PAW SolexMidi TW, SolexMaxi TW, 6096465, 6095436 Installation And Operation Instruction Manual

Page 1

PAW GmbH & Co.KG

Installation and Operation Instructions

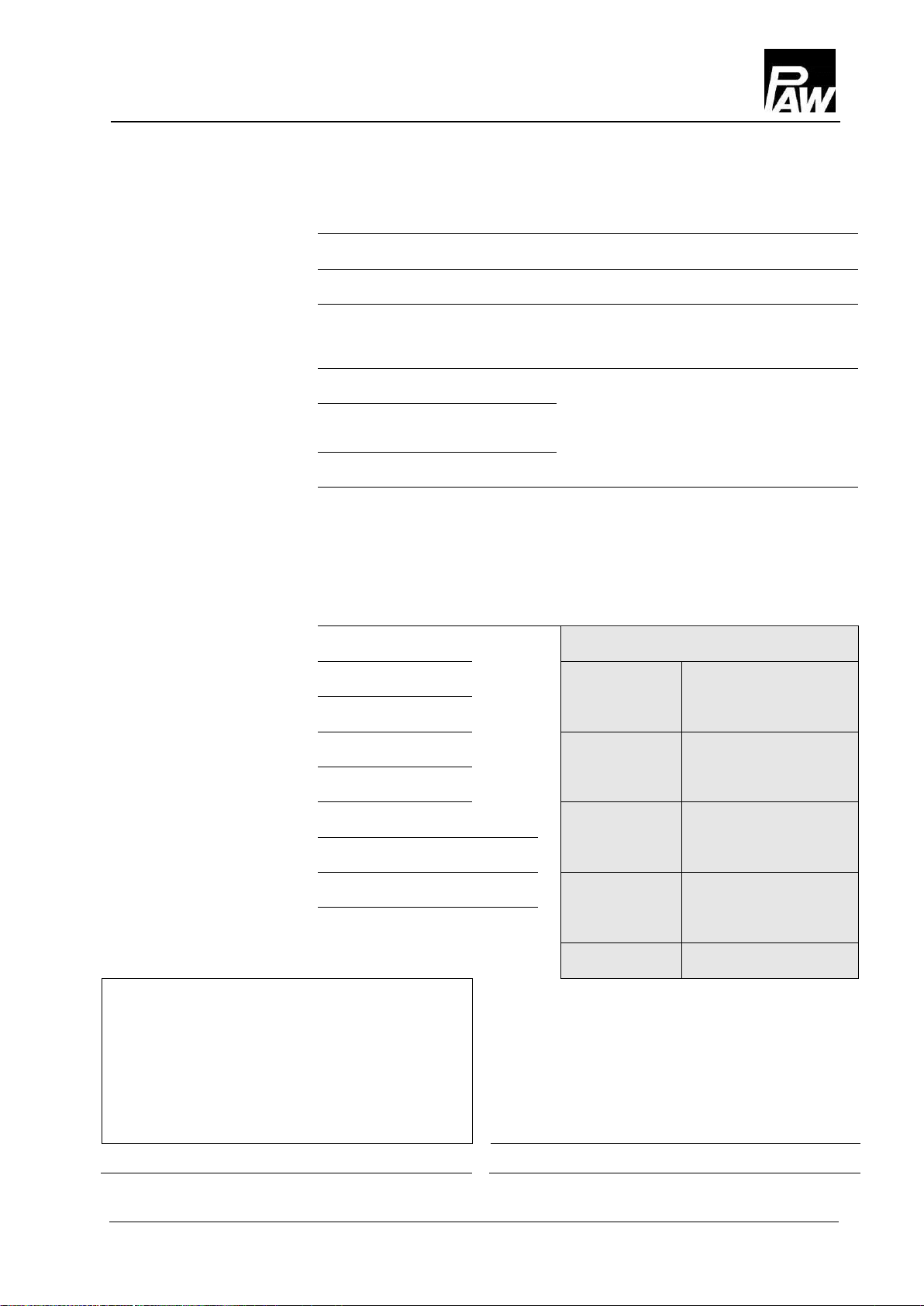

Transfer Stations:

SolexMidi TW - DN 20

SolexMaxi TW - DN 25

[hydraulics]

SolexMidi TW

SolexMaxi TW

Böcklerstr. 11, D-31789 Hameln, Germany

Phone: +49-5151-9856-0, Fax: +49-5151-9856-98

E-mail: info@paw.eu, Web: www.paw.eu

2017/05 99609x4x5-mub-en – V05 1

Page 2

1 General Information

Item no. 99609x4x5-mub-en – Version V05 – Issued 2017/05

Translation of the original instructions

We reserve the right to make technical changes without notice!

Printed in Germany – Copyright by PAW GmbH & Co. KG

PAW GmbH & Co.KG

Böcklerstraße 11

D-31789 Hameln, Germany

2 99609x4x5-mub-en – V05 2017/05

Page 3

1 General Information

Contents

s1 General Information ........................................................................................................... 4

1.1 About these instructions ............................................................................................... 4

1.2 About this product ........................................................................................................ 5

1.3 Designated use ............................................................................................................ 6

2 Safety instructions ............................................................................................................. 7

3 Assembly and installation [specialist] .................................................................................. 9

3.1 Controller connection ................................................................................................. 11

4 Commissioning [specialist] ............................................................................................... 12

4.1 Preparations before flushing and filling ....................................................................... 13

4.2 Flushing and filling the secondary circuit .................................................................... 13

4.3 Flushing and filling the solar circuit ............................................................................. 14

4.4 Parameters: SolexMidi / SolexMaxi with controller SC5.14......................................... 19

5 Maintenance [specialist] ................................................................................................... 20

5.1 Draining the solar station ............................................................................................ 21

5.2 Deinstallation.............................................................................................................. 21

6 Spare parts [specialist] ..................................................................................................... 22

