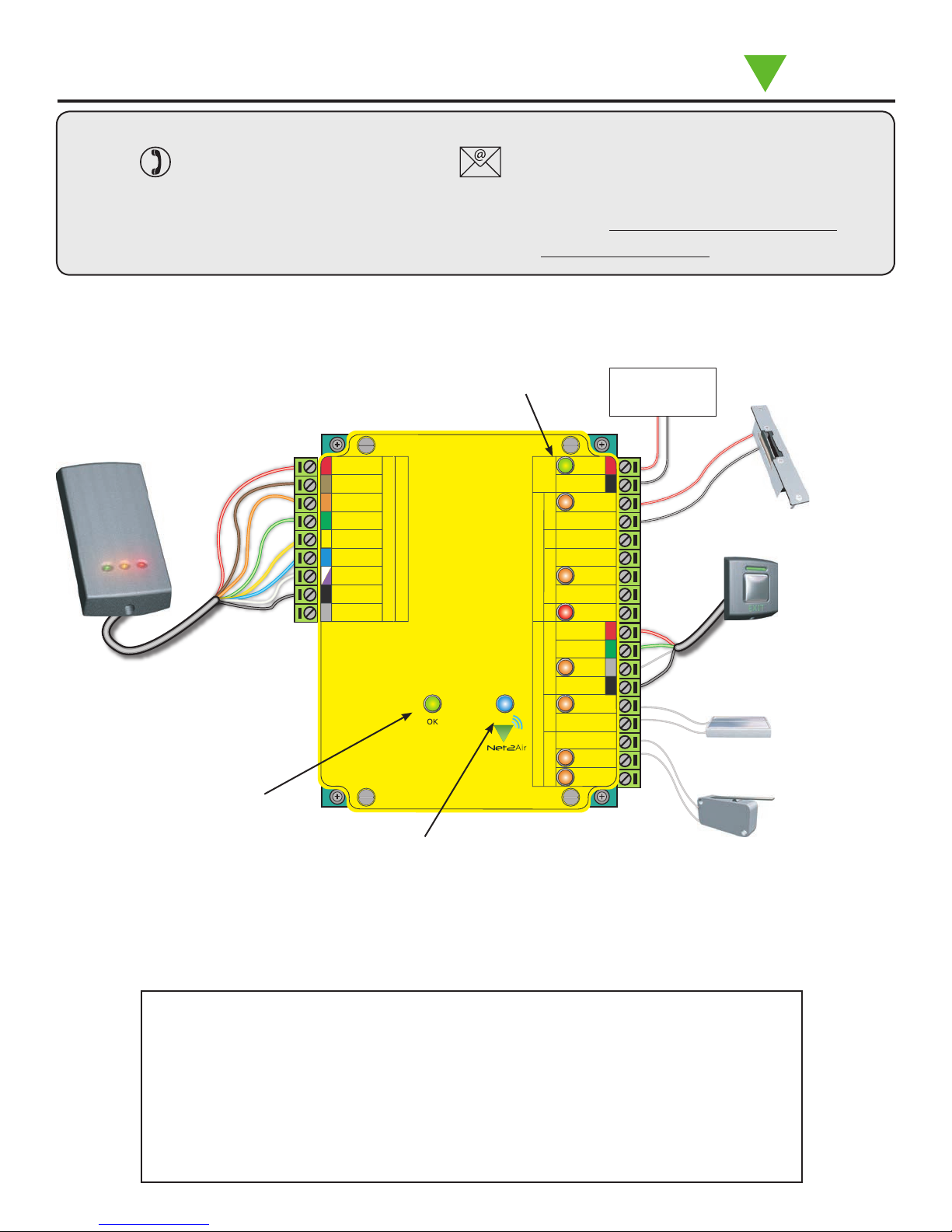

+V out

Red LED

Amber LED

Green LED

Data/D0

Clock/D1

Media Detect

0V

Entry

12V

12V Lock

0V

0V

N.C.

N.O.

