DAT 500

TECHNICAL MANUAL

For Analog/Probus/Devicenet versions

Digital Transmitter

Software version PW13081

Page II

Page 1

0316

TABLE OF CONTENTS

PRECAUTIONS .............................................................................................. Page 2

INTRODUCTION ........................................................................................... Page 3

TECHNICAL FEATURES ................................................................................... Page 4

INSTALLATION .............................................................................................. Page 5

FRONT PANEL OF THE INSTRUMENT .............................................................. Page 10

USING THE KEYBOARD ................................................................................. Page 11

INFO DISPLAY ............................................................................................... Page 13

VIEWING, ZEROING THE WEIGHT AND SELF-CALIBRATION ............................. Page 14

SETTING ....................................................................................................... Page 18

CHART OF THE MENU ................................................................................... Page 20

SETTING PARAMETERS ................................................................................... Page 22

CALIBRATION................................................................................................ Page 25

WEIGHTING PARAMETERS ............................................................................. Page 27

INPUT/OUTPUT PARAMETERS ......................................................................... Page 29

SERIAL OUTPUT PARAMETERS ......................................................................... Page 32

ANALOG OUTPUT PARAMETERS..................................................................... Page 36

SERIAL COMMUNICATION PROTOCOLS ........................................................ Page 38

FIELDBUS PROTOCOLS .................................................................................. Page 46

TROUBLESHOOTING ..................................................................................... Page 50

GROUNDING CONNECTIONS DAT500 ......................................................... Page 51

INTRINSIC SAFETY BARRIERS .......................................................................... Page 52

OPTION 24 VOLT POWER SUPPLY .................................................................. Page 53

Page 2

PRECAUTIONS

READ this manual BEFORE operating or servicing the instrument.

FOLLOW these instructions carefully.

SAVE this manual for future use.

CAUTION

The installation and maintenance of this instrument must be allowed

to qualified personnel only.

Be careful when you perform inspections, testing and adjustment

with the instrument on.

Perform the electrical connections in the absence of the power supply

Failure to observe these precautions may be dangerous.

DO NOT allow untrained personnel to work, clean, inspect, repair

or tamper with this instrument.

Page 3

INTRODUCTION

The DAT 500 is a transmitter of weight to be combined with the load cells to detect the weight in every

situation.

The display allows easy reading of the weight, the status of the instrument, the setting parameters and

errors.

The 4 keys located below the display allow the operator to perform the functions of ZERO, TARE,

GROSS/NET switching, setting of the setpoints weight, setting and tare both theoretical than real.

The DAT 500 uses the serial port RS232 with ASCII and Modbus RTU protocols for connecting to a PC,

PLC and remote units. In parallel with the RS232, a USB port available.

They are always available 2 programmable weight setpoints and the control of the maximum weight

value reached (peak).

The RS422/RS485 serial output allows you to connect up to 32 addressable devices.

The availability of the most common fieldbuses, as an alternative to the RS422/RS485 port, also allows

the transmitter to interface with any supervision device currently offered by the market.

Available versions:

• DAT 500: weight transmitter with serial output RS232, RS422/RS485 and Peak function. Supported protocols are Modbus RTU, continuous, slave and the ones upon request. Two programmable

setpoints, 2 inputs and Peak function.

• DAT 500/A: version with the analog output.

• DAT 500/PROFIBUS: weight transmitter with serial output RS232 and PROFIBUS DP.

• DAT 500/DEVICENET: weight transmitter with serial output RS232 and DEVICENET.

IDENTIFICATION PLATE OF THE INSTRUMENT

It’s important to communicate this data in the event of a request for information or information concerning the instrument together with the program number and version that are shown on the cover of the

manual and are displayed when the instrument is switched on.

WARNINGS

The following procedures must be performed by qualified personnel.

All connections must be performed when the instrument is turned off.

Page 4

TECHNICAL FEATURES

Power supply 24 Vdc ± 15 %

Max. absorption 5W

Insulation Class II

Installation category Cat. II

Operating temperature -10°C ÷ +40°C (max. humidity 85% non-condensing)

Storage temperature -20°C ÷ +50°C

Weight display Numerical with 6 red led digits and 7 segments (h 14

mm)

Led 4 LEDs of 3 mm

Keyboard 4 mechanical keys

Overall dimensions 106 mm x 58 mm x 90 mm (l x h x w)

Installation Panel mount

Case material self-extinguishing Noryl (UL 94 V1)

Connections Screw terminal boards, pitch 5.08 mm

Load cells power supply 5 Vdc/120mA (max 8 cells of 350W in parallel), short-

circuit protected

Input sensitivity 0.02 mV min.

Linearity 0.01% of the full scale

Temperature drift 0.001% of the full scale / °C

Internal resolution 24 bits

Resolution of the weight displayed Up to 60,000 divisions on the net capacity

Measurement range –0.5 mV/V to +3.5 mV/V

Frequency of weight capture 5 Hz - 50 Hz

Digital filter To be selected from 0.2 Hz to 25 Hz

Number of weight decimals 0 ÷ 3 decimal places

Zero calibration and full scale Automatic (theoretical) or executable from the keyboard.

Logic outputs 2 opto-isolated (dry contact), max 24Vdc / 60 mA each

Logic inputs 2 opto-isolated at 24 Vdc PNP (external power supply)

Serial port (# 2) RS232C or RS422/RS485)

Maximum cable length 15m (RS232) and 1000m (RS422 and RS485)

Serial protocols ASCII, Modbus RTU

Baud rate 2400, 9600, 19200, 38400, 115200 to be selected

Program code memory 64 Kbytes FLASH on-board reprogrammable from RS232

Data memory 2 Kbytes

Analog output (optional) Voltage or current

Resolution 16 bits

Calibration Digital from the keyboard

Impedance Voltage: min. 10KΩ; Current: max 300Ω

Linearity 0.03 % of the full scale

Temperature drift 0.001% of the full scale /°C

Fieldbus (optional PROFIBUS DP, DEVICENET,

Buffer dimension 128 byte IN - 128 byte OUT

Page 5

PRG

0

SET

FUN

1 2

NET

8.8.8.8.8.8.

PRECISE DAT 500

48

96

139

130

148

44

90

1

2

3

4

5

6

7

8

+24 Vdc

0 Vdc

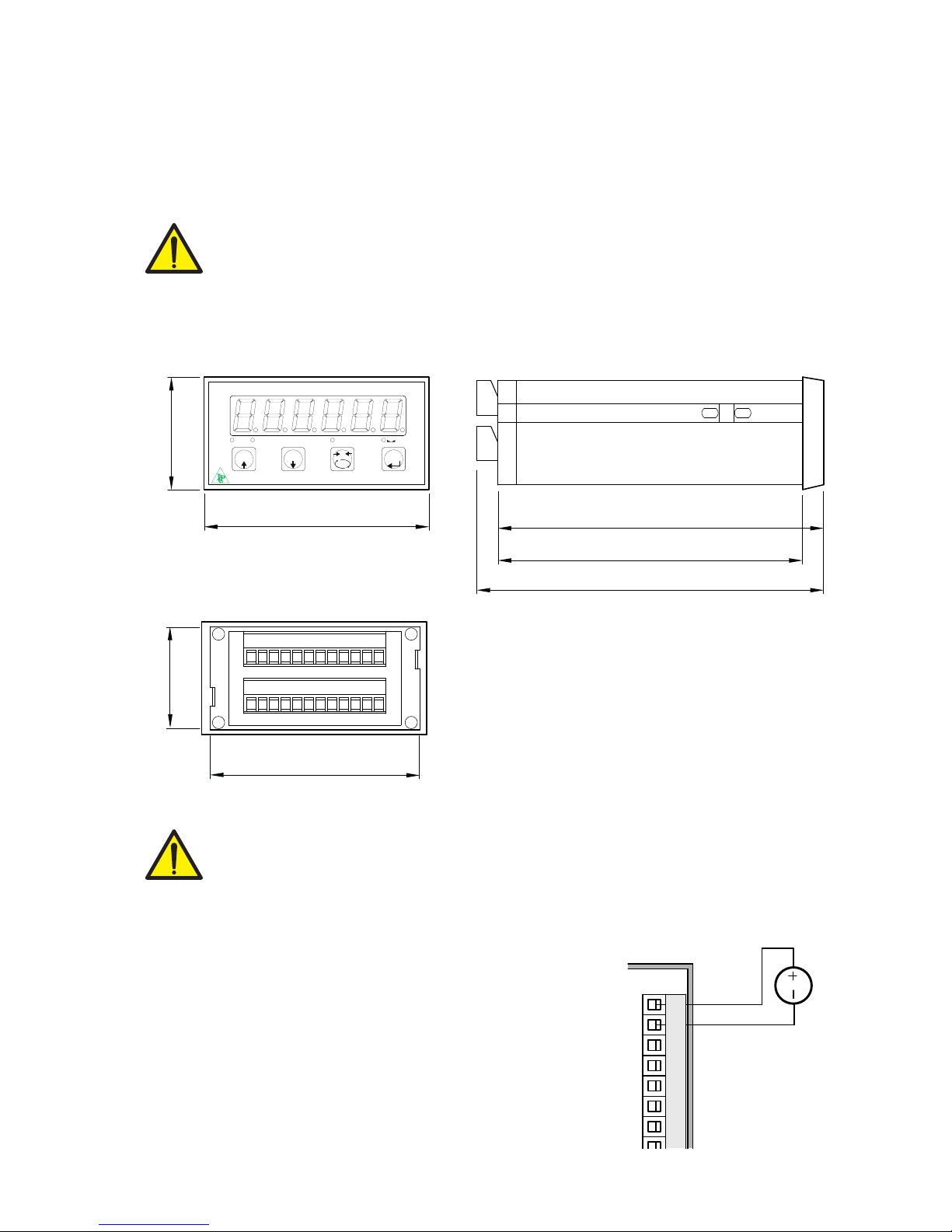

INSTALLATION

GENERAL DATA

The DAT 500 is composed of a motherboard, on which you can add the options available; the motherboard is housed in a plastic enclosure.

The DAT 500 should not be immersed in water, subjected to jets of water and cleaned or

washed with solvents.

Do not expose to heat or direct sunlight.

OVERALL DIMENSIONS

ELECTRIC INSTALLATION

The transmitter DAT 500 uses screw terminal boards, pitch 5.08 mm, for the electrical connection. The load cell cable must be shielded and channeled away from tension cables to

prevent electromagnetic interference.

INSTRUMENT POWER SUPPLY

The instrument is powered through the terminals 1 and 2. The power

cord must be channeled separately from other cables.

The supply voltage is electrically isolated.

Power supply voltage: 24 Vdc/ ± 15% max. 5W.