6.1 Spare parts control and insulation SolexMidi TW (6095436) ...................................... 22

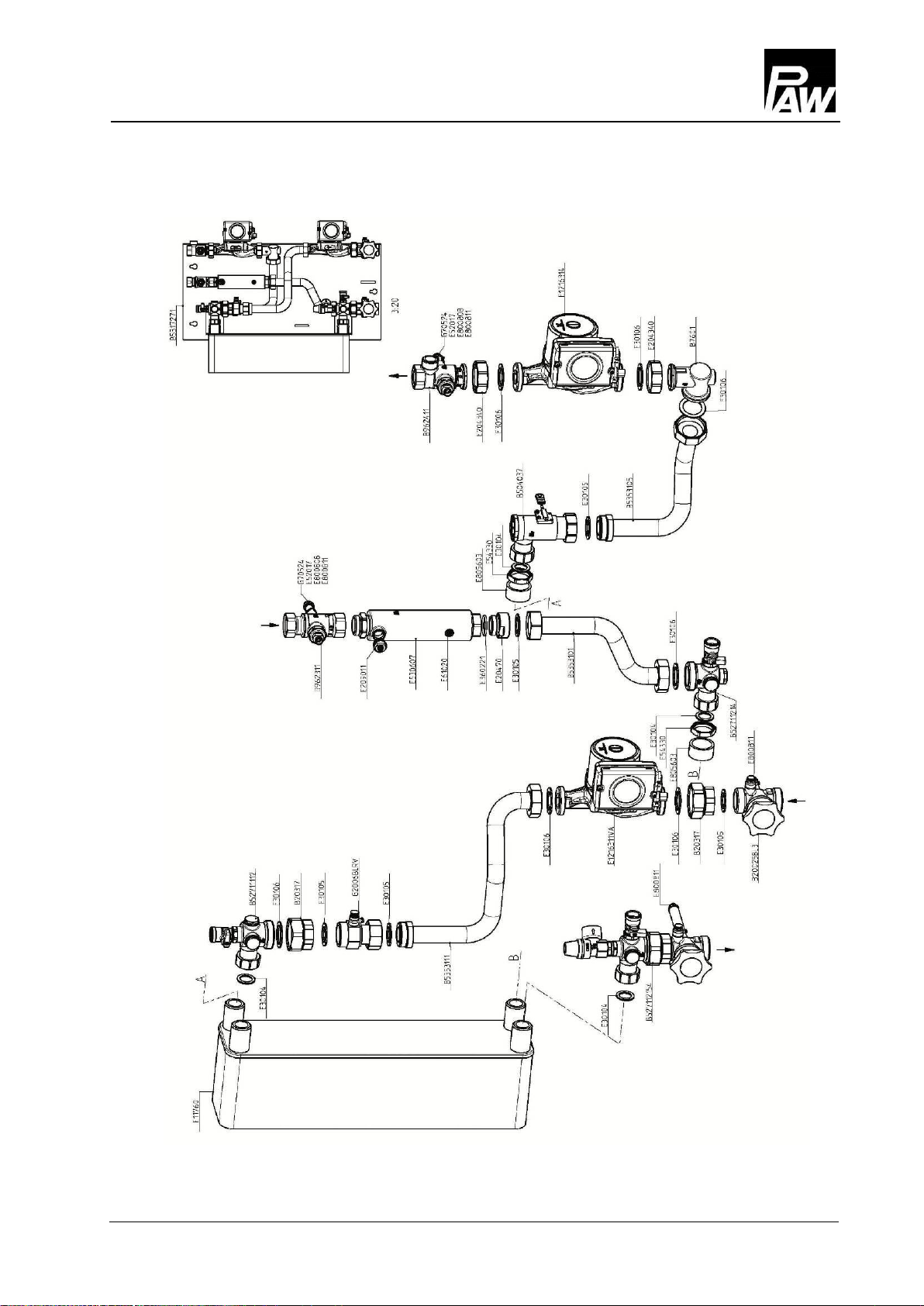

6.2 Spare parts hydraulics SolexMidi TW (6095436) ........................................................ 23

6.3 Spare parts control and insulation SolexMaxi TW (6096465) ..................................... 24

6.4 Spare parts hydraulics SolexMaxi TW (6096465) ....................................................... 25

7 Technical data ................................................................................................................. 26

7.1 Dimensional drawing SolexMidi TW ........................................................................... 27

7.2 Dimensional drawing SolexMaxi TW .......................................................................... 27

7.3 Pressure drop characteristics SolexMidi TW .............................................................. 28

7.4 Pressure drop characteristics SolexMaxi TW ............................................................. 28

8 Function of the check valves [Expert] ................................................................................ 29

9 Commissioning report ...................................................................................................... 31

2017/05 99609x4x5-mub-en – V05 3

Page 4

1 General Information

Carefully read these instructions before installation and commissioning.

Save these instructions in the vicinity of the installation for future reference.

DN 20

Item number

Controller

SC5.14

Flow rate

(maximum)

Collector surface

(maximum)

SolexMidi

TW

6095436

1200 l/h

50 m²

DN 25

Item number

Controller

SC5.14

Flow rate

(maximum)

Collector surface

(maximum)

SolexMaxi

TW

6096465

2000 l/h

100 m²

1 General Information

1.1 About these instructions

These instructions describe the functioning, installation, commissioning and operation of the

SolexMidi TW and SolexMaxi TW transfer stations for charging buffer tanks or domestic hot

water tanks. The chapters called [specialist] are intended for specialists only.

For other components of the solar installation, such as pumps, collectors, storage tanks or

expansion tanks, please observe the instructions of the corresponding manufacturer.

4 99609x4x5-mub-en – V05 2017/05

Page 5

1 General Information

1.2 About this product

The station is a premounted group of valves and fittings checked for leakage and used to

transfer the heat from the primary (solar circuit) to the secondary circuit (heating circuit or

domestic hot water circuit).

It contains a preset controller as well as important fittings for the operation of the system:

Ball valves in the primary circuit (flow and return)

Piston valves in the secondary circuit (flow and return)

Check valves to avoid involuntary gravity circulation in the flow and return of the solar

circuit, non return valve in the return of the secondary circuit

Pressure relief valves to prevent inadmissible overpressures in the station

Pressure gauge for displaying the installation pressure in the primary circuit

Vent valves to easily vent the primary circuit and the secondary circuit

Fill and drain valves with caps to flush, fill and drain the primary circuit

A flow meter (FlowRotor) and temperature sensors for heat quantity balancing (primary)

In the heating circuit, the installation must be equipped with a safety group, that can be ordered

separately.

The expansion tank required for operation must be adapted to the size and the requirements of

the installation and must be ordered separately.

The cap-type valve (DN 20: item no. 5302, DN 25: item no. 5301), which is also separately

available, allows the expansion tank to be easily mounted and separated from the solar thermal

system.

The wrapping materials are made of recyclable materials and can be disposed of with

recyclable materials.

2017/05 99609x4x5-mub-en – V05 5

Page 6

1 General Information

When the sun shines, the collectors can become very hot.

The solar fluid in the circuit can heat up to more than 100 °C.

Only flush and fill the solar circuit when the collector temperatures are

below 70 °C.

