Pavone Sistemi

pesatura elettronica industriale

Rev. 201301

TECHNICAL MANUAL

MC 353 Flow Rate Controller for belt weigher

Software version 1.9

Pag. 2

MC 353 software 1.9

ENG

SYMBOLS

Following are the symbols used throughout the manual to call reader’s attention:

Further details.

Warning! Electric shock risk

Warning! This operation shall be carried out by qualified staff.

Pay special attention to the following points.

WARNINGS

This manual provides texts and pictures to inform the operator about all prescriptions and criteria necessary for installing and using this instrument.

The equipment shall be installed only by qualified personnel that must have read this manual. With

the expression “qualified personnel” is meant the personnel that has been trained and thus expressly

authorised to carry out the installation by the person in charge for the system safety.

Power the instrument with a voltage value within the limits specified in the features.

The user must make sure that the installation is carried out in compliance with the relevant rules in force.

Please contact the nearest Assistance Centre for every fault you find. Any attempt of disassembly or

change that has not been previously authorised will null and void the warranty and will release the

Manufacturer from any responsibility.

The purchased instrument has been designed and produced to be used in the weighing and metering

processes thus any improper use will release the Manufacturer from any responsibility.

Pag. 3

MC 353 software 1.9

ENG

Table of conTenTs

SYMBOLS ..................................................................................................... 2

WARNINGS .................................................................................................. 2

CE DECLARATION OF CONFORMITY - ............................................................ 5

1 - INTRODUCTION ....................................................................................... 6

1.1 - OTHER FUNCTIONS OF MC353 ............................................................. 8

1.2 - TECHNICAL FEATURES ........................................................................... 9

2 - MC353 INSTALLATION ............................................................................ 12

2.1 - INSTALLATION WARNINGS AND INDICATIONS .................................... 12

2.2 - INSTRUCTIONS FOR A CORRECT INSTALLATION ................................... 13

2.3 - ELECTRIC CONNECTIONS ................................................................... 14

3 - MC353 STRUCTURE AND PARAMETERS ................................................... 25

3.1 - PARAMETERING GENERAL FEATURES .................................................... 25

3.2 - MC353 DISPLAYS ................................................................................ 27

3.3 - SET-UP MENU LEVELS ........................................................................... 31

3.4 - PARAMETERS TABLES ............................................................................ 33

3.5 - LIST OF PARAMETERS TO BE SET ........................................................... 36

3.6 - LIST OF PARAMETERS PRIOR TO COMMISSIONING ............................... 42

4 - INSTRUMENT PROCEDURE ...................................................................... 45

4.1 - INSTRUMENT COMMISSIONING PROCEDURE ...................................... 45

4.2 - IN-OUT TEST PROCEDURE .................................................................... 46

4.3 - SIMULATION PROCEDURE .................................................................... 46

4.4 - MACHINE TEST PROCEDURE ................................................................ 47

5 - SYSTEM CALIBRATION ............................................................................ 48

5.1 - BELT HOMING DYNAMIC PROCEDURE ................................................. 48

5.2 - BELT CALIBRATION DYNAMIC PROCEDURE ........................................... 49

5.3 - ZERO STATIC CALIBRATION AND WITH SAMPLE WEIGHT ...................... 50

5.4 - MC353 OPERATION ALARMS ............................................................... 51

6 - ADDITIONAL FUNCTIONS OF MC353 ..................................................... 53

6.1 - DATA LOGGER .................................................................................... 53

6.2 - SAVE AND LOAD SET-UP ...................................................................... 53

Pag. 4

MC 353 software 1.9

ENG

6.2 - FILE LOADING ..................................................................................... 54

6.3 - RECEIPT PRINT ..................................................................................... 55

7 - SERIAL COMMUNICATION AND PROTOCOLS .......................................... 56

7.1 - ASCII COMMUNICATION PROTOCOL .................................................. 56

7.2 - MODBUS COMMUNICATION PROTOCOL ............................................ 61

7.3 - PROFIBUS-DP COMMUNICATION PROTOCOL ....................................... 62

7.4 - SUPERVISION FUNCTIONS .................................................................. 71

7.5 - MASTER / SLAVE COMMUNICATION PROTOCOL .................................. 71

7.6 - REPETITOR TRANSMISSION PROTOCOL ................................................ 72

8 - TROUBLESHOOTING ............................................................................. 73

8.1 - TROUBLESHOOTING ........................................................................... 73

CONFIGURATION AND TEST FORM ............................................................. 76

Pag. 5

MC 353 software 1.9

ENG

- CE DECLARATION OF CONFORMITY -

· ELECTROMAGNETIC COMPATIBILITY DIRECTIVE

2004/108/EC

· EN61000-6-2, EN61000-6-3, EN61010-1, EN45501 STANDARDS

MANUFACTURER

Electronic commercial denomination: “Metering control electronic instrument”

Model: “MC353”

Protection class: “IP 65”

It is forbidden to start-up the electronic equipment provided with certication before

the electric panel it is going to be integrated or assembled has been declared conforming

with the Directives requirements.

CERTIFICATION

WE, THE UNDERSIGNED OF THIS DOCUMENT, DECLARE UNDER OUR OWN

RESPONSIBILITY THAT THE CONCERNED ELECTRONIC EQUIPMENT IS

CONFORMING WITH THE ITALIAN LAW AND THUS WITH THE ELECTROMAGNETIC

COMPATIBILITY DIRECTIVE 2004/108/EC AS WELL AS THE EN61000-6-2, EN610006-3, EN61010-1, EN45501 STANDARDS.

NAME: POSITION:

ISSUE DATE: SIGNATURE:

ELECTRONIC IDENTIFICATION

Pavone Sistemi S.r.l.

Via Dei Chiosi, 18

20873 Cavenago Brianza (MB) - ITALY

Tel. +39.02.95339165 - Fax +39.02.9501252

pavone@pavonesistemi.it - www.pavonesistemi.it

Donato Di Reda

sole director

03/02/2012

Pag. 6

MC 353 software 1.9

ENG

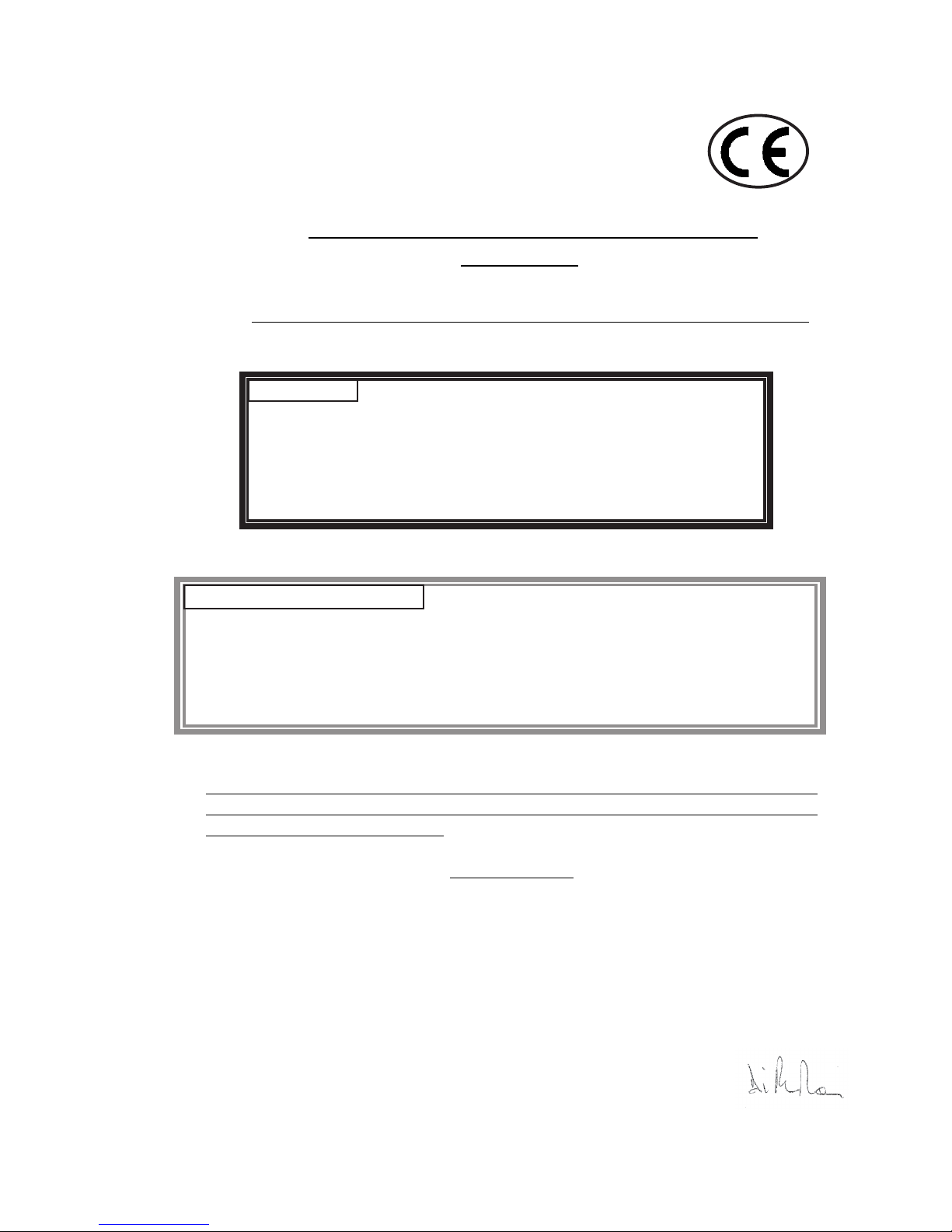

1

Inverter

Encoder

Flow Rate

Motor

Load Cells

MC 353

PLC / PC

MC 353

Inverter

MotorLoad Cells

Weighing Belt

Encoder

PC / PLC

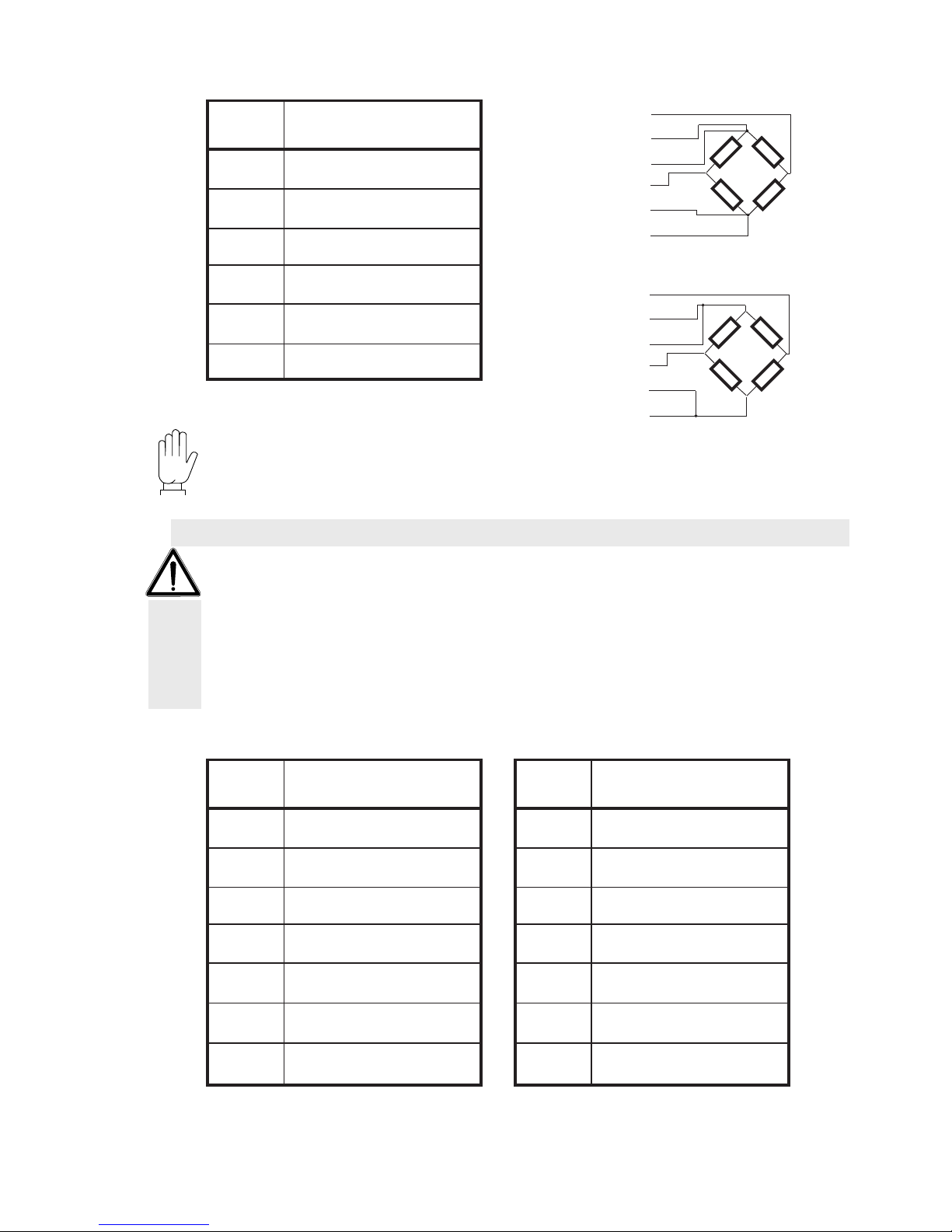

1 - InTRoDUcTIon

The picture shows how the instrument controls the system adjustment ring.

The MC353 can operate as follows according to its set-up:

FLOW RATE TRANSMITTER

The instrument, thanks to the weight (load cells) and the speed (encoder) signal when it receives the run

input, calculates an instantaneous flow rate which is then transmitted externally through a configurable

analogue output (0÷10 V, 0÷5 V, 0÷20 mA, 4÷20 mA).

It is also possible to receive the following outputs:

- Weight totalization output;

- Conveyed weight preset output;

- Conveyed weight set output;

- Serial communication protocol, Ethernet included.

- Generic alarm output;

- Flow rate equal to 0 output;

- Conveyed weight reset input;

- USB device communication port;

- Optional USB HOST port with USB pen drive interface.

FLOW RATE CONTROLLER

The MC 353 control unit is configured with P.I. (instantaneous flow rate) regulator; it processes the weight

and speed variables to get the instantaneous hourly flow rate and the totalized weight. Furthermore it

acts as flow rate self-regulator.

Pag. 7

MC 353 software 1.9

ENG

1

The external supervisor transmits the work set-up (that can be set also through the keyboard) through

the serial communication to the MC353 control unit; the latter, according to the calculated flow rate

value, controls directly (through analogue output) the inverter frequency of the motor where the weighing

system has been installed.

The MC353 control unit has the following features:

- Weight totalization output;

- Conveyed weight total preset and set output;

- Generic alarm output;

- Flow rate out of tolerance alarm output;

- Flow rate output equal to 0;

- Retroaction analogue output (0÷10V;0÷5V, 0÷20 mA; 4÷20 mA);

- Flow rate proportional optional analogue output;

- Optional analogue input for setting-up the flow rate;

- Inputs for the selection of 15 preset set points;

- Conveyed weight reset input;

- Selection of the instrument state from manual to automatic and vice versa by means of the keyboard,

from the instrument rear side through external contact, and by means of serial communication protocol;

- Serial communication protocol, Ethernet included;

- Optional USB HOST port with USB pen drive interface.

Pag. 8

MC 353 software 1.9

ENG

1

1.1 - OTHER FUNCTIONS OF MC353

MASTER-SLAVE OPERATION

This instrument can operate as slave, thus acquiring the flow rate setpoint in continuous duty, through

analogue input (0÷10V / 4÷20mA) or digital input (RS485). The flow rate setpoint is updated according to the current input: the flow rate setpoint is divided and it represents the input scale end (100%).

In case the current setpoint is set to 0, the setpoint will correspond to the input percentage value of the

system maximum flow rate.

The instrument can also operate as master by transmitting the instantaneous flow rate through the optional analogue output or digital transmission (RS485) for the direct connection to instruments in SLAVE

operation.