COM

Alarm

12V

Green LED

Exit

0V

Contact

0V

0V

Tamper

PSU

0V

nott

u Btix

E

yaleR

kcoL

stuptuO

stupnI

rewoP

tcatnoC

repmaT/USP

Net2 nano

01/28/2013

Ins-40075-US Net2 nano control unit - UL

Technical Support

Paxton

Documentation on all Paxton products can be found on our web site - http://www.paxton-access.com/

This access control unit uses wireless communication. It is recommended that a Net2Air

Reader/keypad

1.800.672.7298

supportUS@paxton-access.com

Technical help is available: Monday - Friday from 02:00 AM - 8:00 PM (EST)

For instructions in alternative languages - http://paxton.info/1000

site surveyor is used to determine the best position for the bridge and control units.

This wireless unit requires a Net2Air bridge to communicate with the server PC.

Diagnostic LEDs

12V DC

power supply

Lock release

Not connected

*

This is the heartbeat of the

system and should pulse

regularly. This indicates that

the processor is functioning.

A new unit requires approximately 30 seconds after initial power up to self congure.

The unit will not operate correctly until this function has completed.

LED indications

12V (Green) - Power LED.

Lock (Orange) - The 12V lock output is energised.

Relay (Orange) - The relay is energised - (NO/COM contacts are closed).

Alarm (Red) - 12V Alarm output is active.

Exit (Orange) - The exit button contacts are closed.

Contact (Orange) - The door contacts are closed.

Tamper (Orange) - The tamper contacts are closed.

PSU (Orange) - The PSU contacts are closed.

Net2Air (Blue) - Net2Air interface Tx/Rx activity.

OK (Green ash) - The internal software is running.

*

Net2Air wireless activity (Tx/Rx) - Blue

During this time the OK LED will not be ashing.

Exit button

(push to make)

Door contact switch

(held closed by door)