Page 6

1

2

3

13

14

15

16

17

18

19

20

21

22

23

24

4

5

6

7

8

9

10

11

12

LOAD CELLS

- Exc

+ Exc

+ Sense

- Sense

- Sig

+ Sig

2+SGN

3-EXC

6+EXC

1-SGN

5+SNS

4-SNS

7SHD

+EXC

-EXC

+SGN

-SGN

SHD

1

2

3

4

5

+EXC

-EXC

+SGN

-SGN

SHD

1

2

3

4

5

+EXC

-EXC

+SGN

-SGN

SHD

1

2

3

4

5

+EXC

-EXC

+SGN

-SGN

SHD

1

2

3

4

5

J-BOX CGS4

DAT 500

SENSE-

SENSE+

I OUT+

V OUT+

SIGN-

SIGN+

C OUT

S GND

C OUT

OUT2

C IN

EXC-

EXC+

OUT1

IN2

RX-

RX+

TX -

TX+

IN1

TXD

RXD

24

12

11

10

23

24

19

22

21

20

14

15

16

17

18

13

9

8

3

4

5

12+

-

6

7

+24V

+EXC

-EXC

+SGN

-SGN

SHD

+EXC

-EXC

+SGN

-SGN

SHD

+EXC

-EXC

+SGN

-SGN

SHD

+EXC

-EXC

+SGN

-SGN

SHD

25 pin Connector

FIELDBUS

OPTIONAL

1

2

3

13

14

15

16

17

18

19

20

21

22

23

24

4

5

6

7

8

9

10

11

12

INPUTS

24 VDC

INPUT 1

INPUT 2

+

-

COM. INPUT

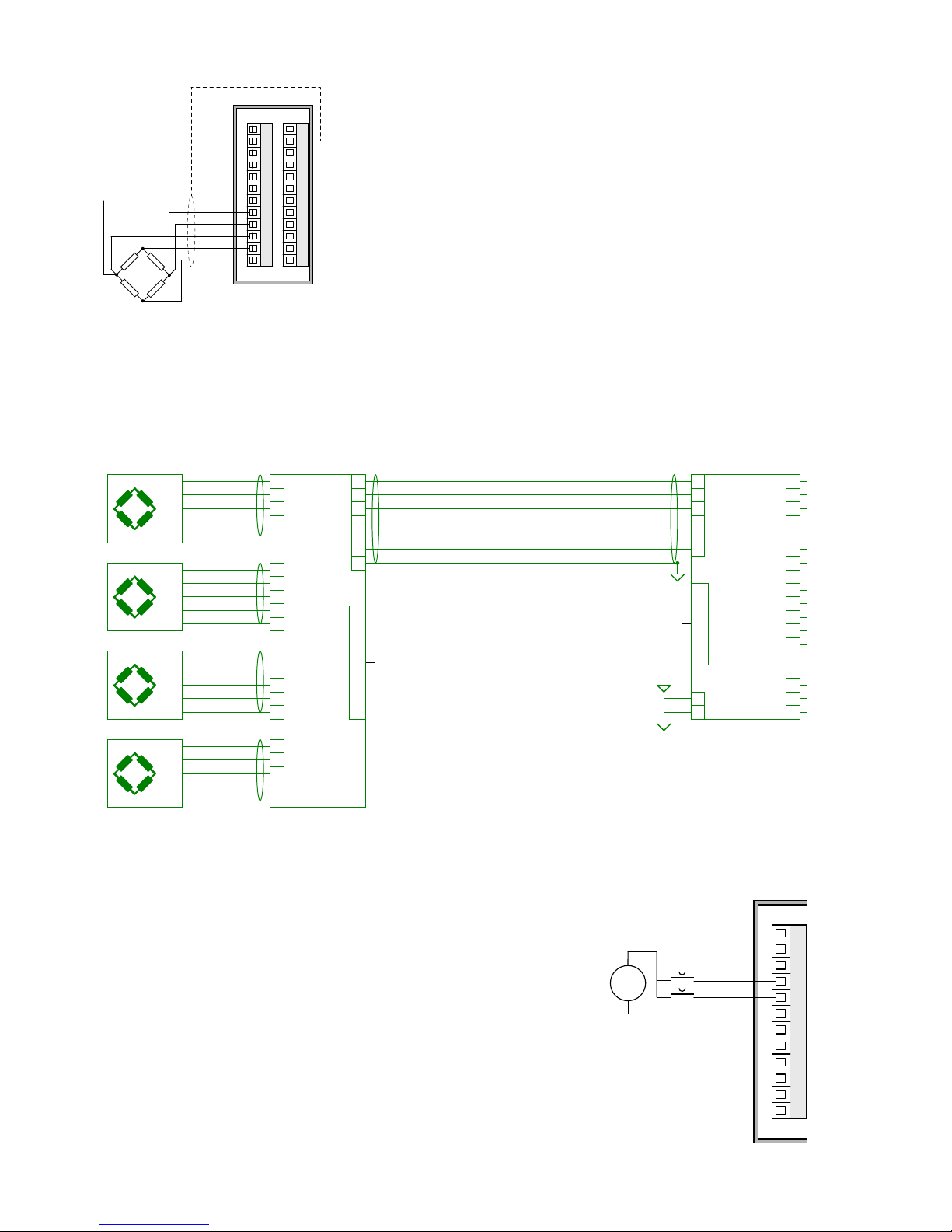

CONNECTIONS OF THE LOAD CELL/S

The cell/s cable must not be channeled with other cables, but must

follow its own path.

The instrument can be connected up to a maximum of 8 load cells

of 350 ohm in parallel. The supply voltage of the cells is 5 Vdc and

is protected by temporary short circuit.

The measuring range of the instrument involves the use of load cells

with a sensitivity of up to 3.5 mV / V.

The cable of the load cells must be connected to terminals 19-24.

In the case of 4-wire load cell cable, jumper the terminals 19 to 22

and 20 to 21.

Connect the cell cable shield to the terminal 2.

In the case of the usage of two or more load cells, use special junction boxes. Below please find their connection.

LOGIC INPUTS

The two logic inputs are opto-isolated.

The cable connecting the logic input should not be channeled with

the power cables.

The function of the two inputs is as follows:

INPUT1 Resetting the displayed value (gross, net or peak)

INPUT 2 PRINT

The activation of the two functions is accomplished by bringing the

external power supply 24 Vdc to the corresponding terminals as

shown in the figure.

Page 7

1

2

3

13

14

15

16

4

OUTPUTS

24 Vdc

100 mA Max

OUTPUT 2

OUTPUT 1

COM. OUTPUT

1

2

3

4

5

6

7

8

9

10

TXD

RXD

S.GND

SHIELD

RS232

(20m max)

1

2

3

13

14

15

16

17

18

19

20

21

22

23

24

4

5

6

7

8

9

10

11

12

S.GND

TXD+

TXD-

RXD+

RXD-

RS422/485

N°32 units max

(1000m max)

1

2

3

4

5

6

7

8

9

VOLTAGE (10 kΩ min)

ANALOG COM.

CURRENT (300 Ω max)

SHIELD

LOGIC OUTPUTS

The two opto-isolated relay outputs are the normally open contact.

The capacity of each contact is 24 Vdc, 100 mA max.

The cable connecting the outputs should not be channeled with the

power cables. The connection should be as short as possible.

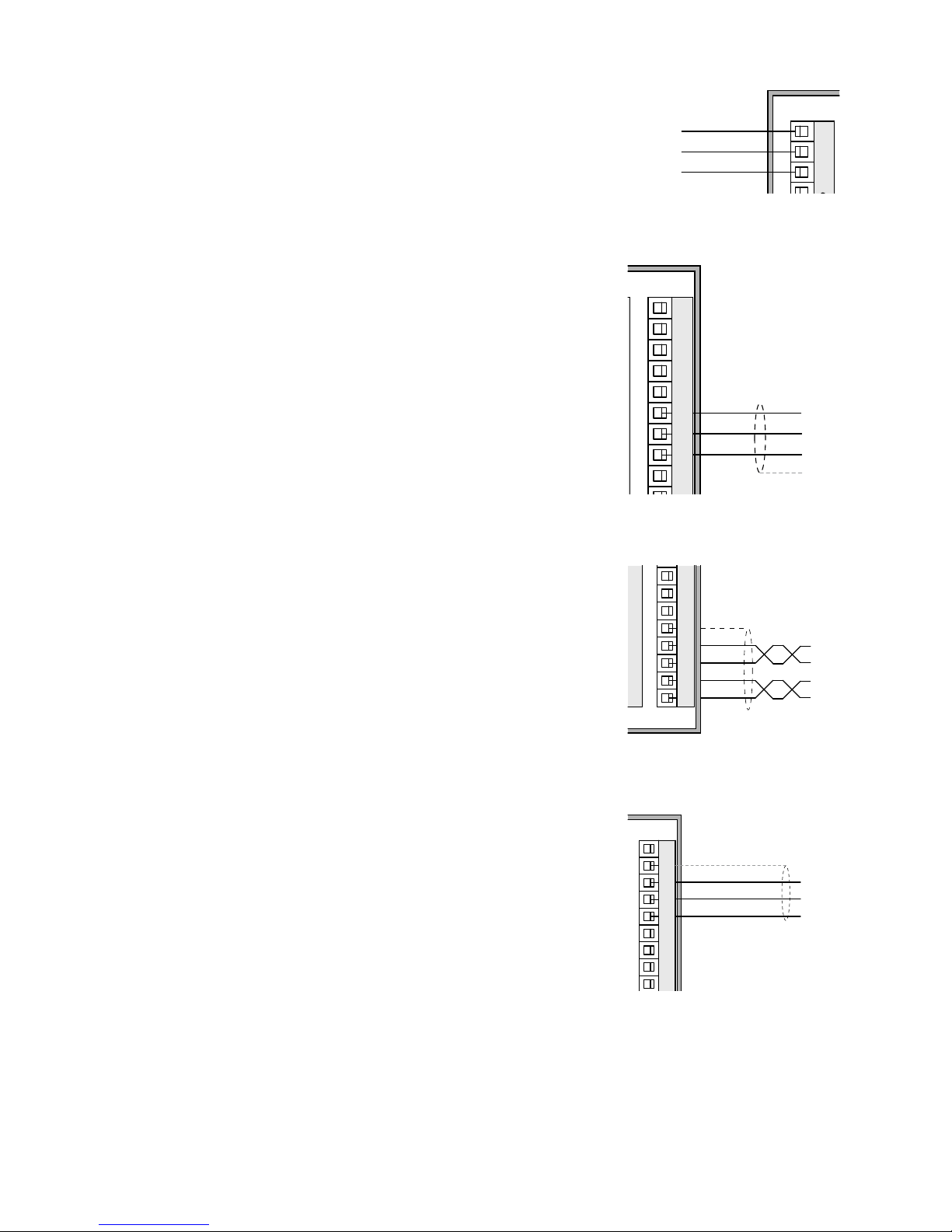

SERIAL COMMUNICATION

RS232:

The RS232 serial port is always present and handles various protocols.

To achieve the serial connection, use a shielded cable, making sure

to connect the shield to one of the two ends: to terminal 8 if connected on the side of the instrument, to the ground if it is connected

on the other side.

The cable must not be channeled with power cables; the maximum

length is 15 meters (EIA RS-232-C), beyond which you should take

the optional RS485 interface.

RS422/RS485:

The serial port RS485 (2-wire) is present in the model DAT 500/

RS485.

To achieve the serial connection, use a suitable shielded cable, making sure to connect the shield to one of the two ends: to terminal

8 if connected on the side of the instrument, to the ground if it is

connected on the opposite side.

The cable should not be channeled with the power cables.

ANALOG OUTPUT (OPTIONAL)

The transmitter provides an analog output in current and voltage.

Analog voltage output: range from -10 to 10 V or -5 to 5 V, with

minimum load of 10 KΩ.

Analog current output: range from 0 to 20 mA or 4 to 20 mA. The

maximum load is 300 Ω.