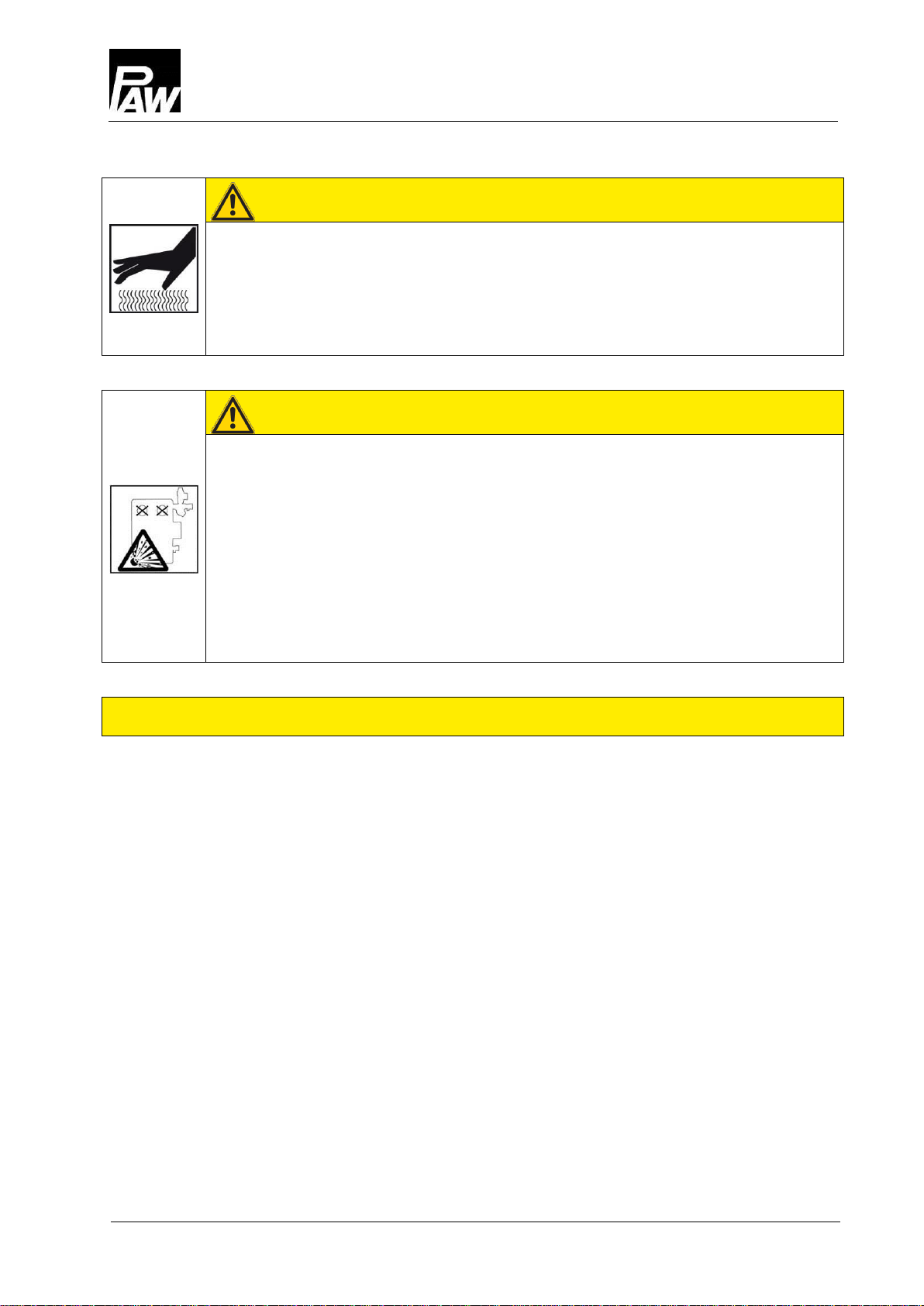

Schematic structure

SolexMidi / SolexMaxi

Scope of delivery

1.3 Designated use

The station may only be used as a transfer station between the solar and the domestic hot

water circuit or storage tank in solar thermal systems taking into consideration the technical limit

values indicated in these instructions. Due to its design the station must be mounted and

operated as described in these instructions!

Only use PAW accessories with the transfer station.

Improper usage excludes any liability claims.

6 99609x4x5-mub-en – V05 2017/05

Page 7

2 Safety instructions

WARNING

Danger of scalding due to vapour escape!

With pressure relief valves there is risk of scalding due to vapour escape.

During installation, check the local conditions and if a discharge line must be

connected to the safety group.

Observe the instructions regarding the pressure relief valve.

The pressures calculated by the installation planner for the expansion tank

and the operating pressure of the installation must be set.

WARNING

Personal injury due to polluted potable water!

The heating water contains harmful substances, that must not be washed into the

domestic hot water circuit.

If the station was used for charging a buffer tank there is still, after draining,

heating water in the valves and fittings and in the pump of the secondary circuit. It

can not be removed without residue.

The station must not be connected to a domestic hot water circuit.

2 Safety instructions

The installation and commissioning as well as the connection of electrical components require

technical knowledge commensurate with a recognised vocational qualification as a fitter for

plumbing, heating and air conditioning technology, or a profession requiring a comparable level

of knowledge [specialist]. The following must be observed during installation and

commissioning:

Relevant local and national regulations

Accident prevention regulations of the professional association

Instructions and safety instructions mentioned in this manual

2017/05 99609x4x5-mub-en – V05 7

Page 8

2 Safety instructions

CAUTION

Risk of burns!

The valves and fittings and the pumps can become heated up to more than

100 °C during operation.

The shell must remain closed during operation.

CAUTION

Personal injury and damage to property due to overpressure!

By closing the two ball valves in the primary circuit you isolate the pressure relief

valve from the heat exchanger. A rise in temperature in the storage tank will

cause high pressures and could result in personal injury or damage to property!

Only close the ball valves for service and maintenance.

If you close the ball valves in case of servicing, do also put the pumps out

of operation and close the ball valves in the secondary circuit.

NOTICE

Material damage due to mineral oils!

Mineral oil products cause lasting damage to seals made of EPDM, whereby the sealant

properties are lost. We do not assume liability nor provide warranty for damage to property

resulting from sealants damaged in this way.

It is imperative to avoid that EPDM gets in contact with substances containing mineral

oils.

Use a silicone- or polyalkylene-based lubricant free of mineral oil such as Unisilikon

L250L and Syntheso Glep 1 from Klüber or a silicone spray.

8 99609x4x5-mub-en – V05 2017/05

Page 9

3 Assembly and installation [specialist]

NOTICE

Material damage due to high temperatures!

Install the fitting group at a sufficient distance from the collector field, since the solar fluid may

be very hot near the collector.

It may be necessary to install an intermediate tank in order to protect the expansion tank.

1. You can use a drilling template in order to facilitate the

installation, which you can find on the station.

2. Copy the mounting holes to the mounting surface.

3. Drill the holes and insert appropriate wall plugs into the

holes.

4. Screw in the screws and let them stick about 4 cm out of

the wall.

5. Remove the station from the packaging.

6. Remove the insulating front shell. Hang the module onto

the screws and tighten the screws.

WARNING

Personal injury due to polluted potable water!

The heating water contains harmful substances, that must not be washed into the

domestic hot water circuit.

If the station was used for charging a buffer tank there is still, after draining,

heating water in the valves and fittings and in the pump of the secondary circuit. It

can not be removed without residue.

The station must not be connected to a domestic hot water circuit.

3 Assembly and installation [specialist]

The location of installation must be dry, load-carrying, frost-proof and protected against

ultraviolet radiation to prevent material damage to the installation. Furthermore, the access to

the control and safety equipment must be guaranteed at all time during operation!

The discharge line of the safety equipment should be guided into a heat-resistant container with

corresponding size. This allows you to avoid uncontrolled discharging into the environment and

to easily refill the circuits!

2017/05 99609x4x5-mub-en – V05 9

Page 10

3 Assembly and installation [specialist]

7. Connect the transfer station to the system:

① Solar flow from the collector

② Solar return to the collector

③ Flow to the storage tank

④ Return from the storage tank

The screw connections in the primary circuit of the

SolexMidi have ¾" internal threads and in the secondary

circuit 1" external threads.

The screw connections in the primary circuit of the

SolexMaxi have 1" internal threads and in the secondary

circuit 1¼" external threads.