Tamper switch

Page1

Page 2

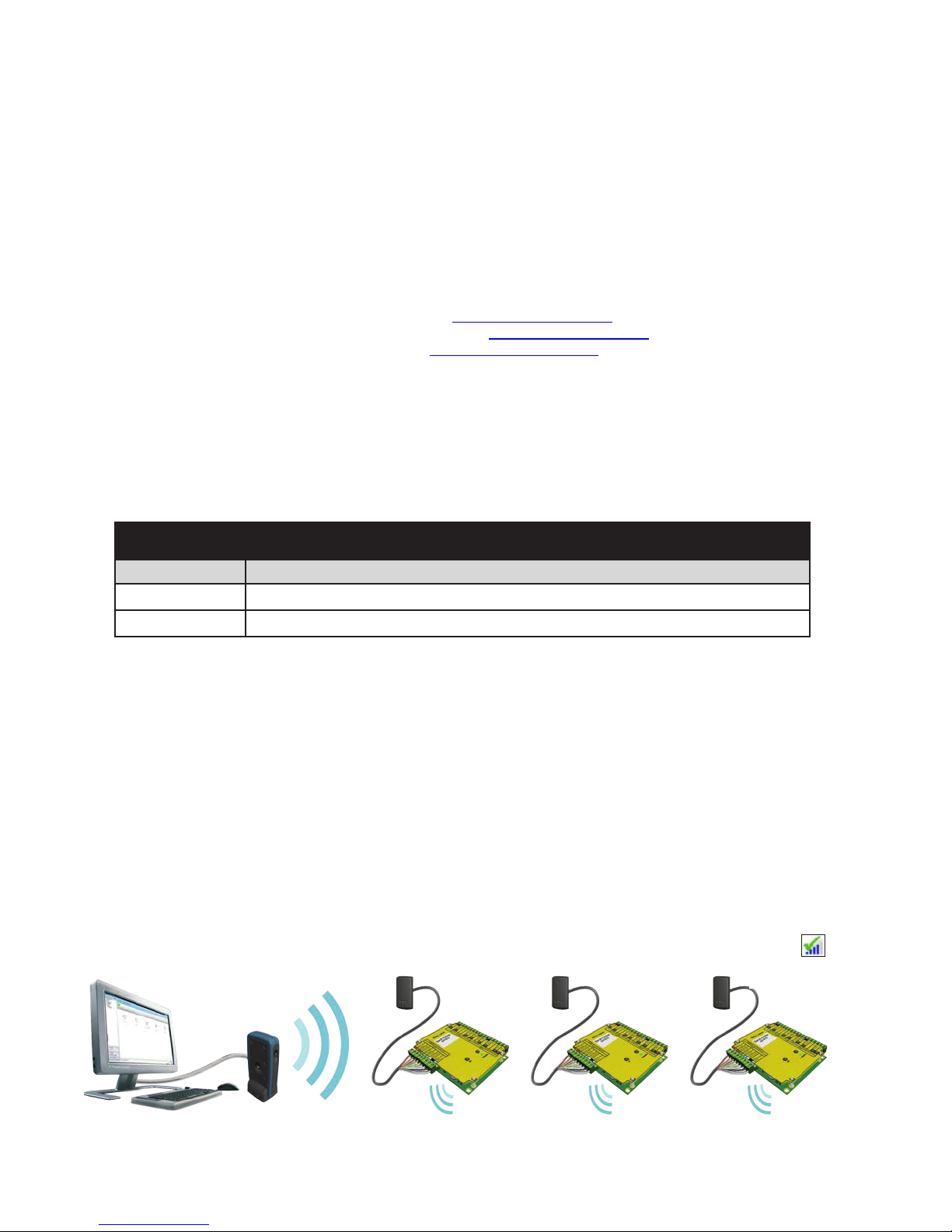

Net2Air wireless communication

Net2Air wireless control units are fully compatible with the hard wired Net2 range but there are several important

dierences that need to be understood before installing wireless equipment. The most important of these is the

location of the control units and their bridge components.

These principles are therefore explained rst before we move on to the control unit itself.

The access control unit connects to the Net2 software running on the PC using Paxton Net2Air proprietary wireless

technology. A Net2Air bridge enables communication from the Net2 software to the Paxton wireless products.

Radio signals do not always behave as you might expect. For example, a cell phone that displays a full signal on

one part of the site will lose signal completely only a few feet away. These problems can be addressed by using the

Net2 site surveyor kit (690-200-US)

See also: XAN1095 - Net2 nano - How does it work? < http://paxton.info/974 >

X AN1096 - How to plan a Net2 nano installation < http://paxton.info/975 >

X Ins-30096-US - Net2Air site surveyor < http://paxton.info/1193 >

Radio frequency

This product should not be installed within 10 feet of other wireless equipment operating on a 2.4Ghz frequency.

To ensure optimum performance other wireless networks should avoid WiFi channels 11, 12 and 13 to reduce the

possibility of interference.

A Net2 nano ACU or a Hands free interface cannot be installed in a Metal cabinet as this would block the RF signal

used for the Net2Air wireless technology.

Options

Part number Description

654-943-US Net2 nano 1 door access control unit

654-549-US Net2 nano 1 door ACU in plastic housing

Net2 nano PC / server operation

Data transfer with wireless technology requires far more control and error checking than with a hard wired data

line connection. Net2 classic runs with a server that originates and controls all the communications on the data

line. This would not be ecient in a wireless environment.

We therefore give the Nano controller the active role. Each Nano is always active and transmits data bursts

(including a regular Heartbeat) every few seconds. The Net2 server then acts upon these requests for service.

The PC requires at least one Net2Air bridge to communicate with a Nano. This can be a local Net2Air USB bridge

(only one per system) and/or multiple Net2Air Ethernet bridge units connected to the PC via a TCP/IP connection.

There is NO Net2 nano detection function. It is recognised that there could be security issues if the wireless

units were detectable from outside the site. During installation, a Nano unit binds with a Net2Air bridge which will

then only talk to registered units. The Server conguration utility also has an ' Enable commissioning' mode which

can be turned o to inhibit Nano units being added.

An entry is then made on the Doors screen and a special icon is used to denote the wireless connection.