To achieve the serial connection, use a suitable shielded cable, making sure to connect the shield to one of the two ends: to terminal

2 if connected on the side of the instrument, to the ground if it is

connected on the opposite side.

Attention: do not connect the analog output to devices that are

switched on.

Page 8

3

8

15

9 6

B_LINE

A_LINE

15

9 6

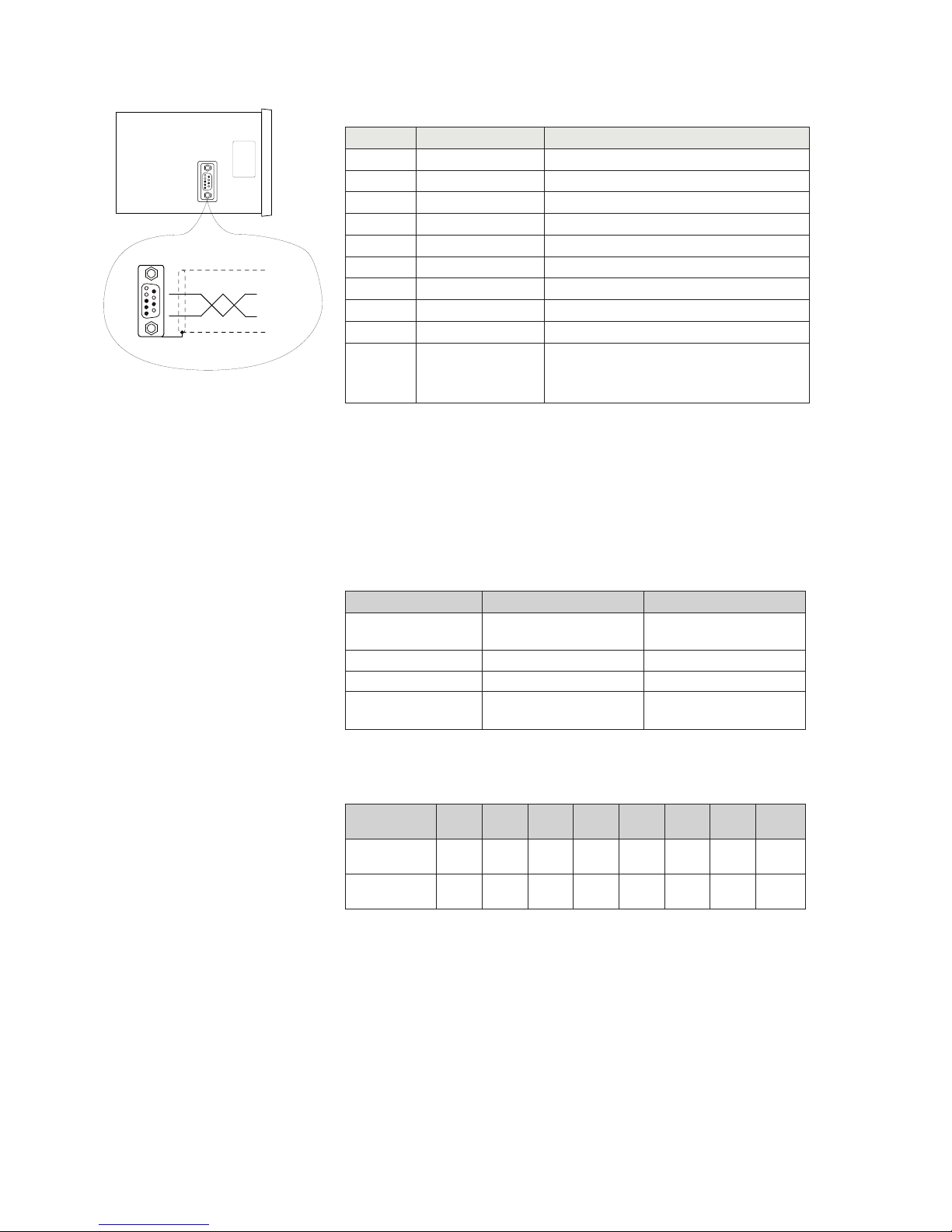

PROFIBUS DP CONNECTION

Pin Signal Description

1 - 2 - 3 B line +RxD/+TxD, level RS485

4 RTS Request to send

5 GND Ground (isolated)

6 + 5V Bus Output +5V termination (isolated)

7 - 8 A line -RxD/-TxD, level RS485

9 - Housing Cable shield Internally connected to protective

earth according to Profibus

specification

For connection to the Profibus Master, use a standard Profibus cable.

The typical impedance of the cable should be between 100 and

130 Ohms (f> 100 kHz). The cable capacity (measured between

conductor and conductor) should be less than 60 pF / m and the

minimum cable cross section should not be less than 0.22 mm2

In a Profibus-DP network, you can use either cable type A to type B

cable, depending on the required performance. The following table

summarizes the features of the cable to be used:

SPECIFICATION TYPE A CABLE TYPE B CABLE

Impedance from 135 to 165 ohm (f

= 3 – 20 MHz)

from 100 to 300 ohm (f

> 100 kHz)

Capacity < 30 pF/m < 60 pF/m

Resistance < 110 ohm/km Conductor cross

section

> 0,34 mm

2

> 0,22 mm

2

The following table shows the maximum length of the wires line with

cable type A and type B, function of the different communication

speed required:

Baud rate

(kbit/s)

9.6 19.2 187.5 500 1500 3000 6000 12000

Cable A

lenght (m)

1200 1200 1000 400 200 100 100 100

Cable B

lenght (m)

1200 1200 600 200 - - - -

For a reliable operation of the Fieldbus, should be used a line termination at both ends.

In the case of multiple DAT 500 instruments, use the line termination

at only one instrument.

For configuring the instrument, the GSD file is available (hms_1810.

GSD) that must be installed in the master.

Page 9

51

5

4

3

2

1

V-

V+

CAN_L

CAN_H

SHIELD

54321

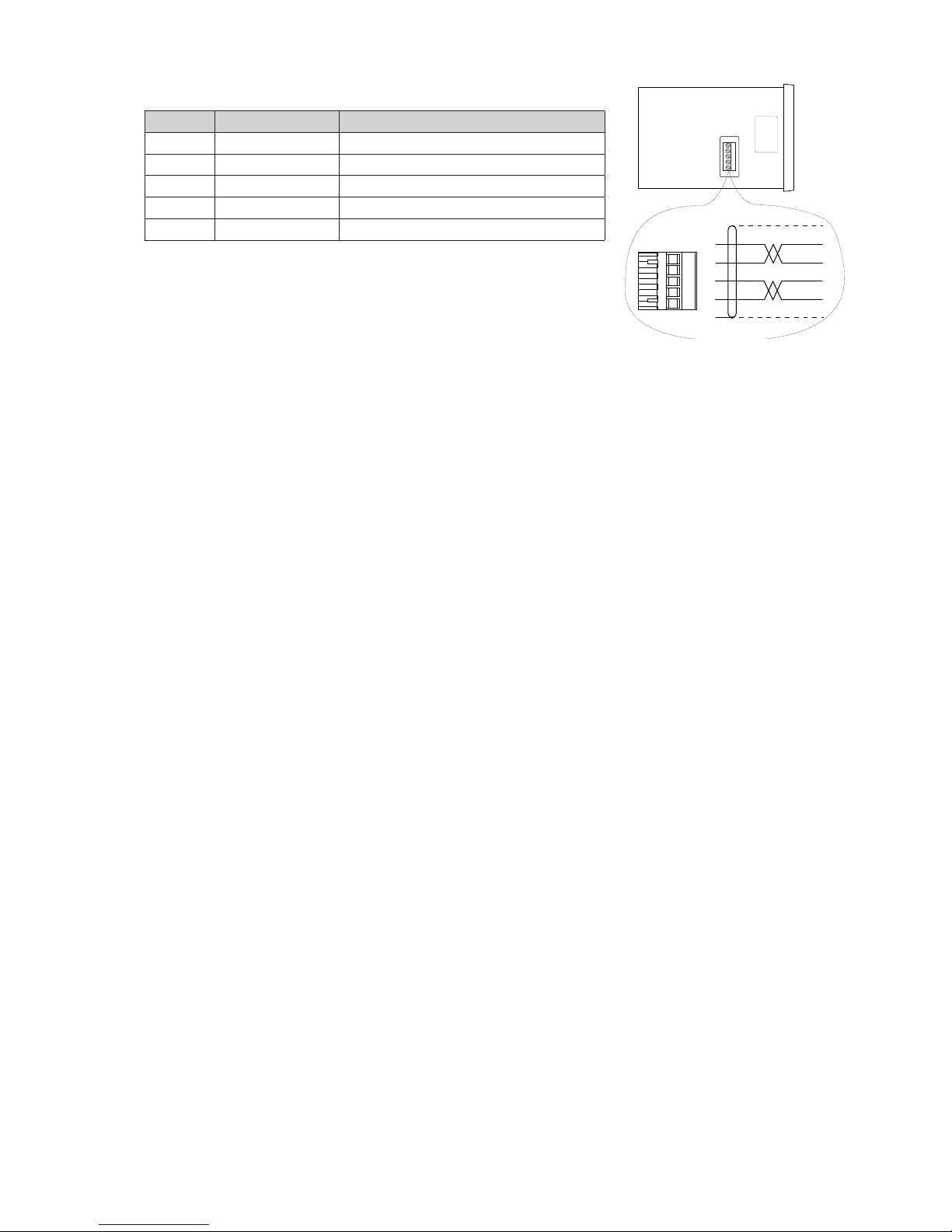

DEVICENET CONNECTION

Pin Signal Description

1 V- Negative power bus

2 CAN_L CAN low bus line

3 SHIELD Shield

4 CAN_H CAN high bus line

5 V+ Positive power bus

To connect to the DeviceNet master, use a standard DeviceNet cable

or shielded twisted-pair cable as shown on the diagram.

The cable must not be channeled with power cables. For reliable

operation of the Fieldbus, should be used as a line termination of

121 Ω value between the terminal CAN_L and CAN_H.

For the configuration of the card is available ESD file that must be

installed in the master.

Page 10

SET FUN 0 PRG

1 2 NET

8.8.8.8.8.8.

PRECISE

DAT 500

FRONT PANEL OF THE INSTRUMENT

The DAT 500 has a bright 6-digit display, 4 status LEDs and four keys.

In this operating mode the display shows the weight and the LEDs indicate the status of weight and the

setpoints.

The set-up parameters are easily accessed and modified through the use of the three front buttons used

to select, edit, confirm and save the new settings.

DISPLAY

On the 6-digit display, it’s usually shown the scale weight. According to the various programming

procedures, the display is used for programming of the parameters to be stored in the memory, or the

messages that indicate the type of operation being carried out and help therefore the Operator in the

management and programming of the instrument.

LED INDICATORS

Below the display there are 4 LED indicators:

1 State of the logic output 1 (ON = closed contact OFF = open contact).

2 State of the logic output 2 (ON = closed contact OFF = open contact).

NET The displayed value is the net weight.