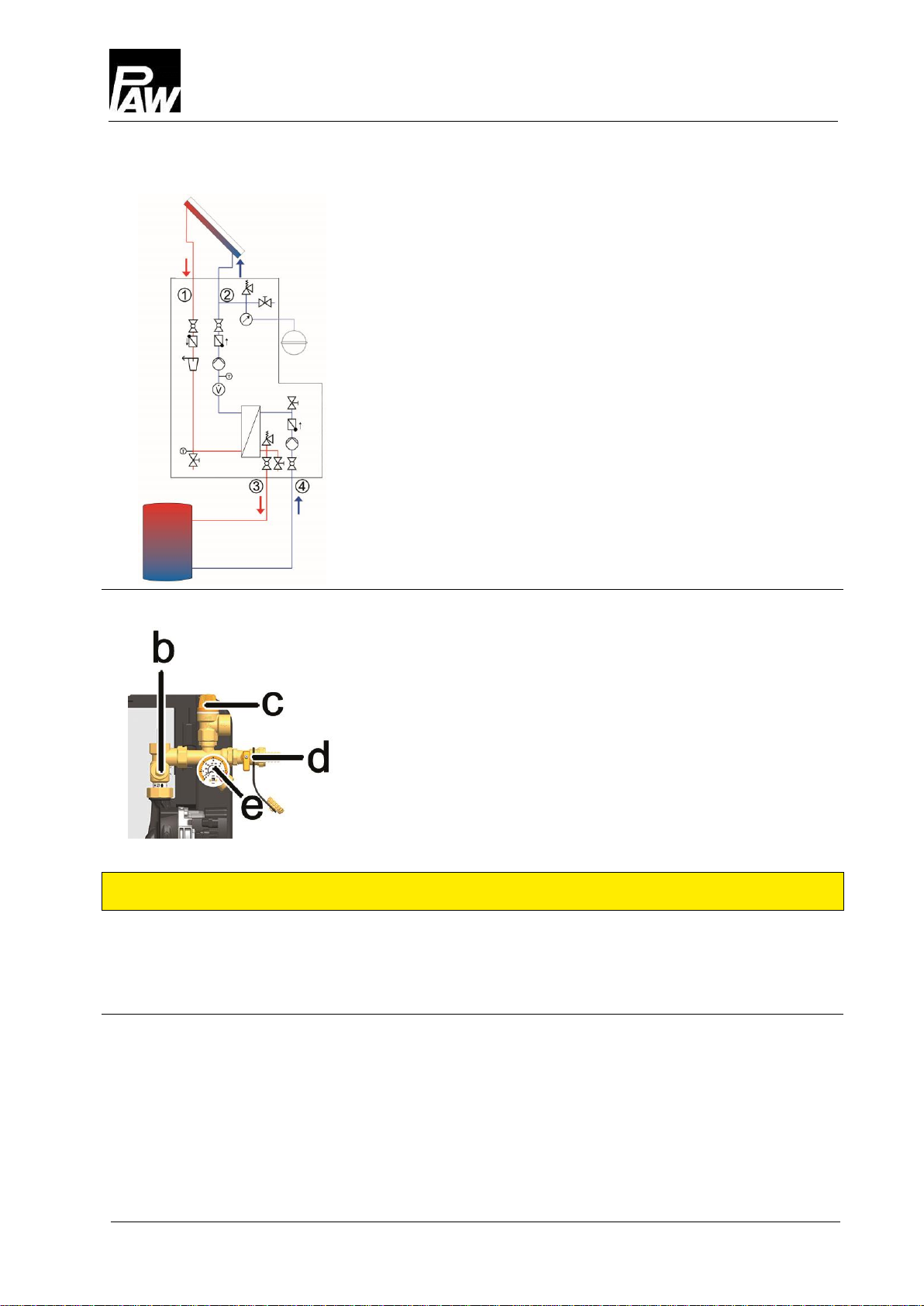

8. Mount the safety group, consisting of the pressure relief

valve [c], the fill valve [d] and the manometer [e] to the

connection of the return ball valve [b].

9. Connect the pipe for the expansion tank below the

pressure gauge and fix the bracket for the expansion

tank.

During servicing at the expansion tank, we recommend

the installation of a cap valve (DN 20: item no. 5302,

DN 25: item no. 5301) on the expansion tank.

NOTICE

Note regarding the expansion tank

The expansion tank must not be connected while flushing and filling in order to avoid that dirt

particles are washed in.

10. Pressurise the expansion tank as specified by the

manufacturer and connect the expansion tank.

Observe the separate instructions regarding the

expansion tank!

11. Check all screw connections and tighten them if

necessary.

10 99609x4x5-mub-en – V05 2017/05

Page 11

3 Assembly and installation [specialist]

WARNING

Risk to life and limb due to electric shock!

Prior to commencing electrical work on the controller, pull the mains plug!

Only after completing all installation work, plug the mains plug of the

controller into a socket.

This avoids an unintentional start of the motors.