PARAMETERS THAT CAN BE SET

It is possible to set the operation parameters through the touch screen user interface; all parameters are

organised on 3 levels with independent access criteria.

All parameters that can be set are listed in a table and clearly identified with a numerical code (address).

The parameters reading and writing access is available on the communication port with supervisor

(Rs422 / RS485 / Ethernet, optional), through the ModBus RTU protocol. Furthermore the parameters

reading and setting can be carried out by sharing files in CSV format on the COM2 communication

port (Rs232 or USB) or directly on USB pen drive connected to the USB Host port (optional).

For operation details see the relevant paragraphs.

DATA IMPORT / EXPORT

To facilitate the data set-up and acquisition in a format that can be used with standard informatic systems

the instrument is provided with files transfer functions (TXT or CSV). It features especially a reading/

writing (even partial) of the memory parameters from CSV files and a data logger procedure to acquire

operation parameters.

To customise the instrument it is possible to set the setpoint names, create Help pages and load the

image displayed upon switching-on (BMP file).

If the instrument is provided with a USB Host option, the import and export of the files mentioned above

can occur directly on USB pen drive.

Pag. 9

MC 353 software 1.9

ENG

1

1.2 - TECHNICAL FEATURES

STRUCTURAL FEATURES

Made of aluminium with polycarbonate screen

Protection class: IP 65

Overall dimensions: 196 mm x 105 mm (l x h)

Panel front projection: 5 mm

Built-in panel front.

Drilling template 187 mm x 97 mm (l x h)

Fixing by means of 4 metallic threaded rods

3 mm rubber seal along all perimeter

Stainless steel coating

Overall dimensions: 186 mm x 95 mm (l x h)

Embedding depth: 70 mm (terminal boards included)

5.08 / 7.5 mm pitch screw terminal board

Standard USB connectors (Host / Device)

RJ45 standard Ethernet connector

Front panel

Assembly

Rear panel

Connections

POWER SUPPLY

24 Vdc (± 15 %)

10W

Cat. II

Operation temperature: -10 °C ÷ + 50 °C

(85% humidity without condensate)

Storage temperature: -20 °C ÷ + 60 °C

Power supply

Max. absorption

Installation category

Temperatures

DISPLAY

5.2” LCD (118 mm x 58 mm visual area) (l x h)

Graphic (240x128 pixel)

Monochromatic (b/w) with high contrast

Backlit with white leds, adjustable intensity

4 wires resistive, suitable for use with gloves and buzzer

Display

Touch screen

Pag. 10

MC 353 software 1.9

ENG

1

LOAD CELLS INPUT

2 input channels for load cells. Acquisition at intervals

or simultaneously at low frequency

5 Vdc / 120mA (max. 8 350 Ohm cells in parallel)

Protected against short circuit

0.02 microV min

< 0.01% of the scale end

< 0.0003% of the scale end / °C

24 bit (16.777.216 points)

Up to 600,000 divisions on the flow rate

7.8 mV/V bipolar

From 12.5Hz to 250Hz

Adjustable from 0.2Hz to 50Hz

No. of channels

Cells supply

Input sensitivity

Linearity

Temperature warmup drift

Internal resolution

Weight resolution

Measure field

Acquisition frequency

Digital filter

ANALOGUE I/O

2 opto-isolated analogue outputs (1 optional)

1 analogue input (optional)

Analogue output: 16 bit

Analogue input: 24 bit

Outputs: 0÷5V, 0÷10V, 0÷20mA, 4÷20mA

Input: 0÷5V, 0÷10V, 4÷20mA

Voltage: 10KΩ min, current 300 max

< 0.03% of the Full Scale

< 0.001% of the Full Scale / °C

No. of channels

Resolution

Measure field

Output impedance

Output linearity

Output temperature

warmup drift

1 2-phase incremental encoder input (up-down, A-B).

As an alternative there are 2 pulse-counting inputs

24Vdc (100mA max)

2 KHz max

ENCODER INPUT

No. of channels

Power supply

Acquisition frequency

Pag. 11

MC 353 software 1.9

ENG

1

6 opto-isolated logic outputs (clean contact)

6 opto-isolated logic inputs (PNP)

30 Vdc max / 60 mA each

12 ÷ 24Vdc (external supply)

Up to 4 external modules with 4 in. / 8 out. each

(16 in. / 32 out. in total)

LOGIC I/O

No. of channels

Output power

Input voltage

Additional I/O

3 independent communication ports (not changed-over)

Rs422 / RS485 / Ethernet (option)

Rs232 / RS485 / USB Device (Virtual Com Port)

Rs232 (only transmission for printer or repetitor,

9600 baud).

15 m (Rs232), 1000 m (RS485)

From 1200 m to 115200 bit/sec

TCP/IP, UDP, ARP, ICMP, ModBus/TCP

USB pen drive interface with FAT16/32 file system

management

It can be implemented with an external module

No. of channels

COM1 interfaces

COM2 interfaces

COM3 interfaces

Wire length

Baud rates

Ethernet protocols

USB Host (optional)

DP Profibus (optional)

COMMUNICATION PORTS

Micro-controller

Code memory

Data memory

Clock / calendar

RISC 32 bit, 44 MHz

Flash 256K Bytes, it can be set on-board (Rs232, USB)

1088 Kbytes standards, it can be expanded

up to 2113 Kbytes

Integrated with a rechargeable buffer battery

CPU

EN61000-6-2, EN61000-6-3, EN61010-1, EN45501

CONFORMITY WITH STANDARDS

Standards

Pag. 12

MC 353 software 1.9

ENG

2

mod.

s.n.

MC 353

2010/0000

2.1 - INSTALLATION WARNINGS AND INDICATIONS

Upon installation it is necessary to arrange after and near the equipment a main switch for an omnipolar

cut-off with contact minimum opening of 3 mm.

For cleaning the instrument make use of a cloth slightly soaked in pure alcohol for both the container

and the display.

During the cleaning the instrument must be OFF.

Environmental pollution level: 2

INSTRUMENT ASSEMBLY

- Only qualified personnel shall carry out the following procedures.

- All connections shall be made with instrument OFF.

The instrument shall be assembled in an opening with a 187 x 97 mm drilling template and shall be

fixed by means of the 4 threaded tie rods supplied together with the instrument.

- Consider that the instrument depth with extractable terminal blocks fitted is of 70 mm, and it is necessary to keep place enough for all connections.

- Do not install the instrument near power equipment (motors, inverters, contactors, etc.) or any equipment

non-conforming with the Electromagnetic Compatibility EC Standards.

- The load cells connection cable shall have a maximum length of 140 mt/mm2.

- The Rs232 serial line shall have a maximum length of 15 meters (EIA RS-232-C Standards).

- All warnings concerning all peripheral devices connections shall be duly followed.

The installation environment can be subject to strong magnetic fields and electric interferences due to

present machinery; it is thus recommended to take all precautions so as to prevent them from affecting

the typical signals of a precision electronic equipment (filters on remote control switches, diodes on 24

Vdc relays, etc.)

INSTRUMENT IDENTIFICATION PLATE

In case of information or indications request concerning the instrument it is important to report such data

along with the programme number and version that are printed on the manual cover and displayed

upon instrument switching-on.

2 - Mc353 InsTallaTIon

Pavone Sistemi s.r.l.

Pag. 13

MC 353 software 1.9

ENG

2

2.2 - INSTRUCTIONS FOR A CORRECT INSTALLATION OF THE LOAD CELLS AND

THE MICROPROCESSOR SYSTEMS

1. Do not carry out weldings with load cells fitted.

2. Use a copper conductor to connect the load upper support plate with the lower one, then connect

both upper plates with the earth line.

3. Use watertight fittings and sheaths to protect the cells wires.

4. Use a watertight connection box and a terminal board with cable clamp to connect the cells in

parallel.

5. All “shielded” cables for signal amplifiers or cells connection extensions shall be inserted alone in

the cable conduit or in a tube as far away as possible from the power cables.

6. The amplifier or cells cable shall be inserted in the panel from one side or the other and it should be

connected directly to the instrument terminal block without being interrupted by additional terminal

blocks or passing through cable conduits with other wires.

7. Use “RC” filters on the coils of remote control switches and the solenoid valves controlled by the

micro-processor.

8. In case of condensate inside the equipment it is recommended to always keep them powered.

9. The electric panel installer shall provide all instrument electric protections (fuses, door lock switch,

etc.).

10. It is recommended to connect the housing of the instrument to the protective earth (possibility to use

the set screws of the control unit).

Pag. 14

MC 353 software 1.9

ENG

2

Set OUT

Pre-Set OUT

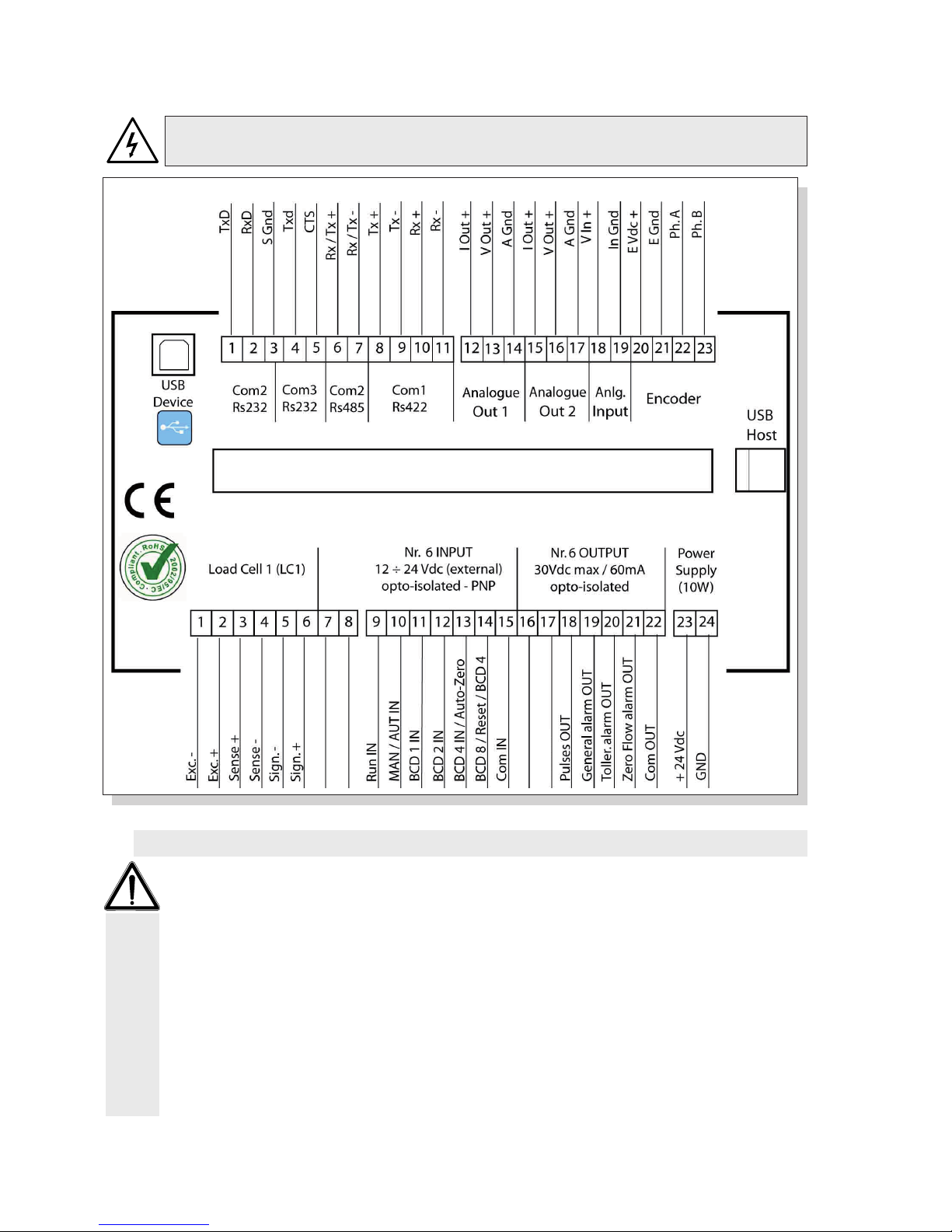

2.3 - ELECTRIC CONNECTIONS

Only qualified personnel shall carry out the procedures described below. All connections shall be

made with instrument OFF.

- The cell cable shall not be inserted together with other cables (for eg. outputs connected with remote

control switches or supply cables), it must be routed in its own path.

- Any cable extension connection shall be carefully shielded, respecting the colour code and using the

cable type supplied by the manufacturer. The extension connections shall be made through welding or

support terminal blocks or connection box supplied as optional.

- The cell cable shall have a number of conductors not higher than those used (4 or 6). In case of a

4-conductors cable connect the reference wires by making a jumper across the relevant poles of the

supply cables.

It is possible to connect up to maximum 8 350 Ohm cells in parallel to the instrument. The cells supply

voltage is of 5 Vdc and is protected against temporary short circuit. The instrument measurement field

foresees the use of load cells with sensitivity from 1 mV/V to 5 mV/V.

TERMINAL BLOCKS DIAGRAM

LOAD CELL CONNECTION (CONTACTS 1÷6 LOwER TERMINAL BLOCk)

Pag. 15

MC 353 software 1.9

ENG

2

The 6 logic inputs are electrically isolated by the instrument through optoisolators.

The logic inputs connection cables must not be inserted together with power or supply cables and you

have to use a cable as short as possible.

The inputs are active when a voltage of 12 / 24 Vdc is applied (PNP logic).

The 6 logic outputs feature a photorelay (clean contact) with a common contact. The capacity of each

contact is of 60 mA / 30Vdc .

6 WIRES CELL CONNECTION

4 WIRES CELL CONNECTION

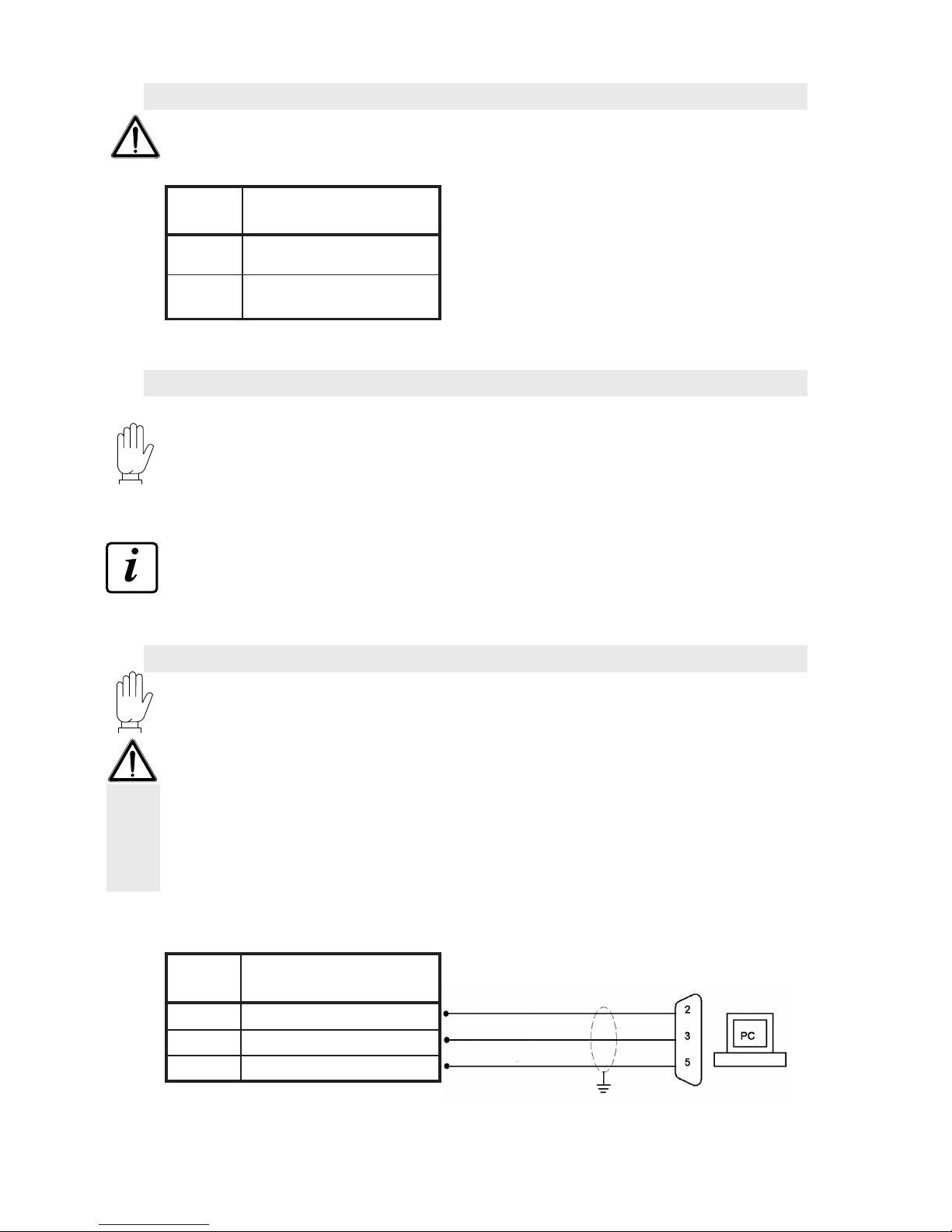

NUM.