0 IT indicates the condition of stable weight.

Page 11

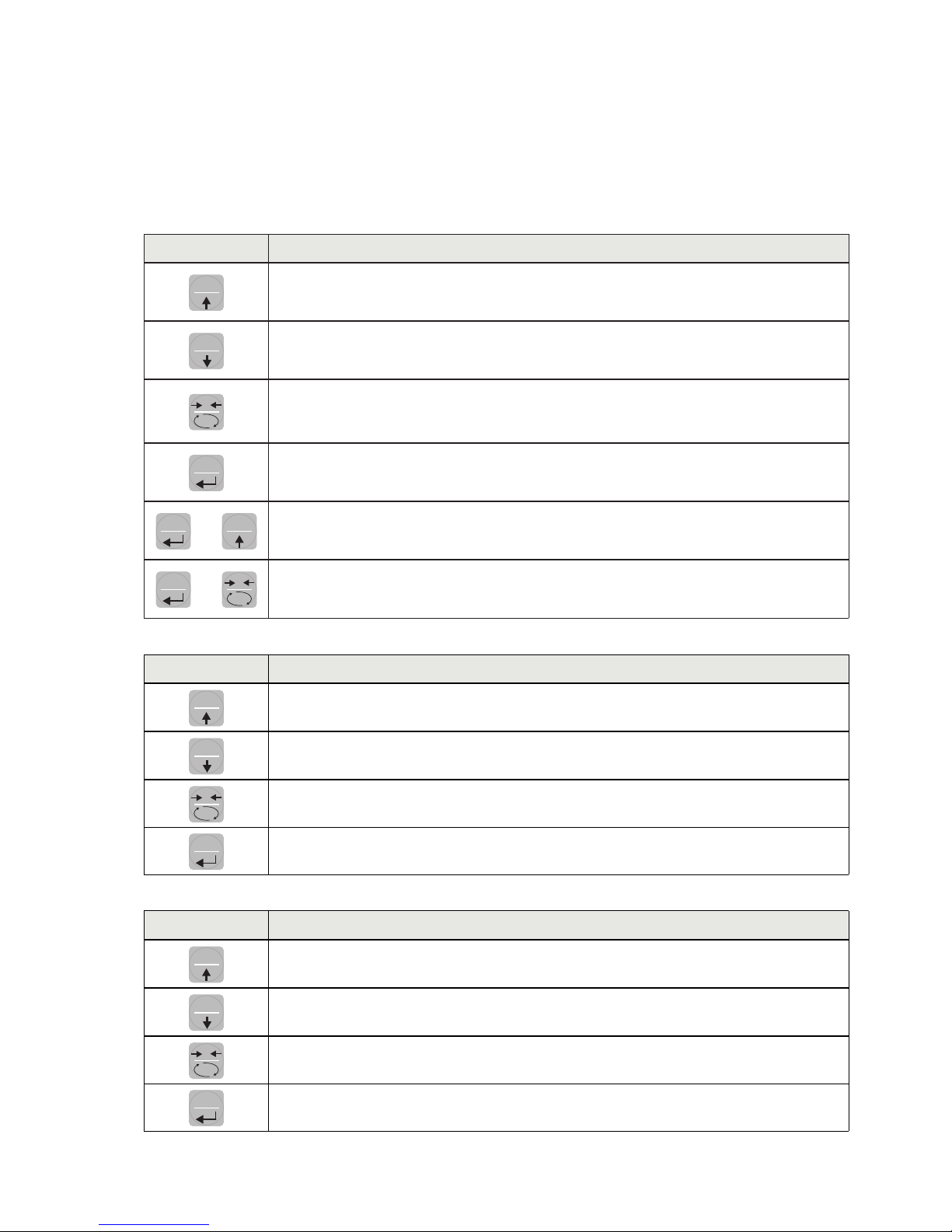

USING THE KEYBOARD

The instrument is programmed and controlled through the keyboard which has 4 keys, with double

functions. The selection of one of the key functions is established automatically by the instrument according to the operation in progress. In general, the management of the programming menus is done by

using the SET and FUN keys to scroll through the items; the PRG key is used to enter its sub-menu or

programmable parameter, while the 0 button allows you exiting the menu or returning to the top level.

KEY FUNCTIONS DURING THE WEIGHT DISPLAY

SET

Access to the menu for the programming of the setpoints

FUN

Select the display view (gross weight, net weight).

(Long press) Selection of the weight/peak display

0

Resetting the displayed value (gross weight, net weight or peak).

(Press and hold for 5 sec.) Calibration of zero, to be executed only if its function

is enabled in the PARAM menu (see item “0 ALL”).

PRG

Sending the weight string on the serial line.

(Long press) Access to the quick set-up menu.

PRG

+

SET

(Press for 3 sec) Access to the setup menu.

PRG

+

0

(Press for3 sec) It accesses the keypad lock/unlock menu and auto-off function of

the display.

KEY

FUNCTION DURING THE MAIN MENU DISPLAY

SET

It selects the next parameter.

FUN

It selects the previous parameter.

0

It exits the programming menu or returns to the upper level.

PRG

It accesses the corresponding sub-menu or programming or confirms the selected

parameter.

KEY

FUNCTION WHEN SETTING THE NUMERICAL VALUES

SET

It increases the value of the flashing digit.

FUN

It decreases the value of the flashing digit.

0

It goes to the next digit.

PRG

It confirms the displayed value.

Page 12

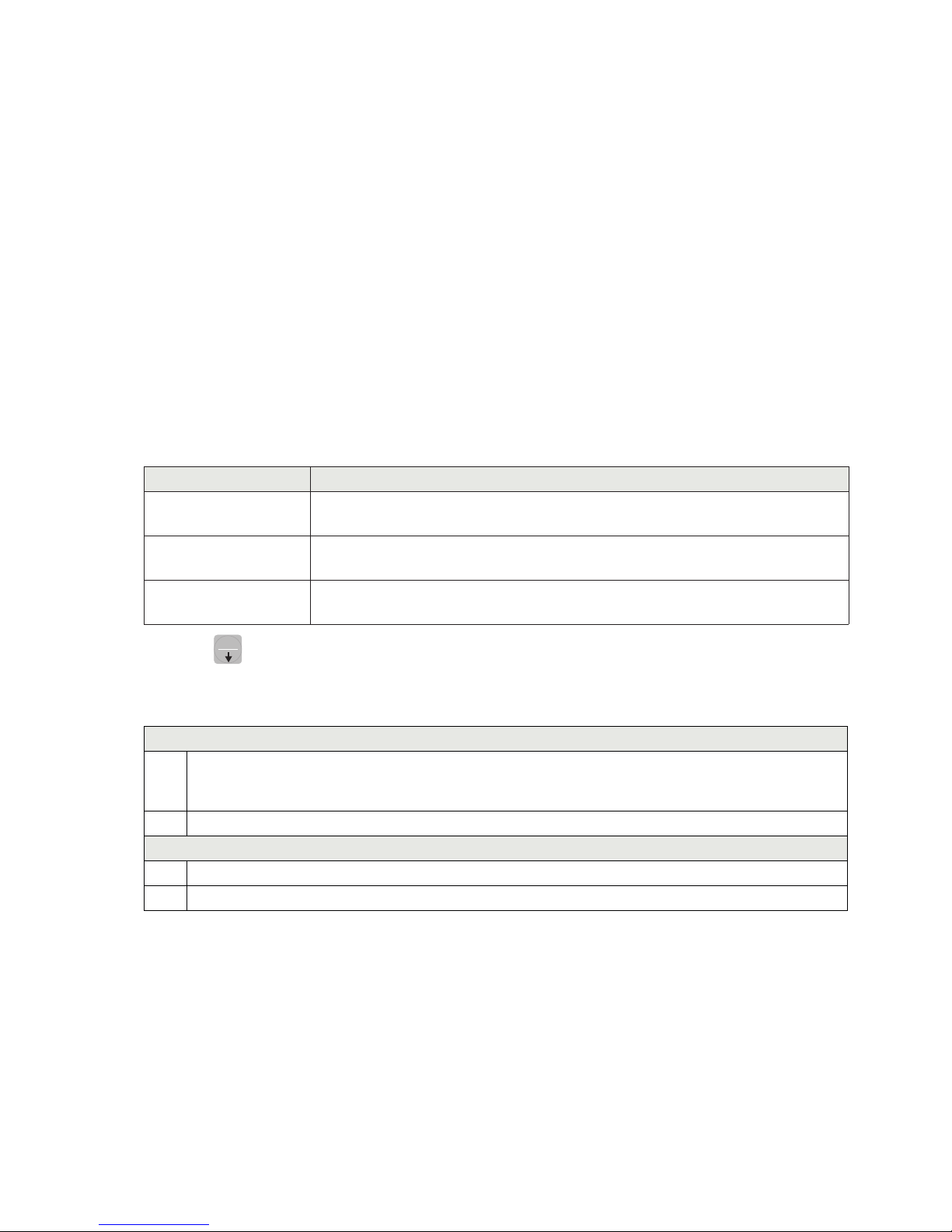

KEY FUNCTION WHEN SETTING THE NUMERICAL VALUES

SET

It selects the next value.

FUN

It selects the previous value.

PRG

It confirms and store the displayed value.

EXIT FROM THE SETTING MENU

Press the

0

key to return to the main menu. Press the

0

. key again. It’s displayed “StORE?”.

Press the

PRG

key to return to the main menu.

To exit without saving any changes, switch off the instrument instead of pressing the

PRG

key.

Page 13

INFO DISPLAY

When the instrument is switched ON, you can test the display, then in sequence you can display the

identification code of the software and its version. Communication codes in the event of a request for

assistance.

ERRORS NOTIFICATION

In the operation mode, the display can report the following error codes.

ϩϩϩϩϩϩ the weight applied to the load cell exceeds by more than 9 divisions the maximum capacity

of the weighing system.

O-L Signal of the load cells absent or outside of the measurement range mV/V.

no CoN Fieldbus network disconnected

E-ProF PROFIBUS interface absent or not operating.

E-dNEt DEVICENET interface absent or not operating.

ϩϩϩϩϩϩ Dash that runs along the perimeter of the display: BLIND function enabled.

ErrNEN Memory error. Press the

PRG

key to reset the memory and return the parameters to their

default values. NOTE: it is also deleted the calibration performed.

Page 14

VIEWING, ZEROING THE WEIGHT AND SELF-CALIBRATION

After being calibrated, at the subsequent switches on, the display shows the current weight.

VIEWING THE NET WEIGHT/GROSS WEIGHT

Press the

FUN

key to toggle between the net weight and the gross weight and vice versa. The value

displayed is signaled by the LED NET (lit: net weight). If you have not entered the tare, the net weight

is equal to the gross weight.

In case of negative weight, it is displayed the minus sign before the most significant digit.

ZEROING, WEIGHT AND SELF-CALIBRATION

These two functions are performed by pressing

0

.

When the instrument is in the operation mode “Net” (“NET” LED on), the

0

key performs the self-

calibration.

When the instrument is in operation mode “Gross” (“NET” LED off), the

0

key clears the gross weight.

SELF-CALIBRATION

The execution of self-calibration is possible under the following conditions:

• Instrument under conditions of “Net” (NET” LED on).

• Positive gross weight.

• Gross weight not greater than the maximum capacity.

• Stable weight.

• Unstable weight. In this condition, we must distinguish two cases:

1. The weight stability control is enabled (the parameter “MOTION” (*) must be other than zero): the

command executed while the weight is unstable only has an effect if the weight stabilizes within 3

seconds from the moment the command was given.

2. The weight stability control is disabled (the parameter “MOTION” (*) is equal to zero): the executed

command takes effect immediately, even with unstable weight.