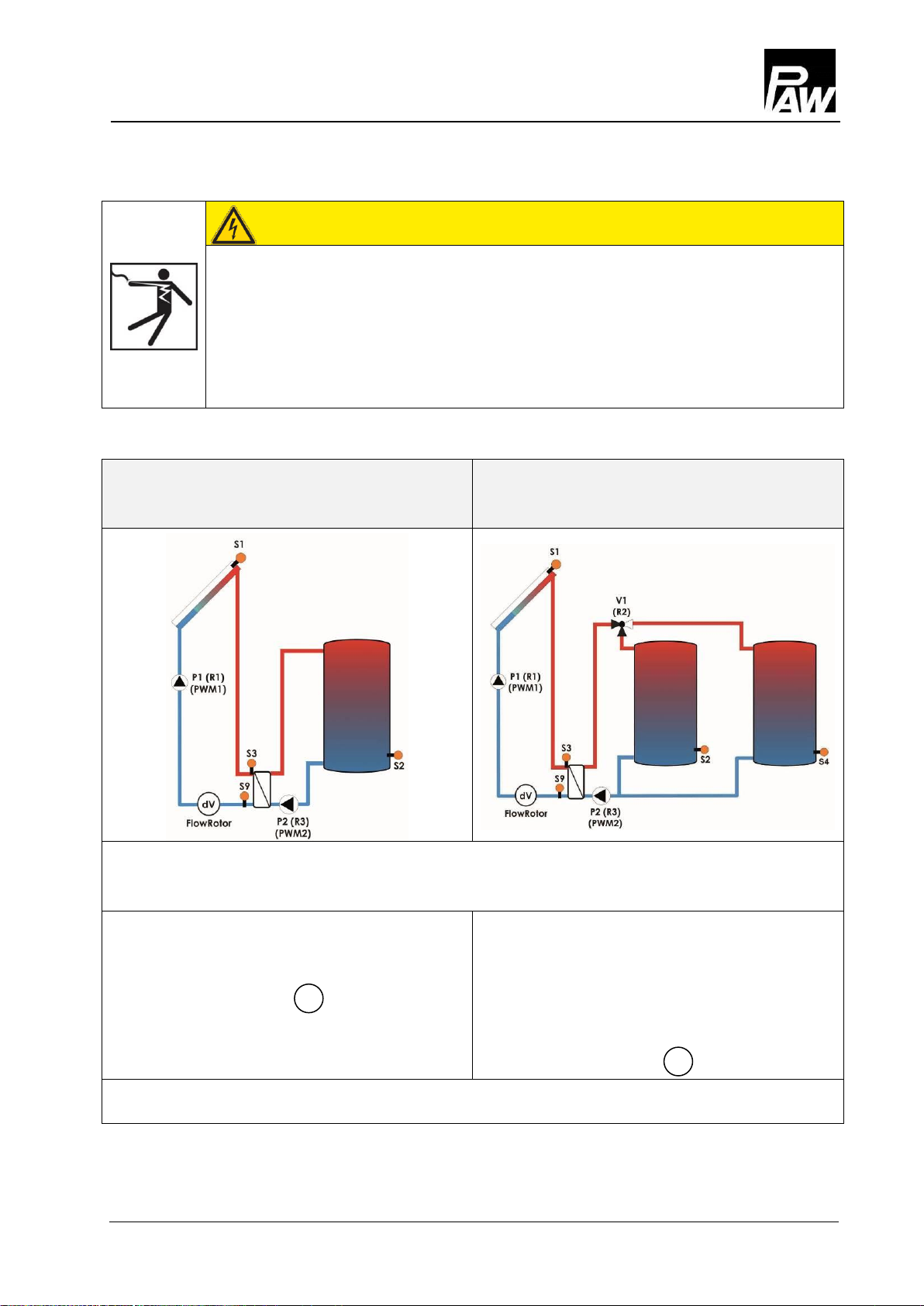

Wiring plan (881) for domestic hot water

systems and heating systems

Wiring plan (882)

for heating systems

Observe the separate instructions regarding the controller SC5.14!

1. Connect the temperature sensors to the controller:

Collector sensor S1

Storage tank bottom: S2

Integrated: S3, S9, (FlowRotor)

Collector sensor S1

Storage tank 1, bottom: S2

Storage tank 2 bottom: S4

(addit. required, item no. E13180)

Integrated: S3, S9, (FlowRotor)

2. Tighten all union nuts and screw connections.

The assembly of the transfer station is now completed and

you can put the station into operation.

dV

dV

3.1 Controller connection

Wiring plan SolexMidi / SolexMaxi

2017/05 99609x4x5-mub-en – V05 11

Page 12

4 Commissioning [specialist]

WARNING

Risk of burns and scalding!

The fittings can heat up to more than 100 °C. Therefore, do not clean or fill the

system with the collectors heated (intense sunshine). Please note that hot solar

fluid can leak from the pressure relief valve when the system pressure is too high!

During venting the solar fluid may escape as vapour and cause scalding!

Only flush and fill the system when the collector temperatures are below

70 °C.

NOTICE

Risk of frost!

It often happens that the solar thermal system cannot be completely drained after flushing.

Thus, there is risk of frost damage when flushing with water. Therefore, do only use the solar

fluid used later to flush and fill the solar installation.

Use a water and propylene glycol mixture with max. 50% of propylene glycol as a solar

fluid.

NOTICE

Note regarding the commissioning

Flush and fill in the following order:

1. Flush the storage tank (to remove scale residues).

2. Fill the secondary circuit.

3. Vent the heat exchanger by means of the pressure relief valve.

4. Flush and fill the solar circuit of the heat exchanger.

5. Flush and fill the collector field.

6. Flush and fill the entire solar circuit.

This guarantees that the dirt particles are not flushed into the heat exchanger or the FlowRotor

and that eventually absorbed heat can be dissipated.

4 Commissioning [specialist]

Observe the following safety instructions regarding the commissioning of the module:

12 99609x4x5-mub-en – V05 2017/05

Page 13

4 Commissioning [specialist]

NOTICE

Note regarding the expansion tank

To prevent that the dirt particles in the solar thermal system are flushed into the expansion

tank, some manufacturers recommend to disconnect the expansion tank from the solar circuit

before flushing and filling. Please observe the instructions of the manufacturer.

Secondary circuit

1. Open the piston valves [C|D].

2. Vent the secondary circuit by operating the fill

and drain valve [A].

Make sure that the electrical components do not

get wet.

3. Fill the secondary circuit by means of the valves

at the domestic hot water tank or at the heating

system.

4. During operation, vent the station at the fill and

drain valve [A] to eliminate air still present in the

heat exchanger.

4.1 Preparations before flushing and filling

4.2 Flushing and filling the secondary circuit

Depending on the application (charging of a storage tank/charging of a buffer tank), the

secondary circuit is filled by means of the valves at the tank or by means of the valves at the

heating system. Make sure that in the first case above only potable water must be used.

In the second case only treated heating water according to VDI 2035 / Ö-Norm H5195-1 must be

used. To avoid that dirt particles are washed into the heat exchanger, shut the ball valves of the

module and wash out the present dirt particles/scale residues before commissioning the tank.

2017/05 99609x4x5-mub-en – V05 13

Page 14

4 Commissioning [specialist]

0°

45°

90°

Check valve is operating,

flow only in flow direction.

Check valve is not operating,

flow in both directions.

Ball valve closed,

no flow.

4.3 Flushing and filling the solar circuit

The fill and drain valves required to flush and fill are integrated in the transfer station.

Make sure not to wash dirt particles that may be present in the system into the heat exchanger

and the expansion tank. Disconnect the expansion tank from the solar circuit during flushing

and filling, if necessary, and only use flush and fill stations with fine filters.

The solar circuit is flushed in the direction of flow. Make sure that the pump in the solar circuit

cannot be switched on.

Ball valve with integrated flow check valve

(normal flow direction in the figure below: downwards)

14 99609x4x5-mub-en – V05 2017/05

Page 15

4 Commissioning [specialist]

The Airstop with manual vent valve is used to vent the solar

installation. To ensure a perfect ventilation of the solar circuit,

the flow velocity must be at least 0.3 m/s in the flow line.

Pipe diameter [mm]

Flow rate at 0.3 m/s

∅ outside

∅ inside

l/h

l/min

15

13

~ 143

~ 2.4

18

16

~ 217

~ 3.6

22

20

~ 339

~ 5.7

28

25

~ 530

~ 8.8

WARNING

Danger of scalding due to vapour escape!

The escaping fluid can have a temperature of more than 100 °C and cause

scalding.

Carefully open the vent plug and close it again, as soon as medium

escapes.

j

Airstop

The air separated from the solar fluid is collected in the upper part of the Airstop and can be

released at the vent plug [j].

Venting the solar thermal system after commissioning

At the beginning, vent the solar installation daily and then weekly or monthly,

depending on the vented air quantity. Thus, an optimum operation of the solar

installation is ensured. Check the system pressure after venting and increase it to the

specified operating pressure, if necessary.

2017/05 99609x4x5-mub-en – V05 15

Page 16

4 Commissioning [specialist]

Primary circuit

1. Switch off the pump in the solar circuit.

2. Disconnect the expansion tank from the solar

installation. This avoids the access of dirt

particles present in the pipes to the expansion

tank. Observe the separate instructions

regarding the expansion tank!

3. The return ball valve [b] must be closed

(90° position, see page 14).

4. Connect the flush and fill station:

- Pressure hose to the fill valve [d]

- Flush hose to the drain valve [g].

5. Open the fill and drain valves [d|g] and put the

flush and fill station into operation.

6. Slowly open and close the return ball valve [b]

during flushing in order to vent the pump section.

7. Flush the solar circuit until the solar fluid exits

without bubbles (see page 15).

8. Close the drain valve [g] with the filling pump

running and increase the system pressure to

about 5 bars. The system pressure can be read

on the pressure gauge [e].