Lower terminal block

(pitch 5.08 mm)

1

Cell supply -

2

Cell supply +

3

Reference cell +

4

Reference cell -

5

Signal cell -

6

Signal cell +

LOGIC INPUTS AND OUTPUTS (CONTACTS 9÷22 LOwER TERMINAL BLOCk)

Note: to use the 4-wires technique make a jumper across terminal 3 and terminal 2, terminal 4 and

terminal 1.

The cell cable SHIELD must be connected with terminal 1 ( CELL SUPPLY -).

NUM.

Lower terminal block

(pitch 5.08 mm)

9

IN 1 - Run

10

IN 2 - Man / Aut

11

IN 3 - BCD1

12

IN 4 - BCD2

13

IN 5 - BCD4 / Auto 0

14

IN 6 - BCD8 / Reset

15

Input common connector

NUM.

Lower terminal block

(pitch 5.08 mm)

16

OUT 1 - Set

17

OUT 2 - Pre-Set

18

OUT 3 - Tot. pulse

19

OUT 4 - General alarm

20

OUT 5 - Flow rate alarm

21

OUT 6 - Flow rate = 0

22

Output common connector

SIGNAL -

POWER SUPPLY +

REFERENCE +

SIGNAL +

REFERENCE -

POWER SUPPLY

SIGNAL -

POWER SUPPLY +

REFERENCE +

SIGNAL +

REFERENCE -

POWER SUPPLY

Pag. 16

MC 353 software 1.9

ENG

2

IN1 - Run static input. Close this contact to enable instrument begin and maintain programmed operations

(weighing, flow regulation, alarms etc.). Input must be kept closed during dosing; open the contact to

stop operations.

IN2 - Manual selection (open) / automatic (closed). The selection through the keyboard has the priority

over the selection of this input. When a selection that does not correspond to the input state is changed

through the keyboard, to commutate the selection with this input it is necessary to first set the selection

according to what had been done by the keyboard, and then commutate it in the desired position. For

example: with the input set to AUTO, it is possible to commutate it to MAN through the keyboard. To

restore the automatic operation using the input it is necessary to first set the input to MAN and then to

AUTO.

IN3 - Bit 1 setpoint selection with BCD coding. The selection is shown on the display. When all inputs

are open the system keeps the last selected combination (even if you switch off the instrument).

IN4 - Bit 2 setpoint selection with BCD coding. The selection is shown on the display. When all inputs

are open the system keeps the last selected combination (even if you switch off the instrument).

IN5 - The function of this input can be selected: the input (closed by pulses) can control the belt homing

remote procedure. Otherwise you can have the function combined with inputs 3, 4 and 6 for selecting the setpoint with BCD coding. (inp. 5 = bit 4). To start AUTOZERO procedure, close input 1027

(parameter INPUT FUNCTION 5 = “belt reset mode”); the above procedure can be activated only

when 3028 RUN STATUS is STOP. Then, set 3028 RUN STATUS = RUN and keep it that way during

the whole duration of the procedure. The duration of the procedure depends upon the time settings of

parameter 0132 BELT LAP TIME, so please wait until this time elapse. During this period, if there are

any anomalies, will be indicated by the alarm output. If, during AUTOZERO procedure duration, no

alarm is raised, you can safely assume that the procedure has successfully ended. Now you can set

again 3028 RUN STATUS = STOP.

IN6 - The function of this input can be selected: the input (closed by pulses) can control the conveyed

total reset, with receipt print if the printer is suitably set. Otherwise you can have the function combined

with inputs 3, 4 and 5 for selecting the setpoint with BCD coding. (inp. 6 = bit 8 if inp. 5 = bit 4; inp.

6 = bit 4 if inp. 5 is selected to control the belt homing procedure).

NOTE: inputs are activated only if activation time exceeds 500 msec.

Pag. 17

MC 353 software 1.9

ENG

2

OUT1 - Total Set reached. This output is active when the total conveyed product exceeds the set value,

anticipated of the set flying material. If the set value is zero, this output is never excited.

The output is disabled when the total conveyed product is reset.

OUT2 - Total PreSet reached. This output is active when the total conveyed product exceeds the SET

value - PRESET value. If the set value is zero, this output is never excited. The output is disabled when

the total conveyed product exceeds the SET value - PRESET value. If the set value is zero this output is

not excited. The output is disabled when the total conveyed product is reset.

OUT3 - Totalization pulse. This output is excited by pulses (0.5 sec.) each time that the quantity of product that is conveyed is equal to the set value, max. 1 impulse per second (1 Hz)

OUT4 - Functioning alarm. This output is activated when at least one of the scheduled alarms occurs

(except alarm 3). You can program this function. OUT4 is deactivated automatically when function is

one again normal. Output is active during RUN or always according to parameter’s 1030 settings.

OUT 5 - Instantaneous flow rate out of tolerance. During belt’s RUN (only in automatic mode), this output is active if instantaneous flow rate exceeds the set limit. OUT5 is deactivated automatically when

function is one again normal, i.e when flow rate is within tolerance. You can program this function.

OUT6 - Null flow rate alarm (Al 3). During the belt movement this output is active when the null flow

rate alarm (minimum weight or encoder signal missing) is triggered according to the conditions defined

by the 1022 parameter selections.

Pag. 18

MC 353 software 1.9

ENG

2

TX

RX

GND

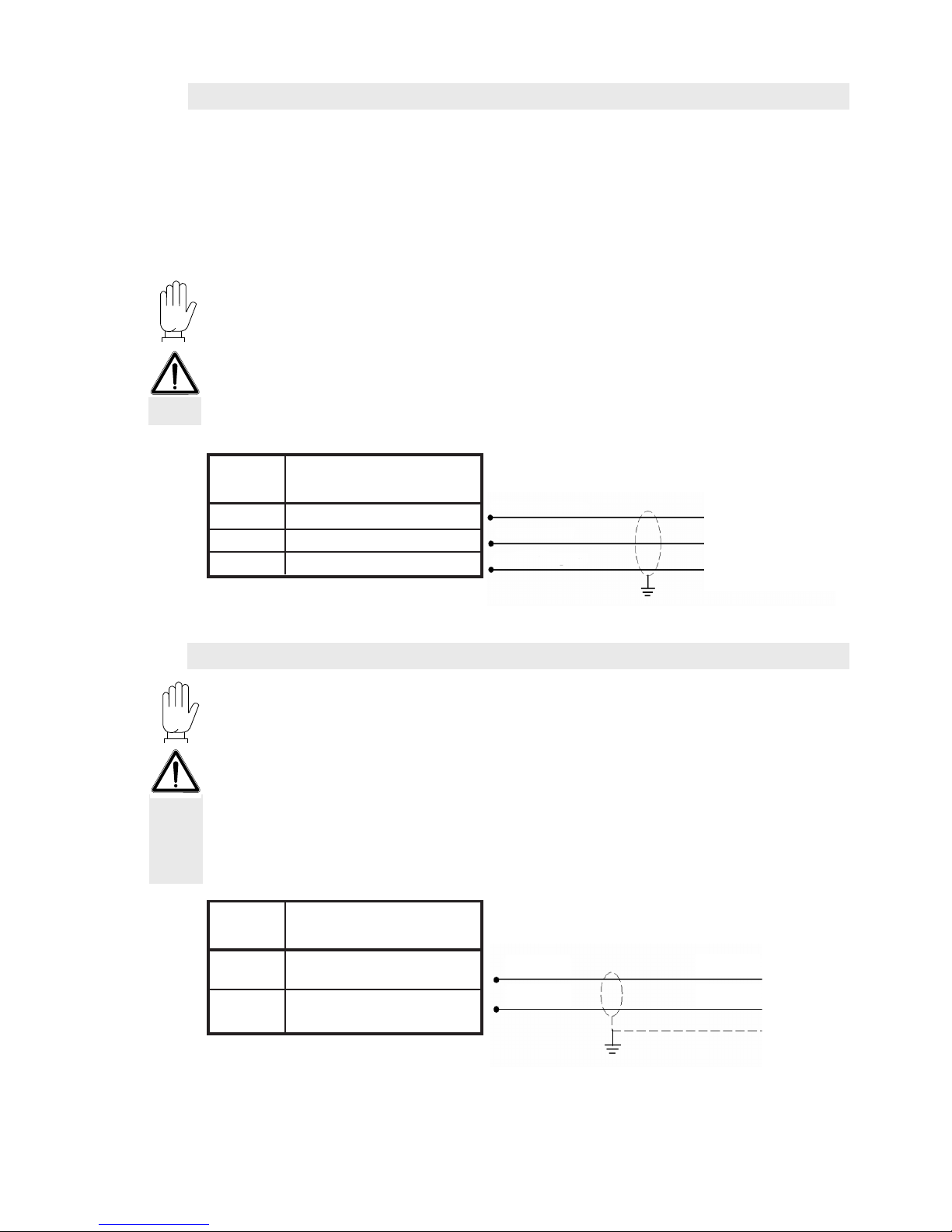

The instrument is supplied by the 2-pole terminal block with 7.5 mm pitch.

The supply cable shall be inserted separately from other supply cables featuring a different voltage,

from the load cell, encoder and logic and analogue input/output cables.

INSTRUMENT POwER SUPPLY (CONTACTS 23-24, LOwER TERMINAL BLOCk)

NUM.

Lower terminal block

(pitch 7.5 mm)

23

+ 24Vdc

24

GND

POWER SUPPLY: 24Vdc +/-15%

POWER: 10W

WARNING: when using this connection it is not possible to use an RS485 interface and the USB device

port, shared on the same COM2 communication port.

To make a serial connection use a shielded cable having care to connect to earth the screen to only

one of the two sides. In case the cable has more conductors than those used connect the screen to the

free conductors.

The serial connection cable shall have a maximum length of 15 metres (EIA RS-232-C Standards), if it

is longer it is necessary to use the instrument Rs422 interface.

- The cable shall not be inserted together with other cables (for eg. outputs connected with remote control

switches or supply cables), it must be possibly routed in its own path.

The PC used for the connection shall be compliant with the EN 60950 Standard.

Following is the drawing of the connection with 9-pole PC connector:

COM2 - RS232 SERIAL PORT (CONTACTS 1÷3, UPPER TERMINAL BLOCk)

NUM.

Upper terminal block

(pitch 5.08 mm)

1

2

3

Data transmission

Data reception

Signal mass

WARNING: when using this connection it is not possible to use an RS485 and RS232 interface, shared

on the same COM2 communication port.

Use this communication port to interface directly with a PC or through a USB port.

For the connection use a USB standard cable.

To connect the instrument through the USB device port it is necessary to install on the PC the suitable

driver for the used operative system. Follow specific instructions for the installation.

COM2 - USB DEVICE PORT (REAR USB FEMALE CONNECTOR)

- Specification 2.0 compliant; full-speed 12Mbps -

Note: verify that GND (pin 24) is grounded

Pag. 19

MC 353 software 1.9

ENG

2

MASTER

RS485

TX+ / RX+

TX+ / RX+

TX- / RX-

TX- / RX-

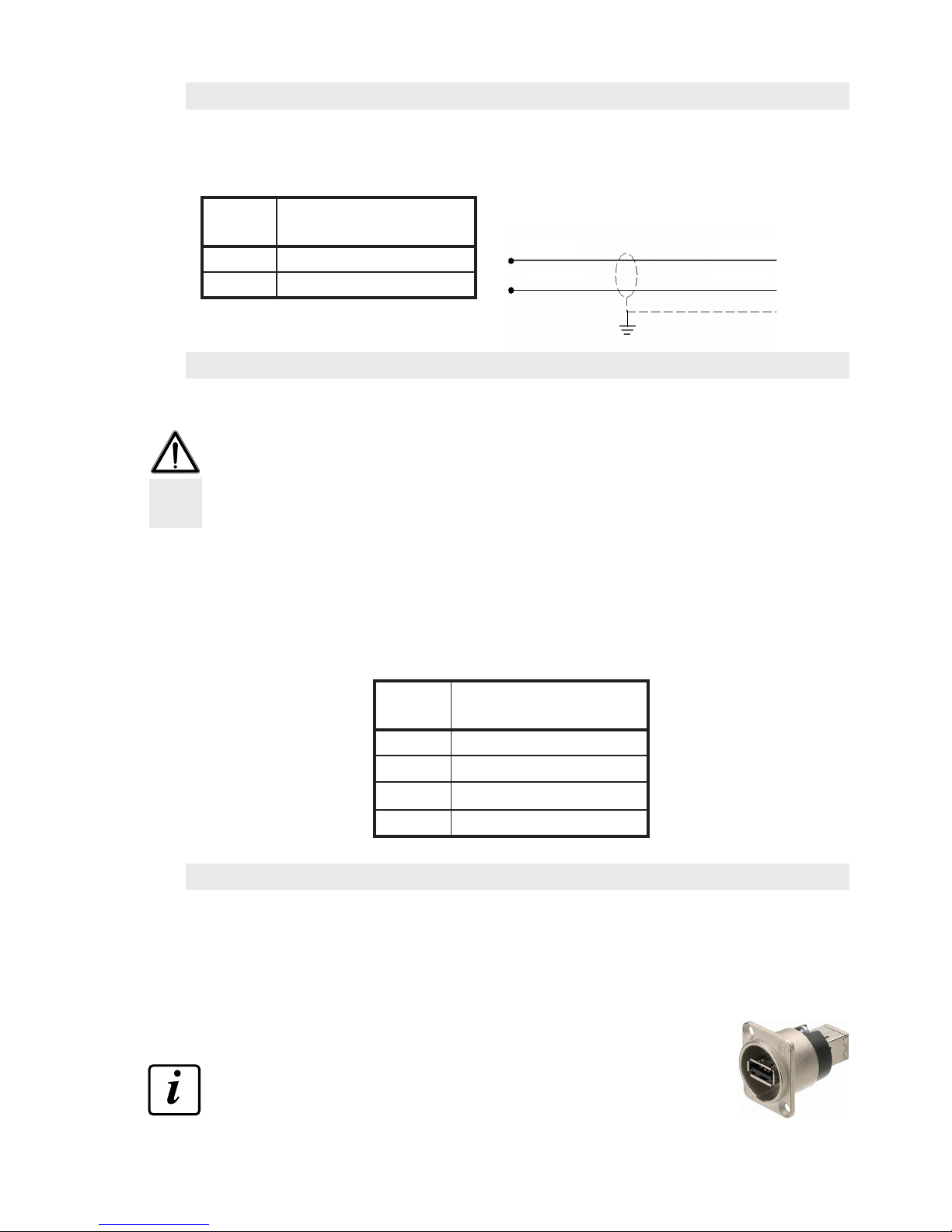

COM3 - RS232 SERIAL PORT (CONTACTS 3÷6, UPPER TERMINAL BLOCk)

NUM.