(*) The operating modes of the parameter “MOTION” are described at page 26

The self-calibration is retained in memory even after the power is turned off.

ZEROING

The reset command of the gross weight is used to correct for small zero shifts of the weighing system

during normal operation.

Normally these zero shifts are due to thermal drifts or to residues of material that accumulate on the

weighing system over the time.

To run the command, it is necessary that the instrument is under conditions of “Gross” (“NET” LED off)

and that the deviation of the weight with respect to the zero of the scale (the one performed with the

calibration of zero) does not exceed (in positive or negative) the number of divisions set in parameter

“0 BAND” (inside the PARAM menu; see page 28).

The reset command of the gross weight does not run if there is even one of the following conditions:

Page 15

• Unstable weight (with control of the stability of the weight enabled). In this case, the reset command

takes effect only if the weight stabilizes within 3 seconds or if the control of the weight stability is

disabled (parameter “MOTION “ equal to zero).

• Gross Weight greater (in positive or negative) than the number of divisions set in parameter “0

BAND” , when the setpoint of auto-calibration is not programmed.

The zero obtained with the resetting of the gross weight is retained in memory even after the power is

turned off.

The reset operation of the gross weight can be repeated several times, but the number of reset divisions

zero is added from time to time, so when the total exceeds the limit value set in parameter “0 BAND”,

the zero cannot be executed. In this case, it is necessary to calibrate the Zero.

Any auto-zero parameter setting when switching on (AUTO 0) reduces (or cancels, in the case of “AUTO

0”> “0 BAND”) the range of action of the reset command.

PEAK FUNCTION

The instrument continuously memorizes the peak value of the gross weight. The peak value is detected

at the same frequency of acquisition of the weight (see table on filters). In addition to visualization, the

peak value can be used in the following functions:

FUNCTION DESCRIPTION

LOGIC OUTPUT The setpoints can be set to have the peak value as a reference. (See the

procedure for setting the logic outputs operations).

SERIAL PORT Acquisition of the peak value (peak hold) through the CONTIN, AUTO, DE-

MAND, and MODBUS SLAVE protocols.

ANALOG OUTPUT

The analog output value can assume the value of the peak (peak old). (See

the procedure for setting the analog output).

Press the

FUN

key and hold it for 3 seconds until the left of the display shows the letter “P”.

INPUT / OUTPUT FUNCTIONS

INPUT

1

Resetting the displayed value (gross weight, net weight or peak). Closed for 5 sec. ->

Calibration of zero, to be executed only if its function is enabled in the PARAM menu (see

item “0 ALL”).

2

Sending the weight string on the serial line or print.

OUTPUT

1 Setpoint 1

2 Setpoint 2

Page 16

sEt 1

123456

SEt 2

123456

Increment

digit

Change

selected digit

EXIT

0SETSET

FUN

FUN

PRG

PRG

SET FUN

PRG

PRG

0

SET

Increment

digit

Change

selected digit

0

PROGRAMMING THE WEIGHT SETPOINTS

The set setpoint values are compared with the weight to drive its logic output. The comparison criterion

is established in the process of set-up of the logic I / O (see relevant paragraph).

To access the Setpoint setting, press the SET key and follow the instructions on the figure below.

During the step of setting the setpoints, both outputs are disabled. If the setpoint value in memory is 0,

the corresponding output is never enabled, regardless of the set-up of the selected setpoints. When the

weight is not detectable or out of range, all outputs are disabled (contact open or closed depending

on the MODE; see the relevant chapter).

Page 17

LOck

0000

blind

off

on

00

+

3 sec.

Select

digit

Change

selected digit

Select

digit

Change

selected digit

EXIT

KEYS CORRESPONDING

0

0

0

SET

SETSET

FUN

FUN

FUN

PRG

PRG

PRG

PRG

SET FUN

PRG

PRG

PRG

0SET FUN

PRG

0

KEYBOARD LOCK/UNLOCK FUNCTION

KEYBOARD LOCK/UNLOCK A function that allows you to enable or disable the keys individually.

When the keys are locked, the only way to access these settings is to press and hold pressed the PRG

+ 0 keys for 3 seconds. For more information on the function, refer to the block diagram above.

SWITCHING THE DISPLAY OFF This function allows turning off the display after a programmable time.

You can select ON / OFF of the parameter BLIND and the setting of a time; the time count starts from

the moment when, after exiting the setup menu, the display shows the weight value. After the set time,

the display turns off and only a dash appears. This dash cycles through the perimeter of the display

counterclockwise. When the display is off, also the 4 keys are disabled, regardless of how you set the

keypad lock (LOCK). The only way to access the settings will be PRG + 0.

Page 18

SETTING

GENERAL DATA

All functions of the DAT 500 are activated and modified by accessing a simple setup menu, shown

afterwards. All settings selected or activated remain stored even after switching off the transmitter.

The DAT 500 is preconfigured with a default setting. The following pages show the values of “Default”

for each parameter.

With the first on-site installation, it’s necessary to change some parameters in order to obtain a correct

indication of the displayed weight (Theoretical adjustment).

The settings of the setup menu can be changed using the front keys or via the utility “INOVATION 2”

software supplied.

CHANGING AND ENTERING THE PARAMETERS:

The setup parameters are grouped into a number of main menus.

To access the setup menu press the PRG key and then the SET key and hold down simultaneously for

3 seconds.

The display shows the message Conf1G that is the first of the main menus

Use the arrow keys to select the menu you want to change.

Press the PRG key to access the selected menu.

KEY FUNCTION DURING THE MAIN MENU PROGRAMMING

SET

It selects the next menu.

FUN

It selects the previous menu.

0

It exits the programming menu or returns to the upper level.

PRG

It accesses the corresponding sub-menu or programming or confirms the selected

parameter.

KEY FUNCTION WHEN SETTING THE NUMERICAL VALUES

SET

It increases the value of the flashing digit.

FUN

It decreases the value of the flashing digit.

0

It goes to the next digit.

PRG

It confirms and store the displayed value.

Page 19

KEY FUNCTION WHEN SETTING THE PROSED VALUES

SET

It selects the next value.

FUN

It selects the previous value.

PRG

It confirms and store the displayed value.

The menu parameters can assume values that can be set or selected.

NOTE To exit and save the modified data, press multiple times the

0

key until the display shown

StorE, then press

PRG

key to go back to the operating mode.

Page 20

Conf1G

CapaC

SEns1t

nEt

dEad L

dspd1J

S1GnaL

CoUnts

opNodE

UpLoad

dnLoad

CaL1br ParaN

fILtEr

Notion

auto 0

0 trac

0 band

1n-oUt

NodE 1

Hyst-1

t1NEr1

dELay1

NodE 2

Hyst-2

t1NEr2

dELay2

tEst1n

tstoUt

SEr1aL

baUd r

Prot-1

prot-2

AddrEs

Pr-Add

dELay

rEN-Co

data F

AnaLoG

f-sCaL

NodE

AnzEro

tEst

ranGE

OffsEt

StorE?

CaL

0

CaL

123456

60000

t-Nap

r-NaP

dELNap

baud2r

dN-Add

SET FUN

0 ALL

F

+

3 sec.

EXIT MENU

ENTER MENU

DEVICENET

1P-Add

SubnEt

SET FUN

SET FUN

ETHERNET IP

PROFINET

0

PRG

PRG

SET

SET

FUN

SET

FUN

SET

FUN

SET

FUN

SET

FUN

FUN

0 0

0 0 0

0

0 0

0

0

PRG

0

PRG

PRG

PRG PRG PRG

SET SET FUN SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

FUNSET

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

FUN

PRG

0

0

PRG

SET

SET

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

DIAGRAM OF THE MENU

Page 21

CapaC

SEns1t

nEt

dEad L

dspd1J

S1GnaL

CaL1br

AnaLoG

StorE?

CaL

0

CaL

123456

60000

5 sec.

EXIT MENU

ENTER MENU

0

PRG

FUN

PRG

SET

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

FUN

PRG

0

0

PRG

SET

SET

PRG

Enter Value

PRG

PRG

Enter Value

PRG

PRG

Enter Value

PRG

PRG

Enter Value

PRG

PRG

Select Value

PRG

PRG

See Value

0

PRG

Enter Value

PRG

PRG

QUICK SETUP MENU

Page 22

Conf1G

PRG

SET

FUN

CaL1br

CapaC

SEns1t

nEt

dEad L

dspd1J

S1GnaL

CoUnts

opNodE

UpLoad

dnLoad

SET FUN

0

0

0

0

0

0

0

0

0

0

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET

FUN

PRG

Enter Value

PRG

PRG

Enter Value

PRG

PRG

Enter Value

PRG

PRG

Enter Value

PRG

PRG

Select Value

PRG

PRG

Read Value

PRG

Read Value

PRG

Select Value

PRG

PRG

PRG

Transmit setup data

to serial port

0

0

Receive setup data

from serial port

CONFIGURATION PARAMETERS

Through the setting of the parameters listed below, the theoretical Full Scale DAT 500 calibration is performed. You must complete these steps with the zero calibration described on page 23. The procedure

ensures a good accuracy of the system (maximum error <1% FS) if there are no mechanical problems.

Program the known values of total capacity and sensitivity of the load cells and the approximate values

of net capacity and calibration. If the parameter SENSIT is not programmed, it is taken the 2.0000

mV/V value.

If the parameter CAPAC is programmed other than 0, according to the data CAPAC, SENSIT, NET and

DEAD L , the instrument automatically runs the following functions:

• Resetting the linearization points.

• Selection of the value of the division, however, to be modified, to the best of 10,000 divisions.

• Calibration of the theoretical approximate calibration of the weight (zero and full scale).

• Automatic programming of the overload setpoint (= NET).

These functions are performed each time you change one of the 4 parameters shown.

When you change the DSPDIV selection., it is automatically recalculated to full-scale calibration. The

selections are incompatible with the calibration parameters or calibration in memory are not accepted.

The selection programmed in Opmode is read from the instrument when it is switched on and it makes

that the instrument operates in that way.

CAPAC CAPACITY OF THE WEIGHING SYSTEM

It defines the value corresponding to the sum of the rated capacity

of the load cells. In the case of systems with only one load cell and

“N” fixed supports, enter the capacity value of the cell for the total

number of supports. This figure represents the full scale value of the

weighing system.

Following the change of the parameter value, the theoretical tare of

the weight is recalculated.

Values: from 1 to 500000

Unit: the same of that displayed

Default: 10000

sEnsit LOAD CELLS SENSITIVITY

Set the value corresponding to the average sensitivity of the load

cells, in mV / V. The instrument accepts values between 0.5 and 4

mV / V. If no value if programmed, it’s assumed it is 2mV/V.

Following the change of the sensitivity value, the theoretical tare of

the weight is recalculated.

Values: from 0.5000 to 4.0000 mV/V

Default: 2.0000

Page 23

Conf1G

PRG

SET

FUN

CaL1br

CapaC

SEns1t

nEt

dEad L

dspd1J

S1GnaL

CoUnts

opNodE

UpLoad

dnLoad

SET FUN

0

0

0

0

0

0

0

0

0

0

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET

FUN

PRG

Enter Value

PRG

PRG

Enter Value

PRG

PRG

Enter Value

PRG

PRG

Enter Value

PRG

PRG

Select Value

PRG

PRG

Read Value

PRG

Read Value

PRG

Select Value

PRG

PRG

PRG

Transmit setup data

to serial port

0

0

Receive setup data

from serial port

nEt CAPACITY OF THE WEIGHING SYSTEM

Programming the net capacity of the weighing system. Values lower

than 1/10 of CAPAC are not accepted.