9. Close the fill valve [d] and switch off the pump of

the flush and fill station.

10. Check the pressure gauge to see whether the

system pressure reduces and eliminate leaks

where necessary.

Observe the pressure (max. 6 bars)!

16 99609x4x5-mub-en – V05 2017/05

Page 17

4 Commissioning [specialist]

11. Reduce the pressure on the drain valve [g] to the

operating pressure.

12. Connect the expansion tank to the solar circuit

and set the operating pressure of the solar

thermal system by means of the flush and fill

station (for the required operating pressure, see

instructions of the expansion tank).

13. Close the fill and drain valves [d|g].

14. Put the ball valve [b] into 0° position

(see page 14).

WARNING

Risk to life and limb due to electric shock!

Check if the sensors and the pumps are properly connected to the

controller and if the controller housing is closed.

Only then should the mains plug of the controller be plugged into a socket.

SC5.14

15. Connect the controller to the mains and set the

solar circuit pump in the manual mode to ON

according to the controller instructions.

16. Let the solar pump run at maximum rotation speed

for at least 15 minutes.

Meanwhile vent the solar installation several times

at the vent plug [j] of the Airstop until the solar

fluid exits without bubbles (see page 14).

17. If necessary, increase the system pressure to the

operating pressure.

2017/05 99609x4x5-mub-en – V05 17

Page 18

4 Commissioning [specialist]

18. Remove the hoses of the flush and fill station and

screw the sealing caps onto the fill and drain

valves.

The sealing caps only serve to protect the valves

against dirt. They are not designed to take up high

system pressures. The ball valves must be closed.

19. Mount the insulating front shell.

20. Set to automatic mode on the controller (see

controller instructions).

The commissioning of the solar installation is now

completed.

Please fill in completely the commissioning report

on page 31.

18 99609x4x5-mub-en – V05 2017/05

Page 19

4 Commissioning [specialist]

Preset system (scheme 881) SolexMidi / SolexMaxi

4.4 Parameters: SolexMidi / SolexMaxi with controller SC5.14

The parameters for the sensors and pumps are preset in the controller. If you select and save

another system, the parameters are reset to the factory setting. In this case you need to set the

following parameters in the menu. In this way you make sure that the installation will work

properly. You can find a detailed description for the operation of the controller in the separate

controller manual.

2017/05 99609x4x5-mub-en – V05 19

Page 20

5 Maintenance [specialist]

WARNING

Risk of burns and scalding!

The valves, fittings and solar fluid can reach temperatures of more than 100 °C.

The solar fluid can escape as vapor and cause scalding.

Only carry out maintenance work when the collector temperatures are

below 50 °C.

Wait until the solar fluid has cooled down to max. 50 °C.

Example: SolexMidi

1. Close the ball valves [a|b] and exit the solar fluid at

the fill and drain valve [g]. Make sure that the solar

fluid is collected in a heat-resistant container.

2. Change the faulty part against the new part.

3. Fill the solar circuit as described in 4.3 Flushing and

filling the solar circuit (see page 14).

5 Maintenance [specialist]

Make sure that the system is not under pressure during service and maintenance works at the

station.

20 99609x4x5-mub-en – V05 2017/05

Page 21

5 Maintenance [specialist]

1. Switch off the controller and make sure that a

restart is not possible.

2. Open the check valves in the flow and return ball

valve [a|b], by turning them to position 45°

(see page 14).

3. Connect a heat-resistant hose to the fill valve [g]

of the transfer station.

Make sure that the solar fluid is collected in a

heat-resistant container.

WARNING

Danger of scalding due to hot solar fluid!

The escaping fluid may be very hot.

Place the collecting container so that people standing nearby are not

endangered when the solar installation is being emptied.

4. Open the fill and drain valve [g] of the transfer station.

5. To accelerate draining of the solar circuit, you can open the vent valve,

if present, at the highest point of the solar thermal system.

6. Dispose of the solar fluid observing the local regulations.

5.2 Deinstallation

1. Drain the solar thermal installation as described above.

2. Disconnect the pipe joints with the solar thermal system.

3. Disconnect the cable connections between controllers and sensors

(collector/storage tank).

4. Loosen the fastening screws of the station and take the station off the wall.

5.1 Draining the solar station

2017/05 99609x4x5-mub-en – V05 21

Page 22

6 Spare parts [specialist]

NOTICE

Complaints and requests/orders of spare parts will only be processed with information on the

serial number!

The serial number can be found in the lower right corner of the support sheet in the station.

In case of a complaint, please send us the completely filled commissioning report on

page 31.