Upper terminal block

(pitch 5.08 mm)

4

TX

5

cts

3

GND

Data transmission

cts

Signal mass

This communication port is only provided with data transmission functions with fixed communication

parameters. The units that can be connected are a repetition printer or display that shall feature an

RS232 serial interface.

Speed: 9600 bps

Word length: 8 bit.

Start bit: 1 bit. Parity bip: 0 bit. Stop bit: 1 bit.

Handshaking: DTR protocol.

Refer to the printer or repetitor manual to select the communication parameters according to the

transmission.

To make a serial connection use a shielded cable having care to connect to earth the screen to only

one of the two sides. In case the cable has more conductors than those used connect the screen to the

free conductors.

The serial connection cable length shall not exceed 15 meters (EIA RS-232-C Standards).

PRINTER -

REPETITOR

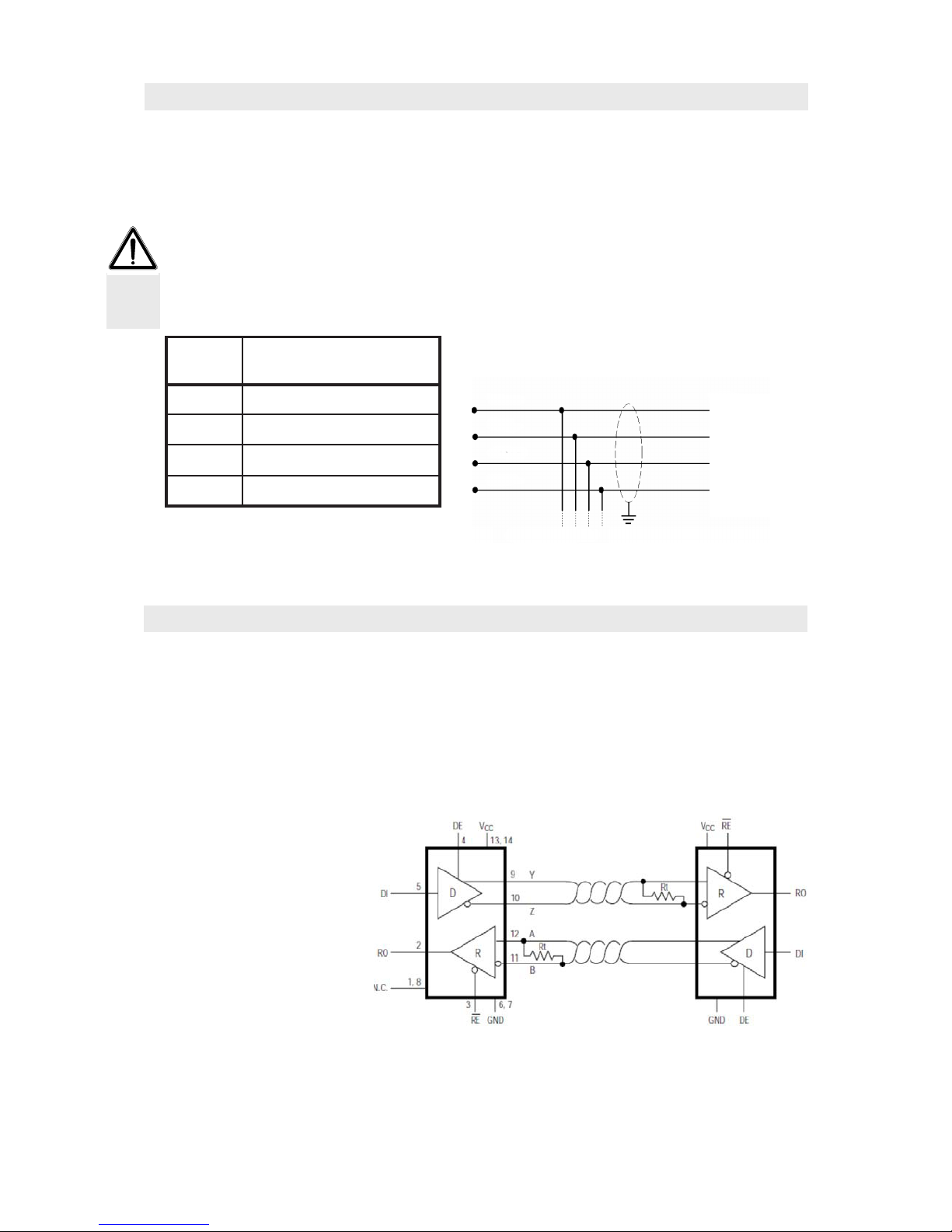

COM2 - RS485 SERIAL PORT (CONTACTS 6-7, UPPER TERMINAL BLOCk)

WARNING: when using this connection it is not possible to use an RS232 interface and the USB communication device port, shared on the same COM2 communication port.

Through the RS485 serial interface it is possible to carry out serial connections for long distances.

This type of connection allows to connect more units to one MASTER using one single serial line. The

maximum number of connected units is 32.

The serial connection cable type shall be suitable for RS485 serial communications with 1 twisted pair

and the relevant shielding.

- The cable shall not be inserted together with other cables (for eg. outputs connected with remote control

switches or supply cables), it must be possibly routed in its own path.

Set the terminal line resistors as specified in the following paragraph.

NUM.

Upper terminal block

(pitch 5.08 mm)

6

7

TX- / RX-

TX+ / RX+

Pag. 20

MC 353 software 1.9

ENG

8

9

TXD-

TXD+

10

RXD+

11

RXD-

TXD+

TXD-

RXD-

RXD+

TXD+

TXD-

RXD-

RXD+

MASTER RS422

2

Through the RS422/RS485 serial interface it is possible to carry out serial connections for long distances.

This type of connection allows also to connect more instruments to one MASTER unit (personal computer,

PLC, etc.), using only one serial line and thus just one MASTER serial port.

The maximum number of connected instruments is 32. Obviously also the master unit shall be equipped

with an RS485 or RS422 serial interface, otherwise it can be supplied as optional.

The serial connection cable type shall be suitable for serial communication with 2 conductor twisted

pairs for RS422, or 1 twisted pair for RS485 and the relevant shielding.

- The cable shall not be inserted together with other cables (for eg. outputs connected with remote control

switches or supply cables), it must be possibly routed in its own path.

Set the terminal line resistors as specified in the following paragraph.

NUM.

Upper terminal block

(pitch 5.08 mm)

Other instrument

For the RS485 connection connect in parallel TXD + with RXD+ and TXD- with RXD-.

COM1 - RS422/485 SERIAL PORT (CONTACTS 8÷11, UPPER TERMINAL BLOCk)

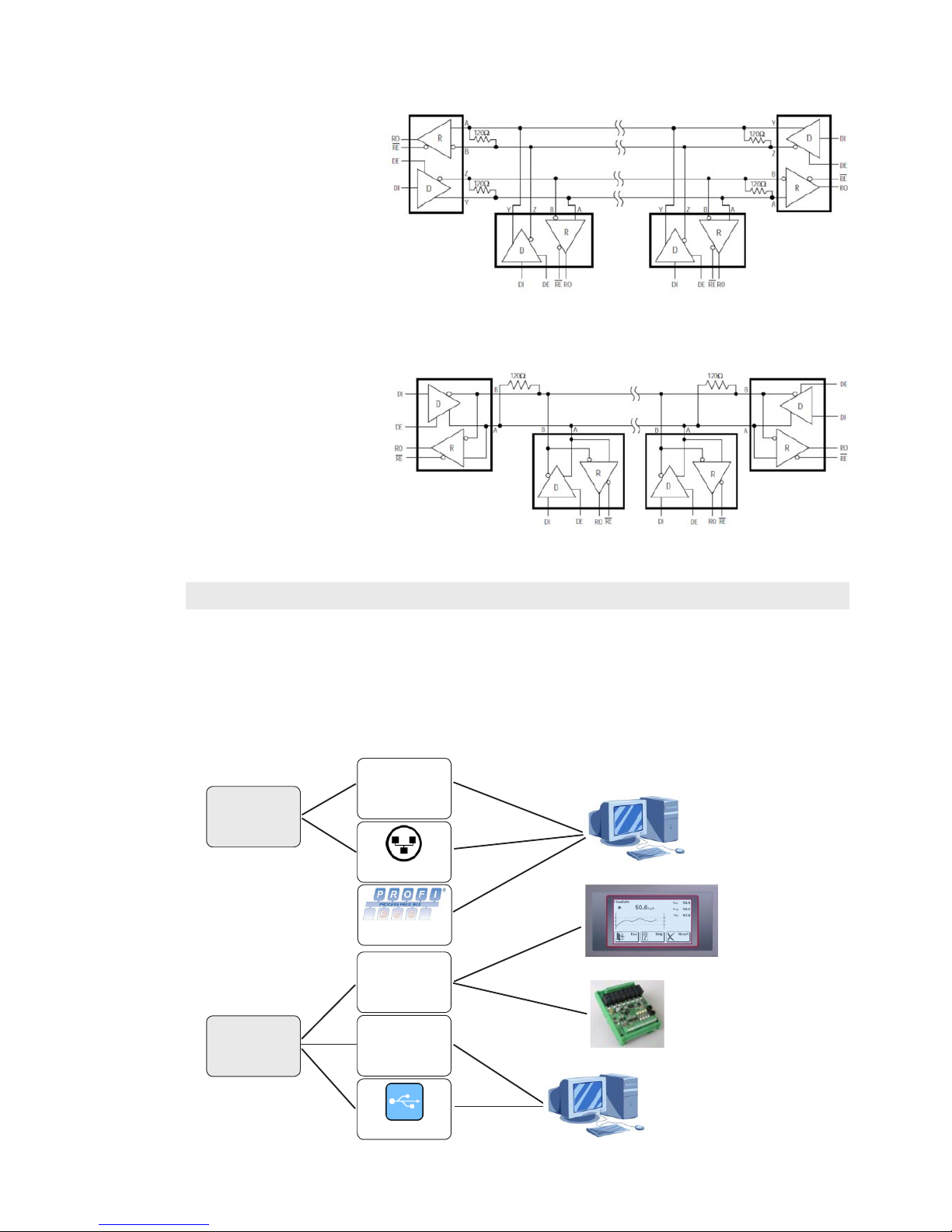

TERMINAL RESISTORS RS485 AND RS422

Data bus transmission on RS485 / RS422 connection is differential type, i.e. signal is the result of

tension difference between the 2 wires composing the bus.RS485 / RS422 transmitters provide an

output (under load) of ±2-3 V between output A and B; receivers recognize output levels up to ±200

mV as a valid signal.

This technique provides excellent disturb immunity even with long cable runs.

To minimize reflections, transmitter must have the possibility to insert the polarizing resistance while first

and last network line element should be equipped with a terminal line resistor, connected inparallel to

the line.

Typically, terminal line resistors must have resistance values between 120 and 560 ohm.

In case of connections with double pairs RS422 and two nodes,

resistances should be near the further receiver while value can be

low up to 120 Ohm (see figure)

Pag. 21

MC 353 software 1.9

ENG

COM 1

Rs422 /

RS485

RS485

RS232

USB device

COM 2

Ethernet

Profibus

2

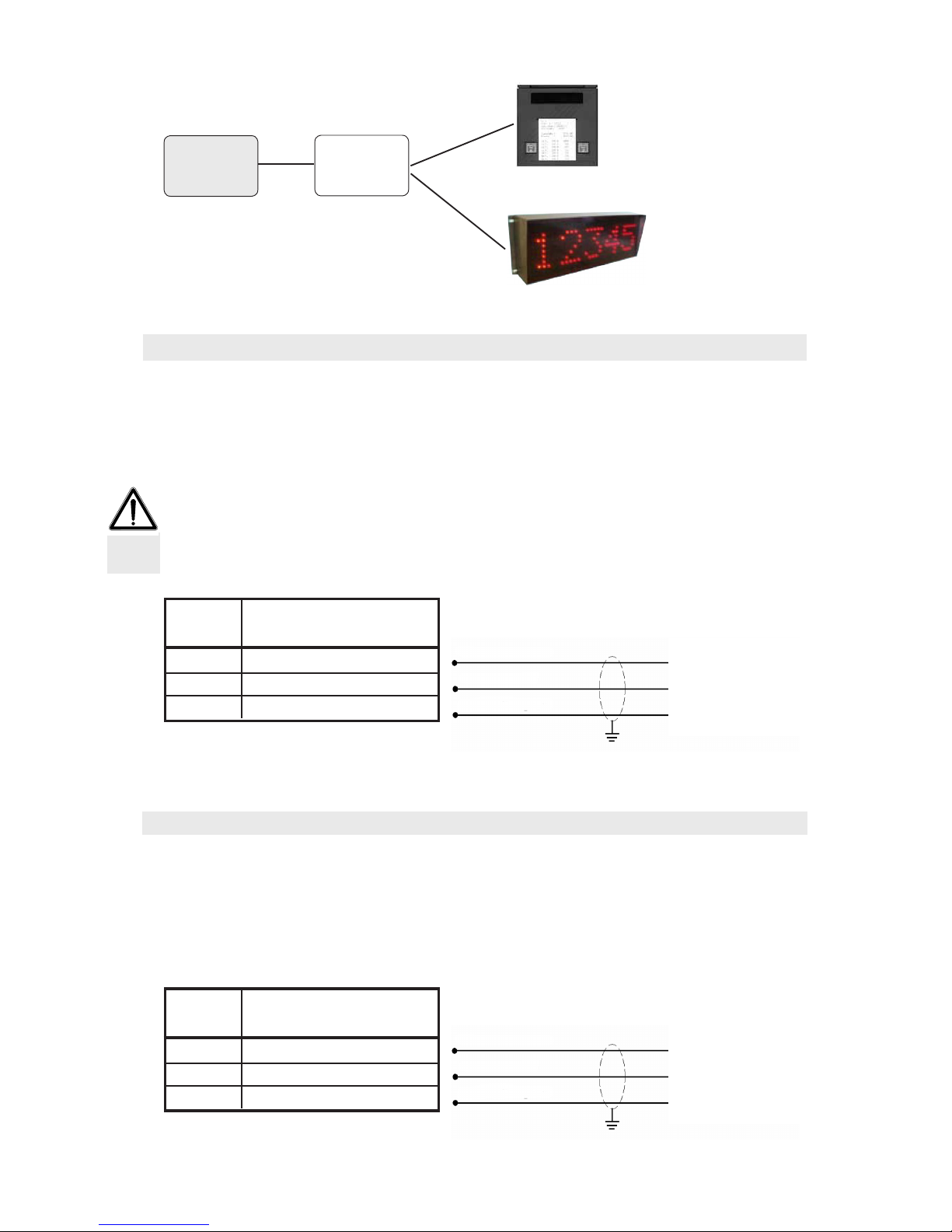

COMMUNICATION PORTS SUMMARY

The instrument is equipped with three independent communication ports: COM1, COM2, COM3.

COM1 has 2 possible interfaces (that can be used alternatively): RS422/RS485, Ethernet or Profibus

(optional).

COM2 has 3 interfaces (that can be used alternatively): RS232, USB device, RS485.

COM3 has an RS232 interface with only transmission functions and CTS management.

Following is a diagram with all possible connections:

Supervision

PC / PLC

service PC:

- programming

- operation display

- firmware update

Additional I/O

module

(optional)

MC353

MASTER / SLAVE

In case of connections with double pairs RS422 and more nodes, same 120 Ohm value is indicated

at the figure, but this is valid

for very long lines (hundreds

of meter). If line is considerably shorter, resistance

value must raise because

impendence at 120 Ohm

would be very low, 60 Ohm

(not counting the receivers

load). It would be better to

use resistances in the ~250

Ohm range.

Same considerations apply

to the RS485 connection.

Use 250 Ohm resistances for

lines not very long.

(optional)

(optional)

Pag. 22

MC 353 software 1.9

ENG

2

RS232

COM 3

13

+ Volt

14

GND

12

+ mA

16

+ Volt

17

GND

15

+ mA

Printer from panel

Repetitor display

MAIN ANALOGUE OUTPUT (CONTACTS 12÷14, UPPER TERMINAL BLOCk)

The instrument is provided with a current and a voltage analogue output.