Net2 Server

Reader

The reader's default indication has all the LED's on. Access granted is denoted with a single ashing Green LED

Access Denied is a single ashing Red LED.

Control unit

.

Page

2

Page 3

Mounting

Cable type

Parts kits

Part number Qty Description

Fitting Kit fk1-095 3 35mm wall plugs

3 8g x 1.5 pozi twin woodscrew

1 M4 x 20 pozi pan machine screw

5 Cable tie

4 Cable clip

1 Diode 1N4001

1 M4 Rubber washer

This product is not suitable for retail sale. All warranties are invalid if this product

is not installed by a trained technician.

Cable specication

Use Max length Type

Reader / Keypad 500 feet

8 core, shielded - Belden 9538, Alpha 1298C (22AWG) General Cable

C0744A / C0745A (22AWG)

Input / Output 100 yds 2 conductor - Alpha 1172C (22AWG) or equivalent

Control unit installation

This unit is for Indoor use only

The ACU shall be installed within the protected premises as both the power and lock wiring is present at the PCB.

A Tamper alarm input is provided on the PCB - See Input/Output Wiring

Where the ACU is being installed within a plastic enclosure, the hub must be connected to the conduit before it is

connected to the plastic enclose. This is to eliminate the potential of any excessive torque loading being applied

to the plastic enclosure during installation.

This housing should be xed to the surface with suitable fasteners; screws and wall plugs are provided for this in

the tting kit. Also provided are cable ties to secure the cabling and a smaller securing screw for the lid.

Wire the components to the Access Control Unit (ACU) as shown on the rst page.

Press the exit button or in the absence of an exit button, short the 0V and exit terminals together.

The congured lock output LED will come on and the lock should release.

The unit will continue to operate in a 'standalone' mode if the PC is shut down. Any Events that occur during this

period are stored in the unit and the PC is updated when it comes back on line.

PC installation

The current specication for compatible PC hardware, network and operating systems is available on our website

at the following link: http://paxton.info/720

Page3

Page 4

Software installation

The Net2 software should be loaded on the controlling PC with at least one Net2Air bridge installed.

Full documentation is supplied with the Net2Air bridge unit and also from the website as follows:

Only ONE Net2Air USB bridge may be used per system. Multiple Net2Air Ethernet bridges may also be congured.

XAN1051 - Installing Net2 software < http://paxton.info/1520 >

XIns-40084-US Net2Air USB bridge < http://paxton.info/1453 >

XIns-40085-US Net2Air Ethernet bridge < http://paxton.info/1192 >

Page

4

Page 5

Enrolling a Net2 nano

A Nano must rst bind to a Net2Air bridge before it will enroll itself onto the Net2 system. The term 'bind' is used

to denote the xed relationship between a Nano and its bridge.

Create a user record in the database and assign a Net2 token to the user. If you are not using PROXIMITY tokens

you should still create the user record and assign a token number (Not a PIN) of your choice. These records can

be deleted after the installation is complete.

Connect a PROXIMITY reader to the Nano and then present the same user token previously assigned. (If you are

enrolling a Keypad only unit, enter the token number on the keypad followed by * ) The Nano will then transmit

the token number and wait for a response from a bridge.

If more than one bridge replies, the Nano checks the signal strength and selects the strongest bridge to

communicate with. The Net2 software conrms that the token number is in the database and if so registers this

Net2 nano/bridge binding.

System checks

Present a token at each reader. An event for each read should appear in the Events screen.

Change the default password for the System Engineer.

Set up other operators if required.

Set up time zones.

Set up access levels.

Users can be added & assigned to the required access level.

Departments can be created if required.

The Net2 CD can assist here with detailed application notes for setting up users and general system operation.

Software conguration

Door name: Name the Door.

Door open time: Set the door open time.

Unlock the Door during: Holds the door unlocked during this

timezone. - Set to 'At No Time' for normal user operation.

Reader: Settings for the Reader and Keypad.

Outputs: Lock, Relay, Alarm. - Selects these outputs to be

used by the Lock, Bell or Alarm functions.