6 Spare parts [specialist]

6.1 Spare parts control and insulation SolexMidi TW (6095436)

22 99609x4x5-mub-en – V05 2017/05

Page 23

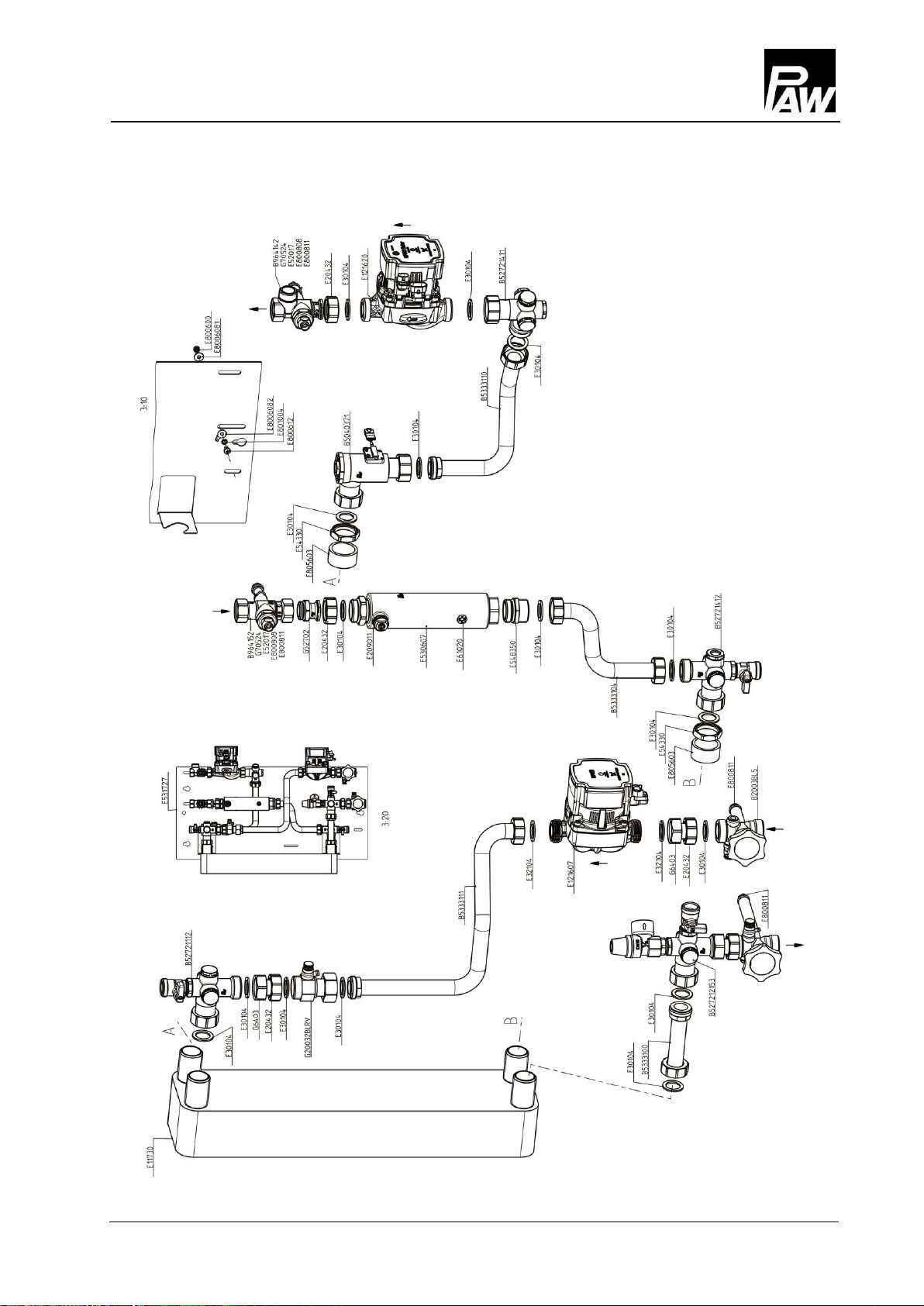

6 Spare parts [specialist]

6.2 Spare parts hydraulics SolexMidi TW (6095436)

2017/05 99609x4x5-mub-en – V05 23

Page 24

6 Spare parts [specialist]

6.3 Spare parts control and insulation SolexMaxi TW (6096465)

24 99609x4x5-mub-en – V05 2017/05

Page 25

6 Spare parts [specialist]

6.4 Spare parts hydraulics SolexMaxi TW (6096465)

2017/05 99609x4x5-mub-en – V05 25

Page 26

7 Technical data

Dimensions

SolexMidi TW

SolexMaxi TW

Height (total)

795 mm

829 mm

Width (total)

674 mm

674 mm

Depth (total)

298 mm

298 mm

Centre distance, flow/return

120 mm

120 mm

Pipe connections primary

¾" internal thread

1" internal thread

Pipe connections secondary

1" external thread

1¼" external thread

Connection for expansion tank

¾" external thread, flat sealing

Outlet pressure relief valve

¾" internal thread

Operating data

Max. admissible pressure

prim.: 6 bars / sec.: 10 bars

Max. Operating temperature

prim.: 120 °C / sec.: 95 °C

Max. stagnation temperature

140 °C

Max. propylene glycol content

50 %

Operating temperature sensors

-25 °C to +120 °C

Equipment

Pressure relief valve

prim.: 6 bars / sec.: 10 bars

Pressure gauge

0 – 6 bars

Flow rate measurement device

prim.: FlowRotor: 2-50 l/min

Sensors

2 x Pt1000 (mounted), 2 x Pt1000 (enclosed)

Check valves

(integrated in the ball valves)

prim.: 2 x 200 mm wc, can be opened

sec.: 1 x 150 mm wc, can be opened

Material

Valves and fittings

Brass

Gaskets

EPDM

Check valves

Brass

Insulation

EPP, = 0,041 W/(m K)

7 Technical data

26 99609x4x5-mub-en – V05 2017/05

Page 27

7 Technical data

7.1 Dimensional drawing SolexMidi TW

7.2 Dimensional drawing SolexMaxi TW

2017/05 99609x4x5-mub-en – V05 27

Page 28

7 Technical data

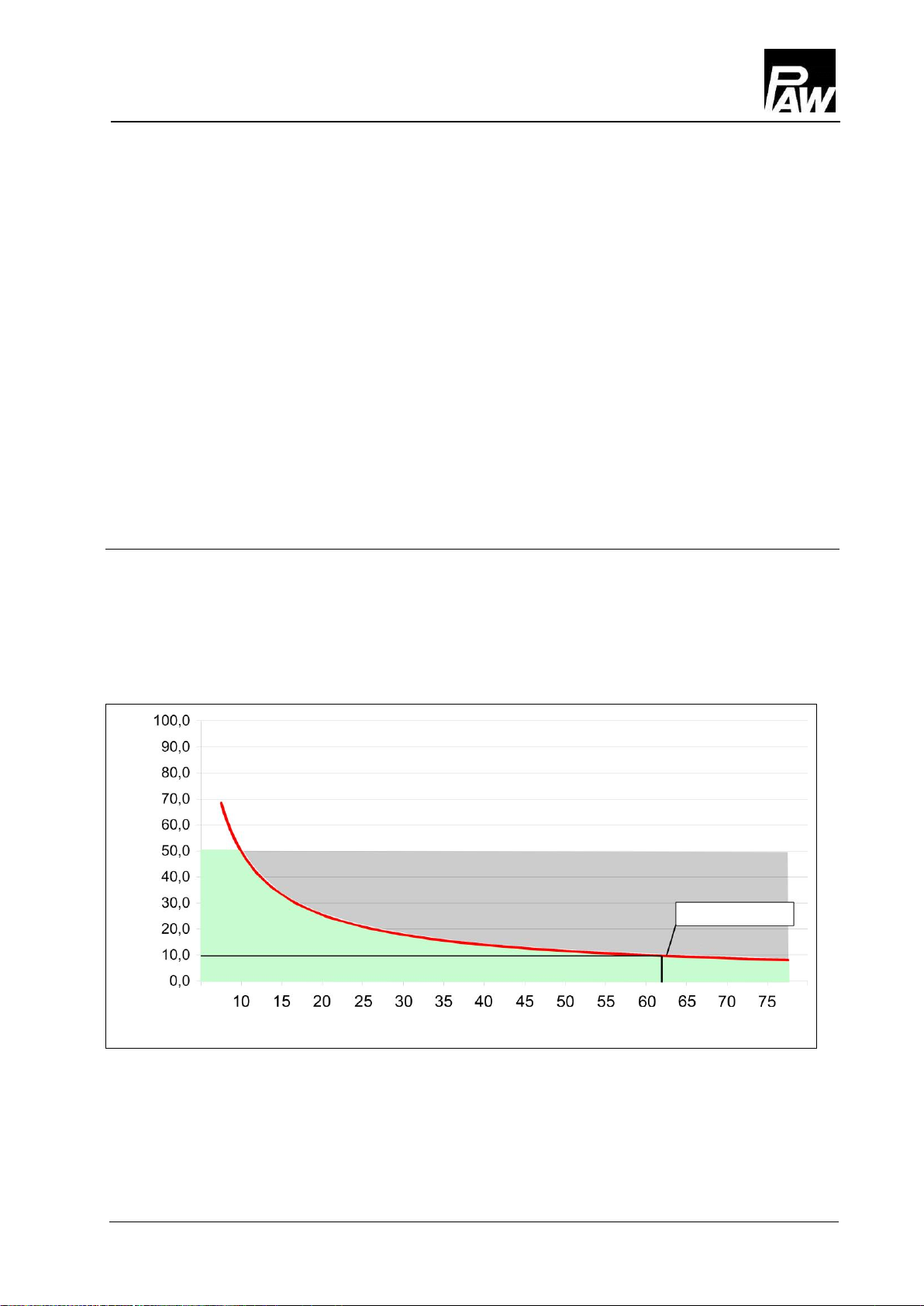

Pressure [mWC]