Features:

- Voltage analogue output: range from 0 to 10 Volts or from 0 to 5 Volts, minimum load 10KOhm;

- Current analogue output: range from 0 to 20 mA or from 4 to 20 mA. The maximum load is 300Ohm.

For the connection use a shielded cable having care to connect to earth the screen to only one of the

two sides.

The analogue transmission is particularly sensitive to the electromagnetic interferences and thus we

recommend that the cables are as short as possible and that they follow an independent path.

NUM.

Upper terminal block

(pitch 5.08 mm)

+ VOLTAGE

- COMMON

+ CURRENT

OPTIONAL ANALOGUE OUTPUT (CONTACTS 15÷17, UPPER TERMINAL BLOCk)

The instrument can have a second optional analogue output with the same features of the serial one.

Features:

- Voltage analogue output: range from 0 to 10 Volts or from 0 to 5 Volts, minimum load 10 KOhm;

- Current analogue output: range from 0 to 20 mA or from 4 to 20 mA. The maximum load is 300 Ohm.

NUM.

Upper terminal block

(pitch 5.08 mm)

+ VOLTAGE

- COMMON

+ CURRENT

Pag. 23

MC 353 software 1.9

ENG

2

19

GND

18

+ Volt / + mA

-

+

-

+

21

20

23

22

OPTIONAL ANALOGUE INPUT (CONTACTS 18÷-19, UPPER TERMINAL BLOCk)

It is possible to have an analogue input as optional with measurement field 0÷5V, 0÷10V, 0÷20mA,

or 4÷20 mA. The measurement field shall be chosen during the order stage and can not be selected

by the instrument.

The ADC has a 24 bit resolution.

NUM.

Upper terminal block

(pitch 5.08 mm)

ENCODER INPUT (CONTACTS 20÷23, UPPER TERMINAL BLOCk)

Connection for 2-phase encoder with 24 Vdc power supply.

- The encoder cable shall not be inserted together with other cables (for eg. outputs connected with

remote control switches or supply cables), it must be routed in its own path.

- Any cable extension connection shall be carefully shielded, respecting the colour code and using the

cable type supplied by the manufacturer. The extension connections shall be made through welding or

support terminal blocks.

The maximum frequency of the encoder signals acquisition is of 2 KHz. Fit the encoder so as to avoid

exceeding such work frequency. Example: if the encoder resolution is of 10000 pulses / rev. the rotation

speed shall not exceed 12 rpm.

The encoder acquisition is of the up-down type (counting in both rotation senses). For this reason both

phase cables (A and B). The rotation sense is automatically detected by the instrument.

NUM.

Upper terminal block

(pitch 5.08 mm)

GND suppl. encoder

24 Vdc suppl. encoder

Encoder phase B

Encoder phase A

This optional interface allows to directly connect a USB pen drive for reading and writing files according

to the FAT16/32 standard FAT files system.

Features:

USB connections: Mass storage device

Communication modes: USB specification 1.1 and 2.0

Pen drive maximum capacity: 2 GB

To facilitate the insertion of the USB pen drive it is possible to transfer to panel

front side the connector (USB “A” female type) through the special accessory upon

request (see side picture).

USB OTG OPTION

Pag. 24

MC 353 software 1.9

ENG

2

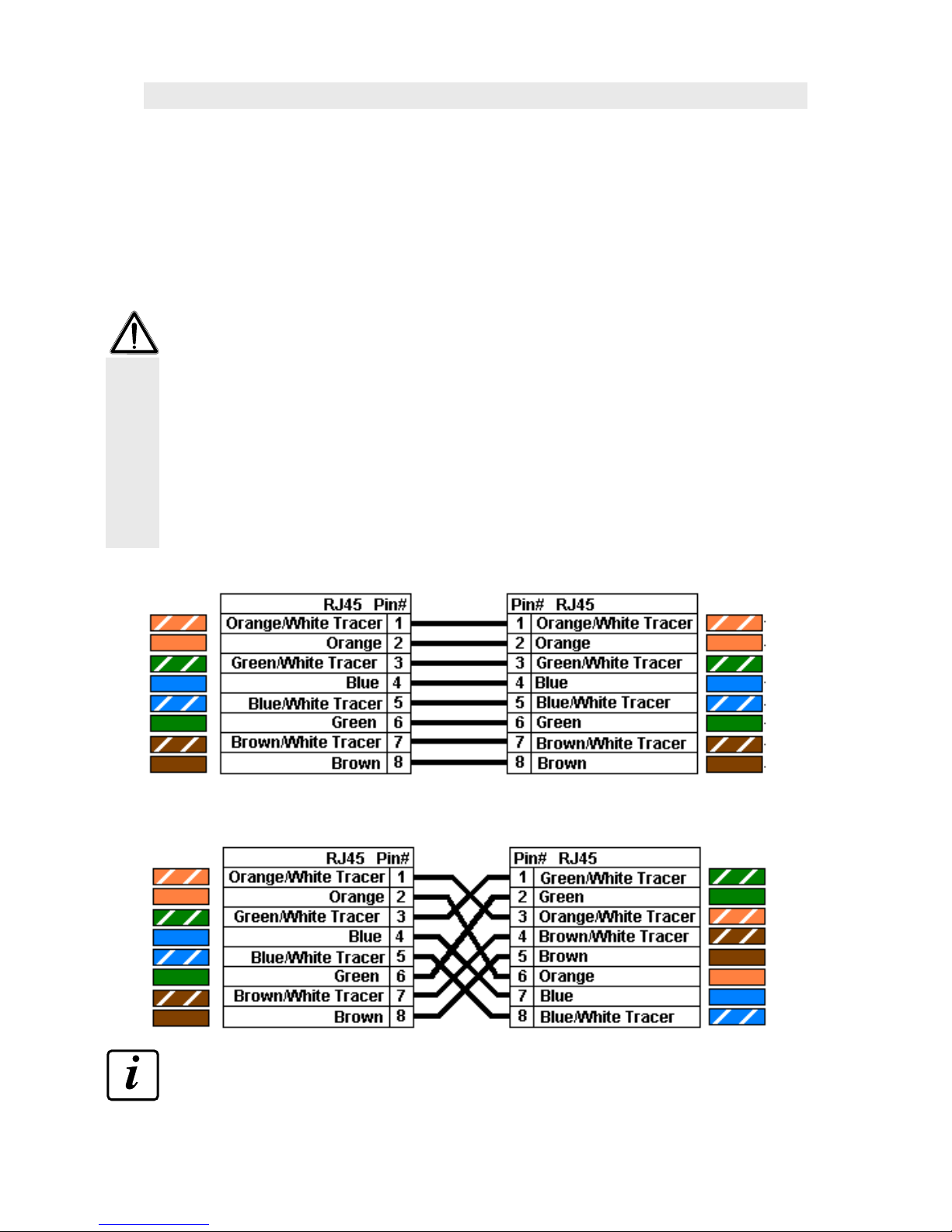

ETHERNET OPTION

Features:

Transmission speed 10 Mbps

Network Compatible with networks 10/100/1000 Base-T

Ethernet protocols TCP/IP, UDP, ARP, ICMP, ModBus/TCP

Communication mode TCP server

LED indicators (2) Presence of Ethernet line and communication / diagnosis

Buffer dimension 256 byte

Connection Timeout Min 30 seconds - Max 90 seconds

Link Timeout (disconnected cable) 30 seconds

- The RJ45 ethernet connection cable has a variable length which depends on the cable type. One Cat5

standard shielded cable can have a maximum length of nearly 180 m.

- It is possible to connect the ethernet communication port directly to the PC without passing through

other network devices (routers, switches, hubs, lan-bridges or other), but it is necessary to use special

RJ45 cables called “crossover”.

- Usually cables are of the “direct” type, and they allow a connection to network devices such as routers or hubs, but not to directly connect the two PCs (even if currently there are network boards with

auto-sensing technology that recognise the cable and the connection type thus allowing PC-PC direct

connections even without using crossover cables).

- Following are the diagrams of the two mentioned cable types and the relevant connection diagram.

- The cable shall not be inserted together with other cables (for eg. outputs connected with remote control

switches or supply cables), it must be possibly routed in its own path.

“Direct” cable diagram

“Crossed” cable diagram

WARNING: for the Ethernet interface configuration please refer to the specific manual.

Pag. 25

MC 353 software 1.9

ENG

3

3 - Mc353 sTRUcTURe anD PaRaMeTeRs

ELECTRONIC SwITCHING-ON

Upon switching-on the display temporarily shows an introduction window, with the indication of the

firmware code and version.

Press set-up during this stage to enter the set-up menu.

Firmware code

Key to enter the set-up menu

It is important to report the firmware code in case of information or indications request regarding the

instrument.

DATA GENERAL DISPLAY

The general display window is divided into 4

sections, each one dedicated to one measure or

one parameter.

The window is divided into 2 pages that can be

viewed with the Next and Prev keys.

This is the standard display during the operation

and in stop conditions. According to the case

press one section to enter one dedicated window

with further details.

In the lower side are 3 “touch” keys with a contextual function.

It changes the base window

display from page 1 to page 2.

It changes the base window

display from page 2 to page 1.

It displays the contextual Help

window that can be set.

This allows you to enter the user

menu for setting the parameters

3.1 - PARAMETERING GENERAL FEATURES

Pag. 26

MC 353 software 1.9

ENG

3

Conferma il valore corrente e lo

memorizza.

Abbandona la programmazione

scartando la modifica.

Visualizza la schermata di Help

contestuale, programmabile.

CONTROL AND PARAMETERS MENU MODE

The menu widows are divided into 2 types: control menu and parameter menu according to the context

and the data set-up menu structure.

One control menu can be made up of 1 to 9 items

per window. In case the controls are more than 9

they are subdivided into more pages.

Press the key with the control description to activate it.

One parameter menu can be made up of 1 to 9

items per window. In case the controls are more

than 9 they are subdivided into more pages.

Press the key with the parameter description to get

access to its set-up.

Control description

Parameter with relative unit

of measurement and value

It allows you to enter the next

page of the menu (items > 9).

It allows to quit the menu and

go back to the upper level of

the general window.

PARAMETERS SET-UP MODE

The parameters set-up procedures are divided into 2 types: set-up of numerical parameters and selection

of parameters with preset value.

Current value

Composition keys

Current selection

Selection keys

Pag. 27

MC 353 software 1.9

ENG

3

3.2 - MC353 DISPLAYS

SECTION 1: TOTAL

In the main window press the “Total” section to enter the detailed window concerning the instantaneous

hourly flow rate, where additional information are reported.

The graphic bar and the percentage value on the

right side indicate that the conveyed total product

proportion according to the set total setpoint.

Totalization pulse state (it becomes dark when active).

Total reset, with confirmation request

Conveyed total weight setpoint. When

the total reaches this value the relevant

output is activated.

When less than this value is missing to

reach the setpoint, the relevant output

is activated.

Output activation advance with respect

with the setpoint value

Set

Preset

Queue

If the total setpoint management function is not selected press any section of the main window to directly

reset the total, with confirmation request.

SECTION 2: SET POINT

In the main window press the section to access the detailed windows of the flow rate setpoint, where

you enter also the setpoint values set-up.

Number of selected setpoint.

Value of the active setpoint

possibly modified

by the master unit.

Name of the selected setpoint that can be set

by the user.

The graphic bar and the percentage value on the

right side indicate the proportion of the active setpoint

value with respect to the scale end, or to the setpoint

whole value in case the setpoint change input is

activated by the master.

Pag. 28

MC 353 software 1.9

ENG

3

With this you enter the 15

setpoint set-up menu. Upon

conrmation of the setpoint

values you enter the relevant

manual output value.

Flow rate setpoint value that can be

selected.

Theoretic adjustment percentage manual output linked with the

setpoint.

Setpoint

Output

manual

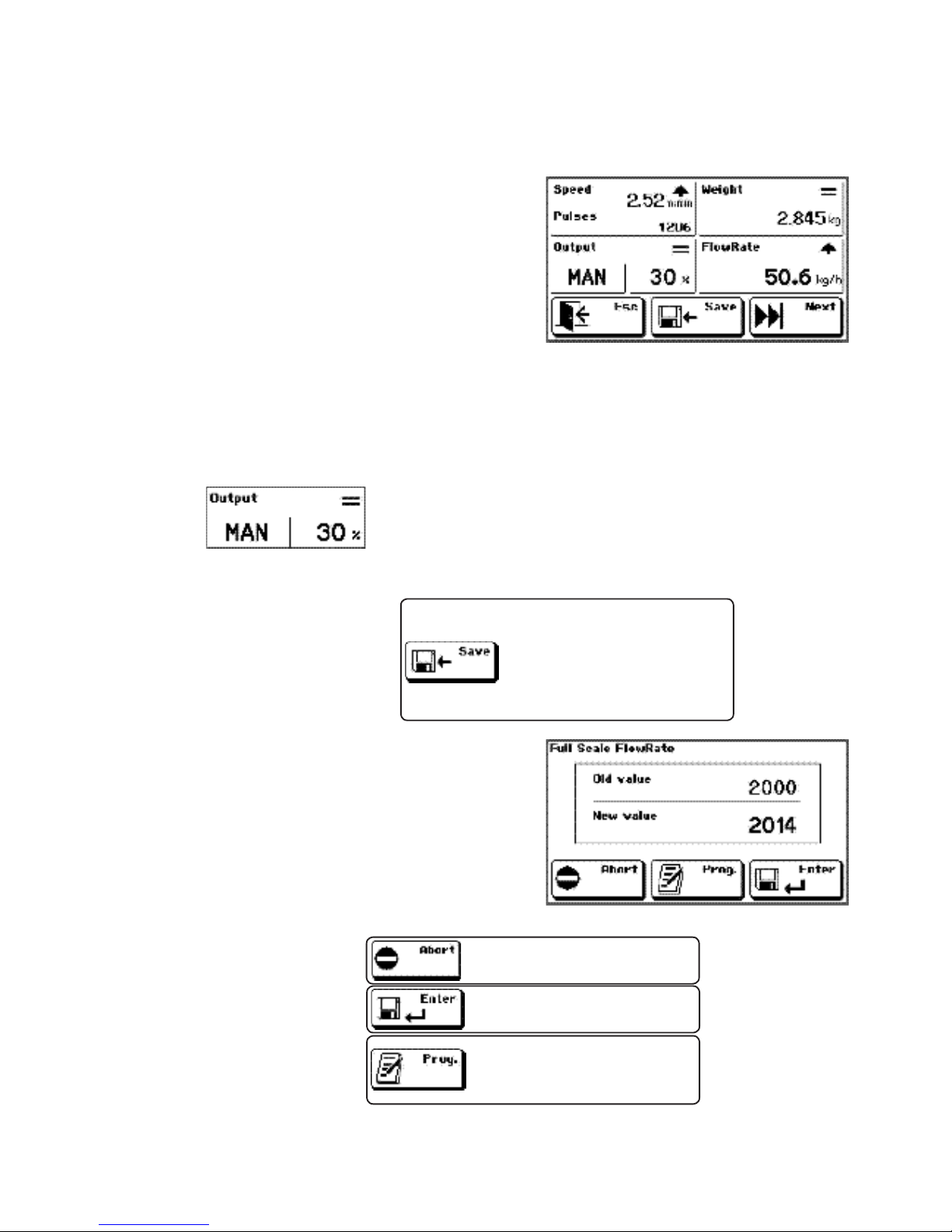

TECHNICAL NOTE: MANUAL OUTPUT LINKED WITH THE SETPOINT

To each setpoint is associated one adjustment manual output percentage.

- When one setpoint value is set or changed, an associated manual output value is suggested which is

calculated proportionally according to the scale end value; it is then possible to change the suggested

value.

- When you select a new setpoint the associated manual output value is taken as adjustment starting

value (both AUTO and MAN).

- When during the operation you change from AUTO to MAN, the output current value is saved in the

manual output parameter associated with the Setpoint.

SECTION 3: MAN / AUTO OUTPUT

The output section can indicate whether the value calculated by the MC 353 in automatic mode for the

adjustment output, or the value calculated in manual mode by the user.