Alarm: Congures the settings for the dierent alarm types.

Codes: Valid keypad codes can be viewed, added and removed

(This tab is only displayed when a keypad is tted)

Events: Shows the events for this control unit only.

Access Rights: Lists users who have access through this door.

Name: Each reader can be named individually if required.

Reader type: Set the reader type, if applicable.

Keypad type: Set the keypad type, if applicable

Reader operating mode: Set the operating mode.

Timed operating modes: A dierent operating

UL compatable readers

mode can be congured within a time window.

Part Type

373-110-US PROXIMITY P75 reader

373-120-US PROXIMITY P75 reader, screw connector

353-110-US PROXIMITY P50 reader

390-747-US PROXIMITY metal reader

390-727-US PROXIMITY metal reader, chrome

390-737-US PROXIMITY metal reader, brass

390-135-US PROXIMITY panel mount reader

Part Type

371-110-US TOUCHLOCK K75 keypad

371-120-US TOUCHLOCK K75 keypad, screw connector

372-110-US TOUCHLOCK K75 stainless steel keypad

372-120-US TOUCHLOCK K75 stainless steel, screw connector

375-110-US PROXIMITY KP75 keypad

375-120-US PROXIMITY KP75 keypad, screw connector

Page5

Page 6

Maintenance

The Net2 nano is designed to take input from Clock and Data readers through its (In/Out) reader port. It can

also be congured for 26bit Wiegand.

It has a Net2Air wireless interface that is used for uploading rmware and user information as well as providing

Event information to the PC on demand.

Following the completed installation of this equipment, no further maintenance or testing is required.

It is advisable to ensure that any third party backup power supplies or recovery procedures are checked

regularly to ensure that the operation of the Paxton system is not compromised.

1 - Short circuiting, mutilation or incineration of the cells must be avoided to prevent one or more of the following

occurrences; Release of toxic materials, release of hydrogen and/or oxygen gas, rise in surface temperature.

2 - If a cell has leaked or vented the control unit must be replaced. The battery is not to be replaced.

Net2 nano reset

The Nano controller holds the address information for the bridge that it has bound with. This will cause

problems if the unit is to be used on another system.

To clear this address information, you need to perform a hardware reset. Link Orange/White on the reader port

and then power cycle the unit.

Make sure that the power is not removed again until after the green OK LED is ashing again. Later versions

of software also ash the reader LED's until the reset process has nished. Remove the Orange/White link.

INPUT / OUTPUT WIRING

The Net2 nano has 3 outputs that can be congured in the Doors screen to perform dierent functions.

This exibility means that a site that requires the Relay output (volt free contacts) for the door function can

congure the Lock output to drive a door bell.

Lock output - This is a transistor 'open drain' output, (not a voltage free contact) that has been designed

to simplify the wiring of the lock. It can be congured to operate in Fail lock, Fail unlock or toggle modes and

removes the need for additional links or diodes normally required when using a relay for output switching.

Relay output - This provides a set of volt free contacts to switch external devices.

Alarm output - This is a transistor driven output that switches to 0V when activated.

Page

6

Page 7

ALARM

12V

12V Lock

0V

0V

N.C.

N.O.

COM

0V

yaleR

kcoL

stuptuO

rewoP

The use of a Fail closed/Secure conguration shall be determined by the local building codes and the local AHJ.

Lock wiring - Lock output (12V DC)

The lock is wired across the 12V Lock and 0V terminals. No diode

12V

re

woP

0V

12V Lock

kco

L

0V

0V

stuptuO

N.C.

yaleR

N.O.

COM

or additonal wiring is required.

Set the 'Lock output' to 'Door lock' and set the release type to

fail locked, fail unlocked, or toggle.

This wiring illustration shows the Lock output congured for the

Door lock function.

See Specication table for Output ratings.

Lock Wiring - Relay output

12V DC power supply

+ -

12V

re

woP

0V

12V Lock

kco

L

0V

0V

stuptuO

N.C.

yaleR

N.O.