Values: from 1 to 500000

Unit: the same of that displayed

Default: 10000

dEad L FIXED CALIBRATION OF THE WEIGHTING SYSTEM

Programming the fixed calibration value of the weighting system.

Values: from 1 to 500000

Unit: the same of that displayed

Default: 00000

dsPd1J DIVISION VALUE

The ratio between the capacity of the system and the division value

represents the resolution of the system (number of divisions).

Following the change of the capacity of the system, it is automatically

selected the division value to the best of 10000 divisions.

Following the change of the division value, if the maximum capacity does not change, the calibration of the weight is automatically

corrected.

Value to be selected:

0.0001 - 0.0002 - 0.0005

0,001 - 0,002 - 0,005

0.01 - 0.02 - 0.05

0.1 - 0.2 - 0.5

1 -2 - 5

10 - 20 - 50

Default: 1

S1GnaL TESTING THE LOAD CELLS SIGNAL

It’s displayed the signal acquired from the load cells expressed in

mV/V.

CoUnts A/D CONVERTER INTERIOR POINTS TEST

View of the interior points of the instrument (1,000,000 at the maximum input signal).

oPNodE SELECTION OF THE OPERATING MODE

Selection of the operating mode of the device (display) when it is

switched on:

Value to be selected:

GROSS, NET, PEAK

Default: GROSS

Page 24

Conf1G

PRG

SET

FUN

CaL1br

CapaC

SEns1t

nEt

dEad L

dspd1J

S1GnaL

CoUnts

opNodE

UpLoad

dnLoad

SET FUN

0

0

0

0

0

0

0

0

0

0

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET

FUN

PRG

Enter Value

PRG

PRG

Enter Value

PRG

PRG

Enter Value

PRG

PRG

Enter Value

PRG

PRG

Select Value

PRG

PRG

Read Value

PRG

Read Value

PRG

Select Value

PRG

PRG

PRG

Transmit setup data

to serial port

0

0

Receive setup data

from serial port

UpLoad RECEIVING DATA FUNCTION

Receiving function from a serial of a file containing the setup data

that will be automatically set in the instrument.

dnLoad SENDING DATA FUNCTION

Sending function from a serial of a file with the content of the setup

memory of the instrument.

EXAMPLE OF SETTING/CALIBRATION

You must weigh a tank, with empty weight of 750 kg and with a

capacity of 1000 liters, containing a product with a specific gravity of 1.33 of which you want to read the weight with a display

resolution of 0.2 Kg.

Before proceeding with the configuration, you should make sure

that the load cells are connected properly to the unit and the tank

is empty. Then you can set the parameters.

They are used:

Nr 3 load cells with capacity of 1000 kg

Sensitivity of respectively 2.0015, 2.0008 and 1.9998 mV/V

(average value = 2.0007 mV/V)

Set the following values in the configuration parameters:

CAPAC = 3000

SEnS1t = 2.0007

nEt = 1500

dEad L = 0

dSpd1J = 0.2

Make sure that the value read in the S1GNAL parameter corresponds

with the calibration weight of the system according to the following

proportion:

3000:2.0007=750:X

Where X is the value of the signal expressed in mV/V corresponding

to the theoretical value of the weight of the empty tank. The value

should be about 0.5 mV/V.

Now you can proceed to the calibration described in the following

paragraph, or you can exit the configuration menu by saving the

data entered.

The instrument should indicate the value corresponding to the weight

of the empty tank (for example 756.8).

You can re-access the configuration menu and enter the weight value

read in the dEad L parameter and enter the value 756.8.

Quit the configuration menu by saving the data.

For greater accuracy, prepare some sample weights or the preweighed material on a certified scale and calibrate as described in

the next paragraph.

Page 25

SET

FUN

CaL1br

SET

FUN

ParaN

CaL

CaL

123450

PRG

SET

SET FUN

PRG

PRG

0

0

120000

CAL

Enter Load

Value

PRG

PRG

With unload

scale

35

0

Load Weight

CALIBRATION

The calibration described herein should be performed with the use of sample masses and/or product

pre-weighed on a weighing scale.

Before proceeding with the calibration of the full scale, always perform the zero calibration.

During the calibration phase, the display shows the weight intermittently with the inscription CaL.

ATTENTION: If you turn off the instrument without exiting the set-up menu, the programming executed

is not stored.

NOTE In the event that after calibration, the system shows linearity errors, you should verify that the

weighted structure is completely free of mechanical constraints.

ZERO CALIBRATION

Perform the operation when the scale has no items (including the

fixed tare), and when the weight is stable. The zero of the system is

done by pressing the key 0.

The weight displayed resets and the display shows Cal alternated

by 0. You can repeat this operation more times.

CALIBRATION OF FULL SCALE

Prior calibration load the sample weight on the system and wait for

the stabilization; the display shows a weight value.

Press the SET key to adjust the weight. The display shows the theoretical weight value with the first digit to the left flashing. With the

arrow keys, enter the actual weight loaded on the system starting

from the first flashing digit. Switch to the next digit by pressing 0.

The confirmation of the last digit (far right) with the PRG key corrects

the weight. The display shows CAL, by altering the actual weight

value entered.

If the set value is higher than the resolution offered by the instrument,

the weight is not accepted and the display shows an error message

for a few seconds.

This procedure can be repeated.

Press the PRG key again to return to the CaLIb. menu.

EXIT FROM CALIBRATION MENU

The exit from the menu CaLIb is performed by pressing the

0

key until the appearance of the message store?.

To store the new calibration and exit the setup menu, press the PRG

key.

To cancel the calibration of zero and full scale:

FUN +0 it cancels the zero calibration.

FUN + SET it cancels the calibration of the full scale.

Page 26

SET

FUN

CaL1br

SET

FUN

Param

CaL

CaL

LIn P1

PRG

SET

SET FUN

PRG

PRG

0

0

12000

LIn P2

Enter Load

Value P1

PRG

With unload

scale

35

0

CaL

Load Weight P1

4 sec.

24000

LIn P9

Enter Load

Value P2

PRG

SET FUN

0

120000

Enter Load

Value P9

PRG

SET FUN

0

0

0

0

0

Load Weight P2

Load Weight P9

PRG

000000

000000

PRG

000000

PRG

LINEARIZATION PROCESS

When planning the sample weight, values greater than the full scale,

or lower than the previous point, or when the weight is not stable,

are not accepted. If the entered value is accepted, it is proposed

the next step, otherwise still the same.

The linearization points are automatically reset each time you change

a data of the theoretical calibration or it is performed a full-scale

calibration.

Page 27

SET

FUN

ParaN

SET

FUN

In-oUt

f1LtEr

Not1on

auto 0

0 trac

0 band

0

0

0

0

0

PRG

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

PRG

Select Value

PRG

PRG

Select Value

PRG

PRG

Enter Value

PRG

PRG

Select Value

PRG

PRG

Enter Value

PRG

0 ALL

0

SET FUN

PRG

Select Value

PRG

WEIGHTING PARAMETERS

The parameters in this menu allow you to adjust the timing of the acquisition and updating of the display

and the manual or automatic zeroing that the transmitter performs.

F1LtEr WEIGHT FILTER

This parameter adjusts the refresh speed of the display and the serial

and analog output.

Low values of the filter speed up the display refresh.

High values of the filter slow down the display refresh.

Value Update Response

0 50 Hz 25 Hz

1 50 Hz 16 Hz

2 25 Hz 8 Hz

3 25 Hz 5 Hz

4 25 Hz 2.5 Hz

5 10 Hz 1.5 Hz

6 10 Hz 1 Hz

7 10 Hz 0.7 Hz

8 5 Hz 0.4 Hz

9 5 Hz 0.2 Hz

Default: 5

Notion WEIGHT STABILITY

This parameter defines the divisions number needed to deem the

weight stable.

A large number of divisions allows the transmitter to detect quickly

the weight stability, which is needed when executing tare and print

commands.

Value Change

0 Always stable weight

1 Stability determined quickly

2 Stability determined with medium parameters

3 Stability determined accurately

4 Stability determined with the highest accuracy

Default: 2

Auto 0 AUTOZERO UPON SWITCHIN ON

This parameter defines the value of the maximum resettable weight

when the instrument is switched on.

This operation corresponds to a zero calibration of the system and

is executed only if the weight is stable and below the set value.

Value from 0 to the value of the CAPAC parameter.

Default: 0

Page 28

SET

FUN

ParaN

SET

FUN

In-oUt

f1LtEr

Not1on

auto 0

0 trac

0 band

0

0

0

0

0

PRG

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

PRG

Select Value

PRG

PRG

Select Value

PRG

PRG

Enter Value

PRG

PRG

Select Value

PRG

PRG

Enter Value

PRG

0 ALL

0

SET FUN

PRG

Select Value

PRG

0 trAc TRACKING THE ZERO

This function allows you to perform a momentary zero calibration

compensating for the temperature drift of the weight.

When you switch off the transmitter, it automatically returns to the

previous zero calibration.

The maximum weight resettable by this parameter is 2% of the range

of the system.

To disable this feature, use the value 0.

Value Change

0 Control OFF

1 0.5 div/sec

2 1 div/sec

3 2 div/sec

4 3 div/sec

Default: 0

0 band ZERO BAND

This parameter defines the number of divisions resettable by the

pressure of the front button of zero or by Input 1.

Values: from 0 to 200

Default: 100

0 ALL ZERO CAL

Enables the function that allows to perform zero calibration by pressing and holding the 0 key or input 1 for 5 sec.

Value:

Off Function disabled

On Function Enabled

Default: Off

Page 29

SET

FUN

In-oUt

SET

FUN

SEr1aL

NodE 1

0

PRG

SET FUN

PRG

Select Value

Hyst-1

t1NEr1

dELay1

NodE 2

0

0

0

0

SET FUN

SET FUN

SET FUN

SET FUN

PRG

Enter Value

PRG

PRG

Enter Value

PRG

PRG

Enter Value

PRG

PRG

Hyst-2

t1NEr2

dELay2

tEst1n

tstoUt

0

0

0

0

0

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

PRG

Enter Value

PRG

Enter Value

PRG

Enter Value

PRG

PRG

PRG

Read and

change status

Read and

change status

PRG

Select Value

PRG

Select Value

PRG

Select Value

PRG

Select Value

PRG

Select Value

PRG

Select Value

PRG

Select Value

PRG

0

0

PRG

PRG

INPUT/OUTPUT PARAMETERS

NodE 1 SETPOINT 1 OPERATION MODE

Select 4 operation criteria of the setpoint 1 in sequence:

NET The relay output is active in Net Weight mode

GROSS The relay output is active in Gross Weight mode

PEAK The relay output is active in Peak mode

Default: GROSS

Comparison with the net weight, gross weight or the peak. In this

last case, the comparison is made with the last peak value acquired,

even when the peak function is not active.

N.O. The relay 1 is normally open

N.C. The relay 1 is normally closed

Default N.O.

POS. The output is operating with positive weight

NEG. The output is operating with negative weight

Default: POS

NORML Output 1 is active with unstable weight

STABL The output is active with stable weight

Default: Norml

Hyst-1 HYSTERESIS OF THE SETPOINT 1

Hysteresis value than the setpoint value set.