Output trend (up, down, stable)

Press the AUTO section to change the MAN operation. The current output

is acknowledged in the manual operation.

If the input state is set to AUTO (closed) a confirmation request is required

on the relevant window.

In case of manual operation the section is divided into 2 “touch” areas.

Press left on MAN to change to AUTO, with any confirmation window according to the selection input state.

Press right on the output value to access the value change

function and to keep the manual operation.

Pag. 29

MC 353 software 1.9

ENG

3

In the main window press the section to enter the detailed window concerning the instantaneous hourly

flow rate, where additional information are reported.

Output trend (up, down, stable)

The display shows the current hourly flow rate values,

the minimum, the maximum and the arithmetic mean

of the previous instantaneous hourly flow rate values

represented in the graphic.

TECHNICAL NOTE: HOURLY FLOW RATE GRAPHIC REPRESENTATION

The graphic shows up to 150 values of hourly flow rate calculated during the operation according to

the set sampling time. If the sampling time is of 3 sec. the graphic represents up to 7 minutes and a half

of operation. When the graphic is completed the last third (50 values) are drawn at the beginning and

the representation goes on from that moment.

The Max, Min and mean values refer to the values on the graphic.

The central reference line refers to the current flow rate setpoint, whereas the hatched lines above and

under the central one represent the setpoint tolerance.

It quits the window and displays

the main screen.

It draws the graphic and recalculates

the data on the last 50 values.

It displays the contextual Help

window that can be set.

SECTION 4: HOURLY FLOw RATE

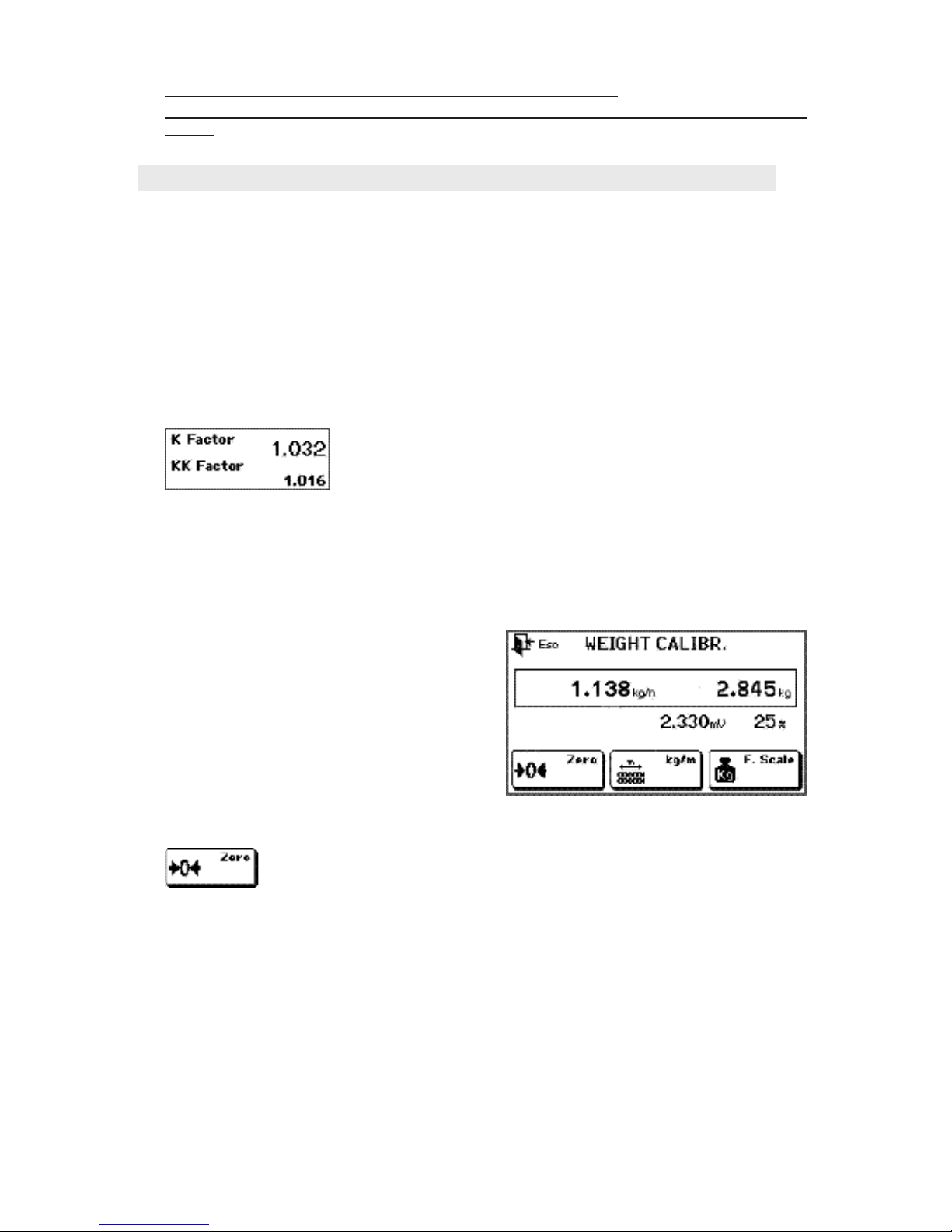

SECTION 5: CORRECTION FACTORS

This section displays the correction factors applied to calculate the hourly

flow rate and the following data. Factor K is determined with the belt

calibration procedure.

Another KK correction coefficient can be set by the serial line through the

described protocols. Such KK coefficient is applied additionally to the K

general coefficient.

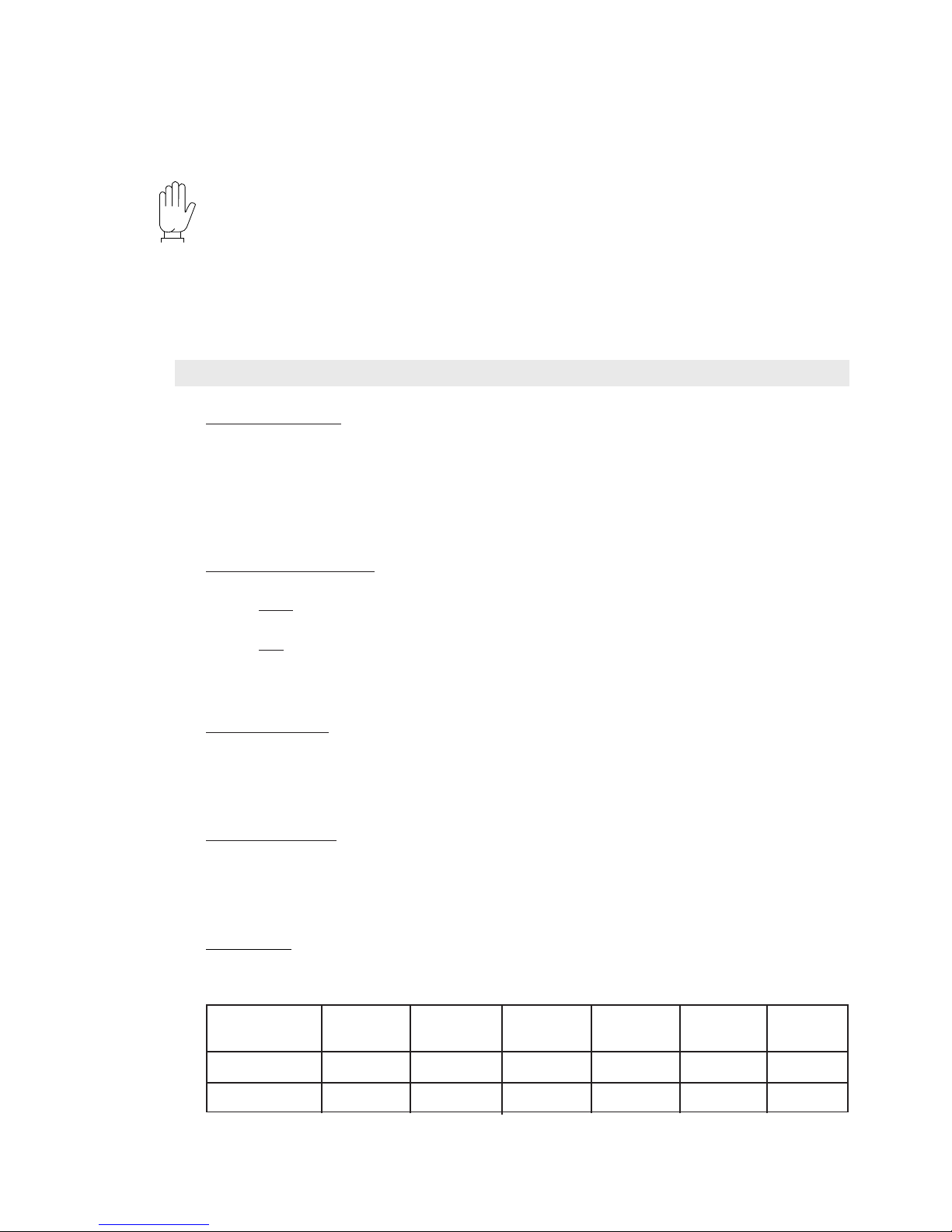

SECTION 6: CURRENT wEIGHT

This section displays the detected current weight. During the run the display

shows also the weight trend (up, down or stable).

In case of non-connected load cells or faults in the connection cables, the

writing NO CONN (not connected) appears instead of the measure.

Pag. 30

MC 353 software 1.9

ENG

3

SECTION 7: STATE AND TIMER

This display shows a message that indicates the instrument operation state, and one timer (hours:minutes:seconds) relevant to the run time, that is

reset upon run start. The state message in the general window indicates

the STOP and RUN conditions whereas in other procedures it can assume

the following data:

belt calibration procedure in progress

System test procedure in progress

Belt homing procedure (preparation)

Belt homing procedure (execution)

Operation simulation procedure in progress

Belt cal.

System test

Reset waiting

Reset in progress

Simulation

SECTION 8: ENCODER SPEED AND PULSES

This section displays the belt instantaneous speed value (in mm/min) and

calculated at each sampling period according to the pulses acquired by the

encoder and the belt sizing parameters. Pulse value refers to the counting

during the sampling period.

During the operation the display shows also the speed trend with respect

to the previous values (up, down, stable).

Pag. 31

MC 353 software 1.9

ENG

3

3.3 - SET-UP MENU LEVELS

The parameters that can be set are organised in 3 different levels: User, Technician and set-up.

For each level it is possible to enable one access password for the menu.

A change of the could parameters can jeopardise the machine operation and thus we recommend it to

be carried out only by qualified personnel and anyway after having read the manual.

USER MENU - ( MENU )

It contains the functions and parameters that can be usually modified by the operator according to the

working needs.

It is possible to enter the user menu by pressing the relevant key in the base general window.

This allows you to enter the user

menu for parameters’s setting.

During the run with this procedure you enter directly the adjustment parameters and not the user menu

that is not available with running instrument.

TECHNICAL MENU - ( MENU -> TECHNICAL MENU )

It contains the test functions and the set-up relevant to the machine type and the operation mode; usually

it must be used in the starting stage (recommended for qualified personnel).

It will only be possible to enter the User Menu and select the suitable TECHNICAL MENU control only

with stopped metering.

SET-UP MENU - (ACCESS RECOMMENDED ONLY FOR qUALIFIED PERSONNEL)

It contains the instrument set-up functions/parameters, the modification of the parameters is usually

reserved to the supplier.

The access to the set-up occurs upon switching-on

when the introduction window is displayed.

Press set-up to access the relevant menu.

Pag. 32

MC 353 software 1.9

ENG

3

PARAMETERS SET-UP MENU - SET-UP LEVELS PROTECTION

It is possible to associate to each level a protection password that can be set through the technical menu,

and it will be required to enter the relevant menu.

If you set 0 as password the access to the menu is free, thus the password request is disabled.

From the TECHNICAL MENU select LEVEL PROTECTION; from here it is possible to determine the Touch

Screen protection level and any set-up of the 3 passwords (4-digit passwords).

The block level can be selected among the 3 following modes:

FREE

LOW LEVEL

HIGH LEVEL

Free access to the sections of the general window and to the user

menu without password.

Free access to the general window sections, but a password is required

(if set) to enter the user menu.

Denied access to the general window sections and a password is required (if set) to enter the user menu. Free access to the general window

sections and to the user menu without password.

Pag. 33

MC 353 software 1.9

ENG

3

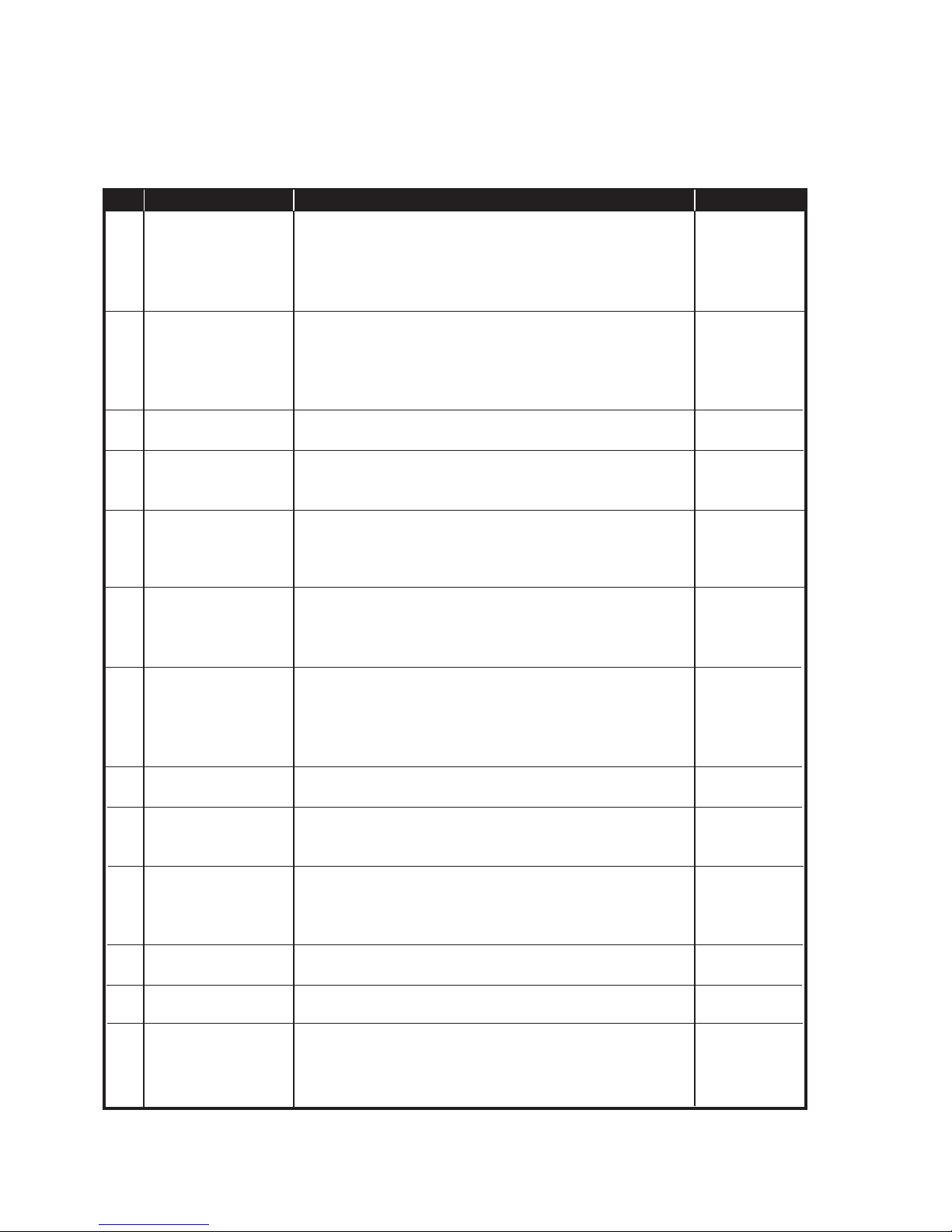

1001

1002

1003

1004

1005

1041

1042

1043

1044

1045

1061

1062

1063

1064

3015

1021

1022

1023

1024

1025

1026

1027

1028

1029

1030

USER MENU

REGULATION PAR.