COM

Fail closed

This wiring illustration shows the Relay output congured for the Door lock function.

See Specication table for Output ratings.

The lock is wired across 12V and COM. A 0V link is then required to complete the circuit. This will be wired from

0v to NO or NC depending on lock type (Fail Open / Fail Closed)

A diode is supplied which should be tted across 12V and COM (Silver end to 12V ) to protect the relay contacts.

The dry relay contacts can be used to switch the power from an independent lock power supply. Wire the 0V to

NC or NO and the lock to COM; the +VCC supply is wired directly to the lock.

12V

re

woP

0V

12V Lock

kco

L

stuptuO

N.C.

yaleR

N.O.

COM

Fail open

12V

rewoP

0V

12V Lock

0V

0V

kcoL

0V

stuptuO

0V

N.C.

yaleR

N.O.

COM

Lock power supply

-

+

Door lock

Lock with an independent supply

Alarm sounder

The Net2 ACU has a local alarm output. This is a transistor

'open drain' output, (not a volt free contact) that is capable of

switching 1A at 12V DC.

A Lock output, Relay output or Alarm output must be congured

to function as the Alarm output.

This local output can be turned on or o for each type of alarm

and can be congured to sound continuously or intermittently to

distinguish between dierent alarm types.

Page7

Page 8

Door Bell - Relay output

12V

rewoP

0V

12V Lock

kcoL

stuptuO

yaleR

0V

0V

N.C.

N.O.

COM

Pressing the bell button on the keypad will energise the

Door bell output for 1 second.

The Lock output, Relay output or Alarm output must be

congured to function as the Door Bell output.

This wiring illustration shows the Relay output congured

for the Door Bell function.

See Specication table for Output ratings.

Exit button

12V

nott

Green LED

u Btix

Exit

E

0V

When the Exit terminal is shorted to 0V, the ACU will illuminate the Exit LED and activate the lock output for the set

'Door open time'. The lock output will remain active while the short to 0V remains and the reader/exit button Green

LED will ash during this period. More than one exit button can be wired in parallel.

A Lock output, Relay output or Alarm output must be congured to function as the Door Lock output.

Where tted, a 'push to make' button is required.

(See Specication table for ratings)

The Exit LED will be ON when the switch is closed. Button Pushed.

Door Contact

tixE

Exit

0V

stupnI

t

Contact

c

atn

oC

0V

repmaT/USP

0V

Tamper

PSU

A NO switch may be tted so that it is held closed while

the door is shut.

The Contact LED will be ON when the switch is closed.

- Door Closed.

When connected, Net2 will check the door position during

access activity and will raise an Alarm in the event of a

'Door Forced' or 'Door left open' condition.

Tamper switch

tixE

Exit

0V

stupnI

t

Contact

c

atn

oC

0V

repmaT/USP

0V

Tamper

PSU

N.O.

N.C

COM

The ACU supplied in a plastic housing has a 'NO' tamper

switch tted and pre-wired into the circuit board.

The Tamper LED will be ON when the switch is closed.

Net2 will monitor the switch position and will raise an

Alarm in the event of a 'Tamper' condition.

tixE

Exit

0V

stupnI

t

Contact

c

atn

oC

0V

repmaT/USP

0V

Tamper

PSU

COM

N.O.

N.C.

PSU monitoring

The PSU LED will be ON when the NO Relay contacts are

closed. - Power OK.

The Net2 software will monitor the relay contacts and will

raise an Alarm in the event of a 'Power Fail' condition.

Page

8

Page 9

12V

rewoP

0V

12V Lock

kcoL

0V

0V

stuptuO

N.C.

yaleR

N.O.

COM

Break Glass tted

12V

rewoP

0V

12V Lock

kcoL

0V

0V

stuptuO

N.C.

yaleR

N.O.

COM

External Fire Door relay tted

N.O.

COM

Panic hardware

A break glass should be tted, in conjunction with a fail open

release to ensure a reliable egress method in the event of an

emergency. This is tted on the 12V supply wire to the lock and

drops the power ensuring that the lock opens.