Pressure [kPa]

Flow rate [m³/h]

Pressure [mWC]

Pres

sure [kPa]

Flow rate [m³/h]

7.3 Pressure drop characteristics SolexMidi TW

7.4 Pressure drop characteristics SolexMaxi TW

28 99609x4x5-mub-en – V05 2017/05

Page 29

8 Function of the check valves [Expert]

Within their application range, the check valves in this station prevent unwanted gravity

circulation. The efficiency of the check valves depends on:

the installation height

the temperature difference between the storage tank and the collector

the type of heat transfer medium

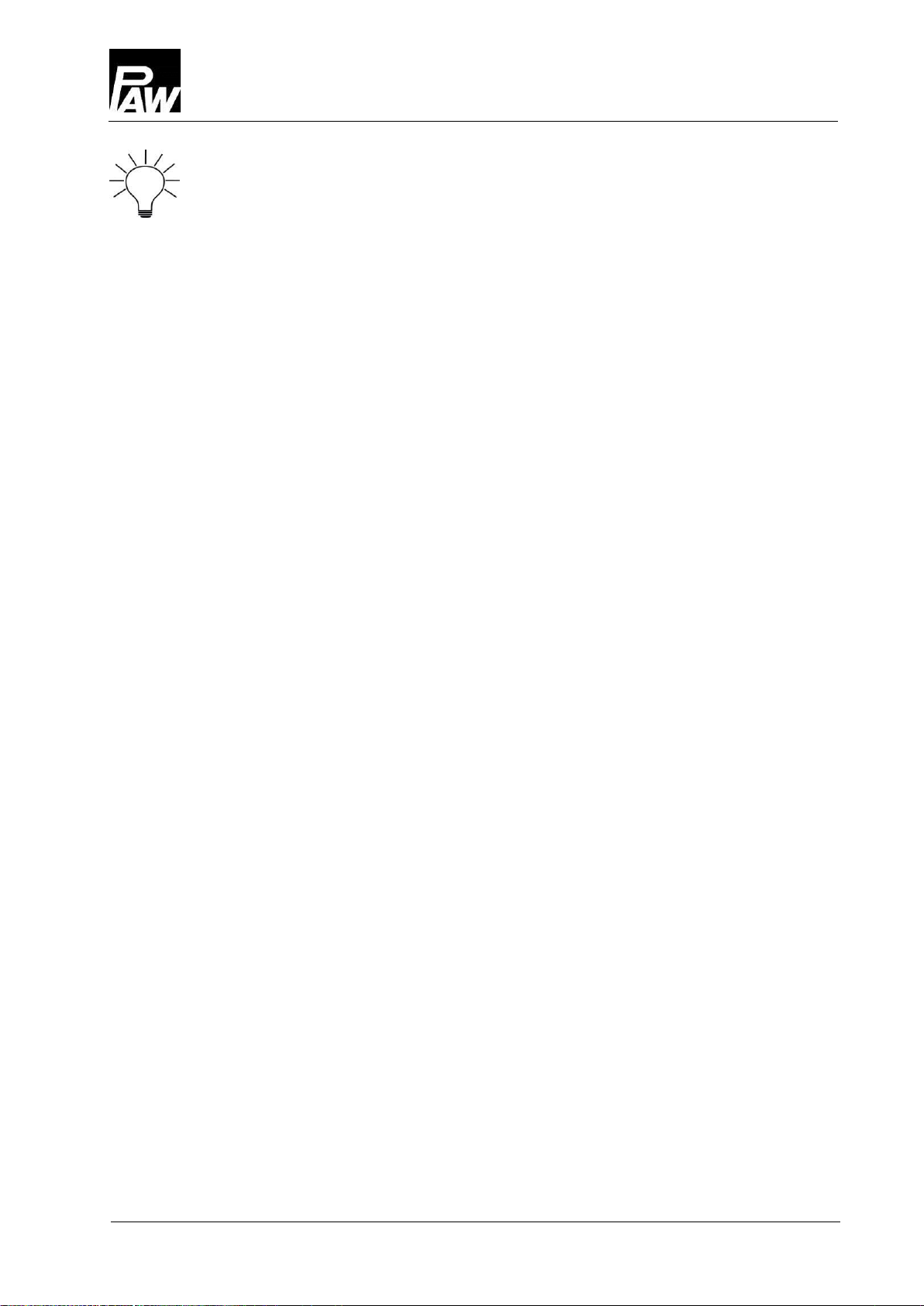

In the diagram below you can see whether the check valves integrated in the station are

sufficient. If the check valves are not sufficient, you need to install additional components to

prevent gravity circulation. You can mount components such as syphons ("heat traps"), 2-way

valves (zone valves) or additional check valves.

Example:

The station comprises two check valves (2 x 200 mm wc = 400 mm wc).

You use a mixture of water and 40% of propylene glycol as a solar fluid.

The installation height between the collector and the storage tank is 10 m.

Installation height in m

Temperature difference storage tank/collector in K

Result:

The check valves prevent gravity circulation up to a temperature difference of about 62 K. If the

temperature difference between the collector and the tank is larger, the difference in density of

the solar fluid will be so large, that the check valves are pushed open.

Circulation

Solar fluid

8 Function of the check valves [Expert]

2017/05 99609x4x5-mub-en – V05 29

Page 30

8 Function of the check valves [Expert]

Do you need to know it exactly?

The density of the solar fluid decreases with rising temperature. In high installations with large

temperature differences, the difference in density will cause gravity circulation. This circulation

can cool down the storage tank.

Calculation example: Δp = Δρ * g * h

collector temperature: 5 °C density solar fluid ρ1 = 1042 kg/m³

tank temperature: 67 °C density solar fluid ρ2 = 1002.5 kg/m³

Δρ = ρ1 - ρ2 = 39,5 kg/m³

g = 9,81 m/s²

Installation height h = 10 m

Δp = 3875 Pa = 395 mm wc

The two check valves in the station (2 x 200 mm wc) are sufficient for an installation height of

10 m and a temperature difference between the collector and the tank of up to 62 K.

30 99609x4x5-mub-en – V05 2017/05

Page 31

9 Commissioning report

Installation operator

Location of installation

Collectors

(number / type)

Collector surface

m²

Installation height

m

(Difference in height between

station and collector field)

Pipes

⌀ = mm

l =

m

Venting (collector field)

Not existent

Vented

Manual vent valve

Automatic deaerator

Airstop (station)

Vented

Solar fluid (type)

% glycol

Antifreeze (tested up to):

°C

Se ri a l nu mb er s

Flow rate l/m

Station

Pump (type)

Flow rate sensor

System pressure

mbars

Temperature

sensor

Expansion tank (type)

Initial pressure

mbars

Controller

Pressure relief valve

Checked

Check valves

Checked

Software version

Plumbing company

Date, signature

9 Commissioning report

2017/05 99609x4x5-mub-en – V05 31

Page 32

PAW GmbH & Co. KG

Böcklerstraße 11

D-31789 Hameln, Germany

www.paw.eu

Phone: +49 (0) 5151 9856 - 0

Fax: +49 (0) 5151 9856 - 98

32 99609x4x5-mub-en – V05 2017/05

Loading...

Loading...