I/O SELECTION

OPERATION TIMERS

VARIABLE FILTERS

GRAND TOTAL

DISPLAY SETTING

TECHNICAL MENU

REGULATION PAR.

I/O SELECTION

OPERATION TIMERS

VARIABLE FILTER

GRAND TOTAL

DISPLAY SETTINGS

TECHNICAL MENU

Sampling Time

Proport. Const.

Integral Const.

Dead Band

Flowrate Limit

Tot. Pulse Value

Al. Min. Weight

Alarm Out Logic

Toler. Out Logic

Al. Regulation

Al. Encoder

Input 5 Function

Input 6 Function

Tolerance alarm

Always alarm

Stop Delay

Weight Timeout

Regulat. Delay

Flow Limit Delay

Limit. Init. Delay

Flowrate Filter

Weight Filter

Minimun Weight

Min. Analog Out

Grand Total

(Specific Procedure)

(Go to Tecnical Menu)

3.4 - PARAMETERS TABLES

Pag. 34

MC 353 software 1.9

ENG

3

0101

0102

0103

0104

0105

0106

0107

0108

0109

0111

0113

0121

0122

0123

0124

0152

0154

0155

0156

0157

0158

0159

0160

0161

0162

0163

0164

n/a

n/a

n/a

TECHNICAL MENU

COMM. PORTS

TEST FUNCTION

ACCESS LEVELS

DATE & TIME

SYSTEM CALIBR.

BELT SPECIFICAT.

DATA LOGGER

SYSTEM TEST

COMM. PORTS

COM1 Protocol

COM1 Baud rate

COM1 Frame Sel.

COM2 Protocol

COM2 Baud rate

COM2 Frame Sel.

COM3 Protocol

Comm. Address

Profibus Address

Profinet IP Address

Profinet S. Mask

TEST FUNCTION

I/O TEST

SYS. SIMULATION

1ST. AN. OUT TEST

2ST. AN. OUT TEST

(OPTIONAL)

ACCESS LEVELS

Touch Panel Lock

User’s Password

Technical Passw.

Service PIN

DATE & TIME

Current Date

Current Time

SYSTEM CALIBR.

BELT ZEROING

BELT CALIBR. ADJ.

WEIGHT CALIBR.

DENSITY CALIBRATION

BELT SPECIFICAT.

Max Flow Rate

Load Cells Cap.

Roller Diameter

Pulses / Round

Encoder Phase

Roller Distance

Belt Tilt Degrees

Load Cell. Sensit.

Belt Speed

Total’s Resolut.

Dead Band Unit

Tolerance Unit

SYSTEM TEST

(Specific Procedure)

DATA LOGGER

Data Log Mode

TECHNICAL MENU - PARAMETERS LIST

Pag. 35

MC 353 software 1.9

ENG

3

0011

0012

0013

0014

0015

0016

0017

0018

0019

0020

0021

0022

0023

0024

0026

0028

SYSTEM SETUP

SYSTEM SETUP

SAVE SETUP

LOAD SETUP

FILES LOADING

FACTORY SETUP

SAVE PROFI I/O

LOAD PROFI I/O

SYSTEM SETUP

Operat. Function

Encoder

Total Batch

Input f. Master

2nd Analog Out

3nd Analog Out

Analog Input

USB Host Port

Language

1st An. Out Range

2st An. Out Range

KK Factory select

Density F.S.

Weight Vis.

Weight F.S.

Speed F.S.

SETUP SAVING

(Specific Procedure)

SETUP LOADING

(Specific Procedure)

FILES LOADING

FILE H01.TXT

FILE H02.TXT

FILE H03.TXT

FILE H04.TXT

FILE H05.TXT

FILE H06.TXT

FILE H07.TXT

FILE H08.TXT

FILE H09.TXT

FILE H010.TXT

FILE SPLASH.BMP

FILE SETPOINT.TXT

FILE INEXT.TXT

FACTORY SETUP

SET WEIGHT ZERO

SET WEIGHT 2mV/V

SET D/A OUT1 Volt

SET D/A OUT1 mA

SET D/A OUT2 Volt

SET D/A OUT2 mA

SET ANALOG IN ZERO

SET ANALOG IN 10V

SET-UP MENU - PARAMETERS LIST

Pag. 36

MC 353 software 1.9

ENG

3

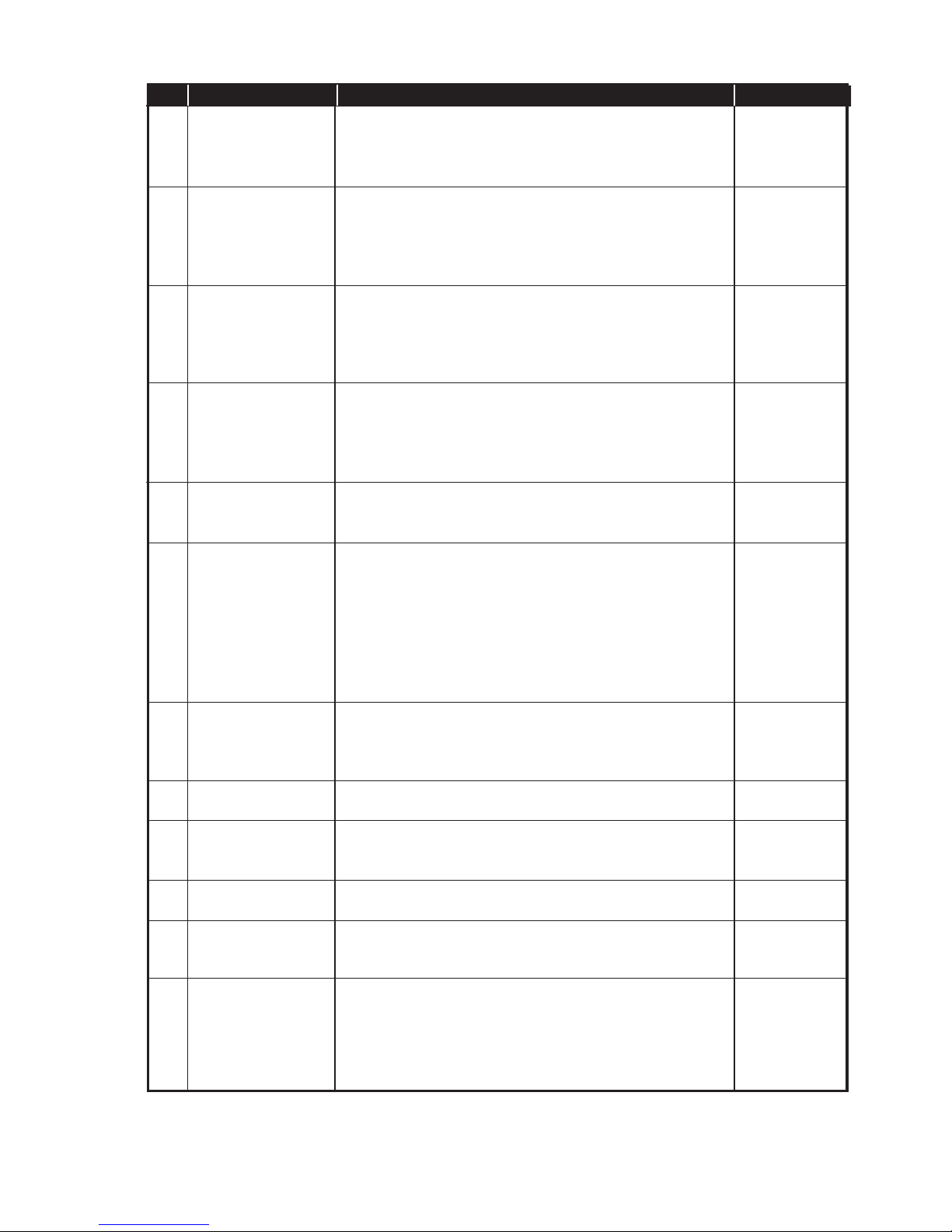

0011

0012

0013

0014

0015

0016

0017

0018

0019

0020

0021

0022

0023

0024

0026

0028

0101

0102

0103

0104

0105

0106

0107

0108

0109

0111

0113

0121

0122

0123

0124

0131

0132

0133

0134

0135

0141

0143

0152

0154

0155

0156

0157

0158

0159

0160

0161

0162

0163

0164

0182

Addr. Name Decription Unit Menù

Operat. Function

Encoder

Total Batch

Input f. Master

2nd Analog Out

3th Analog Out

Analog Input

USB Host Port

Language

1st An.Out Range

2nd An. Out Range

Sel. factor KK

FS density

Weight selection

FS Weight

FS Speed

COM1 Protocol

COM1 Baud rate

COM1 Frame Sel.

COM2 Protocol

COM2 Baud rate

COM2 Frame Sel.

COM3 Protocol

Comm. Address

Comm. Profibus

Profinet IP

Profinet Sn.M.

Touch Panel Lock

User Password

Technical Passw.

Service PIN

Operation Mode

Belt Lap Time

Belt Lap Lenght

Tare Weight

Max Remote Tare

K Factor

KK Factor

Max Flow Rate

Load Cells Cap.

Roller Diameter

Pulses / Round

Encoder Phase

Roller Distance

Belt Tilt

Load Cells Sens.

Belt Speed

Total’s Resolution

Dead Band Unit

Tolerance Unit

Effective Max Flow

Operating mode sel. (transmitter/adjuster)

System encoder availability sel. (no/yes)

Totalization function with setpoint check sel. (no/yes)

Capacity setpoint adj. Master input sel. (no/serial/analogue)

Selection of optional analogue output activation ( no / flow rate / density);

Selection of optional 3rd analogue output activation ( no / density);

Additional analogue input availability sel. (no/yes)

USB Host port availability for memory key sel. (no/yes)

Messages language sel.

Main analogue output range sel. (0÷5V/0÷10V/0÷20mA/4÷20mA)

Optional analogue output 2A range sel. (0÷5V/0÷10V/0÷20mA/4÷20mA)

Abilitation selection about KK factor (false/true)

Density full scale

Weigh visualization selection (weigh, weigh/meter)

Weigh full scale for 3rd analogue output (kg or kg/min, to be selected)

Speed full scale for 3rd analogue output

COM1 protocol sel. (none/ModbusRTU/Ascii/Profibus)

COM1 baud rate sel. (1200/2400/4800/9600/19200/38400/57600)

COM1 data frame format sel. (N81/N82/E81/O81/E72/O72/E71)

COM2 protocol sel. (none/monitor/master/slave)

COM2 baud rate sel. (1200/2400/4800/9600/19200/38400/57600)

COM2 data frame format sel. COM2 (N81/N82/E81/O81/E72/O72/E71)

COM3 protocol sel. (none/printer/repeater)

Serial communication address

Profibus communication address

Address mod. Profinet (32 bit, 8 bit for each IP address field)

Address Subnetmask mod. Profinet (32 bit, 8 bit for each IP address field)

Touch panel block level sel. (none/low/high)

User’s programming menu access password

Engineer’s programming menu access password

Setup menu access service password

Belt reset mode sel. (time/length)

Belt complete rotation time for reset procedure

Belt complete rotation length for reset procedure

Belt tare

Max resettable weight value from input or serial

Correction factor for capacity acknowledgement

Additional correction factor for capacity acknowledgement

System sized hourly max. capacity

System load cells total nominal capacity

Diameter of roller encoder is fitted onto

Encoder nominal resolution

Encoder phases acknowledgement system (x1/x2x/x4)

Rollers gap on weighing bridge

Belt inclination in degrees

Load cells average sensitivity

Belt fixed theoretical speed, if the encoder is disabled

Total conveyed weight resolution compared to capacity unit (10x/100x)

Adjustment deadband measurement unit selection (kg/h / %)

Capacity tolerance measurement unit selection (kg/h / %)

Max. hourly flow rate calculated proportionally to test valuesystem test

Level 1 - SYSTEM

Level 2 - TECHNICAL

Logic

Logic

Logic

Select

Logic

Logic

Logic

Select

Select

Select

Select

Select

kg/dm3

Select

kg-kg/m

m/min

Select

Select

Select

Select

Select

Select

Select

Number

Number

Number

Number

Select

Code

Code

Code

Select

sec

cm

kg

kg

Coeff.

Coeff.

kg/h

kg

cm

°

pls/round

Select

cm

mV/V

m/min

Select

Select

Select

kg/h

System

Setup

Comm.

Ports

Access

Level

Test

Belt

Specification

System

Calibr.

3.5 - LIST OF PARAMETERS TO BE SET

Pag. 37

MC 353 software 1.9

ENG

3

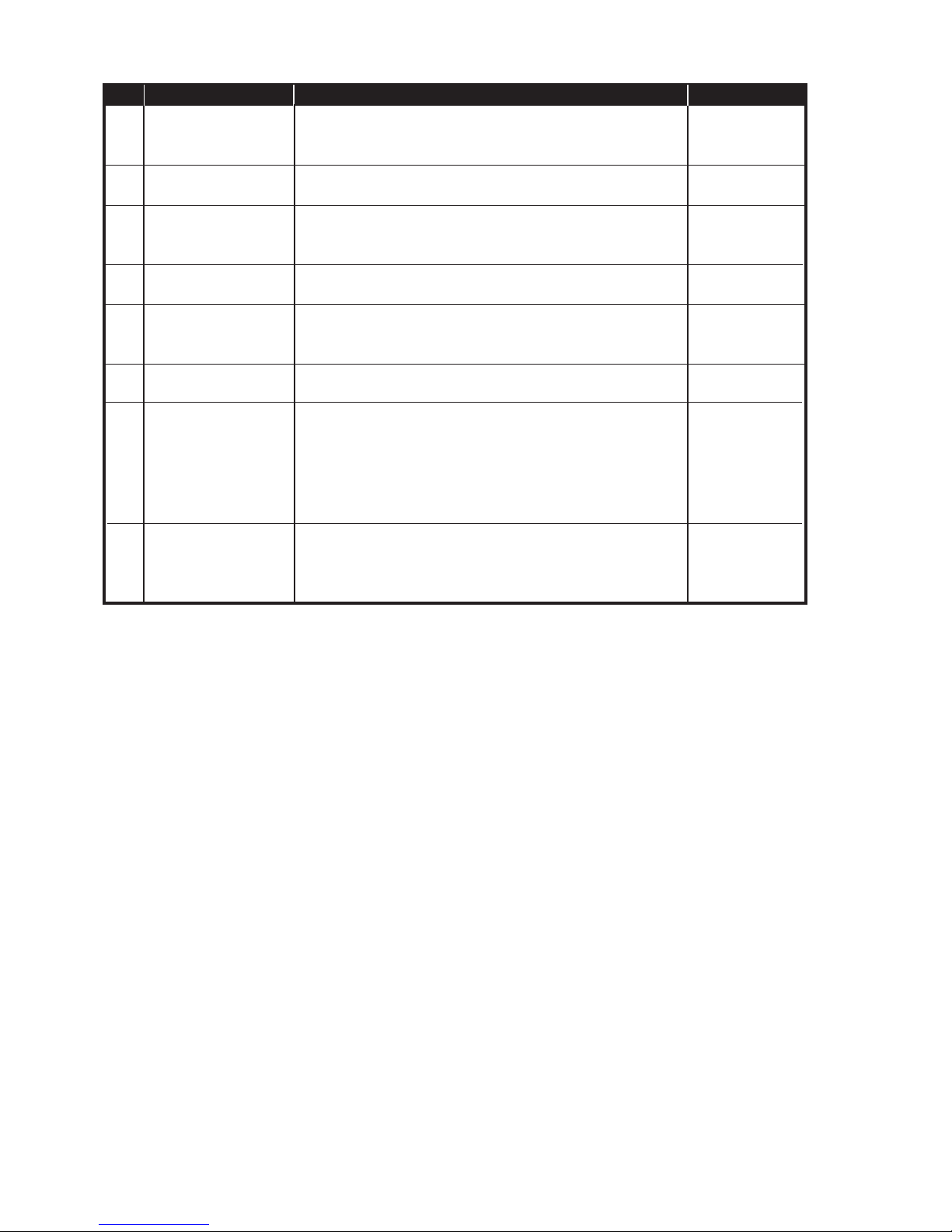

1001

1002

1003

1004

1005

1006

1007

1021

1022

1023

1024

1025

1026

1027

1028

1029

1030

1041

1042

1043

1044

1045

1061

1062

1063

1064

2002

2004

2006

2041

2042

2043

2044

2045

2046

2047

2048

2049

2050

2051

2052

2053

2054

2055

2056

2057

2058

2059

2060

2061

2062

2063

2064

2065

2066

Sampling Time

Proport. Constant

Integral Constant

Dead Band

Flowrate Limit

Dead Band %

Flowrate Limit %

Tot. Pulse Value

Alarm Min.Weight

Alarm Out Logic

Toler. Out Logic

Alarm Regulation

Alarm Encoder

Input 5 Function

Input 6 Function

Tolerance Alarm

Always Alarm

Stop Delay

Weight Timeout

Regulation Delay

Flow Limit Delay

Limit Init. Delay

Flowrate Filter

Weight Filter

Minimun Weight

Min. Analog Out

SET

Pre-SET

Flying

Setpoint 1

Manual Out Set 1

Setpoint 2

Manual Out Set 2

Setpoint 3

Manual Out Set 3

Setpoint 4

Manual Out Set 4

Setpoint 5

Manual Out Set 5

Setpoint 6

Manual Out Set 6

Setpoint 7

Manual Out Set 7

Setpoint 8

Manual Out Set 8

Setpoint 9

Manual Out Set 9

Setpoint 10

Manual Out Set 10

Setpoint 11

Manual Out Set 11

Setpoint 12

Manual Out Set 12

Setpoint 13

Manual Out Set 13

Hourly capacity sampling time

Adjustment algorithm proportionality constant

Adjustment algorithm integration constant

Capacity gap around the Set where adjustment does not occur

Capacity Setpoint tolerance

Capacity gap around the Set where adjustment does not occur %

Capacity Setpoint tolerance %

Totalized weight corresponding to output pulse

Min. weight alarm enable sel. (disabled/no capacity/min. weight)