The diagram shows how to include the break glass in the Net2

lock wiring circuit.

This wiring illustration shows the Relay output congured for the

Door lock function.

Fire Door Interface

A re alarm system must be used to release all re doors.

External relay contacts are held closed by the re alarm's interface

and will be dropped during an alarm condition. The system is fail

safe as the door will release even if the cable burns through.

This wiring illustration shows the Relay output congured for the

Door lock function.

Product compliance and limitations

To comply as a UL listed installation, the following conditions must apply:The power must be provided via a separate DC supply, a UL Listed Access Control (or Burglar Alarm) Class 2,

Power-Limited, power source capable of 4 hours standby must be employed. This is wired into the 0V and

12/24V terminals and the cable secured with the cable ties provided.

Wiring methods shall be in accordance with the National Electrical Code (ANSI/NFPA70), local codes, and the

authorities having jurisdiction.

Software features and functions have not been evaluated by UL.

Server based functions (Antipassback, Time and Attendance, etc) have not been evaluated by UL and cannot be used

for UL 294 installations.

The use of Wiegand readers and the conguration software has not been evaluated by 'UL'

Wiring: - Where an equivalent cable / wire is used it must be ' UL Listed '

All interconnecting devices must be UL Listed.

Exit buttons - A UL listed 'push to make' button must be used.

Door contact - A UL listed 'Normaly Open' (N.O.) switch must be used.

Tamper alarm - Connect to a UL listed burglar alarm unit for supervision.

Alarm sounder - Connections to this alarm output have not been evaluated by UL for burglar alarm use.

Break glass- A UL listed break glass must be used.

For CAN/ULC-S319 installations, terminals, leads and wiring methods must comply with CSA, C22.1, Canadian

electrical code, Part 1, safety standards for electrical installations.

The use of any add-on, expansion, memory or other module manufactured or supplied by the manufacturer's

representative will invalidate the CAN/ULC-S319 certication.

This device complies with Industry Canada licence-exempt RSS standard(s). Operation is subject to the following

two conditions: (1) this device may not cause interference, and (2) this device must accept any interference,

including interference that may cause undesired operation of the device.