Value: from 0 to 999

Default: 2

t1NEr1 SETPOINT 1 TEMPORIZATION

Value of time, in tenths of a second, during which, when the weight

value set is overcome, the output relative to setpoint 1 remains

enabled.

After this time, even if the weight value is still above the setpoint, the

output is automatically disabled.

The function is not activated if the programmed time is equal to zero.

Value: from 0 to 999

Default: 0

dELay1 SETPOINT 1 DELAY

Value of time, in tenths of a second, after which, when the weight value set is overcome, the output relative to setpoint 1 remains enabled.

The function is not activated if the programmed time is equal to zero.

Value: from 0 to 999

Default: 0

Page 30

SET

FUN

In-oUt

SET

FUN

SEr1aL

NodE 1

0

PRG

SET FUN

PRG

Select Value

Hyst-1

t1NEr1

dELay1

NodE 2

0

0

0

0

SET FUN

SET FUN

SET FUN

SET FUN

PRG

Enter Value

PRG

PRG

Enter Value

PRG

PRG

Enter Value

PRG

PRG

Hyst-2

t1NEr2

dELay2

tEst1n

tstoUt

0

0

0

0

0

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

PRG

Enter Value

PRG

Enter Value

PRG

Enter Value

PRG

PRG

PRG

Read and

change status

Read and

change status

PRG

Select Value

PRG

Select Value

PRG

Select Value

PRG

Select Value

PRG

Select Value

PRG

Select Value

PRG

Select Value

PRG

0

0

PRG

PRG

NodE 2 SETPOINT 2 OPERATION MODE

Select 4 operation criteria of the setpoint 2 in sequence:

NET The relay output is active in Net Weight mode

GROSS The relay output is active in Gross Weight mode

PEAK The relay output is active in Peak mode

Default: GROSS

Comparison with the net weight, gross weight or the peak. In this

last case, the comparison is made with the last peak value acquired,

even when the peak function is not active.

N.O. The relay 2 is normally open

N.C. The relay 2 is normally closed

Default N.O.

POS. The output is operating with positive weight

NEG. The output is operating with negative weight

Default: POS

NORML Output 2 is active with unstable weight

STABL Output 2 is active with stable weight

Default: Norml

Hyst-2 HYSTERESIS OF THE SETPOINT 2

Hysteresis value than the setpoint value set

Value: from 0 to 999

Default: 2

t1NEr2 SETPOINT 2 TEMPORIZATION

Value of time, in tenths of a second, during which, when the weight

value set is overcome, the output relative to setpoint 2 remains

enabled.

After this time, even if the weight value is still above the setpoint, the

output is automatically disabled.

The function is not activated if the programmed time is equal to zero.

Value: from 0 to 999

Default: 0

dELay2 SETPOINT 2 DELAY

Value of time, in tenths of a second, after which, when the weight value set is overcome, the output relative to setpoint 2 remains enabled.

The function is not activated if the programmed time is equal to zero.

Value: from 0 to 999

Default: 0

Page 31

SET

FUN

In-oUt

SET

FUN

SEr1aL

NodE 1

0

PRG

SET FUN

PRG

Select Value

Hyst-1

t1NEr1

dELay1

NodE 2

0

0

0

0

SET FUN

SET FUN

SET FUN

SET FUN

PRG

Enter Value

PRG

PRG

Enter Value

PRG

PRG

Enter Value

PRG

PRG

Hyst-2

t1NEr2

dELay2

tEst1n

tstoUt

0

0

0

0

0

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

PRG

Enter Value

PRG

Enter Value

PRG

Enter Value

PRG

PRG

PRG

Read and

change status

Read and

change status

PRG

Select Value

PRG

Select Value

PRG

Select Value

PRG

Select Value

PRG

Select Value

PRG

Select Value

PRG

Select Value

PRG

0

0

PRG

PRG

tEst1n LOGIC INPUTS TEST PROCEDURE

The display shows the inputs status.

0 = input disabled

1= input activated.

The input 1 corresponds to the 1a value on the left.

Enable and disable the inputs to check the corresponding state on

the display. During this procedure, the normal function of the inputs

is not active. Use this procedure only to check the hardware.

tstoUt LOGIC OUTPUTS TEST PROCEDURE.

The display shows the outputs status.

0 = output disabled, 1= output activated.

The input 1 corresponds to the 1a value on the left.

During this procedure, the LEDs reflect the state of the outputs. To set

the digits, use the keys as for the numeric settings.

During this procedure, the normal function of the outputs is not active.

Use this procedure only to check the hardware.

Page 32

SET

FUN

SEr1aL

SET

FUN

Config

baUdr

prot-1

prot-2

0

0

0

PRG

SET FUN

SET FUN

SET FUN

PRG

Select Value

PRG

PRG

Select Value

PRG

PRG

Select Value

PRG

AddrEs

0

SET FUN

PRG

Enter Value

PRG

SERIAL OUTPUT PARAMETERS

This menu allows you to set the serial ports COM1 and COM2 and the communication parameters.

The instrument has two independent serial ports:

COM1 with RS232 or RS422/RS485 interface

COM2 with optional FIELDBUS interface.

baUd r BAUD RATE COM1

It defines the baudrate of the RS232 serial port.

The value must be set to the same value of the PC / PLC or remote

display.

Value to be selected:

2400

9600

19200

38400

115200

Default: 9600

baud2r BAUD RATE COM2 (DEVICENET VERSION)

It defines the baudrate of the DEVICENET interface.

The value must be set to the same value of the PC/PLC.

Value to be selected:

125 250 500 DeviceNet

Default:

125 DeviceNet

Prot-1 COM1 PROTOCOL

It defines how to use the RS232 serial port

None: Serial communication OFF

Contin: Continuous transmission of the weight string. It can be used,

for example, to drive a weight repeater. See details in the relevant

paragraph.

Demand: When the Operator presses the front button or through

Input 2, a string of weight is transmitted. The command is accepted

if the weight is stable. Between two consecutive transmissions the

weight must have a variation of at least 20 divisions.

Autom-: It’s automatically transferred to a string of weight when the

weight stabilizes at a value higher than the minimum weight (20

divisions). Between two consecutive transmissions, the weight must

have a variation of at least 20 divisions.

Slave: ASCII protocol. See details in the relevant paragraph.

Page 33

SET

FUN

SEr1aL

SET

FUN

Config

baUdr

prot-1

prot-2

0

0

0

PRG

SET FUN

SET FUN

SET FUN

PRG

Select Value

PRG

PRG

Select Value

PRG

PRG

Select Value

PRG

AddrEs

0

SET FUN

PRG

Enter Value

PRG

Modbus: MODBUS RTU (slave) protocol. used only if PROT-2 is

configured equal NONE. See details in the relevant paragraph.

Selectable communication patrameters:

n-8-1

n-8-2

E-8-1

o-8-1

Default: n-8-1

Print: Data transfer to the printer.

Value to be selected:

None

Contin

Demand

AutomSlave

Modbus

Print

Default: None

Prot-2 COM2 PROTOCOL:

It defines the Fieldbus use mode

None: Serial communication OFF

PROFIB: PROFIBUS fieldbus (if there is an optional board)

DEVNET: DEVICENET fieldbus (if there is an optional board)

Value to be selected:

None

Profib

Devnet

Default:

None

Page 34

SET

FUN

SEr1aL

SET

FUN

Config

baUdr

prot-1

prot-2

IP-Add

subnEt

dELay

rEN-Co

t-NAP

r-Nap

dELNap

0

0

0

0

0

0

0

0

0

0

PRG

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

PRG

Select Value

PRG

PRG

Select Value

PRG

PRG

Select Value

PRG

PRG

PRG

PRG

Enter Value

PRG

Remote

connection

PRG

PRG

PRG

0

data F

0

SET FUN

PRG

Enter Value

PRG

PRG

trasNEnd-oh

0

rECEIV

End-oh

ErasE

End-oh

PRG

0

IP-Ad1

PRG

000

123

PRG

Enter Value

SET FUN

IP-Ad4

0

PRG

…

PRGPRG

…

0

SnEt 1

PRG

000

123

PRG

Enter Value

SET FUN

SnEt 4

0

PRG

…

PRGPRG

…

AddrEs

0

SET FUN

PRG

Enter Value

PRG

AddrEs COM1 SERIAL COMMUNICATION ADDRESS

Configuration of the address used in the transmission protocols and

in the MODBUS protocol.

Value from 000 to 99.

Default:01

Pr-Add PROGRAMMING OF THE PROFIBUS ADDRESS

Configuration of the address used in the PROFIBUS protocol.

Values: from 0 to 126

Default: 01

dC-Add PROGRAMMING OF THE DEVICENET ADDRESS

Programming of the address used in DEVICENET protocol.

Value: from 0 to 63

Default:01

dELay DELAYED RESPONSE OF THE SLAVE AND MODBUS RTU COM1

PROTOCOLS

Indicative delay of the response string used in the SLAVE protocol.

(expressed in 1/100 sec., max 1 sec).

This value is expressed in milliseconds and represents the delay with

which the instrument sends the response to the request received from

the master.

Value: from 0 to 999 msec

Default: 000

Page 35

SET

FUN

SEr1aL

SET

FUN

Config

baUdr

prot-1

prot-2

IP-Add

subnEt

dELay

rEN-Co

t-NAP

r-Nap

dELNap

0

0

0

0

0

0

0

0

0

0

PRG

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

PRG

Select Value

PRG

PRG

Select Value

PRG

PRG

Select Value

PRG

PRG

PRG

PRG

Enter Value

PRG

Remote

connection

PRG

PRG

PRG

0

data F

0

SET FUN

PRG

Enter Value

PRG

PRG

trasNEnd-oh

0

rECEIV

End-oh

ErasE

End-oh

PRG

0

IP-Ad1

PRG

000

123

PRG

Enter Value

SET FUN

IP-Ad4

0

PRG

…

PRGPRG

…

0

SnEt 1

PRG

000

123

PRG

Enter Value

SET FUN

SnEt 4

0

PRG

…

PRGPRG

…

AddrEs

0

SET FUN

PRG

Enter Value

PRG

rEN-Co REMOTE COMMUNICATION

It enables communication with a PC for the setting via the PC program

data F REMOTE COMMUNICATION

Parameters of the serial COM1 protocols (parity, bits n., stop bits)

except MODBUS.

t-Nap SENDING DATA TO THE PC

This function allows to transfer the mapping of the registers from the

DAT 500 instrument to the PC program. Before starting the transmission of the mapping, you should enable the reception of the map

(Receive button) on the PC program. During transmission, the display

of the instrument displays TRASM, at the end of the transmission it

shows END-OK.

To end the mapping transferring process, press the key 0.

r-Nap RECEIVING DATA FROM THE PC

This function allows to receive the registers mapping from the PC

program.

Before starting the mapping transmission in the PC (Send key), the

receiving function must be enabled on the DAT 500 by pressing the

PRG key. When receiving, the display shows RECEIV, at the end

of the receiving it shows END-OK. To end the process of mapping

transferring, press the 0 key.

dELNap DATA RESET

This function allows you to restore the default mapping of the instrument, while restoring the default mapping of the instrument, ERASE

is displayed.