Alarm output operation logic sel. (NA/NC)

Output operation logic sel. outside capacity tolerance (NA/NC)

Adjustment alarm enable sel. (no/yes)

Encoder alarm enable sel. (no/yes)

Logic input No.5 function sel. (Setpoint sel./belt reset)

Logic input No.6 function sel. (Setpoint sel./belt reset)

Selection to activate the out of tolerance alarm (no/yes)

Selection to activate permanently the alarms, even when not in RUN (no/yes)

Run stop delay

Max. time period where weight can be constant

Adjustment enable delay upon run start

Capacity output enable delay outside tolerance limits

Capacity tolerance control delay upon run start

Hourly capacity filter factor

Weight filter factor

Min. detected weight to calculate a hourly capacity

Adjustment min. value

Conveyed product total setpoint

Conveyed product total preset

Conveyed product weight flight

Capacity setpoint No. 1

Percentage output associated with Setpoint No.1

Capacity setpoint No. 2

Percentage output associated with Setpoint No.2

Capacity setpoint No. 3

Percentage output associated with Setpoint No.3

Capacity setpoint No. 4

Percentage output associated with Setpoint No.4

Capacity setpoint No. 5

Percentage output associated with Setpoint No.5

Capacity setpoint No. 6

Percentage output associated with Setpoint No.6

Capacity setpoint No. 7

Percentage output associated with Setpoint No.7

Capacity setpoint No. 8

Percentage output associated with Setpoint No.8

Capacity setpoint No. 9

Percentage output associated with Setpoint No.9

Capacity setpoint No. 10

Percentage output associated with Setpoint No.10

Capacity setpoint No. 11

Percentage output associated with Setpoint No.11

Capacity setpoint No. 12

Percentage output t associated with Setpoint No.12

Capacity setpoint No. 13

Percentage output associated with Setpoint No.13

sec

%

Coeff.

kg/h

kg/h

%

%

kg

Select

Select

Select

Logic

Logic

Select

Select

Select

Select

sec

sec

sec

sec

sec

Coeff.

Coeff.

kg

%

kg

kg

kg

kg/h

%

kg/h

%

kg/h

%

kg/h

%

kg/h

%

kg/h

%

kg/h

%

kg/h

%

kg/h

%

kg/h

%

kg/h

%

kg/h

%

kg/h

%

Level 1 - USER

Level 0 - OPERATING

Regulation

Parameters

I/O

Selection

Operation

Time

SET-POINT

Variable

Filters

Pag. 38

MC 353 software 1.9

ENG

3

2067

2068

2069

2070

3011

3013

3015

3016

3017

3018

3019

3021

3023

3024

3025

3026

3027

3028

3029

3030

3031

3033

3034

3035

4011

4012

4013

4014

4015

4016

4017

4018

4019

5001

5002

7001

Setpoint 14

Manual Out Set14

Setpoint 15

Manual Out Set15

Flowrate

Total

Grand Total

Setpoint

Alarm Code

Input

Output

Speed

Actual weight

Analog Out 1

Analog Out 2

Analog Input

Tests Status

Run Status

Flowrate Decim.

Total Decimals

Weight Decimals

Weigh / meter

Density

System ready

Num. Set

Auto / Man

Manuale Out

Setpoint Variation

Specific weight

Input IO 1

Output IO 1

Input IO 2

Output IO 2

Command reg.

Run comm. reg.

Test Register

Capacity setpoint No. 14

Percentage output associated with Setpoint No.14

Capacity setpoint No. 15

Percentage output associated with Setpoint No.15

Instant read, calibrated and filtered capacity

Conveyed product total weight

Overall total

Current Setpoint value

Alarm code (*)

Status of logic input (1=close, 0=open) (bit0=IN1, …, bit5=IN6)

Status of logic output (1=active, 0=inactive) (bit0=IN1, …, bit5=IN6)

Belt current speed

Actual net weight

Main analogue output current value

Additional analogue output current value

Analogue input current value

Status (no/testI-O/belt calibre./syst. test./standby zeroing /belt zeroing/dac/simul)

Run status (stop/run)

Number of decimal digits of capacity values

Number of decimal digits of conveyed product total weight

Number of decimal digits of detected weight values

Weigh / meter current value

Density actual value

System ready, then stopped and no alarms (true, false)

Active Setpoint number

Operating mode sel. (automatic/manual)

Manual analogue output value

Capacity Setpoint variation percentage for slave operation

Weight parameter for density calculation

Mod. ext. IO n.1: logic state input (1=close, 0=open) (bit0=IN1, ..... bit3=IN6) (1*)

Mod. ext. IO n.1: logic state out.(1=active, 0=none) (bit0=OUT1, ..... bit7=OUT8)

Mod. ext. IO n.2: logic state input (1=close, 0=open) (bit0=IN1, ..... bit3=IN6)

Mod. ext. IO n.2: logic state out. (1=active, 0=none) (bit0=OUT1, ..... bit7=OUT8)

Oper. control adj. from serial (none/total reset/belt reset/save data)

Control adj. and run IN priority (bit 15=priority / bit 0=status IN)

Profibus network connection test registry

Current

Read only reg.

CMD

kg/h

%

kg/h

%

kg/h

kg

kg

kg/h

Select

Code

Code

m/min

kg

%

%

%

Select

Logic

Numer.

Numer.

Numer.

kg/m

kg/dm

3

Numer.

Numer.

Select

%

%

kg/dm

3

Code

Code

Code

Code

Select

Numer.

Numer.

(*): (no/regulation/encoder/minimum weight/weight error/fix weight/tolerance alarm/error IN EXT)

(1*): BIT15=1 if module communication fail timeout occurs.

(2*): NULL=0, TOTAL RESET=1, RESET BELT=2, SAVE DATA=3.

NOTE: The MODBUS-RTU specifications foresee that the 40001 register is allocated the address 0000.

Test

In Modbus, the fixed selectable options of the relevant parameters are indicated within brackets in the

description in increasing order: (0 / 1 / 2 / 3 / etc...).

Pag. 39

MC 353 software 1.9

ENG

1÷50 51÷500 501÷5000 5001÷50000 50001÷500000 500001÷5000000

0.01 kg/h 0.1kg/h 1 kg/h 0.01 t/h 0.1 t/h 1 t/h

1÷10

0.001

11÷20

0.002

21÷50

0.005

51÷100

0.01

101÷200

0.02

201÷500

0.05

501÷1000

0.1

1001÷2000

0.2

2001÷5000

0.5

5001÷10000

1

10001÷20000

2

20001÷50000

5

50001÷100000

10

3

0.000 kg 0.00kg 0.0kg 0.000 t 0.00 t 0.0 t

TECHNICAL NOTES ABOUT THE BELT SPECIFICATIONS

TECHNICAL NOTE: MAXIMUM HOURLY FLOW RATE

The set-up of this value determines also the indicated hourly flow rate resolution even though the instru-

ment uses a resolution 10 times higher. The unit of measurement of the hourly flow rate can be deduced

from the following table.

The maximum hourly value is also used as analogue output scale end, both the adjustment one and

the optional one for the transmission. Such value can be adjusted with the MACHINE TEST procedure.

Max.

ow rate

Flow rate

resolution

Weigh re-

solution

The instrument does not accept maximum hourly flow rate values that determine a ratio with the load

cells unit of measurement lower than 20 or higher than 50000.

TECHNICAL NOTE: LOAD CELL FLOw RATE

The setting up of this value determines also the weight unit of measurement that can be deduced by

the following table.

The load cells flow rate value, together with the set sensitivity, is processed to get the weight theoretic

adjustment, which is calculated again at the menu output when one of these two parameters has been

modified.

The side table indicates the units

of measurement calculated by the

system according to the installed

load cells max. ow rate.

More in detail the rst square

shows the total cells load, whereas in the lower part is indicated

the relative unit of measurement

(value in kg).

The instrument does not accept values of the load cells flow rate that determine a ratio between a max.

hourly flow rate and load cells unit of measurement lower than 20 or higher than 50000.

The total setpoint output control can not be connected with the general total.

For both totalizers the max value that can be counted is 99999999 (8 digits), and after this value it is

reset. For both totalizers the weight resolution can be selected between 10x and 100x with respect to

the weight unit used for the hourly flow rate.

TECHNICAL NOTES: GENERAL TOTAL

The general total counts the conveyed total weight separately from the standard total (lower level). The

reset of such values is independent.

Pag. 40

MC 353 software 1.9

ENG

3

DR

DR/2

A

B

TECHNICAL NOTE: ENCODER ACqUISITION

The encoder acquisition occurs in 2 phases (A and B), with rotation sense control. The phases connection

does not matter since the instrument detects the prevailing rotation sense.

The encoder nominal resolution can be increased (2x or 4x) according

to the phases acquisition modes, as shown in the following pictures:

C : 1x

P : 2x

S : 4x

DR corresponds to the distance between weighing bridge upstream and downstream rollers.

WEIGHING WITH BELT ON LOAD CELLS

WEIGHING WITH OVERHANG BELT

DR corresponds to the distance between the material load and unload point multiplied by two.

WEIGHING ON BELT

DR=(A/B)xA where A is the distance between the belt fulcrum and the material unload point,

whereas B is the distance between fulcrum and load cell.

The rollers distance (DR) is measured in different ways according to the type of belt the weighing bridge

is installed on. The following picture shows a summary of the different types with relevant identification

mode of the parameter.

TECHNICAL NOTE: ROLLERS DISTANCE

TECHNICAL NOTE: BELT INCLINATION

The set-up of this value affects the saved weight adjustment by compensating the load cells response. It

is possible to set the inclination degree after having adjusted the belt in horizontal position (or having

carried out the theoretic adjustment), or proceed with the sample weight adjustment after having set

the inclination degree.

The detected weight is calculated according to the belt inclination:

COMPENSATED WEIGHT = DETECTED WEIGHT / COS (angle)

Pag. 41

MC 353 software 1.9

ENG

3

TECHNICAL NOTES ABOUT THE SYSTEM SET-UP

This selection enables the flow rate setpoint continuous change function by one master. According to the

selected value, this change can occur through COM2 (RS485) serial line or through analogue input.

In the latter case the instrument must be provided with an analogue input optional board. The set flow

rate setpoint value corresponds to the master input scale end (digital 1000 value or analogue input

scale end) and is modified in proportion to the input.

TECHNICAL NOTE: MASTER INPUT

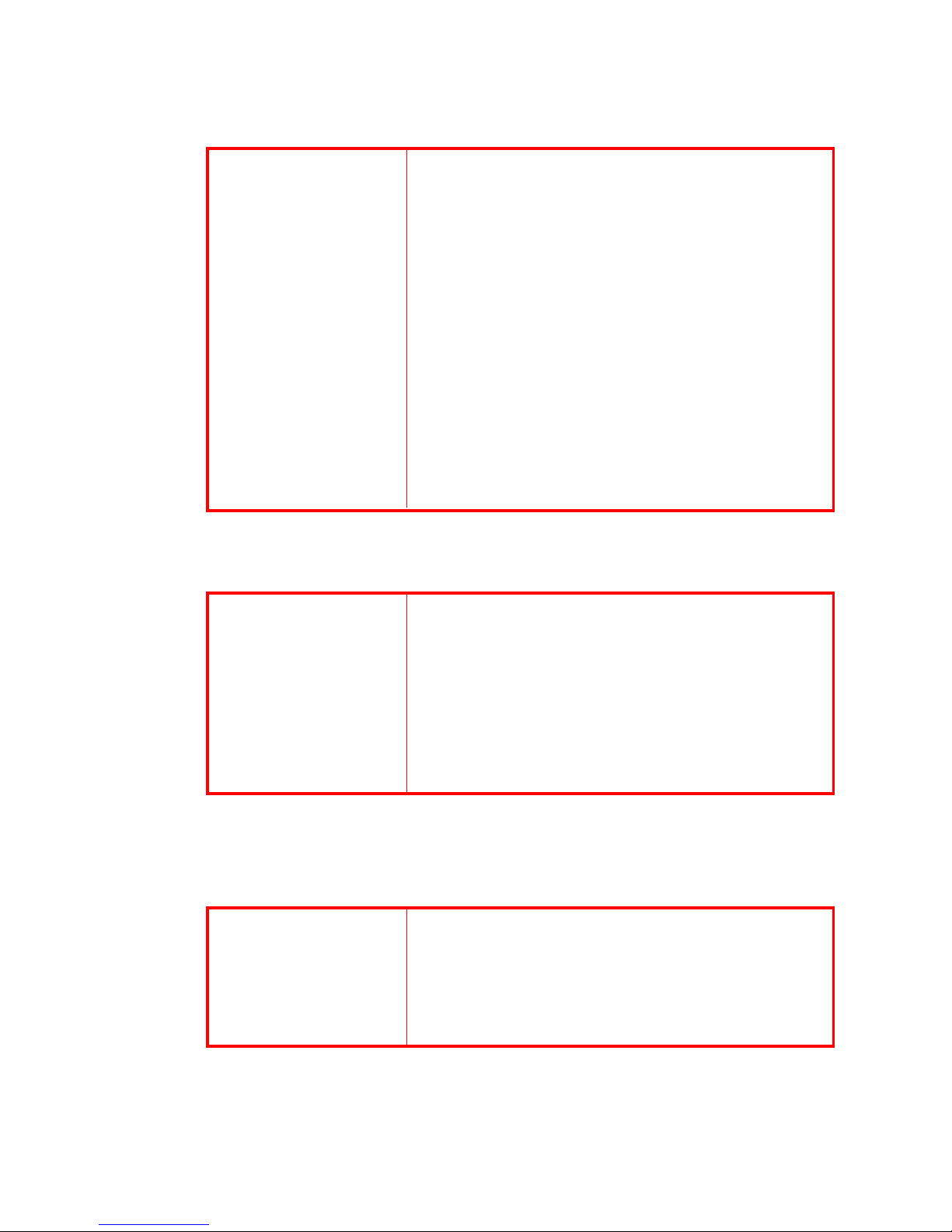

TECHNICAL NOTE: USB HOST PORT