Page9

Page 10

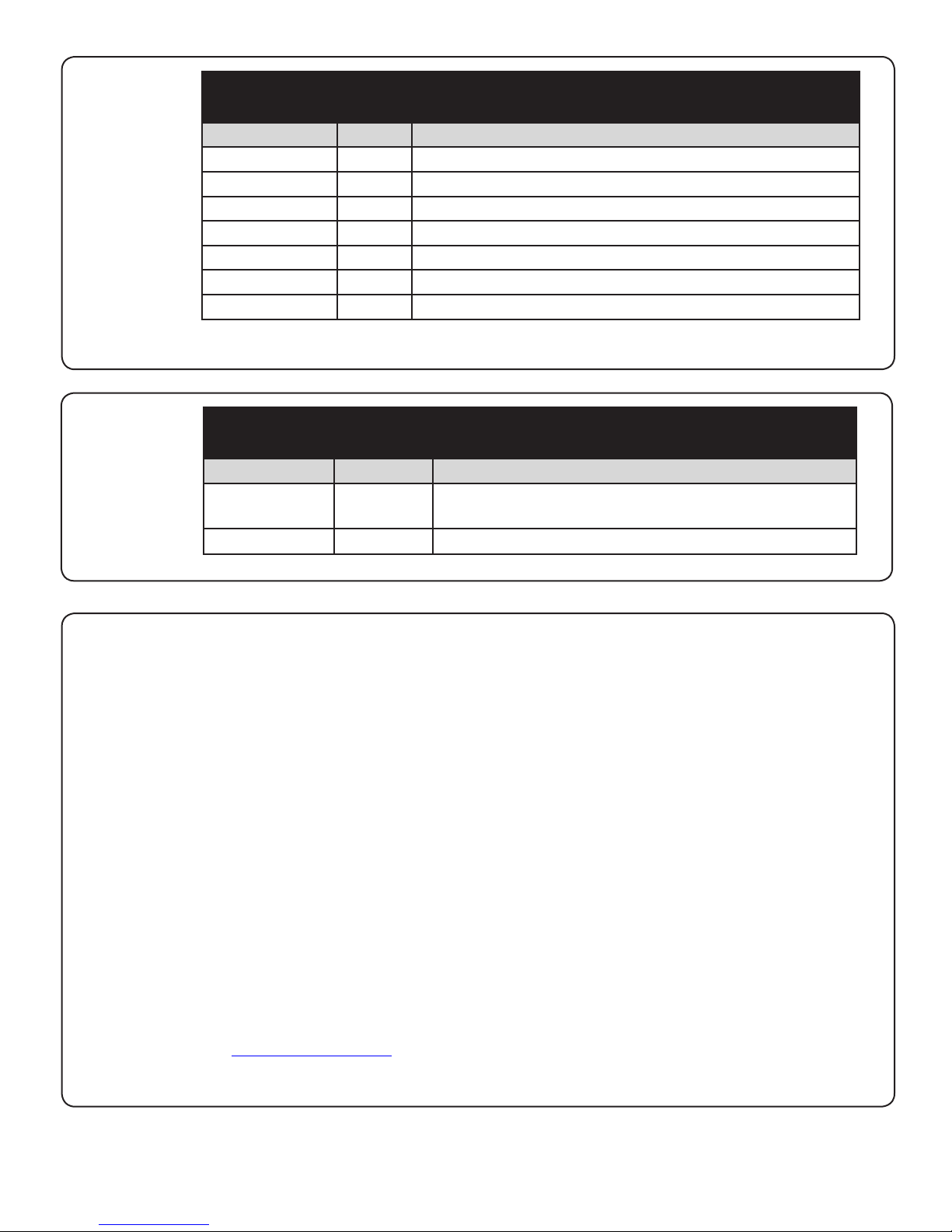

Features

Number of Cards

Number of PIN's

Access Levels

Time Zones

Maximum door open time

Number of Codes

Doors per ACU

Reader ports per ACU

Readers per port

Keypads per port

ACU's per Net2Air bridge - Recommended

Net2Air bridge (data lines) per system

Net2Air wireless range to ACU

Data retention after total power loss

Events stored in ACU with no server connection

Electrical

Input Voltage

Input Current

Relay switchable voltage

Relay switchable current

Dedicated lock output voltage

Dedicated lock output current

Alarm output voltage

Alarm output current

Reader port voltage

Reader port output current

Carrier frequency

Exit button voltage

Exit button current

Environment

Operating temperature - Battery limits

Humidity

Waterproof

Dimensions

Control Unit

Plastic Housing

Specications

Min

1 sec 99,999 sec

1 10

1 100

60 days

Min

120 mA 3 A

11.2V DC 12V DC

11.6V DC 12V DC

10.8V DC 12V DC

11.3V DC 12V DC

Min

0°C (32°F) 55°C (131°F)

85% - Relative humidity

Width

1

4

/8 in 3 1/4 in

7 in 7 in

Max

10,000

10,000

250

64

50

30 yds

3,584

Max

24V DC

2 A

1.1 A

1 A

500 mA

20 mA

Max

Height

1

1

2

2

12V DC

2.405 GHz

No

Depth

7

/8 in

5

/8 in

1

FCC Compliance

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and (2) this device must accept any interference received, including interference that

may cause undesired operation. Changes or modications not expressly approved by the party responsible for compliance could void the

user's authority to operate the equipment.

This equipment must not be co-located with any other transmitter and must be used at a distance in excess of 20cm to the user.

The party that incorporates this equipment into another host device is responsible for verication of the emissions produced by the nal

product and must adhere to the limits specied in FCC Part 15.

Furthermore, a label must be applied to the exterior of the nal product referring to this enclosed module, which states : "Contains

Transmitter Module FCC ID: USE654943" or "Contains FCC ID: USE654943".

Page

10

Loading...

Loading...