Page 36

SET

FUN

AnaLoG

f-sCaL

NodE

AnzEro

tEst

ranGE

offsEt

0

0

0

0

0

0

ConF1G

PRG

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET

FUN

PRG

Enter Value

PRG

PRG

Select Value

PRG

PRG

Enter Value

PRG

PRG

Select Value

PRG

PRG

Select Value

PRG

PRG

-0-

-Fs-

PRG

PRG

SET FUN

0

Set Offset

ANALOG - ANALOG OUTPUT PARAMETERS (DAT 500/A ONLY)

F-SCaL FULL SCALE

It’s the weight corresponding to the full scale of the analog output

that can be different from the capacity of the weighting system.

Value to be set from 000 to 99999.

Default: the same value of the CAPACITY parameter

NodE ANALOG OUTPUT OPERATION MODE

Selection of the value to be associated to the analog output, corresponding to the net weight, gross weight or the peak value.

Value to be selected:

NET

GROSS

PEAK

Default: GROSS

AnZEro ZERO VALUE OF THE ANALOG OUTPUT

Analog value related to the full scale of the analog output to be

subtracted.

tEst ANALOG OUTPUT TEST PROCEDURE

With this procedure it is possible to check the operation of the analog

output, causing the output value through the use of the keyboard.

The display shows the percentage of the output value than the full

scale set.

Use the SET and

FUN

keys to increase/decrease the output value.

ranGE ANALOG OUTPUT RANGE

Select the analog output range.

Value to be selected:

0÷20mA

4÷20mA

0÷10Vdc

0÷5Vdc

Default: 4÷20mA

Page 37

SET

FUN

AnaLoG

f-sCaL

NodE

AnzEro

tEst

ranGE

offsEt

0

0

0

0

0

0

ConF1G

PRG

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET

FUN

PRG

Enter Value

PRG

PRG

Select Value

PRG

PRG

Enter Value

PRG

PRG

Select Value

PRG

PRG

Select Value

PRG

PRG

-0-

-Fs-

PRG

PRG

SET FUN

0

Set Offset

offsEt ADJUSTING THE OFFSET (CALIBRATION)

Measure the analog output value with a multimeter to perform the

calibration of zero (0) and full scale (FS).

Use the

SET

and

FUN

keys to adjust the analog output. Press and

hold down the key for a rapid change.

Press the

0

key to toggle between offset of zero and that of full

scale.

Press the

PRG

key to return to the OFFSET sub-menu. Press the

0

key to return to the ANALOG menu.

Page 38

SERIAL COMMUNICATION PROTOCOLS

CONTINUOUS, AUTOMATIC AND MANUAL TRANSMISSION PROTOCOL

These protocols have been programmed into their programming menu.

The string is transmitted as follows:

STX <status> <net weight> <gross weight> <peak> ETX <chksum> EOT

Where

STX (start of text) = 0x02h

ETX (end of text) = 0x03h

EOT (end of transmission) = 0x04.

<status> = an ASCII character that can take the following values:

“S” = stable weight.

“M” = weight that is not stable (moving).

“O” = weight greater than the maximum capacity.

“E” = weight that cannot be detected.

<net weight> = field consisting of 6 ASCII characters of net weight.

<gross weight> = field consisting of 6 ASCII characters of gross weight.

<peak> = field consisting of 6 ASCII characters of peak.

<chksum> = 2 ASCII control characters calculated considering the characters between STX and ETX

excluded. The control value is obtained by executing the operation of XOR (or exclusive) of the 8-bit

ASCII codes of the characters considered. The result is a character that is expressed in hexadecimal

with 2 digits that can take values from “0” to “9” and “A” to “F”.

<chksum> is the ASCII encoding of the two hexadecimal digits.

In the case of continuous communication protocol, the given string is transmitted at a frequency of 10

Hz, regardless of the weight filter selected.

In the case of automatic and manual communication protocols, between 2 weight transmissions, the

weight must have a variation corresponding at least 20 divisions.

SLAVE TRANSMISSION PROTOCOL

LIST OF THE CONTROLS AVAILABLE:

• Request for the net and gross weight and current peak.

• Change in gross weight.

• Change in net weight.

• Command of reset or automatic calibration or peak reset.

• Programming the two setpoints of weight

• Requesting the programmed setpoints.

• Control of setpoints storage in permanent memory.

The unit connected to the instrument (typically a personal computer) acts as a MASTER and is the only

unit that can start a process of communication.

The process of communication must be made by the transmission of a string by the MASTER, followed

by a reply from the SLAVE concerned.

Page 39

CONTROLS FORMAT DESCRIPTION:

The double quotes enclose constant characters (observe upper and lower case); the <and> symbols

contain variable numeric fields.

REQUEST FOR THE NET AND GROSS WEIGHT AND CURRENT PEAK

Master: <Addr> “N” EOT

DAT 500: “N” <Addr> <status> <net> <gross> <peak> ETX <chksum> EOT

CHANGE IN GROSS WEIGHT

Master: <Addr> “C” “L” EOT

DAT 500: <Addr> “C” “L” ACK EOT

CHANGE IN NET WEIGHT

Master: <Addr> “C” “N” EOT

DAT 500: <Addr> “C” “N” ACK EOT

COMMAND OF RESET OR AUTOMATIC CALIBRATION OR PEAK RESET

Master: <Addr> “A” “A” EOT

DAT 500: <Addr> “A” “A” ACK EOT

PROGRAMMING TWO WEIGHT SETPOINS

Master: <Addr> “S” <s1> <s2> ETX <csum> EOT

DAT 500: <Addr> “S” ACK EOT

REQUESTING FOR THE PROGRAMMED SETPOINT

Master: <Addr> “R” EOT

DAT 500: <Addr> “R” <s1> <s2> ETX <csum> EOT

STORING THE WEIGHT Setpoint IN A PERMANENT MANNER

Master: <Addr> “M” EOT

DAT 500: <Addr> “M” ACK EOT

In the case of communication error or otherwise unrecognized command from DAT 500, it will respond

with the following string:

DAT 500: <Addr> NAK EOT

FIELDS DECRIPTION

The double quotes enclose constant characters (observe upper and lower case); the <and> symbols

contain variable numeric fields.

<addr> = Serial communication address of the instrument; it is the ASCII character obtained by adding

80h to the number of address (i.e. address 1: <Addr> = 80h + 01h = 81h).

<csum> = checksum of the string data. It is calculated by performing the exclusive OR (XOR) of all characters from <Addr> to ETX excluded the latter; the result of the XOR is decomposed into 2 characters

by considering separately the upper 4 bits (first character) and lower 4 bits (second character); the

2 characters obtained are then ASCII encoded (example: XOR = 5Dh; <csum> = “5Dh” namely 35h

and 44h).

ETX (end of text) = 0x03h,

EOT (end of transmission) = 0x04h,

ACK (acknowledgment) = 0x06h,

NAK (No acknowledgment) = 0x15h.

Page 40

<status> = an ASCII character that can take the following values:

“S” = stable weight

“M” = weight that is not stable (moving)

“O” = weight greater than the maximum capacity

“E” = weight that cannot be detected.

<s1>...<s2> = 6 ASCII characters of setpoint.

<net weight> = 6 ASCII characters of net weight.

<gross weight> = 6 ASCII characters of gross weight.

<peak> = 6 ASCII characters of peak.

If the request is made cyclically, the weight is acquired with a maximum frequency of:

Frequency Baud Rate

200Hz 115200

50Hz 38400

35Hz 19200

25Hz 9600

8Hz 2400

Page 41

MODBUS RTU PROTOCOL

The addresses listed in the tables below follow the standard address specified in the guidelines of

the Modicon PI-MBUS-300. Below please find an excerpt that helps the user to communicate with the

instrument.

“All data addresses in Modbus messages are referenced to zero. The first occurrence of a data item

is addressed as item number zero. For example:

The coil known as ‘coil 1’ in a programmable controller is addressed as coil 0000 in the data

address field of a Modbus message.

Coil 127 decimal is addressed as coil 007E hex (126 decimal).

Holding register 40001 is addressed as register 0000 in the data address field of the message. The

function code field already specifies a ‘holding register’ operation. Therefore the ‘4XXXX’ reference

is implicit.”

To confirm a new value in E2prom, run the function of MAKE – BACKUP. If this function is not performed

by switching off, the DAT will return to the value before the change.

If not specified otherwise, the numerical values (such as addresses, codes and data) are expressed as

decimal values .

For any hardware configuration of the instrument (FIELDBUS or Analog), the MODBUS RTU protocol

is always available on COM1 RS232; in the event of Fieldbus absence, the MODBUS RTU protocol is

also available on COM2 RS485.

INSTRUMENT RESPONSE TIMES

In order to respond to most requests, the instrument takes a maximum time of 20 msec.

Exceptions are:

• the e2prom Backup command (max time = 350mSec.)

• writing of the registers of the cells capacity, cells sensitivity, net weight, system calibration, filter

(max time = 550mSec).

COMMUNICATION ERRORS HANDLING

The communication strings are controlled by the CRC (Cyclic Redundancy Check). In the case of a

communication error, the slave does not respond with a string. The master must consider a timeout for

the receipt of the response. In case of no answer, a communication error has occourred.

RECEIVED DATA ERROR HANDLING

In the case of string received correctly, but that cannot be executed, the slave responds with an EXCEPTION RESPONSE according to the following table.

Code Description

1 ILLEGAL FUNCTION (The function is not valid or not supported)

2 ILLEGAL DATA ADDRESS (The address of the specified data is not available)

3 ILLEGAL DATA VALUE (The received data have invalid value)

Page 42

SUPPORTED FUNCTIONS

Function Description

01 READ COIL STATUS (Reading the state of the logic outputs)

02 READ INPUT STATUS (Reading the state of the logic inputs)

03 READ HOLDING REGISTERS (Reading the programmable registers)

04 READ INPUT REGISTERS (Reading the “read only” registers”)

05 FORCE SINGLE COIL (Writing the status of each output)

06 PRESET SINGLE REGISTER (Writing a programmable register)

15 FORCE MULTIPLE COILS (Multiple writing of outputs)

16 PRESET MULTIPLE REGISTERS (Multiple writing of registers)

Funct + 80h EXCEPTION RESPONSE

Page 43

LIST OF THE MODBUS PROTOCOL HOLDING REGISTERS

Addres Holding Register R/W Format Note

40001 Status Register R INT See table A

40002 Gross weight (MSB) R

DINT

40003 Gross weight (LSB) R

40004 Net weight (MSB) R

DINT

40005 Net weight (LSB) R

40006 Peak value (MSB) R

DINT

40007 Peak value (LSB) R

40008 Load cell signal in mV/V R INT

40009 Logic inputs R INT LSB = Input 1

40010 Output R/W INT LSB = Output 1 (it writes only if the setpoint = 0)

40011 Keys status R INT See table B, even if the key lock is enabled

40012 Firmware code and version R INT See table C

40201 Setpoint 1 (MSB) R/W

DINT

40202 Setpoint 1 (LSB) R/W

40203 Setpoint 2 (MSB) R/W

DINT

40204 Setpoint 2 (LSB) R/W

40501 Data Register (MSB) W

DINT

Data related to the Command Register

40502 Data Register (LSB) W

40503 Command Register W INT See table D

41001 Cells capacity (MSB) R/W

DINT

41002 Cells capacity (LSB) R/W

41003 Cells sensitivity R/W INT

41004 Weight division value R/W INT See table E

41005 Tare of the system (MSB) R/W

DINT